Simulation of curing process of epoxy resin with embedded FBGs considering interfacial strain transfer mechanism

-

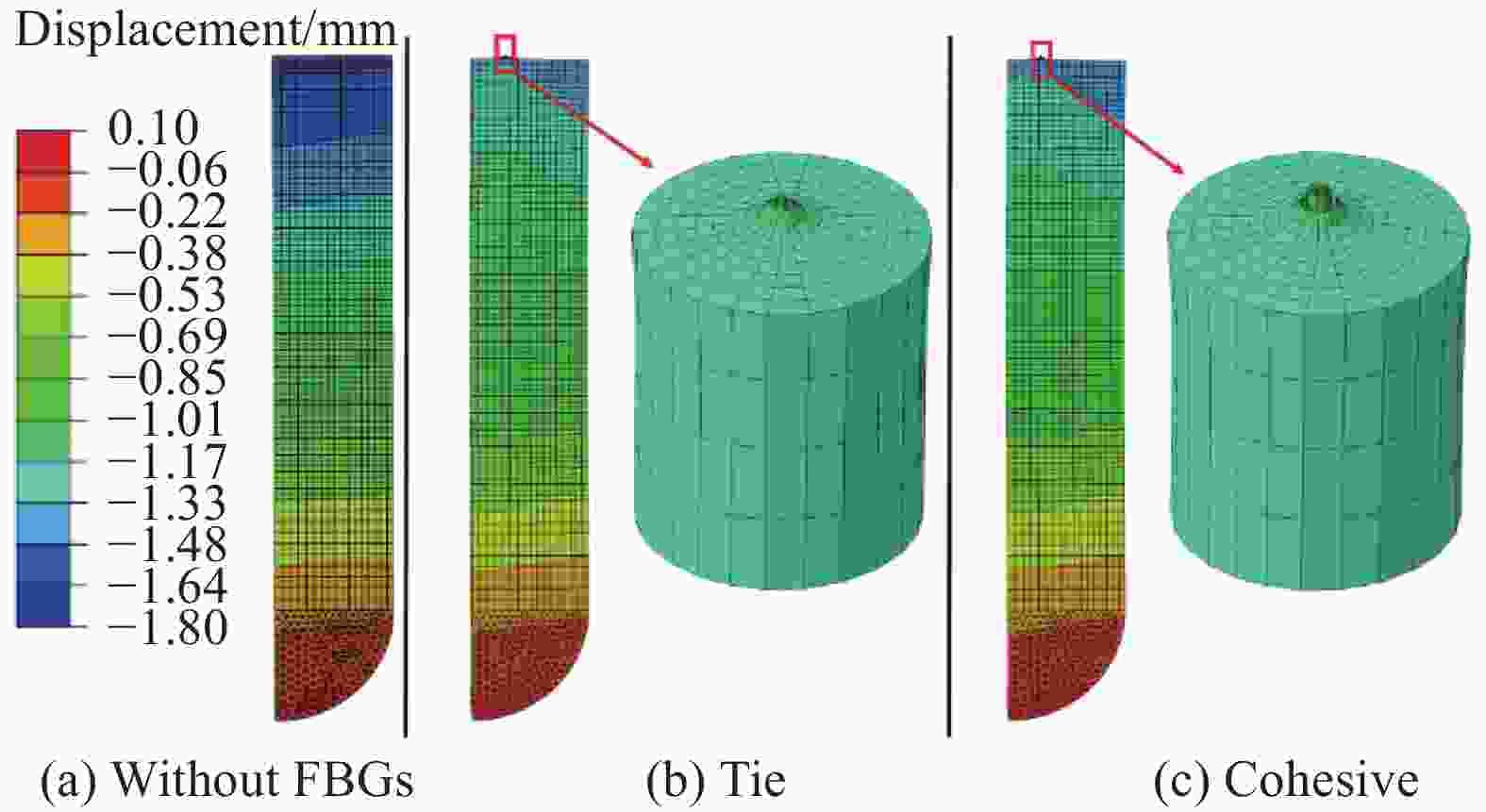

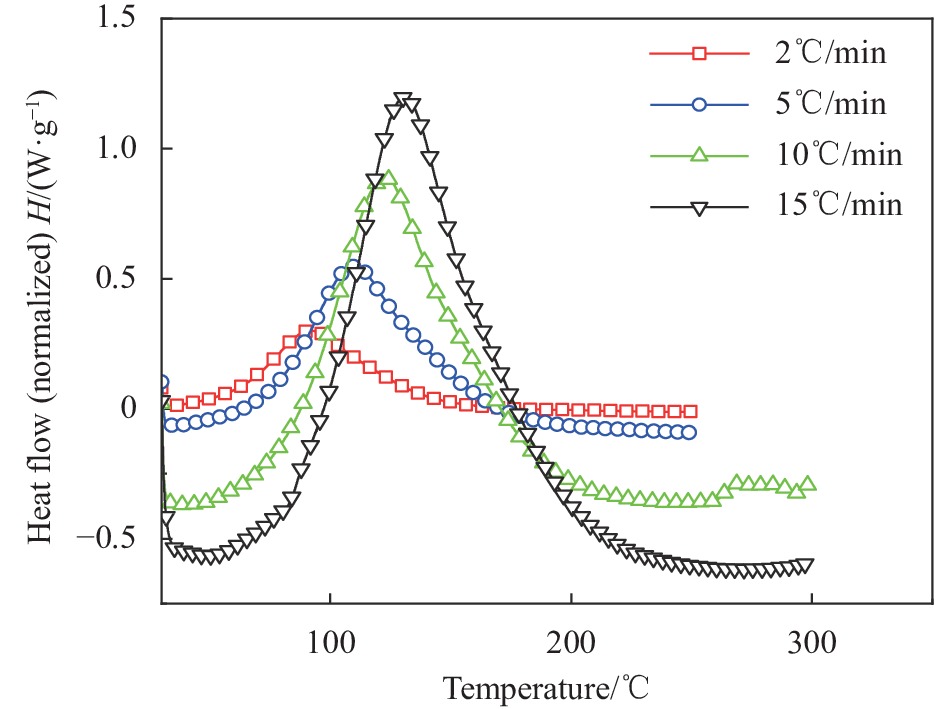

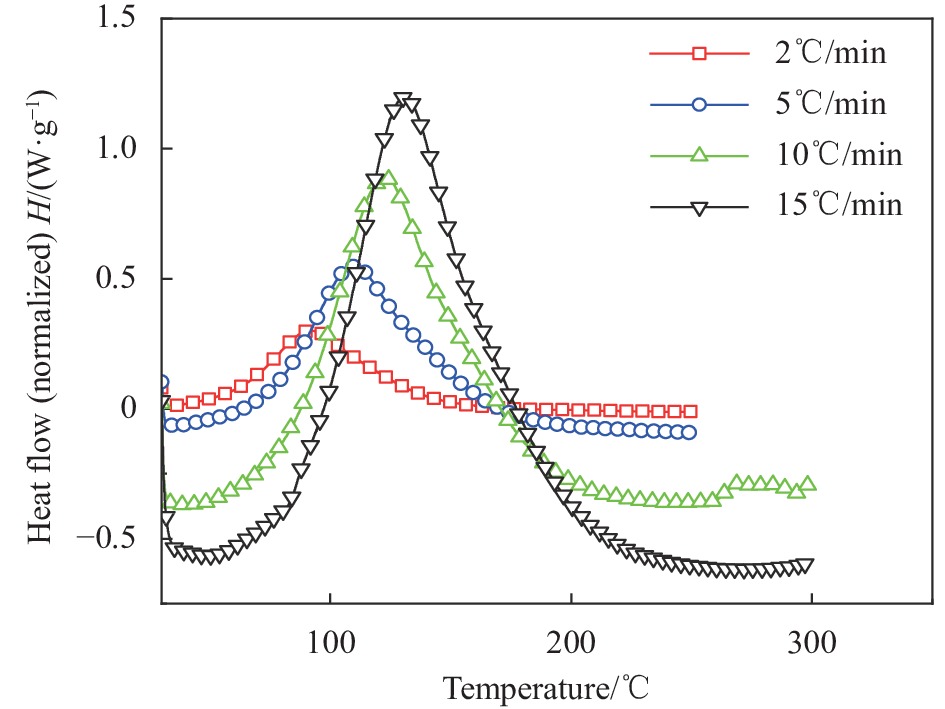

摘要: 采用实验与数值分析相结合的手段对光纤布拉格光栅传感器(Fiber Bragg grating sensor,FBGs)与基体间应变传递机制这一固化监测的基础问题进行了探索。首先,对树脂的固化动力学、热膨胀、化学收缩和玻璃化转变等物化变化进行了表征,然后,借助热电偶和FBGs开展了环氧树脂固化过程的温度和应变监测实验,最后,基于固化过程热-化-力多场耦合数值分析方法开展了固化过程模拟。通过对比纯树脂模型、界面采用绑定约束的含FBGs模型和界面采用内聚力行为的含FBSs模型分析结果,对界面传递机制进行了探讨。结果表明:固化前期界面处存在的剪滞效应和界面滑移行为导致FBGs监测应变相较树脂本体应变明显偏小,其中剪滞效应占主导作用。采用内聚力行为可以较好地描述固化过程界面应变传递机制,数值预测结果与实验值误差较小。

-

关键词:

- 固化监测 /

- 界面 /

- 应变传递 /

- 光纤布拉格光栅传感器(FBGs) /

- 数值分析

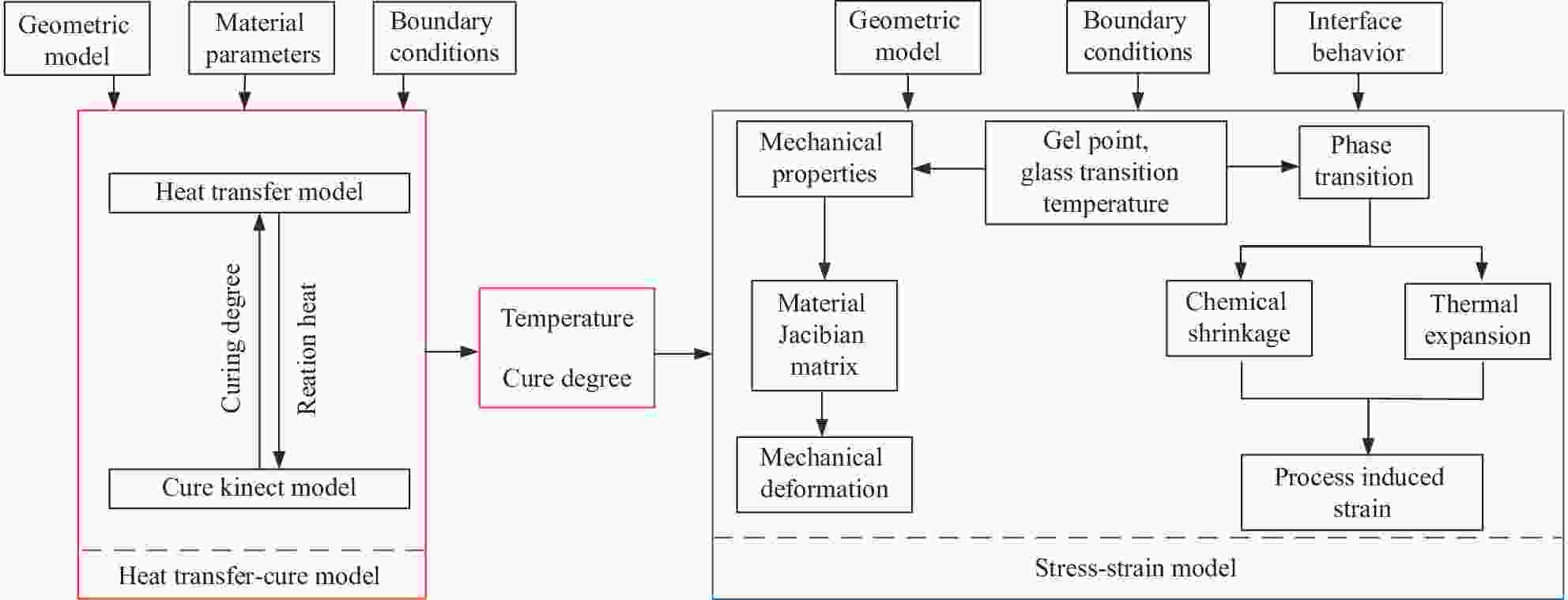

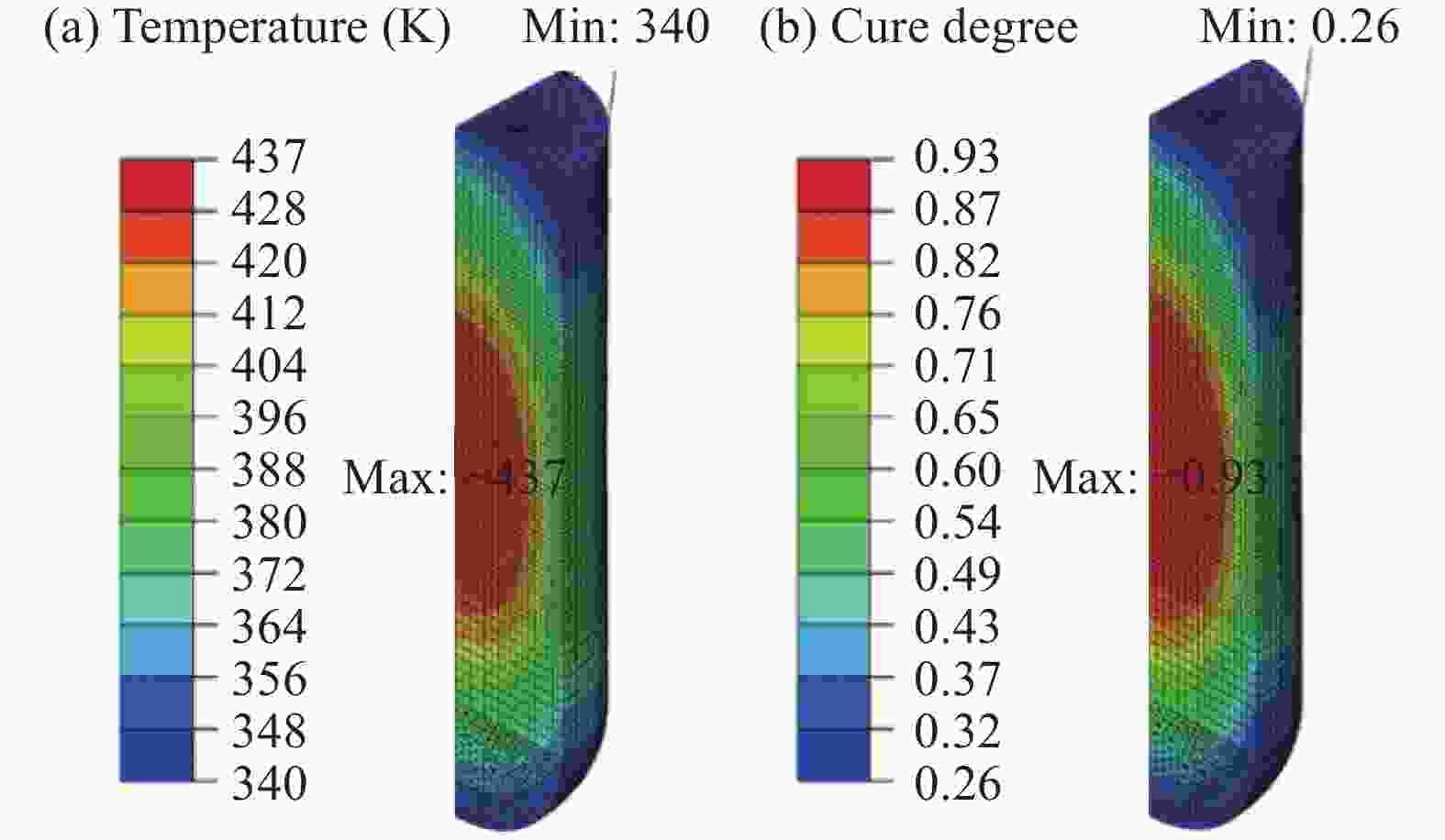

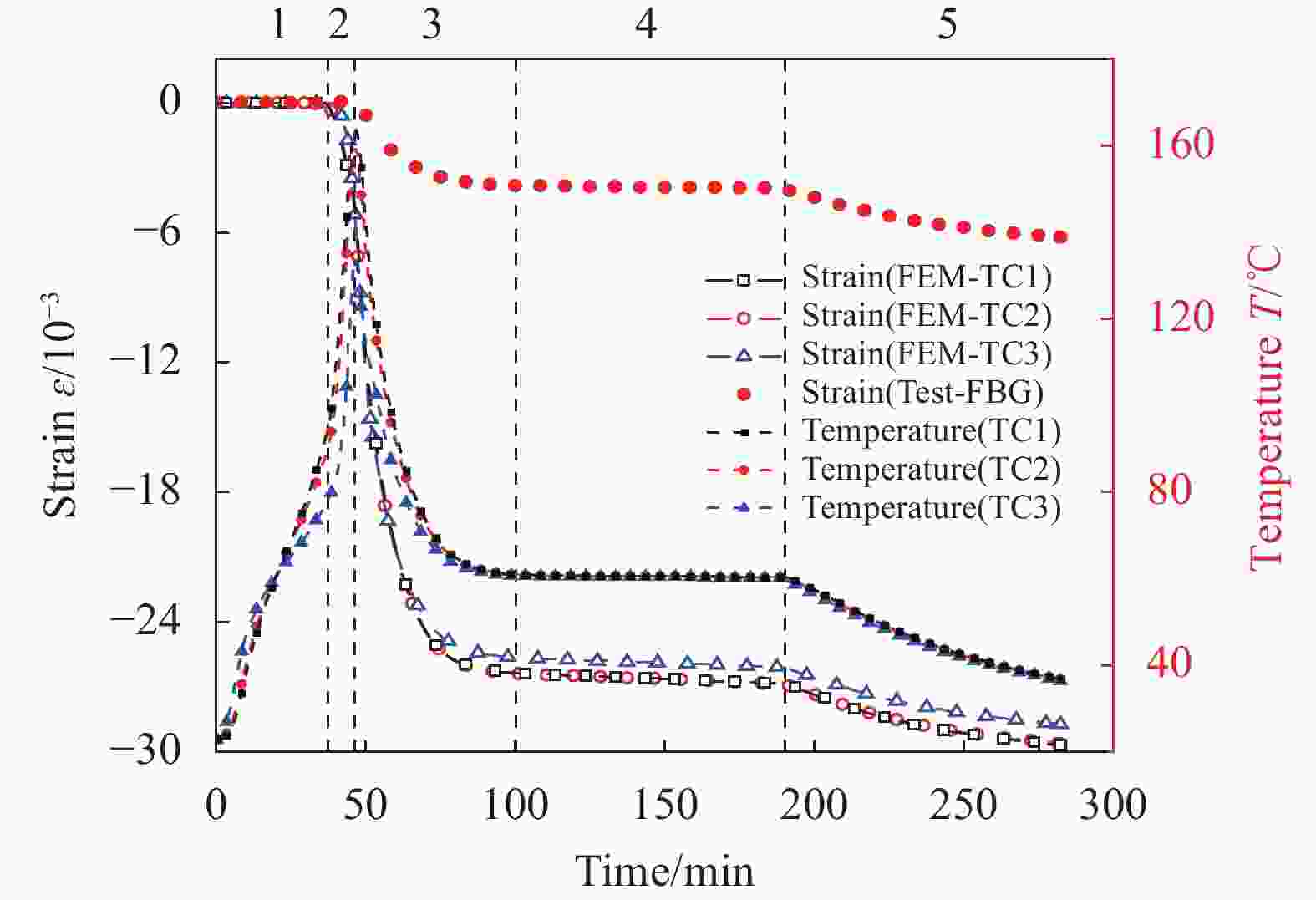

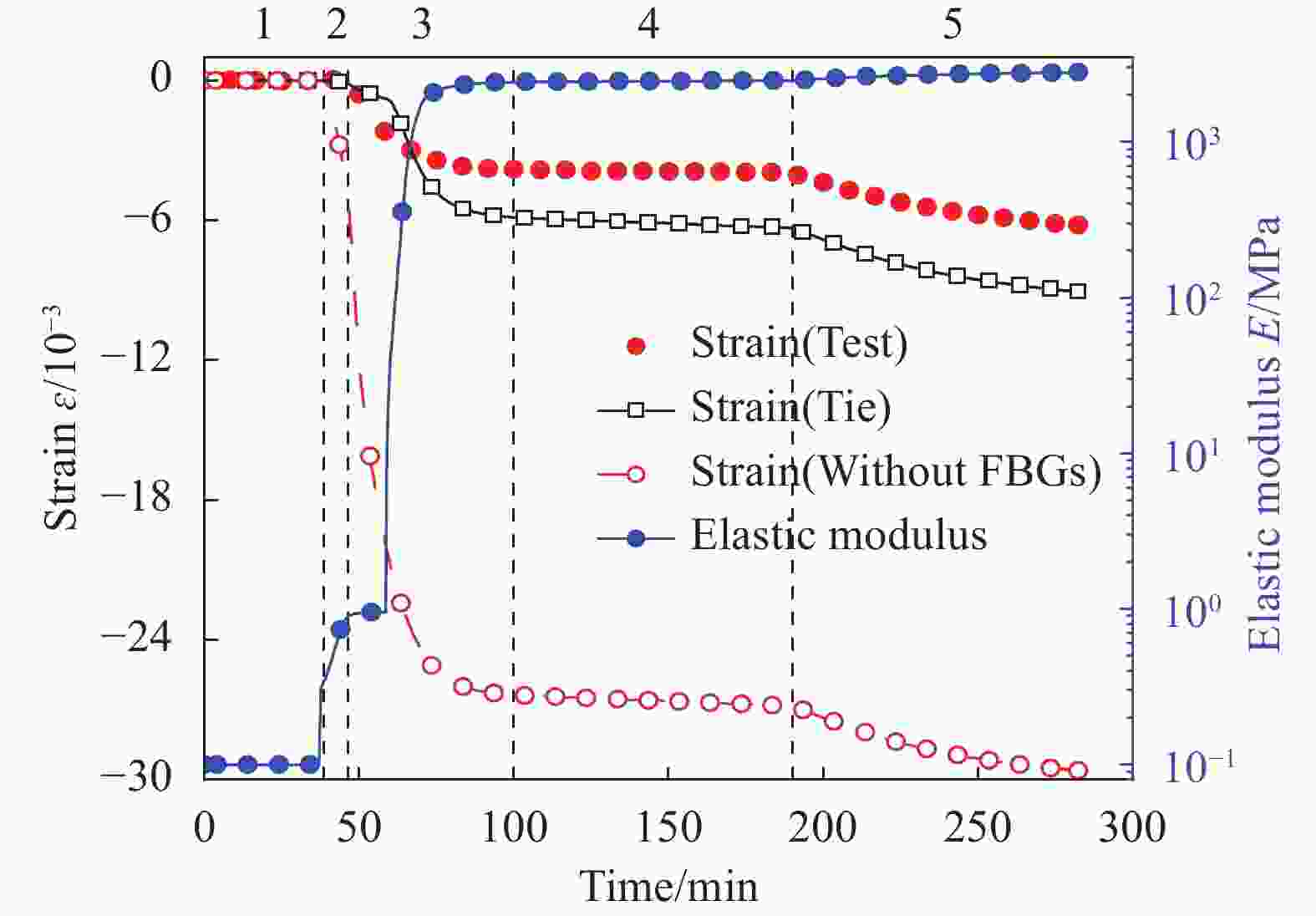

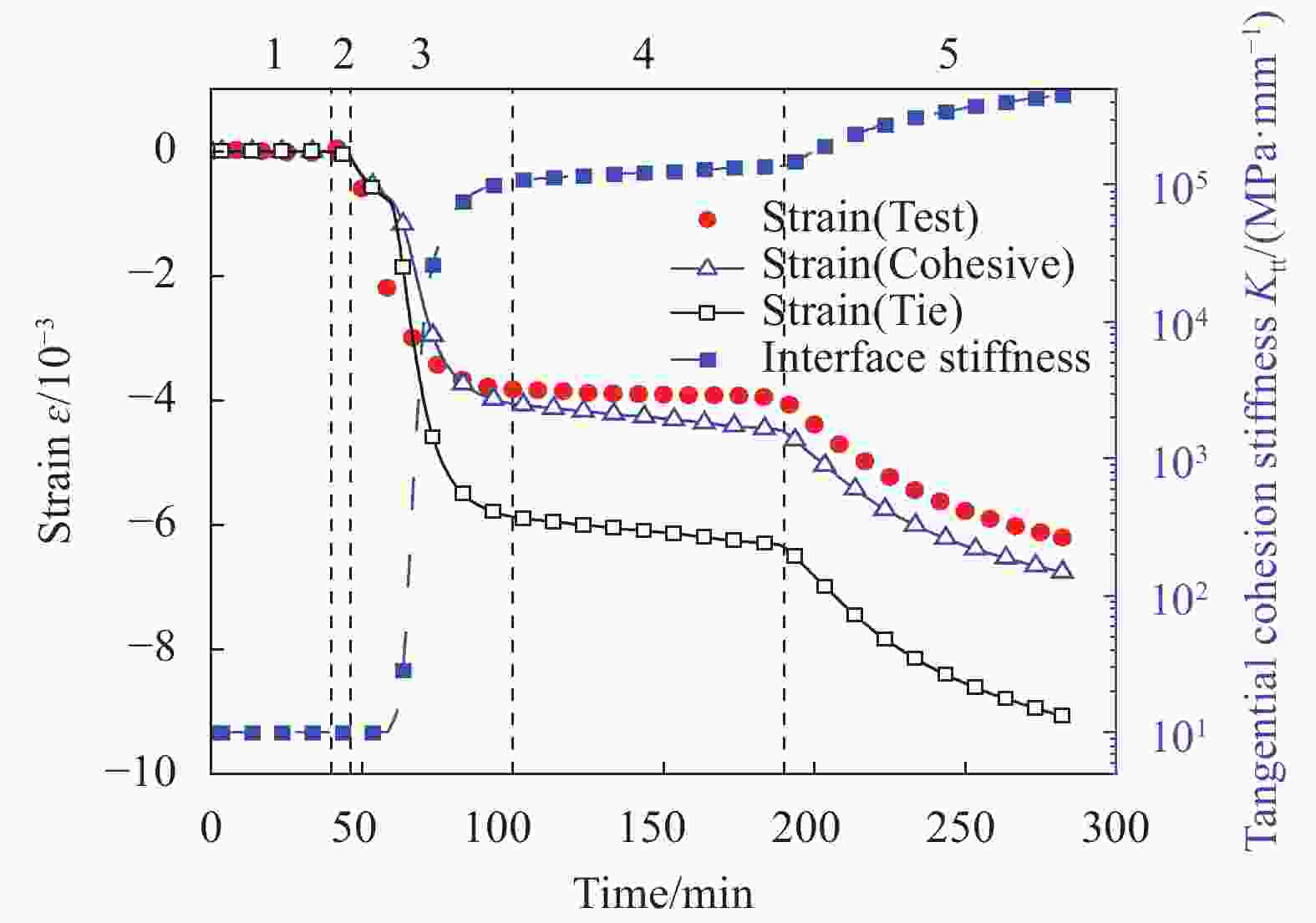

Abstract: The strain transfer mechanism between fiber Bragg grating sensor (FBGs) and matrix, which is the basic problem of cure monitoring, was explored by combining of experimental and numerical analysis. Firstly, curing kinetics, thermal expansion, chemical shrinkage and glass transition behavior of the resin were characterized. Then, the developments of temperature and strain were monitored by thermocouple and FBGs during the curing process of epoxy resin. Finally, the thermal-chemical-mechanical multi-field coupling numerical analysis was used to simulate the curing process. The interface transfer mechanism was discussed by comparing the results of pure resin model, FBGs model with binding constraint and FBSs model with cohesive behavior. The results indicate that the strain monitored by FBGs is significantly smaller than that of the resin due to the shear lag effect and interface slip behavior at the early curing stage, and the shear lag effect plays a dominant role. The interfacial strain transfer mechanism during curing process can be described properly by cohesive behavior, and the error between numerical prediction and experimental value is small.-

Key words:

- cure monitoring /

- interface /

- strain transfer /

- fiber Bragg grating sensor (FBGs) /

- numerical analysis

-

表 1 2511-1 A/BS环氧树脂在80℃恒温固化不同时间后的玻璃化转变温度和固化度

Table 1. Glass transition temperature and curing degree of 2511-1 A/BS epoxy resin after curing at 80℃ for different time

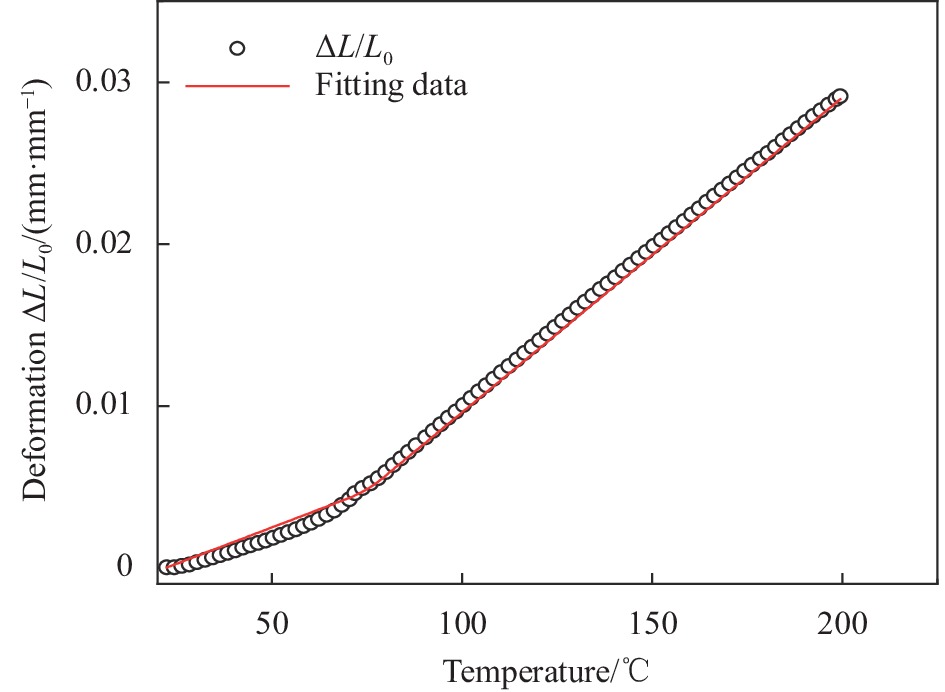

t/min Tg/℃ α 60 25 0.734 120 33 0.864 180 59.7 0.925 300 75 0.985 − −67.7 0 − 81.6 1 Notes:t—Resin curing time; Tg—Glass transition temperature; α—Curing degree of resin. 表 2 2511-1 A/BS环氧树脂热膨胀系数的参数值

Table 2. Parameter values of thermal expansion coefficients of 2511-1 A/BS epoxy resin

Parameter Value T1/K 2 T2/K 12 αEXP1/℃−1 89.5×10−6 αEXP2/℃−1 194.5×10−6 Notes: T1 and T2—Fitting values; αEXP1 and αEXP2—Fitting values of elastic modulus. 表 3 热分析中树脂的热特性

Table 3. Thermal properties of resins in thermal analysis

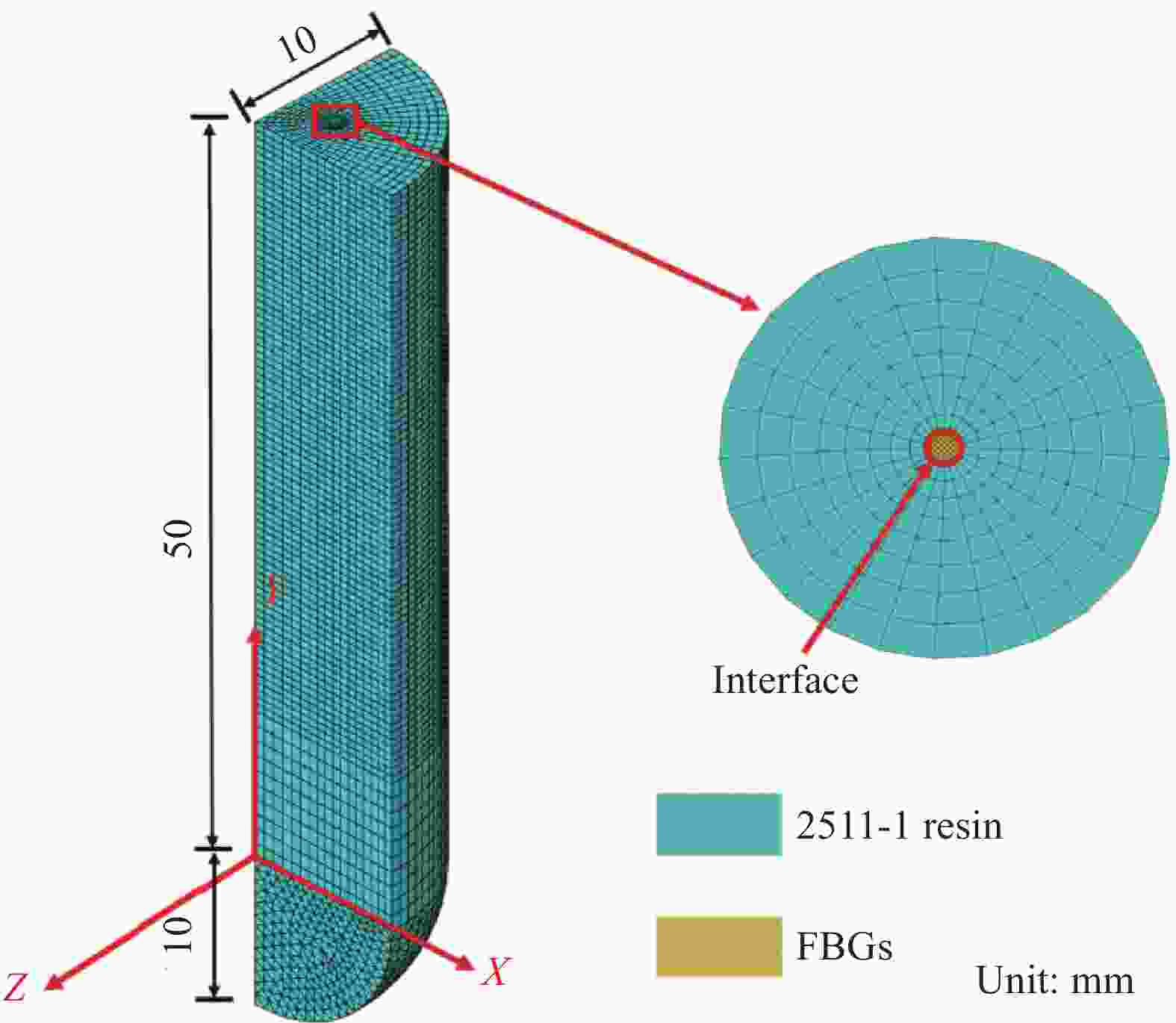

Parameter Value ρr/(kg·m−3) 1088 Cpr/(J·(kg·K)−1) 1800-1500 kr/(W·(m·K)−1) 0.16 Notes: ρr—Density of resin; Cpr—Specific heat capacity of resin; kr—Thermal conductivity coefficient of resin. 表 4 FBGs的计算参数

Table 4. Calculation parameters of FBGs

Parameter Value ρFBGs/(kg·m−3) 2500 CpFBGs/(J·(kg·K)−1) 966 kFBGs/(W·(m·K)−1) 1.1 EFBGs/MPa 72000 νFBGs 0.22 αFBGs 0 Notes: ρFBGs—Density of FBGs; CpFBGs—Specific heat capacity of FBGs; kFBGs—Thermal conductivity coefficient of FBGs; EFBGs—Elastic modulus of FBGs; νFBGs—Poisson's ratio of FBGs; αFBGs—Coefficient of thermal expansion of FBGs. 表 5 实验和仿真的内埋FBGs环氧树脂温度峰值对比

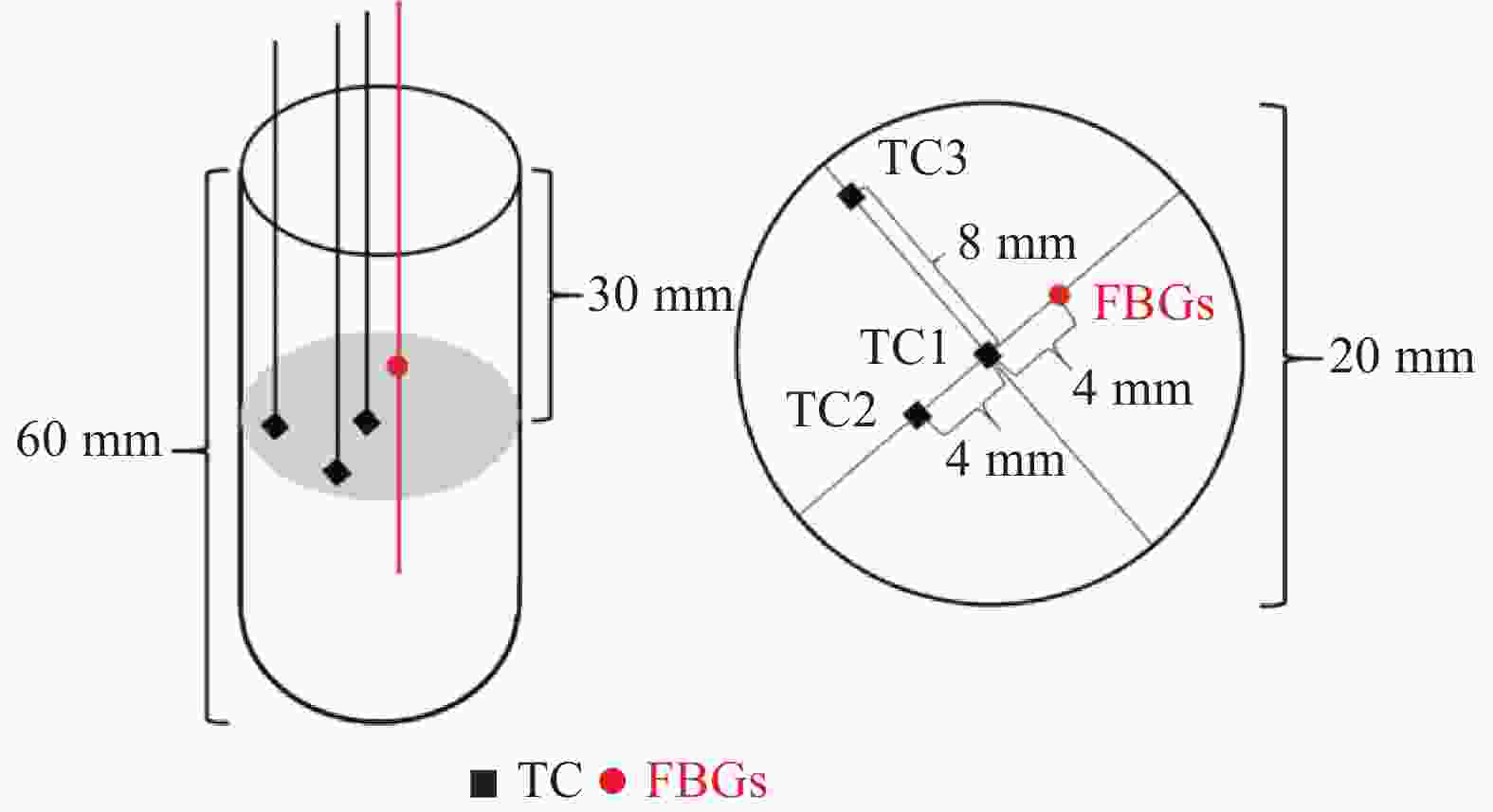

Table 5. Comparison of experimental and simulated temperature peaks of epoxy resin with embedded FBGs

Location Test FEM ∆/% Tp/℃ tm/min Tp/℃ tm/min TC1 165 46.5 164 46.5 0.6 TC2 153 46.7 159 47.0 3.9 TC3 131 47.0 134 47.7 2.3 Notes: Tp—Peak temperature; tm—Time corresponding to peak temperature; ∆—Peak temperature error between simulation and experiment. 表 6 实验和3种模型计算的内埋FBGs环氧树脂固化应变对比

Table 6. Comparison of curing strain of epoxy resin with embedded FBGs calculated by experiment and 3 models

Parameters Test Without FBGs Tie Cohesive Strain/10−6 −3826.4 −26356.7 −5870.9 −4053.2 ∆/% — 589.0 53.4 5.9 Note: ∆—Strain error of simulation relative to experiment. -

[1] BARAN I, CINAR K, ERSOY N, et al. A review on the mechanical modeling of composite manufacturing processes[J]. Archives of Computational Methods in Engineering,2017,24(2):365-395. doi: 10.1007/s11831-016-9167-2 [2] 张江涛, 尚云东, 张梅, 等. 复合材料固化相关黏弹性性能演化及残余应力分析[J]. 复合材料学报, 2017, 34(5):978-986.ZHANG Jiangtao, SHANG Yundong, ZHANG Mei, et al. Analysis on the process dependent viscoelastic properties and residual stresses of composites during cure[J]. Acta Materiae Compositae Sinica,2017,34(5):978-986(in Chinese). [3] HWANG S S, PARK S Y, KWON G C, et al. Cure kinetics and viscosity modeling for the optimization of cure cycles in a vacuum-bag-only prepreg process[J]. The International Journal of Advanced Manufacturing Technology,2018,99(9):2743-2753. [4] KHOUN L, RUI D O, MICHAUD V, et al. Investigation of process-induced strains development by fibre Bragg grating sensors in resin transfer moulded composites[J]. Composites Part A: Applied Science and Manufacturing,2011,42(3):274-282. doi: 10.1016/j.compositesa.2010.11.013 [5] 朱路佳, 刘荣梅. 基于FBG的不同工艺下环氧树脂固化监测研究[J]. 压电与声光, 2017, 39(4):634-637, 642.ZHU Lujia, LIU Rongmei. Study on curing process monitoring of epoxy resin with different precesses based on fiber bragg grating[J]. Piezoelectrics & Acoustooptics,2017,39(4):634-637, 642(in Chinese). [6] FEDOROV A Y, KOSHELEVA N A, MATVEENKO V P, et al. Strain measurement and stress analysis in the vicinity of a fiber Bragg grating sensor embedded in a composite material[J]. Composite Structures,2020,239:111844. doi: 10.1016/j.compstruct.2019.111844 [7] 福田武人, 白云英. 光纤传感器在监测RTM固化过程及复合材料健康状况中的应用[J]. 纤维复合材料, 2002, 19:56-61. doi: 10.3969/j.issn.1003-6423.2002.03.020FUKUDA Takehito, BAI Yunying. Application of optical fiber sensor in monitoring curing process of RTM and health condition of composite materials[J]. Fiber Composites,2002,19:56-61(in Chinese). doi: 10.3969/j.issn.1003-6423.2002.03.020 [8] 武湛君, 张博明, 万里冰. 单根光纤光栅监测复合材料固化工艺过程多目标参量技术的研究[J]. 复合材料学报, 2004, 21(6):82-86. doi: 10.3321/j.issn:1000-3851.2004.06.014WU Zhanjun, ZHANG Boming, WAN Libing. Multi-parameters monitoring for fiber reinforced plastics with a single fiber Bragg gratings[J]. Acta Materiae Compositae Sinica,2004,21(6):82-86(in Chinese). doi: 10.3321/j.issn:1000-3851.2004.06.014 [9] QI Y, JIANG D, JU S, et al. Investigation of strain history in fast and conventional curing epoxy matrix composites by FBGs[J]. Composites Science and Technology,2018,159:18-24. doi: 10.1016/j.compscitech.2018.02.019 [10] 卢少微, 陈铎, 王晓强. 聚合物基复合材料制造过程在线监测技术研究进展[J]. 航空制造技术, 2017, 60(19):72-77.LU Shaowei, CHEN Duo, WANG Xiaoqiang. Review of in-situ cure monitoring techniques for polymer matrix composite manufacturing process[J]. Aeronautical Manufacturing Technology,2017,60(19):72-77(in Chinese). [11] 李雪芹, 刘刚, 张子龙, 等. 基于FBG应变监测的环氧树脂固化收缩及工艺参数优化[J]. 复合材料学报, 2016, 33:2151-2157.LI Xueqin, LIU Gang, ZHANG Zilong, et al. Curing shrinkage and process parameter optimization of epoxy resin based on FBG strain monitoring[J]. Acta Materiae Compositae Sinica,2016,33:2151-2157(in Chinese). [12] KHADKA S, HOFFMAN J, KUMOSA M. FBG monitoring of curing in single fiber polymer composites[J]. Composites Science and Technology,2020,198:108308. doi: 10.1016/j.compscitech.2020.108308 [13] HOFFMAN J, KHADKA S, KUMOSA M. Determination of gel point and completion of curing in a single fiber/polymer composite[J]. Composites Science and Technology,2020,188:107997. doi: 10.1016/j.compscitech.2020.107997 [14] KHADKA S, KUMOSA M, HOFFMAN J. Determination of residual stresses in a single FBG fiber/epoxy composite system[J]. Composites Science and Technology,2022,218:109138. doi: 10.1016/j.compscitech.2021.109138 [15] 康峻铭, 孙亮亮, 王继辉, 等. 电子封装用环氧树脂固化温度与应变的三维有限元模拟[J]. 复合材料学报, 2019, 36(10):2330-2340.KANG Junming, SUN Liangliang, WANG Jihui, et al. Three-dimensional finite element simulation of remperature and strain in epoxy resin used to electronic packaging during curing[J]. Acta Materiae Compositae Sinica,2019,36(10):2330-2340(in Chinese). [16] 丁安心, 俞星辰, 杨鹏, 等. 一种灌封结构用环氧树脂的固化行为表征和模拟[J]. 复合材料学报, 2022, 39(4):1824-1833.DING Anxin, YU Xingchen, YANG Peng, et al. Characterization and simulation on the on the cure behavior of epoxy resin for encapsulation structure[J]. Acta Materiae Compositae Sinica,2022,39(4):1824-1833(in Chinese). [17] 李小阳, 康峻铭, 朱子钊, 等. 环氧树脂灌封结构固化行为 数值模拟和工艺优化[J]. 复合材料学报, 2021, 38(9):2907-2917.LI Xiaoyang, KANG Junming, ZHU Zizhao, et al. Numerical simulation on cure behavior and optimization on cure cycle for encapsulation struture of epoxy resin[J]. Acta Materiae Compositae Sinica,2021,38(9):2907-2917(in Chinese). [18] MINAKUCHI S. In situ characterization of direction-dependent cure-induced shrinkage in thermoset composite laminates with fiber-optic sensors embedded in through-thickness and in-plane directions[J]. Journal of Composite Materials,2015,49:1021-1034. doi: 10.1177/0021998314528735 [19] HU H, LI S, WANG J, et al. Monitoring the gelation and effective chemical shrinkage of composite curing process with a novel FBG approach[J]. Composite Structures, 2017, 176: 187–194. [20] 郭章新, 韩小平, 李金强, 等. 纤维缠绕复合材料固化过程残余应力/应变的三维树脂模拟[J]. 复合材料学报, 2014, 31(4):1006-1012.GUO Zhangxin, HAN Xiaoping, LI Jinqiang, et al. Three-dimensional simulation of residual stress/strain for filament-wound composites during curing process[J]. Acta Materiae Compositae Sinica,2014,31(4):1006-1012(in Chinese). [21] HU H, CAO D, PAVIER M, et al. Investigation of non-uniform gelation effects on residual stress-es of thick laminates based on tailed FBG sensor[J]. Composite Structures,2018,202:1361-1372. doi: 10.1016/j.compstruct.2018.06.074 [22] BARAN I, AKKERMAN R, HATTEL JH. Material characterization of a polyester resin system for the pultrusion process[J]. Composites Part B: Engineering,2014,64:194-201. [23] KHOUN L, CENTEA T, HUBERT P. Characterization methodology of thermoset resins for the processing of compo-site materials—Case study: CYCOM 890 RTM epoxy resin[J]. Journal of Composite Materials,2010,44(11):1397-1415. doi: 10.1177/0021998309353960 [24] 武佳男, 倪爱清, 张盛, 等. 真空辅助成型工艺环氧树脂体系化学流变特性研究[J]. 复合材料科学与工程, 2016, 11:32-38. doi: 10.3969/j.issn.1003-0999.2016.11.006WU Jia'nan, NI Aiqing, ZHANG Sheng, et al. Study on rheological properties of epoxy in vari process[J]. Compo-sites Science and Engineering,2016,11:32-38(in Chinese). doi: 10.3969/j.issn.1003-0999.2016.11.006 [25] 杨喜, 李书欣, 王继辉, 等. 一种实时监测环氧树脂固化过程中化学收缩的方法[J]. 复合材料科学与工程, 2016, 1:74-78. doi: 10.3969/j.issn.1003-0999.2016.05.013YANG Xi, LI Shuxin, WANG Jihui, et al. A real-time monitoring method for the chemical shrinkage in the curing process of epoxy resin[J]. Composites Science and Engineering,2016,1:74-78(in Chinese). doi: 10.3969/j.issn.1003-0999.2016.05.013 -

下载:

下载: