Fracture mechanism of low-density fiber reinforced nanoporous resin composites

-

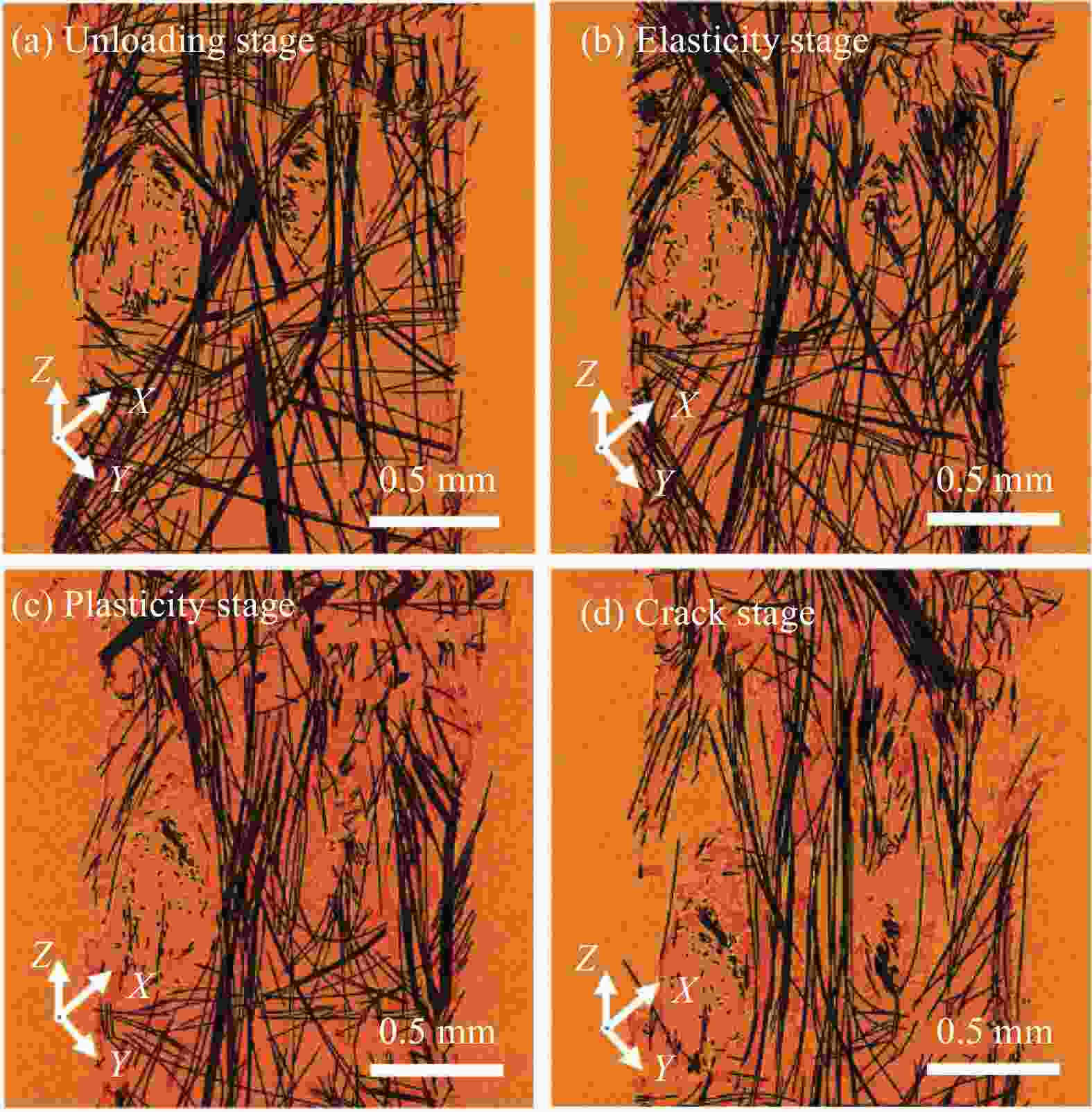

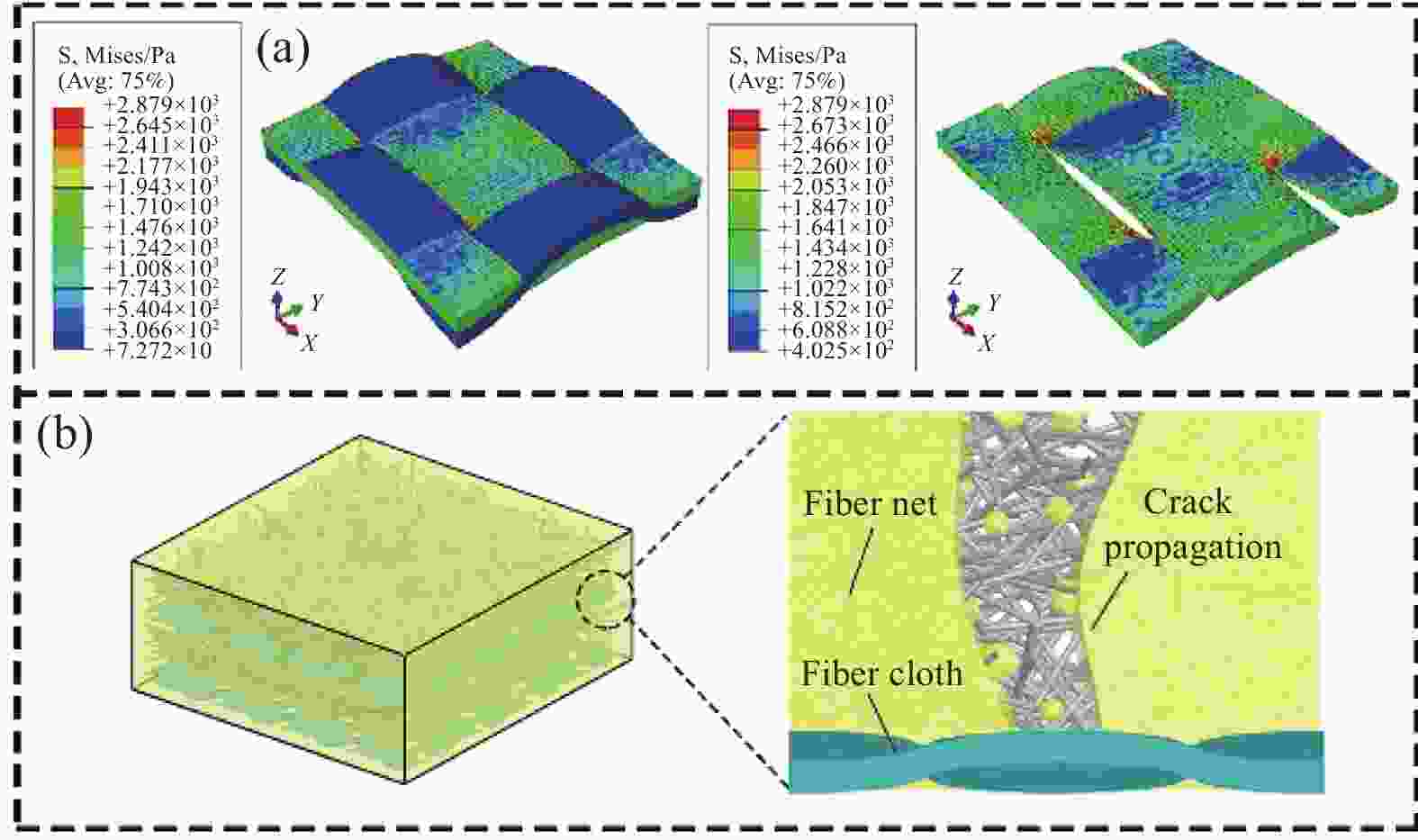

摘要: 纤维增强纳米孔树脂基复合材料(IPC)是一类轻质高效防隔热一体化耐烧蚀材料,具有典型的非均质结构特征。在外加载荷下,内部的纳米孔隙将会衍生出微裂纹。裂纹的萌生、聚合和扩展对复合材料的强度、刚度、变形性等力学性能有着重要的影响。本文分别以石英纤维针刺网胎(NQF)、石英纤维针刺网胎/纤维布(NQCF)为增强体,制备得到不同纤维结构增强的纳米孔酚醛树脂(NPR)基复合材料(NQF/NPR、NQCF/NPR),对比研究了材料拉伸强度、拉伸模量、断裂伸长率及拉伸疲劳性能,并采用CT原位拉伸装置表征了拉伸过程中复合材料的微观结构演变。结果表明:纤维布的引入极大提高了复合材料的力学性能,并且微裂纹首先在针刺区域边缘的树脂基体中出现。在裂纹扩展过程中,纤维结构对树脂基体的损伤起到了不同程度的阻碍作用。最后结合有限元法建立了NPR及纤维布的有限元模型,分析了不同尺度下材料的断裂机制。

-

关键词:

- 低密度纤维 /

- 纳米孔树脂基复合材料 /

- 力学性能 /

- 断裂机制 /

- 微计算机断层扫描(Micro-CT)

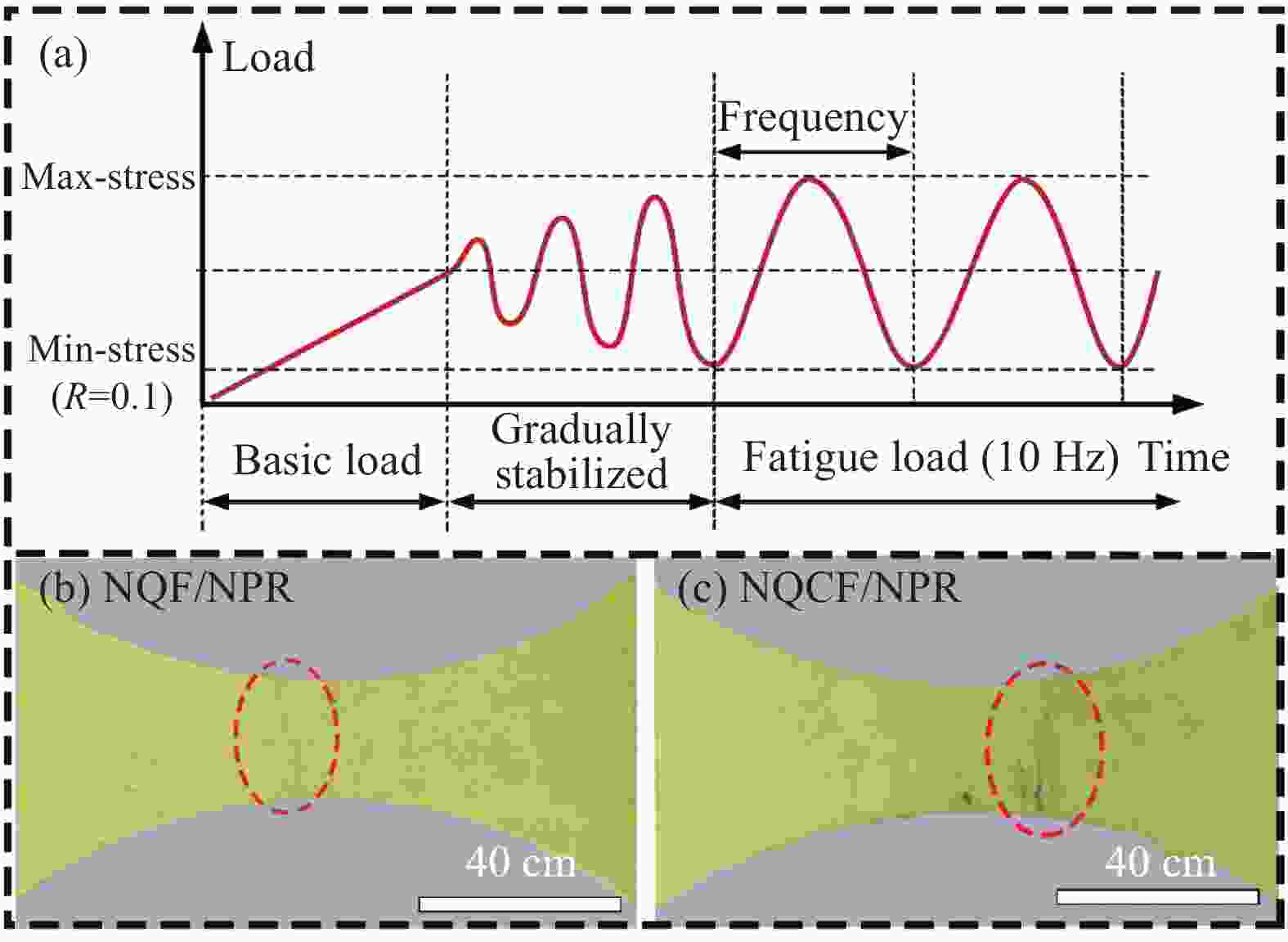

Abstract: Fiber reinforced nanoporous resin composites are a kind of lightweight, good insulation and excellent anti-ablation material, which have a typical heterogeneous structure. Under applied load, the internal nanopores will spawn microcracks. Initiation, aggregation and propagation of these microcracks should play a significant role on the strength, deformation and failure properties of the materials. Herein, nanoporous resin composites with different fiber reinforcements have been prepared using needled quartz fiber mesh (NQF) and needled quartz fiber mesh/fiber cloth (NQCF) respectively. Focusing on the mechanical behavior, the present work studied the tensile strength, tensile modulus, elongation at break, crushing strength, bending strength and the tensile fatigue resistance of composites, and the microstructure evolution of composites have been characterized by CT in situ tensile device. The results show that the mechanical properties of composites are greatly improved by introducing the fiber cloth, and the microcracks firstly initiate in the resin matrix around the edge of the needling areas, while the damage of the resin matrix could be effectively hindered by the fiber structure. Finally, finite element models of nano-porous phenolic resin (NPR) and fiber cloth have been established to analyze the fracture mechanism of materials at different scales. -

图 1 石英纤维针刺网胎(NQF) (a) 和石英纤维针刺网胎/纤维布(NQCF) (b) 结构示意图;纳米孔酚醛树脂(NPR) SEM图像 (c) 及粒径分布 (d);NQF/NPR的照片 (e) 和铺层金相显微结构图 (f);NQCF/NPR的照片 (g) 和铺层金相显微结构图 (h)

Figure 1. Structural illustration of needled quartz fiber mesh (NQF) (a) and needled quartz fiber mesh/cloth (NQCF) (b); SEM image (c) and particle size distribution (d) of nano-porous phenolic (NPR) resin; Photo (e) and microstructure image of laying-metallographic (f) of NQF/NPR; Photo (g) and microstructure image of laying-metallographic (h) of NQCF/NPR

表 1 NQF/NPR、NQCF/NPR的力学性能

Table 1. Mechanical properties of NQF/NPR and NQCF/NPR

Composite Density/(g·cm−3) Tensile strength/MPa Tensile modulus/MPa Elongation/% NQF/NPR 0.45 12.1±1.1 1400±200 1.5±0.1 NQCF/NPR 0.56 21.3±1.0 2980±200 3.5±0.1 表 2 NQF/NPR与NQCF/NPR的疲劳性能

Table 2. Fatigue performance of NQF/NPR and NQCF/NPR

Composite Initial strength/

MPaStrength of 55%

stress level/MPaNQF/NPR 18.4 8.1 NQCF/NPR 24.1 21.2 -

[1] ZOBY E, THOMPSON R, WURSTER K. Aeroheating design issues for reusable launch vehicles-A perspective[C]//34th AIAA Fluid Dynamics Conference and Exhibit. Portland, 2004: 2535. [2] KARIMI M S, OBODIB M J. Investigation and recent developments in aerodynamic heating and drag reduction for hypersonic flows[J]. Heat and Mass Transfer,2019,55(2):547-569. doi: 10.1007/s00231-018-2416-1 [3] 桂业伟. 高超声速飞行器综合热效应问题[J]. 中国科学: 物理学 力学 天文学, 2019, 49(11):139-153.GUI Yewei. Comprehensive thermal effects of hypersonic vehicles[J]. Scientia Sinica Physica, Mechanica & Astronomica,2019,49(11):139-153(in Chinese). [4] 袁海根, 曾金芳, 杨杰, 等. 防热抗烧蚀复合材料研究进展[J]. 化学推进剂与高分子材料, 2006, 4(1):21-25. doi: 10.3969/j.issn.1672-2191.2006.01.005YUAN Haigen, ZENG Jinfang, YANG Jie, et al. Research progress of high temperature thermoprotective and ablation resistant composite materials[J]. Chemical Propellants & Polymeric Materials,2006,4(1):21-25(in Chinese). doi: 10.3969/j.issn.1672-2191.2006.01.005 [5] LAUB B, CHEN Y K, DEC J. Development of a high-fidelity thermal/ablation response model for sla-561 v[C]. 41st AIAA Thermophysics Conference. San Antonio, 2009: 4232. [6] 王瑞杰, 郭建业, 宋寒, 等. 酚醛气凝胶多功能复合材料的设计与性能[J]. 材料导报, 2021, 35(S01): 548-551.WANG Ruijie, GUO Jianye, SONG Han, et al. Design and properties of phenolic aerogel multifunctional composites[J]. Materials Reports, 201, 35(S01): 548-551. [7] 张鸿宇, 钱震, 牛波, 等. 低密度纤维增强酚醛气凝胶复合材料的力学特性及断裂机制[J]. 复合材料学报, 2022, 39(8):3663-3673.ZHANG Hongyu, QIAN Zhen, NIU Bo, et al. Mechanical properties and fracture mechanism of low-density needled fiber preforms reinforced phenolic aerogel composites[J]. Acta Materiae Compositae Sinica,2022,39(8):3663-3673(in Chinese). [8] 钱震, 张鸿宇, 张琪凯, 等. 高强度-中密度纳米孔树脂基防隔热复合材料的制备与性能[J]. 复合材料学报, 2023, 40(1):83-95.QIAN Zhen, ZHANG Hongyu, ZHANG Qikai, et al. Preparation and properties of high strength-medium density nanoporous resin-based ablation/insulation integrated composites[J]. Acta Materiae Compositae Sinica,2023,40(1):83-95(in Chinese). [9] 董金鑫, 朱召贤, 姚鸿俊, 等. 酚醛气凝胶/碳纤维复合材料的结构调控及性能研究[J]. 化工学报, 2018, 69(11):4896-4901.DONG Jinxin, ZHU Zhaoxian, YAO Hongjun, et al. Structural control and properties of phenolic aerogel/carbon fiber composites[J]. CIESC Journal,2018,69(11):4896-4901(in Chinese). [10] 贾献峰, 刘旭华, 乔文明, 等. 酚醛浸渍碳烧蚀体(PICA)的制备, 结构及性能[J]. 宇航材料工艺, 2016, 46(1):77-80. doi: 10.3969/j.issn.1007-2330.2016.01.013JIA Xianfeng, LIU Xiaohua, QIAO Wenming, et al. Preparation and properties of phenolic impregnated carbon ablator[J]. Aerospace Materials and Technology,2016,46(1):77-80(in Chinese). doi: 10.3969/j.issn.1007-2330.2016.01.013 [11] 贾献峰, 王际童, 龙东辉, 等. PICA-X 的制备及其炭化前后性能研究[J]. 宇航材料工艺, 2016, 46(6):46-49.JIA Xianfeng, WANG Jitong, LONG Donghui, et al. Preparation and properties of PICA-X before and after carbonization[J]. Aerospace Materials and Technology,2016,46(6):46-49(in Chinese). [12] 杜善义. 高超声速飞行器的热防护材料及结构问题[C]. 中国力学学会学术大会. 杭州, 2009.DU Shanyi. Thermal protection materials and structure of hypersonic Vehicle[C]. Academic Conference of Chinese Society of Mechanics. Hangzhou, 2009(in Chinese). [13] 朱召贤, 董金鑫, 贾献峰, 等. 酚醛气凝胶/炭纤维复合材料的结构与烧蚀性能[J]. 新型炭材料, 2018, 33(4):370-376.ZHU Zhaoxian, DONG Jinxin, JIA Xianfeng, et al. The microstructure and ablation behavior of carbon fiber/henolic aerogel composites[J]. New Carbon Materials,2018,33(4):370-376(in Chinese). [14] 杜修力, 金浏. 混凝土材料宏观力学特性分析的细观单元等效化模型[J]. 计算力学学报, 2012, 29(5):654-661.DU Xiuli, JIN Liu. Meso-element equivalent model for macro-scopic mechanical properties analysis of concrete materials[J]. Chinese Journal of Computational Mechanics,2012,29(5):654-661(in Chinese). [15] 郑晓霞, 郑锡涛, 缑林虎. 多尺度方法在复合材料力学分析中的研究进展[J]. 力学进展, 2010, 40(1):41-56.ZHENG Xiaoxia, ZHENG Xitao, GOU Linhu. The research progress on multiscale method for the mechanical analysis of composites[J]. Advances in Mechanics,2010,40(1):41-56(in Chinese). [16] LI D S, WISNOM M R. Finite element micromechanical modelling of unidirectional fibre-reinforced metal-matrix composites[J]. Composites Science and Technology,1994,51(4):545-563. doi: 10.1016/0266-3538(94)90088-4 [17] 赵秀阳. 复合材料三维重构及力学性能的有限元数值分析[D]. 济南: 山东大学, 2006.ZHAO Xiuyang. Three-dimensional reconstruction and finite element numerical analysis of mechanical properties of composites[D]. Jinan: Shandong University, 2006(in Chinese). [18] JIA W, FANG L, CHEN Z, et al. A multiscale analysis method for predicting the transverse mechanical properties of unidirectional fibre-reinforced composites[J]. Fibers and Polymers,2020,21(6):1331-1346. doi: 10.1007/s12221-020-9682-5 [19] 惠新育, 许英杰, 张卫红, 等. 平纹编织SiC/SiC复合材料多尺度建模及强度预测[J]. 复合材料学报, 2019, 36(10):2380-2388.HUI Xinyu, XU Yingjie, ZHANG Weihong, et al. Multi-scale modeling and strength prediction of plain woven SiC/SiC composites[J]. Acta Materiae Compositae Sinica,2019,36(10):2380-2388(in Chinese). [20] HE C, GE J, ZHANG B, et al. A hierarchical multiscale model for the elastic-plastic damage behavior of 3D braided composites at high temperature[J]. Composites Science and Technology,2020,196:108230. doi: 10.1016/j.compscitech.2020.108230 [21] ZHANG J, AN P. Modeling quasi-3D needle-punched C/C composites using a linear simplification representative volume element model[J]. AIP Advances,2019,9(3):035344. doi: 10.1063/1.5068727 [22] 谭勇洋, 燕瑛, 李欣, 等. 针刺C/C复合材料拉伸强度及渐进失效数值预测[J]. 航空学报, 2016, 37(12):3734-3741.TAN Yongyang, YAN Ying, LI Xin, et al. Numerical prediction of tensile strength and progressive damage of needled C/C composites[J]. Acta Aeronautica et Astronautica Sinica,2016,37(12):3734-3741(in Chinese). [23] 曹鹏军, 赵文斌, 杨斌, 等. 基于 Micro-CT图像的缎纹织物细观结构分析及渗透率预测[J]. 复合材料学报, 2023, 40(3):1767-1779.CAO Pengjun, ZHAO Wenbin, YANG Bin, et al. Meso-structure analysis and permeability prediction of satin fabric based on Micro-CT[J]. Acta Materiae Compositae Sinica,2023,40(3):1767-1779(in Chinese). [24] 邵梦洁, 谢军波, 杨志, 等. 基于Micro-CT技术的3D机织预制件细观结构分析[J]. 复合材料学报, 2021, 39(8):4129-4138.SHAO Mengjie, XIE Junbo, YANG Zhi, et al. Meso-structure analysis and permeability prediction of satin fabric based on Micro-CT[J]. Acta Materiae Compositae Sinica,2021,39(8):4129-4138(in Chinese). [25] GE L, LI H, ZHONG J, et al. Micro-CT based trans-scale damage analysis of 3D braided composites with pore defects[J]. Composites Science and Technology,2021,211:108830. doi: 10.1016/j.compscitech.2021.108830 [26] 中国国家标准化管理委员会. 纤维增强塑料拉伸性能试验方法: GB/T 1447—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Fiber-reinforced plastic composites-Determination of tensile properties: GB/T 1447—2005[S]. Beijing: Standards Press of China, 2005(in Chinese). [27] 中国国家标准化管理委员会. 纤维增强塑料层合板拉-拉疲劳性能试验方法: GB/T 16779—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of People’s Republic of China. Test method for tensile-tensile fatigue properties of fiber-reinforced plastic laminates: GB/T 16779—2008[S]. Beijing: China Standard Press of China, 2008(in Chinese). [28] 邱爽, 周金宇. 不同应力水平对碳纤维复合材料疲劳剩余刚度的影响[J]. 航空材料学报, 2018, 38(2):110-117.QIU Shuang, ZHOU Jinyu. Effect of different stress levels on fatigue residual stiffness of carbon fiber reinforced composites[J]. Journal of Aeronautical Materials,2018,38(2):110-117(in Chinese). -

下载:

下载: