Research progress on preparation and aging resistance of carbon-based wood electrothermal composites

-

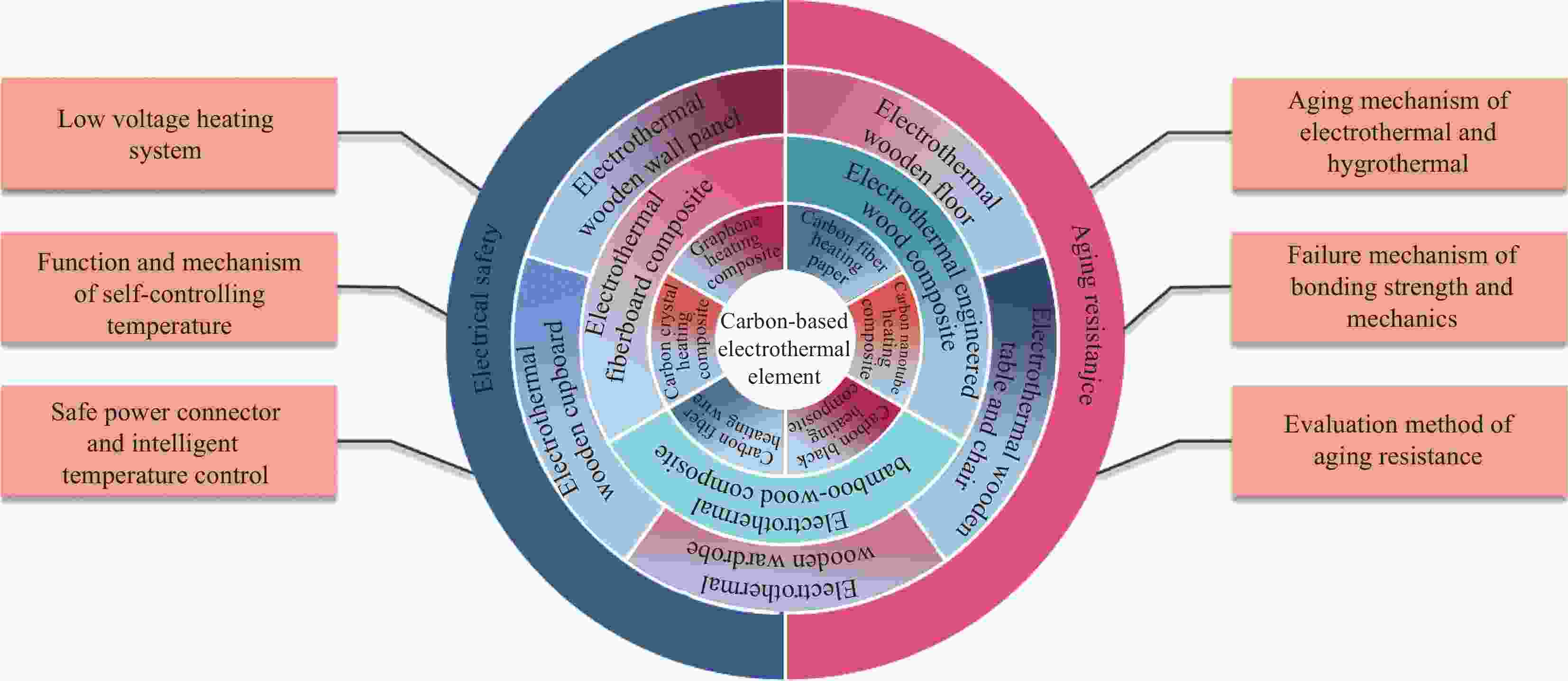

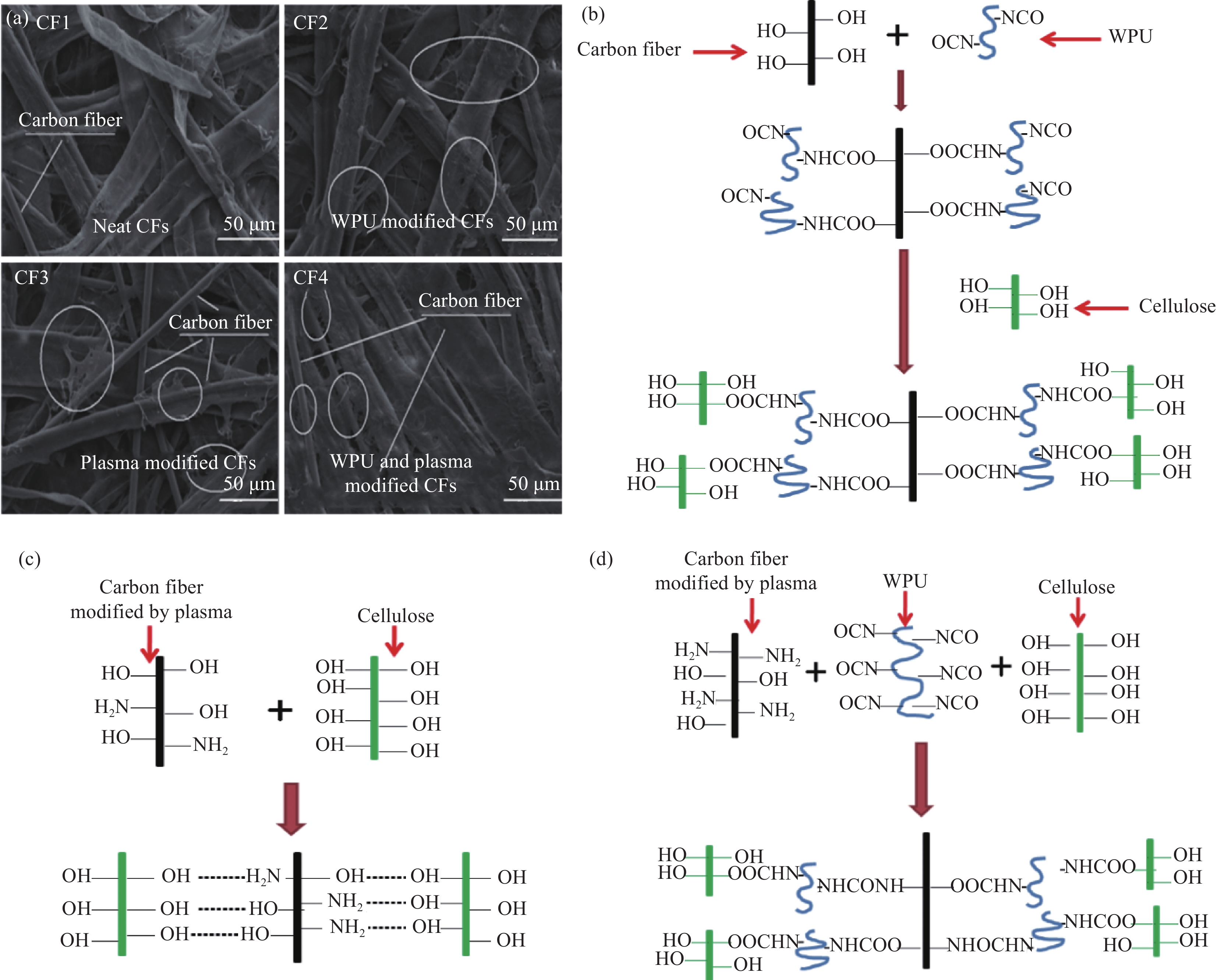

摘要: 碳系木质电热复合材料是以碳系材料为发热元件、木质材料作为基体经胶合形成具有电致发热的新型木质功能材料,可应用于制备电热木质地板、电热木质墙板、电热木质衣柜等木质电热制品,具有供暖与装饰一体化作用,在清洁供暖领域具有广阔应用前景。本文介绍了可应用于木质电热复合材料的碳纤维电热纸、碳纳米管电热复合材料、石墨烯电热复合材料、碳纤维电热线、碳黑电热材料和碳素晶体电热材料制备方法及应用。分析了工艺参数和材料结构对电热实木复合材料、电热纤维板复合材料、电热竹木复合材料的理化性能、导电性及电热性能的影响,并归纳了电热作用、湿热作用对耐老化的影响及电安全性的研究进展,最后展望了碳系木质电热复合材料未来的研究方向。Abstract: Carbon-based wood electrothermal composite is an innovative wooden functional composite that fabricated by carbon material as heating element embedded in wood matrix, which can be widely used to produce electrothermal wooden floor, electrothermal wooden wall panel and electrothermal wooden wardrobe etc. The carbon-based wood electrothermal composites show an integrated function of heating and decoration, and have excellent application prospects in the field of clean heating. In this review, the preparation method and application of carbon fiber heating paper, carbon nanotube heating composite, graphene heating composite, carbon fiber heating wire, carbon black heating composite and carbon crystal heating composite were introduced. Furthermore, the effects of process parameter and structure on the physical and chemical properties, electrical conductivity and electrothermal performances of electrothermal engineered wood composite, electrothermal fiberboard composite and electrothermal bamboo-wood composite were analyzed, as well as the current development of the influence of electrothermal and hygrothermal behaviour on the aging resistance and electric safety were also summarized. Finally, the future development directions of carbon-based wood electrothermal composites were prospected.

-

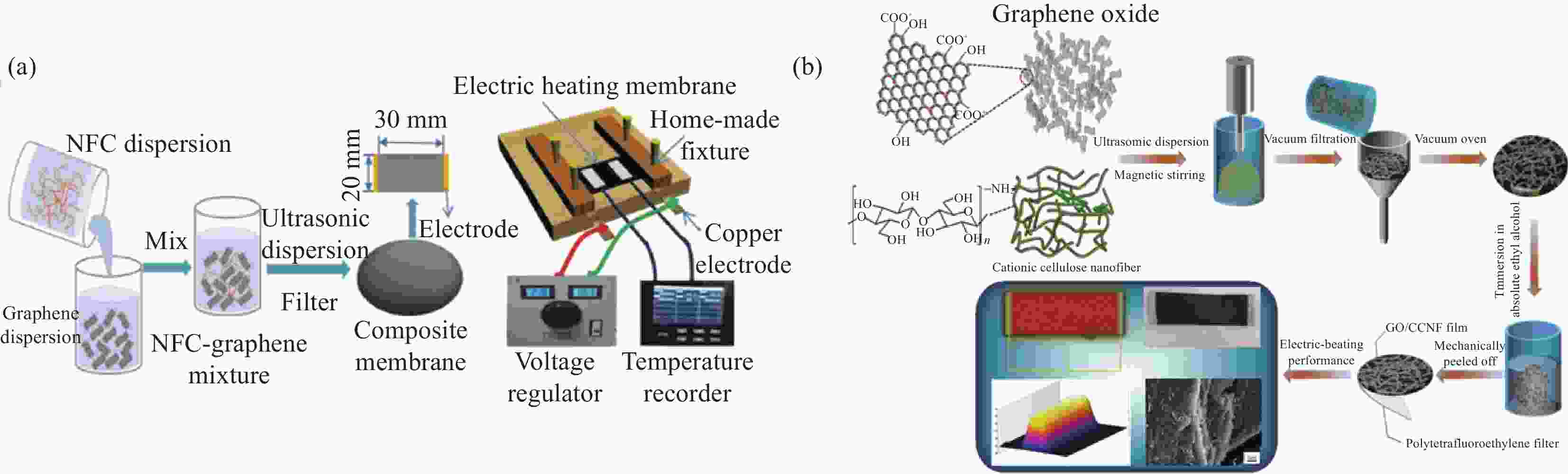

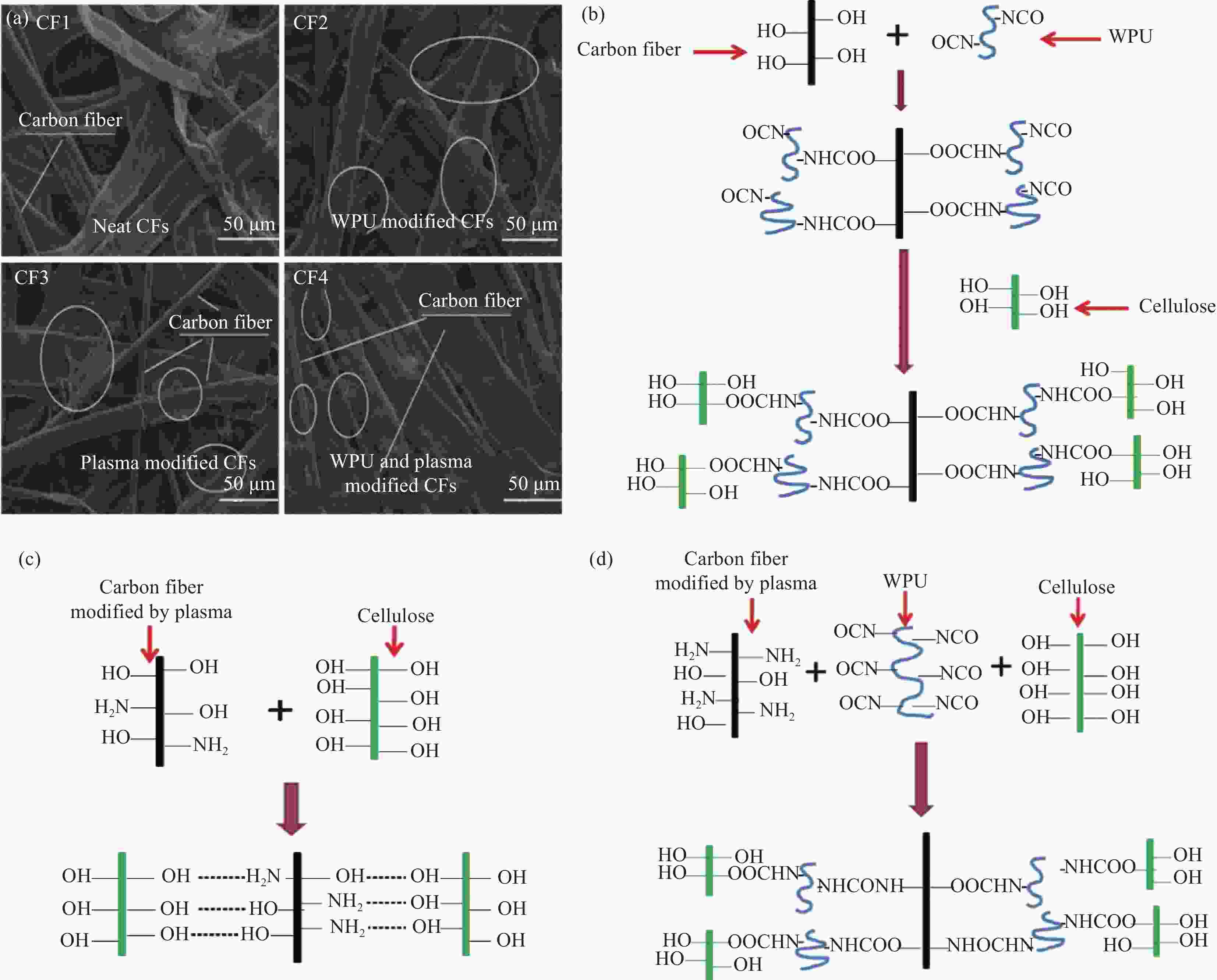

图 1 不同改性处理碳纤维电热纸SEM图像 (a) 和碳纤维(CFs)与纤维素之间的相互作用:(b) 水性聚氨酯(WPU)改性;(c) N2等离子体改性;(d) WPU和N2等离子体改性示意图[16]

Figure 1. SEM images of carbon fiber paper (a) and schematic of interaction between carbon fiber (CFs) and cellulose with different modification methods: (b) Waterborne polyurethane (WPU) modification; (c) N2 plasma modification; (d) WPU and N2 plasma modification[16]

图 2 浸涂法制备多壁碳纳米管(MWCNTs)/纤维素电热复合材料 (a)[19]和冷冻干燥法制备纳米纤维素(NFC)/MWCNTs/石墨烯(GP)电热复合材料 (b) 示意图[29]

Figure 2. Schematic of multi-walled carbon nanotubes (MWCNT)/cellulose electrothermal papers with dip-coating method (a) [19] and nanofibrillated cellulose (NFC)/MWCNTs/graphene (GP) aerogel with freeze-drying method (b)[29]

表 1 碳系电热元件制备方法与最高稳定温度Tmax

Table 1. Preparation method and steady-state maximum temperature Tmax of carbon-based electric heating elements

Carbon-based conductive material Substrate Preparation method Tmax with the

applied voltageRef. Carbon fiber Softwood pulp Wet papermaking 50.4℃/25 V [12] Carbon fiber paper Gas phase polymerization 56.7℃/10 V [13] Eucalyptus dissolving pulp Mixing and filtering 162℃/30 V [17] Carbon nanotubes Cellulose paper Dipping and drying ~70℃/25 V [19] Thermoplastic polyurethane Layer-by-layer ~140℃/10 V [21] Regenerated cellulose Solution casting ~189℃/80 V [22] Graphene Polyimide (PI) Spin coating ~72℃/60 V [30] Polyethylene terephthalate (PET) Filtration-transfer 139℃/30 V [31] Cationic cellulose nanofibers Ultrasonic dispersion and suction filtration 103.6℃/60 V [35] Carbon nanotubes and graphene m-Aramid staple fibers Solution casting ~250℃/60 V [37] Carbon nanotubes and carbon black Polybutylene terephthalate (PBT) Melt compounding ~77℃/12 V [45] Graphene and carbon black Polyvinyl chloride (PVC) Spray deposition ~160℃/30 V [48] Carbon nanotubes, graphene and carbon black PET Screen printing ~175℃/3 V [50] Carbon crystal WPU Coating 105.5℃/50 V [52] 表 2 电热木质地板的电热性能及电安全指标

Table 2. Performance and electric safety index of electrothermal wood floor

Performance Index content Performance Index content Power density ≤250 W/m2 Electrical strength AC voltage of 50 Hz and 3750 V under normal working conditions is tested for 1 min without breakdown and flashover. Temperature rise time ≤30 min Waterproof level Not lower than the IPX7 level. Minimum surface working temperature ≥20℃ Leakage current in wet state Less than 0.25 mA. Maximum surface working temperature ≤40℃ Electrical strength in wet state AC voltage of 50 Hz and 3750 V under normal working conditions is tested for 1 min without breakdown and flashover. Temperature unevenness ≤7℃ Insulation resistance Cold insulation resistance and hot insulation resistance are not less than 50 MΩ. Electric-to-radiant power transfer efficiency ≥55 % (Double surface) Abnormal temperature Work at 1.24 times the rated input power until reaches stable working state for 8 h. During the working period, the maximum surface temperature should not higher than 60℃, and should not show abnormal phenomena such as deformation, color change and delamination. Power deviation ≤±10 % Electromagnetic radiation intensity During normal operation, the root-mean-square value of the electric field, magnetic field, and electromagnetic field parameters in the environment should meet the public exposure control limit values in GB 8702—2014《Controlling limits for electromagnetic environment》. Leakage current ≤0.25 mA -

[1] 傅峰, 袁全平, 梁善庆, 等. 木质导电功能材料制备技术[M]. 北京: 科学出版社, 2019.FU Feng, YUAN Quanping, LIANG Shanqing, et al. Preparation technology of wooden conductive functional materials[M]. Beijing: Science Press, 2019(in Chinese). [2] TIAN M, HAO Y, QU L, et al. Enhanced electrothermal efficiency of flexible graphene fabric Joule heaters with the aid of graphene oxide[J]. Materials Letters,2019,234:101-104. doi: 10.1002/smll.201101305 [3] JEONG Y G, AN J E. Effects of mixed carbon filler compo-sition on electric heating behavior of thermally-cured epoxy-based composite films[J]. Composites Part A: Applied Science and Manufacturing,2014,56(1):1-7. [4] WANG F, LIANG W, WANG Z, et al. Preparation and property investigation of multi-walled carbon nanotube (MWCNT)/epoxy composite films as high-performance electric heating (resistive heating) element[J]. Express Polymer Letters,2018,12(4):285-295. doi: 10.3144/expresspolymlett.2018.26 [5] 袁全平, 梁善庆, 曾宇, 等. 内置电热层电采暖木竹地板技术现状[J]. 林产工业, 2015, 42(8):6-9. doi: 10.3969/j.issn.1001-5299.2015.08.002YUAN Quanping, LIANG Shanqing, ZENG Yu, et al. Discussion on technology status of electric heating wood and bamboo floor with built-in electrothermal layer[J]. China Forest Products Industry,2015,42(8):6-9(in Chinese). doi: 10.3969/j.issn.1001-5299.2015.08.002 [6] 王艳伟, 吴忠其, 王天成, 等. 热压参数对碳纤维发热实木复合基板胶合性能的影响[J]. 林业机械与木工设备, 2017, 45(1):18-22.WANG Yanwei, WU Zhongqi, WANG Tiancheng, et al. Effect of hot-pressing parameters on the adhesive perfor-mance of carbon fiber heating parquet substrates[J]. Forestry Machinery and Woodworking Equipment,2017,45(1):18-22(in Chinese). [7] 牟群英. 电热地板物理性能测试[J]. 安徽农学通报, 2007, 13(5):165-166. doi: 10.3969/j.issn.1007-7731.2007.05.081MOU Qunying. Experimental research on properties of heating floor with thermoelectric film[J]. Anhui Agriculture Science Bulletin,2007,13(5):165-166(in Chinese). doi: 10.3969/j.issn.1007-7731.2007.05.081 [8] 王德华. 电供暖政策导向及电供暖系统应用情况[J]. 科技创新导报, 2018(4):25-27.WANG Dehua. Electric heating policy guidance and electric heating system application[J]. Science and Technology Innovation Herald,2018(4):25-27(in Chinese). [9] RAZAQ A, NYHOLM L, SJDIN M, et al. Paper-based energy-storage devices comprising carbon fiber-reinforced polypyrrole-cladophora nanocellulose composite electrodes[J]. Advanced Energy Materials,2012,2(4):445-454. doi: 10.1002/aenm.201100713 [10] KIM T, CHUNG D. Carbon fiber mats as resistive heating elements[J]. Carbon,2003,41(12):2436-2440. doi: 10.1016/S0008-6223(03)00288-4 [11] 杨小平, 荣浩鸣, 沈曾民. 碳纤维面状发热材料的性能研究[J]. 高科技纤维与应用, 2000, 25(3):39-42.YANG Xiaoping, RONG Haoming, SHEN Zengmin. Study on the properties of carbon fiber facial heating material[J]. Hi-Tech Fiber and Application,2000,25(3):39-42(in Chinese). [12] 李红斌, 房桂干, 施英乔, 等. 碳纤维纸的电热性能研究[J]. 中国造纸, 2019, 38(3):32-36. doi: 10.11980/j.issn.0254-508X.2019.03.006LI Hongbin, FANG Guigan, SHI Yingqiao, et al. Study on electric heating performance of carbon fiber exothermic paper[J]. China Pulp and Paper,2019,38(3):32-36(in Chinese). doi: 10.11980/j.issn.0254-508X.2019.03.006 [13] 汤龙其, 令旭霞, 王士华, 等. 聚吡咯/碳纤维纸电热复合材料的制备及性能[J]. 复合材料学报, 2020, 37(6):1426-1433.TANG Longqi, LING Xuxia, WANG Shihua, et al. Preparation and properties of polypyrrole/carbon fiber paper electrothermal composites[J]. Acta Materiae Compositae Sinica,2020,37(6):1426-1433(in Chinese). [14] GONG X, LIU L, LIU Y, et al. An electrical-heating and self-sensing shape memory polymer composite incorporated with carbon fiber felt[J]. Smart Materials and Structures,2016,25(3):035036. doi: 10.1088/0964-1726/25/3/035036 [15] 施云舟, 王彪. 碳纤维导电纸的研究现状及其应用[J]. 化工新型材料, 2014, 42(4):192-194.SHI Yunzhou, WANG Biao. Research progress and application of carbon fiber reinforced conductive paper[J]. New Chemical Materials,2014,42(4):192-194(in Chinese). [16] SONG J, YUAN Q, LIU X, et al. Combination of nitrogen plasma modification and waterborne polyurethane treatment of carbon fiber paper used for electric heating of wood floors[J]. Bioresources,2015,10(3):5820-5829. [17] LU P, CHENG F, OU Y, et al. A flexible and transparent thin film heater based on a carbon fiber/heat-resistant cellulose composite[J]. Composites Science and Technology,2017,153:1-6. doi: 10.1016/j.compscitech.2017.09.033 [18] YAN J, JEONG Y G. Multiwalled carbon nanotube/polydimethylsiloxane composite films as high performance flexible electric heating elements[J]. Applied Physics Letters,2014,105(5):051907. doi: 10.1063/1.4892545 [19] LEE T W, LEE S E, JEONG Y G. Carbon nanotube/cellulose papers with high performance in electric heating and electromagnetic interference shielding[J]. Composites Science and Technology,2016,131:77-87. doi: 10.1016/j.compscitech.2016.06.003 [20] BU Q, ZHAN Y, HE F et al. Stretchable conductive films based on carbon nanomaterials prepared by spray coating[J]. Journal of Applied Polymer Science,2016,133(15):43243. [21] LUO J, LU H, ZHANG Q, et al. Flexible carbon nanotube/polyurethane electrothermal films[J]. Carbon,2016,110:343-349. doi: 10.1016/j.carbon.2016.09.016 [22] LEE T W, JEONG Y G. Regenerated cellulose/multiwalled carbon nanotube composite films with efficient electric heating performance[J]. Carbohydrate Polymers,2015,133:456-463. doi: 10.1016/j.carbpol.2015.06.053 [23] KIM D H, NA I Y, JANG H K, et al. Anisotropic electrical and thermal characteristics of carbon nanotube-embedded wood[J]. Cellulose,2019,26(9):5719-5730. doi: 10.1007/s10570-019-02485-y [24] 张美云, 丁雪瑶, 杨斌, 等. CNT/芳纶共混浆料分散性及其电致发热纸基材料性能研究[J]. 陕西科技大学学报, 38(5): 1-5, 10.ZHANG Meiyun, DING Xueyao, YANG Bin, et al. Study on the dispersion of CNT/aramid plup and the properties of electro-heating paper-based materials[J]. Journal of Shaanxi University of Science and Technology, 38(5): 1-5, 10(in Chinese). [25] MARIA K H, MIENO T. Production and properties of carbon nanotube/cellulose composite paper[J]. Journal of Nanomaterials,2017,2017:6745029. [26] ZHANG Z, CHU H, WANG K, et al. Multifunctional carbon nano-paper composite[C]//Fourth International Conference on Smart Materials and Nanotechnology in Engineeing. Gold Coast, 2013, 8793. [27] JIAO D, LOSSADA F, GUO J, et al. Electrical switching of high-performance bioinspired nanocellulose nanocompo-sites[J]. Nature Communications,2021,12:1312. doi: 10.1038/s41467-021-21599-1 [28] GHOSH R, MISRA A. Carbon nanotube-based hierarchical paper structure for ultra-high electrothermal actuation in a wide humidity range[J]. ACS Applied Electronic Materials,2021,3:1260-1267. doi: 10.1021/acsaelm.0c01069 [29] ZHUO B, CAO S, LI X, et al. A nanofibrillated cellulose-based electrothermal aerogel constructed with carbon nano-tubes and graphene[J]. Molecules,2020,25(17):3836. doi: 10.3390/molecules25173836 [30] SUI D, HUANG Y, HUANG L, et al. Flexible and transparent electrothermal film heaters based on graphene materials[J]. Small,2011,7(22):3186-3192. [31] LI C, XU Y, BO Z, et al. Flexible graphene electrothermal films made from electrochemically exfoliated graphite[J]. Journal of Materials Science,2016,51(2):1043-1051. doi: 10.1007/s10853-015-9434-x [32] 王仕东, 顾宝珊, 孙世清, 等. 石墨烯电热薄膜材料的制备及表征[J]. 炭素技术, 2019, 38(4):17-22, 47.WANG Shidong, GU Baoshan, SUN Shiqing, et al. Preparation and characterization of graphene electro-thermal film[J]. Carbon Techniques,2019,38(4):17-22, 47(in Chinese). [33] WENG Z, SU Y, WANG D, et al. Graphene-cellulose paper flexible supercapacitors[J]. Advanced Energy Materials,2011,1(5):917-922. doi: 10.1002/aenm.201100312 [34] SHAO C, LI X, LIN S, et al. Characterization of nanocellulose-graphene electric heating membranes prepared via ultrasonic dispersion[J]. Journal of Materials Science,2020,55(1):421-437. doi: 10.1007/s10853-019-04006-5 [35] LIANG S, WANG H, TAO X. Conductive biomass films containing graphene oxide and cationic cellulose nanofibers for electric-heating applications[J]. Nanomaterials,2021,11(5):1187. doi: 10.3390/nano11051187 [36] JANAS D, KOZIOL K. A review of production methods of carbon nanotube and graphene thin films for electrothermal applications[J]. Nanoscale,2014,6:3037. doi: 10.1039/c3nr05636h [37] JEON G W, JEONG Y G. Electric heating films based on m-aramid nanocomposites containing hybrid fillers of graphene and carbon nanotube[J]. Journal of Materials Science,2013,48(11):4041-4049. doi: 10.1007/s10853-013-7216-x [38] 张朋, 刘舒, 魏志凯, 等. 纳米碳材料水性电热涂料的制备与性能研究[J]. 涂料工业, 2017, 47(4):27-32.ZHANG Peng, LIU Shu, WEI Zhikai, et al. Preparation and properties of nano carbon waterborne electric heating coatings[J]. Paint and Coatings Industry,2017,47(4):27-32(in Chinese). [39] 王慧翀. 纳米碳材料电热膜制备及其电热特性研究[D]. 北京: 北京林业大学, 2019.WANG Huichong. Preparation and electrothermal properties of nano-carbon materials electrothermal films[D]. Beijing: Beijing Forestry University, 2019(in Chinese). [40] LI X, SHAO C, ZHUO B, et al. The use of nanofibrillated cellulose to fabricate a homogeneous and flexible graphene-based electric heating membrane[J]. International Jour-nal of Biological Macromolecules,2019,139:1103-1116. doi: 10.1016/j.ijbiomac.2019.08.081 [41] ZHAO H, WU Z, WANG S, et al. Concrete pavement deicing with carbon fiber heating wires[J]. Cold Regions Science and Technology,2011,65(3):413-420. doi: 10.1016/j.coldregions.2010.10.010 [42] 张猛, 富秀荣. 碳纤维发热织物的电热性能研究[J]. 合成纤维, 2015, 44(11):25-27.ZHANG Meng, FU Xiurong. Study on electrothermal performance of carbon fiber heating fabric[J]. Synthetic Fiber in China,2015,44(11):25-27(in Chinese). [43] 戴家傲, 赵海波, 孔凡和. 碳纤维电热线发热规律实验与建模分析[J]. 烟台大学学报(自然科学与工程版), 2019, 32(4):362-368.DAI Jiaao, ZHAO Haibo, KONG Fanhe. Experiment and modeling analysis of temperature rise of carbon fiber heating wire[J]. Journal of Yantai University (Natural Science and Engineering Edition),2019,32(4):362-368(in Chinese). [44] 阙泽利, 赵晓旭, 李哲瑞, 等. 小径级杉木制备内置碳纤维电热线地热地板[J]. 木材工业, 2015, 29(4):9-13.QUE Zeli, ZHAO Xiaoxu, LI Zherui, et al. Electrically heated flooring made with hexagon glulam from small-diameter chinese fir[J]. China Wood Industry,2015,29(4):9-13(in Chinese). [45] DORIGATO A, BRUGNARA M, PEGORETTI A. Synergistic effects of carbon black and carbon nanotubes on the electrical resistivity of poly(butylene-terephthalate) nanocomposites[J]. Advances in Polymer Technology,2018,37:1744-1754. doi: 10.1002/adv.21833 [46] WANG Y, XIE J, WANG X. The ultra-flexible films of super conductive carbon black/poly(vinylidene fluoride) as electrothermal materials[J]. Materials Research Express,2019,6(11):116402. doi: 10.1088/2053-1591/ab4486 [47] 谢炯. 基于超导炭黑的高分子电热膜制备与性能研究[D]. 南京: 南京理工大学, 2018.XIE Jiong. Preparation and properties of polymer electrothermal films based on superconductive carbon black[D]. Nanjing: Nanjing University of Science and Technology, 2018(in Chinese). [48] YURDDASKAL M, DOLUEL E C, KARTAL U, et al. Graphene and carbon black filled conductive nanocompo-site films for heating element applications[J]. Journal of Materials Science Materials in Electronics,2018,29:19005-19012. doi: 10.1007/s10854-018-0026-9 [49] TIAN W, ZHANG Y, LIU J, et al. Rapid electrothermal response and excellent flame retardancy of ethylene-vinyl acetate electrothermal film[J]. Polymers for Advanced Technologies,2020,31(5):1088-1098. doi: 10.1002/pat.4843 [50] LIAO Y, TIAN Y, MA X, et al. Screen-printed high-perfor-mance flexible electrothermal films based on three-dimensional intercalation graphene nanosheets/MWCNT/carbon black composite[J]. ACS Applied Materials and Interfaces,2020,12(42):48077-48083. doi: 10.1021/acsami.0c10924 [51] 葛铁军, 赵越, 毛洪雨. 碳晶柔性电热膜的制备与性能研究[J]. 塑料科技, 2019, 47(6):12-17.GE Tiejun, ZHAO Yue, MAO Hongyu. Study on preparation and properties of carbon crystal flexible electrothermal films[J]. Plastics Science and Technology,2019,47(6):12-17(in Chinese). [52] 葛铁军, 李瑞雄. 碳晶电热膜的发热研究[J]. 现代塑料加工应用, 2021, 33(4):15-18.GE Tiejun, LI Ruixiong. Study on the heating oc carbon crystal electric film[J]. Processing and Application,2021,33(4):15-18(in Chinese). [53] 张海桥. 碳晶电热板系统运行调节的实验及模拟研究[D]. 沈阳: 沈阳化工大学, 2010.ZHANG Haiqiao. Preparation and properties of carbon crystal field emission materials[D]. Shenyang: Shenyang University of Chemical Technology, 2010(in Chinese). [54] HE F, HOU Y, LI K, et al. Investigation of a root zone heating system for greenhouse seedling and its effects on micro-environment[J]. International Journal of Agricultural and Biological Engineering,2020,13(6):47-52. doi: 10.25165/j.ijabe.20201306.5905 [55] 梁善庆, 李思程, 柴媛, 等. 内置电热层实木复合地板表面温度变化规律及模拟[J]. 北京林业大学学报, 2018, 40(11):112-122.LIANG Shanqing, LI Sicheng, CHAI Yuan, et al. Change law and simulation of surface temperature for electric heating engineered wood flooring with built-in electrothermal layer[J]. Journal of Beijing Forestry University,2018,40(11):112-122(in Chinese). [56] 周兆兵, 张峰, 李想, 等. 内置电热实木复合地板基材冷压制备工艺研究[J]. 木材工业, 2018, 32(3):9-12.ZHOU Zhaobing, ZHANG Feng, LI Xiang, et al. Cold-pressing technology for making parquet substrates with built-in electric heating elements[J]. China Wood Industry,2018,32(3):9-12(in Chinese). [57] 包永洁, 梁善庆, 王艳伟, 等. 碳纤维木质电热复合地板电热性能研究[J]. 竹子学报, 2018, 37(2):43-48. doi: 10.3969/j.issn.1000-6567.2018.02.007BAO Yongjie, LIANG Shanqing, WANG Yanwei, et al. The electrothermal properties of carbon-fiber wood electric heating composite floor[J]. Journal of Bamboo Research,2018,37(2):43-48(in Chinese). doi: 10.3969/j.issn.1000-6567.2018.02.007 [58] 周兆兵, 朱兆龙, 薛宏, 等. 内置式发热实木复合地板的电热性能[J]. 东北林业大学学报, 2018, 46(2):53-58. doi: 10.3969/j.issn.1000-5382.2018.02.011ZHOU Zhaobing, ZHU Zhaolong, XUE Hong, et al. Electrothermal performance of built-in heating parquet[J]. Jour-nal of Northeast Forestry University,2018,46(2):53-58(in Chinese). doi: 10.3969/j.issn.1000-5382.2018.02.011 [59] 梁善庆, 李思程, 王慧翀, 等. 石墨导热膜对电热实木复合地板基材传热性能的影响[J]. 东北林业大学学报, 2019, 47(8):76-81. doi: 10.3969/j.issn.1000-5382.2019.08.015LIANG Shanqing, LI Sicheng, WANG Huichong, et al. Effect of thermal conductive graphite film on heat transfer performance of electrothermal parquet flooring substrate[J]. Journal of Northeast Forestry University,2019,47(8):76-81(in Chinese). doi: 10.3969/j.issn.1000-5382.2019.08.015 [60] 周兆兵, 李想, 薛宏, 等. 内置式电热木地板结构设计与优化[J]. 林产工业, 2018, 45(3):46-49.ZHOU Zhaobing, LI Xiang, XUE Hong, et al. Structure design and optimization of built-in heating parquet[J]. China Forestry Products Industry,2018,45(3):46-49(in Chinese). [61] 周兆兵, 李想, 丁建文, 等. 内置发热实木复合地板结构设计及工艺[J]. 林业工程学报, 2019, 4(1):165-169.ZHOU Zhaobing, LI Xiang, DING Jianwen, et al. Structure design and process analysis of internal heating engineered wood flooring[J]. Journal of Forestry Engineering,2019,4(1):165-169(in Chinese). [62] 袁全平, 梁善庆, 傅峰. 碳纤维电热功能复合纤维板的制备工艺[J]. 木材工业, 2017, 31(4):14-18.YUAN Quanping, LIANG Shanqing, FU Feng. Electric heating composites made from carbon fiber paper and fiberboard[J]. China Wood Industry,2017,31(4):14-18(in Chinese). [63] 李祯, 张桂兰, 李博, 等. 木基电热材料电热性能分析及板面温度模拟[J]. 中南林业科技大学学报, 2018, 38(11):117-122.LI Zhen, ZHANG Guilan, LI Bo, et al. Electro thermal performance analysis and simulation of surface temperature of wood based electro thermal materials[J]. Journal of Central South University of Forestry and Technology,2018,38(11):117-122(in Chinese). [64] 李祯, 张桂兰, 李博, 等. 木质/碳毡电热复合材料电热性能研究[J]. 内蒙古农业大学学报(自然科学版), 2017, 38(6):62-67.LI Zhen, ZHANG Guilan, LI Bo, et al. Study on the electric heating properties of wood/graphite composites[J]. Jour-nal of Inner Mongolia Agricultural University (Natural Science Edition),2017,38(6):62-67(in Chinese). [65] 题璞, 林志, 王梓宁, 等. 覆膜纸制备电热功能复合纤维板的性能研究[J]. 西北林学院学报, 2021, 36(1):233-240. doi: 10.3969/j.issn.1001-7461.2021.01.34TI Pu, LIN Zhi, WANG Zining, et al. Properties of electric heating fiberboard preparaed with coated paper[J]. Jour-nal of Northwest Forestry University,2021,36(1):233-240(in Chinese). doi: 10.3969/j.issn.1001-7461.2021.01.34 [66] 张泽前, 吴再兴, 陈玉和, 等. 电热竹木复合地板的制备工艺[J]. 木材工业, 2016, 30(1):14-17.ZHANG Zeqian, WU Zaixing, CHEN Yuhe, et al. Manufacturing technology for electrically heating engineered flooring made from bamboo and wood[J]. China Wood Industry,2016,30(1):14-17(in Chinese). [67] 黄成建, 包永洁, 李能, 等. 不同胶黏剂竹木复合电热地板的基本特性[J]. 浙江农林大学学报, 2017, 34 (2) : 369-373.HUANG Chengjian, BAO Yongjie, LI Neng, et al. Adhesives used to make bamboo/wood composite electro-thermal plywood[J]. Journal of Zhejiang Agriculture and Forestry University, 2017, 34 (2) : 369-373(in Chinese). [68] 包永洁, 黄成建, 陈玉和, 等. 碳纤维纸木质电热复合材料面层电热效果的纵向尺寸效应[J]. 复合材料学报, 2020(12):3214-3219.BAO Yongjie, HUANG Chengjian, CHEN Yuhe, et al. Longitudinal scale effect of electro-thermal effectiveness of front panel of the integrated wooden electric heating composite based on carbon fiber paper[J]. Acta Materiae Compositae Sinica,2020(12):3214-3219(in Chinese). [69] 杨光, 许心梦, 包永洁, 等. 木竹电热复合地板自动铺装系统设计[J]. 木材加工机械, 2019, 30(2):5-8.YANG Guang, XU Xinmeng, BAO Yongjie, et al. Design of automatic paving system for wood-bamboo electrothermal composite floor[J]. Wood Processing Machinery,2019,30(2):5-8(in Chinese). [70] 罗云烽, 李阳, 肈研, 等. 国产T800级炭纤维表面特性及其复合材料微观界面性能[J]. 材料工程, 2014(9):83-88. doi: 10.11868/j.issn.1001-4381.2014.09.014LUO Yunfeng, LI Yang, ZHAO Yan, et al. Surface characteristics of domestic T800-grade carbon fibers and microscopic interphase properties of composites[J]. Journal of Materials Engineering,2014(9):83-88(in Chinese). doi: 10.11868/j.issn.1001-4381.2014.09.014 [71] LUO Y, ZHAO Y, DUAN Y, et al. Surface and wettability property analysis of CCF300 carbon fibers with different sizing or without sizing[J]. Materials and Design,2011,32(2):941-946. doi: 10.1016/j.matdes.2010.08.004 [72] YUAN Q, FU F. Application of carbon fiber paper in integrated wooden electric heating composite[J]. BioResources,2014,9(3):5662-5675. [73] 肖瑞崇. 不同胶黏剂制备的竹木电热复合材料老化性能研究[D]. 北京: 中国林业科学研究院, 2017.XIAO Ruichong. The aging study of bamboo-wood thermoelectric composites prepared by four adhesives[D]. Beijing: Chinese Academy of Forestry, 2017(in Chinese). [74] KIM H I, CHOI W K, Oh S Y, et al. Effects of electrochemical oxidation of carbon fibers on mechanical interfacial properties of carbon fibers-reinforced polarized -polypropylene matrix composites[J]. Journal of the Korean Industrial and Engineering Chemistry,2013,24(5):476-482. [75] HARRY I D, SAHA B, CUMMING I W, et al. Effect of electrochemical oxidation of activated carbon fiber on competitive and noncompetitive sorption of trace toxic metal ions from aqueous solution[J]. Journal of Colloid and Interface Science,2006,304(1):9-20. doi: 10.1016/j.jcis.2006.08.012 [76] SONG J, HU H, ZHANG M, et al. Thermal aging properties and electric heating behaviors of carbon fiber paper-based electric heating wood floors[J]. BioResources,2017,12(4):9466-9475. [77] 王志平, 孙凌丰, 路鹏程, 等. 电热作用对碳纤维/树脂复合材料界面应力的影响[J]. 复合材料学报, 2019, 36(6):1381-1388.WANG Zhiping, SUN Lingfeng, LU Pengcheng, et al. Influence of electro-thermal effect on interfacial stress of carbon fiber reinforced polymer composites[J]. Acta Materiae Compositae Sinica,2019,36(6):1381-1388(in Chinese). [78] 袁全平, 木质电热复合材料的电热响应机理及性能研究[D]. 北京: 中国林业科学研究院, 2015.YUAN Quanping. Performance and electric heating response mechanism of wooden electric heating composites[D]. Beijing: Chinese Academy of Forestry, 2015(in Chinese). [79] 杨小军, 孙友富, 巫朝珍. CFRP-木材复合材界面的湿热效应研究[J]. 木材加工机械, 2009, 20(5):16-18. doi: 10.3969/j.issn.1001-036X.2009.05.005YANG Xiaojun, SUN Youfu, WU Chaozhen. Study on the damp-heat effects of composite material’s interface between CFRP and wood[J]. Wood Processing Machinery,2009,20(5):16-18(in Chinese). doi: 10.3969/j.issn.1001-036X.2009.05.005 [80] 齐磊, 赵栗君, 刘扬涛, 等. 缠绕成型碳纤维/环氧树脂复合材料水煮老化性能的实验研究[J]. 纤维复合材料, 2015, 32(2):19-21. doi: 10.3969/j.issn.1003-6423.2015.02.004QI Lei, ZHAO Lijun, LIU Yangtao, et al. Experimental study on hygrothermal properties of CFRP with filament winding process under boiling water aging treatment condition[J]. Fiber Composites,2015,32(2):19-21(in Chinese). doi: 10.3969/j.issn.1003-6423.2015.02.004 [81] 范诒杰, 申士杰, 陈暑冰. 纤维增强树脂复合材料/竹木胶合界面的处理工艺[J]. 东北林业大学学报, 2017, 45(2):71-74. doi: 10.3969/j.issn.1000-5382.2017.02.015FAN Yijie, SHEN Shijie, CHEN Shubing. Treatment process of bonding interface between FRP and bamboo/wood[J]. Journal of Northeast Forestry University,2017,45(2):71-74(in Chinese). doi: 10.3969/j.issn.1000-5382.2017.02.015 [82] 张泽前. 竹木电热复合板的湿热老化研究[D]. 北京: 中国林业科学研究院, 2015.ZHANG Zeqian. The study of hygrothermal aging of bamboo/wood composite electrothermal plywood[D]. Beijing: Chinese Academy of Forestry, 2015(in Chinese). [83] MENG M, RIZVI M J, LE H R, et al. Multi-scale modelling of moisture diffusion coupled with stress distribution in CFRP laminated composites[J]. Composite Structures,2016,138(15):295-304. [84] 谢可勇, 李晖, 孙岩, 等. 湿热老化对纤维增强树脂基复合材料性能的影响及其机理[J]. 机械工程材料, 2014, 38(8):1-5.XIE Keyong, LI Hui, SUN Yan, et al. Effect of hygrothermal aging on behaviors of fiber reinforced resin composites and its mechanism[J]. Materials for Mechanical Engineering,2014,38(8):1-5(in Chinese). [85] 王威力, 纪丹阳, 陈春露. 国内外复合材料湿热老化研究进展[J]. 纤维复合材料, 2019, 35(1):35-37. doi: 10.3969/j.issn.1003-6423.2019.01.009WANG Weili, JI Danyang, CHEN Chunlu. Research progress on wet-heat aging of composites internal and abroad[J]. Fiber Composites,2019,35(1):35-37(in Chinese). doi: 10.3969/j.issn.1003-6423.2019.01.009 [86] KIM J I, KANG P H, NHO Y C. Positive temperature coefficient behavior of polymer composites having a high melting temperature[J]. Journal of Applied Polymer Science,2004,92:394-401. doi: 10.1002/app.20064 [87] XI Y, ISHIKAWA H, BIN Y Z, et al. Positive temperature coefficient effect of LMWPE–UHMWPE blends filled with short carbon fibers[J]. Carbon,2004,42:1699-1706. doi: 10.1016/j.carbon.2004.02.027 [88] ISAJI S, BIN Y Z, MATSUO M. Electrical conductivity and self-temperature-control heating properties of carbon nano-tubes filled polyethylene films[J]. Polymer,2009,50(4):1046-1053. doi: 10.1016/j.polymer.2008.12.033 [89] WANG X, ZHANG G, LI J, et al. PTC/NTC behavior of PVDF composites filled with GF and CF[J]. Chemical Research in Chinese Universities,2008,24(5):648-652. doi: 10.1016/S1005-9040(08)60136-1 [90] 贾晨, 杨俊红, 马凯, 等. 几种典型碳纤维复合材料在地采暖方面的研究进展[J]. 化工新型材料, 2018, 46(10):263-266.JIA Chen, YANG Junhong, MA Kai, et al. Research progress of several typical carbon fiber reinforced plastics for ground heating[J]. New Chemical Materials,2018,46(10):263-266(in Chinese). [91] 施志钢, 张伟光, 刘龙. 电热膜启动特性和局部聚热的实验研究[J]. 暖通空调, 2018, 48(2):101, 113-116.SHI Zhigang, ZHANG Weiguang, LIU Long. Experimental study on startup characteristics and local heat accumulation of electric radiant heating film[J]. Journal of HV and AC,2018,48(2):101, 113-116(in Chinese). [92] 李欣, 张金专. 热老化对油墨电热膜电热性能的影响研究[J]. 消防科学与技术, 2019, 38(5): 742-745.LI Xin, ZHANG Jinzhuan. Study on the effect of heat aging on the electrothermal properties of ink electric heating film[J]. Fire Science and Technology, 2019, 38(5): 742-745(in Chinese). [93] 国家林业和草原局. 内置电热层电采暖木质地板: LY/T3192-2020[S]. 北京: 中国标准出版社, 2020.National Forestry and Grassland Administration. Electric heating wooden floor with built-in heating layer: LY/T3192—2020[S]. Beijing: China Standard Press, 2020(in Chinese). -

下载:

下载: