Construction and characterization of silver-loaded polyvinyl alcohol-carboxymethyl chitosan-sodium alginate hydrogel wound dressing based on 3D printing

-

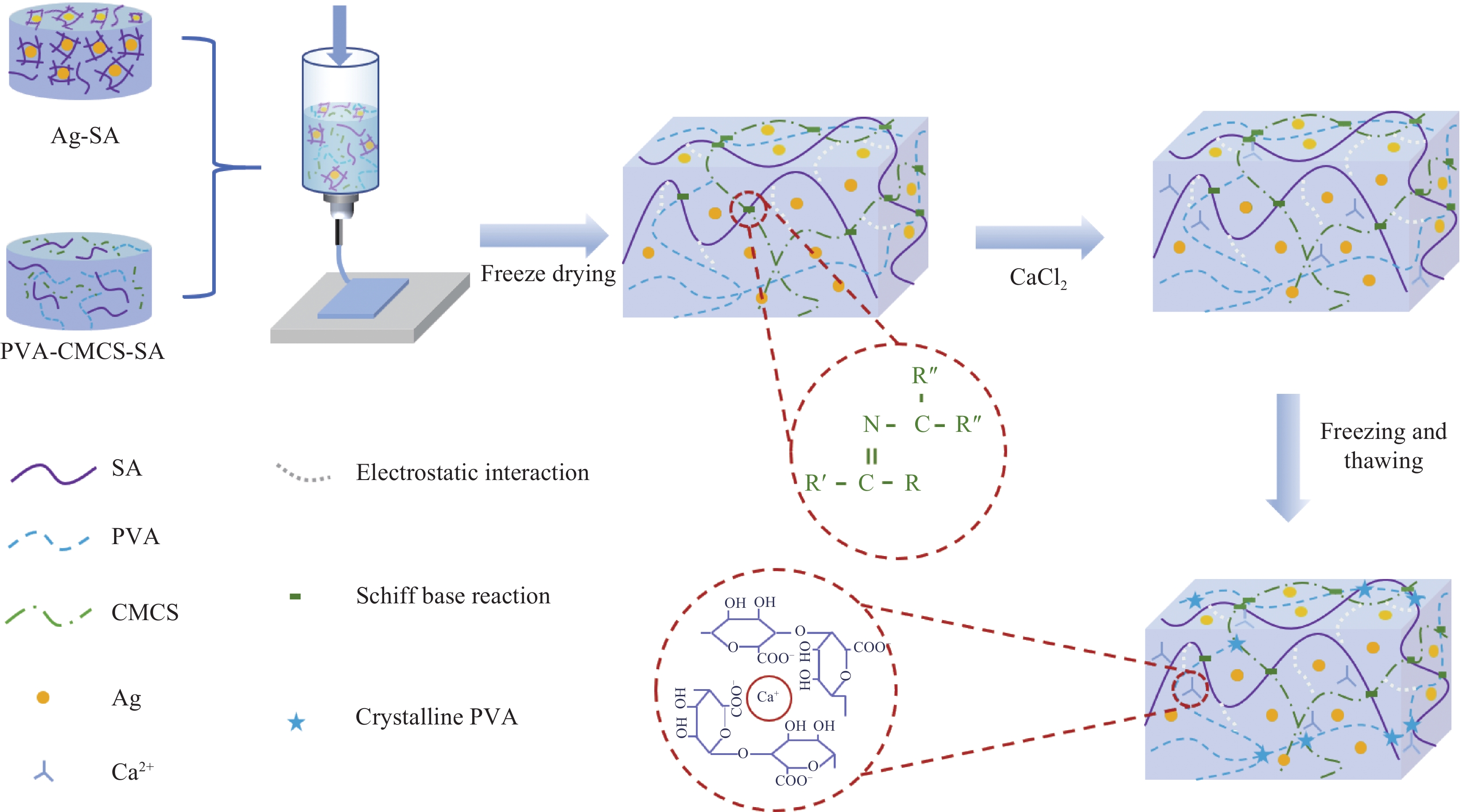

摘要: 为设计一种对伤口无损伤、抗菌效果好、促进伤口愈合的新型伤口敷料,选择聚乙烯醇(PVA)、羧甲基壳聚糖(CMCS)和海藻酸钠(SA)作为原料,将纳米银复合到PVA-CMCS-SA水凝胶中,基于3D打印构建载银PVA-CMCS-SA水凝胶伤口敷料,对水凝胶伤口敷料的微观形貌、力学性能、吸水保湿率、生物相容性、抗菌性能、体外凝血性能等进行研究。结果表明:3D打印制备的水凝胶伤口敷料具有良好的尺寸结构稳定性,力学性能良好,最大抗拉强度可达到1000 kPa左右,循环拉伸和循环压缩性能均表现良好;由于3D打印出的网格结构,3D打印水凝胶伤口敷料的吸水性、保湿性、体外凝血性能、透气性及抗菌性能均表现良好;对大肠杆菌和金黄色葡萄球菌的抑菌率最高分别可达到64%和54%;具有低的细胞毒性和良好的生物相容性;3D打印的方法能够将水凝胶与创可贴结合,保证了伤口敷料的实用性。研究表明3D打印载银水凝胶PVA-CMCS-SA可作为一种良好的伤口敷料材料。Abstract: In order to design a new type of wound dressing that does not damage the wound, has good antibacterial effect, and promotes wound healing, polyvinyl alcohol (PVA), carboxymethyl chitosan (CMCS) and sodium alginate (SA) were selected as raw materials. Silver was compounded into the PVA-CMCS-SA hydrogel, and the silver-loaded PVA-CMCS-SA hydrogel wound dressing was constructed based on 3D printing. The micro-morphology, mechanical properties, water absorption and moisture retention, biocompatibility, antibacterial properties and in vitro coagulation properties of hydrogel wound dressings were then studied. The results show that the hydrogel wound dressing prepared by 3D printing has good dimensional structural stability, good mechanical properties, and the tensile strength can reach about 1000 kPa, and both the cyclic stretching and cyclic compression properties are good. Because of the 3D printed grid structure, the 3D printed hydrogel wound dressing has good water absorption, moisture retention, in vitro clotting, air permeability and antibacterial properties. The highest antibacterial rate against Escherichia coli and Staphylococcus aureus can reach 64% and 54%. It has low cytotoxicity and good biocompatibility. The 3D printing method can combine the hydrogel with the band-aid, ensuring the practicability of the wound dressing. Studies have shown that 3D printed silver-loaded hydrogel PVA-CMCS-SA can be used as a good wound dressing material.

-

Key words:

- wound dressing /

- silver nanoparticles /

- hydrogel /

- 3D printing /

- antibacterial /

- sodium alginate /

- chitosan /

- polyvinyl alcohol

-

图 2 添加0wt% ((a), (b))、0.01wt% ((c), (d))、0.03wt% ((e), (f))和0.05wt% ((g), (h)) 纳米银(AgNPs)的3D打印PVA-CMCS-SA水凝胶伤口敷料的SEM图像

Figure 2. SEM images of 3D printed PVA-CMCS-SA hydrogel wound dressing with addition of 0wt% ((a), (b)), 0.01wt% ((c), (d)), 0.03wt% ((e), (f)) and 0.05wt% ((g), (h)) silver nanoparticles (AgNPs)

表 1 动态力学实验参数

Table 1. Experimental parameters of dynamic mechanics

Test Strain Temperature Frequency Dynamic

strain test0.01%-100% 25℃ 1 Hz Dynamic

temperature test1% 25-40℃,

the heating rate is 3℃/min1 Hz Dynamic

frequency test1% 25℃ 1-100 rad/s 表 2 不同AgNPs含量3D打印PVA-CMCS-SA水凝胶伤口敷料的实际丝径尺寸

Table 2. Actual wire diameter sizes of 3D printed PVA-CMCS-SA hydrogel wound dressings with different AgNPs concentrations

AgNPs

concentrations/wt%Theoretical wire

diameter/mmActual wire

diameter/mmRelative

deformation rate/%0 0.21 0.327 55.7 0.01 0.21 0.316 50.5 0.03 0.21 0.286 36.2 0.05 0.24 0.275 14.6 表 3 不同AgNPs含量3D打印水凝胶伤口敷料的实际间距尺寸

Table 3. Actual spacing sizes of 3D printed hydrogel wound dressings with different AgNPs concentrations

AgNPs

concentrations/wt%Actual spacing

size/mm0 0.457 0.01 0.462 0.03 0.521 0.05 0.561 -

[1] RAHIMI M, AHMADI R, KAFIL H S, et al. A novel bioactive quaternized chitosan and its silver-containing nanocomposites as a potent antimicrobial wound dressing: Structural and biological properties[J]. Materials Science and Engineering: C,2019,101:360-369. doi: 10.1016/j.msec.2019.03.092 [2] 李秀奇. 无机纳米颗粒复合聚氨酯/聚乙烯醇水凝胶的制备及其伤口敷料应用研究[D]. 兰州: 兰州交通大学, 2018.LI Xiuqi. Preparation of polyurethane/polyvinyl alcohol composite hydrogels with inorganic nanoparticles for wound dressing application[D]. Lanzhou: Lanzhou Jiaotong University, 2018(in Chinese). [3] YE H, CHENG J, YU K. In situ reduction of silver nanoparticles by gelatin to obtain porous silver nanoparticle/chitosan composites with enhanced antimicrobial and wound-healing activity[J]. International Journal of Biological Macromolecules,2019,121:633-642. doi: 10.1016/j.ijbiomac.2018.10.056 [4] SONG R, ZHENG J, LIU Y, et al. A natural cordycepin/chitosan complex hydrogel with outstanding self-healable and wound healing properties[J]. International Journal of Biological Macromolecules,2019,134:91-99. doi: 10.1016/j.ijbiomac.2019.04.195 [5] WINTER G D. Formation of the scab and the rate of epithelization of superficial wounds in the skin of the young domestic pig[J]. Nature,1962,193:293-294. doi: 10.1038/193293a0 [6] ODLAND G. The fine structure of the interrelationship of cells in the human epidermis[J]. Journal of Biophysical and Biochemical Cytology,1958,4(5):529-538. doi: 10.1083/jcb.4.5.529 [7] HINMAN C D, MAIBACH H. Effect of air exposure and occlusion on experimental human skin wounds[J]. Nature,1963,200(490):377-378. [8] 范庆宇. 新型医用伤口敷料三七壳聚糖凝胶的药学研究[D]. 大连: 大连理工大学, 2015.FAN Qingyu. Pharmaceutical research of panax-notoginseng/chitosan/carboxymethyl-chitosan gel as a new medical wound dressing[D]. Dalian: Dalian University of Technology, 2015(in Chinese). [9] 姜琼. 新型复合壳聚糖水凝胶伤口敷料的制备及性能评价[D]. 合肥: 安徽大学, 2017.JIANG Qiong. Preparation and properties of new compo-site chitosan hydrogels for potential wound dressings[D]. Heifei: Anhui University, 2017(in Chinese). [10] 张良良. 具有良好力学性能可用于伤口敷料的聚氨酯-聚丙烯酰胺水凝胶的制备与性能[D]. 合肥: 安徽大学, 2018.ZHANG Liangliang. Preparation and properties of polyurethane-polyacrylamide hydrogels with good mechanical properties for wound dressings[D]. Heifei: Anhui University, 2018(in Chinese). [11] LIANG M, CHEN Z, WANG F, et al. Preparation of self-regulating/anti-adhesive hydrogels and their ability to promote healing in burn wounds[J]. Journal of Biomedical Materials Research Part B: Applied Biomaterials,2018,107(5):1471-1482. [12] AMARNATH L, SRINIVAS A, RAMAMURTHI A. In vitro hemocompatibility testing of UV-modified hyaluronan hydrogels[J]. Biomaterials,2006,27(8):1416-1424. doi: 10.1016/j.biomaterials.2005.08.008 [13] KOTHALE D, VERMA U, DEWANGAN N, et al. Alginate as promising natural polymer for pharmaceutical, food, and biomedical applications[J]. Current Drug Delivery,2020,17(9):755-775. doi: 10.2174/1567201817666200810110226 [14] AGRAWAL P, STRIJKERS G J, NICOLAY K. Chitosan-based systems for molecular imaging[J]. Advanced Drug Delivery Reviews,2010,62(1):42-58. doi: 10.1016/j.addr.2009.09.007 [15] LAI W, LIN M C. Nucleic acid delivery with chitosan and its derivatives[J]. Journal of Controlled Release,2009,134(3):158-168. doi: 10.1016/j.jconrel.2008.11.021 [16] CHEN Y, QIU H, DONG M, et al. Preparation of hydroxylated lecithin complexed iodine/carboxymethyl chitosan/sodium alginate composite membrane by microwave drying and its applications in infected burn wound treatment[J]. Carbohydrate Polymers,2019,206:435-445. doi: 10.1016/j.carbpol.2018.10.068 [17] KHORASANI M T, JOORABLOO A, MOGHADDAM A, et al. Incorporation of ZnO nanoparticles into heparinised polyvinyl alcohol/chitosan hydrogels for wound dressing application[J]. International Journal of Biological Macromolecules,2018,114:1203-1215. doi: 10.1016/j.ijbiomac.2018.04.010 [18] TANTIWATCHAROTHAI S, PRACHAYAWARAKORN J. Property improvement of antibacterial wound dressing from basil seed mucilage-ZnO nanocomposite by borax crosslinking[J]. Carbohydrate Polymers,2020,227:115360. [19] 薛海燕, 张颖, 张宝艳, 等. 安石榴苷还原壳聚糖/纳米银溶胶制备表征及其抑菌性能[J]. 农业工程学报, 2018(4):306-314. doi: 10.11975/j.issn.1002-6819.2018.04.038XUE Haiyan, ZHANG Ying, ZHANG Baoyan, et al. Preparation characterization and bacteriostatic properties of punicalagin reducing chitosan/nano silver sol[J]. Transactions of the Chinese Society of Agricultural Engineering,2018(4):306-314(in Chinese). doi: 10.11975/j.issn.1002-6819.2018.04.038 [20] 黄晓飞. 壳聚糖基载银材料的制备及其抗菌性能的研究[D]. 杭州: 浙江大学, 2018.HUANG Xiaofei. Chitosan-based sliver composite materials for antibacterial application[D]. Hangzhou: Zhejiang University, 2018(in Chinese). [21] 李达恒. 含纳米银的抗菌凝胶和敷料的制备与表征[D]. 广州: 南方医科大学, 2016.LI Daheng. Preparation and characterization of antibacterial gel and dressings containing nano-sliver particles[D]. Guangzhou: Southern Medical University, 2016(in Chinese). [22] KIM J S, KUK E, YU K N, et al. Antimicrobial effects of silver nanoparticles[J]. Nanomedicine Nanotechnology Biology and Medicine,2007,3(1):95-101. doi: 10.1016/j.nano.2006.12.001 [23] NGUYEN N T P, NGUYEN L V H, THANH N T, et al. Stabilization of silver nanoparticles in chitosan and gelatin hydrogel and its applications[J]. Materials Letters,2019,248:241-245. doi: 10.1016/j.matlet.2019.03.103 [24] HOQUE J, BHATTACHARJEE B, PRAKASH R G, et al. Dual function injectable hydrogel for controlled release of antibiotic and local antibacterial therapy[J]. Biomacromolecules,2017,19(2):267-278. [25] MORITZ M, GESZKE M. The newest achievements in synthesis, immobilization and practical applications of antibacterial nanoparticles[J]. Chemical Engineering Journal,2013,228(14):596-613. [26] JAYARAMUDU T, VARAPRASAD K, RAGHAVENDRA G M, et al. Green synthesis of tea Ag nanocomposite hydrogels via mint leaf extraction for effective antibacterial activity[J]. Journal of Biomaterials Science, Polymer Edition,2017,28(14):1588-1602. doi: 10.1080/09205063.2017.1338501 [27] ZHANG Z, HE T, YUAN M, et al. The in situ synthesis of Ag/amino acid biopolymer hydrogels as mouldable wound dressings[J]. Chemical Communications,2015,51(87):15862-15865. doi: 10.1039/C5CC05195A [28] LIANG D, LU Z, YANG H, et al. Novel asymmetric wettable AgNPs/chitosan wound dressing: In vitro and in vivo evaluation[J]. ACS Applied Materials & Interfaces,2016,8(6):3958-3968. [29] LEPPINIEMI J, LAHTINEN P, PAAJANEN A, et al. 3D-printable bioactivated nanocellulose–Alginate hydrogels[J]. ACS Applied Materials & Interfaces,2017,9(26):21959-21970. [30] REES A, POWELL L C, CHINGA-CARRASCO G, et al. 3D bioprinting of carboxymethylated-periodate oxidized nanocellulose constructs for wound dressing applications[J]. Biomed Research International,2015,2015:925757. [31] 施高强, 罗高兴, 陈希炜, 等. 3D打印的多聚甲醛硅氧烷仿生纳米银复合材料及性能研究[J]. 解放军医学杂志, 2018, 43(10):36-44.SHI Gaoqiang, LUO Gaoxing, CHEN Xiwei, et al. A novel 3D printed biomimicry, made from oil infused layer on poly(dimethylsiloxane), promotes infected wound healing through antifouling and antimicrobial activity[J]. Medical Journal of Chinese People's Liberation Army,2018,43(10):36-44(in Chinese). [32] CHEN C S, ZENG F, XIAO X, et al. 3D-printed silk sericin-based hydrogel scaffold: A promising visualized dressing material for real-time monitoring of wounds[J]. ACS Applied Materials & Interfaces,2018,10(40):33879-33890. [33] MAVER T, SMRKE D M, KURE I M, et al. Combining 3D printing and electrospinning for preparation of pain-relieving wound-dressing materials[J]. Journal of Sol-Gel Science and Technology,2018,88(1):33-48. doi: 10.1007/s10971-018-4630-1 [34] XIAO L W, FAN R A, TING W L, et al. A 3D printed wound cooling system incorporated with injectable, adsorbable, swellable and broad spectrum antibacterial scaffolds for rapid hematischesis processing[J]. Journal of Materials Chemistry B,2018,6(37):5940-5948. [35] CHEN K, WANG F, LIU S, et al. In situ reduction of silver nanoparticles by sodium alginate to obtain silver-loaded composite wound dressing with enhanced mechanical and antimicrobial property[J]. International Journal of Biological Macromolecules,2020,148:501-509. doi: 10.1016/j.ijbiomac.2020.01.156 -

下载:

下载: