Slot-die coated large-area ZnO films for flexible organic solar cells

-

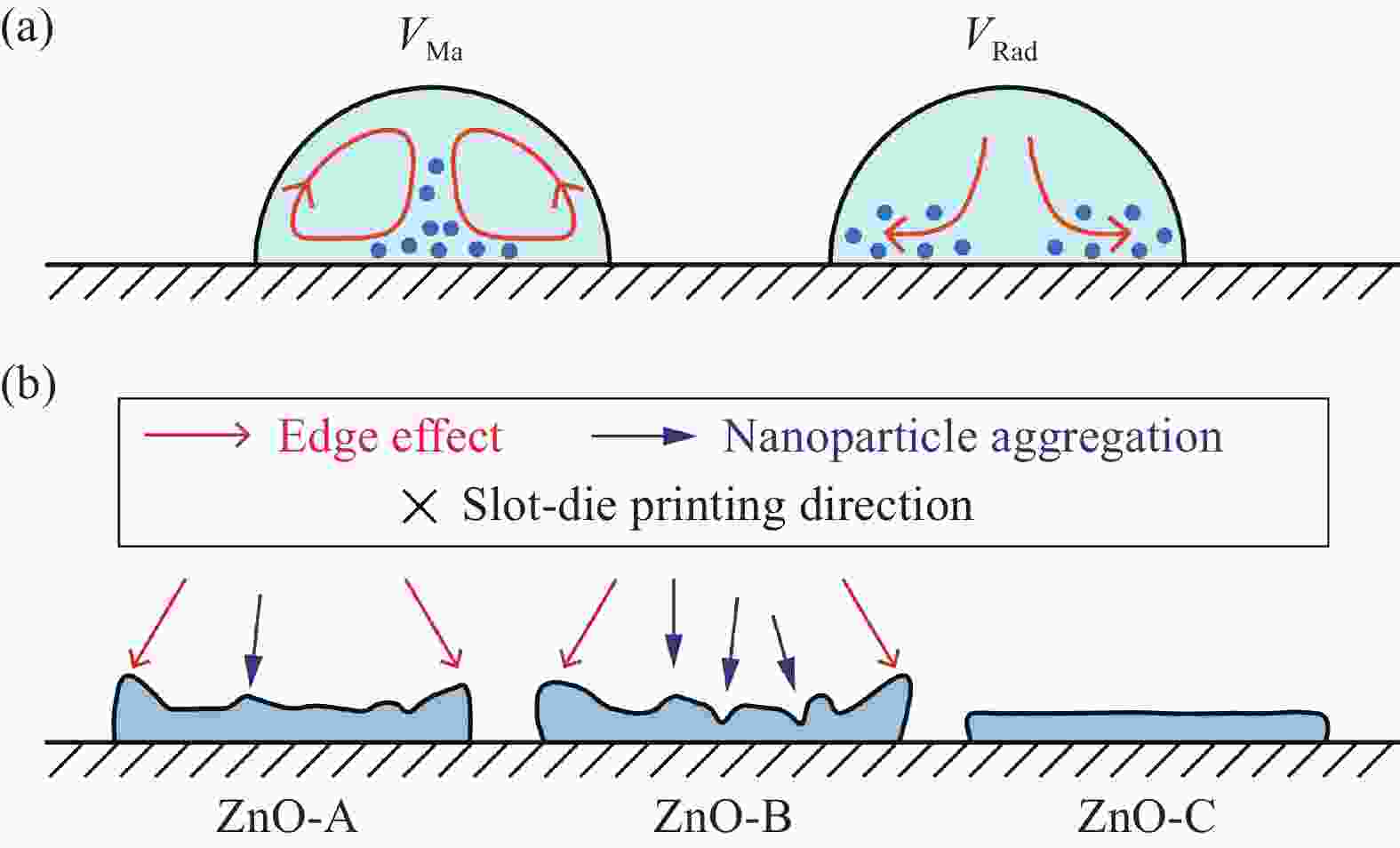

摘要: 发展有机太阳能电池的印刷法制备技术是实现有机光伏产业化的关键。在有机光伏器件中,氧化锌是常用的电子传输层材料。氧化锌纳米粒子在印刷过程中的自聚集,以及大面积薄膜干燥的不均匀,严重影响了大面积印刷有机光伏器件的性能。通过调控氧化锌墨水溶剂和引入墨水分散添加剂,获得一种适用于大面积涂布的氧化锌纳米墨水。其中复合溶剂的使用调控了氧化锌墨水的流变特性,进而改善了涂布薄膜中的边缘效应;而乙醇胺添加剂的引入解决了墨水在存放和印刷过程中的聚集问题。该墨水具有18个月以上保存稳定性,以及优异的狭缝涂布适印性。基于上述墨水,采用狭缝涂布方法制备获得的100×100 mm2尺寸的大面积涂布薄膜具有优异的均匀性。将印刷的大面积氧化锌薄膜作为柔性有机太阳能电池的电子传输层,获得1 cm2柔性有机太阳能电池的效率超过了14%,同时表现优异的重复性。Abstract: The preparation of large-area organic solar cells through coating or printing is the key to realizing the industrialization of organic photovoltaics. In the organic solar cells, ZnO is a commonly used material as an electron transporting layer. However, the self-aggregation of ZnO nanoparticles and the uneven drying of films during printing cause large numbers of defects and poor uniformity in large-area films, which seriously affects the perfor-mance of large-area printed organic photovoltaic devices. In this work, a ZnO nanoink suitable for large-area slot-die coating was developed by regulating solvent and introducing an ink dispersion stabilizer. The rheological pro-perties of ZnO nanoink were regulated by using a mixed solvent, which solved the issue of edge effect in the coated film. The introduction of ethanolamine additives solves the problem of ink aggregation during storage and printing, allowing the ink to maintain long-term stability during 18 months of storage. With this nanoink, large-area films with a size of 100×100 mm2 were obtained by slot-die coating. Such a film shows excellent film uniformity. Using the printed large-area ZnO films as electron transporting layer, an efficiency of higher than 14% is obtained for 1 cm2 flexible organic solar cells.

-

Key words:

- organic solar cells /

- printing photovoltaics /

- slot-die coating /

- ZnO nanoink /

- large area uniformity

-

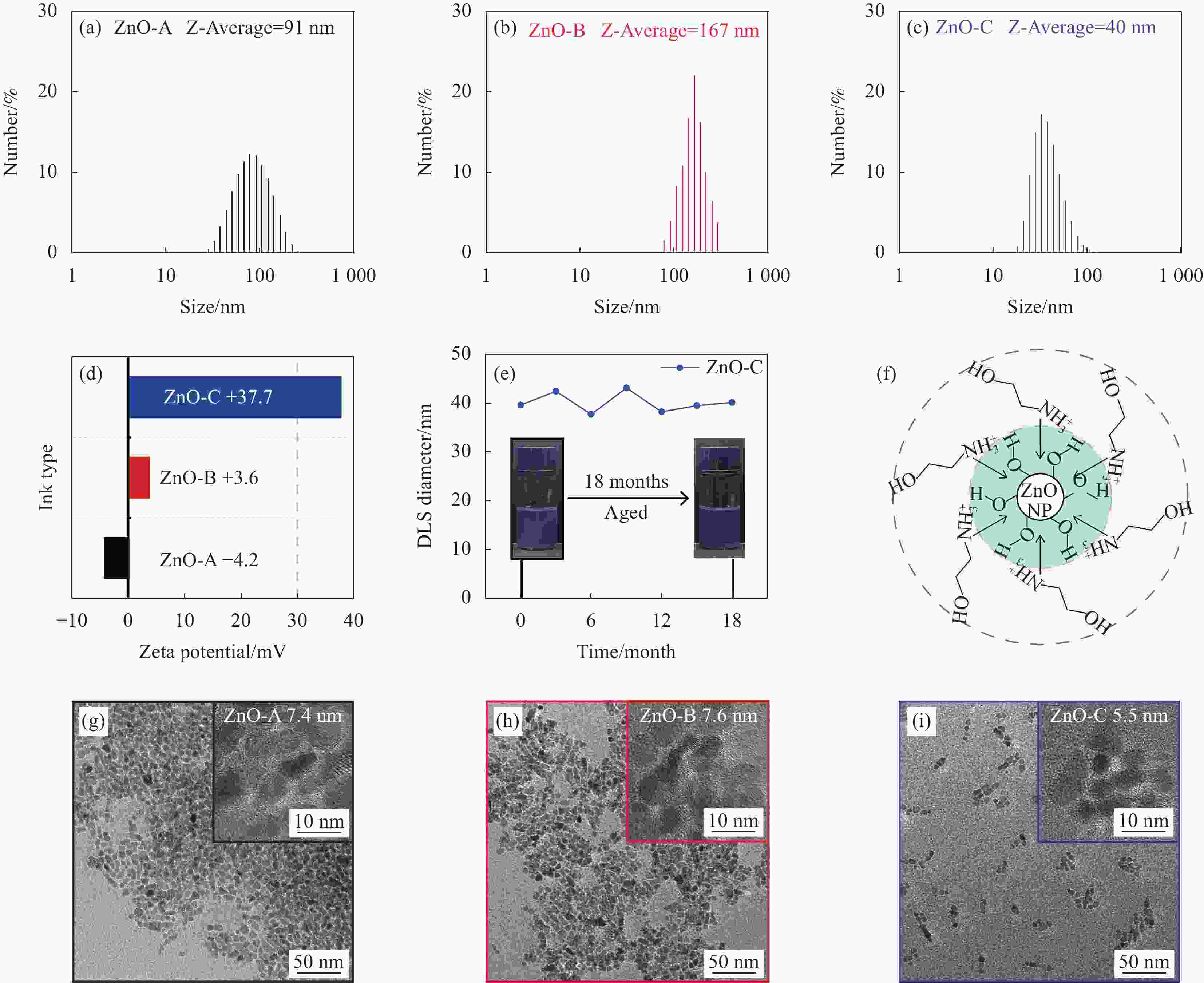

图 1 ZnO-A (a)、ZnO-B (b)和ZnO-C (c)墨水的DLS测试结果;(d)三种氧化锌纳米墨水的Zeta电位;(e) ZnO-C纳米墨水的流体力学半径随老化时间的变化统计图;(f)乙醇胺的配位作用示意图;((g)~(i)) 三种氧化锌纳米粒子的TEM图像

Figure 1. Diameter of ZnO-A (a), ZnO-B (b) and ZnO-C (c) nanoinks measured through DLS; (d) Zeta potential of the ZnO nanoinks; (e) Diameter of ZnO-C nanoink during long-term storage; (f) Diagram of ethanolamine coordination; ((g)-(i)) TEM images of the ZnO nanoparticles

DLS—Dynamic light scattering; Z-average—Average hydrodynamic diameter obtained from DLS light intensity; ZnO-A—ZnO nanoparticle ink dispersed in n-butanol solvent; ZnO-B—ZnO nanoparticle ink dispersed in the mixed solvent containing 66% n-butanol and 34% ethanol; ZnO-C—Zinc oxide nanoparticle ink dispersed in mixed solvents containing 66% n-butanol and 34% ethanol, and added with 1.5 mg/mL ethanolamine

图 2 (a)狭缝涂布印刷示意图;((b)~(d)) 三种氧化锌薄膜的SEM图像;(e)自制的36通道的紫外可见光吸收光谱仪示意图;((f)~(h)) 根据36通道吸收光谱测试薄膜397 nm处的吸收强度绘制的氧化锌薄膜的吸收强度分布图

Figure 2. (a) Schematic diagram of slot-die coating; ((b)-(d)) SEM images of three kinds of ZnO films; (e) Schematic diagram of homemade 36-channel UV-vis absorption spectrometer; ((f)-(h)) Absorption intensity distribution diagram of ZnO films based on absorption intensity at 397 nm

ETL—Electron transporting layer; AgNWs/PET—Ag nanowires/polyethylene terephthalate

图 4 (a)狭缝涂布印刷的100×100 mm2大面积ZnO-C薄膜;(b)本论文所使用的倒置柔性器件结构示意图;基于这三种氧化锌薄膜的1 cm2 PM6:Y6倒置柔性有机太阳能电池最优器件的J-V曲线(c)和器件性能分布图(d)

Figure 4. (a) 100×100 mm2 large-area ZnO-C film fabricated through slot-die coating; (b) Device structure of flexible 1 cm2 PM6:Y6 inverted flexible organic solar cells; (c) J-V characteristics of the optimized devices; (d) Histogram of device performance

表 1 乙醇胺(EA)添加剂含量对ZnO-C的小面积刚性器件性能影响

Table 1. Device performance of the small area rigid ZnO-C solar cells with different concentrations of ethanol amine (EA)

EA/(mg·mL−1) VOC/V JSC/(mA·cm−2) FF/% Average PCE/% Maximum PCE/% 0 0.839 23.00 70.04 13.52 ± 0.46 13.87 0.5 0.837 23.49 71.34 14.02 ± 0.29 14.23 1.0 0.836 24.41 71.90 14.68 ± 0.12 14.71 1.5 0.837 24.46 71.55 14.65 ± 0.19 14.81 2.0 0.835 24.05 71.38 14.33 ± 0.44 14.66 5.0 0.839 23.86 70.91 14.20 ± 0.46 14.59 10.0 0.798 24.28 47.52 9.20 ± 0.96 10.08 Notes: PCE—Photovoltaic conversion efficiency of the 8 individual devices; These devices with an area of 0.09 cm2 had a structure of Glass/ITO/ZnO-C ETL/PM6:Y6/MoO3/Al; VOC—Open circuit voltage; JSC—Short circuit current density; FF—Filling factor. 表 2 基于不同厚度的ZnO-C狭缝涂布薄膜作电子传输层的1 cm2 PM6:Y6倒置柔性有机太阳能电池性能

Table 2. Performance of 1 cm2 PM6:Y6 inverted flexible organic solar cells based on ZnO-C electron transporting layers with different thicknesses

ZnO-C/(mg·mL−1) Thickness/nm VOC/V JSC/(mA·cm−2) FF/% Average PCE/% Maximum PCE/% 20 23 ± 6.4 0.825 22.21 68.03 12.47 ± 0.19 12.66 40 43 ± 5.1 0.825 24.26 68.76 13.76 ± 0.17 13.88 60 59 ± 3.9 0.825 24.79 69.32 14.18 ± 0.14 14.38 80 86 ± 6.6 0.825 23.44 68.94 13.33 ± 0.18 13.56 Note: PCE—Photovoltaic conversion efficiency of the 9 individual devices. 表 3 基于ZnO-A、ZnO-B和ZnO-C薄膜为电子传输层 (ETL) 的1 cm2 PM6:Y6倒置柔性有机太阳能电池性能

Table 3. Performance of 1 cm2 PM6:Y6 inverted flexible organic solar cells based on ZnO-A, ZnO-B, and ZnO-C electron transporting layers (ETL)

ETL Thickness/nm VOC/V JSC/(mA·cm−2) FF/% Average PCE% Maximum PCE/% Rs/(Ω·cm2) Rsh/(Ω·cm2) ZnO-A 65 ± 6.6 0.825 22.98 67.09 12.72 ± 0.35 13.22 6.8 774.72 ZnO-B 63 ± 4.7 0.825 22.50 66.85 12.41 ± 0.30 12.41 7.9 904.08 ZnO-C 59 ± 3.9 0.825 24.79 69.32 14.18 ± 0.14 14.38 6.7 1006.36 Notes: Rs—Series resistance;Rsh—Shunt resistance. 表 4 柔性大面积(≥1 cm2) 有机太阳能电池的进展

Table 4. A recent report of flexible large-area (≥1 cm2 ) organic solar cells progress

Year Device Structure ETL coating method Area/cm2 PCE/% Ref. 2017 PES/Ag/PEI/P3HT:ICBA/CRL/PTB7:PC71BM/

PEDOT:PSS/Silver gridSpin coating 10.5 6.5 [31] 2017 PET-ITO/ZnO NPs/PTB7-Th: p-DTS(FBTTH2)2:PC71BM/MoOX/Ag Spin coating 1.25 8.28 [32] 2018 ITO/ZnO NPs/PTB7-Th:ITIC/MoO3/Ag Spin coating 2.03 7.6 [33] 2019 PET/Ag/Cu-grid/ZnO NPs/PBDB-TF:IT-4F/MoO3/Al Spin coating 1 12.26 [34] 2019 PET/ITO/Sol-gel ZnO/PBDB-T:ITIC/MoO3/Ag Spin coating 1.04 9.77 [35] 2020 PET/AgNWs/ZnO NPs/PM6:Y6/MoO3/Al Spin coating 1 13.6 [27] 2020 PET silver-grid/Sol-gel ZnO/PTB7-Th:COi8DFIC:PC71BM/MoOX/Ag Spin coating 1 12.16 [36] 2020 PET/Nabil transparent electrode/ZnO NPs/

PTB7-Th:EH-IDTBR/MoO3/AgSpin coating 85 5.21 [37] 2021 ITO/PEDOT:PSS/PBDB-T:ITIC:FOIC/ZrAcac/Al Spin coating 1.05 9.81 [38] 2021 PET/Ag grid/AgNWs:PEI-Zn/PBDB-T-2F:Y6:PC71BM/MoO3/Ag Blade coating 54 13.2 [3] 2021 PEN/ITO/Sol-gel ZnO/BTP-eC9/MoOX/Ag Blade coating 1 16.71 [2] 2022 PET/Ag/Cu electrode/Amorphous ITO ZnO NPs/PM6:BTP-4Cl-12/MoO3/Al Spin coating 25.42 12.42 [1] Notes: PES—Polyethersulfone; PEI—Polyethyleneimine; P3HT—Poly(3-hexylthiophene-2,5-diyl); ICBA—Indene-C60 bisadduct; CRL—Charge-recombination layer; PTB7-Th—Poly[4,8-bis(5-(2-ethylhexyl)thiophen-2-yl)benzo[1,2-b;4,5-b']dithiophene-2,6-diyl-alt-(4-(2-ethylhexyl)-3-fluorothieno[3,4-b]thiophene-)-2-carboxylate-2-6-diyl)]; PC71BM—[6,6]-Phenyl C71 butyric acid methyl ester; PEDOT:PSS—Poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonate); p-DTS(FBTTH2)2—7,7-(4,4-Bis(2-ethylhexyl)-4H-silolo[3,2-b:4,5-b']dithiophene-2,6-diyl)bis(6-fluoro-4-(5'-hexyl-[2,2'-bithiophen]-5-yl)-benzo[c][1,2,5] thiadiazole); ITIC—3,9-Bis(2-methylene(3-(1,1-dicyanomethylene)-indanone))-5,5,11,11-tetrakis(4hexylphenyl)-dithieno[2,3-d:2′,3′-d′]-s-indaceno[1,2-b:5,6-b′] dithiophene; IT-4F—3,9-Bis(2-methylene-(3-(1,1-dicyanomethylene)-indanone))-5,5,11,11-tetrakis(4-hexylphenyl)-dithieno[2,3-d:2',3'-d']-s-indaceno[1,2-b:5,6-b'] dithiophene); PBDB-T—Poly[(2,6-(4,8-bis(5-(2-ethylhexyl)thiophen-2-yl)-benzo[1,2-b:4,5-b']dithiophene))-alt-(5,5-(1',3'-di-2-thienyl-5',7'-bis(2-ethylhexyl)benzo[1',2'-c:4',5'-c']dithiophene-4,8-dione)]; COi8DFIC—2,2'-([4,4,11,11-Tetrakis(4-hexylphenyl)-4,11-dihydrothieno4-hexylphenyl)-4,11-dihydrothieno[2',3':4,5]thieno[2,3-d]thieno[2'''',3'''':4''',5''']thieno[2''',3''':4'',5'']pyrano[2'',3'':4',5']thieno[2',3':4,5] thieno[3,2-b]pyran-2,9-diyl]bis{(Z)methylylidene[(2Z)-5,6-difluoro-3-oxo-1H-indene-2,1(3H)-diylidene]})dimalononitrile; EH-IDTBR—5,5'-[[4,4,9,9-Tetrakis(2-ethylhexyl)-4,9-dihydro-s-indaceno[1,2-b:5,6-b']dithiophene-2,7-diyl]bis(2,1,3-benzothiadiazole-7,4-diylmethylidyne)]bis[3-ethyl-2-thioxo-4-thiazolidinone]; FOIC—Three[thieno[3,2-b]thiophene]-2-(5/6-fluoro-3-oxo-2,3-dihydro-1H-inden-1-ylidene)-malononitrile; BTP-4Cl-12—2,2′-((2Z,2′Z)-((12,13-bis(2-butyloctyl)-3,9-diundecyl-12,13-dihydro-[1,2,5]thiadiazolo[3,4-e]thieno[2″,3″:4′,5′]thieno[2′,3′:4,5]pyrrolo [3,2-g]thieno[2′,3′:4,5]thieno[3,2-b]indole-2,10-diyl)bis(methanylylidene))bis(5,6-dichloro-3-oxo-2,3-dihydro-1H-indene-2,1-diylidene))dimalononitrile. -

[1] HAN Y, HU Z, ZHA W, et al. 12.42% Monolithic 25.42 cm2 flexible organic solar cells enabled by an amorphous ITO-modified metal grid electrode[J]. Advanced Materials,2022,34(17):e2110276. [2] LIU X, ZHENG Z, WANG J, et al. Fluidic manipulating of printable zinc oxide for flexible organic solar cells[J]. Advanced Materials,2021,34(3):e2106453. [3] QIN F, SUN L, CHEN H, et al. 54 cm2 large-area flexible organic solar modules with efficiency above 13%[J]. Advanced Materials,2021,33(39):e2103017. doi: 10.1002/adma.202103017 [4] LEVY D H, FREEMAN D, NELSON S F, et al. Stable ZnO thin film transistors by fast open air atomic layer depo-sition[J]. Applied Physics Letters,2008,92(19):192101. doi: 10.1063/1.2924768 [5] NATSUME Y, SAKATA H, Zinc oxide films prepared by sol-gel spin-coating[J]. Thin Solid Films, 2000, 372 (1/2): 30-36. [6] XIA T, KOVOCHICH M, LIONG M, et al. Comparison of the mechanism of toxicity of zinc oxide and cerium oxide nano-particles based on dissolution and oxidative stress properties[J]. ACS Nano,2008,2(10):2121-2134. doi: 10.1021/nn800511k [7] WEI J, JI G, ZHANG C, et al. Silane-capped ZnO nanoparticles for use as the electron transport layer in inverted organic solar cells[J]. ACS Nano,2018,12(6):5518-5529. doi: 10.1021/acsnano.8b01178 [8] PANASIUK Y V, RAEVSKAYA O E, STROYUK O L, et al. Colloidal ZnO nanocrystals in dimethylsulfoxide: A new synthesis, optical, photo- and electroluminescent properties[J]. Nanotechnology,2014,25(7):075601. doi: 10.1088/0957-4484/25/7/075601 [9] KREBS F C, THOMANN Y, THOMANN R, et al. A simple nanostructured polymer/ZnO hybrid solar cell-preparation and operation in air[J]. Nanotechnology,2008,19:424013. doi: 10.1088/0957-4484/19/42/424013 [10] LIU B, HAN Y, LI Z, et al. Visible light–induced degradation of inverted polymer: Nonfullerene acceptor solar cells: initiated by the light absorption of ZnO layer[J]. Solar RRL,2020,5:2000638. [11] YANG K, FU J, HU L, et al. Impact of ZnO photolumine-scence on organic photovoltaic performance[J]. ACS Applied Materials & Interfaces,2018,10(46):39962-39969. [12] FU P, GUO X, ZHANG B, et al. Achieving 10.5% efficiency for inverted polymer solar cells by modifying the ZnO cathode interlayer with phenols[J]. Journal of Materials Che-mistry A,2016,4:16824-16829. doi: 10.1039/C6TA07105H [13] HAN Y, DONG H, PAN W, et al. An efficiency of 16.46% and a T80 lifetime of over 4000 h for the PM6: Y6 inverted orga-nic solar cells enabled by surface acid treatment of the zinc oxide electron transporting layer[J]. ACS Applied Materials & Interfaces,2021,13(15):17869-17881. [14] LIANG Z, ZHANG Q, WIRANWETCHAYAN O, et al. Effects of the morphology of a ZnO buffer layer on the photovoltaic performance of inverted polymer solar cells[J]. Advanced Functional Materials,2012,22(10):2194-2201. doi: 10.1002/adfm.201101915 [15] JI G, ZHAO W, WEI J, et al. 12.88% Efficiency in doctor-blade coated organic solar cells through optimizing the surface morphology of a ZnO cathode buffer layer[J]. Journal of Materials Chemistry A,2019,7:212-220. doi: 10.1039/C8TA08873J [16] WEI J F, ZHANG C J, JI G Q, et al. Roll-to-roll printed stable and thickness-independent ZnO:PEI composite electron transport layer for inverted organic solar cells[J]. Solar Energy,2019,193:102-110. doi: 10.1016/j.solener.2019.09.037 [17] HU L, LIU Y, MAO L, et al. Chemical reaction between an itic electron acceptor and an amine-containing interfacial layer in non-fullerene solar cells[J]. Journal of Materials Chemistry A,2018,6:2273-2278. doi: 10.1039/C7TA10306A [18] QIN F, WANG W, SUN L, et al. Robust metal ion-chelated polymer interfacial layer for ultraflexible non-fullerene organic solar cells[J]. Nature Communications,2020,11:4508. doi: 10.1038/s41467-020-18373-0 [19] YI M B, KU J R, YOON J S, et al. Facile preparation of a polymer-ZnO composite colloid as an electron transport layer and its effects on inverted polymer solar cells[J]. Journal of Physics and Chemistry of Solids,2020,145:109538. doi: 10.1016/j.jpcs.2020.109538 [20] MOUSSODIA R O, BALAN L, MERLIN C, et al. Biocompa-tible and stable ZnO quantum dots generated by functiona-lization with siloxane-core PAMAM dendrons[J]. Journal of Materials Chemistry,2010,20:1147-1155. doi: 10.1039/B917629B [21] SWIATKOWSKI M, KRUSZYNSKI R. Structurally diverse coordination compounds of zinc as effective precursors of zinc oxide nanoparticles with various morphologies[J]. Applied Organometallic Chemistry,2019,33(4):e4812. doi: 10.1002/aoc.4812 [22] ŠARIĆ A, DESPOTOVIĆ I, ŠTEFANIĆ G, et al. The influence of ethanolamines on the solvothermal synthesis of zinc oxide: A combined experimental and theoretical study[J]. Chemistry Select,2017,2(31):10038-10049. doi: 10.1002/slct.201701692 [23] HAYAMI R, ENDO N, ABE T, et al. Zinc–diethanolamine complex: Synthesis, characterization, and formation mechanism of zinc oxide via thermal decomposition[J]. Journal of Sol-Gel Science and Technology,2018,87:743-748. doi: 10.1007/s10971-018-4768-x [24] BOSTROM M, DENIZ V, FRANKS G V, et al. Extended DLVO theory: Electrostatic and non-electrostatic forces in oxide suspensions[J]. Advances in Colloid Interface Science,2006,(123/126):5-15. doi: 10.1016/j.cis.2006.05.001 [25] ZHABROVA G M, EGOROV E V, Sorption and ion exchange on amphoteric oxides and hydroxides[J]. Russian Chemi-cal Reviews, 1961, 30(6): 338-346. [26] BALLERINI G, OGLE K, BARTHÉS-LABROUSSE M G. The acid-base properties of the surface of native zinc oxide layers: An XPS study of adsorption of 1, 2-diaminoethane[J]. Applied Surface Science, 2007, 253(16): 6860-6867. [27] WANG Z, HAN Y, YAN L, et al. High power conversion efficiency of 13.61% for 1 cm2 flexible polymer solar cells based on patternable and mass-producible gravure-printed silver nanowire electrodes[J]. Advanced Functional Materials,2020,31(4):2007276. [28] BHARDWAJ R, FANG X, SOMASUNDARAN P, et al. Self-assembly of colloidal particles from evaporating droplets: Role of DLVO interactions and proposition of a phase diagram[J]. Langmuir,2010,26(11):7833-7842. doi: 10.1021/la9047227 [29] XU B. Paint application manual [M]. Jiangsu: Phoenix Science Press, 2000(in Chinese). [30] PAN W, HAN Y, WANG Z, et al. An efficiency of 14.29% and 13.08% for 1 cm2 and 4 cm2 flexible organic solar cells enabled by sol-gel ZnO and ZnO nanoparticle bilayer electron transporting layers[J]. Journal of Materials Chemistry A,2021,9:16889-16897. doi: 10.1039/D1TA03308E [31] MAO L, TONG J, XIONG S, et al. Flexible large-area orga-nic tandem solar cells with high defect tolerance and device yield[J]. Journal of Materials Chemistry A,2017,5:3186-3192. [32] ZHANG J, ZHAO Y, FANG J, et al. Enhancing performance of large-area organic solar cells with thick film via ternary strategy[J]. Small,2017,13(21):1700388. doi: 10.1002/smll.201700388 [33] LIN Y, JIN Y, DONG S, et al. Printed nonfullerene organic solar cells with the highest efficiency of 9.5%[J]. Advanced Energy Materials,2018,8(13):1701942. doi: 10.1002/aenm.201701942 [34] HAN Y, CHEN X, WEI J, et al. Efficiency above 12% for 1 cm2 Flexible organic solar cells with Ag/Cu grid tr-ansparent conducting electrode[J]. Advanced Science,2019,6(22):1901490. doi: 10.1002/advs.201901490 [35] MENG X, ZHANG L, XIE Y, et al. A general approach for lab-to-manufacturing translation on flexible organic solar cells[J]. Advanced Materials,2019,31(41):e1903649. doi: 10.1002/adma.201903649 [36] WANG G, ZHANG J, YANG C, et al. Synergistic optimization enables large-area flexible organic solar cells to maintain over 98% PCE of the small-area rigid devices[J]. Advanced Materials,2020,32(49):e2005153. doi: 10.1002/adma.202005153 [37] JEONG S, PARK B, HONG S, et al. Large-area nonfullerene organic solar cell modules fabricated by a temperature-independent printing method[J]. ACS Applied Materials & Interfaces,2020,12(37):41877-41885. [38] ZHANG L, YANG F, MENG X, et al. Regulating crystallization to maintain balanced carrier mobility via ternary strategy in blade-coated flexible organic solar cells[J]. Organic Electronics,2021,89:106027. doi: 10.1016/j.orgel.2020.106027 -

下载:

下载: