Research progress of TEMPO oxidation modified natural polysaccharide nanofiber reinforced composites and their functionality

-

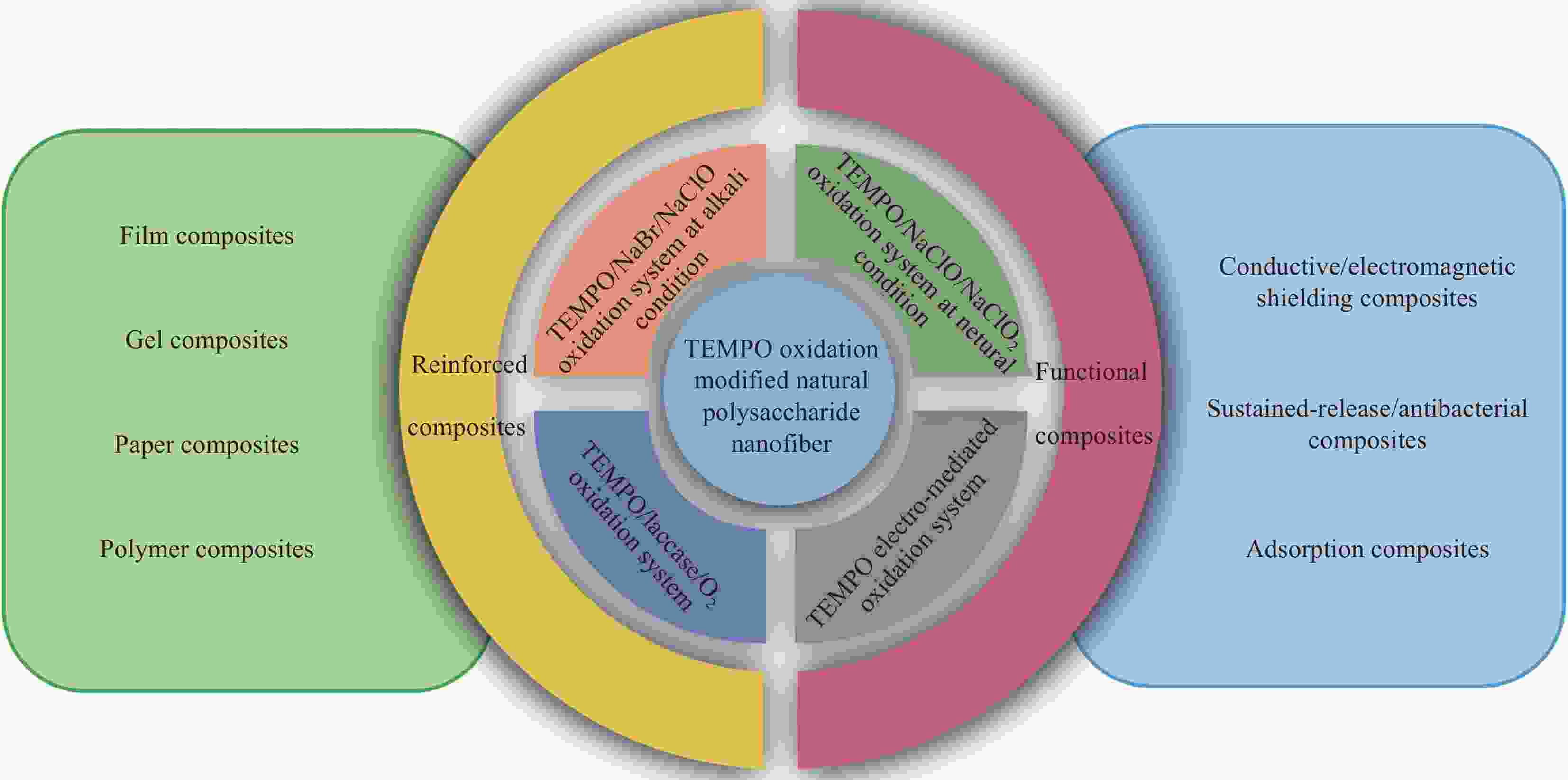

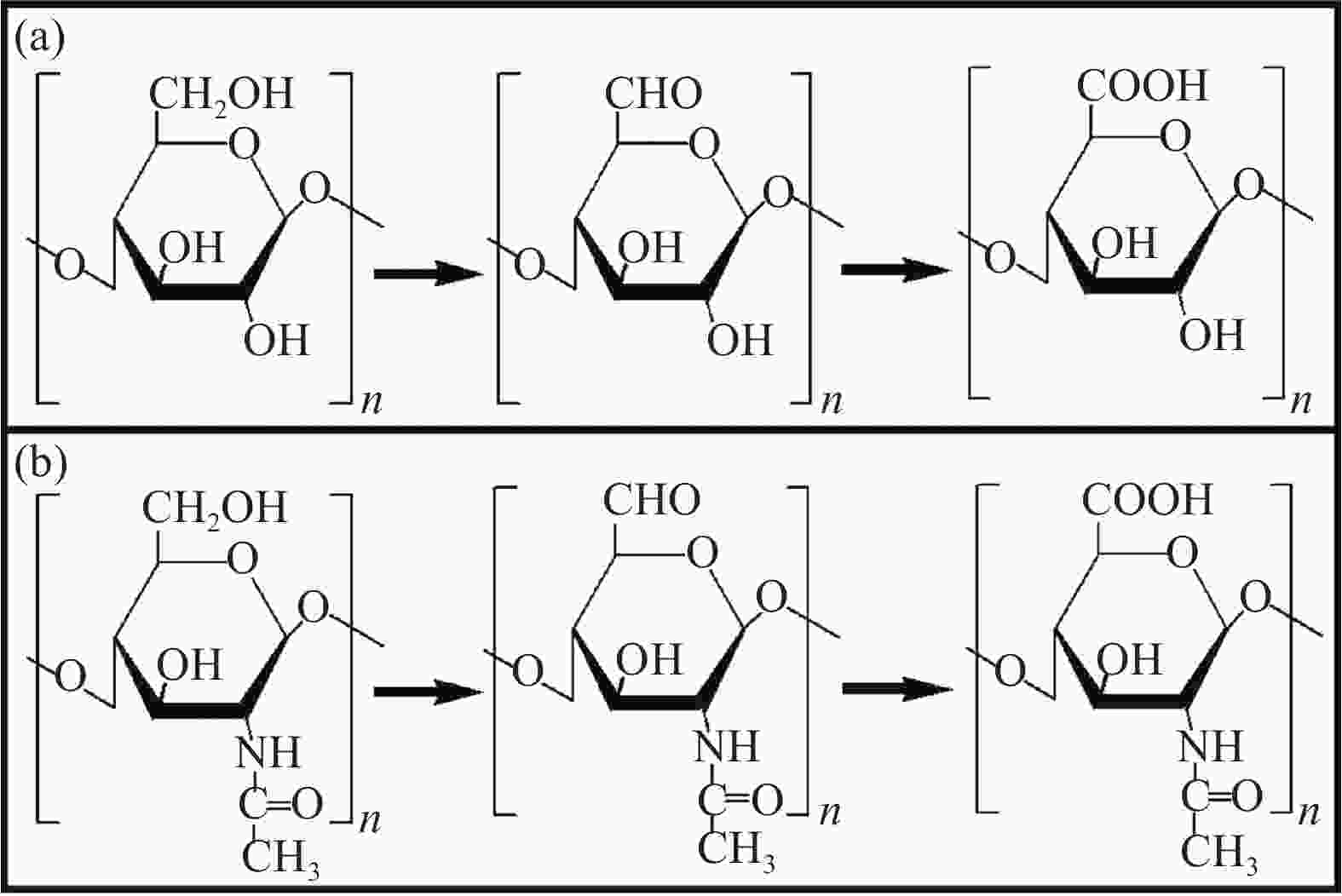

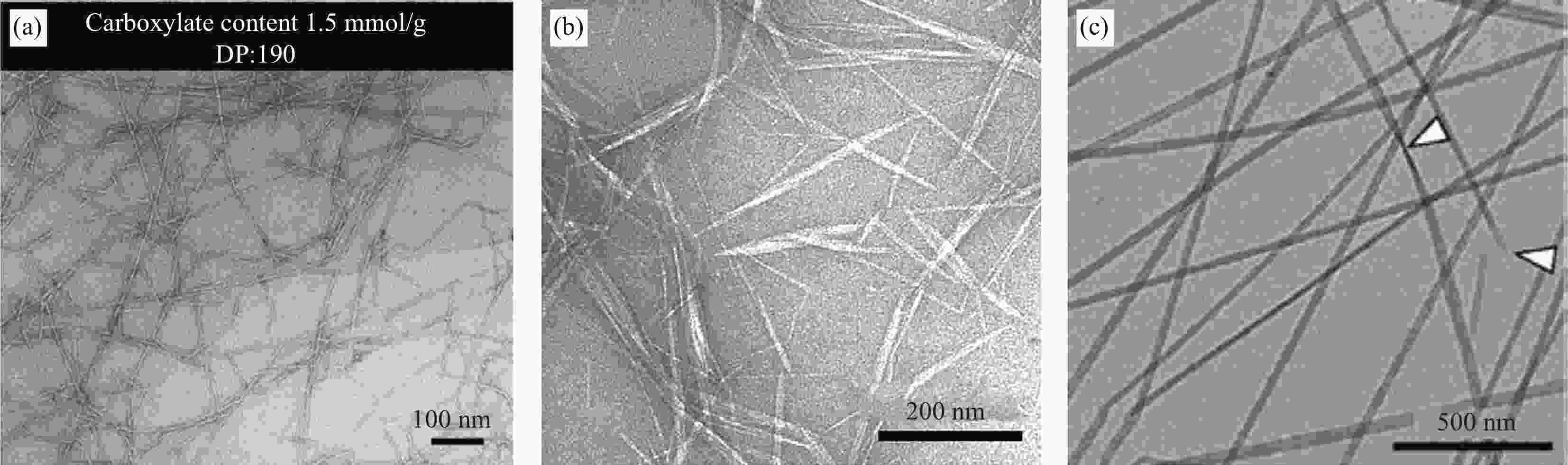

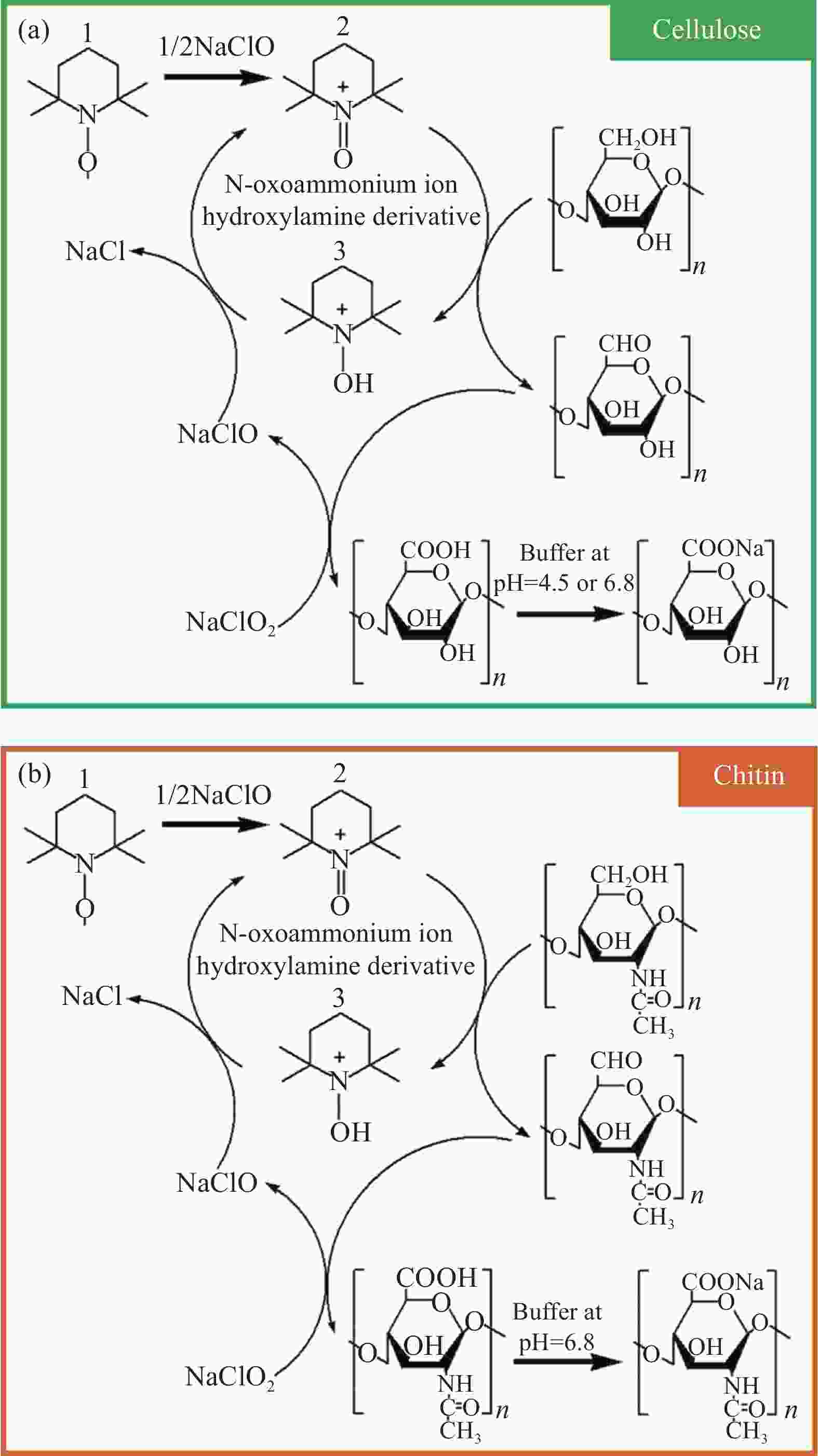

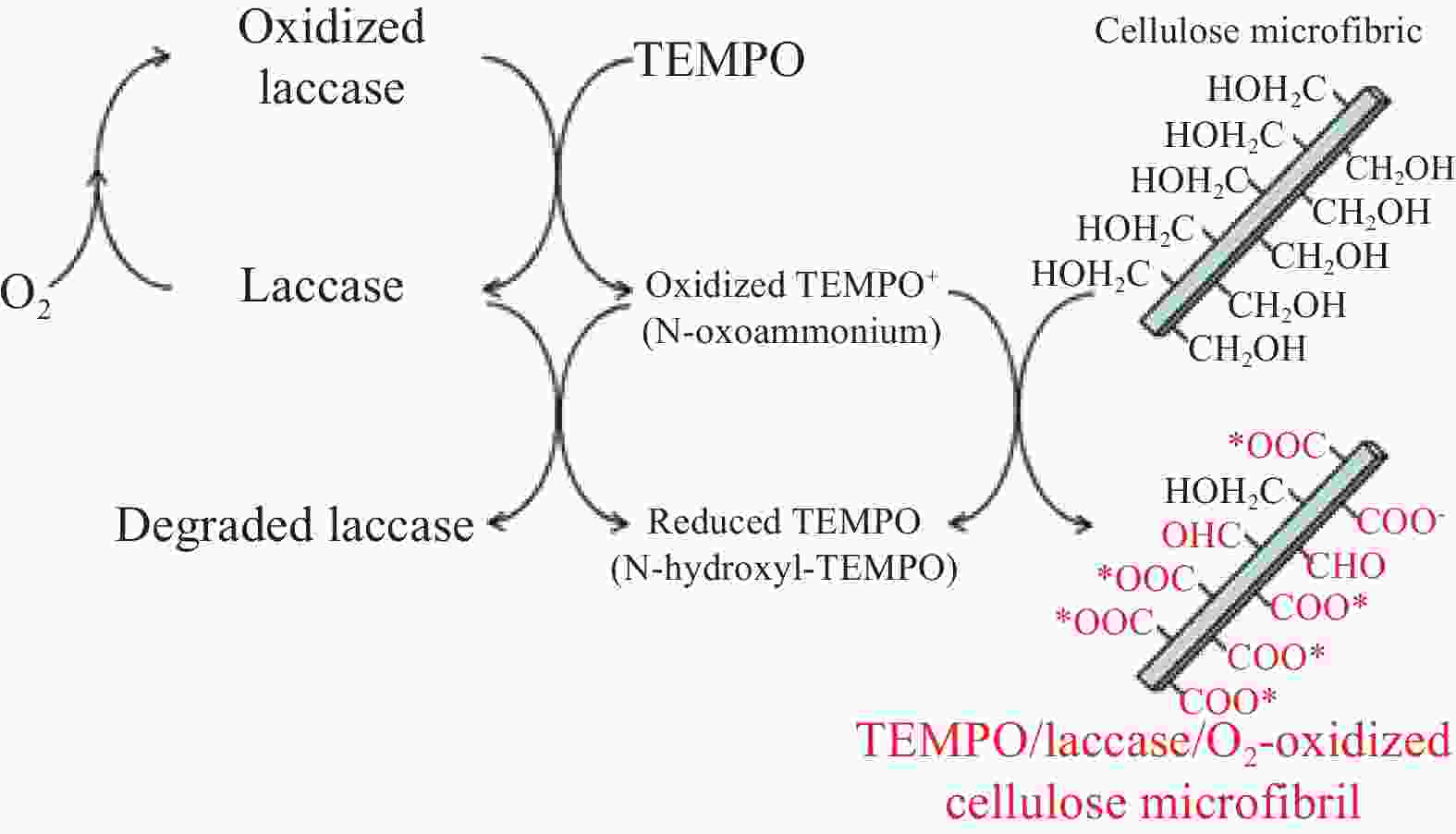

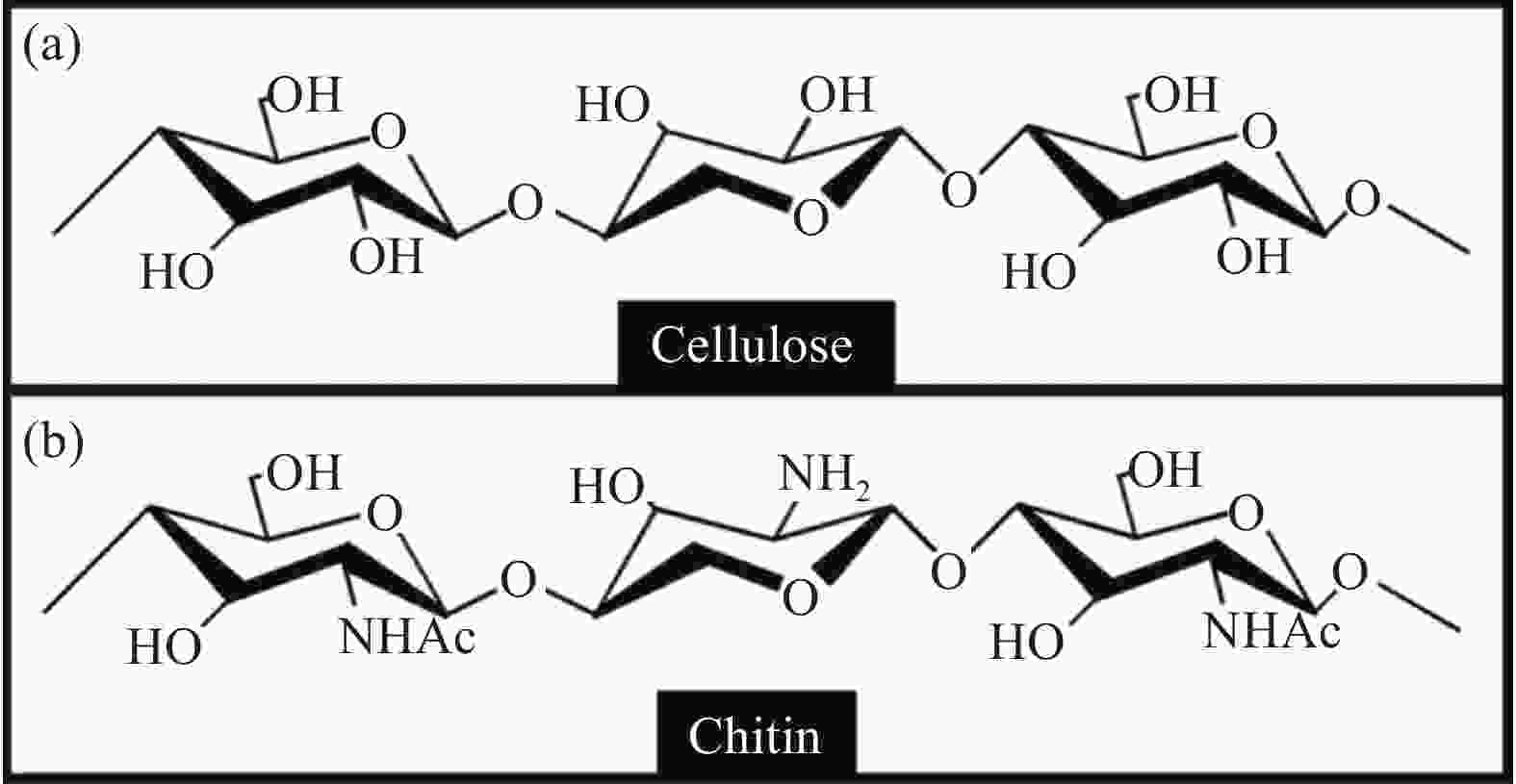

摘要: 纤维素和几丁质具有相似的结构,是自然界中储量丰富的两类天然多糖。经2, 2, 6, 6-四甲基哌啶氮氧化物(TEMPO)氧化修饰制备的纤维素和几丁质纳米纤维,不仅具有多糖类物质的良好亲水性、生物可降解性、生物相容性及丰富的官能团(羟基、羧基、乙酰氨基和氨基等)所带来的特定化学性质,而且还具有纳米纤维的纳米尺寸效应、大比表面积、高表面活性、高结晶度和手性液晶相结构等特点,已成为生物质纳米材料领域的研究重点之一。本文对TEMPO氧化修饰制备天然多糖纳米纤维的方法及剥离机制进行了总结,同时重点综述了TEMPO氧化修饰的天然多糖纳米纤维在薄膜、凝胶、导电、医用、电磁屏蔽及环境等复合材料的增强和功能升级等方面的研究进展,强调了纤维素和几丁质纳米纤维的官能团及纳米尺寸在复合材料中的增效机制。最后,对天然多糖纳米纤维的发展方向及其在各领域应用的机遇与挑战进行了展望。Abstract: Cellulose and chitin are polysaccharides that abundantly exist in nature and have similar structures. Cellulose and chitin nanofibers prepared by using 2,2,6,6-tetramethylpiperidine-1-oxyl radical (TEMPO) oxidization, not only have good hydrophilicity, biodegradability, biocompatibility and the active chemical properties brought by various functional groups (hydroxyl, carboxyl, acetyl, amino, etc.), but also have the characteristics of large specific surface area, chiral liquid crystal phase, high crystallinity, high transparency and specific nano effect caused by nano size. These natural polysaccharide nanofibers have become one of the research focuses in the field of biomass nanomaterials. In this review, the TEMPO oxidation methods used for the preparation of natural polysaccharide nanofibers, as well as the nanofiber extraction mechanism, were comprehensive summarized. At the same time, the up to now research progress on the as-prepared polysaccharide nanofibers-based composites, such as film, gel, conductive, medical, electromagnetic shielding and environmental materials, with focusing on its mechanical enhancement and function upgradation performance were reviewed. Specific focus is giving to the contributions of the functional groups and nano size of cellulose and chitin nanofibers on the performance improvements of the composites. Finally, the development direction of natural polysaccharide nanofibers and the opportunities and challenges of their applications in various fields are prospected.

-

Key words:

- polysaccharide nanofiber /

- cellulose /

- chitin /

- TEMPO-oxidation /

- composite

-

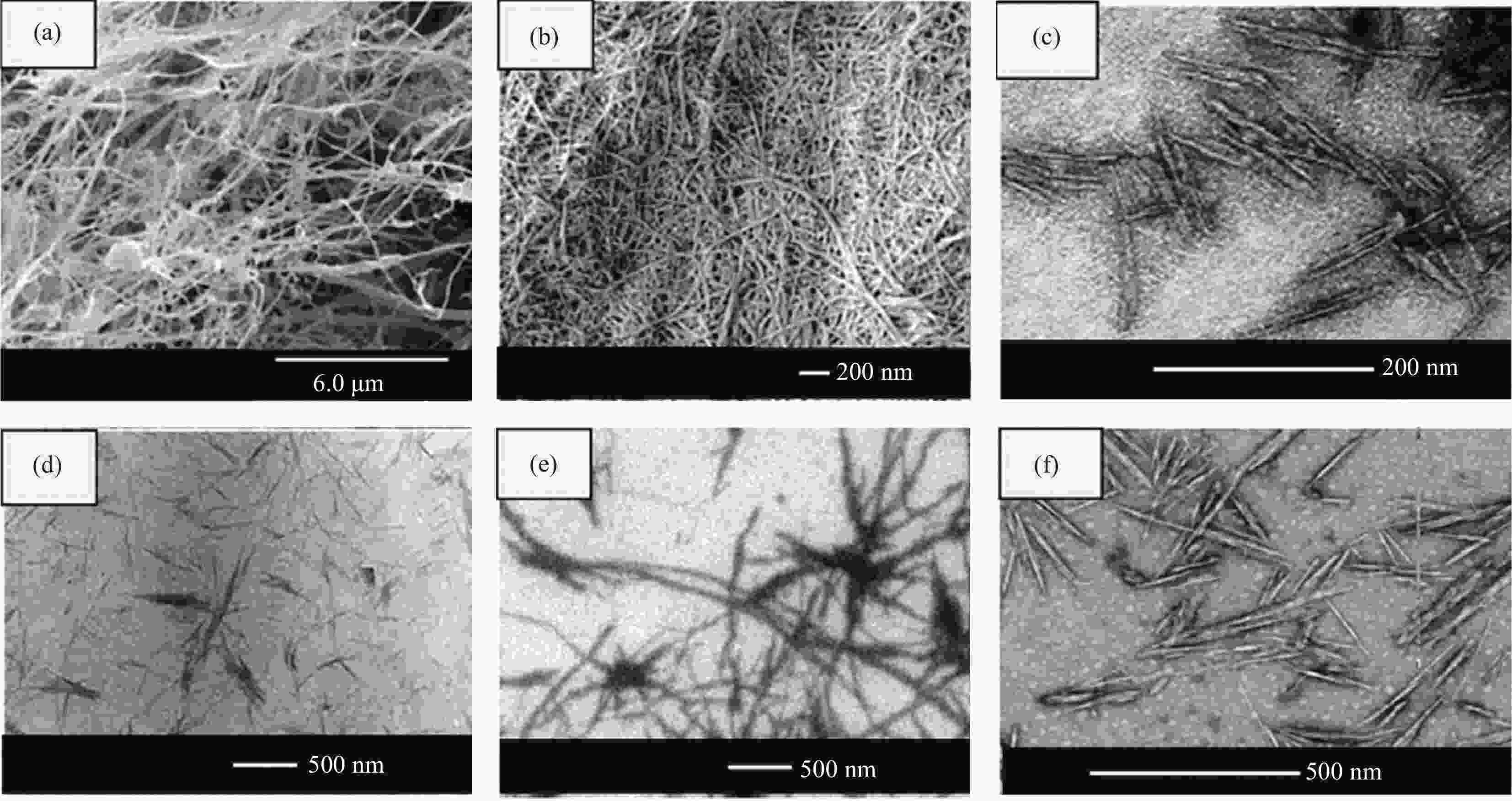

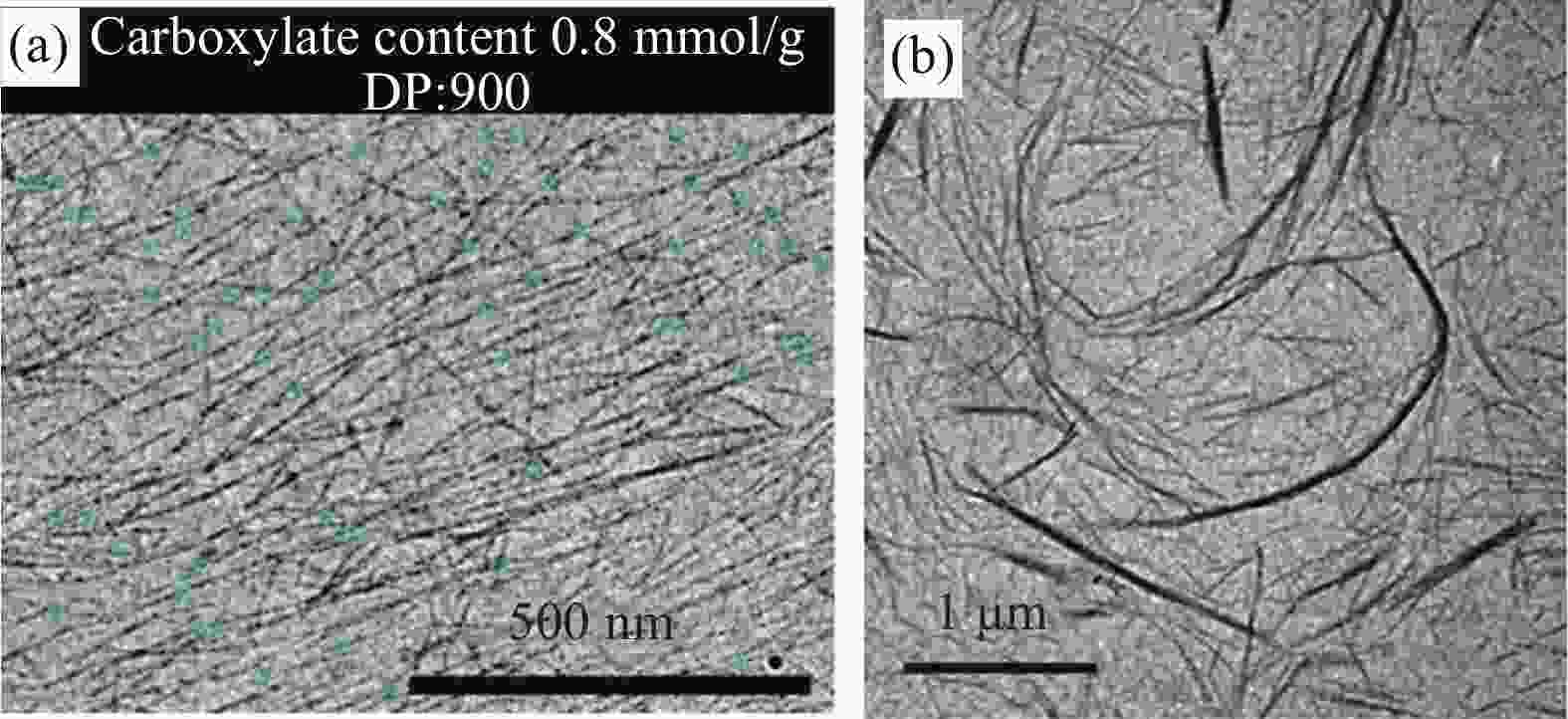

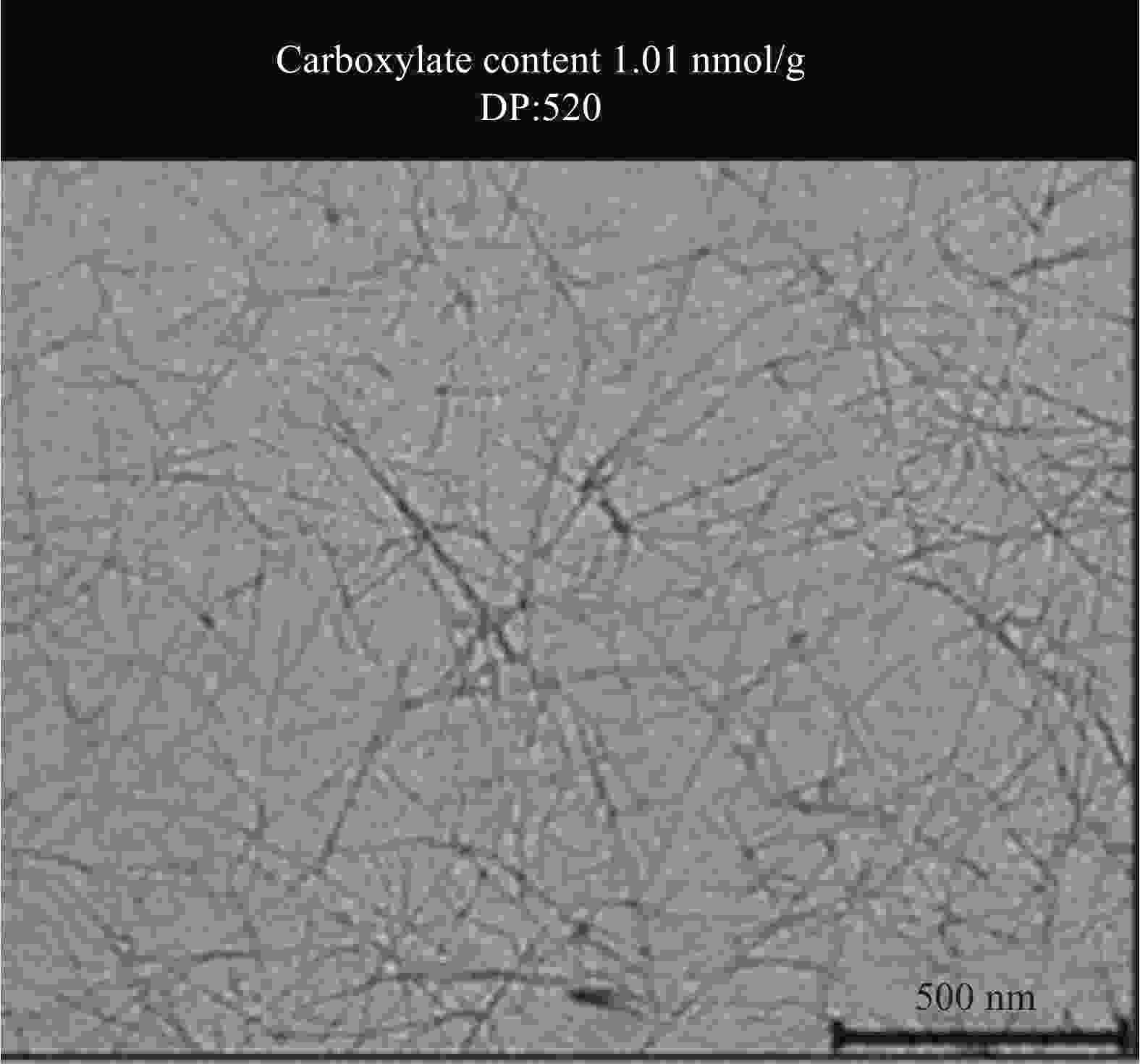

图 2 几种典型的天然多糖纳米纤维的TEM图像:机械法制备的纤维素纳米纤维(CNF)和几丁质纳米纤维(ChNF) ((a)、(b))、酸水解法制备的CNC和ChNC ((c)、(d)) 和低共熔溶剂(DES)处理法制备的CNF和ChNF ((e)、(f))[27]

Figure 2. TEM images of the represent natural polysaccharide nanofibers: Cellulose nanofiber (CNF) and chitin nanofiber (ChNF) prepared by using mechanical treatment ((a), (b)), CNC and ChNC prepared by using acid hydrolysis ((c), (d)), as well as CNF and ChNF prepared by using eutectic solvent (DES) treatment ((e), (f))[27]

Source Product Size

(width×length)/nmWoods, herbs, tunicates and algae Cellulose nanofiber/nanofibril (CNF) 2×500-20×2000 Cellulose nanocrystal/cellulose nanowisker (CNC/CNW) 3×130-10×200 Shrimps and crabs, fungi, yeast cell walls and insect cuticle Chitin nanofiber/nanofibril (ChNF) 20×200-50×400 Chitin nanocrystal/chitin nanowisker (ChNC/ChNW) 16×160-18×240 -

[1] 张俐娜. 天然高分子改性材料及应用[M]. 北京: 化学工业出版社, 2006: 1-13.ZHANG L N. Natural polymer modified material and its application[M]. Beijing: Chemical Industry Press, 2006: 1-13(in Chinese). [2] KLEMM D, HEUBLEIN B, FINK H P, et al. Cellulose: Fascinating biopolymer and sustainable raw material[J]. Angewandte Chemie International Edition,2005,44(22):3358-3393. doi: 10.1002/anie.200460587 [3] ROY D, SEMSARILAR M, GUTHRIE J T, et al. Cellulose modification by polymer grafting: A review[J]. Chemical Society Reviews,2009,38(7):2046-2064. doi: 10.1039/b808639g [4] ISOGAI A, SAITO T, FUKUZUMI H. TEMPO-oxidized cell-ulose nanofibers[J]. Nanoscale,2011,3(1):71-85. doi: 10.1039/C0NR00583E [5] 叶代勇. 纳米纤维素的制备[J]. 化学进展, 2007, 19(10):1568-1575.YE D Y. Preparation of nanocellulose[J]. Progress in Chemistry,2007,19(10):1568-1575(in Chinese). [6] 李伟, 王锐, 刘守新. 纳米纤维素的制备[J]. 化学进展, 2010(10): 2060–2070.LI W, WANG R, LIU S X. Preparation of nanocrystalline cellulose[J]. Progress in Chemistry, 2010(10): 2060-2070(in Chinese). [7] JONOOBI M, OLADI R, DAVOUDPOUR Y, et al. Different preparation methods and properties of nanostructured cellulose from various natural resources and residues: A review[J]. Cellulose,2015,22(2):935-969. doi: 10.1007/s10570-015-0551-0 [8] MOON R J, MARTINI A, NAIRN J, et al. Cellulose nanomaterials review: Structure, properties and nanocomposites[J]. Chemical Society Reviews,2011,40(7):3941. doi: 10.1039/c0cs00108b [9] EICHHORN S J, DUFRESNE A, ARANGUREN M, et al. Review: Current international research into cellulose nano-fibres and nanocomposites[J]. Journal of Materials Science,2010,45(1):1-33. doi: 10.1007/s10853-009-3874-0 [10] OKSMAN K, AITOMÄKI Y, MATHEW A P, et al. Review of the recent developments in cellulose nanocomposite processing[J]. Composites Part A: Applied Science and Manufacturing,2016,83:2-18. doi: 10.1016/j.compositesa.2015.10.041 [11] KIM J H, SHIM B S, KIM H S, et al. Review of nanocellulose for sustainable future materials[J]. International Journal of Precision Engineering and Manufacturing-Green Technology,2015,2(2):197-213. doi: 10.1007/s40684-015-0024-9 [12] FUJISAWA S, IKEUCHI T, TAKEUCHI M, et al. Superior reinforcement effect of TEMPO-oxidized cellulose nano-fibrils in polystyrene matrix: Optical, thermal, and mechanical studies[J]. Biomacromolecules,2012,13(7):2188-2194. doi: 10.1021/bm300609c [13] DUFRESNE A. Nanocellulose: A new ageless bionanomaterial[J]. Materials Today,2013,16(6):220-227. doi: 10.1016/j.mattod.2013.06.004 [14] CAO Y, JIANG Y, SONG Y, et al. Combined bleaching and hydrolysis for isolation of cellulose nanofibrils from waste sackcloth[J]. Carbohydrate Polymers,2015,131:152-158. doi: 10.1016/j.carbpol.2015.05.063 [15] 廖望, 高建领, 刘治国. 纤维素纳米纤维气凝胶的制备方法及应用进展[J]. 西华大学学报:自然科学版, 2020, 39(3):68-75.LIAO W, GAO J L, LIU Z G. Preparation and application of cellulose nanofiber aerogel[J]. Journal of Xihua University (Natural Science Edition),2020,39(3):68-75(in Chinese). [16] FAN Y, SAITO T, ISOGAI A. Chitin nanocrystals prepared by TEMPO-mediated oxidation of α-chitin[J]. Biomacromolecules,2008,9(1):192-198. doi: 10.1021/bm700966g [17] 李雪云, 王合中. TEMPO氧化法制备纳米几丁质晶须粒子的优化及其产品特性表征[J]. 材料导报, 2018, 32(10):5.LI X Y, WANG H Z. Optimization and characterization of TEMPO-mediated oxidization of nanochitin whiskers[J]. Materials Reports,2018,32(10):5(in Chinese). [18] ABDUL KHALIL H P S, BHAT A H, IREANA YUSRA A F. Green composites from sustainable cellulose nanofibrils: A review[J]. Carbohydrate Polymers,2012,87(2):963-979. doi: 10.1016/j.carbpol.2011.08.078 [19] WILLIAMSON R E, BURN J E, HOCART C H. Towards the mechanism of cellulose synthesis[J]. Trends in Plant Science,2002,7(10):461-467. doi: 10.1016/S1360-1385(02)02335-X [20] HAIGLER C H, RAO N R, ROBERTS E M, et al. Cultured ovules as models for cotton fiber development under low temperatures[J]. Plant Physiology,1991,95(1):88-96. doi: 10.1104/pp.95.1.88 [21] VINCENT J F V, MANN D L. Systematic technology transfer from biology to engineering[J]. Philosophical Transactions of the Royal Society A,2002,360(1791):159-173. [22] AUSTIN P R, BRINE C J, CASTLE J E, et al. Chitin: New facets of research[J]. Science,1981,212(4496):749-753. doi: 10.1126/science.7221561 [23] KURITA K. Controlled functionalization of the polysaccharide chitin[J]. Progress in Polymer Science,2001,26(9):1921-1971. doi: 10.1016/S0079-6700(01)00007-7 [24] MINKE R, BLACKWELL J. The structure of α-chitin[J]. Journal of Molecular Biology,1978,120(2):167-181. doi: 10.1016/0022-2836(78)90063-3 [25] WEGST U G K, ASHBY M F. The mechanical efficiency of natural materials[J]. Philosophical Magazine,2004,84(21):2167-2186. doi: 10.1080/14786430410001680935 [26] WEINER S, ADDADI L. Design strategies in mineralized biological materials[J]. Journal of Materials Chemistry,1997,7(5):689-702. doi: 10.1039/a604512j [27] BOULIGAND Y. Twisted fibrous arrangements in biological materials and cholesteric mesophases[J]. Tissue and Cell,1972,4(2):189-217. doi: 10.1016/S0040-8166(72)80042-9 [28] ROMAN M, WINTER W T. Effect of sulfate groups from sulfuric acid hydrolysis on the thermal degradation behavior of bacterial cellulose[J]. Biomacromolecules,2004,5(5):1671-1677. doi: 10.1021/bm034519+ [29] UETANI K, YANO H. Nanofibrillation of wood pulp using a high-speed blender[J]. Biomacromolecules,2011,12(2):348-353. doi: 10.1021/bm101103p [30] LI P, SIRVIÖ J A, HAAPALA A, et al. Cellulose nanofibrils from nonderivatizing urea-based deep eutectic solvent pretreatments[J]. ACS Applied Materials & Interfaces,2017,9(3):2846-2855. [31] MUSHI N E, BUTCHOSA N, SALAJKOVA M, et al. Nanostructured membranes based on native chitin nanofibers prepared by mild process[J]. Carbohydrate Polymers,2014,112:255-263. doi: 10.1016/j.carbpol.2014.05.038 [32] GOODRICH J D, WINTER W T. α-Chitin nanocrystals prepared from shrimp shells and their specific surface area measurement[J]. Biomacromolecules,2007,8(1):252-257. doi: 10.1021/bm0603589 [33] HONG S, YUAN Y, ZHANG K, et al. Efficient hydrolysis of chitin in a deep eutectic solvent synergism for production of chitin nanocrystals[J]. Nanomaterials,2020,10(5):869. doi: 10.3390/nano10050869 [34] DE NOOY A E J, BESEMER A C, VAN BEKKUM H. Highly selective nitroxyl radical-mediated oxidation of primary alcohol groups in water-soluble glucans[J]. Carbohydrate Research,1995,269(1):89-98. doi: 10.1016/0008-6215(94)00343-E [35] DE NOOY A E J, BESEMER A C, VAN BEKKUM H. Highly selective tempo mediated oxidation of primary alcohol groups in polysaccharides[J]. Recueil des Travaux Chimiques des Pays-Bas,1994,113(3):165-166. doi: 10.1002/recl.19941130307 [36] DE NOOY A E J, BESEMER A C, VAN BEKKUM H, et al. TEMPO-mediated oxidation of pullulan and influence of ionic strength and linear charge density on the dimensions of the obtained polyelectrolyte chains[J]. Macromolecules,1996,29(20):6541-6547. doi: 10.1021/ma960492t [37] SAITO T, KIMURA S, NISHIYAMA Y, et al. Cellulose nano-fibers prepared by TEMPO-mediated oxidation of native cellulose[J]. Biomacromolecules,2007,8(8):2485-2491. doi: 10.1021/bm0703970 [38] 王延妮, 徐媚. 制备TEMPO/NaClO/NaBr 氧化纤维素最佳工艺条件探究[J]. 湖北造纸, 2011(4):20-22. doi: 10.3969/j.issn.1006-9631.2011.04.007WANG Y N, XU M. Study on the optimum technological conditions for TEMPO/NaClO/NaBr oxidized cellulose preparation[J]. HU BEI ZAO ZHI,2011(4):20-22(in Chinese). doi: 10.3969/j.issn.1006-9631.2011.04.007 [39] FUJISAWA S, OKITA Y, FUKUZUMI H, et al. Preparation and characterization of TEMPO-oxidized cellulose nano-fibril films with free carboxyl groups[J]. Carbohydrate Polymers,2011,84(1):579-583. doi: 10.1016/j.carbpol.2010.12.029 [40] ISHII D, SAITO T, ISOGAI A. Viscoelastic evaluation of average length of cellulose nanofibers prepared by TEMPO-mediated oxidation[J]. Biomacromolecules,2011,12(3):548-550. doi: 10.1021/bm1013876 [41] LASSEUGUETTE E, ROUX D, NISHIYAMA Y. Rheological properties of microfibrillar suspension of TEMPO-oxidized pulp[J]. Cellulose,2008,15(3):425-433. doi: 10.1007/s10570-007-9184-2 [42] LIN N, BRUZZESE C, DUFRESNE A. TEMPO-oxidized nanocellulose participating as crosslinking aid for alginate-based sponges[J]. ACS Applied Materials & Interfaces,2012,4(9):4948-4959. [43] QIN Z Y, TONG G L, FRANK CHIN Y C, et al. Preparation of ultrasonic-assisted high carboxylate content cellulose nanocrystals by tempo oxidation[J]. BioResources,2011,6(2):1136-1146. [44] LI L, ZHAO S, ZHANG J, et al. TEMPO-mediated oxidation of microcrystalline cellulose: Influence of tempera-ture and oxidation procedure on yields of water-soluble products and crystal structures of water-insoluble residues[J]. Fibers and Polymers,2013,14(3):352-357. doi: 10.1007/s12221-013-0352-8 [45] QIAN Y, QIN Z, VU N M, et al. Comparison of nanocrystals from tempo oxidation of bamboo, softwood, and cotton linter fibers with ultrasonic-assisted process[J]. BioResources,2012,7(4):4952-4964. [46] FAN Y, SAITO T, ISOGAI A. TEMPO-mediated oxidation of β-chitin to prepare individual nanofibrils[J]. Carbohydrate Polymers,2009,77(4):832-838. doi: 10.1016/j.carbpol.2009.03.008 [47] SAITO T, NISHIYAMA Y, PUTAUX J L, et al. Homogeneous suspensions of individualized microfibrils from TEMPO-catalyzed oxidation of native cellulose[J]. Biomacromolecules,2006,7(6):1687-1691. doi: 10.1021/bm060154s [48] SHINODA R, SAITO T, OKITA Y, et al. Relationship between length and degree of polymerization of TEMPO-oxidized cellulose nanofibrils[J]. Biomacromolecules,2012,13(3):842-849. doi: 10.1021/bm2017542 [49] SAITO T, HIROTA M, TAMURA N, et al. Oxidation of bleached wood pulp by TEMPO-NaClO-NaClO2 system: Effect of the oxidation conditions on carboxylate content and degree of polymerization[J]. Journal of Wood Science,2010,56(3):227-232. doi: 10.1007/s10086-009-1092-7 [50] TANAKA R, SAITO T, ISOGAI A. Cellulose nanofibrils prepared from softwood cellulose by TEMPO-NaClO-NaClO2 systems in water at pH 4.8 or 6.8[J]. International Journal of Biological Macromolecules,2012,51(3):228-234. doi: 10.1016/j.ijbiomac.2012.05.016 [51] YE W, HU Y, MA H, et al. Comparison of cast films and hydrogels based on chitin nanofibers prepared using TEMPO-NaBr-NaClO and TEMPO-NaClO-NaClO2 systems[J]. Carbohydrate Polymers,2020,237:116125. doi: 10.1016/j.carbpol.2020.116125 [52] SAITO T, HIROTA M, TAMURA N, et al. Individualization of nano-sized plant cellulose fibrils by direct surface carboxylation using TEMPO catalyst under neutral conditions[J]. Biomacromolecules,2009,10(7):1992-1996. doi: 10.1021/bm900414t [53] JIANG J, YE W, LIU L, et al. Cellulose nanofibers prepared using the TEMPO/laccase/O2 System[J]. Biomacromolecules,2017,18(1):288-294. doi: 10.1021/acs.biomac.6b01682 [54] JIANG J, YE W, YU J, et al. Chitin nanocrystals prepared by oxidation of α-chitin using the O2/laccase/TEMPO system[J]. Carbohydrate Polymers,2018,189:178-183. doi: 10.1016/j.carbpol.2018.01.096 [55] FABBRINI M, GALLI C, GENTILI P, et al. An oxidation of alcohols by oxygen with the enzyme laccase and mediation by TEMPO[J]. Tetrahedron Letters,2001,42(43):7551-7553. doi: 10.1016/S0040-4039(01)01463-0 [56] D’ACUNZO F, GALLI C, MASCI B. Oxidation of phenols by laccase and laccase-mediator systems[J]. European Journal of Biochemistry,2002,269(21):5330-5335. doi: 10.1046/j.1432-1033.2002.03256.x [57] BARRECA A M, SJÖGREN B, FABBRINI M, et al. Catalytic efficiency of some mediators in laccase-catalyzed alcohol oxidation[J]. Biocatalysis and Biotransformation,2004,22(2):105-112. doi: 10.1080/10242420410001692750 [58] ARACRI E, VIDAL T, RAGAUSKAS A J. Wet strength development in sisal cellulose fibers by effect of a laccase–TEMPO treatment[J]. Carbohydrate Polymers,2011,84(4):1384-1390. doi: 10.1016/j.carbpol.2011.01.046 [59] ARACRI E, VALLS C, VIDAL T. Paper strength improvement by oxidative modification of sisal cellulose fibers with laccase–TEMPO system: Influence of the process variables[J]. Carbohydrate Polymers,2012,88(3):830-837. doi: 10.1016/j.carbpol.2012.01.011 [60] JIANG J, CHEN H, YU J, et al. Rate-limited reaction in TEMPO/laccase/O2 oxidation of cellulose[J]. Macromolecular Rapid Communications,2021,42(3):2000501. doi: 10.1002/marc.202000501 [61] ISOGAI T, SAITO T, ISOGAI A. Wood cellulose nanofibrils prepared by TEMPO electro-mediated oxidation[J]. Cellulose,2011,18(2):421-431. doi: 10.1007/s10570-010-9484-9 [62] WEN Y, YUAN Z, LIU X, et al. Preparation and characterization of lignin-containing cellulose nanofibril from poplar high-yield pulp via TEMPO-mediated oxidation and homogenization[J]. ACS Sustainable Chemistry & Engineering,2019,7(6):6131-6139. [63] ROL F, BELGACEM M N, GANDINI A, et al. Recent advances in surface-modified cellulose nanofibrils[J]. Progress in Polymer Science,2019,88:241-264. doi: 10.1016/j.progpolymsci.2018.09.002 [64] LIU S, LIANG H, SUN T, et al. A recoverable dendritic polyamidoamine immobilized TEMPO for efficient catalytic oxidation of cellulose[J]. Carbohydrate Polymers,2018,202:563-570. doi: 10.1016/j.carbpol.2018.09.016 [65] JIAO L, BIAN H, GAO Y, et al. Highly dispersible cellulose nanofibrils produced via mechanical pretreatment and TEMPO-mediated oxidation[J]. Fibers and Polymers,2018,19(11):2237-2244. doi: 10.1007/s12221-018-8565-5 [66] ISOGAI A, HÄNNINEN T, FUJISAWA S, et al. Review: Catalytic oxidation of cellulose with nitroxyl radicals under aqueous conditions[J]. Progress in Polymer Science,2018,86:122-148. doi: 10.1016/j.progpolymsci.2018.07.007 [67] ISOGAI A, BERGSTRÖM L. Preparation of cellulose nano-fibers using green and sustainable chemistry[J]. Current Opinion in Green and Sustainable Chemistry,2018,12:15-21. doi: 10.1016/j.cogsc.2018.04.008 [68] HEINZE T, EL SEOUD O A, KOSCHELLA A. Miscellaneous cellulose derivatives and reactions[M]//Cellulose Derivatives. Berlin: Springer, 2018: 479-531. [69] ISLAM M S, CHEN L, SISLER J, et al. Cellulose nanocrystal (CNC)-inorganic hybrid systems: Synthesis, properties and applications[J]. Journal of Materials Chemistry B,2018,6(6):864-883. doi: 10.1039/C7TB03016A [70] ISOGAI T, SAITO T, ISOGAI A. TEMPO electromediated oxidation of some polysaccharides including regenerated cellulose fiber[J]. Biomacromolecules,2010,11(6):1593-1599. doi: 10.1021/bm1002575 [71] YE W, LIU L, WANG Z, et al. Investigation of pretreatment methods for improving tempo-mediated oxidation and nanofibrillation efficiency of α-chitin[J]. ACS Sustainable Chemistry& Engineering,2019,7(24):19463-19473. [72] JIANG J, YU J, LIU L, et al. Preparation and hydrogel properties of ph-sensitive amphoteric chitin nanocrystals[J]. Journal of Agricultural and Food Chemistry,2018,66(43):11372-11379. doi: 10.1021/acs.jafc.8b02899 [73] FUKUZUMI H, SAITO T, IWATA T, et al. Transparent and high gas barrier films of cellulose nanofibers prepared by TEMPO-mediated oxidation[J]. Biomacromolecules,2009,10(1):162-165. doi: 10.1021/bm801065u [74] YANG Q, SAITO T, BERGLUND L A, et al. Cellulose nano-fibrils improve the properties of all-cellulose composites by the nano-reinforcement mechanism and nanofibril-induced crystallization[J]. Nanoscale,2015,7(42):17957-17963. doi: 10.1039/C5NR05511C [75] FAN Y, FUKUZUMI H, SAITO T, et al. Comparative characterization of aqueous dispersions and cast films of different chitin nanowhiskers/nanofibers[J]. International Journal of Biological Macromolecules, Elsevier,2012,50(1):69-76. doi: 10.1016/j.ijbiomac.2011.09.026 [76] SHIMIZU M, SAITO T, ISOGAI A. Water-resistant and high oxygen-barrier nanocellulose films with interfibrillar cross-linkages formed through multivalent metal ions[J]. Journal of Membrane Science,2016,500:1-7. doi: 10.1016/j.memsci.2015.11.002 [77] RODIONOVA G, LENES M, ERIKSEN Ø, et al. Surface chemical modification of microfibrillated cellulose: Improvement of barrier properties for packaging applications[J]. Cellulose,2011,18(1):127-134. doi: 10.1007/s10570-010-9474-y [78] SPENCE K, VENDITTI R, ROJAS O, et al. Water vapor barrier properties of coated and filled microfibrillated cellulose composite films[J]. BioResources,2011,6(4):4370-4388. doi: 10.15376/biores.6.4.4370-4388 [79] QI Z D, SAITO T, FAN Y, et al. Multifunctional coating films by layer-by-layer deposition of cellulose and chitin nanofibrils[J]. Biomacromolecules,2012,13(2):553-558. doi: 10.1021/bm201659b [80] YU J, ZHU Y, MA H, et al. Contribution of hemicellulose to cellulose nanofiber-based nanocomposite films with enhanced strength, flexibility and UV-blocking properties[J]. Cellulose,2019,26(10):6023-6034. doi: 10.1007/s10570-019-02518-6 [81] 王志国, 蒋杰, 司玉丹, 等. 纤维素纳米纤维对聚乙烯醇复合膜性能的影响[J]. 中国造纸学报, 2017, 32(4):27-31. doi: 10.11981/j.issn.1000-6842.2017.04.27WANG Z G, JIANG J, SI Y D, et al. Effect of cellulose nano-fibers on the property of cellulose nanofiber/polyvinyl alcohol composite film[J]. Transactions of China Pulp and Paper,2017,32(4):27-31(in Chinese). doi: 10.11981/j.issn.1000-6842.2017.04.27 [82] SAITO T, UEMATSU T, KIMURA S, et al. Self-aligned integration of native cellulose nanofibrils towards producing diverse bulk materials[J]. Soft Matter,2011,7(19):8804. doi: 10.1039/c1sm06050c [83] LIU L, WANG R, YU J, et al. Robust self-standing chitin nanofiber/nanowhisker hydrogels with designed surface charges and ultralow mass content via gas phase coagulation[J]. Biomacromolecules,2016,17(11):3773-3781. doi: 10.1021/acs.biomac.6b01278 [84] GAO K, GUO Y, NIU Q, et al. Effects of chitin nanofibers on the microstructure and properties of cellulose nano-fibers/chitin nanofibers composite aerogels[J]. Cellulose,2018,25(8):4591-4602. doi: 10.1007/s10570-018-1899-8 [85] BASU A, LINDH J, ÅLANDER E, et al. On the use of ion-crosslinked nanocellulose hydrogels for wound healing solutions: Physicochemical properties and application-oriented biocompatibility studies[J]. Carbohydrate Polymers,2017,174:299-308. doi: 10.1016/j.carbpol.2017.06.073 [86] 王志国, 蒋杰, 司玉丹, 等. 纳米纤维素-聚乙烯醇复合凝胶的制备及表征[J]. 南京工业大学学报: 自然科学版, 2017, 39(6):19-24.WANG Z G, JIANG J, SI Y D, et al. Preparation and characterization of nanocellulose-polyvinyl alcohol gels[J]. Journal of Nanjing University of Technology: Natural Science Edition,2017,39(6):19-24(in Chinese). [87] GRANDE R, TROVATTI E, CARVALHO A J F, et al. Continuous microfiber drawing by interfacial charge complexation between anionic cellulose nanofibers and cationic chitosan[J]. Journal of Materials Chemistry A,2017,5(25):13098-13103. doi: 10.1039/C7TA02467C [88] JIANG F, HU S, HSIEH Y. Aqueous synthesis of compressible and thermally stable cellulose nanofibril–silica aerogel for CO2 adsorption[J]. ACS Applied Nano Materials,2018,1(12):6701-6710. doi: 10.1021/acsanm.8b01515 [89] ZHU H, FANG Z, WANG Z, et al. Extreme light management in mesoporous wood cellulose paper for optoelectronics[J]. ACS Nano,2016,10(1):1369-1377. doi: 10.1021/acsnano.5b06781 [90] HUANG J, ZHOU Y, DONG L, et al. Enhancement of mechanical and electrical performances of insulating presspaper by introduction of nanocellulose[J]. Composites Science and Technology,2017,138:40-48. doi: 10.1016/j.compscitech.2016.11.020 [91] SYVERUD K, STENIUS P. Strength and barrier properties of MFC films[J]. Cellulose,2009,16(1):75-85. doi: 10.1007/s10570-008-9244-2 [92] MIYAWAKI S, KATSUKAWA S, ABE H, et al. Additive for papermaking and paper containing the same: EP, EP2267222 A4[P]. 2009-03-25. [93] NYGÅRDS S. Nanocellulose in pigment coatings: Aspects of barrier properties and printability in offset[D]. Norrköping: Linköping University, 2011. [94] WANG Z, ZHANG W, YU J, et al. Preparation of nanocellulose/filter paper (NC/FP) composite membranes for high-performance filtration[J]. Cellulose, Springer,2019,26(2):1183-1194. [95] 张文文, 俞娟, 张丽君, 等. 纳米纤维素/滤纸浆复合微滤膜的制备与性能[J]. 林业科学, 2020, 56(9): 112–118.ZHANG W W, YU J, ZHANG L J, et al. Preparation and properties of cellulose nanofibers/filter paper pulp composite microfiltration membranes[J] Scientla Silvae Sinicae, 2020, 56(9): 112–118(in Chinese). [96] TANG H, WU J, LI D, et al. High-strength paper enhanced by chitin nanowhiskers and its potential bioassay applications[J]. International Journal of Biological Macromolecules,2020,150:885-893. doi: 10.1016/j.ijbiomac.2020.02.154 [97] CHENG Q, WANG S, RIALS T G. Poly (vinyl alcohol) nanocomposites reinforced with cellulose fibrils isolated by high intensity ultrasonication[J]. Composites Part A: Applied Science and Manufacturing,2009,40(2):218-224. doi: 10.1016/j.compositesa.2008.11.009 [98] CHEN G, DUFRESNE A, HUANG J, et al. A novel thermoformable bionanocomposite based on cellulose nanocrystal-graft-poly(ε-caprolactone)[J]. Macromolecular Materials and Engineering,2009,294(1):59-67. doi: 10.1002/mame.200800261 [99] GOETZ L, MATHEW A, OKSMAN K, et al. A novel nanocomposite film prepared from crosslinked cellulosic whiskers[J]. Carbohydrate Polymers,2009,75(1):85-89. doi: 10.1016/j.carbpol.2008.06.017 [100] TANPICHAI S, QUERO F, NOGI M, et al. Effective Young’s modulus of bacterial and microfibrillated cellulose fibrils in fibrous networks[J]. Biomacromolecules,2012,13(5):1340-1349. doi: 10.1021/bm300042t [101] SAITO T, KURAMAE R, WOHLERT J, et al. An ultrastrong nanofibrillar biomaterial: The strength of single cellulose nanofibrils revealed via sonication-induced fragmentation[J]. Biomacromolecules,2013,14(1):248-253. doi: 10.1021/bm301674e [102] IWATAKE A, NOGI M, YANO H. Cellulose nanofiber-reinforced polylactic acid[J]. Composites Science and Technology,2008,68(9):2103-2106. doi: 10.1016/j.compscitech.2008.03.006 [103] KHAKALO A, FILPPONEN I, ROJAS O J. Protein-mediated interfacial adhesion in composites of cellulose nano-fibrils and polylactide: Enhanced toughness towards material development[J]. Composites Science and Technology,2018,160:145-151. doi: 10.1016/j.compscitech.2018.03.013 [104] QIU K, NETRAVALI A N. Fabrication and characterization of biodegradable composites based on microfibrillated cellulose and polyvinyl alcohol[J]. Composites Science and Technology,2012,72(13):1588-1594. doi: 10.1016/j.compscitech.2012.06.010 [105] KALIA S, BOUFI S, CELLI A, et al. Nanofibrillated cellulose: surface modification and potential applications[J]. Colloid and Polymer Science,2014,292(1):5-31. doi: 10.1007/s00396-013-3112-9 [106] MULYADI A, DENG Y. Surface modification of cellulose nanofibrils by maleated styrene block copolymer and their composite reinforcement application[J]. Cellulose,2016,23(1):519-528. doi: 10.1007/s10570-015-0787-8 [107] JING X, FENG P, CHEN Z, et al. Highly stretchable, self-healable, freezing-tolerant, and transparent polyacrylic acid/nanochitin composite hydrogel for self-powered multifunctional sensors[J]. ACS Sustainable Chemistry & Engineering,2021,9(28):9209-9220. [108] THIELEMANS W, WARBEY C R, WALSH D A. Permselective nanostructured membranes based on cellulose nanowhiskers[J]. Green Chemistry,2009,11(4):531. doi: 10.1039/b818056c [109] LIEBNER F, HAIMER E, POTTHAST A, et al. Cellulosic aerogels as ultra-lightweight materials. Part 2: Synthesis and properties[J]. Holzforschung, 2009, 63(1): 3-11. [110] AGUIÉ-BÉGHIN V, MOLINARI M, HAMBARDZUMYAN A, et al. Preparation of ordered films of cellulose nanocrystals[M]//Model Cellulosic Surfaces. Washington: American Chemical Society, 2010: 115–136. [111] RUSLI R, EICHHORN S J. Determination of the stiffness of cellulose nanowhiskers and the fiber-matrix interface in a nanocomposite using Raman spectroscopy[J]. Applied Physics Letters,2008,93(3):033111. doi: 10.1063/1.2963491 [112] CRANSTON E D, GRAY D G. Birefringence in spin-coated films containing cellulose nanocrystals[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2008,325(1-2):44-51. [113] PARALIKAR S A, SIMONSEN J, LOMBARDI J. Poly(vinyl alcohol)/cellulose nanocrystal barrier membranes[J]. Journal of Membrane Science,2008,320(1-2):248-258. doi: 10.1016/j.memsci.2008.04.009 [114] HABIBI Y, DUFRESNE A. Highly filled bionanocompo-sites from functionalized polysaccharide nanocrystals[J]. Biomacromolecules,2008,9(7):1974-1980. doi: 10.1021/bm8001717 [115] NOGI M, YANO H. Transparent nanocomposites based on cellulose produced by bacteria offer potential innovation in the electronics device industry[J]. Advanced Materials,2008,20(10):1849-1852. doi: 10.1002/adma.200702559 [116] MANEERUNG T, TOKURA S, RUJIRAVANIT R. Impregnation of silver nanoparticles into bacterial cellulose for antimicrobial wound dressing[J]. Carbohydrate Polymers,2008,72(1):43-51. doi: 10.1016/j.carbpol.2007.07.025 [117] CAPADONA J R, SHANMUGANATHAN K, TYLER D J, et al. Stimuli-responsive polymer nanocomposites inspired by the sea cucumber dermis[J]. Science,2008,319(5868):1370-1374. doi: 10.1126/science.1153307 [118] BERGENSTRÅHLE M, WOHLERT J, LARSSON P T, et al. Dynamics of cellulose-water interfaces: NMR spin-lattice relaxation times calculated from atomistic computer simulations[J]. The Journal of Physical Chemistry B,2008,112(9):2590-2595. doi: 10.1021/jp074641t [119] LU J, ASKELAND P, DRZAL L T. Surface modification of microfibrillated cellulose for epoxy composite applications[J]. Polymer,2008,49(5):1285-1296. doi: 10.1016/j.polymer.2008.01.028 [120] WANG B, SAIN M. Isolation of nanofibers from soybean source and their reinforcing capability on synthetic polymers[J]. Composites Science and Technology,2007,67(11-12):2521-2527. doi: 10.1016/j.compscitech.2006.12.015 [121] PETERSSON L, KVIEN I, OKSMAN K. Structure and thermal properties of poly (lactic acid)/cellulose whiskers nanocomposite materials[J]. Composites Science and Technology,2007,67(11-12):2535-2544. doi: 10.1016/j.compscitech.2006.12.012 [122] KAMEL S. Nanotechnology and its applications in lignocellulosic composites, a mini review[J]. Express Polymer Letters,2007,1(9):546-575. doi: 10.3144/expresspolymlett.2007.78 [123] ANDRESEN M, STENSTAD P, MØRETRØ T, et al. Nonleaching antimicrobial films prepared from surface-modified microfibrillated cellulose[J]. Biomacromolecules,2007,8(7):2149-2155. doi: 10.1021/bm070304e [124] DALMAS F, CHAZEAU L, GAUTHIER C, et al. Large deformation mechanical behavior of flexible nanofiber filled polymer nanocomposites[J]. Polymer,2006,47(8):2802-2812. doi: 10.1016/j.polymer.2006.02.014 [125] YANG W, ZHAO Z, WU K, et al. Ultrathin flexible reduced graphene oxide/cellulose nanofiber composite films with strongly anisotropic thermal conductivity and efficient electromagnetic interference shielding[J]. Journal of Materials Chemistry C,2017,5(15):3748-3756. doi: 10.1039/C7TC00400A [126] XU P, LI B, YU J, et al. Enhancing the adsorption of methylene blue onto hemp hurd powder by tailoring its surface properties[J]. Science of Advanced Materials,2019,11(5):661-671. doi: 10.1166/sam.2019.3482 [127] AHOLA S, ÖSTERBERG M, LAINE J. Cellulose nano-fibrils—adsorption with poly(amideamine) epichlorohydrin studied by QCM-D and application as a paper strength additive[J]. Cellulose,2008,15(2):303-314. doi: 10.1007/s10570-007-9167-3 [128] WAN Z, CHEN C, MENG T, et al. Multifunctional wet-spun filaments through robust nanocellulose networks wrapping to single-walled carbon nanotubes[J]. ACS Applied Materials & Interfaces,2019,11(45):42808-42817. [129] YANO S, MAEDA H, NAKAJIMA M, et al. Preparation and mechanical properties of bacterial cellulose nanocompo-sites loaded with silica nanoparticles[J]. Cellulose,2008,15(1):111-120. doi: 10.1007/s10570-007-9152-x [130] HOEPFNER S, RATKE L, MILOW B. Synthesis and characterisation of nanofibrillar cellulose aerogels[J]. Cellulose,2008,15(1):121-129. doi: 10.1007/s10570-007-9146-8 [131] ELAZZOUZI-HAFRAOUI S, NISHIYAMA Y, PUTAUX J L, et al. The shape and size distribution of crystalline nanoparticles prepared by acid hydrolysis of native cellulose[J]. Biomacromolecules,2008,9(1):57-65. doi: 10.1021/bm700769p [132] TSIOPTSIAS C, STEFOPOULOS A, KOKKINOMALIS I, et al. Development of micro- and nano-porous composite materials by processing cellulose with ionic liquids and supercritical CO2[J]. Green Chemistry,2008,10(9):965. doi: 10.1039/b803869d [133] GARDNER D J, OPORTO G S, MILLS R, et al. Adhesion and surface issues in cellulose and nanocellulose[J]. Journal of Adhesion Science and Technology,2008,22(5-6):545-567. doi: 10.1163/156856108X295509 [134] WANG N, DING E, CHENG R. Preparation and liquid crystalline properties of spherical cellulose nanocrystals[J]. Langmuir,2008,24(1):5-8. doi: 10.1021/la702923w [135] QIAN X. The effect of cooperativity on hydrogen bonding interactions in native cellulose Iβ from ab initio molecular dynamics simulations[J]. Molecular Simulation,2008,34(2):183-191. doi: 10.1080/08927020801961476 [136] PÄÄKKÖ M, VAPAAVUORI J, SILVENNOINEN R, et al. Long and entangled native cellulose I nanofibers allow flexible aerogels and hierarchically porous templates for functionalities[J]. Soft Matter,2008,4(12):2492. doi: 10.1039/b810371b [137] CAPADONA J R, VAN DEN BERG O, CAPADONA L A, et al. A versatile approach for the processing of polymer nanocomposites with self-assembled nanofibre templates[J]. Nature Nanotechnology,2007,2(12):765-769. doi: 10.1038/nnano.2007.379 [138] GEA S, TORRES F G, TRONCOSO O P, et al. Biocompo-sites based on bacterial cellulose and apple and radish pulp[J]. International Polymer Processing,2007,22(5):497-501. doi: 10.3139/217.2059 [139] LEITNER J, HINTERSTOISSER B, WASTYN M, et al. Sugar beet cellulose nanofibril-reinforced composites[J]. Cellulose,2007,14(5):419-425. doi: 10.1007/s10570-007-9131-2 [140] ZULUAGA R, PUTAUX J-L, RESTREPO A, et al. Cellulose microfibrils from banana farming residues: isolation and characterization[J]. Cellulose,2007,14(6):585-592. doi: 10.1007/s10570-007-9118-z [141] NAIRN J A. Numerical implementation of imperfect interfaces[J]. Computational Materials Science,2007,40(4):525-536. doi: 10.1016/j.commatsci.2007.02.010 [142] SHIMAZAKI Y, MIYAZAKI Y, TAKEZAWA Y, et al. Excellent thermal conductivity of transparent cellulose nano-fiber/epoxy resin nanocomposites[J]. Biomacromolecules,2007,8(9):2976-2978. doi: 10.1021/bm7004998 [143] IFUKU S, NOGI M, ABE K, et al. Surface modification of bacterial cellulose nanofibers for property enhancement of optically transparent composites: Dependence on acetyl-group DS[J]. Biomacromolecules,2007,8(6):1973-1978. doi: 10.1021/bm070113b [144] ZHANG C, ZHUANG X, LI X, et al. Chitin nanowhisker-supported sulfonated poly (ether sulfone) proton exchange for fuel cell applications[J]. Carbohydrate Polymers,2016,140:195-201. doi: 10.1016/j.carbpol.2015.12.029 [145] YANG W, SHAO B, LIU T, et al. Robust and mechanically and electrically self-healing hydrogel for efficient electromagnetic interference shielding[J]. ACS Applied Materials & Interfaces,2018,10(9):8245-8257. [146] LUAN Q, ZHOU W, ZHANG H, et al. Cellulose-based composite macrogels from cellulose fiber and cellulose nano-fiber as intestine delivery vehicles for probiotics[J]. Journal of Agricultural and Food Chemistry,2018,66(1):339-345. doi: 10.1021/acs.jafc.7b04754 [147] MA H, YU J, LIU L, et al. An optimized preparation of nanofiber hydrogels derived from natural carbohydrate polymers and their drug release capacity under different pH surroundings[J]. Carbohydrate Polymers,2021,265:118008. doi: 10.1016/j.carbpol.2021.118008 [148] WU C N, FUH S C, LIN S P, et al. TEMPO-oxidized bacterial cellulose pellicle with silver nanoparticles for wound dressing[J]. Biomacromolecules, 2018, 19(2):544-554. [149] TIMOFEI S, SCHMIDT W, KURUNCZI L, et al. A review of QSAR for dye affinity for cellulose fibres[J]. Dyes and Pigments,2000,47(1-2):5-16. doi: 10.1016/S0143-7208(00)00058-9 [150] FECHT H J, BRÜHNE K. Carbon-based nanomaterials and hybrids: Synthesis, properties, and commercial applications[M]. Stanford: Pan Stanford Publishing, 2019. [151] BATMAZ R, MOHAMMED N, ZAMAN M, et al. Cellulose nanocrystals as promising adsorbents for the removal of cationic dyes[J]. Cellulose,2014,21(3):1655-1665. doi: 10.1007/s10570-014-0168-8 [152] CHEN W, LI Q, WANG Y, et al. Comparative study of aerogels obtained from differently prepared nanocellulose fibers[J]. ChemSusChem,2014,7(1):154-161. doi: 10.1002/cssc.201300950 [153] HUSSAIN A, LI J, WANG J, et al. Hybrid monolith of graphene/TEMPO-oxidized cellulose nanofiber as mechanically robust, highly functional, and recyclable adsorbent of methylene blue dye[J]. Journal of Nanomaterials,2018,2018:1-12. [154] ZHANG L, LU H, YU J, et al. Synthesis of lignocellulose-based composite hydrogel as a novel biosorbent for Cu2+ removal[J]. Cellulose,2018,25(12):7315-7328. doi: 10.1007/s10570-018-2077-8 [155] YUE Y, WANG X, WU Q, et al. Highly recyclable and super-tough hydrogel mediated by dual-functional TiO2 nanoparticles toward efficient photodegradation of organic water pollutants[J]. Journal of Colloid and Interface Science,2020,564:99-112. doi: 10.1016/j.jcis.2019.12.069 -

下载:

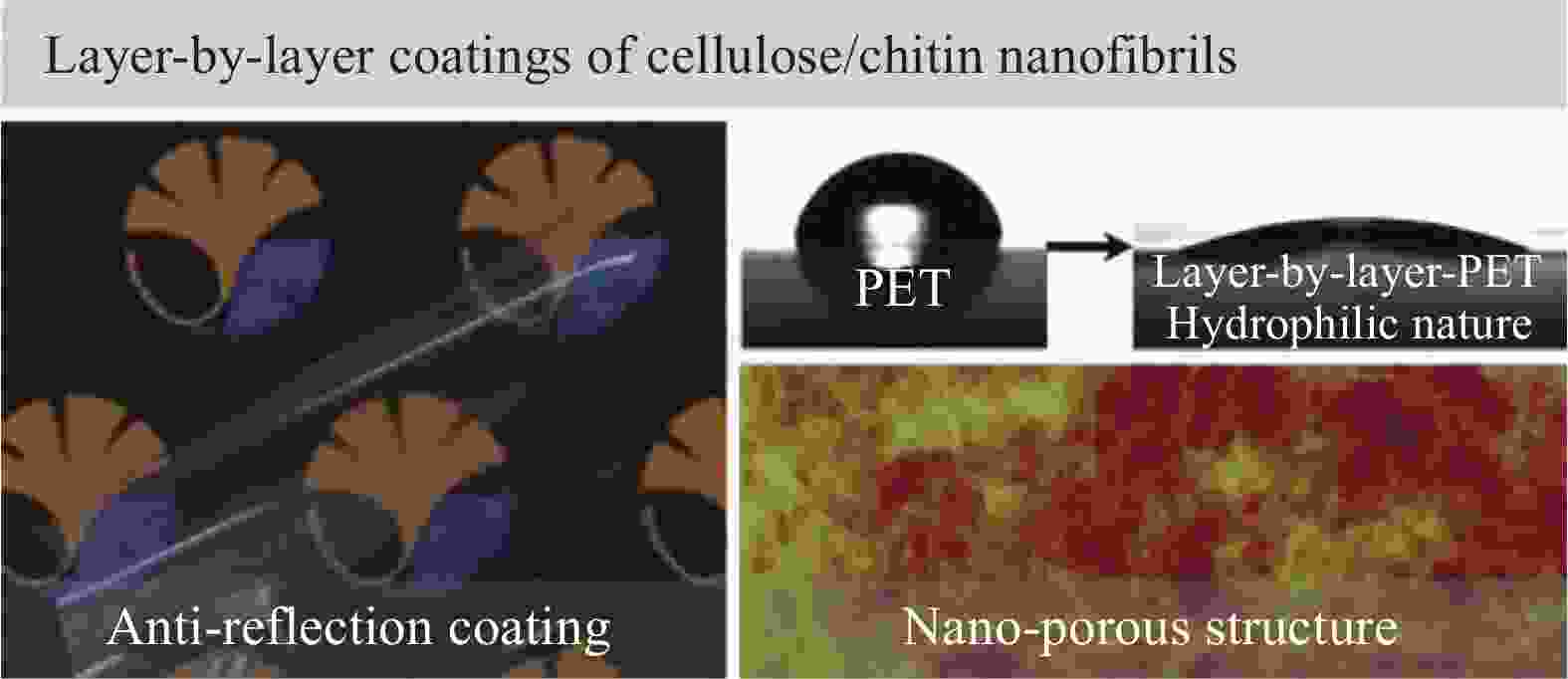

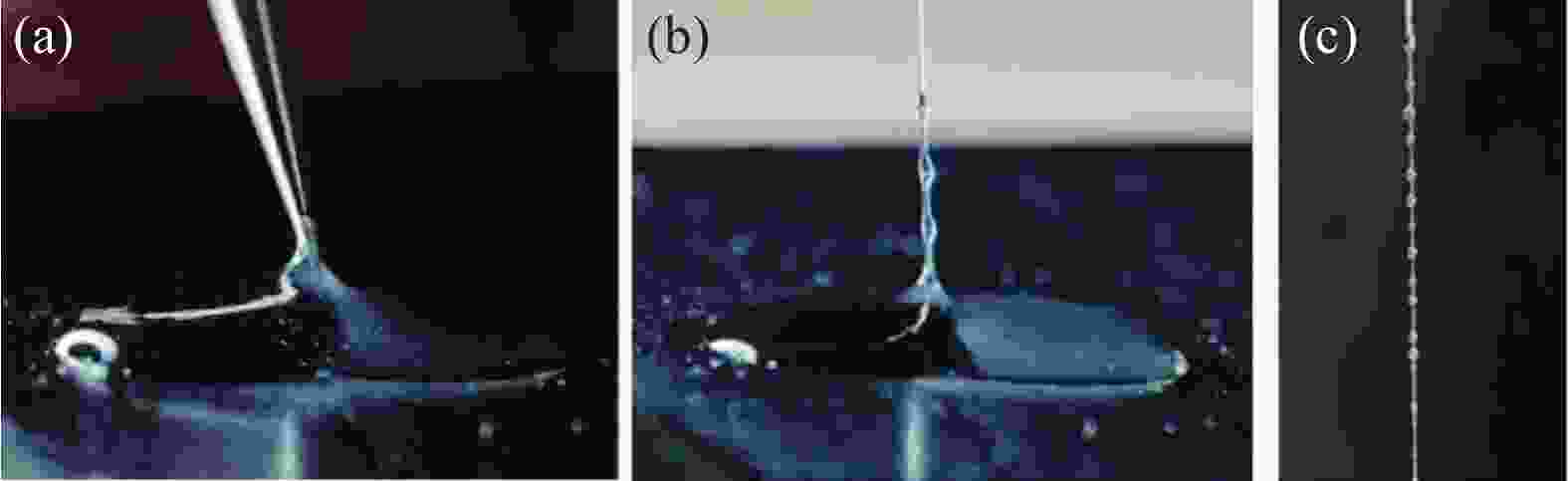

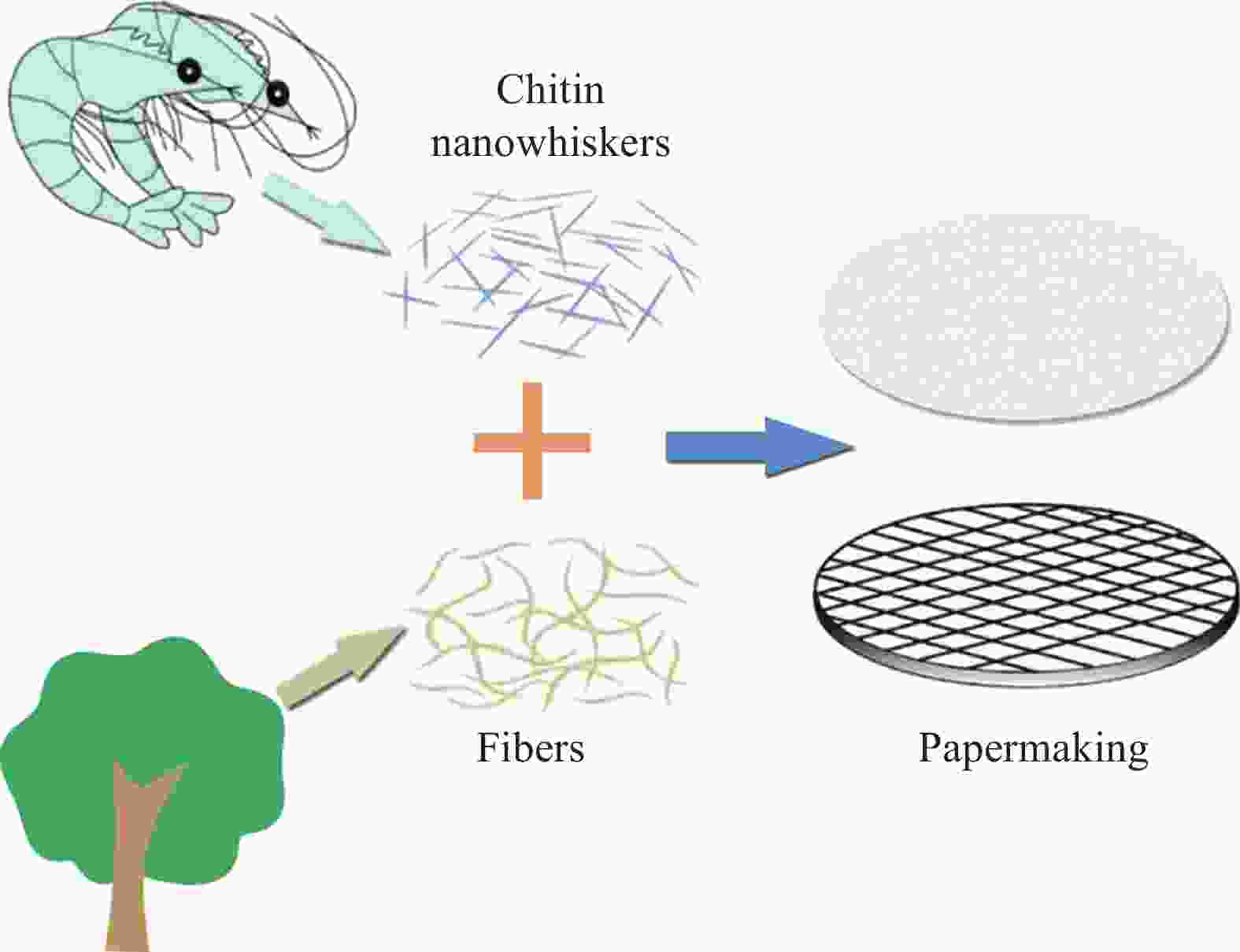

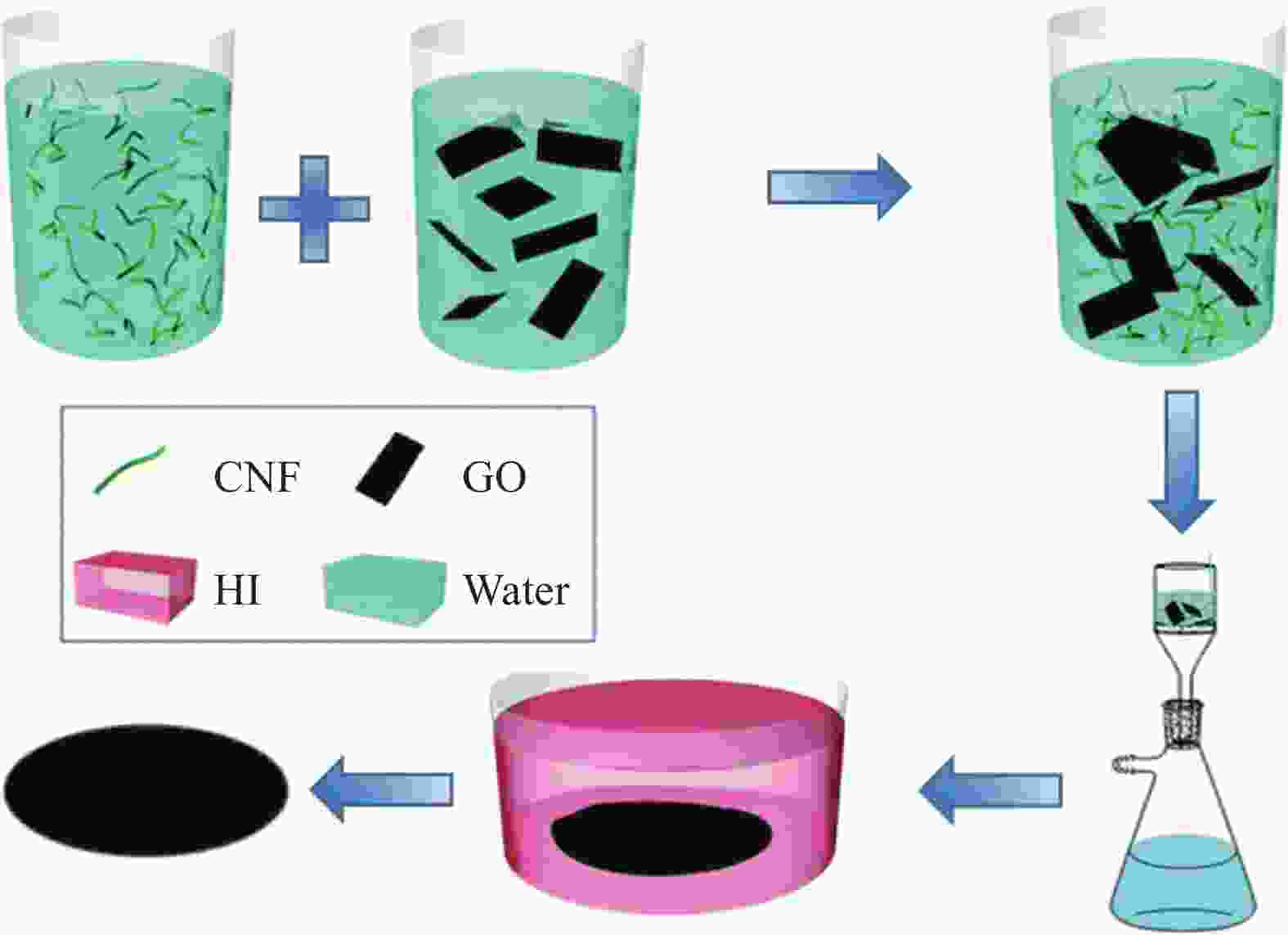

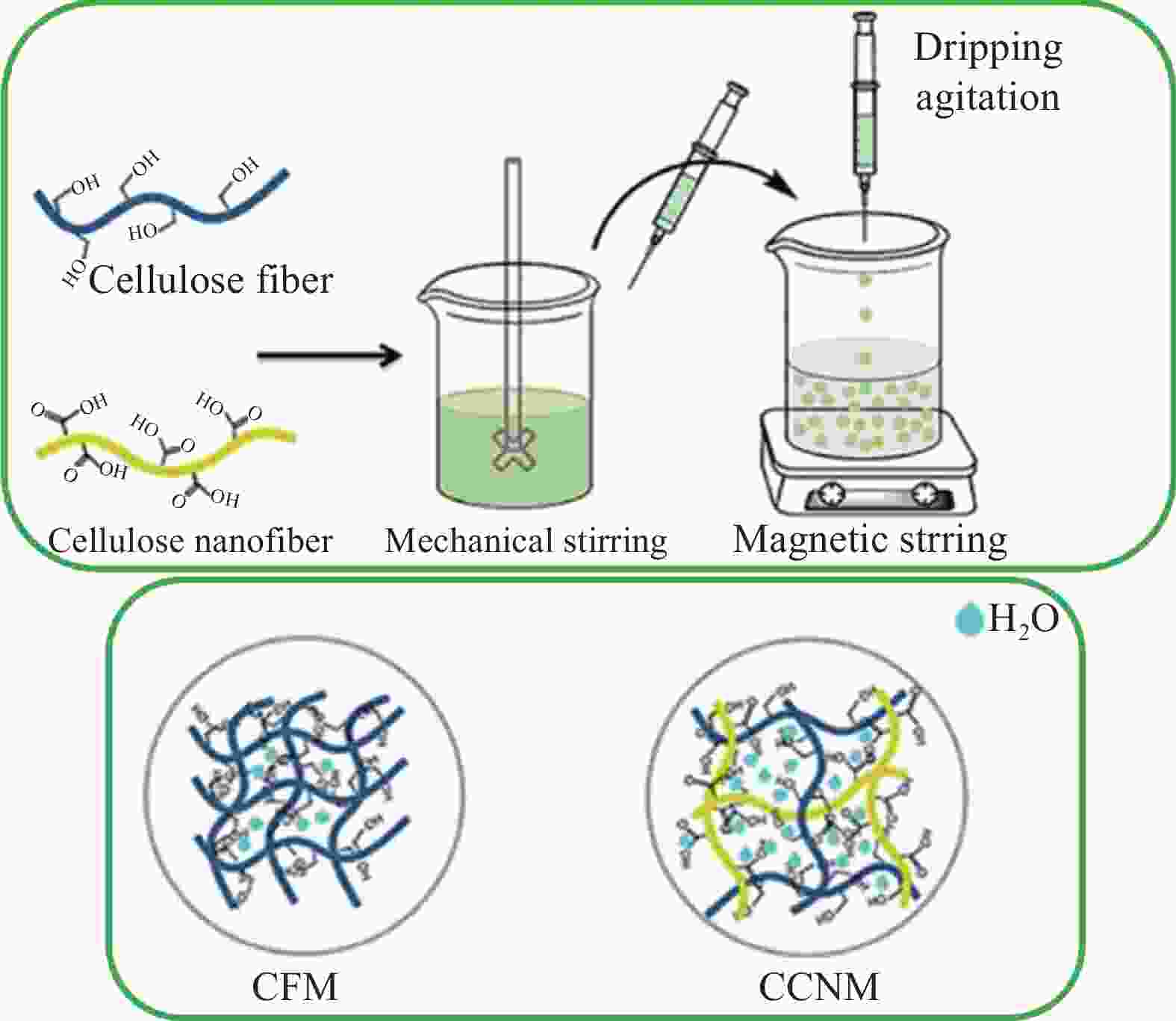

下载: