Textile-based for supercapacitors: A review

-

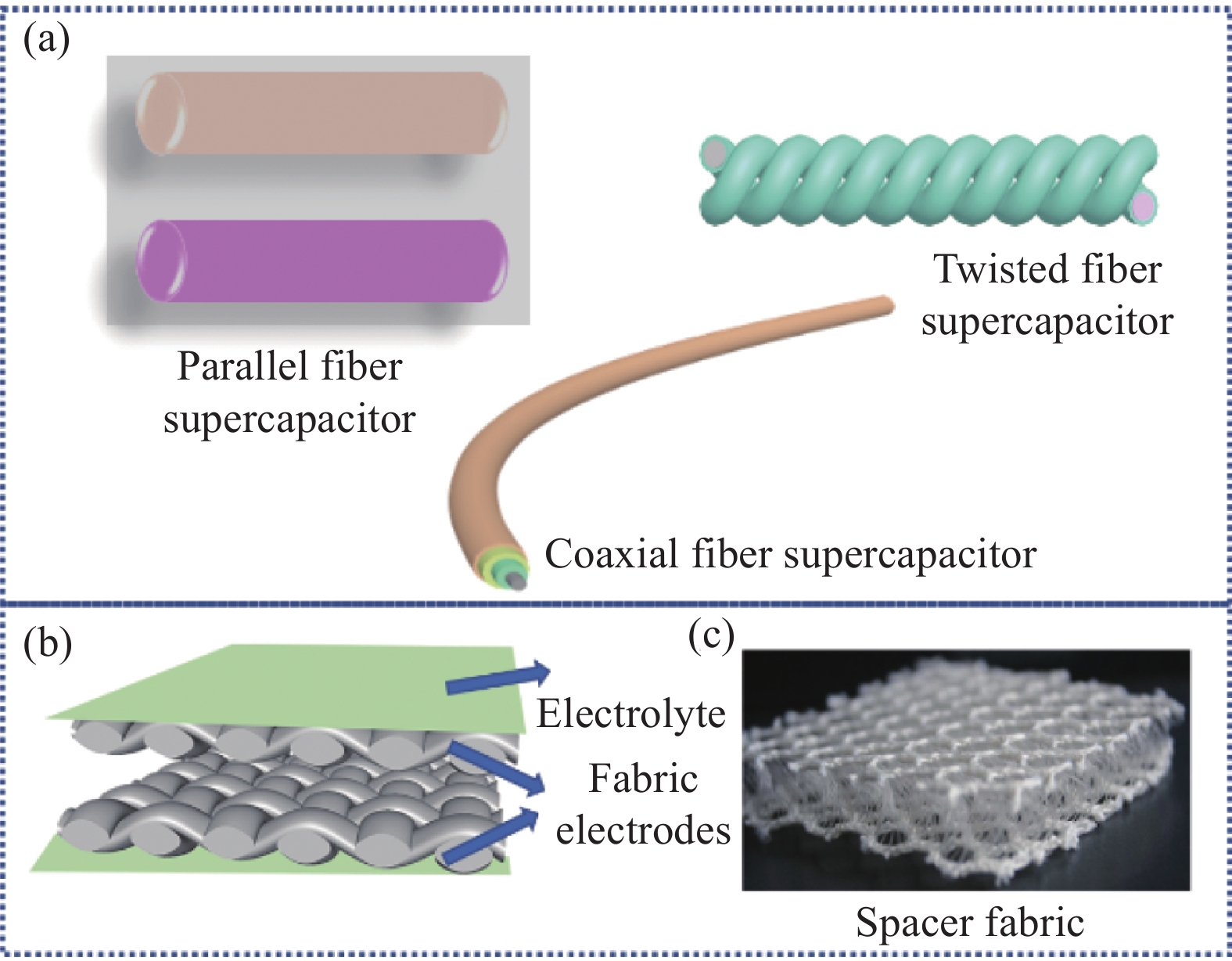

摘要: 纺织基能源存储是柔性可穿戴纺织品微电子信号收集系统重要的供能元件。从纤维、纱线、织物多角度总结现阶段柔性超级电容器的研究进展,对不同基体类型的超级电容器的制备方法及优缺点进行归纳总结。聚焦纺织超级电容器的工艺特点,深入分析材料性能改进提升应采取的方式方法。最后,针对纺织基超级电容器发展存在的问题进行说明并对未来需要攻克的重点难点进行分析及展望。Abstract: Textile-based energy storage is an important energy supply element of the microelectronic signal collection system for flexible wearable textiles. The recent research progress of flexible supercapacitors from multiple perspectives of fibers, yarns and fabrics, and states the preparation methods, advantages and disadvantages of supercapacitors of different matrix types are summarized. Focusing on the technological characteristics of textile supercapacitors, analysis the method that should be adopted to improve the performance of materials. Finally, an explanation for the presence of textile-based supercapacitor development and the key work of future which need to overcome is given an analysis and outlook.

-

图 4 (a)湿法纺丝[12];(b)湿法纺丝制备的碳纳米纤维电镜图[13];(c)加捻法制备碳纳米纤维[14];((d)~(f))不同加捻方式制备的碳纳米纤维的电镜图[14];(g) 化学气相沉积(CVD)法制备碳纳米纤维[15];(h)CVD法所得纤维照片[15]

Figure 4. (a) Wet spinning[12]; (b) Electron micrographs of carbon nanofibers prepared by wet spinning[13]; (c) Carbon nanofibers prepared by twisting method[14]; ((d)-(f)) Electron micrographs of carbon nanofibers prepared by different twisting methods[14]; (g) Carbon nanofibers prepared by chemical vapor deposition (CVD) method[15]; (h) Photos of fibers obtained by CVD method[15]

SWCNTs—Single-walled carbon nanotube; CNT—Carbon nanotube; PVA—Polyvinyl alcohol

图 5 (a)同轴湿法纺丝示意图及纤维结构图[26];(b)中空石墨烯纤维制备流程及中空结构成型机制[29];(c)自卷曲中空石墨烯纤维SEM图及成型机制[30]

Figure 5. (a) Structural diagram of coaxial spinning fibers[26]; (b) Preparation of hollow graphene fiber and formation of hollow structures[29]; (c) Forming mechanism of hollow self-curling graphene fiber and the SEM images of the fiber[30]

CMC—Carboxymethyl cellulose; GO/PEDOT : PSS/VC—Graphene oxide/poly(3, 4-ethylenedioxythiophene) : poly(styrenesulfonate)/Vitamin C

图 6 (a)浸渍制备棉纱线基超电的流程图[31];(b)棉纱线基超电制备流程图[34];(c)活性物质负载棉纱线照片[34];(d)上机图[34]

Figure 6. (a) Flow chart of cotton yarn-based supercapacitor preparation by impregnation[31]; (b) Flow chart of cotton yarn-based supercapacitor preparation[34]; (c) Photo of active substance-loaded cotton yarn[34]; (d) Upstream diagram[34]

CT—Cotton thread; BSA—Bovine albumin; CNPs—Carbon nanoparticles; PAMD—Polymer-assisted metal deposition

图 7 (a) 聚酰亚胺(PI)长丝图[37];(b)负载rGO后图[37];(c)负载rGO后电镜图[37];(d)聚苯胺/CuS/聚对苯二甲酸乙二醇酯(PANI/CuS/PET)长丝超电制备流程图[39];(e)可拉伸长丝超电制备流程图[40]

Figure 7. (a) Polyimide (PI) filament diagram[37]; (b) Diagram after rGO loading[37]; (c) Electron microscope diagram after rGO loading[37]; (d) Flow chart of polyaniline/CuS/polyethylene terephthalate (PANI/CuS/PET) filament super-electric preparation[39]; (e) Flow chart of stretchable filament super-electric preparation[40]

图 8 (a) 棉织物吸附SWCNTs的原理图[41];((b), (c)) 棉织物吸附SWCNTs的照片[41];((d), (e))微观形貌[41];(f)纱线超电织入织物中制备织物超电示意图及电化学测试图[43]

Figure 8. (a) Schematic diagram of cotton fabric adsorption of SWCNTs[41]; ((b), (c)) Photos of cotton fabric adsorption of SWCNTs[41]; ((d), (e)) Microscopic morphology[41]; (f) Yarn superelectricity woven into the fabric schematic diagram and electrochemical test diagram of the prepared fabric superelectricity[43]

-

[1] BEGUIN F, PRESSER V, BALDUCCI A, et al. Carbons and electrolytes for advanced supercapacitors[J]. Advanced Materials,2014,26(14):2219-2251. doi: 10.1002/adma.201304137 [2] ZHI M, XING C, LI J, et al. Nanostructured carbon-metal oxide composite electrodes for supercapacitors: A review[J]. Nanoscale,2013,5(1):72-88. doi: 10.1039/C2NR32040A [3] LU X, LI G, TONG Y. A review of negative electrode materials for electrochemical supercapacitors[J]. Science China-Technological Sciences,2015,58(11):1799-1808. doi: 10.1007/s11431-015-5931-z [4] BRUCE P G, FREUNBERGER S A, HARDWICK L J, et al. Li-O2 and Li-S batteries with high energy storage[J]. Nature Materials,2012,11(1):19-29. doi: 10.1038/nmat3191 [5] CHAN C K, PENG H, LIU G, et al. High-performance lithium battery anodes using silicon nanowires[J]. Nature nano-technology,2008,3(1):31-35. doi: 10.1038/nnano.2007.411 [6] ARMAND M, TARASCON J M. Building better batteries[J]. Nature,2008,451(7179):652-657. doi: 10.1038/451652a [7] KIM B H, BUI N N, YANG K S, et al. Electrochemical properties of activated polyacrylonitrile/pitch carbon fibers produced using electrospinning[J]. Bulletin of the Korean Chemical Society, 2009, 30(9): 1967-1972. [8] MA X, NING G, KAN Y, et al. Synthesis of S-doped mesoporous carbon fibres with ultrahigh S concentration and their application as high performance electrodes in supercapacitors[J]. Electrochimica Acta,2014,150:108-113. doi: 10.1016/j.electacta.2014.10.128 [9] SHI Z, XING L, LIU Y, et al. A porous biomass-based sandwich-structured Co3O4@carbon fiber@Co3O4 composite for high-performance supercapacitors[J]. Carbon,2018,129:819-825. doi: 10.1016/j.carbon.2017.12.105 [10] DING M, QU Y, ZHANG X, et al. Reduced graphene oxide/g-C3N4 modified carbon fibers for high performance fiber supercapacitors[J]. New Journal of Chemistry,2021,45(2):923-929. doi: 10.1039/D0NJ05072E [11] YU N, YIN H, ZHANG W, et al. High-performance fiber-shaped all-solid-state asymmetric supercapacitors based on ultrathin MnO2 nanosheet/carbon fiber cathodes for wearable electronics[J]. Advanced Energy Materials, 2016, 6: 1501458 [12] VIGOLO B, PENICAUD A, COULON C, et al. Macroscopic fibers and ribbons of oriented carbon nanotubes[J]. Science,2000,290:1331-1334. doi: 10.1126/science.290.5495.1331 [13] BEHABTU N, YOUNG C C, PASQUALI M, et al. Strong, light, multifunctional fibers of carbon nanotubes with ultra-high conductivity[J]. Science,2013,339(6116):182-186. doi: 10.1126/science.1228061 [14] LIMA M D, FANG S L, LEPRO X, et al. Biscrolling nanotube sheets and functional guests into yarns[J]. Science,2011,331(6013):51-55. doi: 10.1126/science.1195912 [15] ZHONG X H, LI Y L, LIU Y K, et al. Continuous multi-layered carbon nanotube yarns[J]. Advance Materials, 2010, 22(6): 692-696. [16] REN J, LI L, CHEN C, et al. Twisting carbon nanotube fibers for both wire-shaped micro-supercapacitor and micro-battery[J]. Advanced Materials,2013,25(8):1155-1159. doi: 10.1002/adma.201203445 [17] XUE M, XIE Z, ZHANG L, et al. Microfluidic etching for fabrication of flexible and all-solid-state micro supercapacitor based on MnO2 nanoparticles[J]. Nanoscale,2011,3(7):2703-2708. doi: 10.1039/c0nr00990c [18] CHEN X, QIU L, REN J, et al. Novel electric double-layer capacitor with a coaxial fiber structure[J]. Advanced Materials,2013,25(44):6436-6441. doi: 10.1002/adma.201301519 [19] CHOI C, LEE J A, CHOI A Y, et al. Flexible supercapacitor made of carbon nanotube yarn with internal pores[J]. Advanced Materials,2014,26(13):2059-2065. doi: 10.1002/adma.201304736 [20] HOU Y, CHENG Y, HOBSON T, et al. Design and synthesis of hierarchical MnO2 nanospheres/carbon nanotubes/conducting polymer ternary composite for high performance electrochemical electrodes[J]. Nano Letters,2010,10(7):2727-2733. doi: 10.1021/nl101723g [21] XU Z, GAO C. Graphene chiral liquid crystals and macroscopic assembled fibres[J]. Nature Communications,2011,2:52. [22] LI X, ZHAO T, WANG K, et al. Directly drawing self-assembled, porous, and monolithic graphene fiber from chemical vapor deposition grown graphene film and its electrochemical properties[J]. Langmuir,2011,27(19):12164-12171. doi: 10.1021/la202380g [23] DONG Z, JIANG C, CHENG H, et al. Facile fabrication of light, flexible and multifunctional graphene fibers[J]. Advanced Materials,2012,24(14):1856-1861. doi: 10.1002/adma.201200170 [24] HUANG T, ZHENG B, KOU L, et al. Flexible high performance wet-spun graphene fiber supercapacitors[J]. RSC Advances,2013,3(46):23957-23962. doi: 10.1039/c3ra44935a [25] KONSTANTIN O V K, JALILI R, ESRAFILZADEH D, et al. High-performance multifunctional graphene yarns: Toward wearable all-carbon energy storage textiles[J]. ACS Nano,2014,8(3):2456-2466. doi: 10.1021/nn406026z [26] KOU L, HUANG T, ZHENG B, et al. Coaxial wet-spun yarn supercapacitors for high-energy density and safe wearable electronics[J]. Nature Communications,2014,5:3754. [27] HU Y, CHENG H, ZHAO F, et al. All-in-one graphene fiber supercapacitor[J]. Nanoscale,2014,6(12):6448-6451. doi: 10.1039/c4nr01220h [28] CHEN S, TAN P, WU X, et al. High-performance wearable micro-supercapacitors based on microfluidic-directed nitrogen-doped graphene fiber electrodes[J]. Advanced Functional Materials, 2017, 27(36): 1702493. [29] QU G X, CHENG J L, PENG H S, et al. A fiber supercapacitor with high energy density based on hollow graphene/conducting polymer fiber electrode[J]. Advance Materials,2016,28(19):3646-3652. doi: 10.1002/adma.201600689 [30] LAN X X, TIAN Z Q, SHEN P K. Hollow graphene fibers with archimedean-type spirals for flexible and wearable electronics[J]. ACS Applied Nano Materials,2021,4:6985-6994. doi: 10.1021/acsanm.1c01026 [31] YE X, ZHOU Q, JIA C, et al. A knittable fibriform super-capacitor based on natural cotton thread coated with graphene and carbon nanoparticles[J]. Electrochimica Acta,2016,206:155-164. doi: 10.1016/j.electacta.2016.04.100 [32] WEI C, XU Q, CHEN Z, et al. An all-solid-state yarn super-capacitor using cotton yarn electrodes coated with polypyrrole nanotubes[J]. Carbohydrate Polymers,2017,169:50-57. doi: 10.1016/j.carbpol.2017.04.002 [33] LIU N, MA W, TAO J, et al. Cable-type supercapacitors of three-dimensional cotton thread based multi-grade nanostructures for wearable energy storage[J]. Advanced Materials,2013,25(35):4925-4931. doi: 10.1002/adma.201301311 [34] LIU L, YU Y, YAN C, et al. Wearable energy-dense and power-dense supercapacitor yarns enabled by scalable graphene-metallic textile composite electrodes[J]. Nature Communications,2015,6:7260. [35] DU X, ZHAN W, WANG Y, et al. Preparation of activated carbon hollow fibers from ramie at low temperature for electric double-layer capacitor applications[J]. Bio-resource Technology,2013,149:31-37. doi: 10.1016/j.biortech.2013.09.026 [36] HU X, XIONG W, WANG W, et al. Hierarchical manganese dioxide/poly(3, 4-ethylenedioxythiophene) core-shell nanoflakes on ramie-derived carbon fiber for high-performance flexible all-solid-state supercapacitor[J]. ACS Sustainable Chemistry & Engineering,2016,4(3):1201-1211. [37] LIU L, WENG W, DAI X, et al. Highly conductive graphene-bonded polyimide yarns for flexible electronics[J]. RSC Advances,2016,6(110):108362-108368. doi: 10.1039/C6RA24206E [38] NIE W, LIU L, LI Q, et al. A wearable fiber-shaped super-capacitor based on a poly(lactic acid) filament and high loading polypyrrole[J]. RSC Advances,2019,9(33):19180-19188. doi: 10.1039/C9RA02171J [39] BA Y, ZHOU S, JIAO S, et al. Fabrication of polyaniline/copp-er sulfide/poly(ethylene terephthalate) thread electrode for flexible fiber-shaped supercapacitors[J]. Journal of Applied Polymer Science, 2018, 135(42): 46769. [40] PENG H, DENG J, LI X, et al. Superelastic supercapacitors with high performances during stretching[J]. Advanced Materials,2015,27(2):356-362. doi: 10.1002/adma.201404573 [41] CUI Y, LA MANTIA F, HU L, et al. Aqueous supercapacitors on conductive cotton[J]. Nano Research,2010,3(6):452-458. doi: 10.1007/s12274-010-0006-8 [42] WANG Z, LU X H, XIAO X, et al. Flexible solid-state supercapacitors based on carbon nanoparticles/MnO2 nano-rods hybrid structure[J]. ACS Nano,2012,6(1):656-661. doi: 10.1021/nn2041279 [43] PU X, LI L, LIU M, et al. Wearable self-charging power textile based on flexible yarn supercapacitors and fabric nanogenerators[J]. Advanced Materials,2016,28(1):98-105. doi: 10.1002/adma.201504403 [44] ZHANG J, CHEN M, GE Y, et al. Manganese oxide on carbon fabric for flexible supercapacitors[J]. Journal of Nanomaterials,2016:2870761. [45] MA C, RUAN S, WANG J, et al. Free-standing carbon nano-fiber fabrics for high performance flexible super-capacitor[J]. Journal of Colloid and Interface Science,2018,531:513-522. doi: 10.1016/j.jcis.2018.06.093 [46] YANG Y, HUANG Q, NIU L, et al. Waterproof, ultrahigh areal-capacitance, wearable supercapacitor fabrics[J]. Advanced Materials, 2017, 29: 1606679. [47] ZHANG C, TIAN J, RAO W, et al. Polypyrrole@metal-organic framework (UIO-66)@cotton fabric electrodes for flexible supercapacitors[J]. Cellulose,2019,26(5):3387-3399. doi: 10.1007/s10570-019-02321-3 -

下载:

下载: