Effect of carbon nanotube reinforcement on the mechanical and EMI shielding properties of CF/PEEK composites

-

摘要: 为了制备兼具优异力学性能和电磁干扰屏蔽效能的结构功能一体化耐高温热塑性复合材料,对添加不同组分碳纳米管(CNT)的连续碳纤维增强聚醚醚酮复合材料(CF-CNT/PEEK)的力学性能、电导率以及电磁干扰屏蔽效能(EMI SE)进行了研究。考察用上浆后的CNT (SCNT)作为导电填料制备的SCF-SCNT/PEEK层合板力学性能、界面形貌和屏蔽效能,并与不进行表面修饰、仅活化的CNT (ACNT)的效果做对比实验。结果表明,适量的CNT会使CF/PEEK层合板的力学性能、电导率和EMI SE得到提高;SCNT比ACNT更容易在PEEK中均匀分散,且与SCF和PEEK的结合更好。所有样品中,仅添加1wt%SCNT的SCF-SCNT/PEEK层合板与不添加CNT的层合板相比,拉伸强度提高了20.8%,达到778 MPa;弯曲强度提高了25.9%,达到1684 MPa;电导率提升5倍,达到0.15 S/cm;电磁干扰屏蔽效能提升69.76%,平均值达到34.97 dB。

-

关键词:

- 碳纤维 /

- 聚醚醚酮(PEEK) /

- 复合材料 /

- 电磁屏蔽(EMI SE) /

- 界面改性 /

- 力学性能

Abstract: In order to prepare a high temperature resistant thermoplastic composite material with integrated structure and function, which has excellent mechanical properties and electromagnetic interference shielding effectiveness at the same time, the mechanical properties, electrical conductivity and electromagnetic interference shielding effectiveness (EMI SE) of continuous carbon fiber reinforced polyether ether ketone composites (CF-CNT/PEEK) with different components of carbon nanotubes (CNT) were studied. The mechanical properties, interface morphology and shielding effectiveness of SCF-SCNT/PEEK laminates prepared with CNT modified PEEK sizing agent (SCNT) as conductive fillers were investigated, and the effect of the CNT (ACNT) without surface modification and only activation comparative experiment were compared. The results show that an appropriate amount of CNT will improve the mechanical properties, electrical conductivity and shielding effectiveness of the CF/PEEK laminate. SCNT is easier to uniformly disperse in PEEK than ACNT, and has a better combination with SCF and PEEK. In all samples, the tensile strength of SCF-SCNT/PEEK laminates with only 1wt%SCNT increased by 20.8% to 778 MPa compared with laminates without CNTs. Bending strength is increased by 25.9% to 1684 MPa. The conductivity is increased by 5 times, reaching 0.15 S/cm. The electromagnetic interference shielding efficiency is increased by 69.76%, with an average value of 34.97 dB. -

近些年来,随着科学技术的发展,越来越多的通信设备被研发出来。尤其是5G技术投入使用,使得人们在享受更快更便利生活的同时,也面临着日益增多的电磁波辐射。对于航空航天领域来说,克服电磁波对飞机的干扰是保障人身安全必不可少的一步。然而,伴随着碳纤维增强复合材料替代合金在飞机上的大量使用,如何在保证树脂基复合材料力学性能的同时提高复合材料的电磁干扰屏蔽效能(Electromagnetic interference shielding effectiveness,EMI SE)成为了一个亟待解决的难题。

碳纤维增强复合材料虽然表现出十分优异的力学性能和功能性[1],但其导电性相对合金却显著降低,EMI SE也就随之降低。碳纳米管(Carbon nanotube,CNT)是一种具有良好导电性的材料,其电阻率最小可以达到5.1×10−6 Ω·cm[2]。而且由于其巨大的比表面积,引入适量的CNT,有望在改善电磁屏蔽性能的同时使得树脂基复合材料的力学性能也获得进一步提升[3]。然而,大部分关于电磁屏蔽功能材料的研究都着重关注EMI SE的提高,材料强度尽管可能也有所提升,却很难达到几百兆帕[4-7],难以实现结构-功能一体化。

并且,CNT虽然具有优异的导电性,但是其在树脂基体中极易团聚,导致最终在基体中形成的导电通路并不理想,甚至根本无法形成导电通路。因此,要想真正达到用CNT来提升复合材料的导电性,如何使CNT均匀分散是一个需要克服的难题。有人提出可以通过化学气相沉积(CVD)等方法对CNT进行处理来减少团聚[8-11],但这些方法由于工艺控制复杂、效率低等,很难用于工业生产,且较少有适用于耐高温基体树脂的报道。

另一方面,目前与碳纤维搭配使用的树脂基体以热固性树脂,尤其是环氧树脂居多[12-16]。但是热固性树脂不耐高温和无法二次加工等缺点随使用量的增大而日益尖锐。与此同时,以聚醚醚酮(PEEK)为代表的热塑性树脂基复合材料(CFRTP)则因其可回收、可反复熔融加工,以及优异的冲击韧性、耐湿热性、耐溶剂腐蚀性等优势而越加受到航空界的关注[17-18]。然而,正是由于PEEK优良的耐腐蚀性和化学稳定性[19-21],导致它与CF的界面相互作用相对环氧树脂而言更弱,在受到外力时,容易发生层间分层破坏。

本文设计并制备了CNT网络和CF织物协同增强PEEK热塑性复合材料,拟提供一种可工业化制备兼具优异力学性能和EMI SE的耐高温热塑性复合材料的途径和优化工艺。使用统一上浆剂对CF和CNT同时进行表面处理,以期改善CNT、CF与PEEK之间的界面相互作用,从而分别避免CNT团聚和CF与基体的脱粘。研究了CNT含量和界面改性对材料结构与性能的影响。

1. 实验材料及方法

1.1 原材料

碳纳米管(CNT),XFM19,南京先丰纳米材料科技有限公司;碳纤维织物(T300 3K 5枚缎纹),日本东丽(Toray)公司;聚醚醚酮粉末(PEEK),吉林省中研高分子材料股份有限公司;导电银胶DAD-2,上海市合成树脂研究所;浓硫酸、浓硝酸、米氏酸、丙酮、二甲基亚砜(DMSO)、乙醇、邻苯二甲酸氢钾、氢氧化钠,国药集团化学试剂有限公司;去离子水。

1.2 实验仪器与设备

过滤反应釜装置,定制,斯谱瑞(上海)生物科技有限公司;球磨机,PDM-DECO-V2L,长沙德科仪器设备有限公司;0.5MN真空热压机,FCC-D500×500×1/ZK,宜兴市宜轻机械有限公司。

1.3 磺化聚醚醚酮(SPEEK)及其上浆剂的制备

于500 mL的三口烧瓶中加入300 mL浓硫酸,并将此烧瓶固定于50℃的油浴中。称取15 g提前烘干的PEEK粉末,用电动搅拌器边慢速搅拌边缓慢加入PEEK粉末,以防止PEEK粉末加入过快导致PEEK粉末团聚。全部加完PEEK粉末后,将电动搅拌器的转速提高到400 r/min,持续反应3.5 h。反应结束后,将溶液缓慢倒入冰水中,静置12 h。最后用去离子水重复洗涤产物至表面呈中性。烘干后即得到磺化聚醚醚酮(SPEEK)。将制备好的SPEEK以0.1wt%的质量分数溶于DMSO中,得到SPEEK上浆剂。

1.4 酸化碳纳米管的制备

以V(H2SO4)∶V(HNO3)=3∶1的比例向反应釜中加入1500 mL浓硫酸和500 mL浓硝酸,保持65℃水浴。用电动搅拌器充分搅拌均匀后,缓慢加入10 g CNT。持续反应3 h后,将原液用去离子水稀释至pH值为2~3,并静置分层。最后用水泵抽滤后,充分烘干,得到酸化碳纳米管(Acidified-CNT,ACNT)。

1.5 SCF-CNT/PEEK层合板的制备

采用定制压机制备SCF-CNT/PEEK层合板。将碳纤维织物(CF)放置在70℃水浴加热的丙酮中反应10 h,以去除CF表面的环氧浆料,反应结束用去离子水充分洗涤CF后烘干。同时将米氏酸以m(米氏酸)∶V(乙醇)=1.5∶100的比例溶于乙醇中,并用超声分散仪使其充分溶解,而后用溶解好的米氏酸浸泡上述去好浆的CF,期间不断翻动CF,使其活化均匀。洗涤烘干后得到活化CF,即为ACF。最后用1.3节中制备好的SPEEK上浆剂分别浸泡ACNT与ACF,并用恒温振荡器振荡24 h,使SPEEK上浆剂分散均匀。上浆结束后充分烘干得到SCNT与SCF。按照表1配方,保持总质量为25 g,以SCNT质量占总体系质量的分数为1wt%、3wt%、5wt%,分别称取SCNT与PEEK粉末,配制成SCF-1wt%SCNT/PEEK、SCF-3wt%SCNT/PEEK、SCF-5wt%SCNT/PEEK体系;另外按照ACNT质量占总体系质量的分数为0wt%、1wt%称取ACNT与PEEK粉末,配制成SCF-0wt% ACNT/PEEK和SCF-1wt%ACNT/PEEK体系。

表 1 不同组分SCF-CNT/PEEK层合板中原料的质量Table 1. The mass of raw materials in SCF-CNT/PEEK laminates with different componentsNo. Sample Mass of SCNT/g Mass of ACNT/g Mass of PEEK/g 1 SCF-0wt%ACNT/PEEK 0 0 25.00 2 SCF-1wt%ACNT/PEEK 0 0.25 24.75 3 SCF-1wt%SCNT/PEEK 0.25 0 24.75 4 SCF-3wt%SCNT/PEEK 0.75 0 24.25 5 SCF-5wt%SCNT/PEEK 1.25 0 23.75 Notes: PEEK—Poly(ether-ether-ketone); SCF—Sized carbon fiber; SCNT—Sized carbon nanotube; ACNT—Activated carbon nanotube. 将两种CNT粉末与PEEK充分球磨24 h混合均匀后,按照图1的方式铺层,其中SCF按照0°/90°铺层。而后放进定制压机中,以加工温度395℃、预压力0.7 MPa,维持10 min;预成型压力0.8 MPa,维持5 min;成型压力1 MPa,维持20 min的工艺条件来成型,保压并自然冷却至室温后脱模,得到SCF-SCNT/PEEK与SCF-ACNT/PEEK两种层合板,其厚度约为1 mm。按照CNT含量及类型的不同,分别编号,详见表1。

依据ASTM标准[22-23],将层合板裁切成100 mm×10 mm和50.8 mm×12.7 mm两种样条;依据测试仪器的要求,另外将层合板裁切成22.86 mm×10.16 mm的样条。

1.6 测试与表征

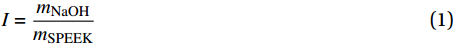

采用酸碱滴定法测试SPEEK上浆剂的磺化度。使用邻苯二甲酸氢钾配制成标准液,用其标定氢氧化钠溶液,得到氢氧化钠溶液的准确浓度。再用氢氧化钠溶液标定SPEEK上浆剂的磺化度。依据以下公式计算SPEEK的磺化度:

I=mNaOHmSPEEK (1) D=MSPEEK⋅I1000−MSO3Na⋅I (2) 式中:I表示离子交换速率;D表示磺化度(%)

;mNaOH表示滴定SPEEK上浆剂的过程中使用的NaOH的质量(g);mSPEEK表示配制的上浆剂中含有的SPEEK的质量(g);MSPEEK表示SPEEK的相对分子质量,为288 g/mol;MSO3Na表示磺酸钠基团的相对分子质量,为103 g/mol。 采用X射线光电子能谱仪(美国Thermo Scientific公司,Escalab 250Xi)测试CNT酸化前后表面基团的种类。

采用热重分析仪(德国NETZSCH公司,TG209F1 Libra)来测试ACNT表面羧基的含量以及SCNT中SPEEK的上浆量。

采用傅里叶红外光谱仪(美国Thermo Scientific公司,Nicolet iS50)来表征ACNT与SPEEK的化学相互作用。

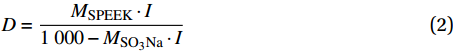

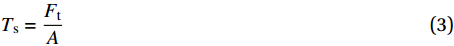

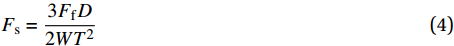

采用微机控制电子万能试验机(中国万测,ETM 105D),依据ASTM D3039拉伸测试标准[22],拉伸测试的速率为 2.0 mm/min,样条两端分别粘贴加强片。依据ASTM D790弯曲测试标准[23],弯曲测试的速率为 1.1 mm/min。依据以下公式计算拉伸强度与弯曲强度:

Ts=FtA (3) Fs=3FfD2WT2 (4) 式中:Ts表示拉伸强度(MPa);Ft表示拉伸断裂力(N);A表示拉伸断裂面积(mm2);Fs表示弯曲强度(MPa);Ff表示弯曲断裂力(N);D表示测试时的跨距(mm);W表示试样的宽度(mm);T 2表示试样厚度的平方(mm2)。

采用矢量网络分析仪(德国Rohde&Schwarz公司,ZNB20)测试层合板的EMI SE。将裁切好的22.86 mm×10.16 mm的样条,充分打磨后装入仪器的夹具中,采用波导法在无线电波段−X波段(8.2~12.4 GHz)测试样品。

采用扫描电子显微镜(日本JEOL公司,JSM-IT300)观察经拉伸断裂后样条的纤维拔出情况。

采用场发射扫描电子显微镜(日本Hitachi公司,S-4800)观察CNT在树脂中的分布情况。

采用金相显微镜(德国Axiovert公司,40MAT)、镶嵌机( 特鲁利(苏州)材料科技有限公司,CM-2M)与研磨抛光机( 特鲁利(苏州)材料科技有限公司,GP-1B)组合,在层合板液氮脆断后,使用镶嵌机与酚醛树脂,将层合板样品压制成直径为30 mm的圆块。在研磨抛光机上分别使用800 CW、1000 CW、1500 CW、2 000 CW粗糙度的砂纸各打磨1 h抛光后,使用金相显微镜观察形貌。

采用数字万用表(美国Keysight公司,34461A),依据ASTM D257电阻测试标准[24]测试复合材料层合板的电导率。在裁切好的层合板的表面上均匀涂覆导电银胶后,使用四探针法测试层合板的体积电阻[25]。

2. 结果与讨论

2.1 SPEEK的表征

图2为SPEEK的FTIR图谱与磺化度测试图。可以发现,PEEK分子结构中芳香族化合物典型的的C—C键在1490 cm−1处,但是由于磺化反应的发生,磺酸基团取代了苯环上C—H中的H,使得原本1490 cm−1处的单峰分裂成1491 cm−1和1472 cm−1两个峰。与此同时,与PEEK相比,SPEEK在1012 cm−1和1079 cm−1处出现了来自于磺酸基团的对称和不对称拉伸振动的两个新的特征峰。由此可以证明,PEEK成功发生了磺化反应。

表2为对进行磺化反应3.5 h后得到的产物SPEEK的磺化度的测定。经过重复多次实验后,得到SPEEK的磺化度约为7.8%。

表 2 SPEEK磺化度酸碱滴定法测定结果Table 2. Sulfonation degree of SPEEK measured by acid-base titrationNo. 1 2 3 4 5 Sulfonation degree/% 7.9 7.6 7.8 7.7 7.5 2.2 ACNT与SCNT的表征

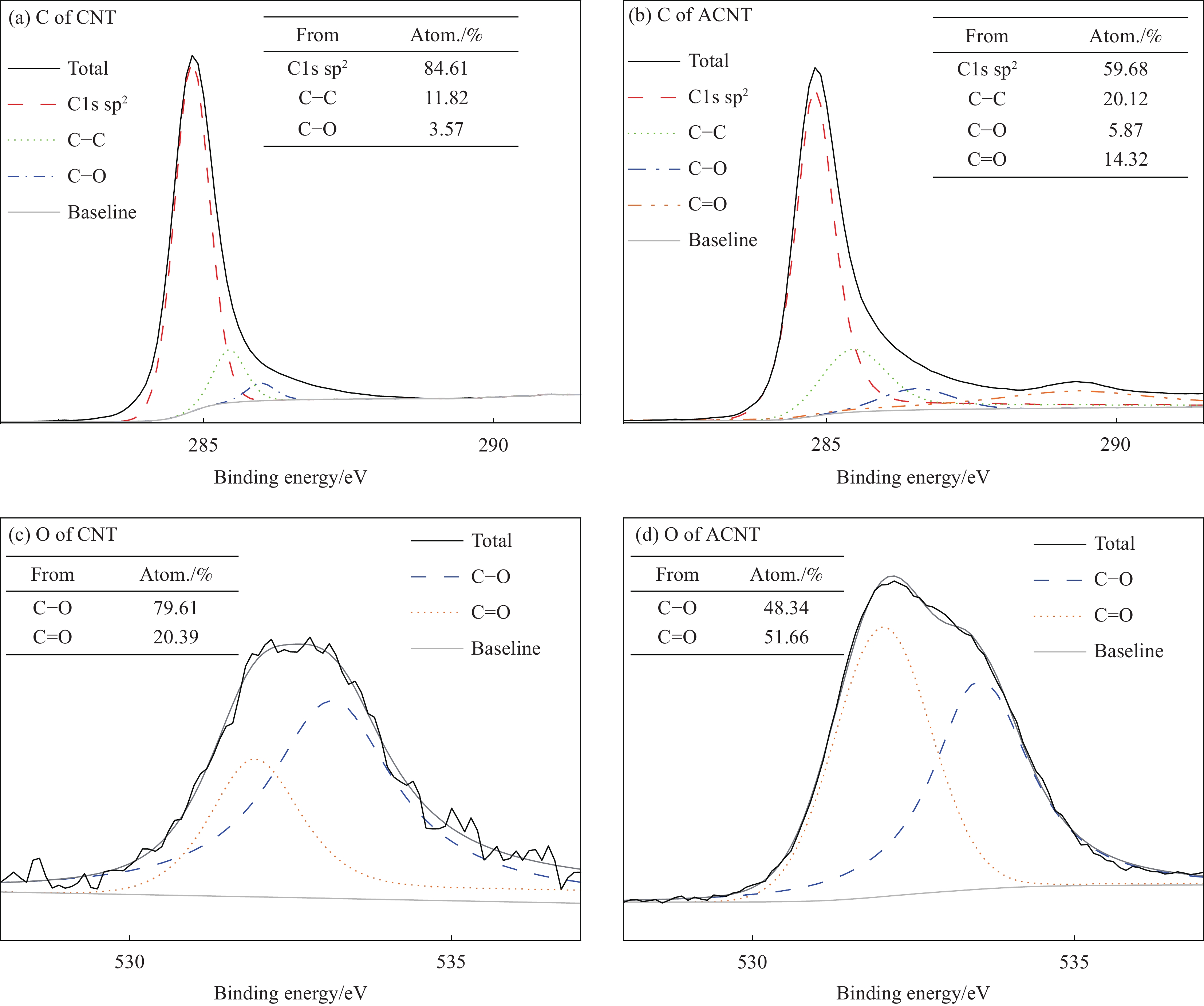

表3为CNT酸化前后表面的碳元素与氧元素含量。显然,经混合酸处理后得到的ACNT表面的氧元素含量明显上升。因而,进一步用XPS对酸化前后的CNT进行分析,结果如图3所示。对于C元素,如图3(a)与3(b)所示,酸化前CNT表面主要是C—C键和C—O键,C=O键几乎不存在,而酸化后ACNT表面的C=O增多,含量增加到14.32%。另外,氧元素的XPS分析图(图3(c)和3(d)) 也有同样的现象,C=O含量从20.39%增多到51.66%。

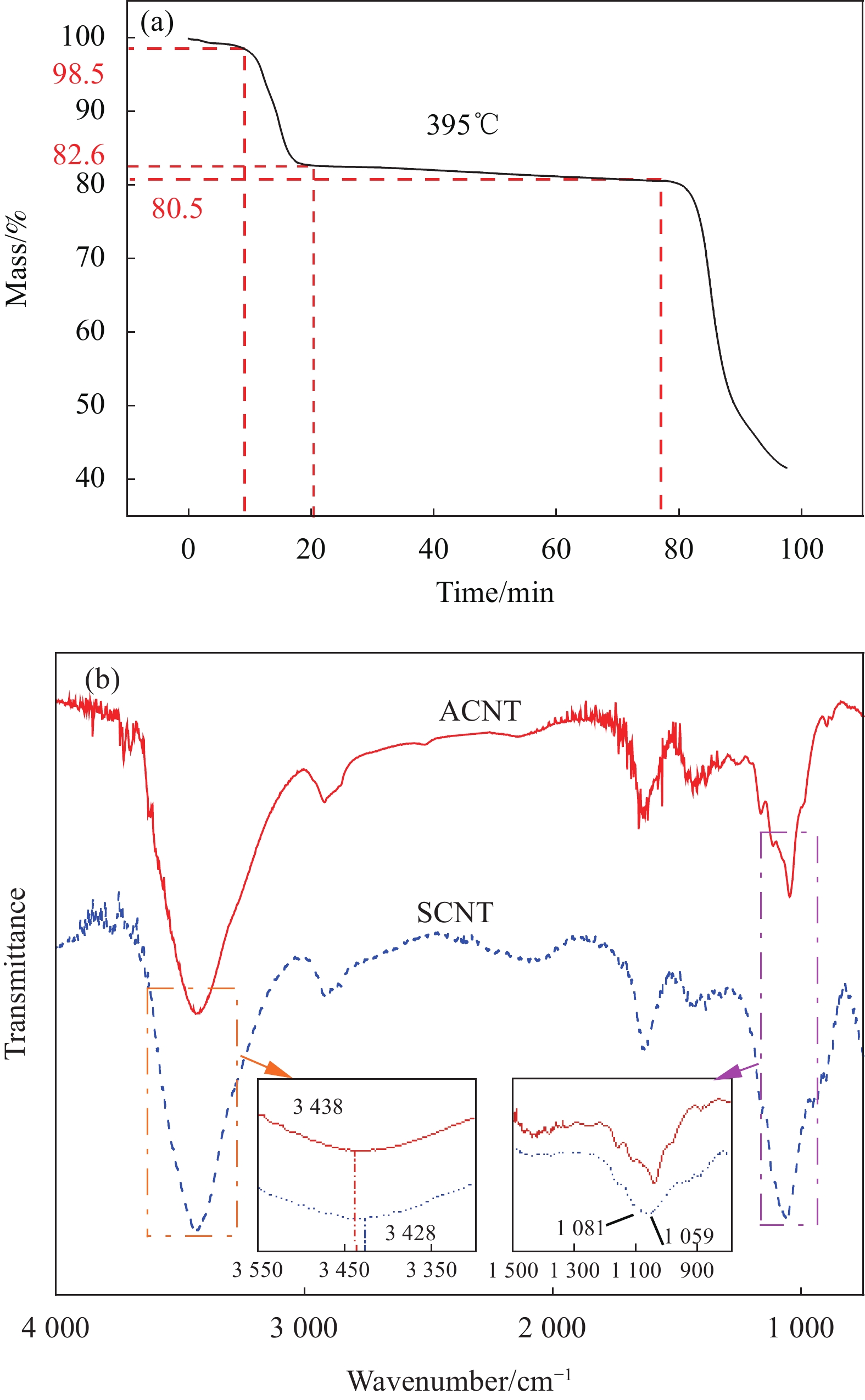

表 3 CNT酸化前后表面C与O元素相对原子数分数Table 3. Relative atomic fractions of C and O elements on the surface of CNT before and after acidificationName C/at% O/at% O/C CNT 98.82 1.18 0.012 ACNT 86.32 13.68 0.158 Notes:O/C—Relative atomic fractions of C is divided by the relative atomic fractions of O. 由于ACNT表面的羧基在高温时容易脱去,而CNT本身结构稳定,不会发生明显的化学变化,质量变化较小,因此使用热重分析法表征CNT经混合酸处理后表面羧基的接枝率,结果如图4(a)所示。羧基在650℃时全部分解,因此可见ACNT羧基化程度约为16%。

图4(b)为ACNT与SCNT从50℃逐渐升温的热重分析曲线,从中可见,SCNT在前面一段时间分解速率比ACNT更快,这是由于二者均存在羧基分解的同时,SCNT表面的SPEEK浆料也在分解。因此取395℃时的质量百分比之差作为SCNT在到达395℃时损失的SPEEK上浆剂的量,即1.5%为SCNT表面的SPEEK分解的质量百分比。

2.3 SPEEK与ACNT的相互作用

CNT在经混合酸作用后,表面会接枝一定量的羧基,提升SPEEK与CNT界面之间的相互作用力。经磺化反应后,由于引入了磺酸基团,SPEEK不再像PEEK一样耐高温,因此同样使用热重分析法,从50℃升温到395℃,保持1 h后再升温到800℃,模拟模压成型时的温度变化,以考察SPEEK在成型温度395℃下的分解情况。从图5(a)可见,SPEEK在395℃时约分解19.5%。

结合2.2中SPEEK在395℃时分解的质量分数,可以计算得到SCNT表面的SPEEK上浆量约为7.7%。

图5(b)为ACNT与SCNT的红外光谱图。由于ACNT表面的羧基与SPEEK中的磺酸基团形成了分子间氢键,使得SCNT中羧基中的羟基峰向长波方向移动了10 cm−1。且在1081 cm−1和1059 cm−1处出现了磺酸基团的两个振动峰。由此可见,SCNT的表面确实存在着SPEEK。

2.4 SCF-CNT/PEEK层合板的力学性能与界面形貌

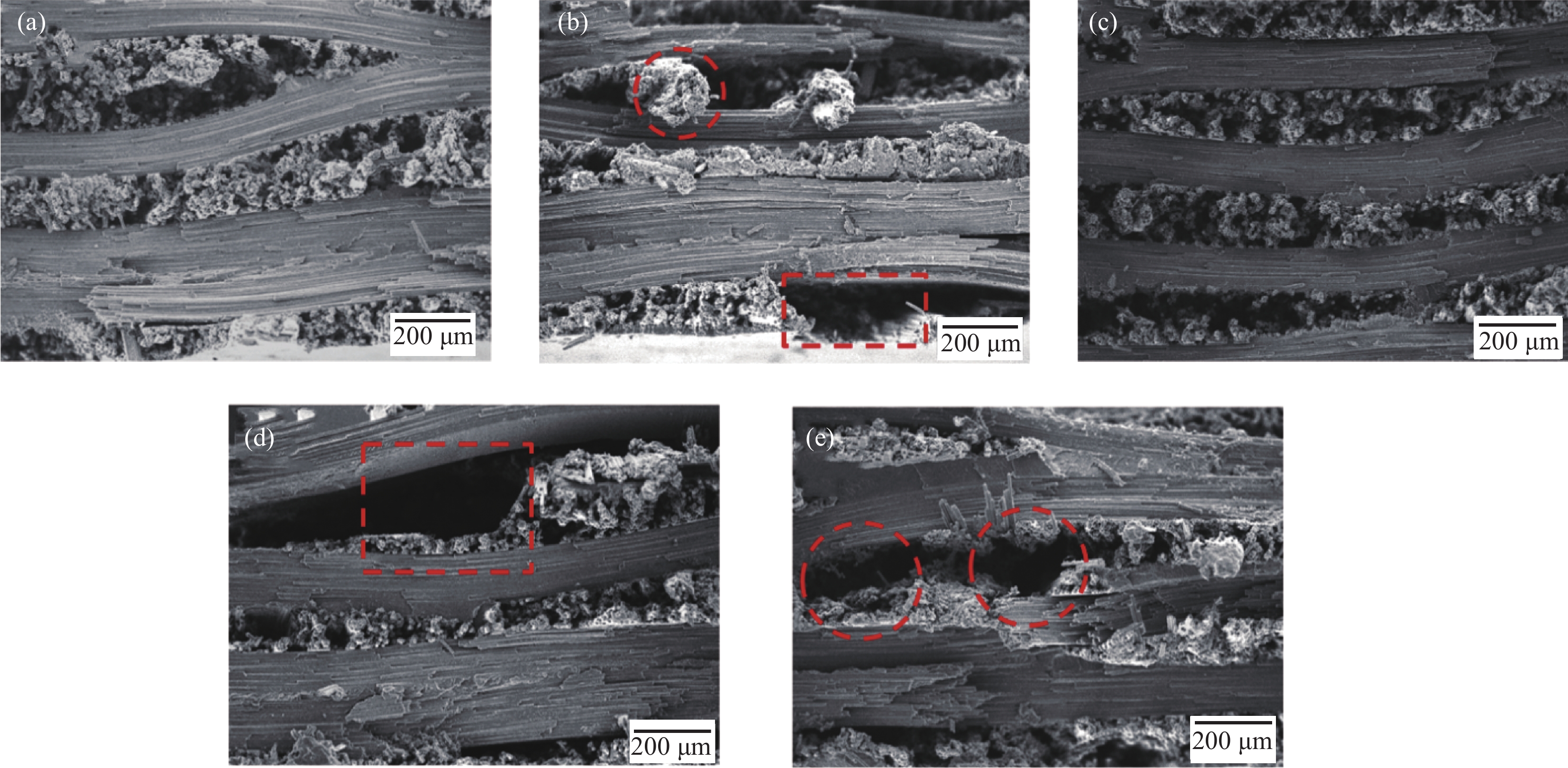

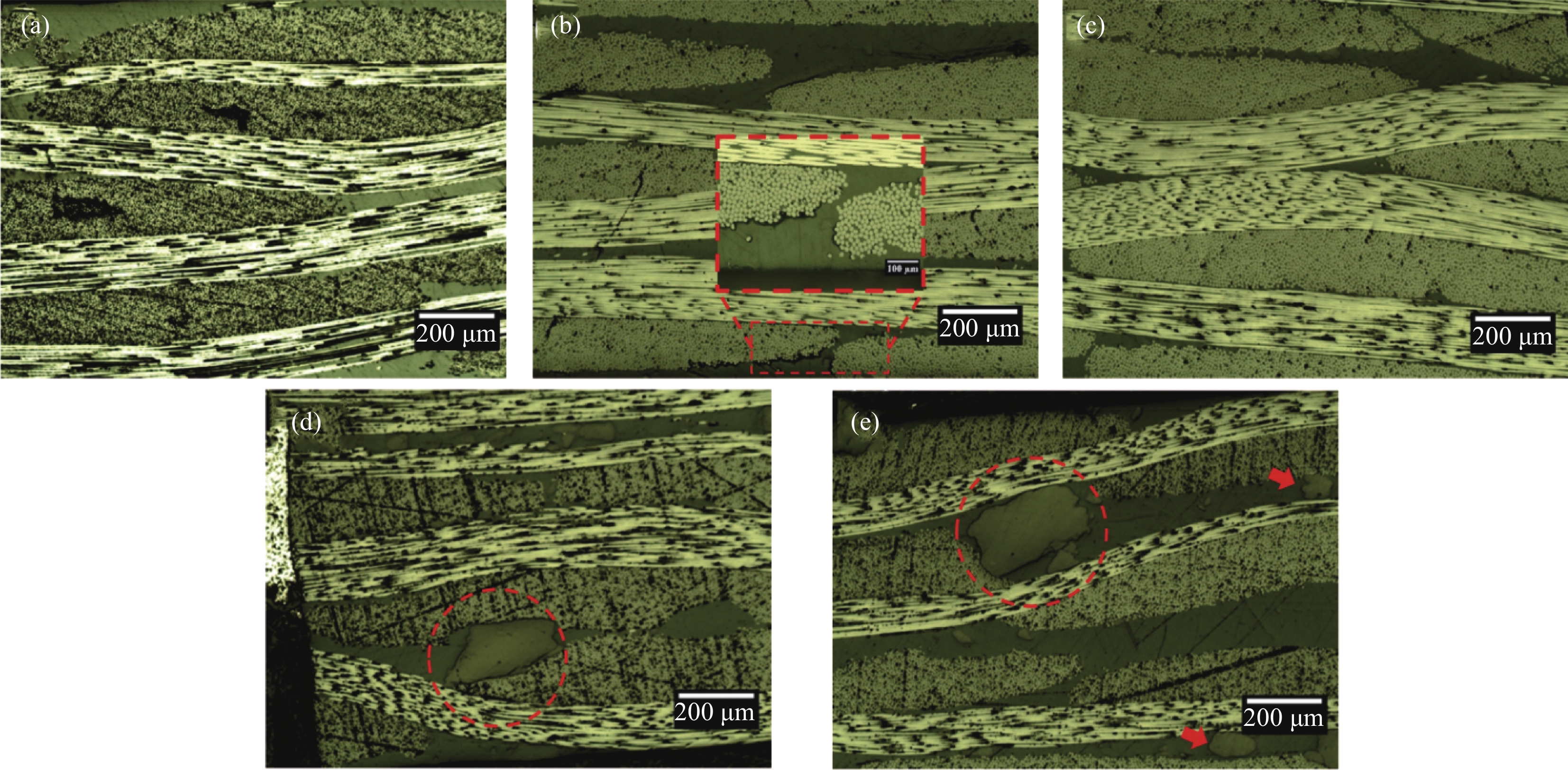

图6为SCF-CNT/PEEK层合板的力学性能。由图可见,随着SCNT在体系中的含量增多,SCF-SCNT/PEEK的拉伸性能、拉伸模量以及弯曲性能、弯曲模量均呈现先上升后下降的趋势。这是由于,当体系中的SCNT含量适当时,由于CNT表面经过处理和修饰,丰富的羧基、磺酸基以及与PEEK相容性很好的SPEEK使得SCNT与SCF以及PEEK都能有良好的界面结合,这样PEEK与SCF中间除了有直接结合之外,还有SCNT作为“楔子”,使得PEEK与SCF之间的互锁作用增强,从而提升了SCF-SCNT/PEEK层合板的力学性能,如SCF-1wt%SCNT/PEEK的拉伸强度与SCF-0wt%ACNT/PEEK相比增加了20.8%,达到778 MPa;弯曲强度增加了25.9%,达到1684 MPa。然而,当SCNT加入过量时,过多的SCNT会包裹在SCF表面,使得PEEK树脂难以浸润到SCF丝束内部;更严重时,过量的SCNT会团聚到一起结成块,使得SCF发生严重变形,从而大大降低SCF-SCNT/PEEK层合板的力学性能,如SCF-5wt%SCNT/PEEK与SCF-1wt%SCNT/PEEK相比,其拉伸强度降低了38.2%,弯曲强度降低了31.1%。拉伸模量、弯曲模量同样也呈现出了与拉伸强度和弯曲强度相同的规律,但是由于模量主要取决于纤维本身的性能,所以受到的影响较小,造成的模量变化也较小。图7层合板拉伸断裂后断面的扫描电镜图像与图8层合板金相显微镜图像可以很好的佐证这一观点。

![]() 图 7 不同CNT组分层合板拉伸断裂后断面SEM图像:(a) SCF-0wt%ACNT/PEEK;(b) SCF-1wt%ACNT/PEEK;(c) SCF-1wt%SCNT/PEEK;(d) SCF-3wt%SCNT/PEEK;(e) SCF-5wt%SCNT/PEEKFigure 7. SEM images of the laminates with different contents of CNT:(a) SCF-0wt%ACNT/PEEK; (b) SCF-1wt%ACNT/PEEK; (c) SCF-1wt%SCNT/PEEK; (d) SCF-3wt%SCNT/PEEK; (e) SCF-5wt%SCNT/PEEK

图 7 不同CNT组分层合板拉伸断裂后断面SEM图像:(a) SCF-0wt%ACNT/PEEK;(b) SCF-1wt%ACNT/PEEK;(c) SCF-1wt%SCNT/PEEK;(d) SCF-3wt%SCNT/PEEK;(e) SCF-5wt%SCNT/PEEKFigure 7. SEM images of the laminates with different contents of CNT:(a) SCF-0wt%ACNT/PEEK; (b) SCF-1wt%ACNT/PEEK; (c) SCF-1wt%SCNT/PEEK; (d) SCF-3wt%SCNT/PEEK; (e) SCF-5wt%SCNT/PEEK![]() 图 8 不同CNT组分层合板金相显微镜图像:(a) SCF-0wt%ACNT/PEEK;(b) SCF-1wt%ACNT/PEEK;(c) SCF-1wt%SCNT/PEEK;(d) SCF-3wt%SCNT/PEEK;(e) SCF-5wt%SCNT/PEEKFigure 8. Metallurgical microscope images of the laminates with different contents of CNT:(a) SCF-0wt% ACNT/PEEK; (b) SCF-1wt%ACNT/PEEK; (c) SCF-1wt%SCNT/PEEK; (d) SCF-3wt%SCNT/PEEK; (e) SCF-5wt%SCNT/PEEK

图 8 不同CNT组分层合板金相显微镜图像:(a) SCF-0wt%ACNT/PEEK;(b) SCF-1wt%ACNT/PEEK;(c) SCF-1wt%SCNT/PEEK;(d) SCF-3wt%SCNT/PEEK;(e) SCF-5wt%SCNT/PEEKFigure 8. Metallurgical microscope images of the laminates with different contents of CNT:(a) SCF-0wt% ACNT/PEEK; (b) SCF-1wt%ACNT/PEEK; (c) SCF-1wt%SCNT/PEEK; (d) SCF-3wt%SCNT/PEEK; (e) SCF-5wt%SCNT/PEEK如图7所示,SCF-0wt%ACNT/PEEK层合板经SPEEK修饰后仍然存在局部拉伸断裂时大量拔出的现象,而添加1wt% ACNT后,SCF-1wt%ACNT/PEEK还出现了由于局部ACNT团聚使得SCF粘结在一起而后大块拔出的现象,使得层合板的力学性能变差。而SCF-1wt%SCNT/PEEK的断面整齐均匀,证明SCNT分散均匀,且与CF和PEEK结合良好,因而SCF-1wt%SCNT/PEEK的力学性能最好。但是,当SCNT过量时,由于SCNT团聚,又出现了CF大块拔出的情况,如图7(d)~7(e)所示。

图8是不同CNT组分层合板的金相显微镜图像。类似的,当不添加CNT时,SCF-0wt%ACNT/PEEK内CF排列规整,树脂浸润性好,而当添加ACNT后,SCF-1wt%ACNT/PEEK中的大孔隙明显减少,但是团聚的ACNT会包裹住SCF,使得树脂无法充分浸润SCF,限制了力学性能的提升;而SCF-1wt%SCNT/PEEK中由于SCNT分散均匀,不会存在上述CNT包裹SCF的现象,三者界面结合良好,因而SCF-1wt%SCNT/PEEK的力学性能最好。但是SCNT过量时,大量团聚的SCNT会压迫SCF,使得SCF严重变形,力学性能大大降低,如图8(d)~8(e)所示。

为了验证“楔子”结构的存在以及金相显微镜中SCNT在树脂中团聚,使用场发射扫描电子显微镜(FESEM)对上述样品进行分析。图9为FESEM观察SCF-SCNT/PEEK体系中SCF与PEEK中SCNT得到的高倍电镜图像。图9(a)中,由于SCNT表面经过SPEEK修饰,可以和PEEK良好的结合在一起,并且,由于受到SCF表面活性基团的作用,整体呈现出垂直于SCF表面的排布,形成了SCF与PEEK之间的“楔子”。图9(b)为该“楔子”结构的100000倍扫描电镜图像。而在图9(c)和9(d)中,由于SCNT过量,使得靠近的SCNT彼此相互作用,形成了被PEEK包裹着的团聚体,与金相显微镜中的大块团聚相对应。

2.5 SCF-CNT/PEEK层合板的电磁干扰屏蔽效能与电导率

利用矢量网络分析仪测出的数据,依据以下公式计算EMI SE [20,26]:

ETotal=ER+EA+EMR (5) 式中:ETotal表示总屏蔽效能值;ER表示因反射而产生的屏蔽效能值;EA表示因吸收而产生的的屏蔽效能值;EMR表示因多重反射而产生的屏蔽效能值。

当ETotal≥15 dB时,EMR可以忽略不计,式(5)可以简化为:

ETotal≈ER+EA (6) ER=−10lg(1−R) (7) EA=−10lg[T/(1−R)] (8) 式中:R,T分别是反射率、透射率的功率系数,另外可设A为吸收率的功率系数,三者的关系及计算公式如下:

R+A+T=1 (9) R=|S11|2=|S22|2 (10) T=|S12|2=|S21|2 (11) A=1−R−T (12) 式中:S11、S22、S12、S21分别是输入反射参数、输出反射参数、反向透射参数和正向透射参数。

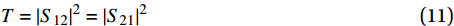

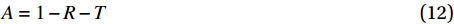

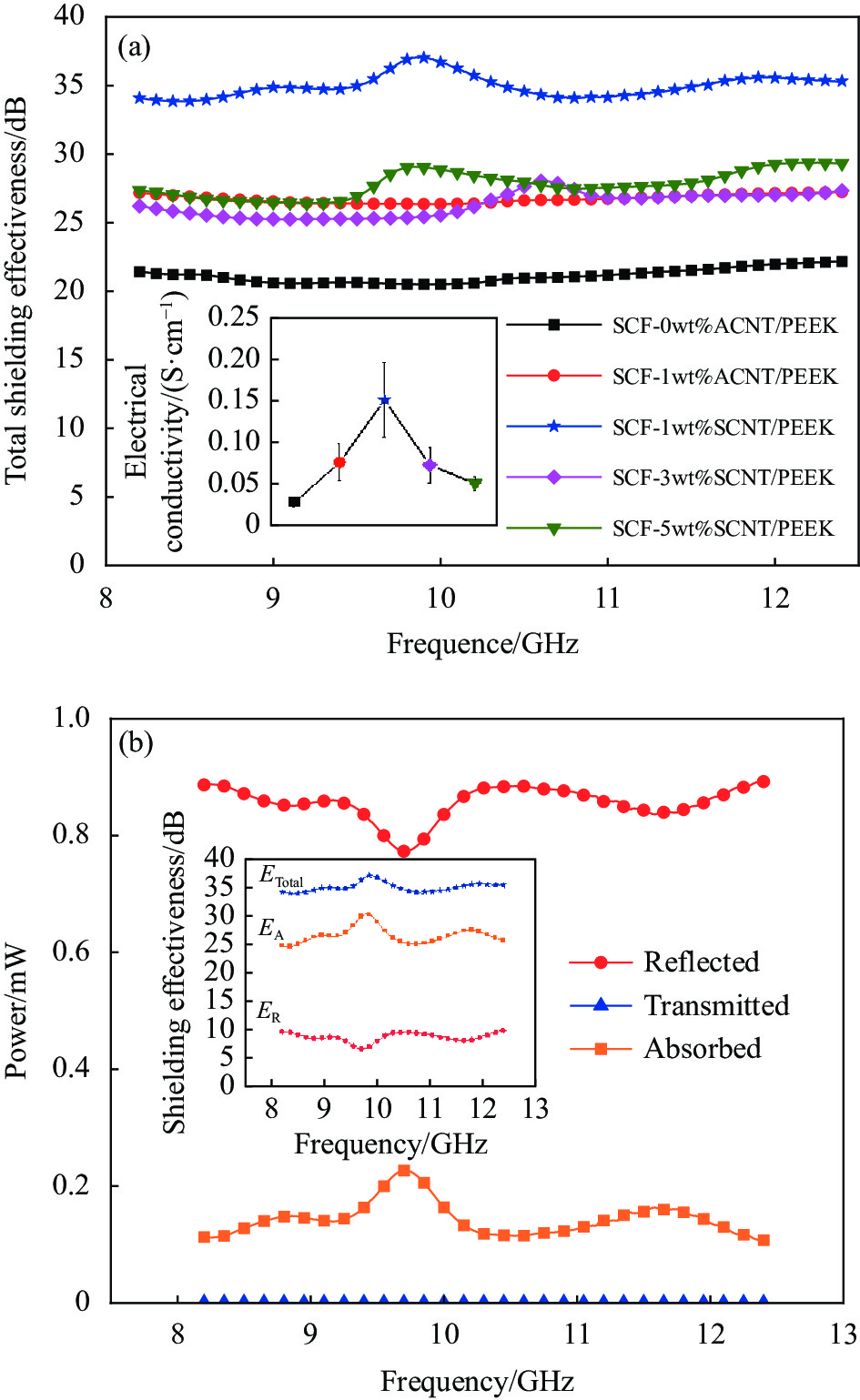

图10(a)是SCF-CNT/PEEK层合板的电磁干扰屏蔽效能图及电导率图。从中可见,与力学性能类似,SCF-CNT/PEEK层合板的电磁干扰屏蔽效能也呈现出先上升后下降的趋势,其中SCF-1wt%SCNT/PEEK最高可以达到34.97 dB,高于用于商用电磁屏蔽的标准规定的20 dB的要求,可以达到99.9%以上的屏蔽效果。这是由于SCF-0wt%ACNT/PEEK中仅由CF形成导电通路,经过与PEEK复合后,导电通路中浸润了不导电的PEEK,因而导电性变差,屏蔽效能降低。而SCF-1wt%ACNT/PEEK中由于加入了导电填料ACNT,使得在不导电的PEEK基体中也能依靠ACNT来形成导电通路,提高了导电性,从而提高了电磁屏蔽效能。但是由于ACNT在PEEK中无法完全均匀分散,仍有团聚,而适量的SCNT在PEEK分散性更好,基本不存在团聚,使得SCF-1wt%SCNT/PEEK的导电性更好,屏蔽效能最高。SCF-CNT/PEEK层合板的体积电导率可以很好地佐证这一观点。SCF-1wt%SCNT/PEEK的电导率最高,达到0.15 S/cm,而不加CNT的SCF-0wt%ACNT/PEEK的电导率最低,仅有0.03 S/cm。依据公式(5~12),将SCF-1wt%SCNT/PEEK的能量系数和电磁屏蔽效能做成图10(b),可以看出SCF-1wt%SCNT/PEEK体系中,R参数值最大,平均值可达0.88 mW,而A参数仅有0.11 mW,因此SCF-1wt%SCNT/PEEK体系主要是反射屏蔽为主。而被吸收进层合板内的电磁波,EA值比ER值更高,所以在趋肤深度内,电磁波主要被吸收屏蔽。当SCNT过量后,团聚使得CNT形成的导电通路反而变差,因此导电性变差,屏蔽效能降低。

![]() 图 10 (a)不同CNT组分层合板的总屏蔽效能值(ETotal);(b) SCF-1wt% SCNT/PEEK层合板的反射率(R)、透射率(T)、吸收率(A)参数与电磁干扰屏蔽效能(EMI SE)组成Figure 10. (a) Total shielding effectiveness (ETotal) spectra of the laminates with different contents of CNT; (b) Reflected (R), transmitted (T), absorbed (A) index and the component of the electromagnetic interference shielding effectiveness (EMI SE) of SCF-1wt% SCNT/PEEK

图 10 (a)不同CNT组分层合板的总屏蔽效能值(ETotal);(b) SCF-1wt% SCNT/PEEK层合板的反射率(R)、透射率(T)、吸收率(A)参数与电磁干扰屏蔽效能(EMI SE)组成Figure 10. (a) Total shielding effectiveness (ETotal) spectra of the laminates with different contents of CNT; (b) Reflected (R), transmitted (T), absorbed (A) index and the component of the electromagnetic interference shielding effectiveness (EMI SE) of SCF-1wt% SCNT/PEEK3. 结 论

(1)磺化聚醚醚酮(SPEEK)中存在的磺酸基团能与经过活化处理的碳纤维(ACF)表面以及活化碳纳米管(ACNT)表面的羧基形成分子间氢键,从而与CF和CNT产生较强的相互作用。又由于SPEEK与PEEK的结构高度相似,二者相容性好。 在高温模压成型的过程中SPEEK仅发生1.5%的分解,绝大部分SPEEK保留在CF和SCNT的表面。在适当的CNT质量分数下,使用SPEEK上浆法进行表面处理的CNT可有效分散在PEEK基体中,避免CNT团聚对SCF-SCNT/PEEK体系性能的影响。

(2)在SCF/PEEK中加入适量的ACNT可以使得层合板的力学性能得到明显的提升,尤其是当ACNT表面经过与PEEK相容性良好的SPEEK修饰后(SCNT),其拉伸强度可以达到778 MPa,相比不添加CNT的层合板提升了20.8%;弯曲强度可以达到1684 MPa,相比不添加CNT的层合板提升了25.9%。

(3)加入适量的CNT还可以使SCF/PEEK体系的电导率提高,因而提高层合板的电磁屏蔽性能(EMI SE)。与不添加CNT的SCF-0wt%ACNT/PEEK层合板的0.03 S/cm相比,添加1wt%SCNT的层合板(SCF-1wt%SCNT/PEEK),其电导率提升了约5倍,可以达到0.15 S/cm。在X波段,SCF-1wt%SCNT/PEEK层合板的平均值可以达到34.97 dB,相比不添加CNT的SCF/PEEK层合板提高了69.76%。

-

图 7 不同CNT组分层合板拉伸断裂后断面SEM图像:(a) SCF-0wt%ACNT/PEEK;(b) SCF-1wt%ACNT/PEEK;(c) SCF-1wt%SCNT/PEEK;(d) SCF-3wt%SCNT/PEEK;(e) SCF-5wt%SCNT/PEEK

Figure 7. SEM images of the laminates with different contents of CNT:(a) SCF-0wt%ACNT/PEEK; (b) SCF-1wt%ACNT/PEEK; (c) SCF-1wt%SCNT/PEEK; (d) SCF-3wt%SCNT/PEEK; (e) SCF-5wt%SCNT/PEEK

图 8 不同CNT组分层合板金相显微镜图像:(a) SCF-0wt%ACNT/PEEK;(b) SCF-1wt%ACNT/PEEK;(c) SCF-1wt%SCNT/PEEK;(d) SCF-3wt%SCNT/PEEK;(e) SCF-5wt%SCNT/PEEK

Figure 8. Metallurgical microscope images of the laminates with different contents of CNT:(a) SCF-0wt% ACNT/PEEK; (b) SCF-1wt%ACNT/PEEK; (c) SCF-1wt%SCNT/PEEK; (d) SCF-3wt%SCNT/PEEK; (e) SCF-5wt%SCNT/PEEK

图 10 (a)不同CNT组分层合板的总屏蔽效能值(ETotal);(b) SCF-1wt% SCNT/PEEK层合板的反射率(R)、透射率(T)、吸收率(A)参数与电磁干扰屏蔽效能(EMI SE)组成

Figure 10. (a) Total shielding effectiveness (ETotal) spectra of the laminates with different contents of CNT; (b) Reflected (R), transmitted (T), absorbed (A) index and the component of the electromagnetic interference shielding effectiveness (EMI SE) of SCF-1wt% SCNT/PEEK

表 1 不同组分SCF-CNT/PEEK层合板中原料的质量

Table 1 The mass of raw materials in SCF-CNT/PEEK laminates with different components

No. Sample Mass of SCNT/g Mass of ACNT/g Mass of PEEK/g 1 SCF-0wt%ACNT/PEEK 0 0 25.00 2 SCF-1wt%ACNT/PEEK 0 0.25 24.75 3 SCF-1wt%SCNT/PEEK 0.25 0 24.75 4 SCF-3wt%SCNT/PEEK 0.75 0 24.25 5 SCF-5wt%SCNT/PEEK 1.25 0 23.75 Notes: PEEK—Poly(ether-ether-ketone); SCF—Sized carbon fiber; SCNT—Sized carbon nanotube; ACNT—Activated carbon nanotube. 表 2 SPEEK磺化度酸碱滴定法测定结果

Table 2 Sulfonation degree of SPEEK measured by acid-base titration

No. 1 2 3 4 5 Sulfonation degree/% 7.9 7.6 7.8 7.7 7.5 表 3 CNT酸化前后表面C与O元素相对原子数分数

Table 3 Relative atomic fractions of C and O elements on the surface of CNT before and after acidification

Name C/at% O/at% O/C CNT 98.82 1.18 0.012 ACNT 86.32 13.68 0.158 Notes:O/C—Relative atomic fractions of C is divided by the relative atomic fractions of O. -

[1] DINI Y, ROUCHON D, FAURE V J, et al. Large improvement of CNT yarn electrical conductivity by varying chemical doping and annealing treatment[J]. Carbon,2020,156:38-48. DOI: 10.1016/j.carbon.2019.09.022

[2] EBBESEN T W, LEZEC H J, HIURA H, et al. Electrical conductivity of individual carbon nanotubes[J]. Nature,1996,382:54-56. DOI: 10.1038/382054a0

[3] LIANG J Y, GU Y Z, BAI M, et al. Electromagnetic shielding property of carbon fiber felt made of different types of short-chopped carbon fibers[J]. Composites Part A: Applied Science and Manufacturing,2019,121:289-298. DOI: 10.1016/j.compositesa.2019.03.037

[4] BALARAJU J N, RADHAKRISHNAN P, EZHILSELVI V, et al. Studies on electroless nickel polyalloy coatings over carbon fibers/CFRP composites[J]. Surface and Coatings Technology,2016,302:389-397. DOI: 10.1016/j.surfcoat.2016.06.040

[5] ZHU S, SHI R J, QU M C, et al. Simultaneously improved mechanical and electromagnetic interference shielding properties of carbon fiber fabrics/epoxy composites via interface engineering[J]. Composites Science and Technology,2021,207:108696.

[6] HASSAN E A M, GE D T, ZHU S, et al. Enhancing CF/PEEK composites by CF decoration with polyimide and loosely-packed CNT arrays[J]. Composites Part A: Applied Science and Manufacturing,2019,127:105613.

[7] YUAN X Y, JIANG J, WEI H W, et al. PAI/MXene sizing-based dual functional coating for carbon fiber/PEEK composite[J]. Composites Science and Technology,2021,201:108496.

[8] RIFE J L, KUNG P, HOOPER R J, et al. Structural and mechanical characterization of carbon fibers grown by laser induced chemical vapor deposition at hyperbaric pressures[J]. Carbon,2020,162:95-105. DOI: 10.1016/j.carbon.2020.02.018

[9] YUAN J H, AMANO Y, MACHIDA M. Surface modified mechanism of activated carbon fibers by thermal chemical vapor deposition and nitrate adsorption characteristics in aqueous solution[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2019,580:123710.

[10] QIN J J, WANG C G, YAO Z Q, et al. Mechanical property deterioration and defect repair factors of carbon fibers during the continuous growth of carbon nanotubes by chemical vapor deposition[J]. Ceramics International,2021,47(13):1-7.

[11] FENG L, LI K Z, SI Z S, et al. Compressive and interlaminar shear properties of carbon/carbon composite laminates reinforced with carbon nanotube-grafted carbon fibers produced by injection chemical vapor deposition[J]. Materials Science and Engineering: A,2015,626:449-457. DOI: 10.1016/j.msea.2014.12.044

[12] ZHANG Z S, FU K K, LI Y. Improved interlaminar fracture toughness of carbon fiber/epoxy composites with a multiscale cellulose fiber interlayer[J]. Composites Communications,2021,27:100898.

[13] ZHANG H, WU K F, XIAO G M, et al. Experimental study of the anisotropic thermal conductivity of 2D carbon-fiber/epoxy woven composites[J]. Composite Structures,2021,267:113870.

[14] YANG L N, HAN P, GU Z. Grafting of a novel hyperbranched polymer onto carbon fiber for interfacial enhancement of carbon fiber reinforced epoxy composites[J]. Materials & Design,2021,200:109456.

[15] RAVINDRAN A R, LADANI R B, KINLOCH A J, et al. Improving the delamination resistance and impact damage tolerance of carbon fibre-epoxy composites using multi-scale fibre toughening [J]. Composites Part A: Applied Science and Manufacturing, 2021, 150: 106624.

[16] KIRAN M D, GOVINDARAJU H K, SURESHA B, et al. Fracture toughness study of epoxy composites reinforced with carbon fibers with various thickness[J]. Materials Today: Proceedings,2021,46(7):2630-2634.

[17] 杨洋, 见雪珍, 袁协尧, 等. 先进热塑性复合材料在大型客机结构零件领域的应用及其制造技术[J]. 玻璃钢, 2017, 4:1-15. YANG Yang, JIAN Xuezhen, YUAN Xierao, et al. Application and manufacturing technology of advanced thermoplastic composite materials in the field of large passenger aircraft structural parts[J]. Glass Fiber Reinforced Plastics,2017,4:1-15(in Chinese).

[18] 陈吉平, 李岩, 刘卫平, 等. 连续纤维增强热塑性树脂基复合材料自动铺放原位成型技术的航空发展现状[J]. 复合材料学报, 2019, 36(4):784-794. CHEN Jiping, LI Yan, LIU Weiping, et al. Aerospace development status of continuous fiber-reinforced thermoplastic resin matrix composite material automatic placement and in-situ molding[J]. Acta Materiae Compositae Sinica,2019,36(4):784-794(in Chinese).

[19] HEUBERGER R, STOCK C, SAHIN J, et al. PEEK as a replacement for CoCrMo in knee prostheses: Pin-on-disc wear test of PEEK-on-polyethylene articulations[J]. Biotribology,2021,27:100189.

[20] MANZOOR F, GOLBANG A, JINDAL S, et al. 3D printed PEEK/HA composites for bone tissue engineering applications: Effect of material formulation on mechanical performance and bioactive potential[J]. Journal of the Mechanical Behavior of Biomedical Materials,2021,121:104601.

[21] CHENG B X, DUAN H T, CHEN Q, et al. Effect of laser treatment on the tribological performance of polyetheretherketone (PEEK) under seawater lubrication[J]. Applied Surface Science,2021,566:150668.

[22] ASTM International. Standard test method for tensile properties of polymer matrix composite materials: ASTM D3039/D3039M-17[S]. West Conshohocken, USA: ASTM International, 2017.

[23] ASTM International. Standard test method for flexural properties of unreinforced and reinforced plastics and electrical Insulating materials: ASTM D790-03[S]. West Conshohocken, USA: ASTM International, 2003.

[24] ASTM International. Standard test method for DC resistance or conductance of insulating materials: ASTM D257-99[S]. West Conshohocken, USA: ASTM International, 1999.

[25] 宿昌厚, 鲁效明. 论四探针法测试半导体电阻率时的厚度修正[J]. 计量技术, 2005, 8:5-7. SU Changhou, LU Xiaoming. On the thickness correction of the four-probe method in measuring the resistivity of semiconductors[J]. Measurement Technique,2005,8:5-7(in Chinese).

[26] 王艳, 范泽文, 赵建, 等. 3D打印制备碳纳米管/环氧树脂电磁屏蔽复合材料[J]. 复合材料学报, 2019, 36(1):1-6. WANG Yan, FAN Zewen, ZHAO Jian, et al. 3D-printed carbon nanotubes/epoxy composites for electromagnetic interference shielding[J]. Acta Materiae Compositae Sinica,2019,36(1):1-6(in Chinese).

-

期刊类型引用(10)

1. 徐建蓉,梅启林,姜端洋,蔡永祺,刘备,丁国民. Ca~(2+)辅助增强CNT/PEEK界面结合及其导电复合材料制备与性能. 复合材料学报. 2025(01): 283-298 .  本站查看

本站查看

2. 赵宏婷,王鹤峰,罗居杰,贾宜委,何艳骄,树学峰. N, S共掺杂碳/PVDF纳米复合膜的电磁屏蔽效能及其力学性能. 复合材料学报. 2025(02): 845-853 .  本站查看

本站查看

3. 朱再斌,凌辉,杨小平,李刚,王超. 碳纳米管膜层间增强增刚碳纤维增强树脂基复合材料的压缩强度与导热性能. 复合材料学报. 2024(03): 1235-1248 .  本站查看

本站查看

4. 施水娟,卞达,李佳红,王恺璇,徐鹏程,赵鹏,赵永武,陈义. 不同注射温度和热处理对聚醚醚酮/碳纤维复合材料摩擦磨损性能的影响. 塑料科技. 2024(04): 23-27 .  百度学术

百度学术

5. 周杰,何相明,耿闻,李闯,李伟. 碳纳米管改性热固性树脂的研究进展. 广州化工. 2024(14): 11-13 .  百度学术

百度学术

6. 王文波,宋彦平,李年,王振洋. 激光诱导石墨烯的纳米银颗粒原位修饰及其导电性能调控. 复合材料学报. 2024(08): 4124-4133 .  本站查看

本站查看

7. 李纪康,刘雁雁,王维超,郑振荣. 纳米材料在防护纺织品中的应用研究. 天津纺织科技. 2023(03): 1-5 .  百度学术

百度学术

8. 李亚洲 ,杨强 ,彭瑞龙 ,王富 ,李涤尘 . 聚醚醚酮及其复合材料激光粉末床熔融成形的研究现状与展望. 精密成形工程. 2023(11): 46-60 .  百度学术

百度学术

9. 任天翔,滕晓波,黄兴,马金星,赵德方,占海华. 聚醚醚酮的改性及应用研究进展. 塑料科技. 2022(09): 123-128 .  百度学术

百度学术

10. 杨琴,汪莹,刘逸众. 热塑性树脂聚醚醚酮(PEEK)改性研究进展. 长沙航空职业技术学院学报. 2022(04): 33-37 .  百度学术

百度学术

其他类型引用(8)

-

下载:

下载: