Research and discussion on processing technology of carbon fiber reinforced carbon matrix composites

-

摘要: 碳纤维增强碳基复合材料(C/C)具有热膨胀系数低、耐腐蚀、抗热冲击、耐磨损等特点,在武器装备、航空航天、汽车制造等领域得到日益广泛的应用。传统加工技术难以实现对C/C复合材料的高精度加工。激光加工技术对加工对象的尺寸、材质和形状要求低,易与其他先进加工技术相结合,具有其他加工方法所不具备的优势。本论文主要对C/C复合材料的制备、应用和加工方式进行了论述,详细阐述了激光加工C/C复合材料的原理机制和工艺特点,以及不同应用场合下加工工艺的选择策略。通过传统加工方法和特种加工方法的对比,概述了加工C/C复合材料所面临的问题和挑战,提出了C/C复合材料激光加工与其他先进制造技术相结合的发展趋势。Abstract: Carbon fiber reinforced carbon matrix composites (C/C) have the characteristics of low thermal expansion coefficient, corrosion resistance, thermal shock resistance, and wear resistance, which are widely used in military equipment, aerospace, automobile manufacturing and other fields. But it is difficult to achieve high precision machining of C/C composites by traditional processing technology. Laser processing technology has low requirements for the size, material and shape. It is easy to combine with other advanced processing technologies and has the characteristics that other methods do not have. This paper mainly reviews the preparation, application and processing methods of C/C composites, elaborates the mechanism and process characteristics of laser processing of C/C composites and the selection strategy of processing technology in different applications. Through the comparison of traditional processing methods and special processing methods, the problems and challenges faced by the processing of C/C composites are summarized, and the development trend of the combination of laser processing of C/C composites and other advanced manufacturing technologies is proposed.

-

复合材料是运用先进的材料制备技术将不同性质的材料组分优化组合而成的新型材料,各组分的互相作用使其拥有优异的综合性能。随着航空航天事业的不断发展,对材料的要求也越来越高,普通的合金材料已不能满足日益严苛的工况要求。碳纤维增强碳基复合材料(C/C)[1]属于高温结构材料,且强度随着温度的升高而增加。具有高尺寸稳定性、化学惰性、高导热系数[2]、高导电性、稳定的摩擦因数、抗核辐射、高温下的高模量等优点。C/C复合材料的基体相为碳,增强体为碳纤维,二者在保持基本特性一致的同时通过界面作用叠加互补,产生了优于各单个组分材料的新性能。可通过改变C/C复合材料的组分比例、纤维取向、结构、制备工艺等调控其性能,满足不同的工况要求。

但是C/C复合材料属于一种典型的难加工材料,传统加工技术难以对其实现高精度加工。例如,切削加工过程中刀具磨损量大,且刀具易撕扯碳纤维使其拔出造成分层,加工精度低;电火花加工不产生切削力的影响,但因存在放电间隙,需反复调整电极尺寸和电参数,且加工前需要通过铣削粗加工去除大部分材料,使得加工效率大幅降低;高压水射流加工过程需要加入大量的水沙,易造成C/C复合材料内部应力集中,加工区域变形明显,对生产环境污染大。在使用激光加工不同形状的C/C复合材料时,不需要更换“刀具”,只需改变激光器的输出参数。相比于切削、电火花加工和高压水射流等加工方式,激光加工C/C复合材料的精度高、质量稳定。加工过程中无刀具磨损,无切削力作用,并且可实现局部区域加工,对非激光辐照区域影响较小,因此激光加工C/C复合材料的优势不言而喻。本文通过分析C/C复合材料激光加工研究现状,指出激光加工复合材料的发展趋势,旨在为我国新型航空航天C/C复合材料构件的研发和精密加工提供理论依据和技术参考。

1. C/C复合材料制备方法

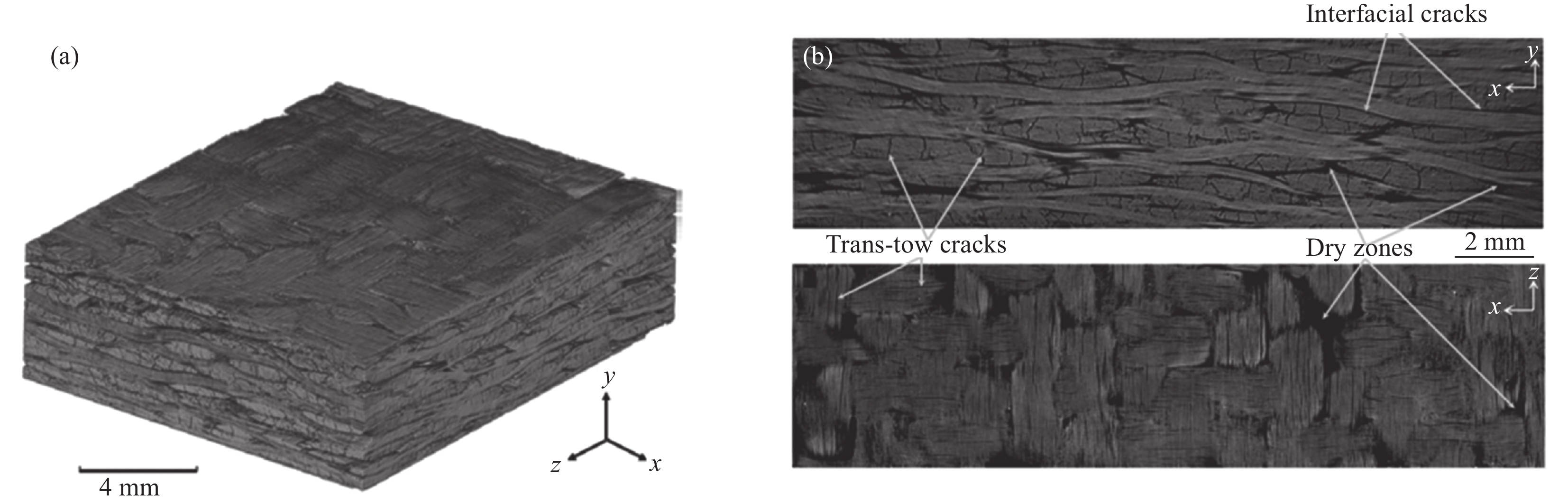

C/C复合材料是碳基复合材料的典型代表,以碳为基体相,碳纤维为增强体,碳的种类主要有纤维碳、树脂碳、沉积碳及热解碳[3],其形貌如图1所示。C/C复合材料的制备方法较复杂且成本较高,决定C/C复合材料性能的主要因素包括制备工艺类型、高温处理温度、预制体结构、气孔率、碳基体和碳纤维的性能,其制备过程主要包括两个步骤,即碳纤维增强体的编织成型[4]以及致密化过程[5]。

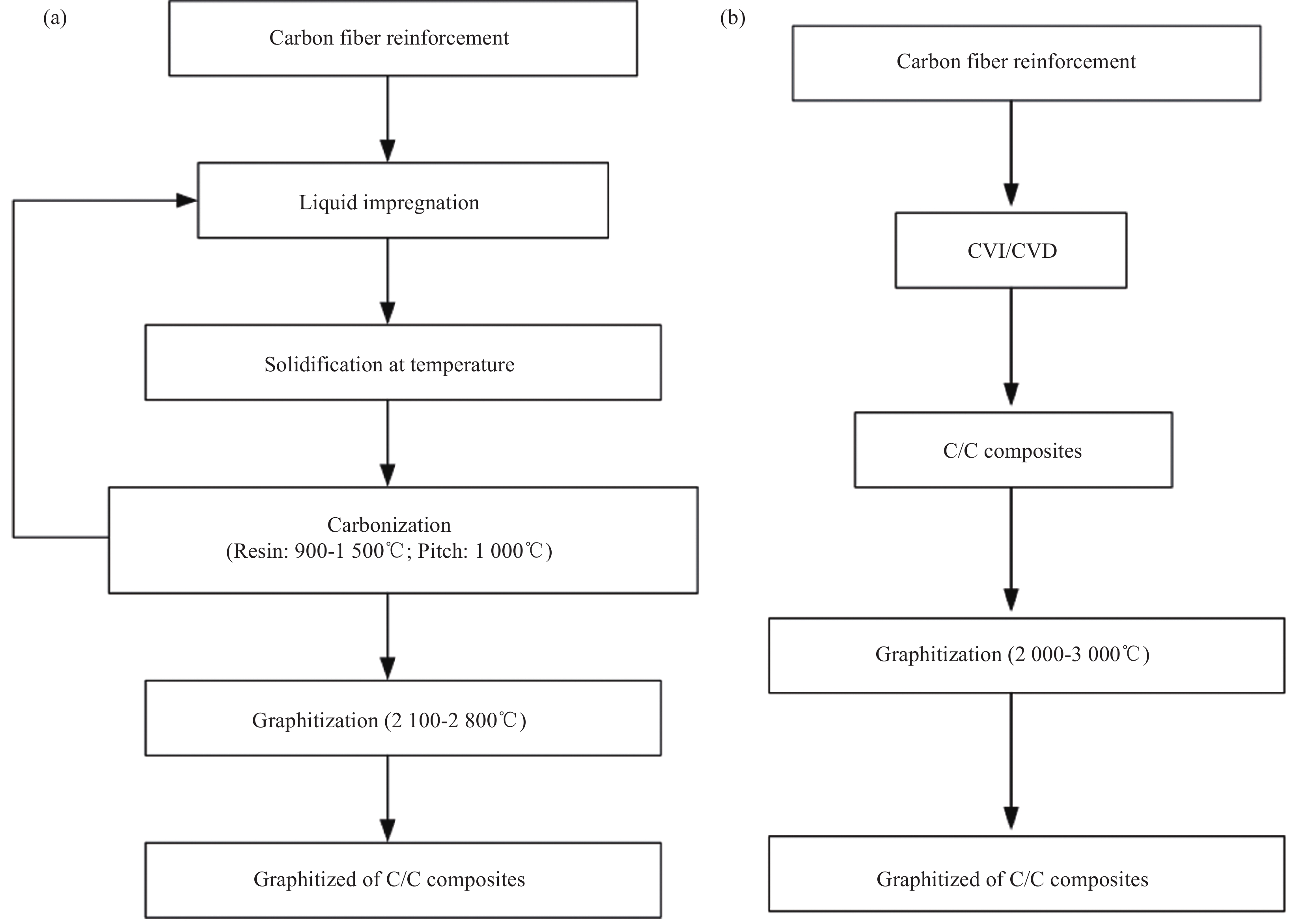

目前,制备碳基体的主要方法是通过对碳纤维增强材料的结焦聚合物基体碳化,随后高温处理;或者在碳纤维预制体气孔中气相沉积碳氢化合物,并热分解生成热解碳,再高温处理。在制备碳基体的过程中,聚合物热解生成的碳基质容易产生气孔、裂纹[8],导致材料不密实[9]。最常用的致密化方法是液相浸渍-碳化法、化学气相沉积法(CVD)以及化学气相渗透法(CVI)[10-11],如图2所示。

液相浸渍-碳化法适用于制备长纤维复合材料,张哲等[12]发现碳化后预制体表面的大尺寸孔隙明显增多,而当树脂溶液浓度增大,浸渍后材料内大尺寸孔隙有所减少,且预制体表面更加密实,其密度随浸渍固化碳化周期的增加而增大。液相浸渍-碳化法[13]获得的C/C复合材料纤维排列定向、孔隙率较低、基体较密实,但如果浸渍时基体与增强体的热膨胀系数相差较大,会由于收缩率的不同而产生裂纹,影响材料性能。

CVD法适用于C/C复合材料的大批量生产,是利用气态物质在固体上产生化学反应生成固态沉积的工艺。可以在常压或真空条件下进行,设备简单、操作过程易于控制、灵活性强,材料的化学成分可随气相的组成不同而改变。但CVD法的缺点是沉积温度较高,一般在900~1200℃左右,且沉积物是柱状结构,不易弯曲,反应气体具有一定的毒性和腐蚀性。

CVI法[14]通过气固反应生成基体,使基体与纤维紧密结合,对纤维损伤小,预制体的各部分受热均匀且承受压力相对较低,一次可同时沉积多个部件,广泛应用于C/C复合材料的成型加工。但是,CVI法致密化生成碳基体的时间较长,若提高沉积速率就需提高沉积温度,这样又会造成间隙孔外口封闭,形成较高的孔隙率,并且在制备过程中需要尾气处理装置,成本相对较高。

C/C复合材料制备[15]过程中纤维排列方式多种多样,从一维到多维,可根据此特性来定制产品性能:一维纤维增强体可在单一方向上获得很高的抗拉强度;二维纤维增强体具有较低的界面结合强度,会影响层间剪切性能,使材料产生各向异性;三维纤维增强体相比于低维度的C/C复合材料具有更好的结构完整性。

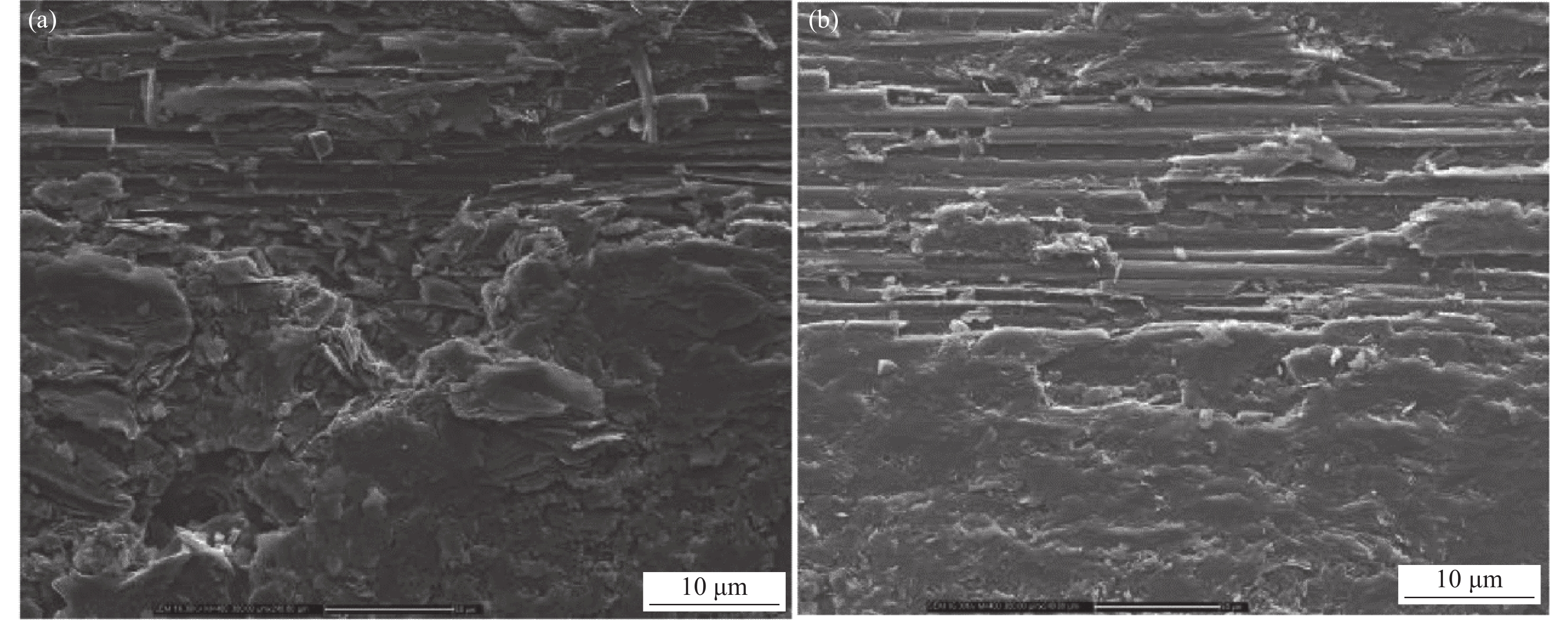

为了研究预制体形态和基体碳的微观结构对C/C复合材料热物理性能的影响,Luo等[16]制备了五种不同的C/C复合材料,探讨了C/C复合材料的热膨胀和传热机制。预制体1#、4#和5#由聚丙烯腈基碳纤维层压 (每层方向为90°) 再逐步针刺[17]制成,预制体2#通过使用短切的聚丙烯腈基碳纤维热压制成,预制体3#通过铺层碳布制成。五种制备方法得到的基体碳和预制体结构不同导致C/C复合材料的热物理性能也存在差异,其微观结构如图3所示。

2. C/C复合材料的应用

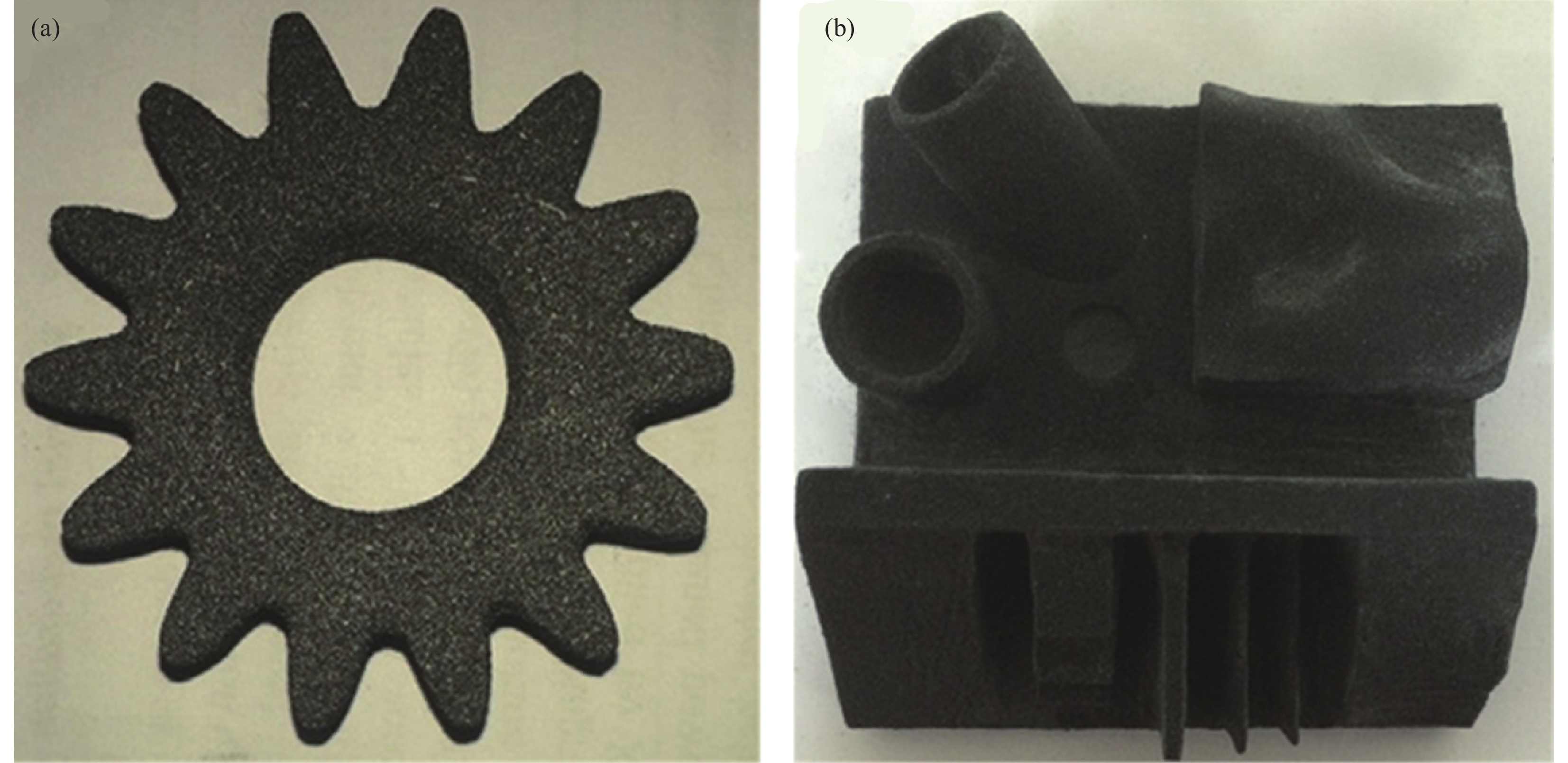

C/C复合材料被广泛应用于航空航天[18]密封件和制动装置、汽车刹车盘、高压容器、生物医疗设备。生物学家使用C/C复合材料研制了人工呼吸器、人工髋关节[19]、假肢和吸附碳布块[20]。复合材料吸附碳布块具有止痛、吸附毒物、加速伤口愈合、无过敏反应等优点。使用C/C复合材料制成的气瓶和容器,与普通钢容器相比质量减轻50%~67%,且耐腐蚀性和防爆性都有所提高。碳纳米管强韧化C/C复合材料[21]可用于制作建筑加固装置,其中碳纳米管[22]可以完全和其他材料融为一体,形成新型的复杂体系,既保留了自身微结构又增添了新的功能,可以很好地与现有结构结合,C/C复合材料制成的零件如图4所示。

作为柔性高速动态密封装置的指尖密封[24],在航空发动机、燃气轮机等重大设备的高速密封部位应用广泛。张延超等[25]在传统金属基指尖密封研制的基础上,将C/C复合材料、石墨烯、陶瓷材料、高分子材料等应用于指尖密封,开展了新材料指尖密封、指尖密封摩擦配副分析、设计及试验研究,探索提升指尖密封性能及服役寿命新途径。在航空发动机涡轮前后气路封严工况条件下,C/C复合材料的应用可有效降低泄露和磨损[26]。其制造成本只有刷式密封的40%~50%,并且在同样条件下与4级篦齿密封的泄漏量相比减少了20%~70%。C/C复合材料的密度一般在1.40~2.00 g·cm−3,与金属材料相比,C/C复合材料应用在航空航天结构件中可以减重15%~30%,能够有效地降低结构质量。C/C复合材料飞机制动装置能够完成500~5000次的起降,起降次数远超传统的金属材质刹车盘,C/C复合材料航空构件如图5所示。

3. C/C复合材料的加工工艺

与常规均质材料不同,C/C复合材料结构复杂,且硬度高、脆性大,属于典型的难加工材料。若加工方式选取不当,可能对复合材料造成严重损伤,导致工件尺寸精度超差和材料浪费。随着我国加工制造技术的飞速发展以及复合材料的广泛应用,针对C/C复合材料加工技术的探讨,对后续航空航天领域的产品结构设计、工艺方法选择及工艺装备研发都有重要意义。目前,国内外学者在C/C复合材料加工技术方面进行了大量的理论和实验研究,并取得了一定的成果。

3.1 机械加工C/C复合材料

3.1.1 车削加工C/C复合材料

车削加工C/C复合材料是最传统且最为直接的一种加工方法,C/C复合材料具有各向异性的特点,纤维取向和基体组成都对加工效果有较大的影响。另外,材料的高耐磨性[27]和硬度会加剧刀具磨损,因此在切削过程中会遇到一系列在加工均质材料时未遇到的问题。Ferreira等[28]使用不同材质刀具对C/C复合材料进行了车削实验,探讨了不同切削速度和进给速度对刀具磨损的影响。研究结果表明,切削速度对刀具磨损率的影响最大,刀具后刀面的磨损率随切削长度的增加而增大。表面制备有涂层的硬质合金刀具耐磨性更好,涂层可有效保护硬质合金刀具免受C/C复合材料在加工过程中对刀具的磨损。蒋建纯等[29]通过观察C/C复合材料在不同切削条件下切屑的断口形貌以及前后刀面和刀尖的磨损情况,分析了切削过程中刀具的磨损机制。研究结果表明,适当提高切削速度可有效提高加工质量,切削速度越低,粗糙度越高,C/C复合材料纤维拔出越多,亚表面损伤越严重。为减少车削过程中刀具对材料的损伤,研究人员将超声振动与车削结合[30],实验证明超声辅助车削加工的材料表面纤维连续性更好,材料表面损伤较少,加工质量明显优于普通车削,车削加工形貌如图6所示。

3.1.2 钻削加工C/C复合材料

C/C复合材料结构件成型后,通常需要再制孔来满足连接要求,加工中钻削轴向力是影响C/C复合材料钻孔质量的主要因素,当钻削力过大,切削刃在接触到复合材料底部时,底层材料在较大钻削力的推挤下易造成碳纤维撕扯[32],钻孔出口处会出现明显的撕裂和边缘塌陷[33],如图7所示。为此,蔺小军等[34]使用不同直径及类型的钻头,研究了钻削参数对钻削轴向力的影响。实验结果表明,钻削轴向力会随钻头转速和进给速度的增加而增大,在钻削C/C复合材料时应选择横刃长度短或横刃中负前角切削段短的钻头。为探究不同涂层钻头对钻孔质量和刀具磨损的影响,鞠伟华等[31]分别使用金刚石涂层整体硬质合金钻头和多元涂层整体硬质合金钻头钻削C/C复合材料。金刚石涂层整体硬质合金钻头钻孔后,刀具出现涂层剥落和前刀面磨损。多元涂层整体硬质合金钻头钻孔后,刀具出现后刀面磨损,涂层脱落和基体磨损严重,已无法继续正常使用。

3.1.3 磨削加工C/C复合材料

C/C复合材料构件大多数是通过直接成型制造完成的,但为了得到更好的表面质量,通常还需要进行磨削等后续精加工。磨削主要是针对零件的表面加工,也是C/C复合材料类零件获得高尺寸精度最常用的工艺。但磨削过程中碳纤维会受到砂轮剪切力的影响发生断裂和脱落,周井文等[35]研究了不同磨削参数对碳纤维增强复合材料表面加工形貌的影响,磨削加工后材料表面无明显凹坑,呈现出有序排列的竖脊状形貌。研究发现,磨削加工质量受纤维排列方向及砂轮进给速度的影响,研究人员对纤维铺层内部进行对比后发现,45°纤维铺层断口最明显。磨削参数对纤维区域的表面粗糙度及纤维断裂程度影响较大[36],磨削的深度和进给速度增大的同时,表面粗糙度也随之增加。张立峰等[37]还发现碳纤维的排列方向对磨削力有较大影响,法向磨削力和切向磨削力会随磨削深度的增大而升高。沿纤维纵向磨削时产生的磨削力比横向大,沿纤维法向磨削时产生的磨削力最大。磨削加工C/C复合材料过程中,砂轮的磨粒先接触到材料表层基体,随着时间的变化表层基体会发生脱落,导致纤维大量暴露和断裂,砂轮反复与工件摩擦[38],会产生较高的磨削温度,导致磨削表面损伤严重,表面应力增大,且加工效率较低。

3.2 线切割加工C/C复合材料

线切割C/C复合材料属于非接触加工,对材料的厚度和硬度要求不高,可以加工各种轮廓形状复杂和精密细小的零件,加工精度相较于普通机械加工高。但由于C/C复合材料导电率低,线切割加工C/C复合材料效率较低,在加工厚度较大的零件时易出现折丝现象,由于热量的集中,材料表面会生成大量熔融颗粒,如图8(a)所示。砂线切割[31]利用砂线往复运动使砂线与工件产生切削力达到加工的目的,适用于切割脆性材料。但是对C/C复合材料的加工效果并不理想,切割面平行于编织方向的位置出现层状脆性断裂,切割面垂直于编织方向的位置纤维裸露现象严重,如图8(b)所示。在加工尺寸大的零件时需采用粗粒度砂线,会致使表面质量更加恶化。砂线切割多用于C/C复合材料的粗加工,与线切割相比砂线切割加工效率高,但表面质量较差,若对C/C复合材料零件精度要求较高时,后续还需要进行磨削处理。

3.3 水射流加工C/C复合材料

磨料高压水射流属于特种加工技术,适合微小零件的切割和精密钻孔。为提高C/C复合材料的制孔精度和制孔质量,蔡志刚等[39]利用磨料水射流钻孔技术加工C/C复合材料。研究结果表明,材料的切割深度随射流压力的增大而增加,但射流压力较高时材料层间剪切力过大会造成材料表面分层。为进一步解决加工C/C复合材料过程中出现表面分层问题,Yin等[40]先对C/C复合材料进行预加工,然后利用磨料水射流进行扩孔,通过模拟仿真ANSYS软件建立了磨料水射流加工C/C复合材料的有限元模型。采用合理失效准则,对C/C复合材料冲击制孔和切割制孔过程进行了数值模拟,分析了C/C复合材料在水射流作用下的破坏过程和加工中应力、应变的变化趋势。研究结果表明,水射流切割制孔比水射流冲击制孔造成的材料表面分层现象少,但材料表面分层问题并没有完全解决。朱超凡等[41]进一步研究了C/C复合材料的水射流切割制孔机制,加工效果如图9所示,从图中可以观察到水射流加工导致的材料内部分层严重,加工效果并不理想。

3.4 电火花加工C/C复合材料

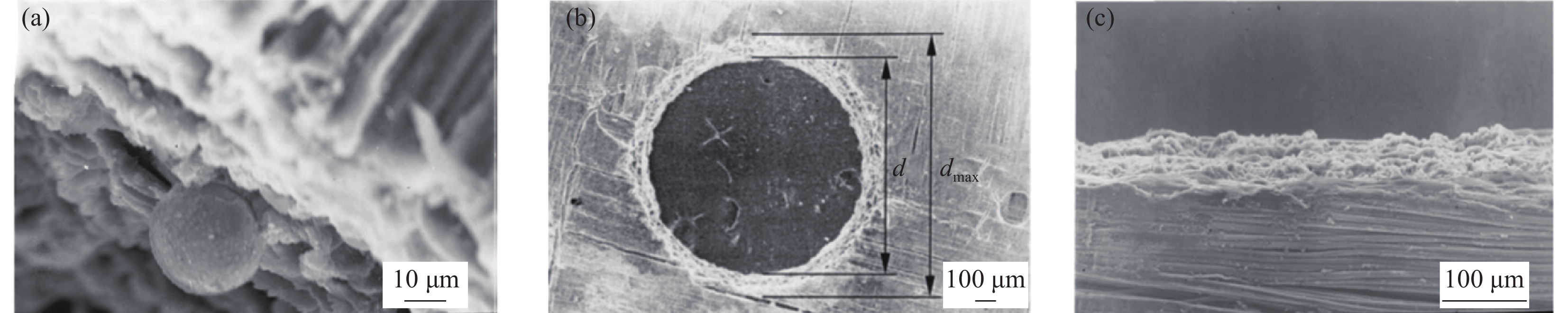

电火花加工同样属于非接触式的加工工艺,可加工各种硬度的材料。George等[42]在响应面法(RSM)的基础上通过数学建模拟合,设计了C/C复合材料电火花加工的模拟实验,对所有拟合模型都进行了方差分析并绘制了模型响应面。研究结果表明,影响C/C复合材料电火花加工质量最重要的因素是脉冲电流,其次是间隙电压,最后是脉冲导通时间。为进一步探究电火花与碳纤维增强复合材料的作用机制,Guu等[43]从加工参数角度研究了电火花加工的特性,图10(a)为电火花加工碳纤维复合材料微观形貌图,从图中可以观察到许多球状结构,原因是电火花放电时表面材料聚集形成气态微颗粒,随后微颗粒从气态重新凝固成固态并形成球体。电火花加工碳纤维增强复合材料的过程中,放电火花产生极高的温度会迅速气化电介质流体,在电极周围产生压力脉冲。冲击压力和放电产生的高热应力在加工表面引起的分层现象如图10(b)所示。随着电火花脉冲电流增大,C/C复合材料中温度梯度越高,生成的重铸层越厚,如图10(c)所示。

3.5 激光加工C/C复合材料

材料的二次加工是功能化构件制备过程中的重要环节,是走向工程应用的关键技术。由于C/C复合材料结构的特殊性,材料成型后构件的尺寸精度往往达不到使用要求,所以根据不同应用场合对C/C复合材料的加工工艺选择尤为重要。车削加工多用于加工C/C复合材料零件的回转表面,加工过程对刀具、夹具以及加工路线都有较高要求。目前多用高速钢车刀和硬质合金车刀车削C/C复合材料。磨削属于表面精加工,对C/C复合材料表面粗糙度要求较高时,通常采用磨削处理。当加工厚度尺寸较大的零件,可选择线切割或高压水射流加工。

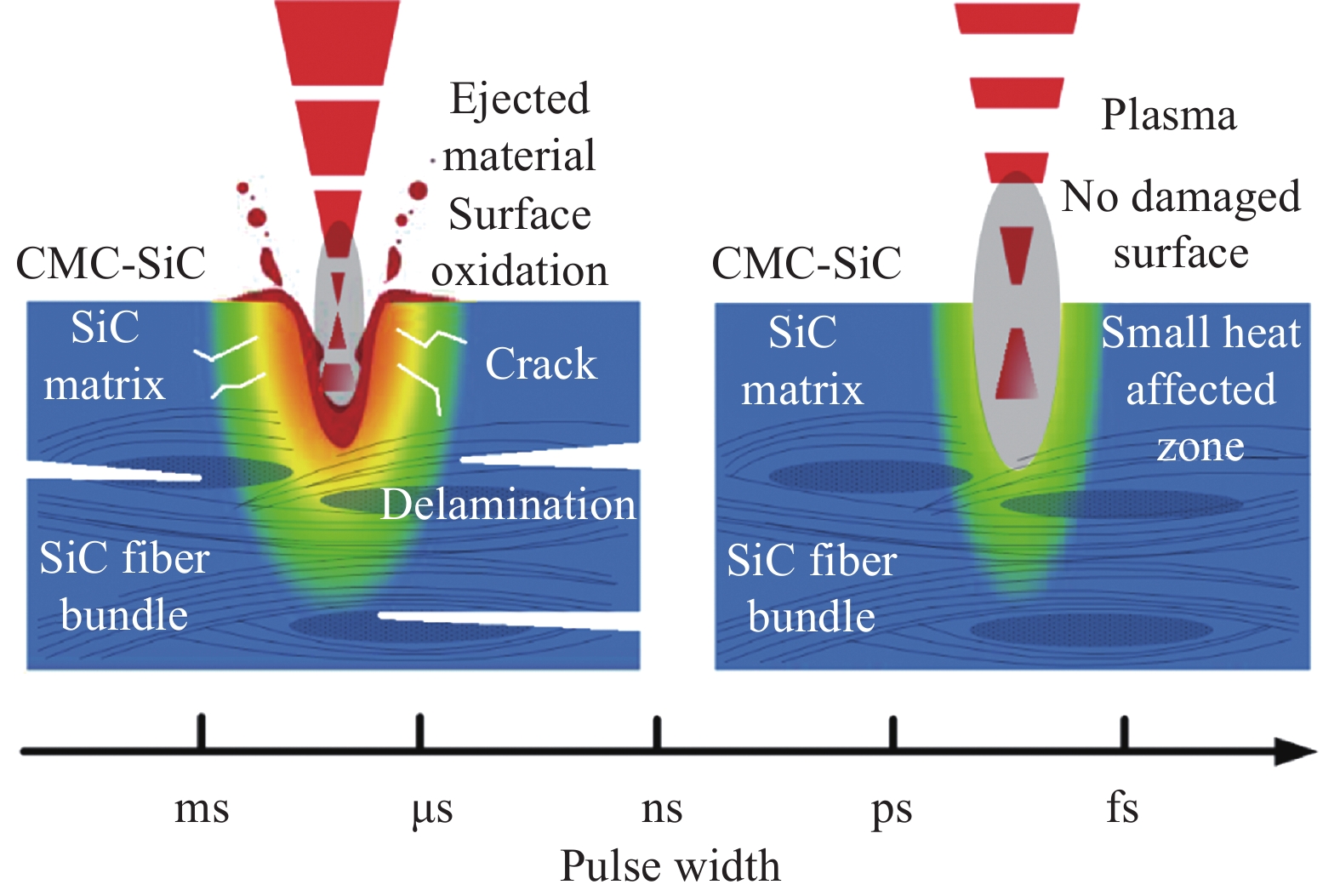

若需要进行C/C复合材料的微纳结构制备且加工精度要求较高,例如核包壳管封装微孔、航空发动机涡轮叶片的气膜冷却孔、飞行器构件尖锐前缘,此时则应该使用激光进行精密加工。激光加工是一种非接触式新型加工方法,适用于各种难加工材料的高精度加工。脉冲宽度[44]是影响激光束与C/C复合材料相互作用效果的重要因素,不同脉冲宽度激光对纤维增强复合材料的作用机制如图11所示。连续激光和大功率长脉冲激光主要靠热量积累使材料熔化和气化,实现材料去除。纳秒脉冲激光的热作用较小,在C/C复合材料的烧蚀过程中光热和光化学作用同时起效。皮秒、飞秒脉冲激光具有极短的脉宽和极高的峰值功率,在对C/C复合材料表面刻蚀过程中几乎不产生热影响,可以很大程度上减轻C/C复合材料的亚表面损伤,在提高材料去除率和能量利用率的同时也改善了成品的质量。

3.5.1 激光对C/C复合材料的作用机制

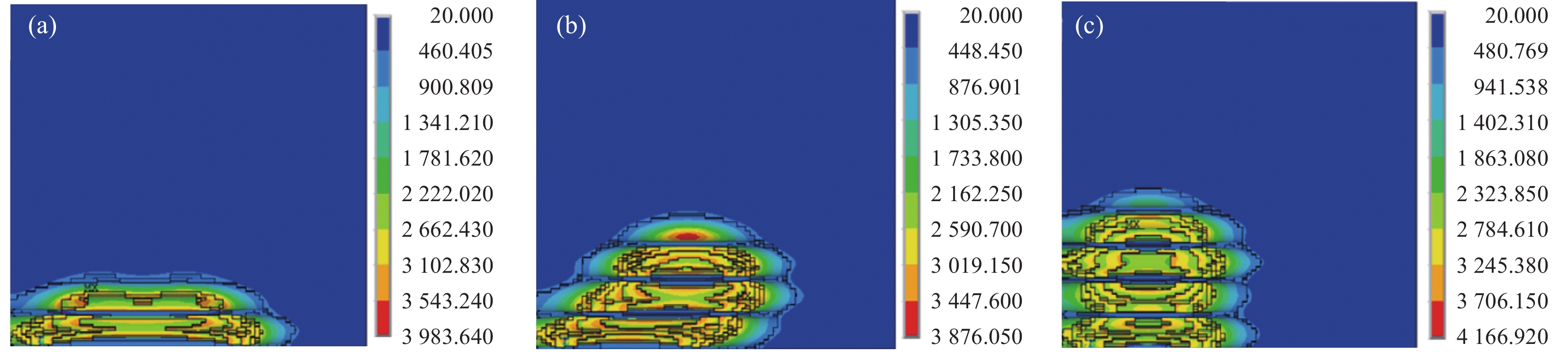

在激光与C/C复合材料的相互作用机制研究方面,为了分析激光加工过程中瞬态热行为,Xu等[45]基于有限元软件建立了激光烧蚀碳纤维增强复合材料的非均匀模型,模拟了脉冲激光烧蚀碳纤维的过程,研究了激光扫描方向对材料热影响区的影响,图12是激光扫描方向与纤维方向呈不同夹角的仿真结果,从图中可以观察到随着激光扫描方向与材料内部纤维铺设方向夹角的增大,产生的热影响区也随之增大,同时纤维的断裂长度先增大后减少。

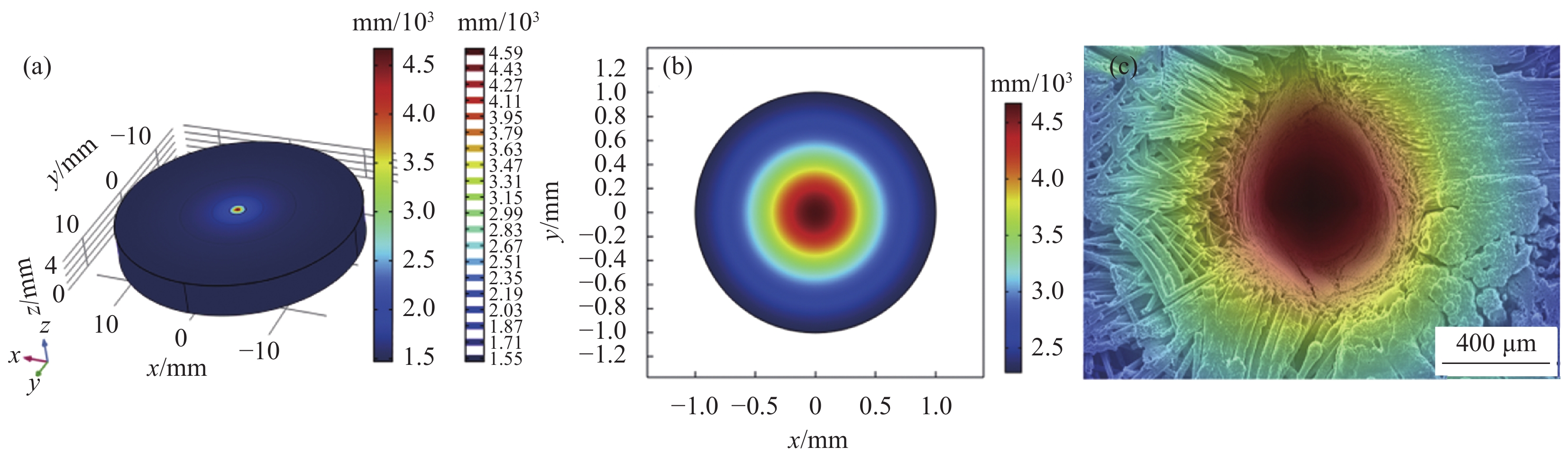

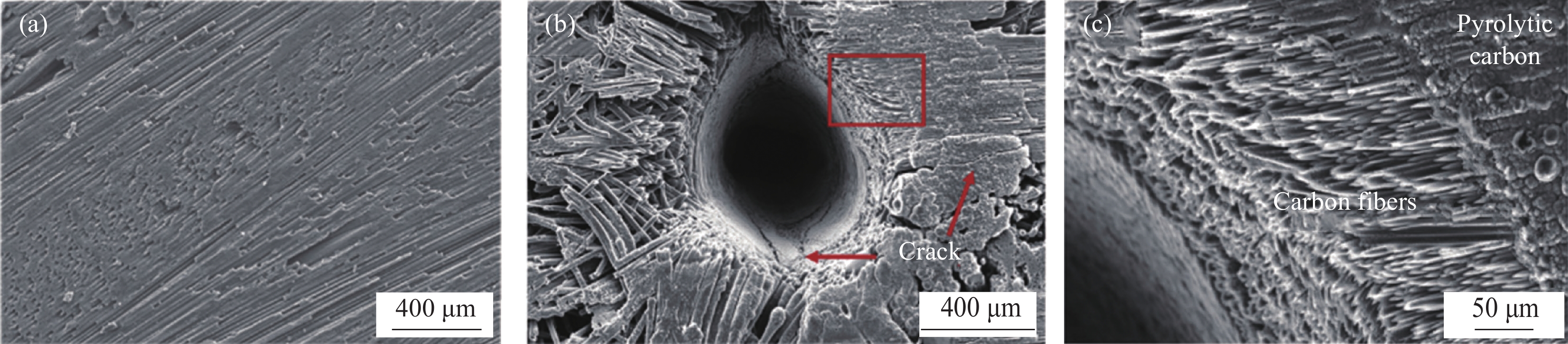

在C/C复合材料的激光加工缺陷产生机制分析方面,Geng等[46]利用有限元仿真软件建立几何模型,分析了激光烧蚀C/C复合材料表面温度的变化。从图13(c)中可以观察到烧蚀孔的内部和外部有明显的微裂纹,仿真结果还表明激光光斑中心区域的温度极高,C/C复合材料裂纹的产生规律与热应力的释放有关,激光烧蚀过程的快速加热和冷却会对材料产生明显的温度梯度,材料中碳纤维的烧蚀速率低于碳基体的烧蚀速率。

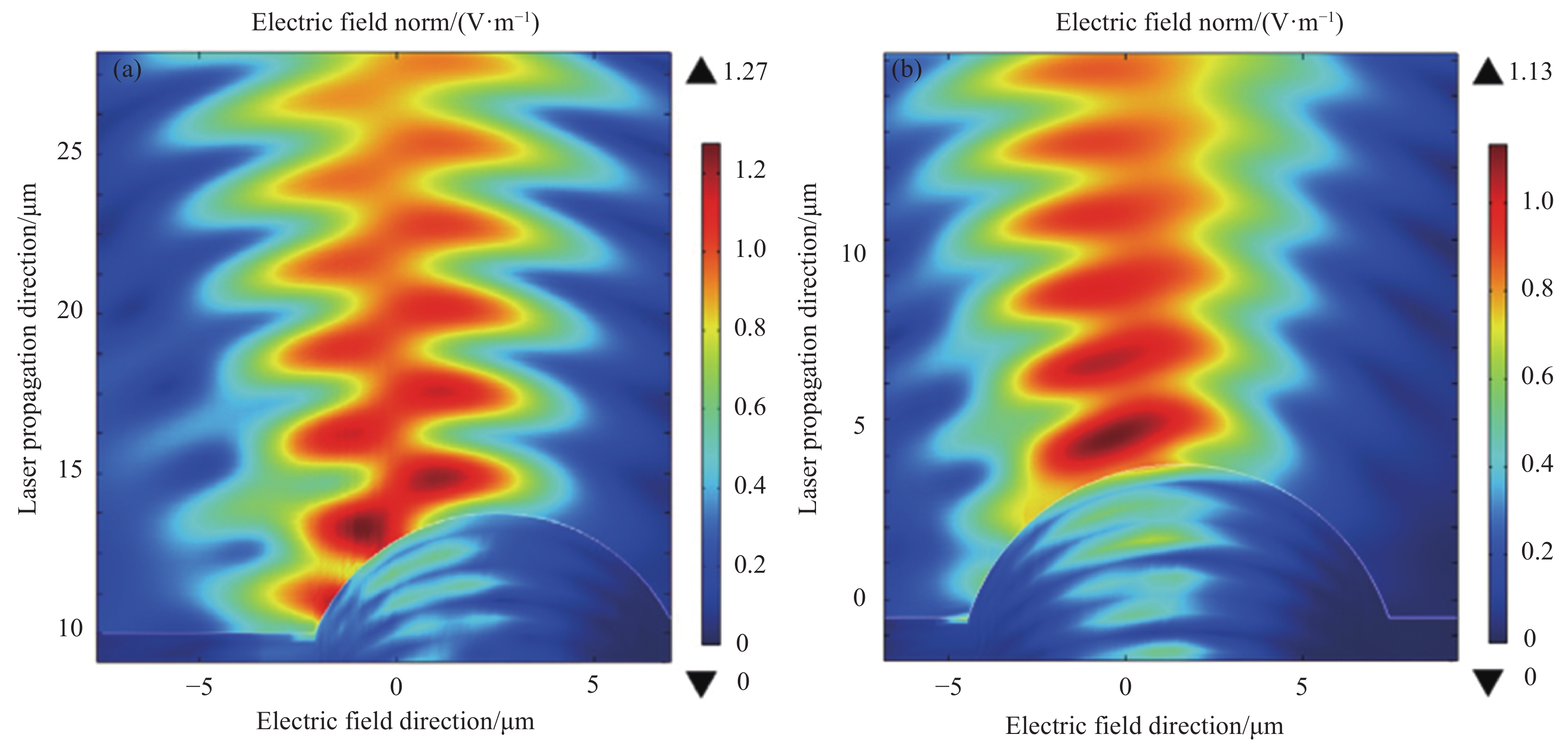

Zhai等[47]通过有限元软件中的波动光学模块来模拟激光加工过程中材料表面的电磁场分布,研究了碳纤维增强复合材料表面粗糙度[48]对烧蚀效果的影响。研究结果表明,当激光辐照在材料表面的不同微凸面上,由于微凸面的衍射和反射作用[49],最终导致表面材料无法均匀去除,如图14所示。研究人员利用仿真计算软件从热学、力学、光学等角度对激光加工碳纤维增强复合材料的作用机制进行分析,但是由于C/C复合材料结构复杂且各向异性,激光加工过程中又涉及到物理、化学、光学等多参量耦合影响,仅仅依靠单一能量场计算仿真的方法很难全面揭示激光对C/C复合材料的作用机制。

为了更为全面地揭示激光与C/C复合材料耦合的光-热-力等因素的相互作用机制,需要根据热应力耦合分析、激光诱导等离子体流体力学、波动光学、射线光学等方法及理论,进一步研究并完善C/C复合材料表面微结构的激光刻蚀机制,更加准确地掌握表面微结构的生成条件和演化机制。通过深入分析C/C复合材料加工缺陷的产生原因,为激光加工工艺的优化以及加工质量的改善奠定理论基础。

3.5.2 CO2连续激光加工

连续激光适用于材料表面高速大去除量加工,Gureev等[50]使用CO2连续激光对C/C复合材料表面进行加工,研究了激光烧蚀对C/C复合材料表面的影响规律,并测得了材料对激光的反射率。研究发现,激光辐照下C/C复合材料中碳基体的石墨化过程为非均相结晶过程[51],激光烧蚀改变了碳的晶体结构,C/C复合材料经激光辐照后,内部形成了类石墨结构[52],使得C/C复合材料在高温环境中的氧化稳定性比激光加工前提高了1.5~10倍。实验还发现C/C复合材料表面的反射率取决于材料表面的微观起伏程度和激光辐照方式。图15显示了C/C 复合材料表面烧蚀形貌,在烧蚀孔的内部和边缘区域可以明显地观察到裂纹,并且经激光辐照后材料的导电性有所增加,其原因为热影响区[53]的价区和导电区之间的禁带宽度减小。

为了研究激光器种类和加工参数对C/C复合材料热作用的影响,Kuznetsov等[54]分别使用连续激光和脉冲激光切割C/C复合材料。结果表明,低速连续激光切割C/C复合材料的热影响区较大,在合理调节参数的情况下,脉冲激光可以有效抑制热影响区的形成。Liu等[55]观察了CO2连续激光烧蚀附着有SiC-ZrC涂层的C/C复合材料所生成的微观结构,图16显示了1 000 W激光功率作用下材料的表面形貌,图16(a)为烧蚀区域中心呈现的圆形端部的海绵状微观结构。图16(b) 为在烧蚀区域边缘的过渡区呈现的二维排列的椎体结构。

Sulaiman等[56]对C/C复合材料进行了气体辅助激光切割实验,研究了激光功率强度对切缝形貌的影响,加工过程中使用高压氮气作为辅助气体避免氧化反应。研究结果表明,由于导热系数的差异,等离子体的耦合效应在切缝入口区域表现的较为明显,材料表面等离子体[57]的瞬态行为影响切缝两侧条纹结构的形貌,切割效果如图17所示。CO2激光的加工效率较高,但由于连续激光烧蚀材料过程热影响区明显,不利于C/C复合材料的高精度加工。

3.5.3 长脉冲及短脉冲激光加工

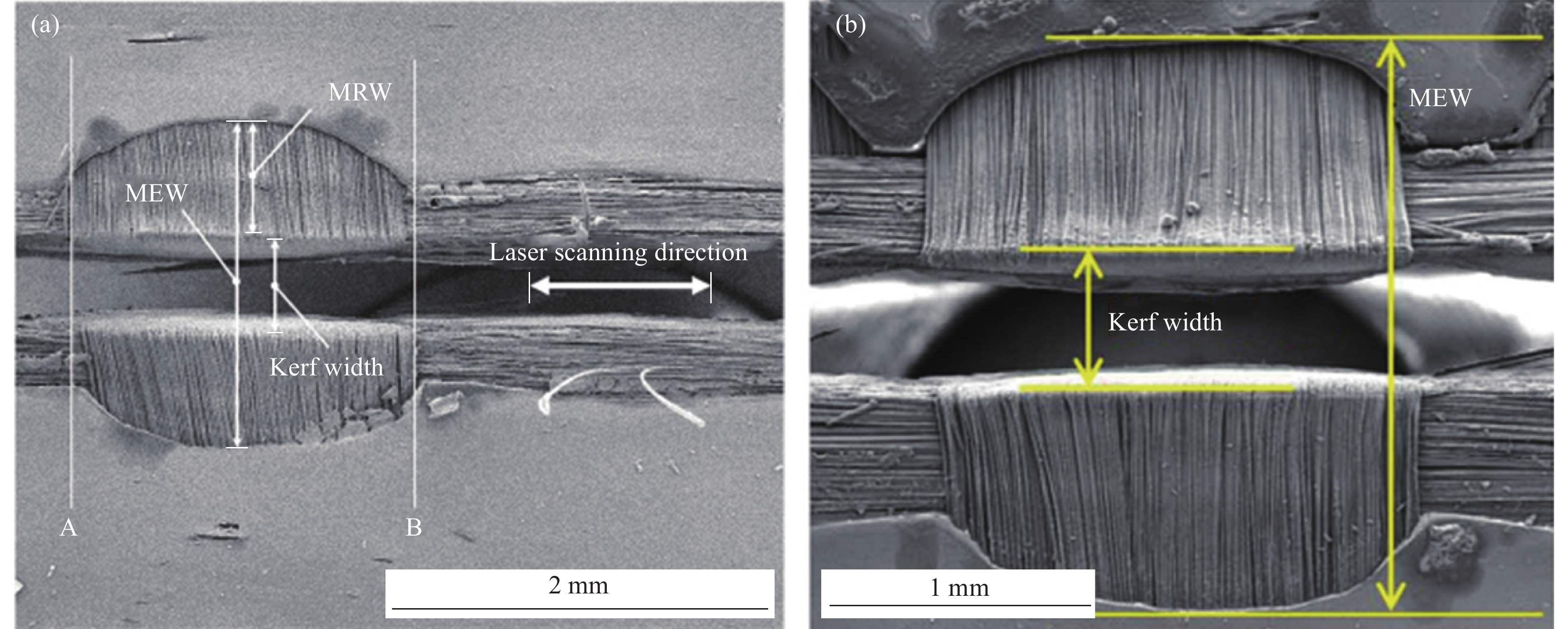

为了降低激光加工过程中的热损伤,花银群等[58]使用毫秒脉冲激光分别进行了在空气中和水下切割碳纤维复合材料的对比实验,实验结果表明,水下切割碳纤维复合材料能有效地减小热影响区范围,且纤维拔出长度大幅下降,在激光烧蚀过程中通过氧气辅助加工可增大切缝深度[59]。Xu等[45]使用纳秒紫外激光对碳纤维增强复合材料进行加工,分析了激光扫描方向与碳纤维铺设方向之间的夹角变化对加工形貌和热损伤的影响。研究结果表明,辐照夹角会影响加工表面的平整度,随着激光扫描方向与纤维铺设方向之间夹角的改变,烧蚀区域的形貌会发生不同程度的变化[60]。吸收的热量沿碳纤维的轴向传导比垂直方向传导更快,这种热量传导的差异随扫描方向的变化而改变[61]。碳纤维增强复合材料内部纤维与基体材料成分的差异导致了基体烧蚀宽度与表面烧蚀宽度不一致[62],如图18所示。在激光烧蚀的过程中,随着扫描次数的增加,切缝内的压力逐渐增加,加工区域边缘逐渐形成熔融形态的切割面,碳纤维与基体材料熔合在一起,可以在一定程度上阻止纤维的分层和拔出[63]。

![]() 图 18 速度250 mm/s、功率1600 W时不同扫描次数时微槽形貌SEM图像对比[64]: (a) 扫描5次; (b) 扫描10次Figure 18. SEM images comparison of micro groove morphology under different scanning times at the speed of 250 mm/s and power of 1600 W[64]: (a) Scanning for 5 times; (b) Scanning for 10 timesMEW—Matrix evaporation width; MRW—Matrix recession width; A, B—Thermal damage is more prominent in the region where the fibers are aligned perpendicular to the laser scanning direction

图 18 速度250 mm/s、功率1600 W时不同扫描次数时微槽形貌SEM图像对比[64]: (a) 扫描5次; (b) 扫描10次Figure 18. SEM images comparison of micro groove morphology under different scanning times at the speed of 250 mm/s and power of 1600 W[64]: (a) Scanning for 5 times; (b) Scanning for 10 timesMEW—Matrix evaporation width; MRW—Matrix recession width; A, B—Thermal damage is more prominent in the region where the fibers are aligned perpendicular to the laser scanning direction3.5.4 超短脉冲激光加工

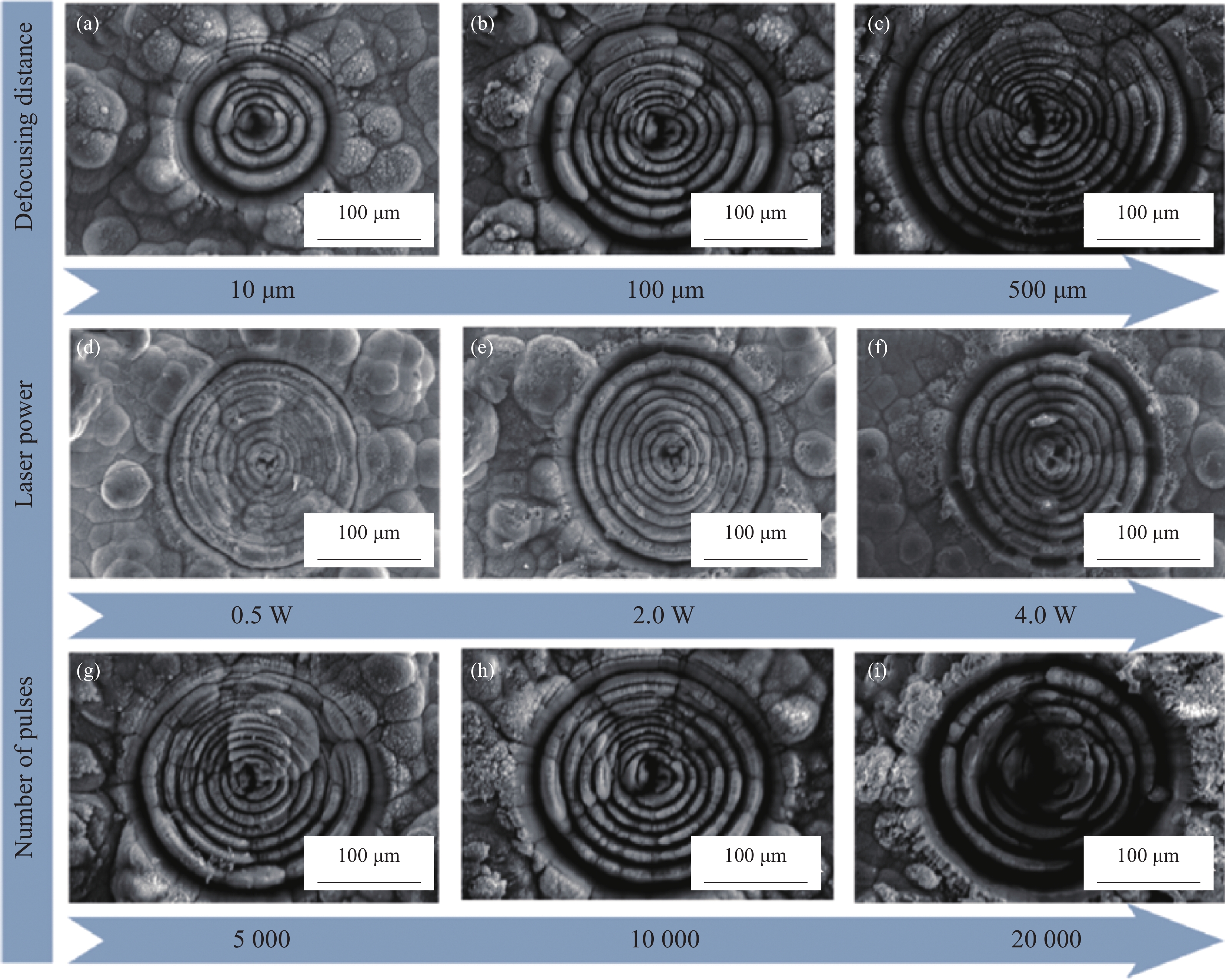

近年来随着超短脉冲激光加工技术的进步,利用超短脉冲激光加工复合材料成为了当前的研究热点,由于超短脉冲激光理论上对材料可实现无热影响的精密加工,被认为是最有潜力的加工技术。Zhai等[65]利用飞秒脉冲激光[66-67]衍射效应进行了加工实验,通过改变离焦量、加工功率、脉冲数在碳纤维增强复合材料表面制备了多级同心圆结构,如图19所示。实验结果表明,飞秒激光脉冲对材料的持续作用时间极短且脉冲之间有一定的时间间隔,同时脉冲峰值能量密度高,对材料造成的热损伤很小[68]。Wang等[69]在空气中分别使用高功率皮秒激光和低功率飞秒激光对碳纤维增强复合材料表面进行微加工,分析了加工前后材料的表面形貌、元素成分及含量。实验结果表明,由于皮秒激光的功率相对较高,碳纤维和基体容易氧化,氧化后的材料表面更易产生热烧蚀现象[70]。

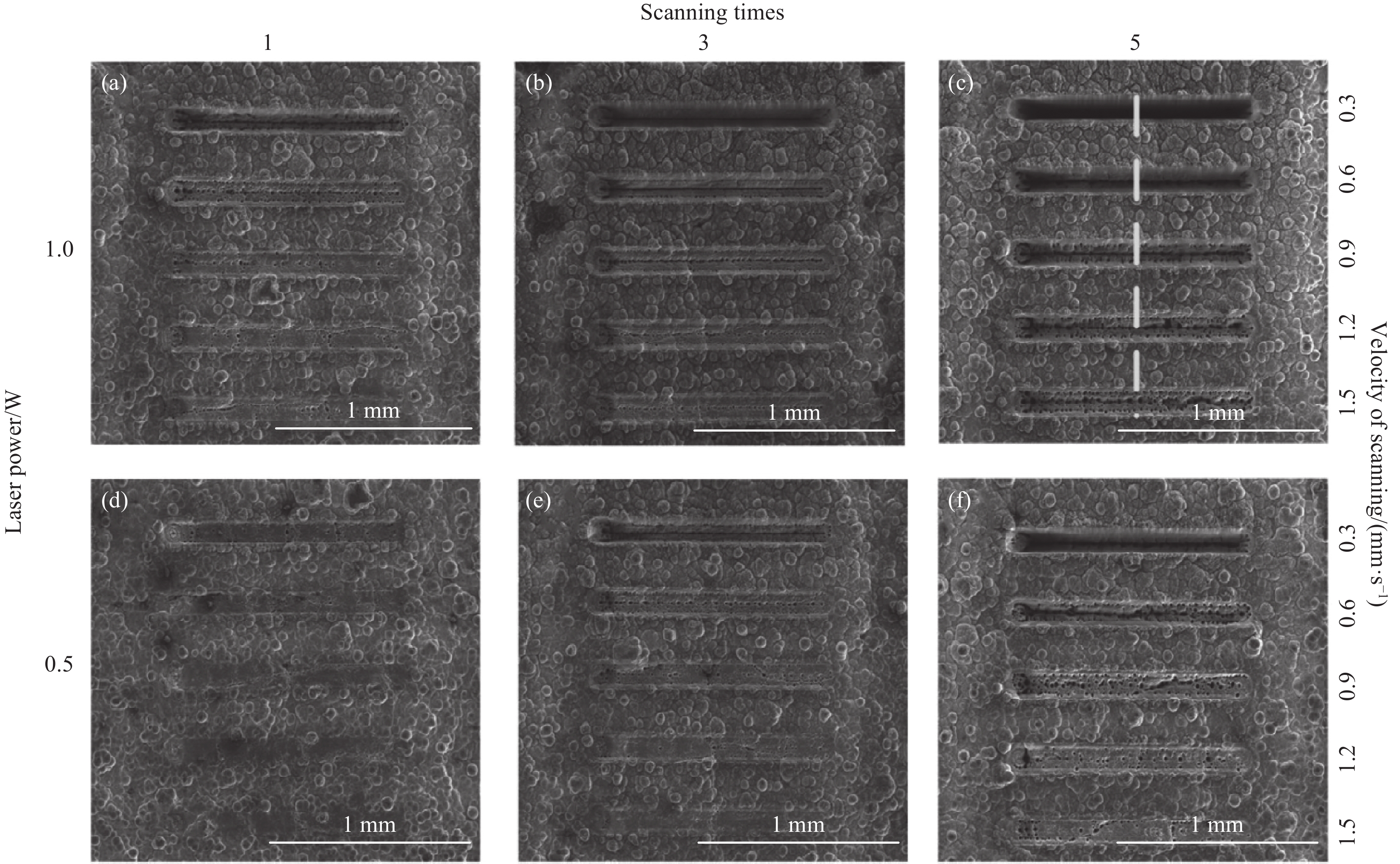

张若衡[71]使用皮秒激光和飞秒激光分别对碳纤维增强复合材料进行了加工,分析了其表面微孔的加工规律。研究结果表明,加工功率、光斑重叠率、步进速度等因素都对材料的加工质量有重要影响。Zhai等[72]利用飞秒激光在碳纤维增强复合材料表面进行了一系列不同参数的加工实验,从图20中可以观察到随着激光功率和扫描次数的增加,微槽逐渐变宽,随着扫描速度增大,微槽随之变窄。加工区域轮廓清晰,没有出现机械加工中常见的崩边、纤维拔出以及连续激光、长脉冲激光加工中明显的热影响区与重铸层。

![]() Figure 20. Surface morphology of carbon fiber reinforced composites processed by femtosecond laser[72]: ((a)-(c)) Number of

Figure 20. Surface morphology of carbon fiber reinforced composites processed by femtosecond laser[72]: ((a)-(c)) Number ofscanning is 1, 3, 5 times under 1 W power respectively; ((d)-(f)) Number of scanning is 1, 3, 5 times under 0.5 W power respectively 为了对比飞秒激光对碳纤维增强复合材料[73]表面及内部刻蚀效果的差异, Zhai等[74]利用飞秒激光分别在表面涂层部分及纤维编织部分进行了加工实验。碳纤维增强复合材料内部纤维部分加工形貌如图21所示,内部与表面材料的结构与形貌存在的巨大差异是造成飞秒激光加工质量不同的主要原因。超短脉冲激光凭借其极短的脉宽和极高的脉冲峰值功率,通过合理调节工艺参数,使用超短脉冲加工C/C复合材料可以有效抑制热影响区的形成,获得更好的加工质量。

4. 激光加工技术发展趋势

激光加工C/C复合材料过程中,虽不产生直接作用力,但是连续激光及大功率长脉冲激光的热效应非常明显,具有效率高、质量较低的特点。由于加工过程中材料受热不均匀,热应力导致的变形会影响加工质量。而超短脉冲激光加工则存在质量高、效率低的问题。当重复多次加工时,光斑重叠率的下降会影响加工精度。由于功率及焦距的限制,激光加工不适宜切割较厚的材料,加工深度也难以达到预期的效果。

近年来,以飞秒激光技术为核心的超快光学及强场物理科学发展迅猛。飞秒激光随着钛宝石自锁模振荡器、啁啾脉冲放大技术、全固态飞秒、光纤飞秒等重大技术的发展和突破,在高重频、大功率、高稳定性等方向上取得了长足的进步。因此,近几年飞秒激光技术在材料精密加工领域的优势逐渐显现。为突破技术瓶颈,进一步提高超短脉冲激光对复合材料的加工效率与质量,将超短脉冲激光加工与其他先进制造技术结合起来,相互配合并扬长避短,可以更好地实现C/C复合材料的精密加工。

4.1 水射流辅助激光加工

为了控制激光加工复合材料过程中热作用导致的材料氧化,朱超凡等[41]提出了一种加工C/C复合材料的新思路,将激光和水射流组合,首先用激光对C/C复合材料进行预处理,再使用高压磨料水射流进行加工,这样既保留了高能激光束的加工效率,又解决了水射流加工C/C复合材料时精度不高的问题。Sun等[75]进一步研究了水射流辅助激光加工工艺,将激光束与低压水流耦合,水柱成为激光的导向载体[76],分别进行了平行和非平行的多道次实验。由于水流比气体有更大的动力学能量,水射流引导的激光切割碳纤维复合材料,在降低热作用方面有重要帮助。将水射流辅助激光加工技术应用于C/C复合材料,可以有效抑制热影响区的形成并增加刻蚀深度。

4.2 超声振动辅助激光加工

为了改善激光加工硬脆材料时工件表面产生的微裂纹问题,张昌娟等[77]将超声振动[78]与激光加工相结合,将高功率激光束聚焦在工件表面,同时对切削刀具施以复合振动,这样既可以减少刀具磨损,又提高了表面加工质量。Alavi等[79]研究了超声振动辅助激光在不锈钢表面的制孔工艺。研究结果表明,超声辅助激光加工的微孔形貌质量有所改善。Fan等[80]利用超声振动辅助激光熔覆制备涂层。研究证明,施加超声振动后制备的熔覆层耐磨性比未施加超声振动时提高了2倍,摩擦系数降低了73%,熔覆层硬度也提高了39%。在C/C复合材料的激光加工中施以超声振动辅助,能够有效地改善加工质量,同时超声振动对材料的力学性能也会产生一定的影响,在一定程度上减小材料内部应力的集中。

4.3 电磁场辅助激光加工

长脉冲激光加工的热影响区明显但材料去除率高,微细电火花加工的质量高但效率低。Ahmari等[81]将激光和微细电火花结合,在镍钛基形状记忆合金表面制备微孔,结合了激光加工和微细电火花加工的优势。相较于单一加工方式,加工效率提高了50%~65%,材料去除率提高了40%~65%。为实现更好的加工效果,Bachmann等[82]将激光加工技术与稳态磁场结合,研究了激光焊接过程中磁场对熔池的影响,将两个磁铁固定在工件两侧,中间连接一块水冷板用于冷却,并通以保护气体。研究结果表明,电磁场可以提高等离子体的扩散速率,削弱激光的冲击效应。电流与磁场相结合形成与熔融体运动方向相反的洛伦兹力,有利于焊缝内部应力均匀的分布,使工件冷却后变形更小,加工质量更高。Lu等[83]使用毫秒和纳秒脉冲激光在不同电磁场下进行了微孔加工,加工的孔深更大且飞溅较少。激光加工C/C复合材料时外加电磁场会加快等离子体的扩散,同时加工过程中会产生电搅拌作用,修复微裂纹,提高激光加工的质量。

4.4 化学腐蚀辅助激光加工

激光加工与化学腐蚀的结合可以实现材料表面的精确微加工。为了改善加工后表面粗糙度并减少熔渣,Kray等[84]将激光刻蚀与化学腐蚀相结合对难加工材料进行了加工,把化学液体喷射流与不同种类激光源组合在一起,使材料发生热化学和光化学反应,且能够将化学反应限制在激光辐射区域的同时提高反应速度。改善了加工后材料表面的粗糙度,实现了表面材料的无损去除。Mehrafsun等[85]使用不同浓度的磷酸溶液与激光束相结合对金属表面进行加工,研究了激光功率、进给速度和电解液浓度对加工效果的影响。在化学腐蚀辅助激光加工中,激光烧蚀可以在工件表面产生热冲击,从而激发电解液的非均相化学反应,使电流在入射激光的中心位置和外围之间的材料内产生流动。研究发现,随着激光功率增加,电解质溶液沸腾会产生大量气泡,气泡通过偏转和全反射会影响激光能量的分布,导致去除区域加宽。在C/C复合材料的激光加工中施以化学腐蚀辅助,尽管化学腐蚀辅助激光加工的去除效率相对较低,但加工过程更温和,加工后材料表面更平滑、尺寸精度更高,不易产生明显的热影响区和重铸层。

综上所述,水射流辅助激光加工适用于C/C复合材料的精密切割,加工中流动的高压射流[86]可减小C/C复合材料因激光辐照而产生的热影响区范围。超声振动辅助激光加工适用与C/C复合材料的高精度表面加工,超声振动[87]会加速等离子体的流动,使残留物和碎屑迅速排出。电磁场辅助有利于提高C/C复合材料的激光加工效率,电磁场可以提高等离子体的扩散速率,减少激光的冲击效应,使加工过程中的飞溅更少。同时产生电搅拌作用,能够修复材料的微裂纹和气孔等缺陷[88]。化学腐蚀辅助激光加工C/C复合材料过程中,材料同时产生热化学和光化学反应,能够提高加工效率的同时通过激光参数调节精确调控材料去除量。

5. 总结与展望

碳纤维增强碳基复合材料 (C/C) 结构复杂,且硬度高、脆性大,属于典型的难加工材料,若加工方式选取不当,可能对复合材料造成严重损伤,导致工件尺寸精度超差和材料浪费。

(1) C/C复合材料在常规车削、钻削、磨削等机械加工中易造成刀具磨损,最终导致纤维拔出、分层。线切割及电火花加工的效率较低,由于热量的集中,材料表面会生成较厚的重铸层并附着大量熔融颗粒。水射流加工效率较高,但射流压力过高时易造成材料分层及纤维撕裂。这些加工缺陷严重影响C/C复合材料的加工精度。

(2) 激光加工C/C复合材料的精度高、质量稳定。加工过程中无刀具磨损、无切削力作用,并且可实现局部区域加工,对非激光辐照区域影响较小,具备的优势不言而喻。相对于连续激光及长脉冲激光,超短脉冲激光加工C/C复合材料可以有效减少热致缺陷,提高加工质量。但是,对C/C复合材料激光加工理论及配套工艺的研究还处于基础阶段,相关方面的研究集中在分析改变加工参数对C/C复合材料加工效果的影响。

(3) 为进一步提高激光对C/C复合材料的加工效率与质量,需将激光加工技术与其他先进制造技术相结合,扬长避短,发挥各自的优势。利用激光复合加工技术实现C/C复合材料的优质高效加工,将用以满足不同领域和工况环境下C/C复合材质构件结构设计复杂化和构件组合形式多样化的发展需求。

-

图 18 速度250 mm/s、功率1600 W时不同扫描次数时微槽形貌SEM图像对比[64]: (a) 扫描5次; (b) 扫描10次

Figure 18. SEM images comparison of micro groove morphology under different scanning times at the speed of 250 mm/s and power of 1600 W[64]: (a) Scanning for 5 times; (b) Scanning for 10 times

MEW—Matrix evaporation width; MRW—Matrix recession width; A, B—Thermal damage is more prominent in the region where the fibers are aligned perpendicular to the laser scanning direction

图 20 飞秒激光加工碳纤维增强复合材料的表面形貌图[72]: ((a)~(c)) 功率为1 W,

扫描次数分别为1、3、5次; ((d)~(f)) 功率为0.5 W, 扫描次数分别为1、3、5次 Figure 20. Surface morphology of carbon fiber reinforced composites processed by femtosecond laser[72]: ((a)-(c)) Number of

scanning is 1, 3, 5 times under 1 W power respectively; ((d)-(f)) Number of scanning is 1, 3, 5 times under 0.5 W power respectively -

[1] 李崇俊, 马伯信, 金志浩. 碳/碳复合材料的新发展[J]. 材料科学与工程学报, 1999, 18(3): 135-140. LI Chongjun, MA Boxin, JIN Zhihao. Recent developments of carbon-carbon composites[J]. Materials Science & Engineering, 1999, 18(3): 135-140(in Chinese).

[2] GOLECKI I, XUE L, LEUNG R, et al. Properties of high thermal conductivity carbon-carbon composites for thermal management applications[C]. USA: 1998 High-Temperature Electronic Materials, Devices and Sensors Conference, 1998: 190-195.

[3] 陈洁, 熊翔, 肖鹏. 高导热C/C复合材料的研究进展[J]. 材料导报, 2006(S2): 431-435. CHEN Jie, XIONG Xiang, XIAO Peng. Research and development of high-thermal conductivity carbon/carbon composites[J]. Materials Reports, 2006(S2): 431-435(in Chinese).

[4] KUMAR C V, KANDASUBRAMANIAN B. Advances in ablative composites of carbon based materials: A review[J]. Industrial & Engineering Chemistry Research, 2019, 58(51): 22663-22701.

[5] 解齐颖, 张祎, 朱阳, 等. 超高温陶瓷改性碳/碳复合材料[J]. 材料工程, 2021, 49(7): 46-55. XIE Qiying, ZHANG Wei, ZHU Yang, et al. Ultra-high temperature ceramics modified carbon/carbon composites[J]. Journal of Materials Engineering, 2021, 49(7): 46-55(in Chinese).

[6] ALGHAMDI A, MUMMERY P, SHEIKH M A. Multi-scale 3D image-based modelling of a carbon/carbon composite[J]. Modelling and Simulation in Materials Science and Engi-neering, 2013, 21(8): 1-13.

[7] ALGHAMDI A, KHAN A, MUMMERY P, et al. The characterisation and modelling of manufacturing porosity of a 2D carbon/carbon composite[J]. Journal of Composite Materials, 2014, 48(23): 2815-2829.

[8] CHOWDHURY P, SEHITOGLU H, RATEICK R. Damage tolerance of carbon-carbon composites in aerospace application[J]. Carbon, 2018, 126: 382-393.

[9] 张登科, 王光辉, 方登科, 等. 碳纤维增强树脂基复合材料的应用研究进展[J]. 化工新型材料, 2021, 50(1): 1-5. ZHANG Dengke, WANG Guanghui, FANG Dengke, et al. Progress in application and research of carbon fiber reinforced resin matrix composites[J]. New Chemical Materials, 2021, 50(1): 1-5(in Chinese).

[10] 季根顺, 王丽, 贾建刚, 等. CVI法制备C/C复合材料的温度梯度[J]. 兰州理工大学学报, 2018, 44(1): 17-20. JI Genshun, WANG Li, JIA Jiangang, et al. The temperature gradient in preparation of C/C composites with CVI method[J]. Journal of Lanzhou University of Technology, 2018, 44(1): 17-20(in Chinese).

[11] WINDHORST T, GORDON B. Carbon-carbon composites: A summary of recent developments and applications[J]. Materials & Design, 1997, 18(1): 11-15.

[12] 张哲, 赵鹏, 孙国栋, 等. 酚醛树脂溶液浓度对液相浸渍-碳化法制备C/C复合材料浸渍效率的影响[J]. 固体火箭技术, 2019, 42(6): 771-778. ZHANG Zhe, ZHAO Peng, SUN Guodong, et al. Effect of concentration of phenolic resin on impregnation efficiency of carbon/carbon composites prepared by liquidimpregnation-carbonization method[J]. Journal of Solid Rocket Technology, 2019, 42(6): 771-778(in Chinese).

[13] 李铁虎, 杨峥, 郑修麟, 等. 用改进的低压渍浸碳化法制备C/C复合材料的工艺研究[J]. 西北工业大学学报, 1994, 12(2): 155-158. LI Tiehu, YANG Zheng, ZHENG Xiulin, et al. Laboratory production of carbon/carbon composite by improved lpic[J]. Journal of Northwestern Polytechnical University, 1994, 12(2): 155-158(in Chinese).

[14] 李文强. 碳纤维增强碳化硅基复合材料烧蚀计算研究[D]. 大连: 大连理工大学, 2021. LI Wenqiang. Numerical calculation research on ablation of carbon fiber reinforced silicon carbide matrix composite[D]. Dalian: Dalian University of Technology, 2021(in Chinese).

[15] 徐林, 杨文彬, 陈铮, 等. 高性能二维碳/碳复合材料的制备与性能[J]. 复合材料学报, 2016, 33(12): 2877-2883. XU Lin, YANG Wenbin, CHEN Zheng, et al. Preparation and properties of high performance two-dimensional carbon/carbon composites[J]. Acta Materiae Compositae Sinica, 2016, 33(12): 2877-2883(in Chinese).

[16] LUO R, LIU T, LI J, et al. Thermophysical properties of carbon/carbon composites and physical mechanism of thermal expansion and thermal conductivity[J]. Carbon, 2004, 42(14): 2887-2895.

[17] LUO R. Fabrication of carbon/carbon composites by an electrified preform heating CVI method[J]. Carbon, 2002, 40(11): 1957-1963

[18] 乔淑欣. 航天用C/C复合材料及其应用制备工艺[J]. 宇航材料工艺, 2013, 43(2): 18-21. QIAO Shuxin. C/C composites and preparation process in aerospace application[J]. Aerospace Materials & Technology, 2013, 43(2): 18-21(in Chinese).

[19] 张磊磊, 胡涛, 李贺军, 等. 炭/炭复合材料人工髋关节磨损颗粒研究[J]. 无机材料学报, 2010, 25(4): 349-353. ZHANG Leilei, HU Tao, LI Hejun, et al. Wear particles of carbon/carbon composite artificial hip joints[J]. Journal of Inorganic Materials, 2010, 25(4): 349-353(in Chinese).

[20] 倪昕晔, 熊信柏, 尤瑞金, 等. 碳/碳复合材料表面掺镁羟基磷灰石生物涂层的体外性能[J]. 中国组织工程研究, 2017, 21(34): 5443-5448. NI Xinye, XIONG Xinbo, YOU Ruijin, et al. In vitro properties of magnesium doped hydroxyapatite coating on the surface of carbon/carbon composites[J]. Chinese Journal of Tissue Engineering Research, 2017, 21(34): 5443-5448(in Chinese).

[21] 张雨雷, 付艳芹, 付前刚, 等. 纳米管/线多尺度强韧化C/C复合材料研究现状与展望[J]. 航空材料学报, 2021, 41(3): 11-24. ZHANG Yulei, FU Yanqin, FU Qiangang, et al. Research status and prospect on nanotube/nanowire multi-scale-reinforced C/C composites[J]. Journal of Aeronautical Materials, 2021, 41(3): 11-24(in Chinese).

[22] GAO B, ZHANG R, HE M, et al. Effect of a multiscale reinforcement by carbon fiber surface treatment with graphene oxide/carbon nanotubes on the mechanical properties of reinforced carbon/carbon composites[J]. Composites Part A: Applied Science and Manufacturing, 2016, 90: 433-440.

[23] YI X, TAN Z, YU W, et al. Three dimensional printing of carbon/carbon composites by selective laser sintering[J]. Carbon, 2016, 96: 603-607.

[24] ZHANG Y, ZHANG Y, WANG T, et al. Experimental study on performances of carbon seal and finger seal under high-speed and high-pressure condition[J]. IOP Conference Series, Materials Science and Engineering, 2018, 382(2): 22044.

[25] 张延超, 刘凯, 周连杰, 等. 基于系统响应特征的指尖密封泄漏特性分析[J]. 航空动力学报, 2013, 28(1): 205-210. ZHANG Yanchao, LIU Kai, ZHOU Lianjie, et al. Analysis of leakage characteristics of finger seal based on system response[J]. Journal of Aerospace Power, 2013, 28(1): 205-210(in Chinese).

[26] ZHANG Y C, ZHOU Y M, YIN M H, et al. Experimental investigation on friction and wear performance of C/C composite finger seal[J]. Journal of Tribology, 2020, 144: 021701.

[27] YEN B K, ISHIHARA T. An investigation of friction and wear mechanisms of carbon-carbon composites in nitrogen and air at elevated temperatures[J]. Carbon, 1996, 34(4): 489-498.

[28] FERREIRA J R, COPPINI N L, LEVY NETO F. Characteristics of carbon-carbon composite turning[J]. Journal of Materials Processing Technology, 2001, 109(1): 65-71.

[29] 蒋建纯, 熊翔, 杨文堂, 等. 炭/炭复合材料切削加工试验研究[J]. 新型炭材料, 2000, 15(3): 38-42. JIANG Jianchun, XIONG Xiang, YANG Wentang, et al. An investigation of carbon/carbon composite machining[J]. New Carbon Materials, 2000, 15(3): 38-42(in Chinese).

[30] 郭孟, 樊会涛, 李辉. 面向航空航天的C/C复合材料加工技术研究[J]. 装备制造技术, 2014(3): 182-185. GUO Meng, FANG Huitao, LI Hui. C/C composites processing technology research applied in the field of aerospace[J]. Equipment Manufacturing Technology, 2014(3): 182-185(in Chinese).

[31] 鞠伟华. C/C复合材料加工工艺及质量评价研究[D]. 哈尔滨: 哈尔滨工业大学, 2016. JU Weihua. Study on the mechanical process and quality evaluating of C/C composite material[D]. Harbin: Harbin Institute of Technology, 2016(in Chinese).

[32] SHAN C, LIN X, WANG X, et al. Defect analysis in drilling needle-punched carbon-carbon composites perpendicular to nonwoven fabrics[J]. Advances in Mechanical Engineering, 2015, 7(8): 1-11.

[33] 刘琼, 黄国钦. 2D C/C-SiC复合材料钻削加工试验研究[J]. 福建工程学院学报, 2019, 17(1): 7-16. LIU Qiong, HUANG Guoqin. Experimental study on drilling processing of 2D C/C-SiC composites[J]. Journal of Fujian University of Technology, 2019, 17(1): 7-16(in Chinese).

[34] 蔺小军, 崔栋鹏, 单晨伟, 等. C/C复合材料钻削轴向力研究[J]. 航空制造技术, 2015(15): 60-64. LIN Xiaojun, CUI Dongpeng, SHAN Chenwei, et al. Experimental study on thrust force in drilling carbon/carbon composites[J]. CNC Machining Technology, 2015(15): 60-64(in Chinese).

[35] 周井文, 秦文津, 穆英娟, 等. 碳纤维复合材料铣削与磨削加工对比研究[J]. 金刚石与磨料磨具工程, 2020, 40(4): 76-80. ZHOU Jingwen, QIN Wenjin, MU Yingjuan, et al. Compara-tive study on machining of CFRP by end mill and abrasive router[J]. Diamond & Abrasives Engineering, 2020, 40(4): 76-80(in Chinee).

[36] 刘琼, 黄国钦, 徐西鹏. 2D-C/SiC复合材料磨削加工表面形成机制[J]. 福州大学学报, 2018, 46(2): 228-233. LIU Qiong, HUANG Guoqin, XU Xipeng. Surface forming mechanism of grinding 2D-C/SiC composites[J]. Journal of Fuzhou University, 2018, 46(2): 228-233(in Chinese).

[37] 张立峰, 王盛, 李战, 等. 纤维方向对单向C/SiC复合材料磨削加工性能的影响[J]. 中国机械工程, 2020, 31(3): 373-377. ZHANG Lifeng, WANG Sheng, LI Zhan, et al. Effects of fiber direction on grinding performances for unidirectional C/SiC composites[J]. China Mechanical Engineering, 2020, 31(3): 373-377(in Chinese).

[38] PI V N, LE X H, TUNG L A, et al. Cost optimization of internal grinding[J]. Journal of Materials Science and Engineering, 2016, 6(11/12): 291-296.

[39] 蔡志刚, 陈晓川, 王迪, 等. 碳碳复合材料的水射流钻孔技术研究[J]. 机械工程学报, 2019, 55(3): 226-232. CAI Zhigang, CHEN Xiaochuan, WANG Di, et al. Research on water jet drilling technology for carbon-carbon composites[J]. Journal of Mechanical Engineering, 2019, 55(3): 226-232(in Chinese).

[40] YIN D Y, ZHU C F, CHEN X C, et al. Finite-element analysis and an experimental study into the water jet reaming process of carbon-carbon composites[J]. Mechanics of Composite Materials, 2021, 57(2): 257-268.

[41] 朱超凡, 陈晓川, 鲍劲松. 面向碳-碳复合材料的激光和水射流组合制孔工艺仿真建模和实验研究[J]. 现代制造工程, 2020(1): 10-17. ZHU Chaofan, CHEN Xiaochuan, BAO Jinsong. Simulation modeling and experimental study on hole making process combined laser and water jet for carbon-carbon composite material[J]. Modern Manufacturing Engi-neering, 2020(1): 10-17(in Chinese).

[42] GEORGE P M, RAGHUNATH B K, MANOCHA L M, et al. Modelling of machinability parameters of carbon-carbon composite-A response surface approach[J]. Journal of Materials Processing Technology, 2004(153/154): 920-924.

[43] GUU Y H, HOCHENG H, TAI N H, et al. Effect of electrical discharge machining on the characteristics of carbon fiber reinforced carbon composites[J]. Journal of Materials Science, 2001, 36(8): 2037-2043.

[44] 翟兆阳, 梅雪松, 王文君, 等. 碳化硅陶瓷基复合材料激光刻蚀技术研究进展[J]. 中国激光, 2020, 47(6): 24-34. ZHAI Zhaoyang, MEI Xuesong, WANG Wenjun, et al. Research advancement on laser etching technology of silicon carbide ceramic matrix composite[J]. Chinese Journal of Lasers, 2020, 47(6): 24-34(in Chinese).

[45] XU L Y, LU J R, LI K M, et al. Removal mechanism of CFRP by laser multi direction interaction[J]. Optics & Laser Technology, 2021, 143: 107281.

[46] GENG L, LIU X, FU Q, et al. Laser ablative behavior of C/C modified by Si reactive infiltration[J]. Carbon, 2020, 168: 650-658.

[47] ZHAI Z, WANG W, ZHAO J, et al. Influence of surface morphology on processing of C/SiC composites via femtosecond laser[J]. Composites: Part A, Applied Science and Manufacturing, 2017, 102: 117-125.

[48] AN Q, CHEN J, MING W, et al. Machining of SiC ceramic matrix composites: A review[J]. Chinese Society of Aeronautics and Astronautics & Beihang University, 2020,1683:1-28.

[49] 周一倩. 基于光纤聚焦的激光表面织构加工及其摩擦学行为研究[D]. 北京: 清华大学, 2009. ZHOU Yiqian. Micro laser surface texturing based on optical fiber focusing and tribological behavior of textured surfaces[D]. Beijing: Tsinghua University, 2009(in Chinese).

[50] GUREEV D M, KUZNETSOV S I, PETROV A L. Influence of laser treatment on the structure and properties of carbon-carbon composites[J]. Proceedings of SPIE-International Society for Optical Engineering,1999,3688(10):259-265.

[51] ZOU L, HUANG B, HUANG Y, et al. An investigation of heterogeneity of the degree of graphitization in carbon-carbon composites[J]. Materials Chemistry and Physics, 2003, 82(3): 654-662.

[52] GUREEV D M, KUZNETSOV S I, PETROV A L. Changes in the structure and surface properties of carbon-carbon composites under the action of laser radiation[J]. Russian Laser Research, 2000, 21(3): 274-276.

[53] 李艳, 崔红, 嵇阿琳, 等. 热处理对C/C复合材料热膨胀行为的影响[J]. 材料导报, 2012, 26(12): 25-28. LI Yan, CUI Hong, JI Alin, et al. Effects of heat treatment on thermal expansion coefficient of C/C composites[J]. Materials Reports, 2012, 26(12): 25-28(in Chinese).

[54] KUZNETSOV S I, GUREEV D M, LEVIN D S, et al. Laser-beam pattern cutting of carbon-carbon composites[C]. Russian Federation: International Conference on Laser & Laser Information Technologies, International Society for Optics and Photonics, 2001, 4644: 83-88.

[55] LIU Q, ZHANG L, JIANG F, et al. Laser ablation behaviors of SiC-ZrC coated carbon/carbon composites[J]. Surface and Coatings Technology, 2011, 205(17/18): 4299-4303.

[56] AL-SULAIMAN F A, YILBAS B S, AHSAN M. CO2 laser cutting of a carbon/carbon multi-lamelled plain-weave structure[J]. Journal of Materials Processing Technology, 2006, 173(3): 345-351.

[57] QIAN J P, LU L P, LI P Y, et al. Thermal shock resistance of graphite and carbon/carbon composites in plasma disruption simulation tests[J]. Nuclear Materials, 1994(212/215): 1183-1188.

[58] 花银群, 陈瑞芳, 肖淘, 等. 激光切割碳纤维复合材料的实验研究[J]. 激光技术, 2013, 37(5): 565-570. HUA Yinqun, CHEN Ruifang, XIAO Tao, et al. Experimental study about laser cutting of carbon fiber reinforced polymer[J]. Laser Technology, 2013, 37(5): 565-570(in Chinese).

[59] KONONENKO T V, FREITAG C, KOMLENOK M S, et al. Oxygen-assisted multipass cutting of carbon fiber reinforced plastics with ultra-short laser pulses[J]. Journal of Applied Physics, 2014, 115(10): 103107.

[60] 袁根福, 曾晓雁. 硬脆性无机材料激光成形加工研究与应用现状[J]. 激光与光电子学进展, 2002(6): 47-51. YUAN Genfu, ZENG Xiaoyan. Status and prospect of laser machining researches and applications on hard and brickle materials[J]. Laser & Optoelectronics Progress, 2002(6): 47-51(in Chinese).

[61] 吴恩启, 石玉芳, 李美华, 等. 编织碳纤维复合材料平面内热传导规律研究[J]. 中国激光, 2016, 43(7): 168-173. WU Enqi, SHI Yufang, LI Meihua, et al. In-plane thermal conduction of woven carbon fiber reinforced polymer[J]. Chinese Journal of Lasers, 2016, 43(7): 168-173(in Chinese).

[62] 高燕, 宋怀河, 陈晓红. C/C复合材料的研究进展[J]. 材料导报, 2002, 16(7): 44-47. GAO Yan, SONG Huaihe, CHEN Xiaohong. Progress in research on C/C composites[J]. Materials Reports, 2002, 16(7): 44-47(in Chinese).

[63] JUNG K, KAWAHITO Y, KATAYAMA S. Ultra-high speed disk laser cutting of carbon fiber reinforced plastics[J]. Journal of Laser Applications, 2012, 24(1): 12007.

[64] OH S, LEE I, PARK Y, et al. Investigation of cut quality in fiber laser cutting of CFRP[J]. Optics & Laser Technology, 2019, 113: 129-140.

[65] ZHAI Z, ZHANG R, TANG A, et al. Fabrication of microstructure on C/SiC surface via femtosecond laser diffraction[J]. Materials Letters, 2021, 293: 129711.

[66] ZHAI Z, WANG F, DUAN H. Experimental study on 800 nm femtosecond laser cutting of polyamide in air[J]. Optik, 2019, 194: 163080.

[67] ZHAI Z, WANG F, MEI X, et al. Preparation of graphene directly on liquid EB curing ink film by femtosecond laser[J]. Optik, 2020, 223: 165485.

[68] 蒋翼, 陈根余, 周聪, 等. 碳纤维复合材料皮秒激光切割工艺研究[J]. 激光技术, 2017, 41(6): 821-825. JIANG Yi, CHEN Genyu, ZHOU Cong, et al. Research of carbon fiber reinforced plastic cut by picosecond laser[J]. Laser Technology, 2017, 41(6): 821-825(in Chinese).

[69] WANG J, LIU Y, WANG C, et al. Character and mechanism of surface micromachining for C/SiC composites by ultrashort plus laser[J]. Advances in Applied Ceramics, 2017, 116(2): 99-107.

[70] 方光武, 宋迎东, 高希光. 针刺C/SiC复合材料应力-应变模型及试验验证[J]. 复合材料学报, 2016, 33(4): 827-832. FANG Guangwu, SONG Yingdong, GAO Xiguang. Model and test validation of stress-strain for needled C/SiC composite[J]. Acta Materiae Compositae Sinica, 2016, 33(4): 827-832(in Chinese).

[71] 张若衡. SiC/SiC复合材料的超快激光加工工艺与特性研究[D]. 西安: 中国科学院研究生院(西安光学精密机械研究所), 2016. ZHANG Ruoheng. Machining technology and properties investigation of SiC/SiC composites by ultra-short pulse laser[D]. Xi’an: Chinese Academy of Sciences(Xi’an Institute of Optics & Precision Mechanics), 2016(in Chinese).

[72] ZHAI Z, WANG W, MEI X, et al. Effect of the surface microstructure ablated by femtosecond laser on the bonding strength of EBCs for SiC/SiC composites[J]. Optics Communications, 2018, 424: 137-144.

[73] DITTMAR H, GÄBLER F, STUTE U. UV-laser ablation of fibre reinforced composites with ns-pulses[J]. Physics Proedria, 2013, 41: 266-275.

[74] ZHAI Z, ZHANG Y, CUI Y, et al. Investigations on the ablation behavior of C/SiC under femtosecond laser[J]. Optik, 2020, 224: 165719.

[75] SUN D, HAN F, YING W. The experimental investigation of water jet-guided laser cutting of CFRP[J]. International Journal of Advanced Manufacturing Technology, 2019, 102(1): 719-729.

[76] 刘敬明, 曹凤国. 激光复合加工技术的应用及发展趋势[J]. 电加工与模具, 2006(4): 5-9. LIU Jingming, CAO Fengguo. Application and development trend of laser combined machining technology[J]. Electrical Machining and Mould, 2006(4): 5-9(in Chinese).

[77] 张昌娟, 焦锋, 赵波, 等. 激光超声复合切削硬质合金的刀具磨损及其对工件表面质量的影响[J]. 光学精密工程, 2016, 24(6): 1413-1423. ZHANG Changjuan, JIAO Feng, ZHAO Bo, et al. Tool wear in laser ultrasonically assisted cutting cemented carbide and its effect on surface quality[J]. Optics and Precision Engineering, 2016, 24(6): 1413-1423(in Chinese).

[78] 段鹏, 焦锋, 牛赢, 等. 激光超声复合加工硬质合金的切削特性研究[J]. 机械科学与技术, 2017, 36(4): 592-597. DUAN Peng, JIAO Feng, NIU Ying, et al. Machinability of tungsten carbide with assistance of laser and ultrasonic vibration[J]. Mechanical Science and Technology for Aerospace Engineering, 2017, 36(4): 592-597(in Chinese).

[79] ALAVI S H, HARIMKAR S P. Evolution of geometric and quality features during ultrasonic vibration-assisted continuous wave laser surface drilling[J]. Journal of Materials Processing Technology, 2016, 232: 52-62.

[80] FAN Z, WANG K, DONG X, et al. The role of the surface morphology and segmented cracks on the damage forms of laser re-melted thermal barrier coatings in presence of a molten salt (Na2SO4+V2O5)[J]. Corrosion Science, 2017, 115: 56-67.

[81] AL-AHMARIAB A, RASHEEDA M S, MOHAMMEDA M K, et al. A hybrid machining process combining micro-EDM and laser beam machining of nickel-titanium based shape memory alloy[J]. Materials and Manufacturing Processes, 2015,1072:954.

[82] BACHMANN M, AVILOV V, GUMENYUK A, et al. About the influence of a steady magnetic field on weld pool dyna-mics in partial penetration high power laser beam welding of thick aluminum parts[J]. International Journal of Heat and Mass Transfer, 2013, 60: 309-321.

[83] LU Y, SUN G F, WEN D P, et al. Effects of applying electric and magnetic fields on laser drilling[J]. International Journal of Advanced Manufacturing Technology, 2016, 84(9/12): 2293-2300.

[84] KRAY D, FELL A, HOPMAN S, et al. Laser chemical processing (LCP)-A versatile tool for microstructuring applications[J]. Applied Physics A, 2008, 93(1): 99-103.

[85] MEHRAFSUN S, MESSAOUDI H. Dynamic process behavior in laser chemical micro machining of metals[J]. Manufacturing and Materials Processing, 2018, 54: 1-18.

[86] 陈雪辉, 李翔, 吴超, 等. 水射流辅助激光加工碳化硅的影响研究[J]. 激光与光电子学进展, 2019, 56(1): 225-231. CHEN Xuehui, LI Xiang, WU Chao, et al. Influence of water jet assisted laser processing silicon carbide[J]. Laser & Optoelectronics Progress, 2019, 56(1): 225-231(in Chinese).

[87] 刘斌, 戴玉堂, 殷广林, 等. 超声波辅助飞秒激光加工光纤材料的工艺探索[J]. 中国激光, 2016, 43(3): 66-71. LIU Bin, DAI Yutang, YIN Guanglin, et al. Exploration on ultrasonic vibration aided femtosecond laser machining process of fiber optic materials[J]. Chinese Journal of Lasers, 2016, 43(3): 66-71(in Chinese).

[88] 徐家乐. 电磁超声复合能场辅助激光熔覆钴基合金涂层组织及性能研究[D]. 镇江: 江苏大学, 2019. XU Jiale. Study on microstructure and properties of co-based coatings by laser cladding coupled with electromagnetic/ultrasonic compound energy field[D]. Zhenjiang: Jiangsu University, 2019(in Chinese).

-

期刊类型引用(10)

1. 翟兆阳,李欣欣,张延超,刘忠明,杜春华,张华明. 连续光纤激光切割金属薄壁材料工艺研究. 红外与激光工程. 2024(02): 33-43 .  百度学术

百度学术

2. 陶洋,李存静,逄增媛,张典堂. 展宽布/网胎针刺C/C复合材料制备及力学性能. 复合材料学报. 2024(04): 1934-1944 .  本站查看

本站查看

3. 董志刚,王中旺,冉乙川,鲍岩,康仁科. 碳纤维增强陶瓷基复合材料超声振动辅助铣削加工技术的研究进展. 机械工程学报. 2024(09): 26-56 .  百度学术

百度学术

4. 席翔,李海龙,陈友元,裴景奇,廖城坤,薛琳,储洪强,冉千平. 碳纤维增强碳基复合材料的介电性能对应力的自感知. 高分子材料科学与工程. 2024(05): 115-124 .  百度学术

百度学术

5. 钱奇伟,张昕,杨贞军,沈镇,校金友. 基于CT图像深度学习的三维编织C/C复合材料微观组分与缺陷智能识别. 复合材料学报. 2024(07): 3536-3543 .  本站查看

本站查看

6. 翟兆阳,李欣欣,张延超,刘忠明,杜春华,张华明. 基于正交试验的金属薄壁材料激光切割工艺优化. 中国机械工程. 2024(07): 1279-1289 .  百度学术

百度学术

7. 何金玲. 纤维复材浆料流变性能分析及矿混匀质量应用研究. 粘接. 2024(09): 87-90 .  百度学术

百度学术

8. 姚先龙. 碳基复合材料的应用及相关制备方法. 信息记录材料. 2023(01): 36-38 .  百度学术

百度学术

9. 石磊,罗浩,罗瑞盈. 胶层厚度对C/C复合材料剪切粘接性能的影响. 炭素技术. 2023(04): 22-26 .  百度学术

百度学术

10. 刘科众,陈舟,王泽鹏,韩保恒. C/C复合材料增密过程孔隙结构及演化研究. 机械设计与制造工程. 2022(10): 33-36 .  百度学术

百度学术

其他类型引用(10)

-

下载:

下载: