Hot press molding characteristics and three-point bending characteristics of Al-carbon fiber reinforced polypropylene hybrid hat-shaped rail

-

摘要: 金属-复合材料混合结构在热模压成形中将不可避免地出现材料破裂、回弹、分层、厚度减薄及起皱等缺陷,同时织物增强复合材料在热模压过程受到压边力的约束还会发生纤维剪切变形,上述工艺缺陷和纤维剪切变形行为都将对后续的结构性能造成显著影响。然而,混合结构在成形过程中的缺陷无法直接观测,成形后采用机械切割方法探究成形缺陷可能造成材料二次损伤。更重要的是,切割后的试件无法继续开展后续的结构性能测试,导致成形性能与结构性能分析孤立开展,大大增加了产品失效的风险。本文针对铝合金(Al)-碳纤维增强聚丙烯(Carbon fiber reinforced polypropylene,CF/PP)混合帽型梁的热模压成形特性及三点弯曲特性进行了实验研究。利用X射线扫描断层(X-ray computed tomography,X-ray CT)无损检测技术从纤维夹角变化、厚度变化、分层和回弹变形4个方面探究了混合结构的成形性特性,进一步又通过静态三点弯曲实验探究了成形后混合帽型结构的抗弯曲性能。结果表明,Al-CF/PP在热模压过程中受到压边力的限制,CF/PP的纤维夹角将从初始的正交构型变换为非正交构型;厚度增加和厚度减薄的现象都有发生;圆角过渡区域分层现象十分明显;结构整体无明显的回弹变形;弯曲实验中混合结构发生了显著的塑性变形,实验结束时Al和CF/PP均出现了明显的断裂失效。

-

关键词:

- 金属-复合材料混合帽型梁 /

- 成形性能 /

- CT无损检测 /

- 三点弯曲 /

- 热模压

Abstract: In the hot press molding process of metal-composite hybrid structures, various defects including fracture, spring-back, delamination, thickness thinning and wrinkle will inevitably occur. Meanwhile fiber yarns in fabric reinforced composites will undergo significant shear deformations with restrictions of blank holding force. The above defects and shear deformations will lead to a significant impact on subsequent structural performances. However, these forming defects of hybrid structures cannot be observed directly during the forming process, and the mechanical cutting method might cause secondary damage to explore these forming defects. More importantly, the damaged specimen cannot be continuously investigated in the subsequent structural performance test, which causes the isolated analysis between forming performance and structural performance and greatly increases the risk of failure. In this study, the hot press molding and three-point bending characteristics of Al-carbon fiber reinforced polypropylene (CF/PP) hybrid hat-shaped rail were studied experimentally. The X-ray computed tomography (X-ray CT) non-destructive test technology was used to investigate the formability of Al-CF/PP hybrid structure on the fiber angle variations, thickness variations, delamination and spring-back deformations, respectively. Moreover, the static three-point bending test was carried out to explore the bending characteristics of the hybrid structure. The results show that the fiber angles convert from orthogonal configurations to non-orthogonal configuration; both thickness increase and thickness reduction occur; delamination occurs significantly around the fillet transition areas; spring-back deformations are unapparent; significant plastic deformations can be found in the bending test and fracturing failures occur in both Al and CF/PP in the end of the test. -

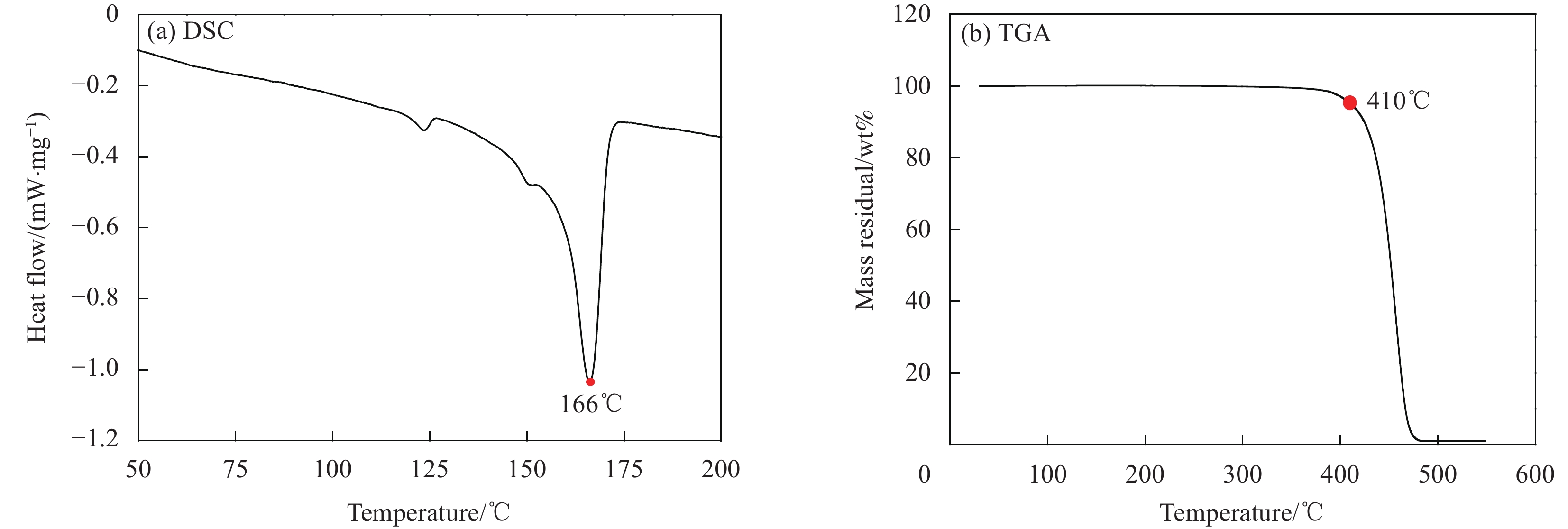

表 1 单层CF/PP预浸料描述

Table 1. Characteristics descriptions of single CF/PP prepreg

Material Thickness/

mmSurface density/

(g·m−2)Matrix Rein-

forcementCF/PP 0.3 198 PP CF 表 2 初始结构和成形结构中第4层和第5层CF/PP纤维夹角变化的对比

Table 2. Comparisons in fiber angle variations of the 4th and 5th CF/PP prepregs between initial and formed structures

Layer Status Left Middle Right Before stamping/(°) 90 90 90 4th After stamping/(°) 99.5 99 100 Increment rate/% 11 10 11 Before stamping/(°) 90 90 90 5th After stamping/(°) 100.5 100 99 Increment rate/% 12 11 10 表 3 Al-CF/PP混合梁沿轴向4个不同位置处的横截面切片中9个不同点处的厚度值对比

Table 3. Comparisons in thickness values of nine different points of the cross-sectional slice images at four different positions along the longitude direction of the Al-CF/PP hybrid rail

Point Length-

60 mmLength-

120 mmLength-

180 mmLength-

240 mmA 2.5 mm 2.5 mm 2.4 mm 2.4 mm B 3.6 mm 3.0 mm 3.2 mm 2.8 mm C 3.5 mm 3.3 mm 3.3 mm 3.0 mm D 2.5 mm 2.4 mm 2.5 mm 2.3 mm E 2.4 mm 2.1 mm 2.2 mm 2.1 mm F 2.5 mm 2.5 mm 2.5 mm 2.5 mm G 3.6 mm 3.3 mm 3.4 mm 3.0 mm H 2.9 mm 2.8 mm 2.6 mm 2.5 mm I 2.5 mm 2.4 mm 2.5 mm 2.3 mm 表 4 成形后的Al-CF/PP混合梁和模具中沿轴向方向4个不同位置处的横截面切片中4个不同圆角处的夹角值对比

Table 4. Comparisons in angles at four rounded corners of the cross-sectional slice images at four different positions along the longitude direction between the formed Al-CF/PP rail and the mold

Point Length-60 mm Length-120 mm Length-180 mm Length-240 mm Mold B 101° 101° 101° 101° 100° D 101° 101° 101° 101° 100° F 101° 101° 101° 101° 100° H 101° 101° 101° 101° 100° -

[1] 刘强, 马小康, 宗志坚. 斜纹机织碳纤维/环氧树脂复合材料性能及其在电动汽车轻量化设计中的应用[J]. 复合材料学报, 2011, 28(5):83-88.LIU Qiang, MA Xiaokang, MO Zhijian. Properties of twill-weave carbon fabric/epoxy composites and its application on light-weight design for electric vehicles[J]. Acta Mate-riae Compositae Sinica,2011,28(5):83-88(in Chinese). [2] 朱国华, 成艾国, 王振, 等. 电动车轻量化复合材料车身骨架多尺度分析[J]. 机械工程学报, 2016, 52(6):145-152. doi: 10.3901/JME.2016.06.145ZHU Guohua, CHENG Aiguo, WANG Zhen, et al. Analysis of lightweight composite body structure for electrical vehicle using the multiscale approach[J]. Journal of Mechanical Engineering,2016,52(6):145-152(in Chinese). doi: 10.3901/JME.2016.06.145 [3] 聂昕, 雷发桂, 朱国华, 等. 基于参数映射的玻纤增强PMH结构数值方法[J]. 机械工程学报, 2019, 55(6):129-137. doi: 10.3901/JME.2019.06.129NIE Xin, LEI Fagui, ZHU Guohua, et al. Numerical methods of glass fiber reinforced PMH structure based on parameter mapping[J]. Journal of Mechanical Engineering,2019,55(6):129-137(in Chinese). doi: 10.3901/JME.2019.06.129 [4] 许现哲, 刘通, 王文丽, 等. 碳纤维增强聚合物复合材料车身T型接头静态性能与失效机制[J]. 复合材料学报, 2019, 36(10):2227-2234.XU Xianzhe, LIU Tong, WANG Wenli, et al. Performance and failure mechanics of carbon fiber reinforced polymer composite T-joint in quasi-static loading for automobile structures[J]. Acta Materiae Compositae Sinica,2019,36(10):2227-2234(in Chinese). [5] YANG H, LEI H, LU G. Crashworthiness of circular fiber reinforced plastic tubes filled with composite skeletons/aluminum foam under drop-weight impact loading[J]. Thin-Walled Structures,2021,160:107380. doi: 10.1016/j.tws.2020.107380 [6] GOWID S, MAHDI E, RENNO J, et al. Experimental investigation of the crashworthiness performance of fiber and fiber steel-reinforced composites tubes[J]. Composite Structures,2020,251:112655. doi: 10.1016/j.compstruct.2020.112655 [7] COSTAS M, DÍAZ J, ROMERA LE, et al. Static and dynamic axial crushing analysis of car frontal impact hybrid absorbers[J]. International Journal of Impact Engineering,2013,62:166-181. doi: 10.1016/j.ijimpeng.2013.06.011 [8] 宋凯, 吴永强, 姚威, 等. 复合材料层合板加强薄壁铝梁吸能特性试验研究[J]. 汽车工程学报, 2016, 6(4):277-285.SONG Kai, WU Yongqiang, YAO Wei, et al. Experimental investigation on energy-absorbing characteristics of thin-walled aluminum beam strengthened by CFRP plates[J]. Chinese Journal of Automotive Engineering,2016,6(4):277-285(in Chinese). [9] 王雪琴, 张震东, 马大为, 等. 碳纤维增强环氧树脂复合材料圆管多胞填充结构吸能特性的准静态压缩试验研究[J]. 复合材料学报, 2021, 38(9):2894-2903.WANG Xueqin, ZHANG Zhendong, MA Dawei, et al. Quasi-static compression experimental study on energy absorption characteristics of multicellular structures filled with carbon fiber reinforced epoxy composite tubes[J]. Acta Materiae Compositae Sinica,2021,38(9):2894-2903(in Chinese). [10] 沈勇, 柯俊, 吴震宇. 不同编织角碳纤维增强聚合物复合材料-Al方管的吸能特性[J]. 复合材料学报, 2020, 37(3):591-600.SHEN Yong, KE Jun, WU Zhenyu. Energy-absorbing characteristics of carbon fiber reinforced polymer composite-Al square tubes with different braiding angles[J]. Acta Materiae Compositae Sinica,2020,37(3):591-600(in Chinese). [11] 孙佳睿, 马其华, 蔡明, 等. 横向压溃载荷下碳纤维缠绕薄壁钢管的失效分析[J]. 玻璃钢/复合材料, 2019(9):5-13.SUN Jiarui, MA Qihua, CAI Ming, et al. Failure analysis of carbon fiber winded thin-walled steel tube under transverse crushing load[J]. Fiber Reinforced Plastics/Compo-sites,2019(9):5-13(in Chinese). [12] 万云, 童谷生. 金属与复材混杂层板受高速冲击时的吸能分析[J]. 兵器材料科学与工程, 2016, 39(1):22-26.WAN Yun, TONG Gusheng. Analysis of absorption energy for hybridized laminates of metal and composite under high velocity impact[J]. Ordnance Material Science and Engineering,2016,39(1):22-26(in Chinese). [13] COSTAS M, MORIN D, LANGSETH M, et al. Axial crushing of aluminum extrusions filled with PET foam and GFRP. An experimental investigation[J]. Thin-Walled Structures,2016,99:45-57. doi: 10.1016/j.tws.2015.11.003 [14] SHIRAVAND A, ASGARI M. Hybrid metal-composite conical tubes for energy absorption: Theoretical development and numerical simulation[J]. Thin-Walled Structures,2019,145:106442. doi: 10.1016/j.tws.2019.106442 [15] COSTAS M, MORIN D, LANGSETH M, et al. Static crushing of aluminium tubes filled with PET foam and a GFRP skeleton. Numerical modelling and multiobjective optimization[J]. International Journal of Mechanical Sciences,2017,131:205-217. [16] WANG Z, JIN X, LI Q, et al. On crashworthiness design of hybrid metal-composite structures[J]. International Jour-nal of Mechanical Sciences,2020,171:105380. doi: 10.1016/j.ijmecsci.2019.105380 [17] CUI Z, LIU Q, SUN Y, et al. On crushing responses of filament winding CFRP/aluminum and GFRP/CFRP/aluminum hybrid structures[J]. Composites Part B: Engineering,2020,200:108341. doi: 10.1016/j.compositesb.2020.108341 [18] LIU Q, MO Z, WU Y, et al. Crush response of CFRP square tube filled with aluminum honeycomb[J]. Composites Part B: Engineering,2016,98:406-414. doi: 10.1016/j.compositesb.2016.05.048 [19] HUANG Z, ZHANG X. Crashworthiness and optimization design of quadruple-cell aluminum/CFRP hybrid tubes under transverse bending[J]. Composite Structures,2020,235:111753. doi: 10.1016/j.compstruct.2019.111753 [20] ZHU G, LIAO J, SUN G, et al. Comparative study on metal/CFRP hybrid structures under static and dynamic loading[J]. International Journal of Impact Engineering,2020,141:103509. doi: 10.1016/j.ijimpeng.2020.103509 [21] SUN G, WANG Z, HONG J, et al. Experimental investigation of the quasi-static axial crushing behavior of filament-wound CFRP and aluminum/CFRP hybrid tubes[J]. Composite Structures,2018,194:208-225. doi: 10.1016/j.compstruct.2018.02.005 [22] 李哲夫, 谈源, 张俭, 等. 热模压预成型工艺参数对复合材料帽型长桁质量的影响[J]. 复合材料学报, 2021, 38(10):3277-3287.LI Zhefu, TAN Yuan, ZHANG Jian, et al. Effects of hot stamp forming process parameters on quality of the hat-shaped structure preforms of composites[J]. Acta Mate-riae Compositae Sinica,2021,38(10):3277-3287(in Chinese). [23] 彭雄奇, 堵同亮, 郭早阳. 机织复合材料各向异性超弹性本构模型[J]. 机械工程学报, 2012, 48(20): 45-50.PENG Xiongqi, DU Tongliang, GUO Zaoyang. Anisotropic hyperelastic constitutive model for woven composite fabrics under large deformation[J]. Journal of Mechanical Engineering, 2012, 48(20): 45-50(in Chinese). [24] 张琦, 高强, 赵升吨. 碳纤维复合材料板热冲压成形试验研究[J]. 机械工程学报, 2012, 48(18): 72-77.ZHANG Qi, GAO Qiang, ZHAO Shengdun. Thermostamping experimental study on carbon fiber composite sheet[J]. Journal of Mechanical Engineering, 2012, 48(18): 72-77(in Chinese). [25] GUO Y, ZHAI C, LI F, et al. Formability, defects and strengthening effect of steel/CFRP structures fabricated by using the differential temperature forming process[J]. Composite Structures,2019,216:32-38. doi: 10.1016/j.compstruct.2019.01.106 [26] ATRIAN A, FERESHTEH-SANIEE F. Deep drawing process of steel/brass laminated sheets[J]. Composites Part B: Engineering,2013,47:75-81. doi: 10.1016/j.compositesb.2012.10.023 [27] 李磊, 郎利辉, HAMZA Blala, 等. 编织纤维金属层板成形性能及充液成形工艺分析[J]. 中南大学学报(自然科学版), 2020, 51(9):2422-2429.LI Lei, LANG Lihui, HAMZA Blala, et al. Analysis of forming properties and hydroforming process of braided fiber metal laminates[J]. Journal of Central South University (Science and Technology),2020,51(9):2422-2429(in Chinese). [28] DING Z, WANG H, LUO J, et al. A review on forming technologies of fibre metal laminates[J]. International Journal of Lightweight Materials and Manufacture, 2021(4): 110-126. [29] HEGGEMANN T, HOMBERG W. Deep drawing of fiber metal laminates for automotive lightweight structures[J]. Composite Structures,2019,216:53-57. doi: 10.1016/j.compstruct.2019.02.047 [30] 王健, 郑学丰, 付昌云, 等. 碳纤维/环氧树脂复合材料-铝合金层合板深拉成型特性[J]. 复合材料学报, 2019, 36(12):2786-2794.WANG Jian, ZHENG Xuefeng, FU Changyun, et al. Deep drawing characteristics of carbon fiber/epoxy resin composite-aluminum alloy laminates[J]. Acta Materiae Compositae Sinica,2019,36(12):2786-2794(in Chinese). [31] NARESH K, KHAN K A, UMER R, et al. The use of X-ray computed tomography for design and process modeling of aerospace composites: A review[J]. Materials & Design,2020,190:108553. [32] CAO J, AKKERMAN R, BOISSE P, et al. Characterization of mechanical behavior of woven fabrics: Experimental methods and benchmark results[J]. Composites Part A: Applied Science and Manufacturing,2008,39(6):1037-1053. doi: 10.1016/j.compositesa.2008.02.016 -

下载:

下载: