Damage and repair study of in-situ polymerized carbon fiber reinforced PMMA composites

-

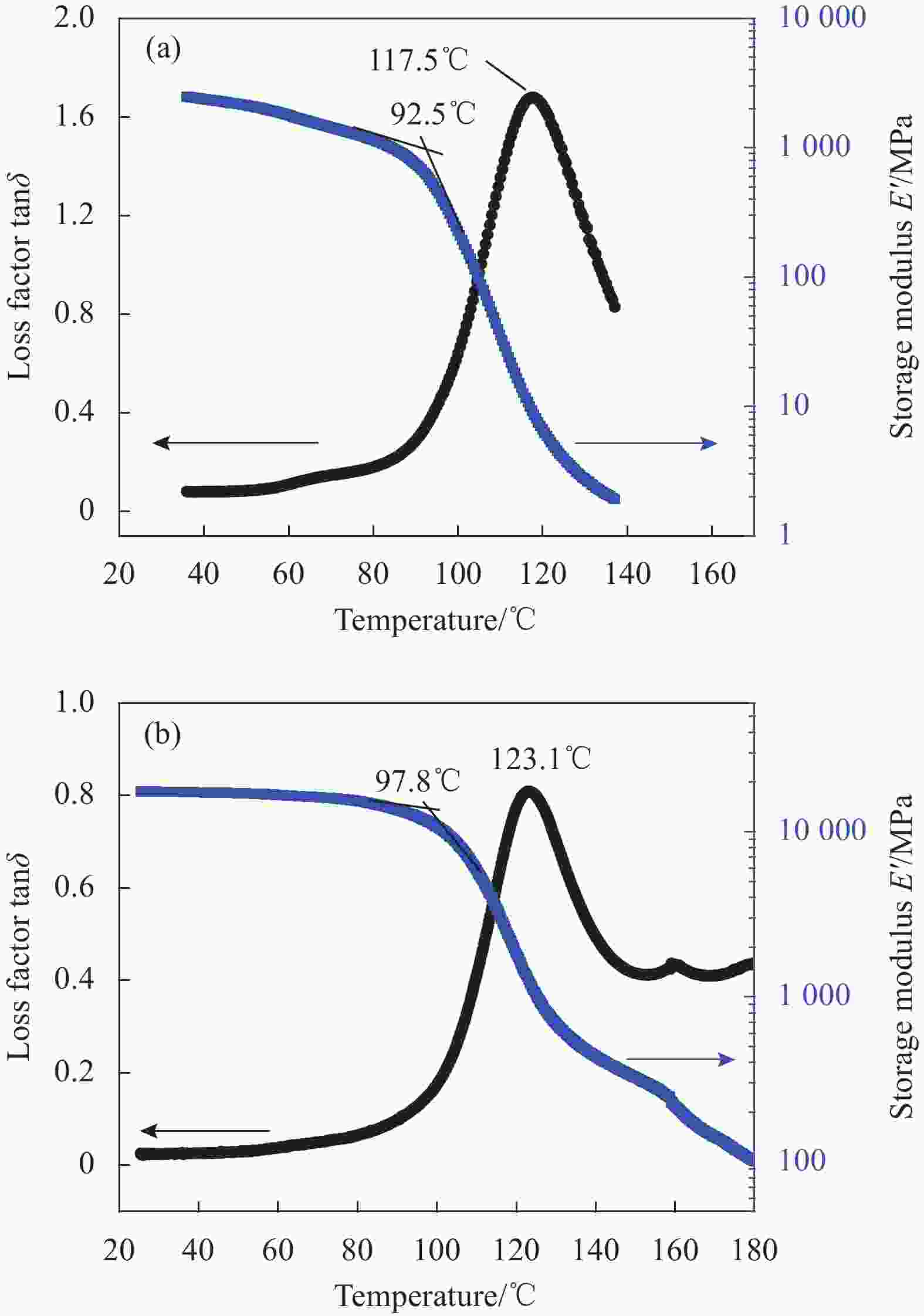

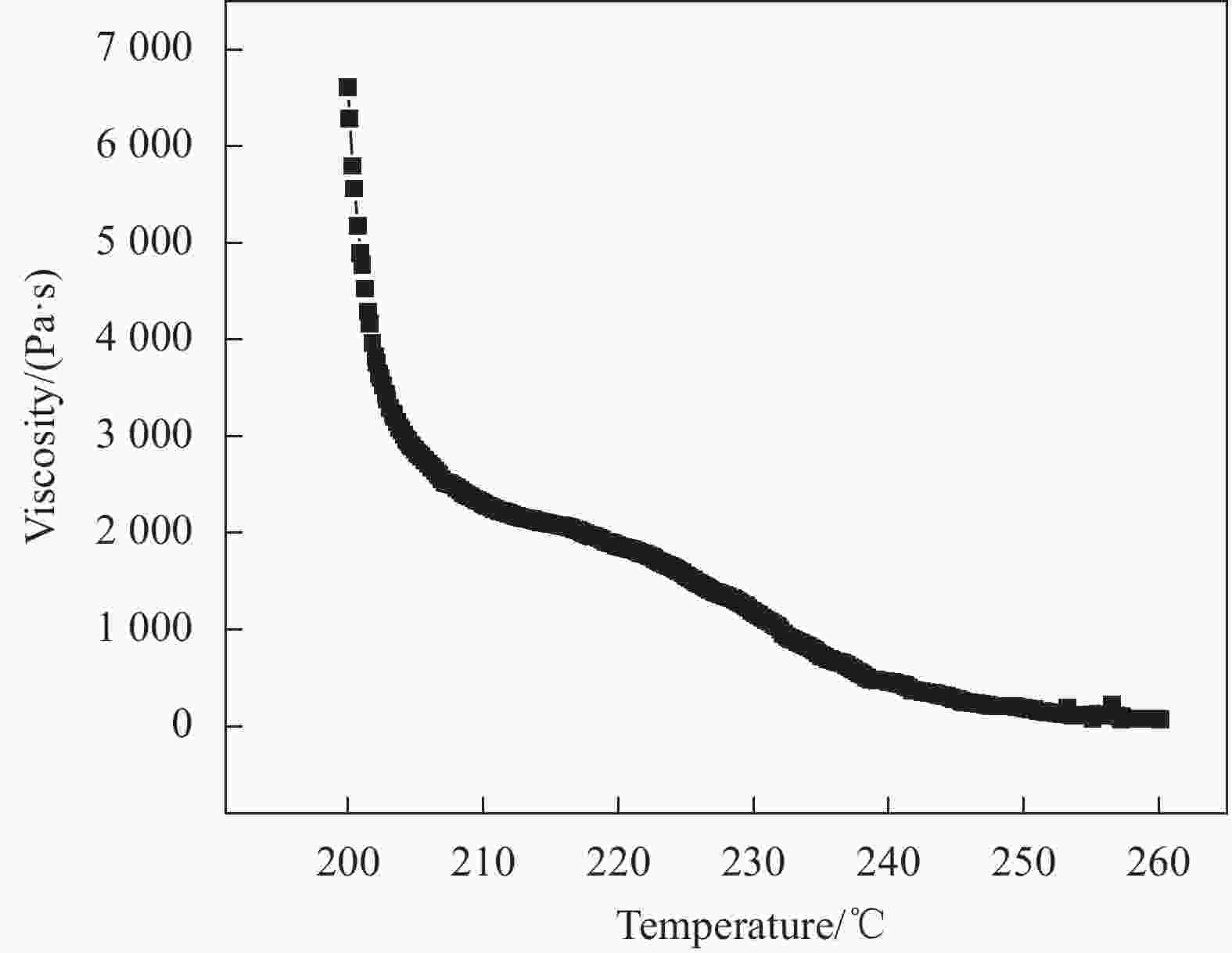

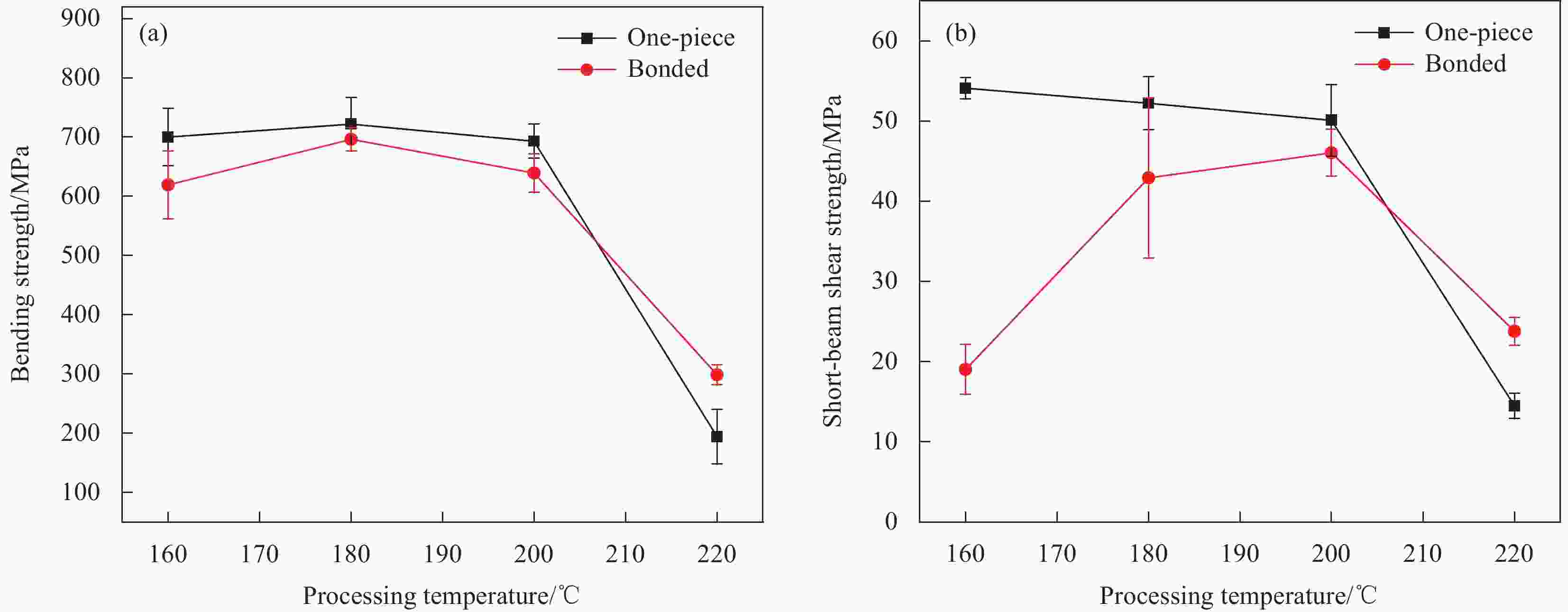

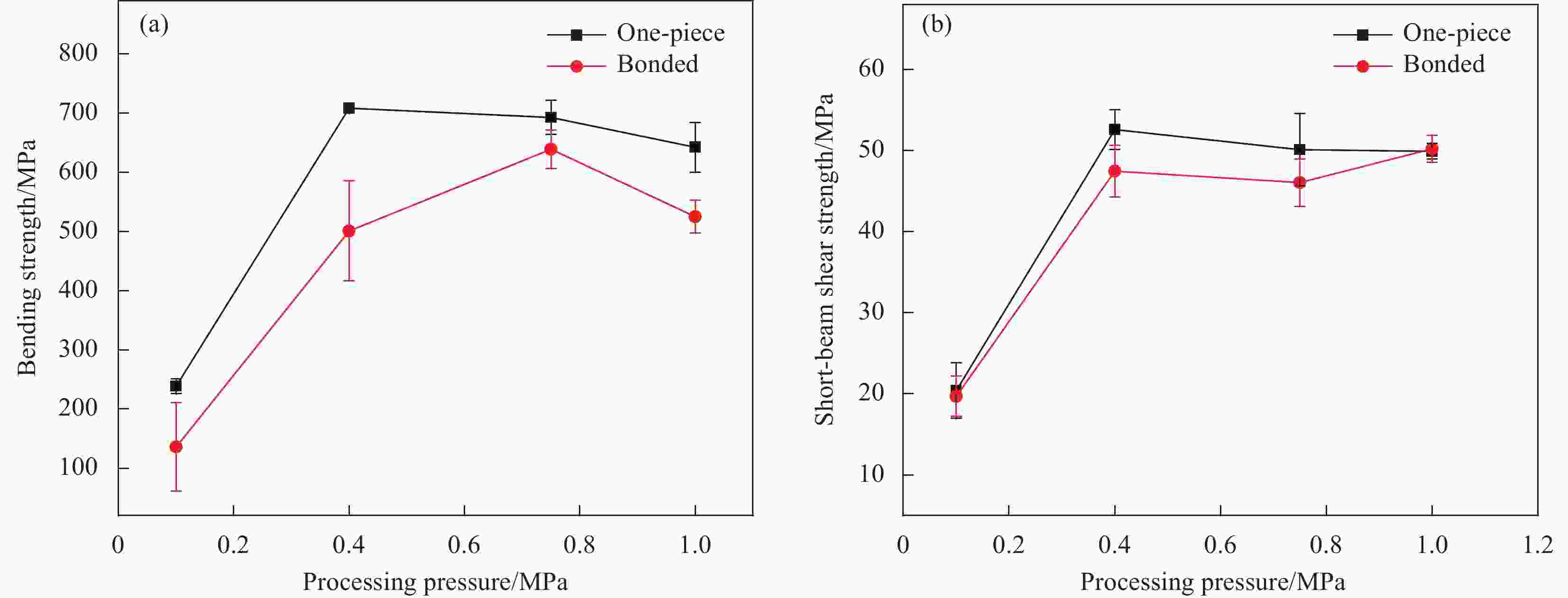

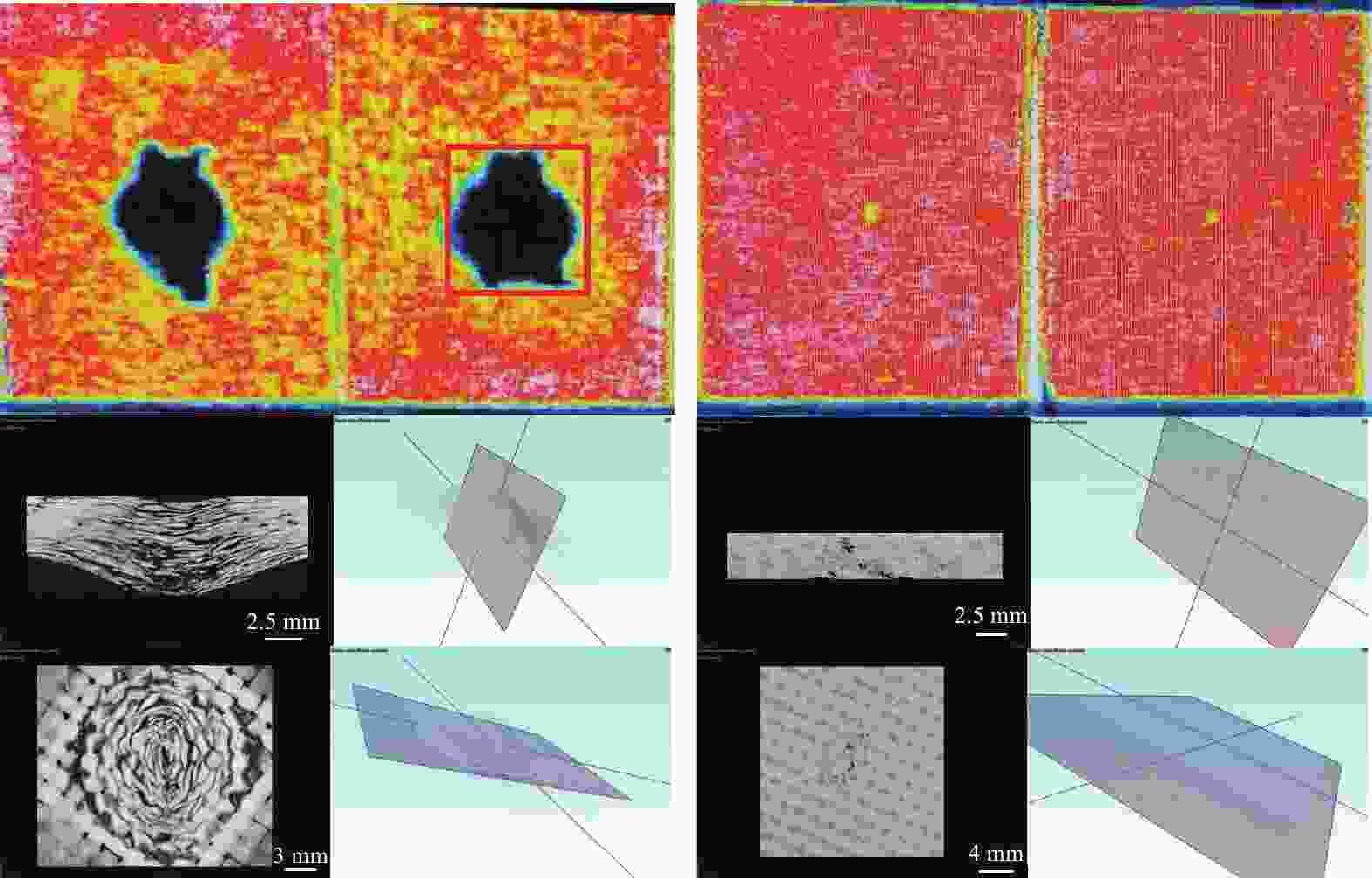

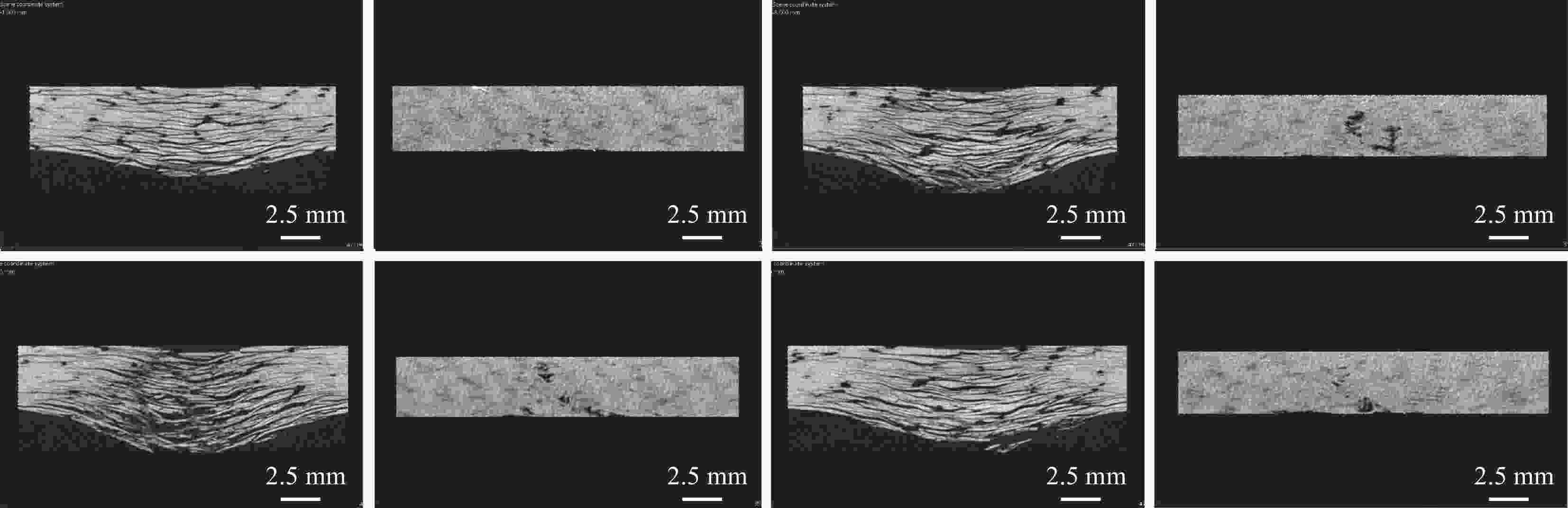

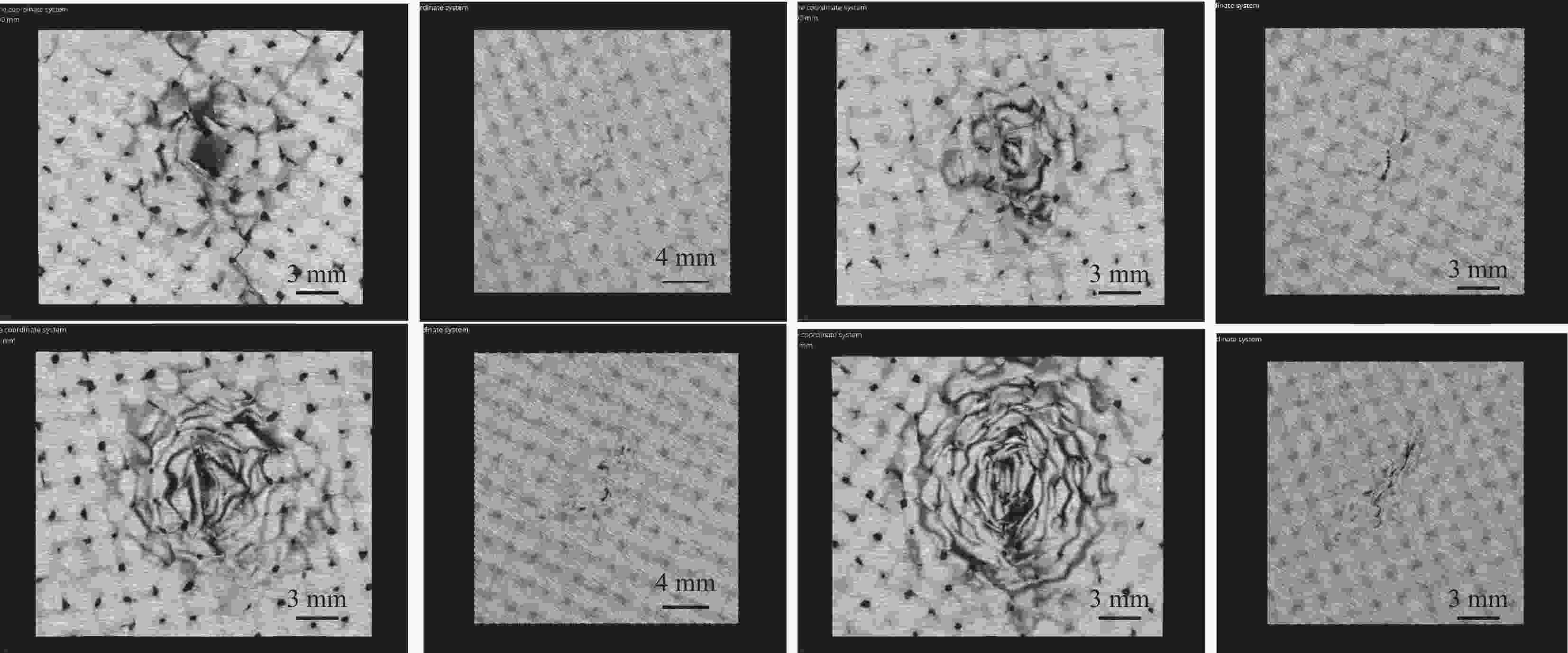

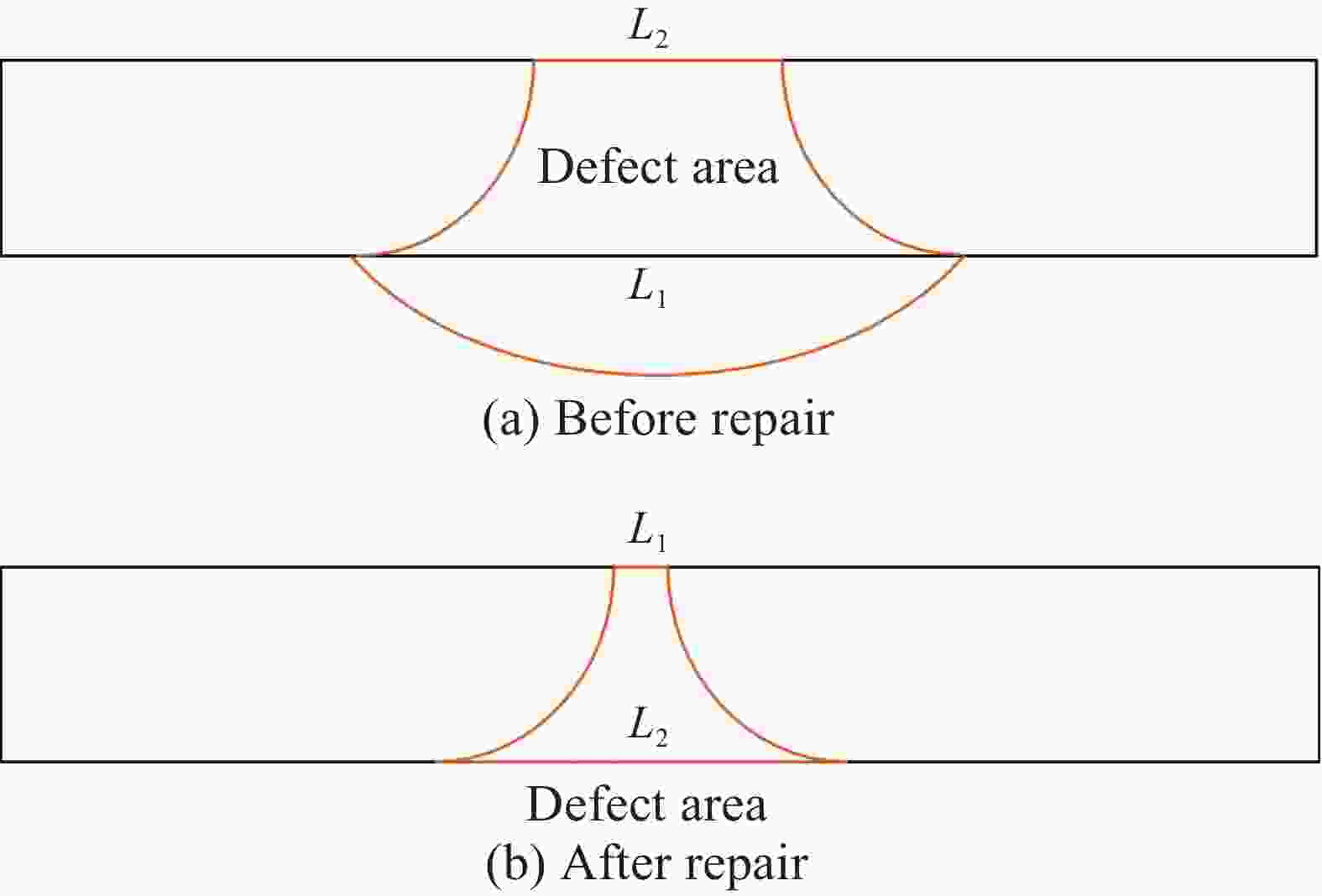

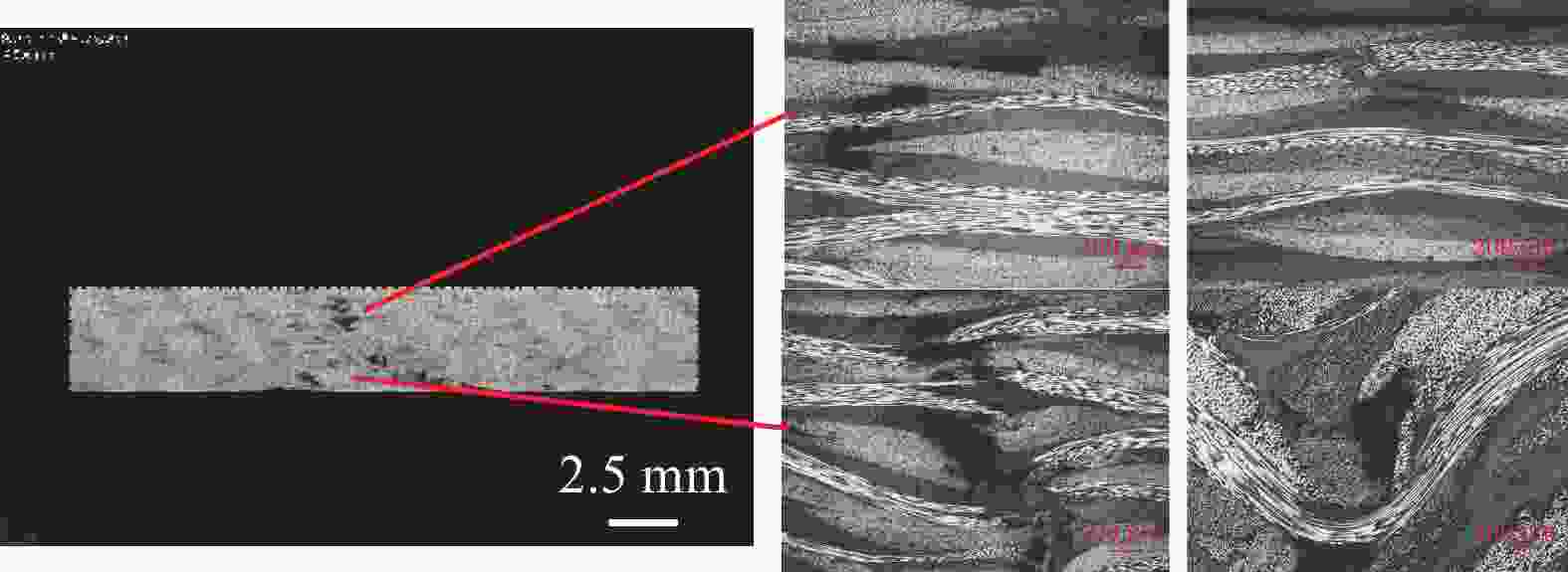

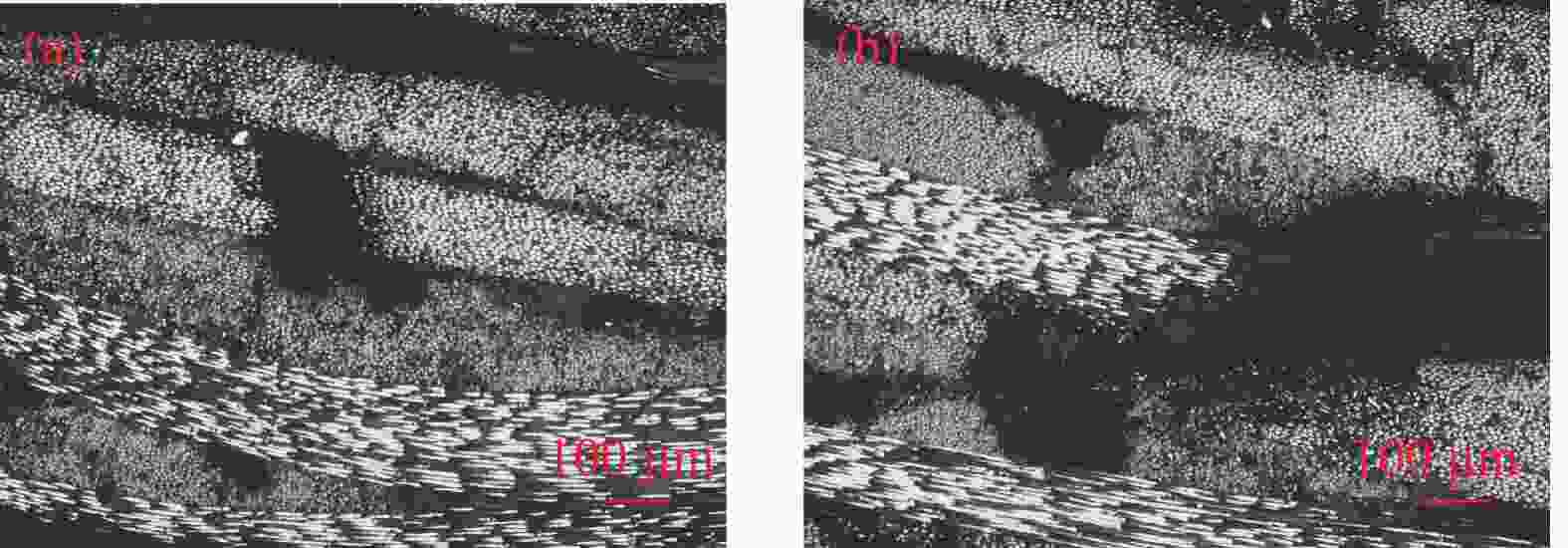

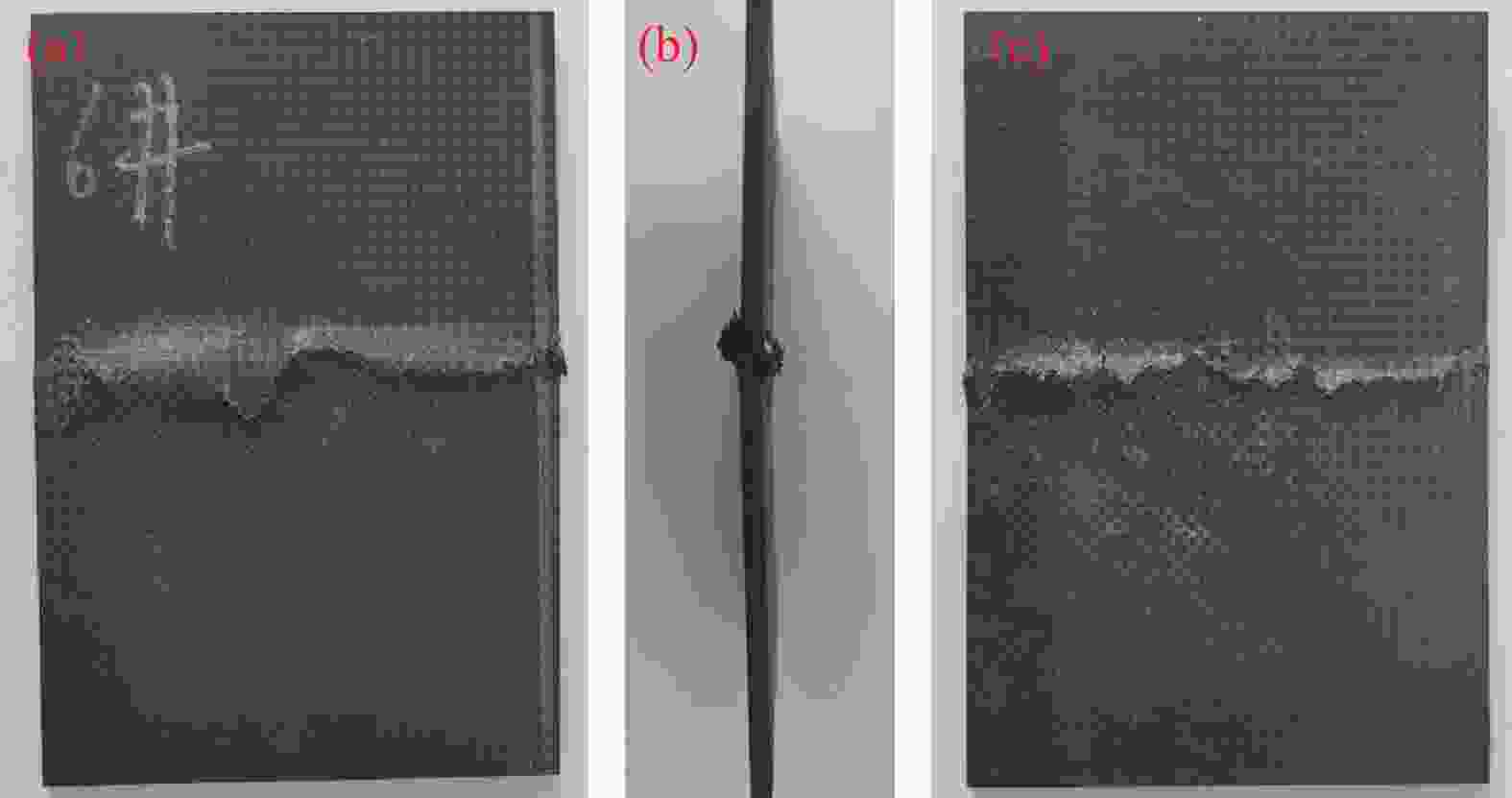

摘要: 基于热塑性复合材料易修复的特性,开展了碳纤维增强聚甲基丙烯酸甲酯(PMMA)基复合材料修复技术研究。研究了工艺温度、压力和时间对复合材料力学性能的影响规律。结果表明:在200℃、0.75 MPa压力下保持10 min可以获得优化的复合材料力学性能。引入低速冲击损伤,使用热压修复工艺修复碳纤维增强PMMA基复合材料的损伤。通过X射线断层扫描测试、超声波无损检测技术和断面摄像方法评估了此复合材料的损伤行为和修复效果。结果表明:低速冲击对碳纤维增强PMMA基复合材料的损伤分为低变形量区域的纵向开裂与分层和高变形量区域的纤维断裂与基体失效的混合模式。碳纤维增强PMMA基复合材料损伤试样经过热压修复后,损伤外形恢复良好,损伤区域大小显著减少,内部的开裂和分层等损伤恢复良好,复合材料压缩强度从140 MPa恢复至263 MPa,达到未损伤复合材料压缩性能(307 MPa)的85.7%。Abstract: According to the repairability of thermoplastic composites, the repair process of carbon fiber reinforced PMMA composites was studied. The effects of temperature, pressure, and time on the mechanical properties of the composites were compared. Results show that the optimal repaired properties of composites could be obtained at 200℃ and 0.75 MPa pressure for 10 minutes. By introducing low-speed impact damage, the damaged parts of the composites were repaired by a hot pressing process. The composite's damage behaviors and repair effect were investigated by nondestructive testing and cross-section photography. Experimental results show that the impact damage of carbon fiber reinforced PMMA composites can be divided into two types: Lengthways cracking and delamination in small deformation areas and the mixed-mode of fiber fracture and resin failure in big deformation areas. After repairing, the damaged shape and the internal delamination damages of the damaged samples are recovered well, the volume of the damaged area is significantly reduced, and the compressive strength of the composite is recovered from 140 MPa to 263 MPa, which is 85.7% of the undamaged composite (307 MPa).

-

Key words:

- hot press /

- repair /

- damage analysis /

- thermoplastic resin /

- composites

-

表 1 整体成型与粘接PMMA基复合材料试样修复结果对比

Table 1. Comparison of repair results between one-piece and bonded PMMA composite samples

Specimen

numberTreatment process Bending strength/MPa Bending modulus/GPa Short-beam shear strength/MPa One-piece Bonded One-piece Bonded One-piece Bonded 1 0.1 MPa/180℃/10 min 565 503 47.3 41.9 37.1 40.9 2 0.1 MPa/200℃/10 min 224 136 34.9 25.9 20.4 19.7 3 0.4 MPa/200℃/10 min 708 501 39.5 44.1 52.6 47.5 4 0.75 MPa/160℃/10 min 700 619 54.5 46.1 54.1 19.0 5 0.75 MPa/180℃/10 min 722 696 50.9 44.4 52.2 42.9 6 0.75 MPa/200℃/10 min 693 639 50.2 44.2 50.1 46.1 7 0.75 MPa/220℃/10 min 194 298 38.2 36.6 14.5 23.8 8 1.0 MPa/180℃/10 min 684 628 43.8 38.4 53.3 53.5 9 1.0 MPa/200℃/10 min 642 525 44.1 37.8 49.9 50.2 10 1.0 MPa/200℃/30 min Bulging Bulging Bulging Bulging Bulging Bulging 表 2 PMMA基复合材料修复前后试样厚度

Table 2. Thicknesses of PMMA composite samples before and after repair

Before/mm After/mm 1 3.99 4.02 2 3.97 4.00 3 3.98 4.00 4 4.02 4.03 Average 3.99 4.01 -

[1] ANDREW J J, ARUMUGAM V, SARAVANAKUMAR K, et al. Compression after impact strength of repaired GFRP composite laminates under repeated impact loading[J]. Composite Structures,2015,133:911-920. [2] SLATTERY P G, MCCARTHY C T, O'HIGGINS R M. Assessment of residual strength of repaired solid laminate composite materials through mechanical testing[J]. Compo-site Structures,2016,147:122-130. [3] CHIU W K, ZHOU Z, WANG J, et al. Battle damage repair of a helicopter composite main rotor blade[J]. Composites Part B: Engineering,2012,43(2):739-753. doi: 10.1016/j.compositesb.2011.07.014 [4] REYES G, SHARMA U. Modeling and damage repair of woven thermoplastic composites subjected to low velocity impact[J]. Composite Structures,2010,92(2):523-531. doi: 10.1016/j.compstruct.2009.08.038 [5] GANESH V V, CHAWLA N. Effect of particle orientation anisotropy on the tensile behavior of metal matrix compo-sites: Experiments and microstructure-based simulation[J]. Materials Science & Engineering A,2005,391(1-2):342-353. [6] NAEBE M, ABOLHASANI M M, KHAYYAM H, et al. Crack damage in polymers and composites: A review[J]. Polymer Reviews,2016,56(1):31-69. doi: 10.1080/15583724.2015.1078352 [7] KANG T J, KIM C. Impact energy absorption mechanism of largely deformable composites with different reinforcing structures[J]. Fibers & Polymers,2000,1(1):45-54. [8] BALLERE L, VIOT P, LATAILLADE J L, et al. Damage tolerance of impacted curved panels[J]. International Journal of Impact Engineering,2009,36(2):243-253. doi: 10.1016/j.ijimpeng.2008.03.004 [9] TAMIN M N. Micromechanical analysis of mode I crack growth in carbon fibre reinforced polymers[M]//Damage and Fracture of Composite Materials and Structures. Berlin: Springer, 2012. [10] RKOLOOR S, ABDUL-LATIFJ A, GONG X, et al. Evolution characteristics of delamination damage in CFRP compo-sites under transverse loading[M]. Berlin: Springer, 2012. [11] TAMIN M N. Damage and fracture of composite materials and structures[J]. Advanced Structured Materials,2012,18(2):265-273. [12] GUILLAUMAT L, BATSALE J C, MOURAND D. Real time infrared image processing for the detection of delamination in composite plates[J]. Composites Part A: Applied Science & Manufacturing,2004,35(7-8):939-944. doi: 10.1016/j.compositesa.2004.01.021 [13] USAMENTIAGA R, VENEGAS P, GUEREDIAGA J, et al. Automatic detection of impact damage in carbon fiber composites using active thermography[J]. Infrared Phy-sics & Technology,2013,58:36-46. [14] MAIER A, SCHMIDT R, OSWALD-TRANTA B, et al. Non-destructive thermography analysis of impact damage on large-scale CFRP automotive parts[J]. Materials,2014,7(1):413-429. doi: 10.3390/ma7010413 [15] IBRAHIM M E, SMITH R A, WANG C H. Ultrasonic detection and sizing of compressed cracks in glass- and carbon-fibre reinforced plastic composites[J]. NDT & E International,2017,92:111-121. [16] CASTAINGS M, SINGH D, VIOT P. Sizing of impact damages in composite materials using ultrasonic guided waves[J]. NDT & E International,2012,46:22-31. [17] POLIMENO U, MEO M, ALMOND D P, et al. Detecting low velocity impact damage in composite plate using nonlinear acoustic/ultrasound methods[J]. Applied Compo-site Materials,2010,17(5):481-488. doi: 10.1007/s10443-010-9168-5 [18] CLOETENS P, PATEYRON-SALOME M, BUFFIERE J Y, et al. Observation of microstructure and damage in materials by phase sensitive radiography and tomography[J]. Journal of Applied Physics,1997,81(9):5878-5886. doi: 10.1063/1.364374 [19] DAVIS G R, ELLIOTT J C, LEE W K, et al. Fatigue cracks in aluminum samples studied with X-ray phase contrast imaging and with absorption microtomography[J]. Advances in X-Ray Analysis, 2002, 45: 123-126. [20] WRIGHT P, FU X, SINCLAIR I, et al. Ultra high resolution computed tomography of damage in notched carbon fiber—Epoxy composites[J]. Journal of Composite Materials,2008,42(19):1993-2002. doi: 10.1177/0021998308092211 [21] KING A, JOHNSON G, ENGELBERG D, et al. Observations of intergranular stress corrosion cracking in a grain-mapped polycrystal[J]. Science,2008,321(5887):382-385. doi: 10.1126/science.1156211 [22] POULSEN H F, NIELSEN S F, LAURIDSEN E M, et al. Three-dimensional maps of grain boundaries and the stress state of individual grains in polycrystals and powders[J]. Jour-nal of Applied Crystallography,2001,34(6):751-756. doi: 10.1107/S0021889801014273 [23] LARSON B C, YANG W, ICE G E, et al. Three-dimensional X-ray structural microscopy with submicrometre resolution[J]. Nature,2002,415(6874):887-890. doi: 10.1038/415887a [24] ROLLAND H, SAINTIER N, WILSON P, et al. In situ X-ray tomography investigation on damage mechanisms in short glass fibre reinforced thermoplastics: Effects of fibre orientation and relative humidity[J]. Composites Part B: Engi-neering,2017,109:170-186. doi: 10.1016/j.compositesb.2016.10.043 [25] COSMI F, BERNASCONI A. Micro-CT investigation on fatigue damage evolution in short fibre reinforced polymers[J]. Composites Science & Technology,2013,79:70-76. [26] ASTM. Standard test method for glass transition tempera-ture (DMA Tg) of polymer matrix composites by dynamic mechanical analysis (DMA): ASTM D7028-07[S]. West Conshohocken: ASTM International, 2007. [27] ASTM. Standard test method for deflection temperature of plastics under flexural load in the edgewise position: ASTM D648-18[S]. West Conshohocken: ASTM International, 2018. [28] ASTM. Standard test method for measuring the damage re-sistance of a fiber-reinforced polymer matrix composite to a drop-weight Impact event: ASTM D7136/D7136 M-20[S]. West Conshohocken: ASTM International, 2020. [29] ASTM. Standard test method for compressive residual strength properties of damaged polymer matrix composite laminates: ASTM D7137/D7137 M-17[S]. West Conshohocken: ASTM International, 2017. [30] WYPYCH G. Handbook of polymers: Second edition[M]. Toronto: ChemTec Publishing, 2016. [31] BOUVET C, RIVALLANT S. Damage tolerance of compo-site structures under low-velocity impact[J]. Dynamic Deformation, Damage and Fracture in Composite Materials and Structures,2016,19:7-33. -

下载:

下载: