Shear stability test and strength prediction of composite laminates

-

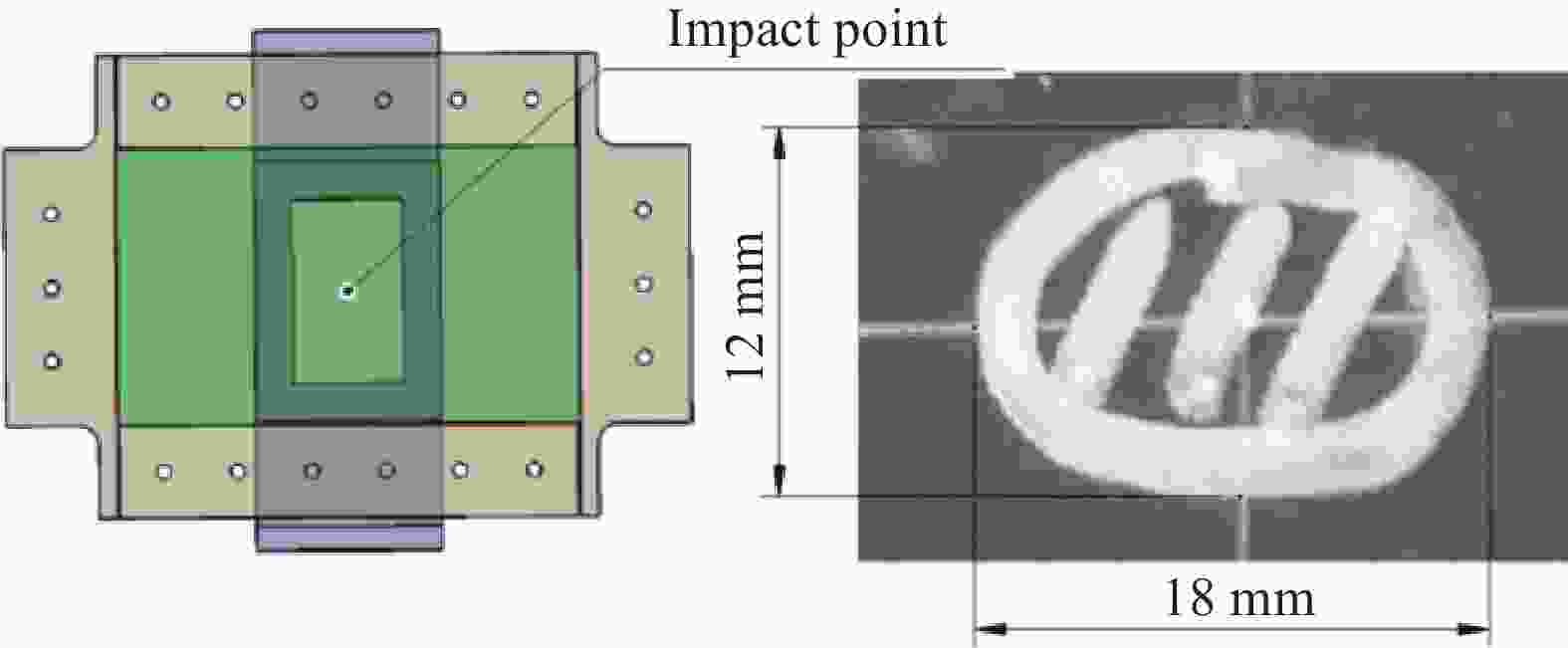

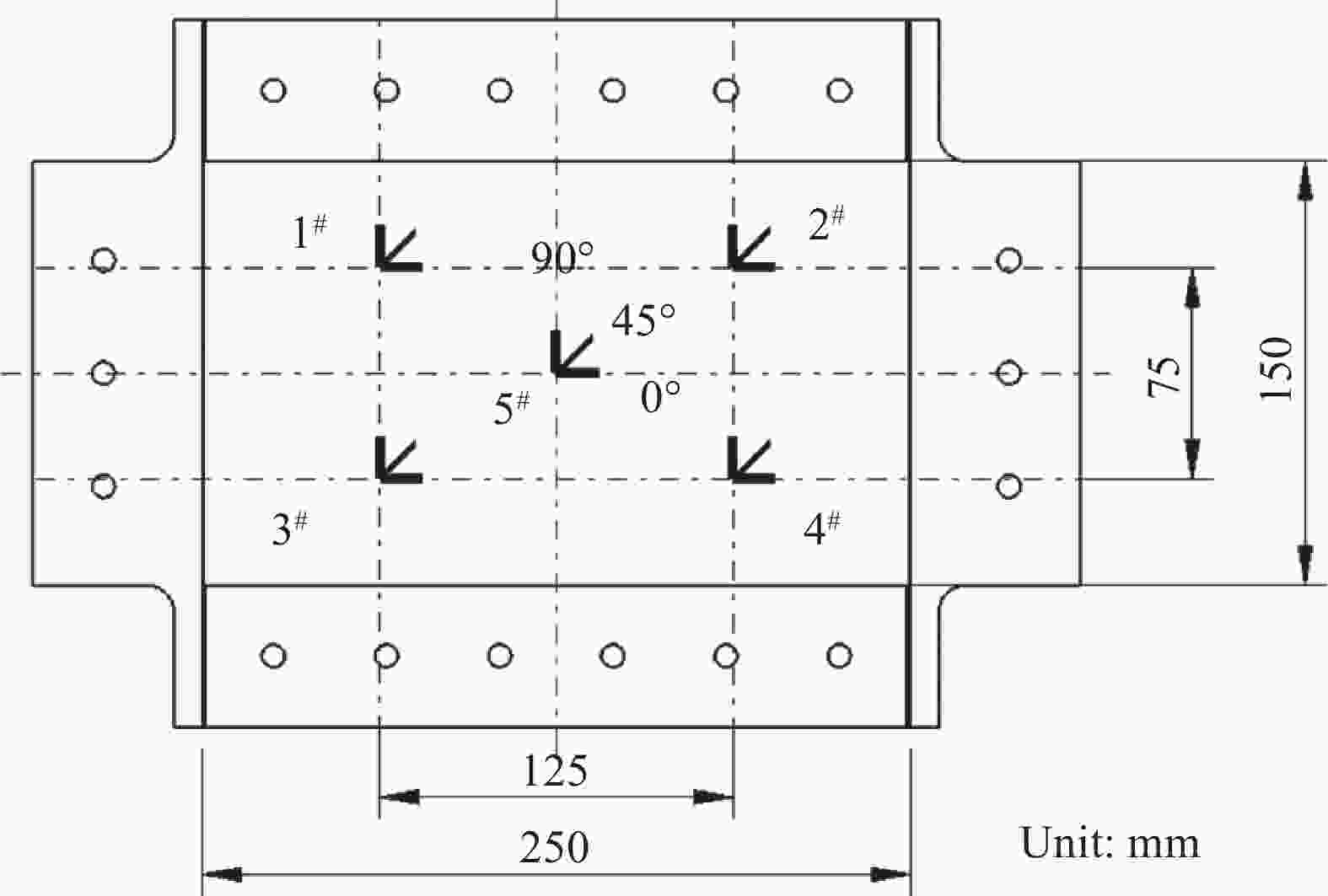

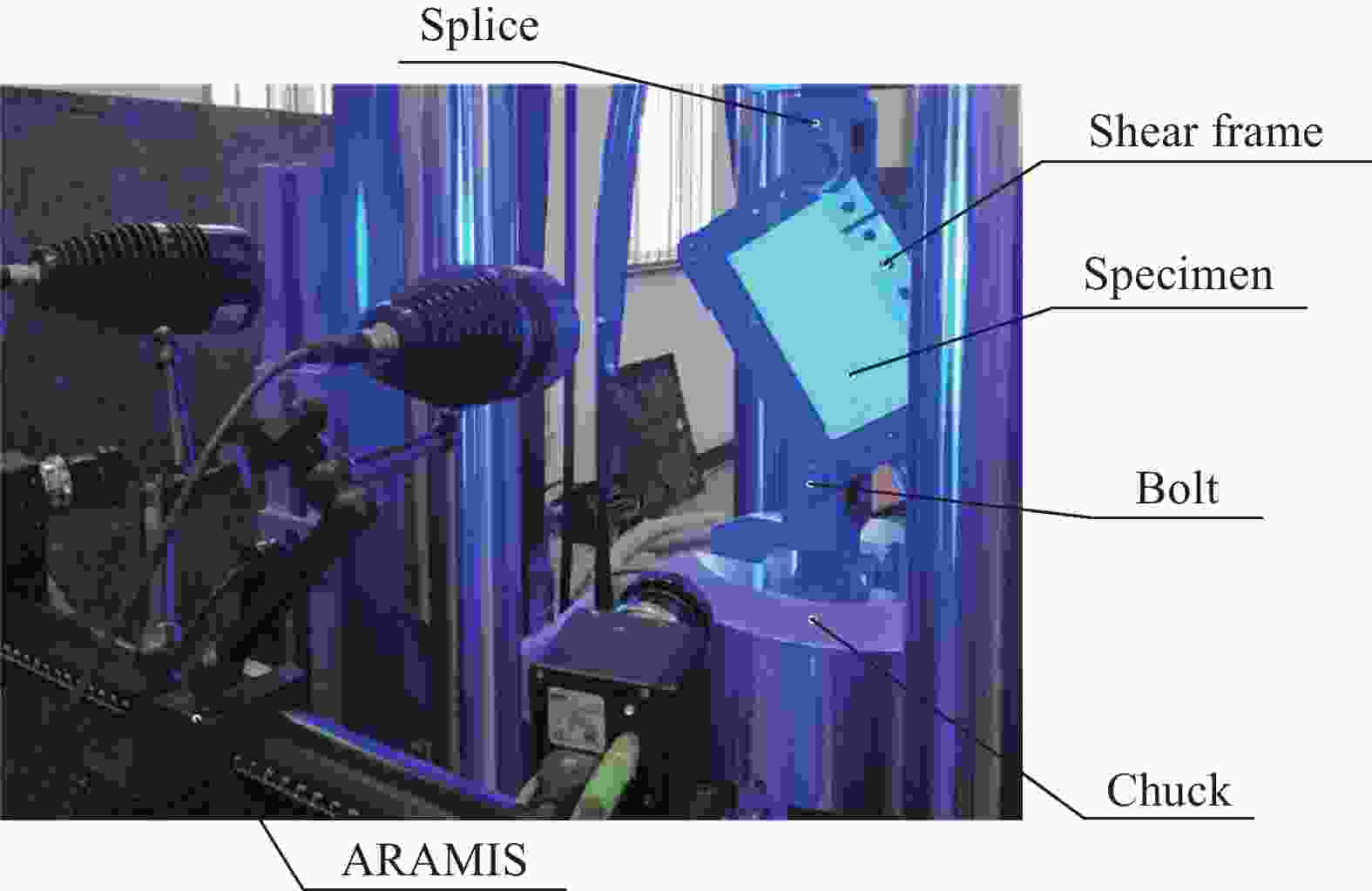

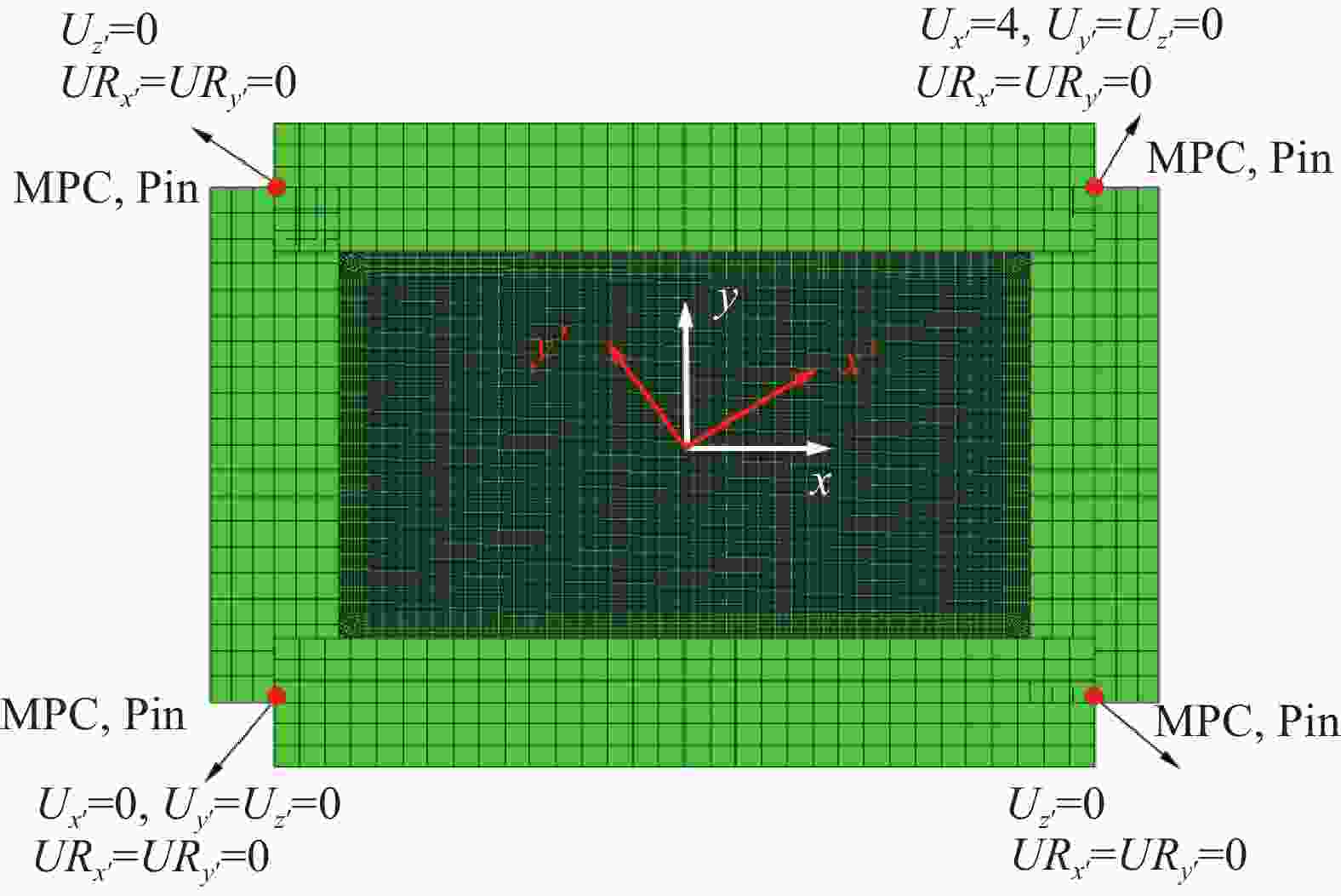

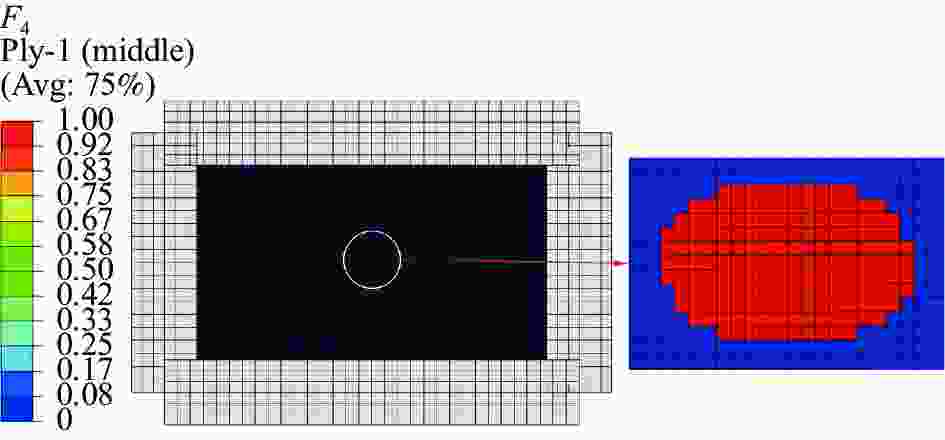

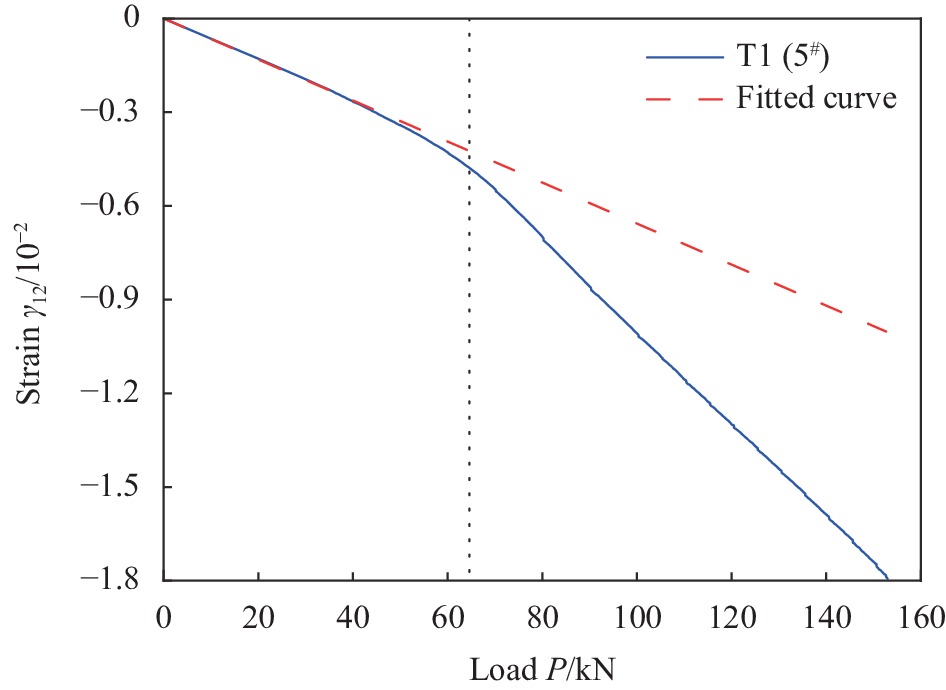

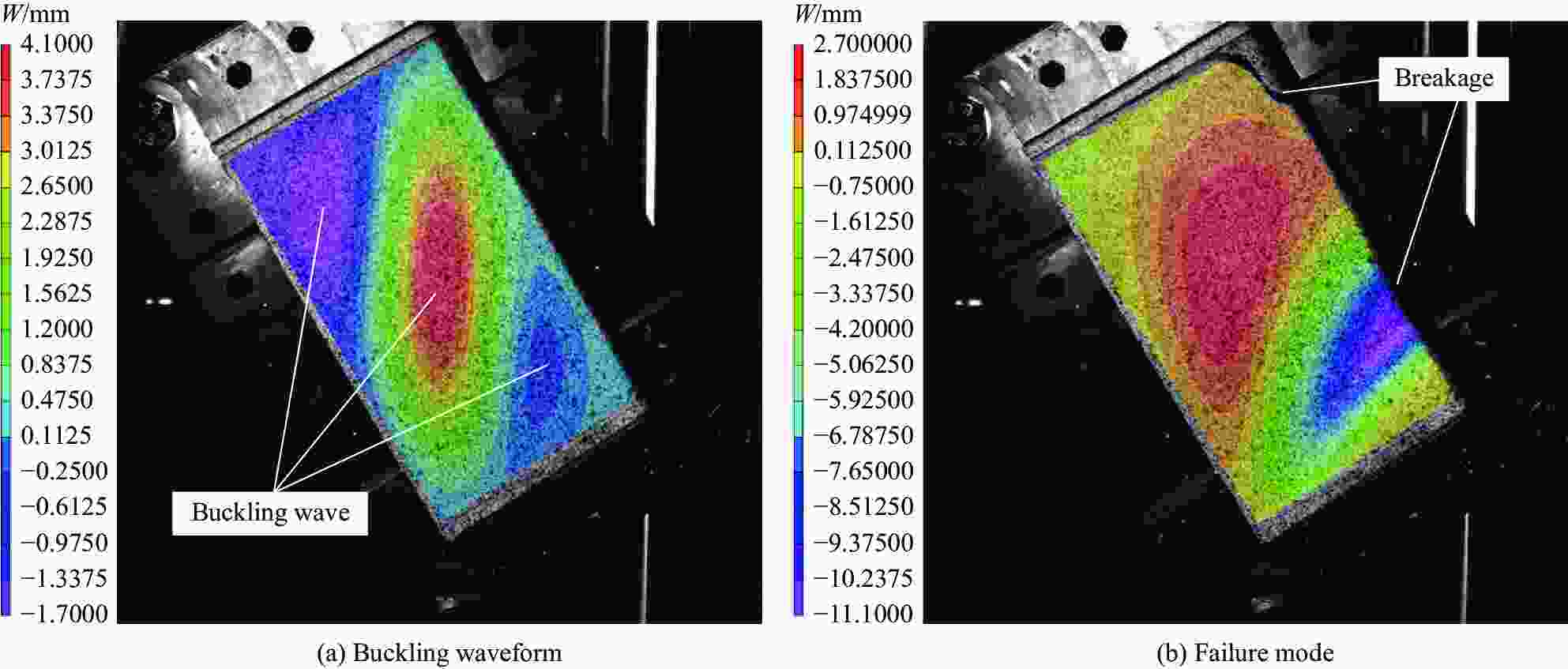

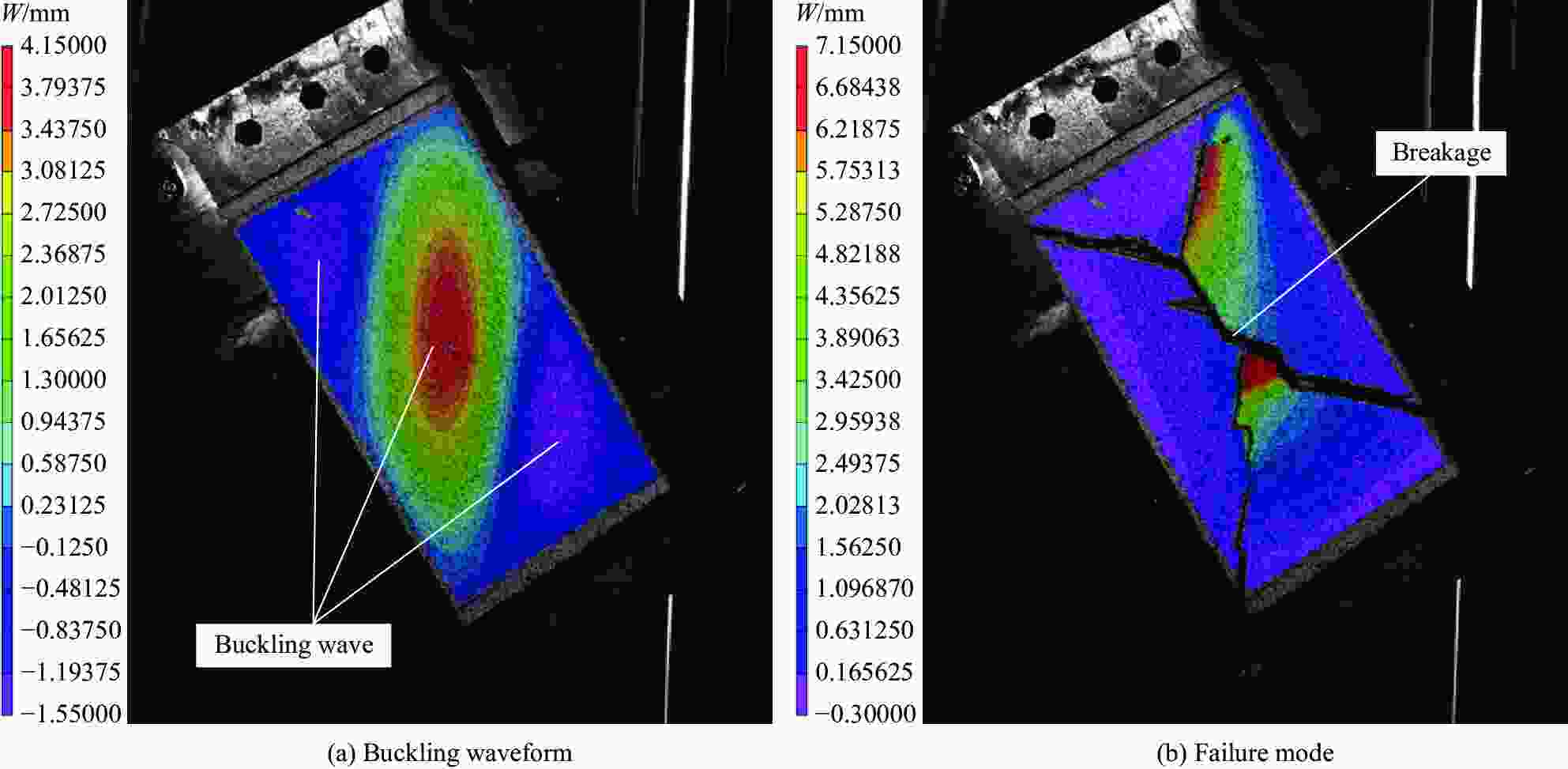

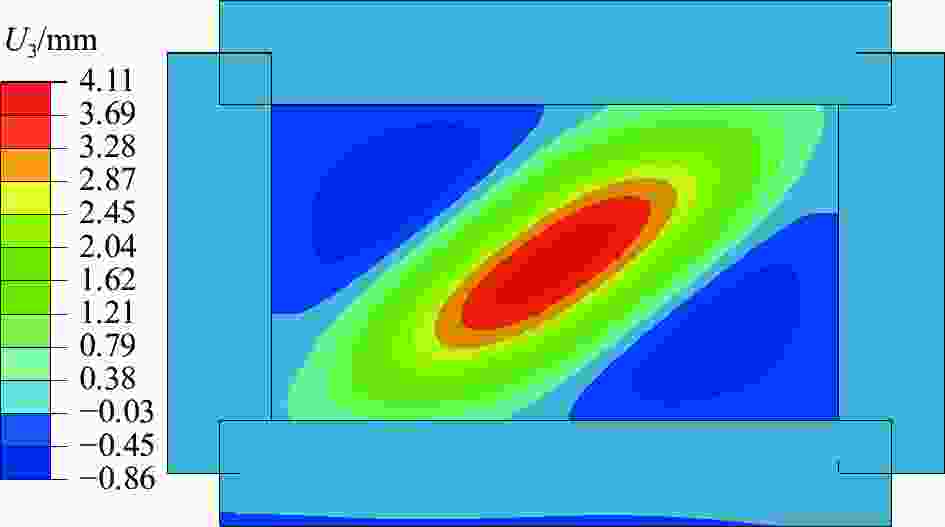

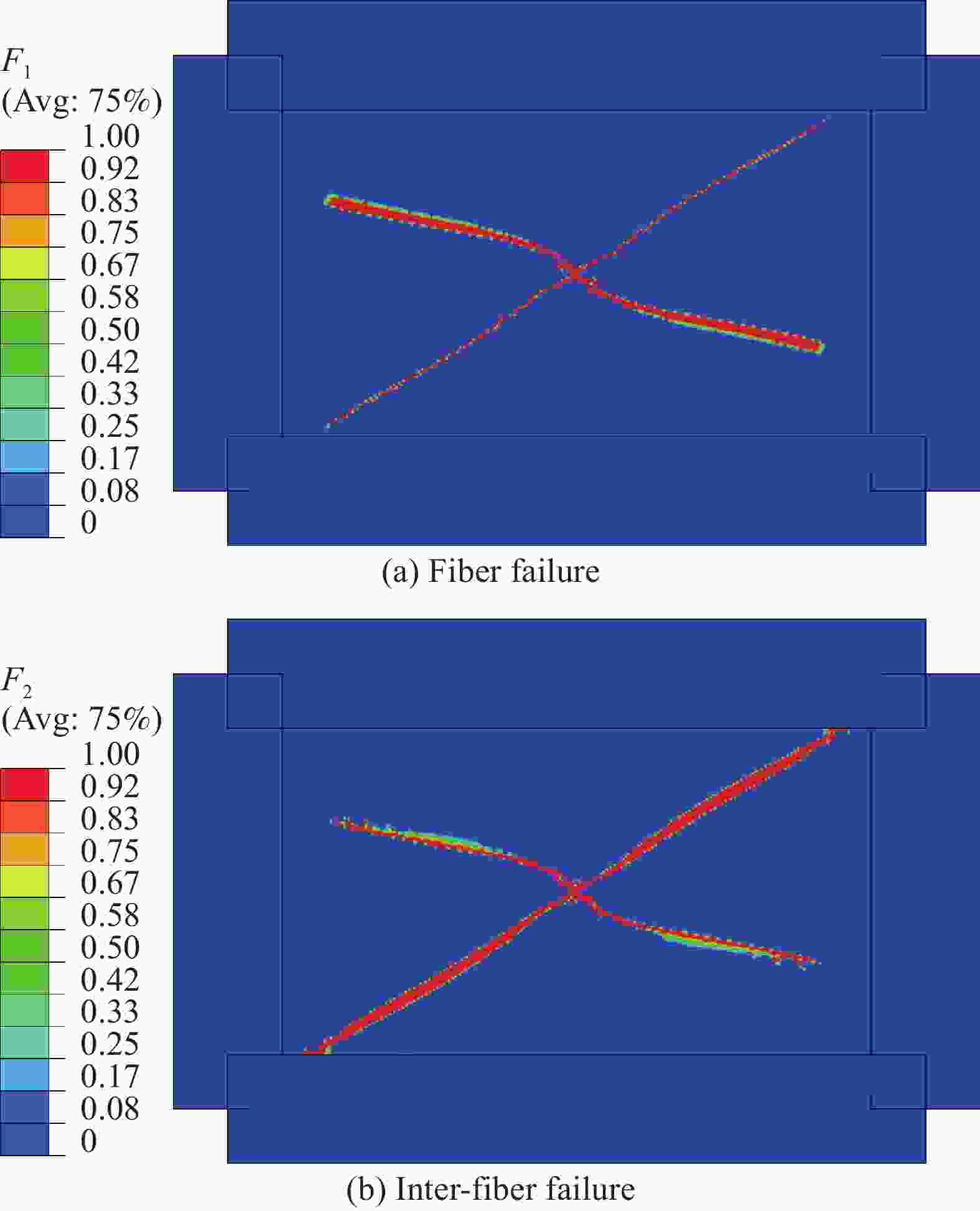

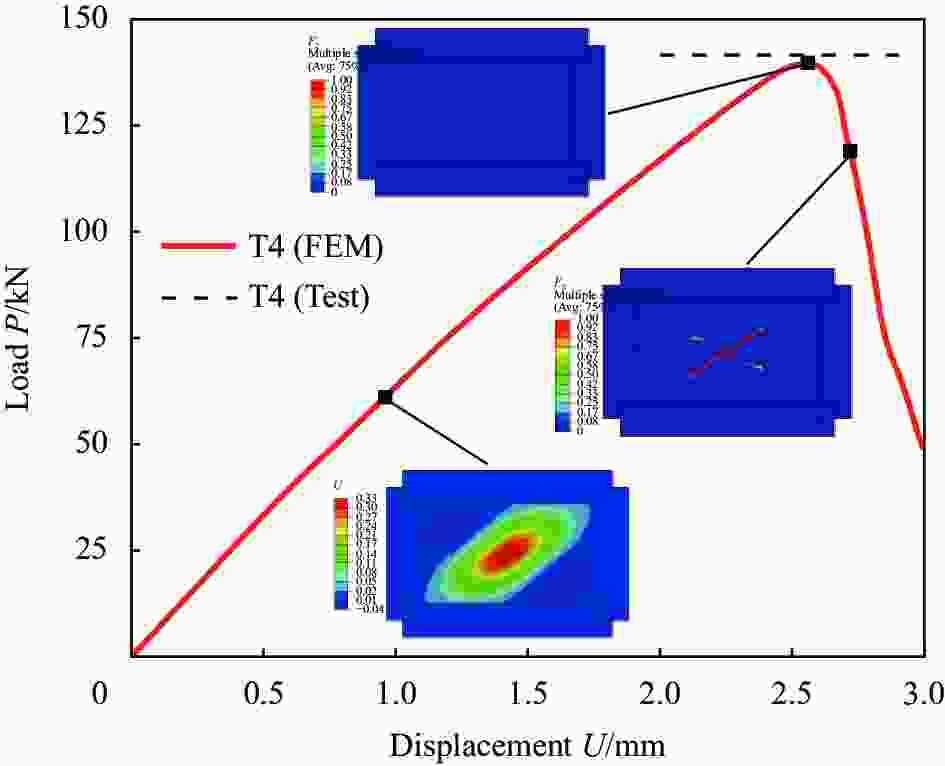

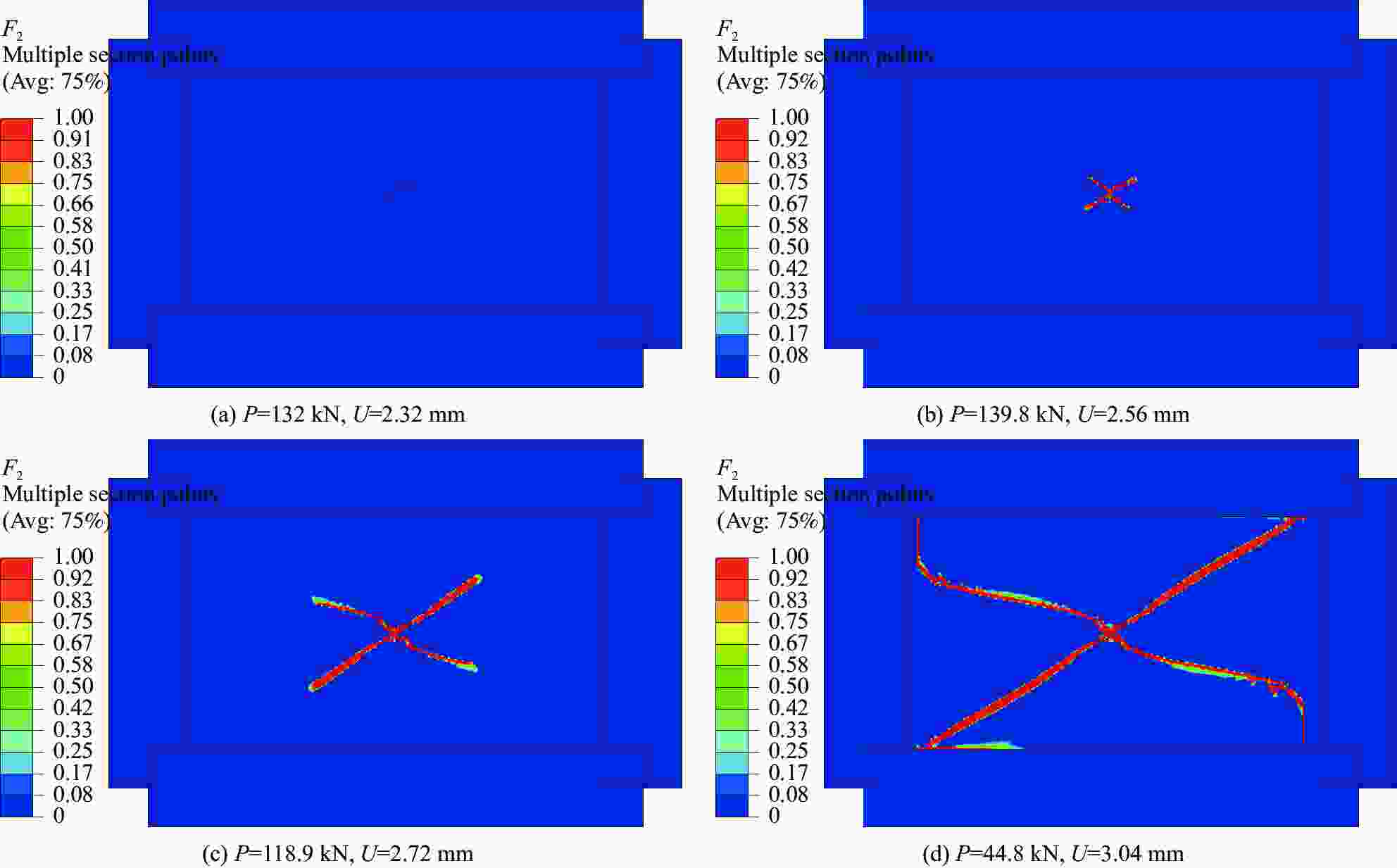

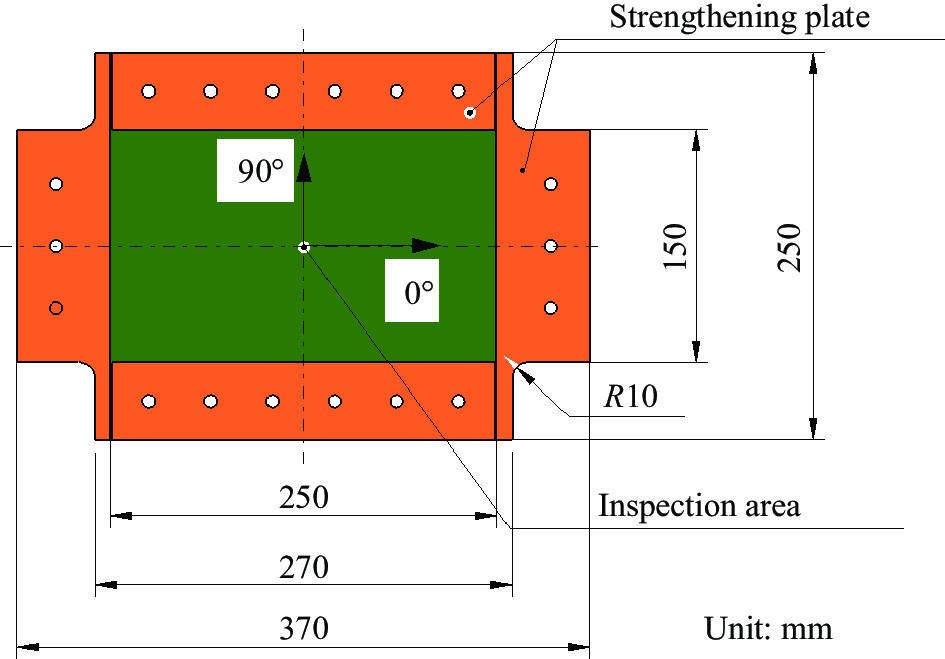

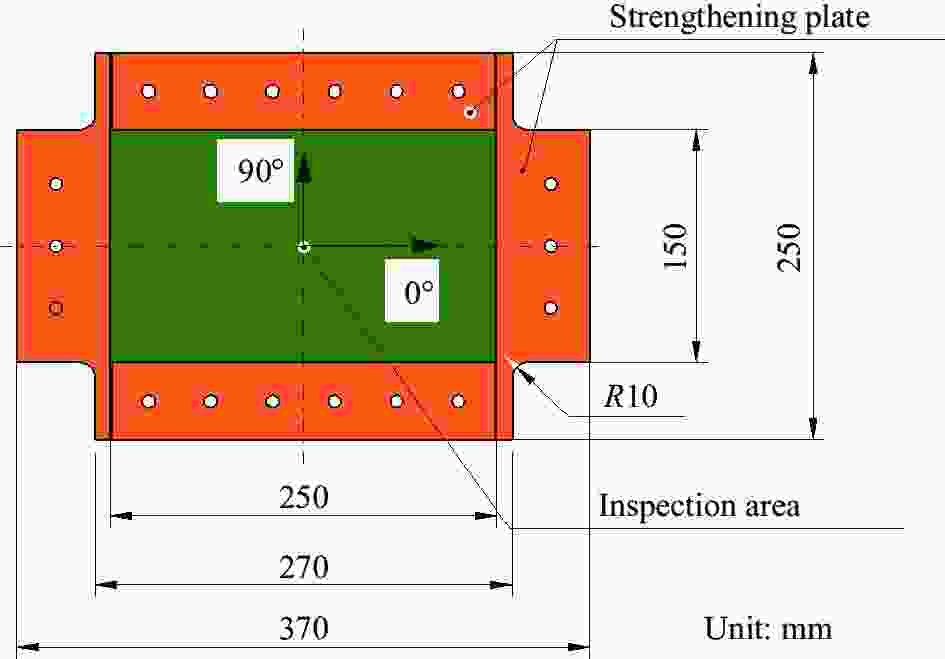

摘要: 对无损伤及含冲击损伤的复合材料层合板进行了剪切稳定性试验,基于数字图像相关方法(Digital image correlation,DIC)对层合板屈曲后屈曲行为进行了实时测量。试验结果表明:引入冲击损伤后,复合材料层合板剪切屈曲波形、屈曲载荷无明显变化,失效模式转变,承载能力下降了9.69%。随后,基于断裂面失效理论,建立了考虑剪切非线性效应的复合材料渐进损伤失效模型,并对复合材料层合板剪切失效过程进行了模拟。模型采用软化夹杂法将冲击损伤等效简化,直接将损伤区的几何边界信息写入材料模型中,不需要对冲击损伤区进行切割,从而保证了整体网格质量。与试验结果对比发现:模型考虑剪切非线性对屈曲载荷预测无明显影响,对后屈曲承载能力的预测精度影响较大,不考虑剪切非线性效应时的误差可达20%以上;软化夹杂法可以有效地模拟冲击损伤,预测的含冲击损伤的复合材料层合板的屈曲载荷、破坏载荷误差分别为−3.17%、−1.27%。Abstract: The shear stability tests of composite laminates without damage and with impact damage were carried out. The post buckling behavior of composite laminates was measured in real time based on digital image correlation (DIC). The test results show that after the introduction of impact damage, the shear buckling waveform and buckling load of composite laminates do not change significantly, and the failure mode changes, the bearing capacity decreased by 9.69%. Then, based on the fracture surface failure theory, a progressive damage failure model of composite materials considering shear nonlinear effect was established, and the shear failure process of composite laminates was simulated. The softened inclusion method was used to simplify the impact damage, and the geometric boundary information of the damage area was directly written into the material model. There was no need to cut the impact damage area, so as to ensure the overall grid quality. Compared with the experimental results, it is found that the model considering shear nonlinearity has no obvious influence on the prediction of buckling load, and has a great influence on the prediction accuracy of post buckling capacity. The error without considering shear nonlinearity can reach more than 20%; The softened inclusion method can effectively simulate the impact damage. The predicted buckling load and failure load errors of composite laminates with impact damage are −3.17% and −1.27% respectively.

-

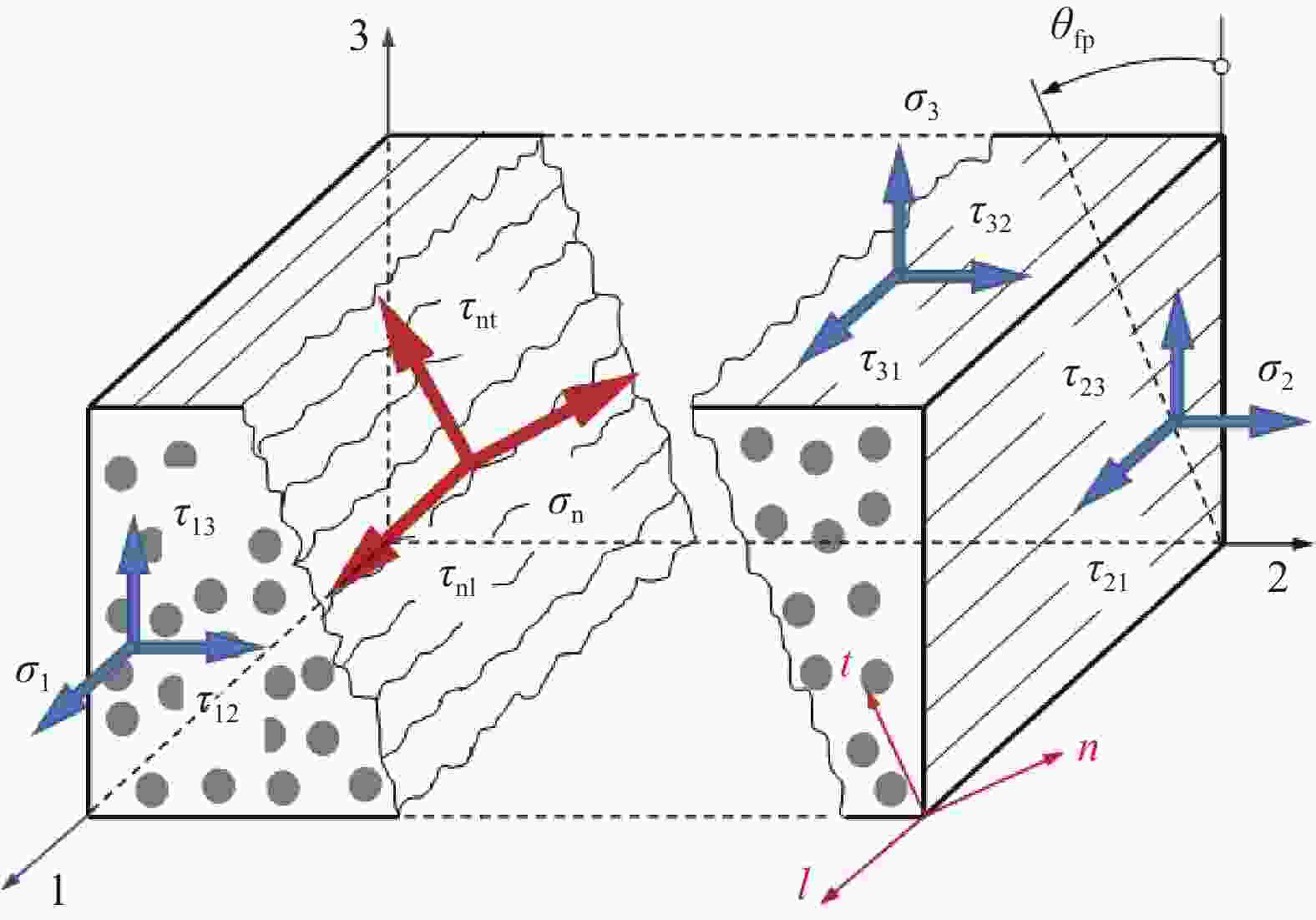

图 5 基体潜在断裂面上的应力分量[24]

Figure 5. Stress components on potential fracture surface of matrix[24]

$ {\sigma _1} $, $ {\sigma _2} $, $ {\sigma _3} $, $ {\tau _{12}} $, $ {\tau _{13}} $, $ {\tau _{23}} $, $ {\tau _{21}} $, $ {\tau _{31}} $, $ {\tau _{32}} $—Stress components in the material's principal axis coordinate system; $ {\theta _{{\text{fp}}}} $—Angle of the potential fracture surface of matrix; $ {\sigma _{\text{n}}} $, ${\tau _{{\text{nt}}}} $, ${\tau _{{\text{nl}}}} $—Stress components on potential fracture surface of matrix

表 1 CCF300/BA3202碳纤维增强环氧树脂复合材料性能参数

Table 1. Material properties of CCF300/BA3202 carbon fiber reinforced epoxy composite

Parameter Value E1/GPa 118 E2/GPa 8.98 G12/GPa 4.21 ν12 0.306 XT/MPa 1835 XC/MPa 1296 YT/MPa 82.5 YC/MPa 240 SL/MPa 166 GIC/(N·mm−1) 0.744 GIIC/(N·mm−1) 1.90 Notes:$ {E_1} $—Longitudinal elastic modulus; $ {E_2} $—Ransverse elastic modulus; $ {G_{12}} $—Shear modulus; $ {\nu _{{\text{12}}}} $—Poisson's ratio; $ {X_{\text{T}}} $—Longitudinal tensile strength; $ {X_{\text{C}}} $—Longitudinal compressive strength; $ {Y_{\text{T}}} $—Transverse tensile strength; $ {Y_{\text{C}}} $—Transverse compressive strength; $ {S_{\text{L}}} $—Shear strength; GIC—Mode I fracture toughness ; GIIC—Mode II fracture toughness. 表 2 材料性能退化方案

Table 2. Material performance degradation scheme

Fail mode No damage zone Impact damage zone None — $ \begin{gathered} {E_1} \to \eta {E_1} \\ {E_2} \to \eta {E_2} \\ G_{12}^{{\text{eq}}} \to \eta G_{12}^{{\text{eq}}} \\ \end{gathered} $ Fiber failure $ \begin{gathered} {E_1} \to (1 - {d_{{\text{FF}}}}){E_1} \\ {E_2} \to (1 - {d_{{\text{FF}}}}){E_2} \\ G_{12}^{{\text{eq}}} \to (1 - {d_{{\text{FF}}}})G_{12}^{{\text{eq}}} \\ {\nu _{12}} \to (1 - {d_{{\text{FF}}}}){\nu _{12}} \\ \end{gathered} $ $ \begin{gathered} {E_1} \to (1 - {d_{{\text{FF}}}})\eta {E_1} \\ {E_2} \to (1 - {d_{{\text{FF}}}})\eta {E_2} \\ G_{12}^{{\text{eq}}} \to (1 - {d_{{\text{FF}}}})\eta G_{12}^{{\text{eq}}} \\ {\nu _{12}} \to (1 - {d_{{\text{FF}}}}){\nu _{12}} \\ \end{gathered} $ Inter-fiber failure $ \begin{gathered} {E_2} \to (1 - {d_{{\text{IFF}}}}){E_2} \\ G_{12}^{{\text{eq}}} \to (1 - {d_{{\text{IFF}}}})G_{12}^{{\text{eq}}} \\ {\nu _{12}} \to (1 - {d_{{\text{IFF}}}}){\nu _{12}} \\ \end{gathered} $ $ \begin{gathered} {E_2} \to (1 - {d_{{\text{IFF}}}})\eta {E_2} \\ G_{12}^{{\text{eq}}} \to (1 - {d_{{\text{IFF}}}})\eta G_{12}^{{\text{eq}}} \\ {\nu _{12}} \to (1 - {d_{{\text{IFF}}}}){\nu _{12}} \\ \end{gathered} $ Notes: $ G_{12}^{{\text{eq}}} $—Equivalent shear modulus; η—Stiffness reduction factor; $ {d_{{\text{FF}}}} $—Fiber damage state variable; $ {d_{{\text{IFF}}}} $—Matrix damage state variable. 表 3 CCF300/BA3202复合材料层板剪切试验结果

Table 3. Shear test results of CCF300/BA3202 composite laminates

Number Buckling load/kN Fracture load/kN Test Average Test Average T1 64.6 64.2 153.5 156.8 T2 65.0 156.2 T3 63.1 160.7 T4 63.0 141.6 -

[1] 杜善义, 关志东. 我国大型客机先进复合材料技术应对策略思考[J]. 复合材料学报, 2008, 25(1):1-10. doi: 10.3321/j.issn:1000-3851.2008.01.001DU Shanyi, GUAN Zhidong. Strategic considerations for development of advanced composite technology for large commercial aircraft in China[J]. Acta Materiae Compositae Sinica,2008,25(1):1-10(in Chinese). doi: 10.3321/j.issn:1000-3851.2008.01.001 [2] STEVENS K A, RICCI R, DAVIES G. Buckling and post-buckling of composite structures[J]. Composites,1995,26(3):189-199. doi: 10.1016/0010-4361(95)91382-F [3] KUMAR N J, BABU P R, PANDU R. Investigations on buckling behaviour of laminated curved composite stiffened panels[J]. Applied Composite Materials,2014,21(2):359-376. doi: 10.1007/s10443-013-9337-4 [4] DEGENHARDT R, CASTRO S G P, ARBELO M A, et al. Future structural stability design for composite space and airframe structures[J]. Thin-Walled Structures,2014,81(7):29-38. [5] GLISZCZYNSKI A, KUBIAK T. Progressive failure analysis of thin-walled composite columns subjected to uniaxial compression[J]. Composite Structures,2017,169:52-61. doi: 10.1016/j.compstruct.2016.10.029 [6] GENG X, JI F, WANG J, et al. Experimental and numerical investigations of compression stability of stiffened composite panel with ply interleaving[J]. Journal of Composite Materials,2017,51(26):3647-3656. doi: 10.1177/0021998317692397 [7] AKTERSKAIA M, JANSEN E, HALLETT S R, et al. Analysis of skin-stringer debonding in composite panels through a two-way global-local method[J]. Composite Structures,2018,202:1280-1294. doi: 10.1016/j.compstruct.2018.06.064 [8] RAIMOND A, RICCIO A. Inter-laminar and intra-laminar damage evolution in composite panels with skin-stringer debonding under compression[J]. Composites Part B: Engineering,2016,94:139-151. doi: 10.1016/j.compositesb.2016.03.058 [9] 谭翔飞, 何宇廷, 冯宇, 等. 航空复合材料加筋板剪切稳定性及后屈曲承载性能[J]. 复合材料学报, 2018, 35(2):320-331.TAN Xiangfei, HE Yuting, FEND Yu, et al. Stability and post-buckling carrying capacity of aeronautic composite stiffened panel under shear loading[J]. Acta Materiae Compositae Sinica,2018,35(2):320-331(in Chinese). [10] 汪厚冰, 林国伟, 韩雪冰, 等. 复合材料帽形加筋壁板剪切屈曲性能[J]. 航空学报, 2019, 40(8):126-136.WANG Houbing, LIN Guowei, HAN Xuebing, et al. Shear buckling performance of composite hat-stiffened panels[J]. Acta Aeronautica et Astronautica Sinica,2019,40(8):126-136(in Chinese). [11] 李真, 程立平, 李卫平. 复合材料机身帽型长桁加筋壁板剪切失稳及张力场计算[J]. 科学技术与工程, 2021, 21(23):10080-10085. doi: 10.3969/j.issn.1671-1815.2021.23.056LI Zhen, CHENG Liping, LI Weiping. Calculation of shear instability and diagonal tension of composite fuselage hat-stringer panel[J]. Science Technology and Engineering,2021,21(23):10080-10085(in Chinese). doi: 10.3969/j.issn.1671-1815.2021.23.056 [12] 罗靓, 沈真, 杨胜春. 炭纤维增强树脂基复合材料层合板低速冲击性能实验研究[J]. 复合材料学报, 2008, 25(3):20-24. doi: 10.3321/j.issn:1000-3851.2008.03.004LUO Liang, SHEN Zhen, YANG Shengchun. Experimental study on low-velocity impact performance of carbon fiber reinforced composite laminates[J]. Acta Materiae Compositae Sinica,2008,25(3):20-24(in Chinese). doi: 10.3321/j.issn:1000-3851.2008.03.004 [13] CAPUTO F, LUCA A D, SEPE R. Numerical study of the structural behaviour of impacted composite laminates subjected to compression load[J]. Composites Part B Engineering,2015,79:456-465. doi: 10.1016/j.compositesb.2015.05.007 [14] FARDIN E, CHRISTOS K. An efficient approach to determine compression after impact strength of quasi-isotropic composite laminates[J]. Composites Science and Technology,2014,98:28-35. doi: 10.1016/j.compscitech.2014.04.015 [15] DEBSKI H, ROZYLO P, GLISZCZYNSKI A, et al. Numerical models for buckling, postbuckling and failure analysis of pre-damaged thin-walled composite struts subjected to uniform compression[J]. Thin-Walled Structures,2019,139:53-65. doi: 10.1016/j.tws.2019.02.030 [16] LI N, CHEN P H. Prediction of compression-after-edge-impact (CAEI) behaviour in composite panel stiffened with I-shaped stiffeners[J]. Composites Part B,2017,110:402-419. doi: 10.1016/j.compositesb.2016.11.043 [17] SEBASTIAN C, PATTERSON E A. Calibration of a digital image correlation system[J]. Experimental Techniques,2015,39(1):21-29. doi: 10.1111/ext.12005 [18] American Society for Testing and Materials. Standard test method for tensile properties of polymer matrix composite materials: ASTM D3039—2017[S]. West Conshohocken: ASTM, 2017. [19] American Society for Testing and Materials. Standard test method for compressive properties of polymer matrix composite materials using a combined loading compression (CLC) test fixture: ASTM D6641—2016[S]. West Conshohocken: ASTM, 2016. [20] American Society for Testing and Materials. Standard test method for in-plane shear response of polymer matrix composite materials by tensile test of a ±45° laminate: ASTM D3518—2018[S]. West Conshohocken: ASTM, 2018. [21] American Society for Testing and Materials. Determination of the mode I interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites: ASTM D5528—2013[S]. West Conshohocken: ASTM, 2013. [22] American Society for Testing and Materials. Determination of the mode II interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites: ASTM D7905—2019[S]. West Conshohocken: ASTM, 2019. [23] HASHIN Z. Fatigue failure criteria for unidirectional fiber composites[J]. Journal of Applied Mechanics,1980,47:329-334. doi: 10.1115/1.3153664 [24] LI N, GU J F, CHEN P H. Fracture plane based failure criteria for fibre-reinforced composites under three-dimensional stress state[J]. Composite Structures,2018,204:466-474. doi: 10.1016/j.compstruct.2018.07.103 [25] PUCK A, SCHURMANN H. Failure analysis of CFRP laminates by means of physically based phenomenological models[J]. Composites Science and Technology,2002,62(12):1633-1662. [26] CHIRMAIER F J, WEILAND J, KÄRGER L, et al. A new efficient and reliable algorithm to determine the fracture angle for Puck’ s 3D matrix failure criterion for UD composites[J]. Composites Science and Technology,2014,100:19-25. doi: 10.1016/j.compscitech.2014.05.033 [27] 杨凤祥, 陈静芬, 陈善富, 等. 基于剪切非线性三维损伤本构模型的复合材料层合板失效强度预测[J]. 复合材料学报, 2020, 37(9):2207-2222.YANG Fengxiang, CHEN Jingfen, CHEN Shanfu, et al. Failure strength prediction of composite laminates using three-dimensional damage constitutive model with nonlinear shear effects[J]. Acta Materiae Compositae Sinica,2020,37(9):2207-2222(in Chinese). [28] LINDE P, DE BOER H. Modelling of inter-rivet buckling of hybrid composites[J]. Composite Structures,2006,73:221-228. doi: 10.1016/j.compstruct.2005.11.062 [29] OUYANG T, BAO R, SUN W, et al. A fast and efficient numerical prediction of compression after impact (CAI) strength of composite laminates and structures[J]. Thin-Walled Structures,2020,148:106588. doi: 10.1016/j.tws.2019.106588 [30] LIU D C, CAO D F, HU H X, et al. Numerical study on failure behavior of open-hole composite laminates based on LaRC criterion and extended finite element method[J]. Journal of Mechanical Science and Technology,2021,35(3):1037-1047. doi: 10.1007/s12206-021-0217-9 [31] REITINGER R, RAMM E. Buckling and imperfection sensitivity in the optimization of shell structures[J]. Thin-Walled Structures,1995,23:159-177. doi: 10.1016/0263-8231(95)00010-B -

下载:

下载: