| [1] |

唐红艳, 王继辉, 徐鹏遥. 复合材料在舰艇上的国外应用现状及进展[J]. 船舶, 2006(2):6-11. doi: 10.3969/j.issn.1001-9855.2006.02.002TANG Hongyan, WANG Jihui, XU Pengyao. Worldwide application and development of compound material in naval ships[J]. Ship and Boat,2006(2):6-11(in Chinese). doi: 10.3969/j.issn.1001-9855.2006.02.002

|

| [2] |

司卫华. 船舶复合材料国外最新进展[J]. 塑料工业, 2011, 39(6):1-7.SI Weihua. The foreign latest progress of composite materials for ships[J]. China Plastics Industry,2011,39(6):1-7(in Chinese).

|

| [3] |

任茶仙, 张铎. 复合材料层合结构铺层顺序优化设计的免疫遗传算法[J]. 强度与环境, 2007, 34(2):43-50.REN Chaxian, ZHANG Duo. Immuntity genetic algorithm for stacking sequence optimization in composite laminated structures[J]. Structure & Environment Engineering,2007,34(2):43-50(in Chinese).

|

| [4] |

蔡忠云, 唐文勇, 陈念众, 等. 复合材料船体层合板的极限强度分析[J]. 船舶力学, 2009, 13(1):72-81. doi: 10.3969/j.issn.1007-7294.2009.01.010CAI Zhongyun, TANG Wenyong, CHEN Nianzhong, et al. Ultimate strength analysis of composite laminated ship panels[J]. Journal of Ship Mechanics,2009,13(1):72-81(in Chinese). doi: 10.3969/j.issn.1007-7294.2009.01.010

|

| [5] |

章向明, 王安稳, 姚国文, 等. 复合材料偏心加筋壳特性分析[J]. 海军工程大学学报, 2005, 17(3):19-26. doi: 10.3969/j.issn.1009-3486.2005.03.005ZHANG Xiangming, WANG Anwen, YAO Guowen, et al. Analysis of behaviors of composite laminated eccentrically stiffened shell[J]. Journal of Naval University of Engineering,2005,17(3):19-26(in Chinese). doi: 10.3969/j.issn.1009-3486.2005.03.005

|

| [6] |

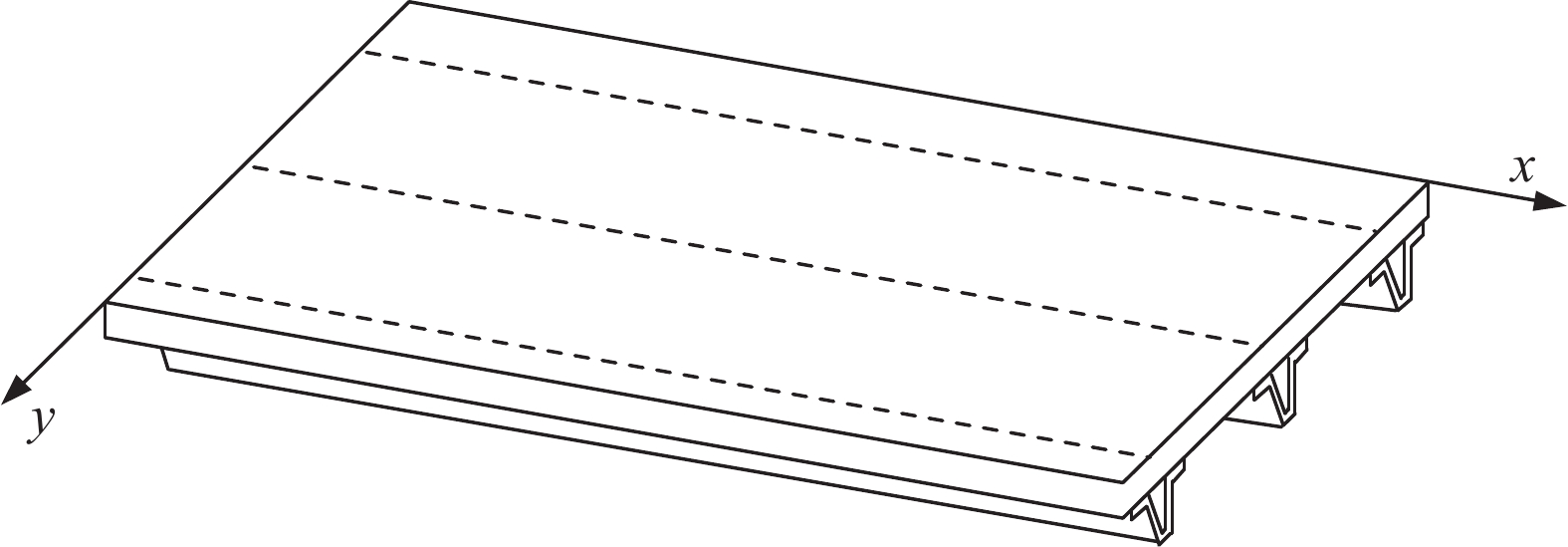

葛东云, 莫与明, 何柏灵, 等. 复合材料帽型加筋板轴压试验及承载能力预测[J]. 复合材料学报, 2016, 33(7):1531-1539.GE Dongyun, MO Yuming, HE Boling, et al. Test and ultimate load capacity prediction of hat-stiffened composite panel under axial compression[J]. Acta Materiae Compo-sitae Sinica,2016,33(7):1531-1539(in Chinese).

|

| [7] |

YETMAN J E. Skin stiffener debonding of top-hat stiffened composite structures[D]. Southampton: University of Southampton, 2016.

|

| [8] |

RICCIO A, RAIMONDO A, FRAGALE S, et al. Delamination buckling and growth phenomena in stiffened composite panels under compression. Part I: An experimental study[J]. Journal of Composite Materials,2014,48(23):2843-2855. doi: 10.1177/0021998313502741

|

| [9] |

张永强, 刘龙权, 余音. 复合材料帽型加筋板冲击损伤后的弯曲性能[J]. 实验室研究与探索, 2020, 39(6):32-36. doi: 10.3969/j.issn.1006-7167.2020.06.008ZHANG Yongqiang, LIU Longquan, YU Yin. Bending performance of composite top-hat stiffened panel after impact damage[J]. Research and Exploration in Laboratory,2020,39(6):32-36(in Chinese). doi: 10.3969/j.issn.1006-7167.2020.06.008

|

| [10] |

张国凡, 孙侠生, 吴存利. 复合材料帽型加筋壁板的失效机制分析与改进设计[J]. 复合材料学报, 2017, 34(11):2479-2486.ZHANG Guofan, SUN Xiasheng, WU Cunli. Failur mechanism analysis and design of omega stiffened composite panel[J]. Acta Materiae Compositae Sinica,2017,34(11):2479-2486(in Chinese).

|

| [11] |

徐丽, 李宏源, 王大政, 等. 复合材料帽型骨材强度及刚度影响因素研究[J]. 武汉理工大学学报, 2014, 3(5):974-978.XU Li, LI Hongyuan, WANG Dazheng, et al. Research of influencing factors on strength and stiffness of composite cap-shape cirder[J]. Journal of Wuhan University of Technology,2014,3(5):974-978(in Chinese).

|

| [12] |

梅蕾, 李宏源, 徐丽, 等. 复合材料船舶帽型加筋结构静力分析[J]. 舰船科学技术, 2015, 37(4):41-46. doi: 10.3404/j.issn.1672-7649.2015.04.008MEI Lei, LI Hongyuan, XU Li, et al. Static analysis of hat stiffeners on the composite ship[J]. Ship Science and Technology,2015,37(4):41-46(in Chinese). doi: 10.3404/j.issn.1672-7649.2015.04.008

|

| [13] |

胡珍伍. 标准化玻璃钢示范渔船船体结构优化设计研究[D]. 大连: 大连理工大学, 2013.HU Zhenwu. Research on hull structure optimal design for standardized FRP fishing vessel[D]. Dalian: Dalian University of Technology, 2013.

|

| [14] |

NISHIHARA S. Analysis of ultimate strength of stiffened rectangular plate(4th report)-On the ultimate bending moment of ship hull girder[J]. Journal of the Society of Naval Architects of Japan, 1983, 154: 367-375.

|

| [15] |

PAIK P K, MANSOUR A E. A simple formula-ion for predicting the ultimate strength of ships[J]. Journal of Marine Science and Technology,1995,1(1):52-62. doi: 10.1007/BF01240013

|

| [16] |

KUTT L M, PIASZCZYK C M, CHEN Y K. Evaluation of longitudinal ultimate strength of various ship hull configurations[J]. SNAME Trans,1985,93:33-55.

|

| [17] |

JONES B J. Design equations and criteria of or-thotropic composite pannels[R]. West Bethesda: Department of Defense, 2004.

|

| [18] |

史明, 陈普会. 基于多学科耦合的复合材料帽型加筋板制造仿真[J]. 复合材料学报, 2021, 38(12):4162-4172.SHI Ming, CHEN Puhui. Simulation of manu facture of the hat-stiffened composite plate based on multidisciplinary coupling[J]. Acta Materiae Compositae Sinica,2021,38(12):4162-4172(in Chinese).

|

| [19] |

吴德财, 徐元铭, 贺天鹏. 新的复合材料格栅加筋板的平铺等效刚度法[J]. 力学学报, 2007, 39(4):495-502. doi: 10.3321/j.issn:0459-1879.2007.04.010WU Decai, XU Yuanming, HE Tianpeng. A new smeared stiffener theory for grid-stiffened composite panels[J]. Chinese Journal of Theoretical and Applied Mechanics,2007,39(4):495-502(in Chinese). doi: 10.3321/j.issn:0459-1879.2007.04.010

|

| [20] |

KIDANEA S, LI G Q, HELMS J, et al. Buckling loadanalysis of grid stiffened composite cylinders[J]. Composites,2003,34B:1-9.

|

| [21] |

NAVIN J, NORMAN F K J. Optimal design of grid-stiffened composite panels using global and localbuckling analyses[J]. Journal of Aircraft,1998,35(3):478-486. doi: 10.2514/2.2321

|

| [22] |

赵群, 丁运亮, 金海波. 基于压弯刚度匹配论则的复合材料加筋板结构优化设计[J]. 南京航空航天大学学报, 2010, 42(3):357-362. doi: 10.3969/j.issn.1005-2615.2010.03.020ZHAO Qun, DING Yunliang, JIN Haibo. Structural optimization design of composite stiffened panels based on matching regulations of compression and bending stiffnesses[J]. Journal of Nanjing University of Aeronautics & Astronautics,2010,42(3):357-362(in Chinese). doi: 10.3969/j.issn.1005-2615.2010.03.020

|

| [23] |

胡明勇, 王安稳, 章向明, 等. 复合材料帽形加筋梁强度及刚度实用计算与试验[J]. 海军工程大学学报, 2014, 26(5):53-56.HU Mingyong, WANG Anwen, ZHANG Xiangming, et al. Experimenal research and calculation of strength and stiffness of hat-stiffened composite beam[J]. Journal of Naval University of Engineering,2014,26(5):53-56(in Chinese).

|

下载:

下载: