Aramid nanofiber reinforce dipping of fibers and its effect on the interfacial adhesive properties of aramid fiber to rubber

-

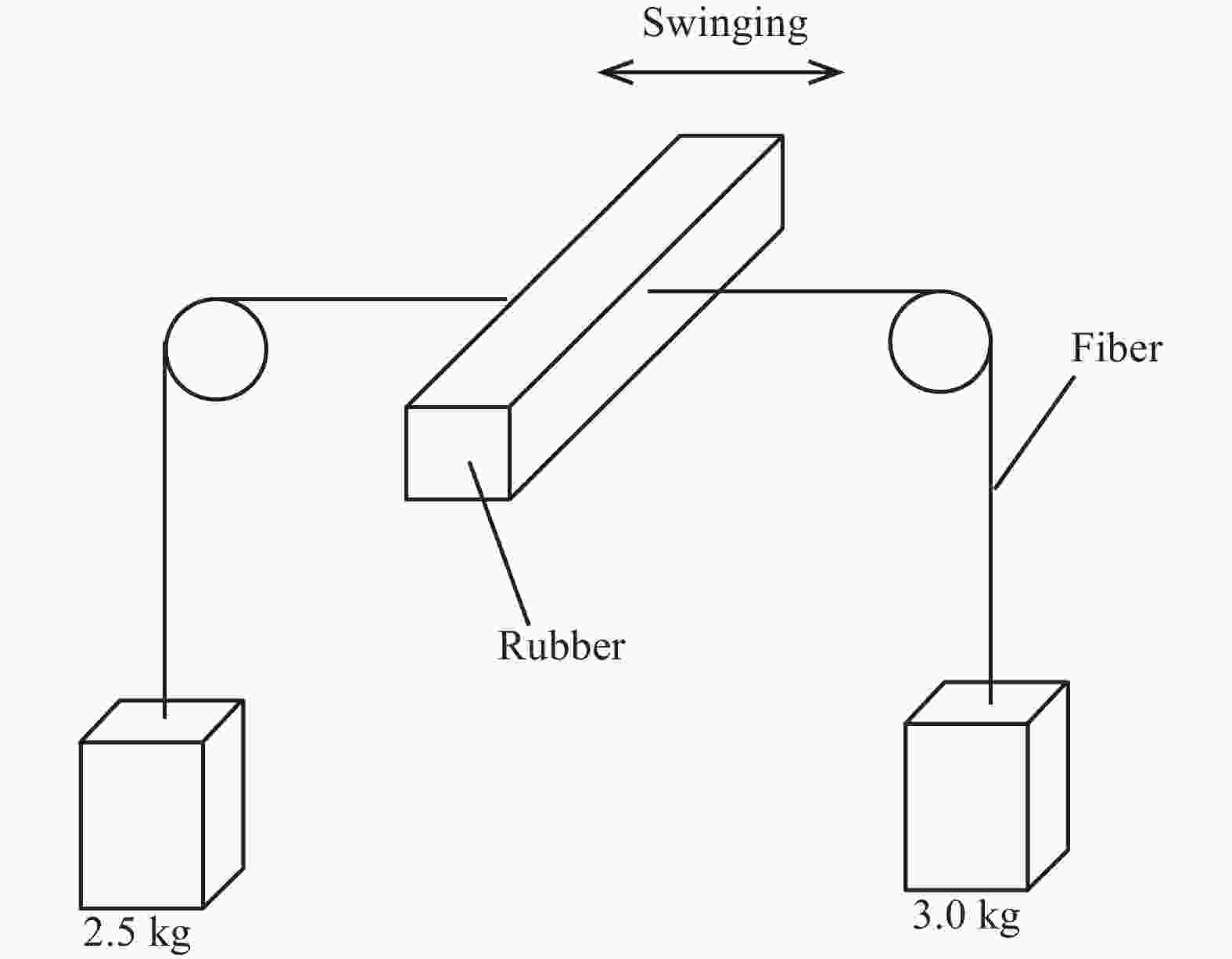

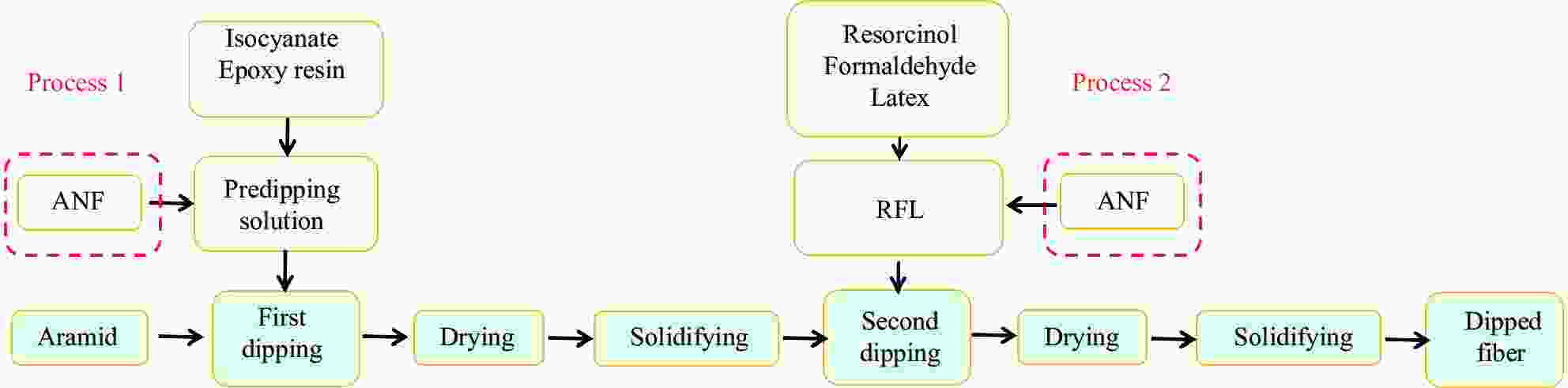

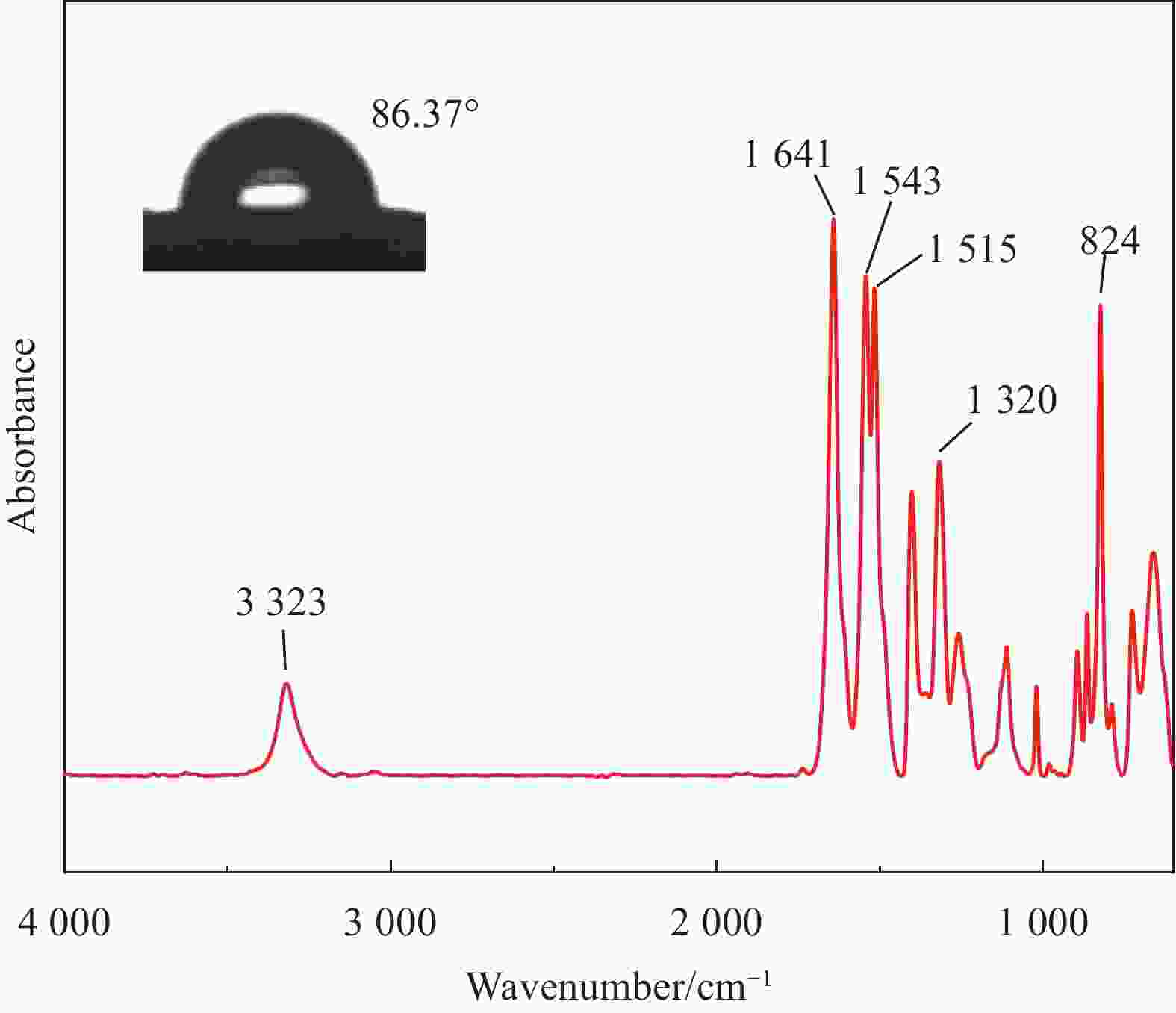

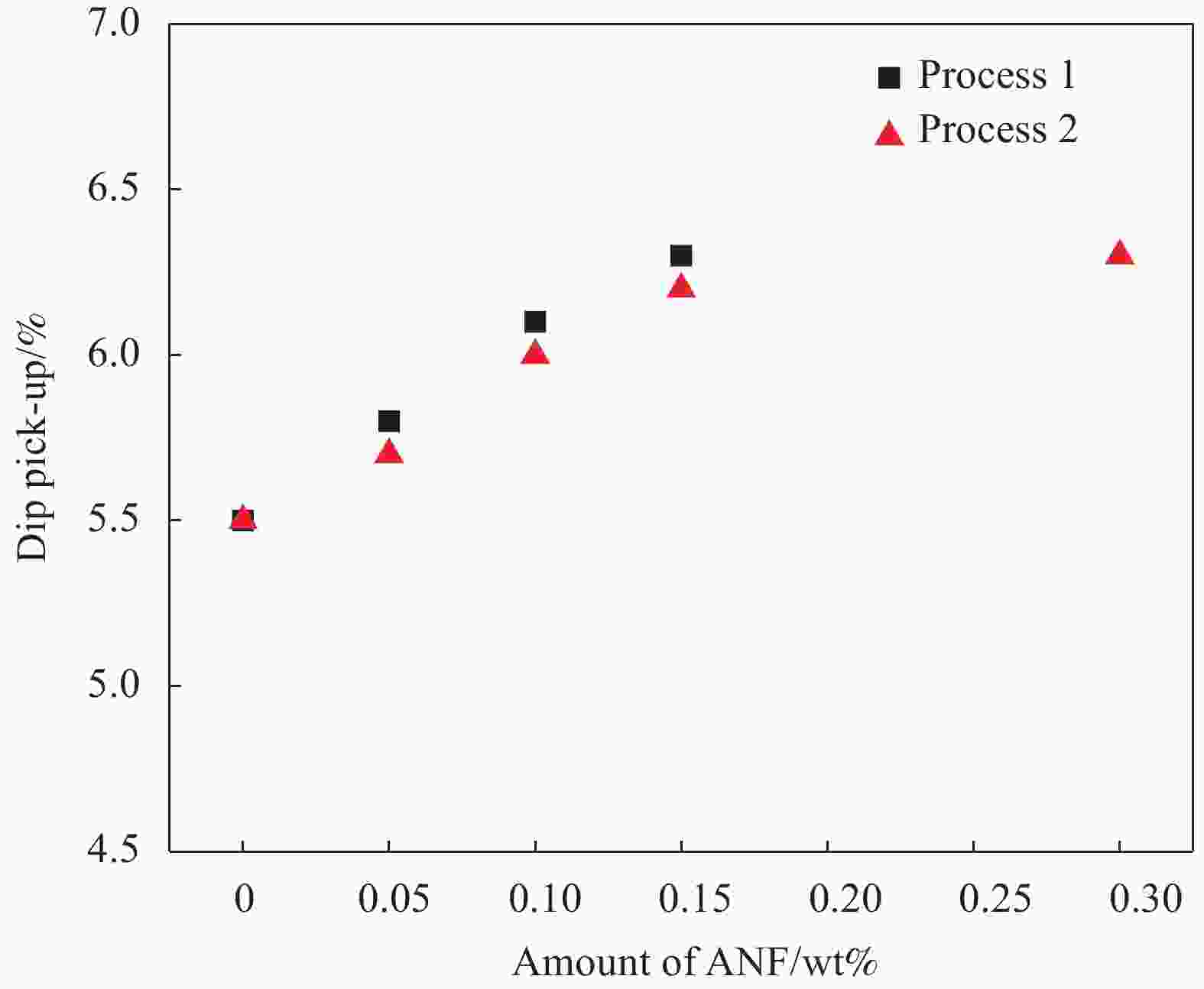

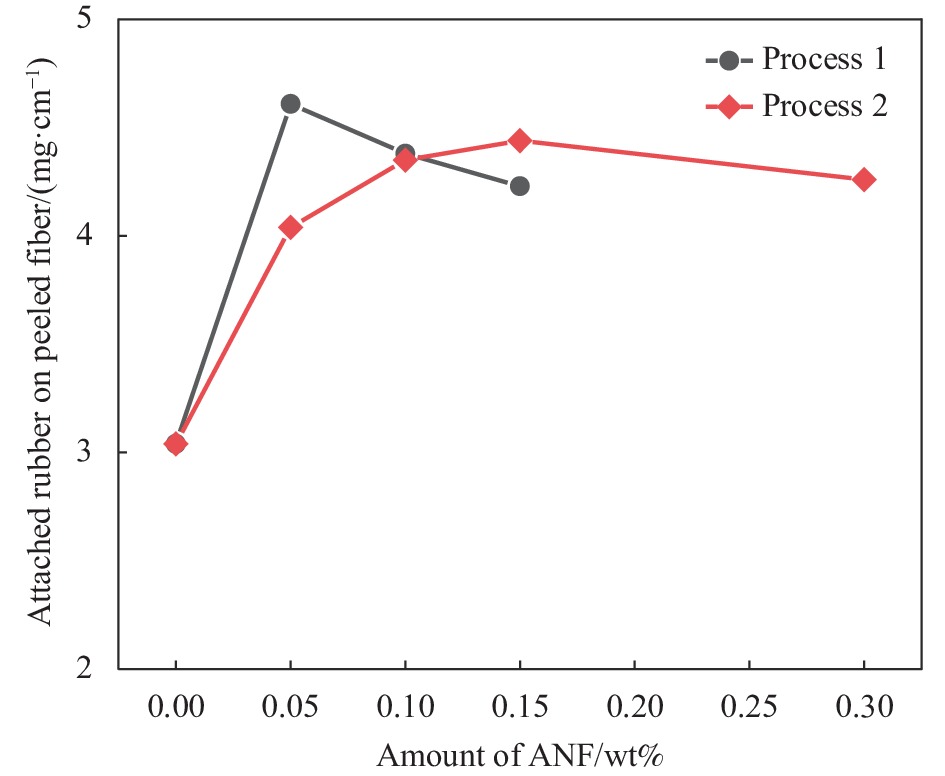

摘要: 为进一步提高芳纶纤维/橡胶复合材料的界面黏合性能,在传统“二浴”法浸渍间苯二酚-甲醛-胶乳(RFL)的基础上,分别在预处理液、RFL浸胶液中加入芳纶纳米纤维(ANF),研究ANF的添加工艺和用量对芳纶纤维/橡胶复合材料界面黏合性能的影响。结果表明,在预处理液中仅添加0.05wt%ANF, H抽出力为209.0 N,剥离力为19.8 N/根,动态黏合疲劳寿命9829次,比未增强体系分别提高18.1%、14.4%和41.0%;在RFL浸胶液中添加0.15wt%ANF,H抽出力为206.5 N,剥离力为20.1 N/根,动态黏合疲劳寿命8095次,比未增强体系分别提高15.9%、16.1%和16.1%。在预处理体系中添加ANF可更有效地提高动态黏合性能,原因在于ANF与芳纶纤维、预处理液中的异氰酸酯之间产生良好的化学作用,有利于界面处模量过渡,提高应力传递效率。Abstract: In order to further improve the interfacial adhesive properties of aramid fiber/rubber composites, based on the traditional "two-step" method was used to dip resorcinol-formaldehyde-latex (RFL), and aramid nanofibers (ANF) was added to the predipping solution and RFL dipping solution, respectively. The effects of addition process and content of ANF on the interfacial adhesion properties of aramid fiber/rubber composites were studied. The results show that when only 0.05wt% ANF is added to the predipping solution, the H pull-out force is 209.0 N, the peel force of single fiber is 19.8 N, and the dynamic fatigue life is 9829 times, which are 18.1%, 14.4% and 41.0% higher than those of the unreinforced system. Added 0.15wt% ANF to the RFL dipping solution, the H pull-out force is 206.5 N, the peel force of single fiber is 19.8 N, and the dynamic fatigue life is 8095 times, which are 15.9%, 16.1% and 16.1% higher than those of the unreinforced system. Adding ANF to the pretreatment system can effectively improve the dynamic adhesion properties, because the ANF has a good chemical effect with aramid fiber and isocyanate in the predipping solution, which is beneficial to the modulus transition at the interface and improves the stress transfer efficiency.

-

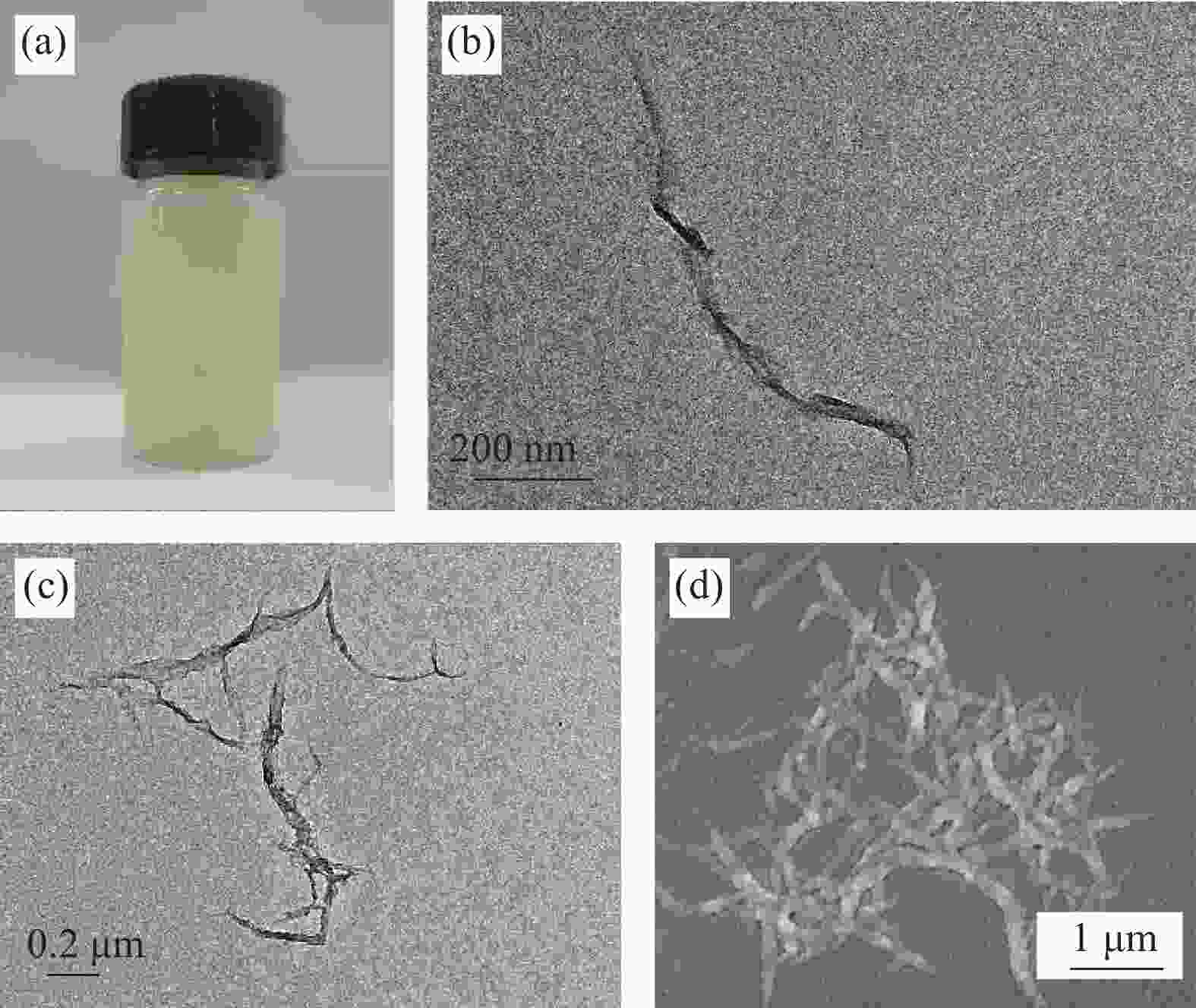

图 5 (a) 稳定的ANF水分散液(0.01wt%);(b) 单根ANF的TEM图像(0.01wt%水分散液);(c) 几根ANF缠结的TEM图像(0.01wt%水分散液);(d) ANF团聚的SEM图像(0.3wt%水分散液)

Figure 5. (a) Stable aqueous dispersion of ANF (0.01wt%); (b) TEM image of a single ANF (0.01wt% aqueous dispersion); (c) TEM image of several entangled ANF (0.01wt% aqueous dispersion); (d) SEM image of agglomerated ANF (0.3wt% aqueous dispersion)

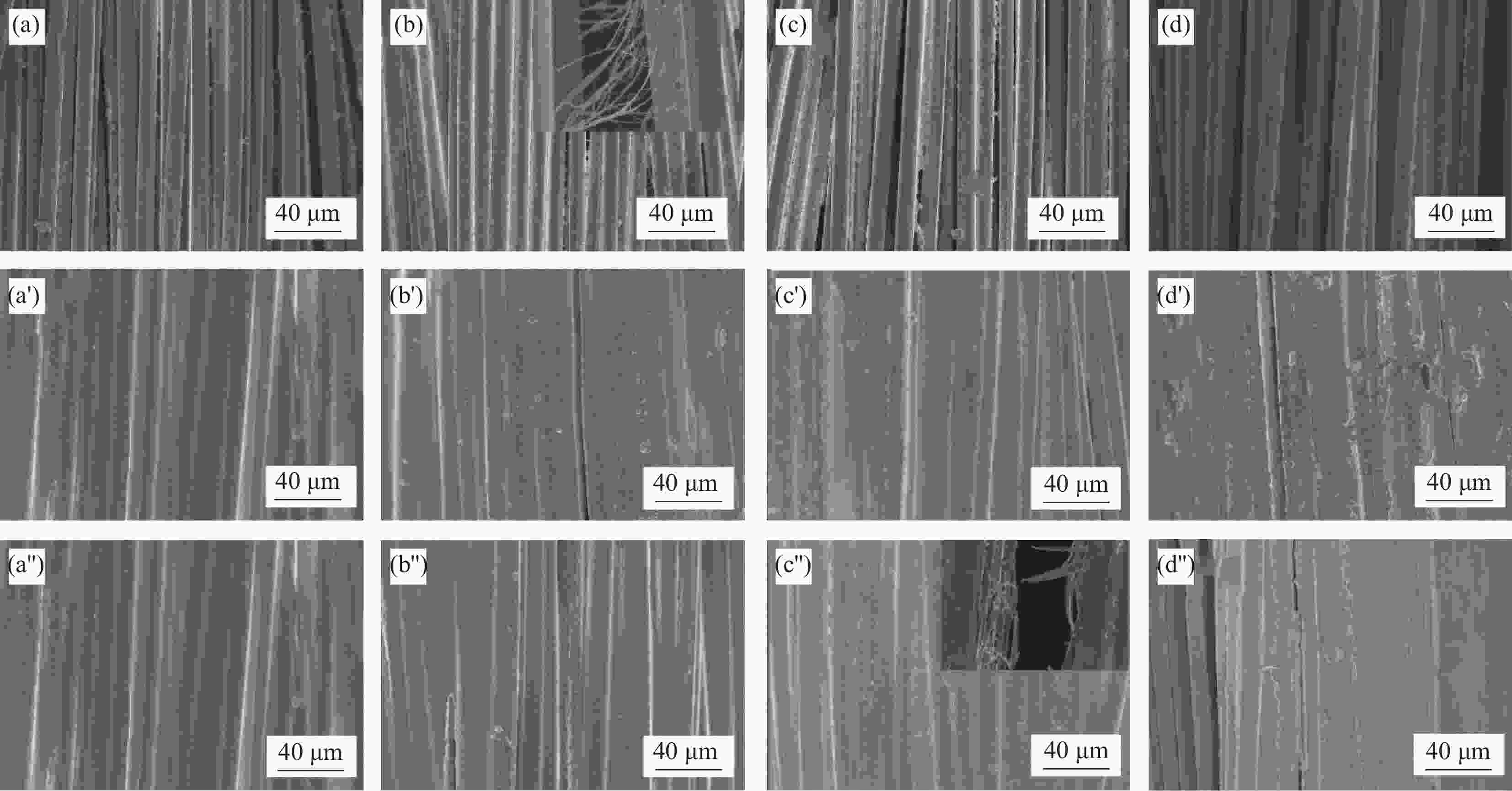

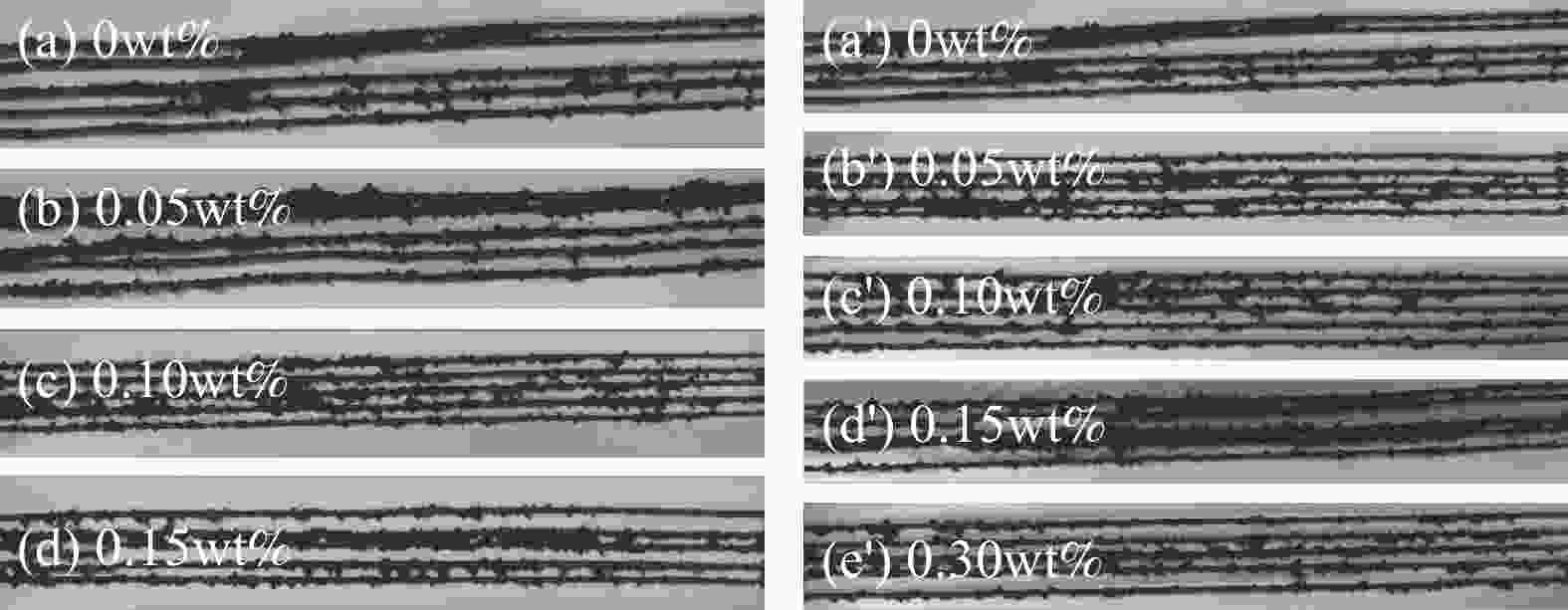

图 7 不同添加工艺下ANF对处理后芳纶纤维表面形貌的影响:工艺一不同ANF添加量下一浴处理后的纤维表面形貌:(a) 0wt%;(b) 0.05wt%;(c) 0.10wt%;(d) 0.15wt%;工艺一不同ANF添加量下二浴处理后的纤维表面形貌:(a') 0wt%;(b') 0.05wt%;(c') 0.10wt%;(d') 0.15wt%;工艺二不同ANF添加量下二浴处理后的纤维表面形貌:(a'') 0wt%;(b'') 0.10wt%;(c'') 0.15wt%;(d'') 0.30wt% (工艺一图7(c)和工艺二图7(d'')出现明显涂层不均匀)

Figure 7. Effects of ANF on the surface morphologies of treated aramid fibers via different addition processes: Surface morphologies of fibers after first dipping treatment with different amounts of ANF in process 1: (a) 0wt%; (b) 0.05wt%; (c) 0.10wt%; (d) 0.15wt%; Surface morphologies of fibers after second dipping treatment with different amounts of ANF in process 1: (a') 0wt%; (b') 0.05wt%; (c') 0.10wt%; (d') 0.15wt%; Surface morphologies of fibers after second dipping treatment with different amounts of ANF in process 2: (a'') 0wt%; (b'') 0.10wt%; (c'') 0.15wt%; (d'') 0.30wt% (There is obvious uneven coating in process 1 Fig.7(c) and process 2 Fig.7(d''))

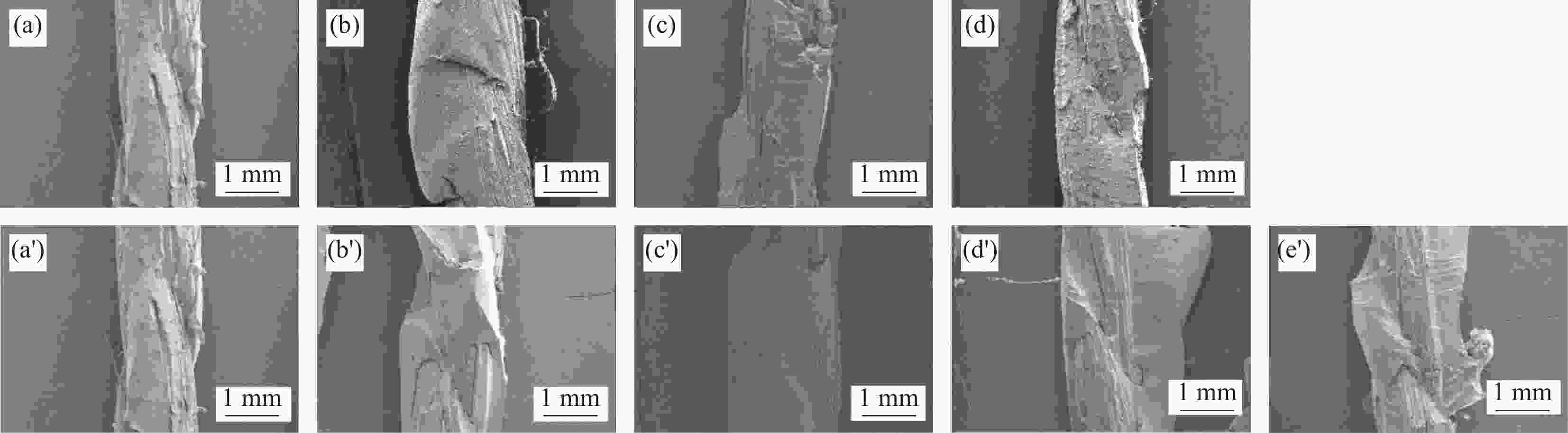

图 10 不同添加工艺下H抽出后纤维表面的附胶情况:工艺一:(a) 0wt%;(b) 0.05wt%;(c) 0.10wt%;(d) 0.15wt%;工艺二:(a') 0wt%;(b') 0.05wt%;(c') 0.10wt%;(d') 0.15wt%;(e') 0.30wt%

Figure 10. Attached rubber on the fiber surface after H pull-out via different processes: Process 1: (a) 0wt%; (b) 0.05wt%; (c) 0.10wt%; (d) 0.15wt%; Process 2: (a') 0wt%; (b') 0.05wt%; (c') 0.10wt%; (d') 0.15wt%; (e') 0.30wt%

图 12 不同添加工艺下剥离后纤维的表面形貌:工艺一:(a) 0wt%;(b) 0.05wt%;(c) 0.10wt%;(d) 0.15wt%;工艺二:(a') 0wt%;(b') 0.05wt%;(c') 0.10wt%;(d') 0.15wt%;(e') 0.30wt%

Figure 12. Surface morphologies of peeled fiber via different processes: Process 1: (a) 0wt%; (b) 0.05wt%; (c) 0.10wt%; (d) 0.15wt%; Process 2: (a') 0wt%; (b') 0.05wt%; (c') 0.10wt%; (d') 0.15wt%; (e') 0.30wt%

表 1 工艺一、工艺二中分别加入最佳ANF用量对芳纶纤维/橡胶复合材料动态黏合性能的影响

Table 1. Effect of adding the optimum amount of ANF to process 1 and process 2 on the dynamic adhesive properties of aramid fiber/rubber composites

RFL Process 1

0.05wt%ANFProcess 2

0.15wt%ANFFatigue life/time 6968 9829 8095 Improvement compared to RFL − 41.0% 16.1% 表 2 ANF用量对间苯二酚-甲醛-胶乳(RFL)胶膜交联密度及杨氏模量的影响

Table 2. Effect of ANF dosage on the crosslink density and Young's modulus of resorcinol-formaldehyde-latex (RFL) films

Amount of ANF 0 0.05wt% 0.10wt% 0.15wt% 0.30wt% Crosslink density/(10−4 mol·mL−1) 1.62 1.76 1.82 1.85 1.90 Young's modulus/GPa 0.1757 – 0.2394 0.2555 0.2836 -

[1] WENNEKES W B. Adhesion of RFL-treated cords to rubber: New insights into interfacial phenomena[D]. Enschede: University of Twente, 2017. [2] YANG G, PARK M, PARK S J. Recent progresses of fabrication and characterization of fibers-reinforced composites: A review[J]. Composites Communications,2019,14:34-42. doi: 10.1016/j.coco.2019.05.004 [3] 袁玥, 李鹏飞, 凌新龙. 芳纶纤维的研究现状与进展[J]. 纺织科学与工程学报, 2019, 36(1):146-152. doi: 10.3969/j.issn.2096-5184.2019.01.027YUAN Yue, LI Pengfei, LING Xinlong. Research status and progress of aramid fibers[J]. Journal of Textile Science and Engineering,2019,36(1):146-152(in Chinese). doi: 10.3969/j.issn.2096-5184.2019.01.027 [4] 马千里, 刘震, 林威宏, 等. 对位芳纶增强橡胶复合材料产业发展现状[J]. 中国橡胶, 2018, 34(2):28-32. doi: 10.3969/j.issn.1009-5640.2018.02.007MA Qianli, LIU Zhen, LIN Weihong, et al. Current status of industrial development of para-aramid reinforced rubber composites[J]. China Rubber,2018,34(2):28-32(in Chinese). doi: 10.3969/j.issn.1009-5640.2018.02.007 [5] WANG L, SHI Y X, CHEN S X, et al. Highly efficient mussel-like inspired modification of aramid fibers by UV-accelerated catechol/polyamine deposition followed chemical grafting for high-performance polymer composites[J]. Chemical Engineering Journal,2016,314:583-593. [6] 张艳华, 黄玉东, 浦丽莉, 等. 芳纶-RFL-轮胎橡胶体系性能增强研究[J]. 高科技纤维与应用, 2006, 31(2):12-19. doi: 10.3969/j.issn.1007-9815.2006.02.004ZHANG Yanhua, HUANG Yudong, PU Lili, et al. Study on reinforcing the properties of the aramid-RFL-tire rubber system[J]. Hi-Tech Fiber and Application,2006,31(2):12-19(in Chinese). doi: 10.3969/j.issn.1007-9815.2006.02.004 [7] WENNEKES W B, DATTA R N, NOORDERMEER J W M, et al. Fiber adhesion to rubber compounds[J]. Rubber Che-mistry and Technology,2010,81(3):523-540. [8] YANG X, TU Q Z, SHEN X M, et al. A novel method for deposition of multi-walled carbon nanotubes onto poly(p-phenylene terephthalamide) fibers to enhance interfacial adhesion with rubber matrix[J]. Polymers,2019,11(2):374. doi: 10.3390/polym11020374 [9] LEE J U, PARK B, KIM B S, et al. Electrophoretic deposition of aramid nanofibers on carbon fibers for highly enhanced interfacial adhesion at low content[J]. Composites Part A: Applied Science and Manufacturing,2016,84:482-489. doi: 10.1016/j.compositesa.2016.02.029 [10] KARAKASSIDES A, GANGULY A, TSIRKA K, et al. Radially grown graphene nanoflakes on carbon fibers as reinforcing interface for polymer composites[J]. ACS Applied Nano Materials,2020,3(3):2402-2413. doi: 10.1021/acsanm.9b02536 [11] 邹立, 罗鹏, 孙琰, 等. 纳米填料对芳纶纤维与天然橡胶粘合性能的影响[J]. 橡胶工业, 2020, 67(1):17-22.ZOU Li, LUO Peng, SUN Yan, et al. Effect of nano-fillers on adhesion of aramid fiber to NR[J]. China Rubber Industry,2020,67(1):17-22(in Chinese). [12] ZHANG B, WANG W C, TIAN M, et al. Preparation of aramid nanofiber and its application in polymer reinforcement: A review[J]. European Polymer Journal,2020,139:109996. doi: 10.1016/j.eurpolymj.2020.109996 [13] YAN H C, LI J L, TIAN W T, et al. A new approach to the preparation of poly(p-phenylene terephthalamide) nano-fibers[J]. RSC Advances,2016,6(32):26599-26605. doi: 10.1039/C6RA01602B [14] MA T B, ZHAO Y S, RUAN K P, et al. Highly thermal conductivities, excellent mechanical robustness and flexibi-lity, and outstanding thermal stabilities of aramid nano-fiber composite papers with nacre-mimetic layered structures[J]. ACS Applied Materials and Interfaces,2020,12(1):1677-1686. doi: 10.1021/acsami.9b19844 [15] ZHOU G D, WANG W T, PENG M. Functionalized aramid nanofibers prepared by polymerization induced self-assembly for simultaneously reinforcing and toughening of epoxy and carbon fiber/epoxy multiscale composite[J]. Composites Science and Technology,2018,168(10):312-319. [16] NASSER J, STEINKE K, ZHANG L S, et al. Enhanced interfacial strength of hierarchical fiberglass composites through an aramid nanofiber interphase[J]. Composites Science and Technology,2020,192:108109. doi: 10.1016/j.compscitech.2020.108109 [17] ZHANG B, SHAO X M, LIANG T Z, et al. Enhanced interfacial adhesion of aramid fiber reinforced rubber compo-sites through bio-inspired surface modification and aramid nanofiber coating[J]. Journal of Applied Polymer Science,2021,138(39):51011. doi: 10.1002/app.51011 [18] PATTERSON B A, MALAKOOTI M H, LIN J J, et al. Aramid nanofibers for multiscale fiber reinforcement of polymer composites[J]. Composites Science and Technology,2018,161:92-99. doi: 10.1016/j.compscitech.2018.04.005 [19] NASSER J, LIN J J, STEINKE K, et al. Enhanced interfacial strength of aramid fiber reinforced composites through adsorbed aramid nanofiber coatings[J]. Composites Science and Technology,2019,174:125-133. doi: 10.1016/j.compscitech.2019.02.025 [20] 中国国家标准化管理委员会. 硫化橡胶与纤维帘线静态粘合强度的测定H抽出法: GB/T 2942—2009[S]. 北京: 中国标准出版社, 2009.Standardization Administration of the People’s Republic of China. Rubber, vulcanized—Determination of static adhension to textile cord—H-pull test: GB/T 2942—2009[S]. Beijing: China Standards Press, 2009(in Chinese). [21] 中国国家标准化管理委员会. 浸胶芳纶帘子布技术条件和评价方法: GB/T 36795—2018[S]. 北京: 中国标准出版社, 2018.Standardization Administration of the People’s Republic of China. Dipped aramid cord fabric technical requirements and evaluation methods: GB/T 36795—2018[S]. Beijing: China Standards Press, 2018(in Chinese). [22] 常梅英, 张小彦, 朱宏伟. 剥离法测定锦纶66浸胶单根帘线粘合力[J]. 轮胎工业, 2003(10):623-625. doi: 10.3969/j.issn.1006-8171.2003.10.012CHANG Meiying, ZHANG Xiaoyan, ZHU Hongwei. Deter-mination of adhesive strength of nylon 66 dipped single cord by peeling method[J]. Tyre Industry,2003(10):623-625(in Chinese). doi: 10.3969/j.issn.1006-8171.2003.10.012 [23] 中国国家标准化管理委员会. 浸胶帘线、线绳动态粘合性能试验方法: GB/T 39639—2020[S]. 北京: 中国标准出版社, 2020.Standardization Administration of the People’s Republic of China. Test methods of dynamic adhesive properties for dipped cords: GB/T 39639—2020[S]. Beijing: China Standards Press, 2020(in Chinese). [24] COX H L. The elasticity and strength of paper and other fibrous materials[J]. British Journal of Applied Physics,1951,3(3):72-79. [25] WEI F, LI J L, ZHENG Y Y. Improved thermo-oxidative stability of three-dimensional and four-directional braided carbon fiber/epoxy hierarchical composites using graphene-reinforced gradient interface layer[J]. Polymer Testing,2015,44:177-185. doi: 10.1016/j.polymertesting.2015.04.010 -

下载:

下载: