Research progress on interlaminar property of carbon nanotube-continuous fiber reinforced resin matrix composites

-

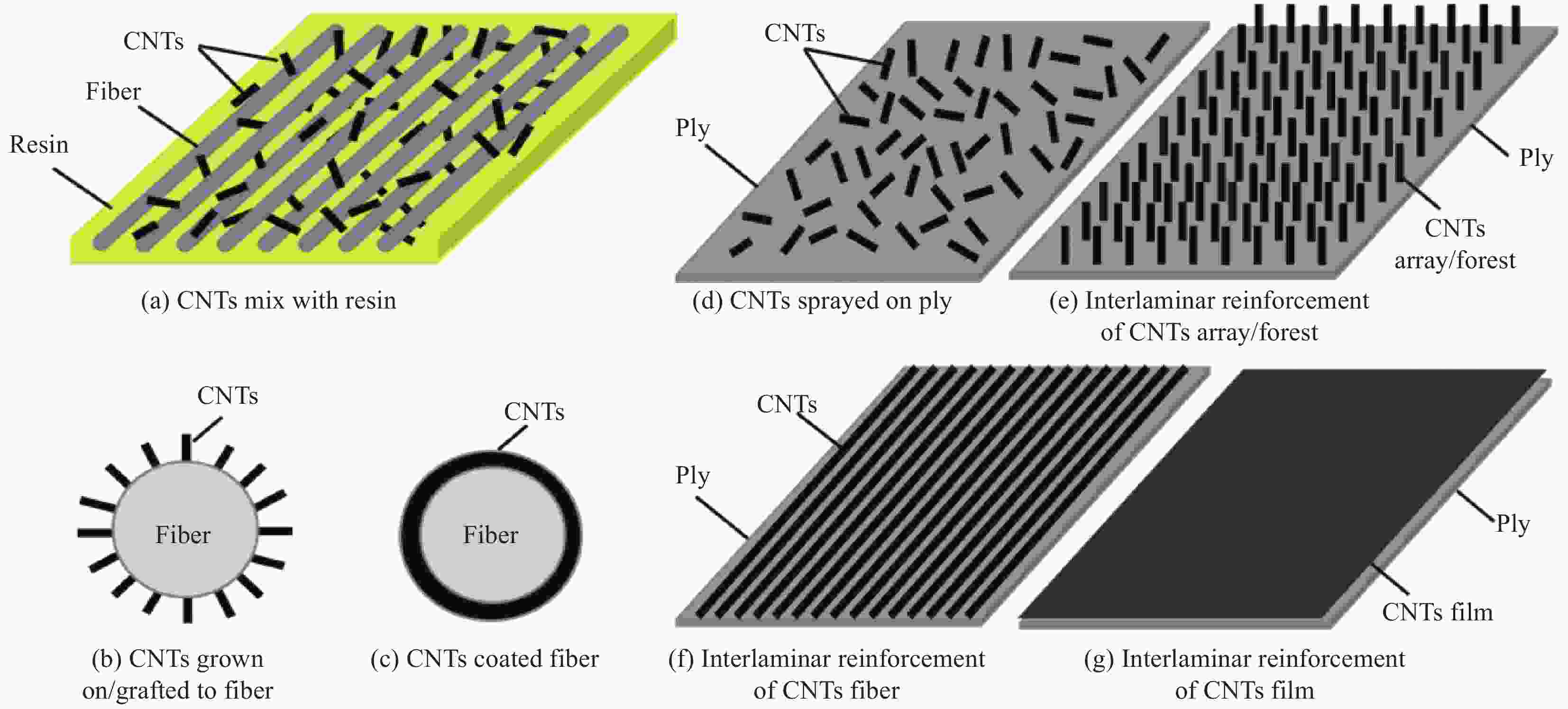

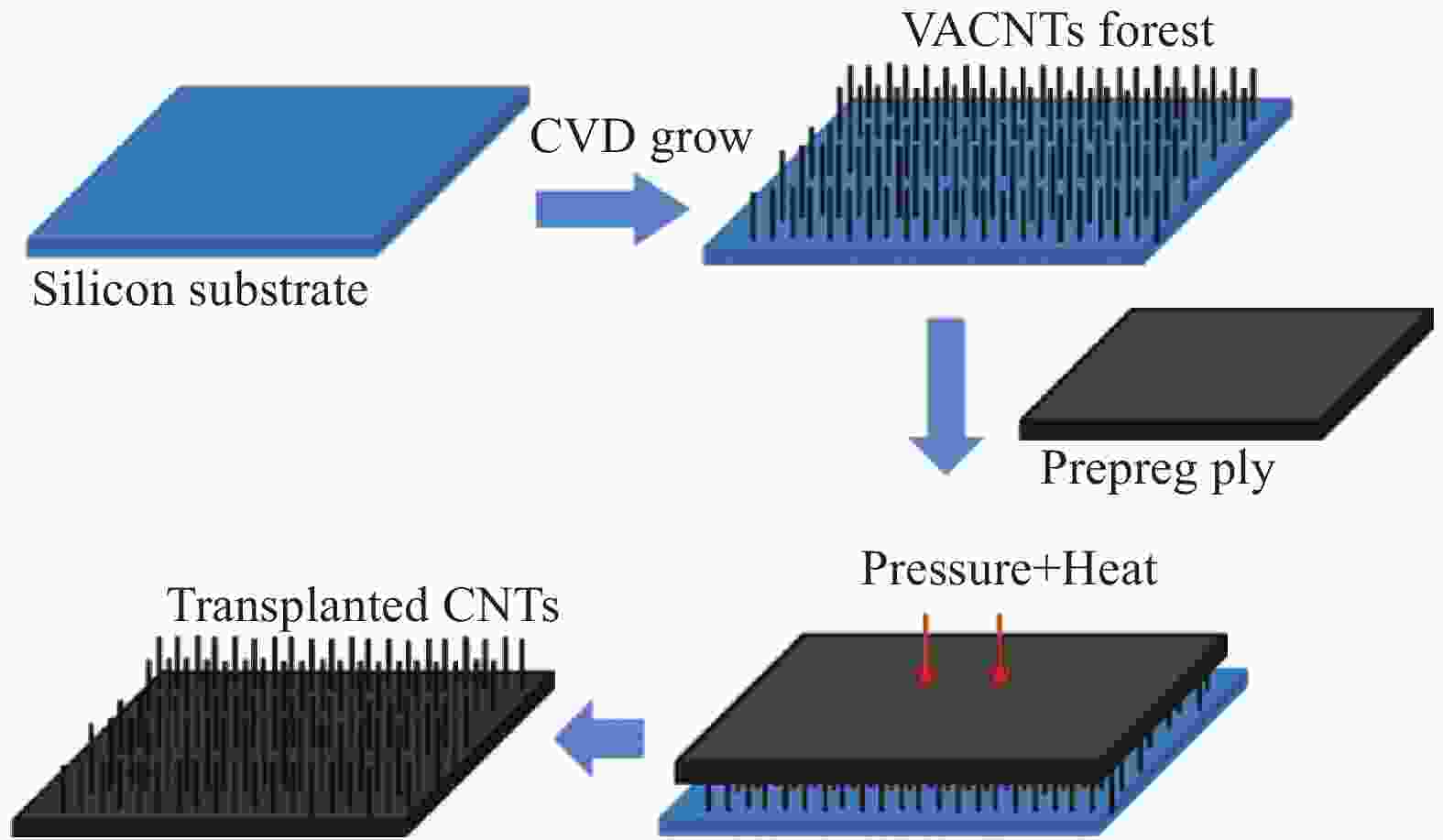

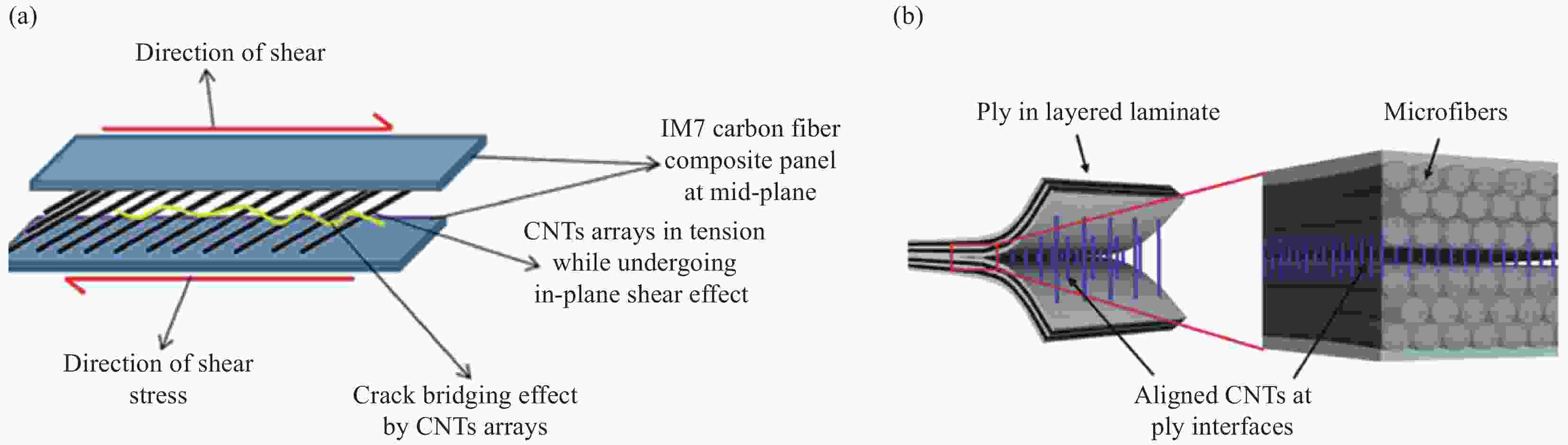

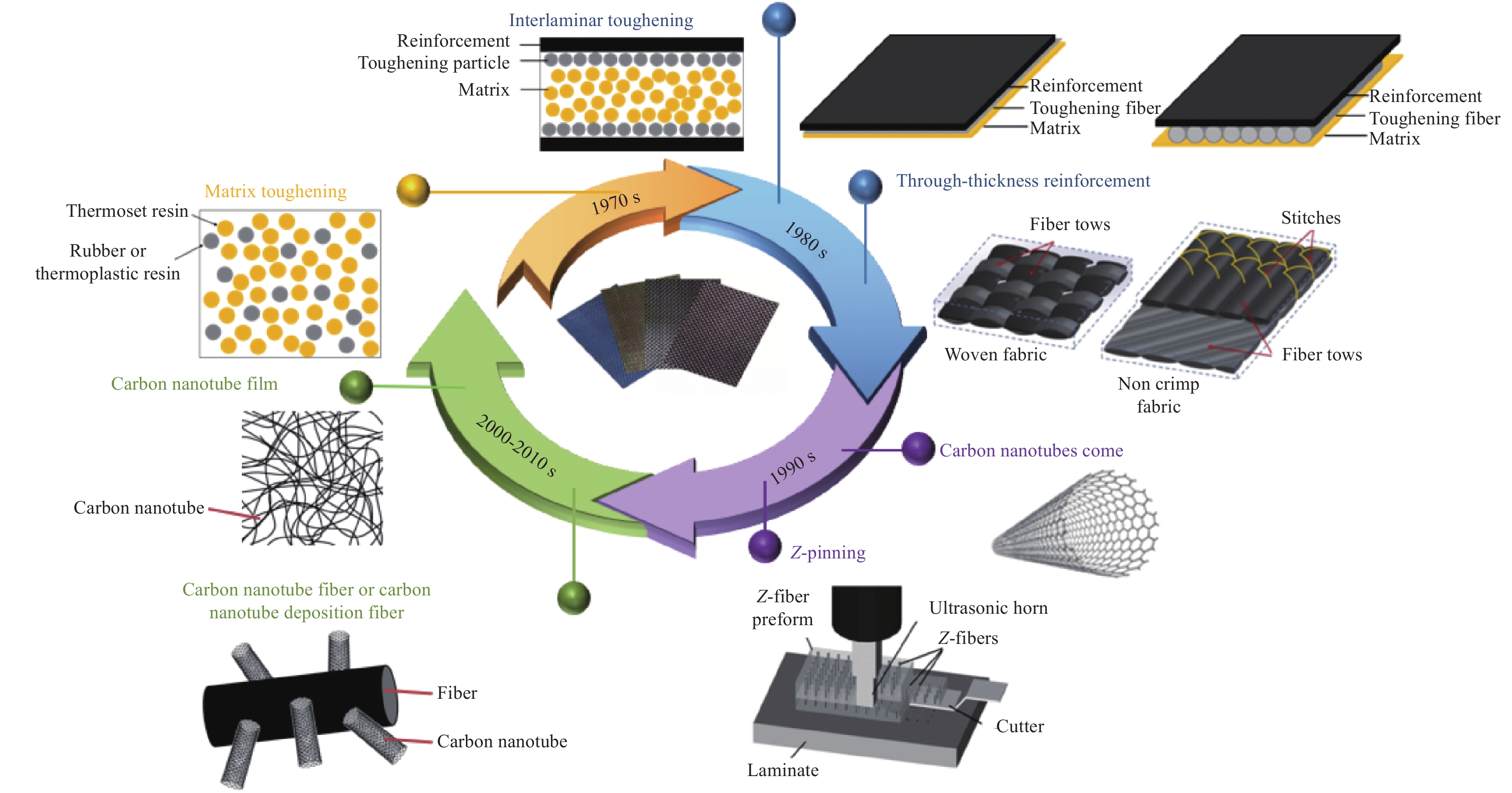

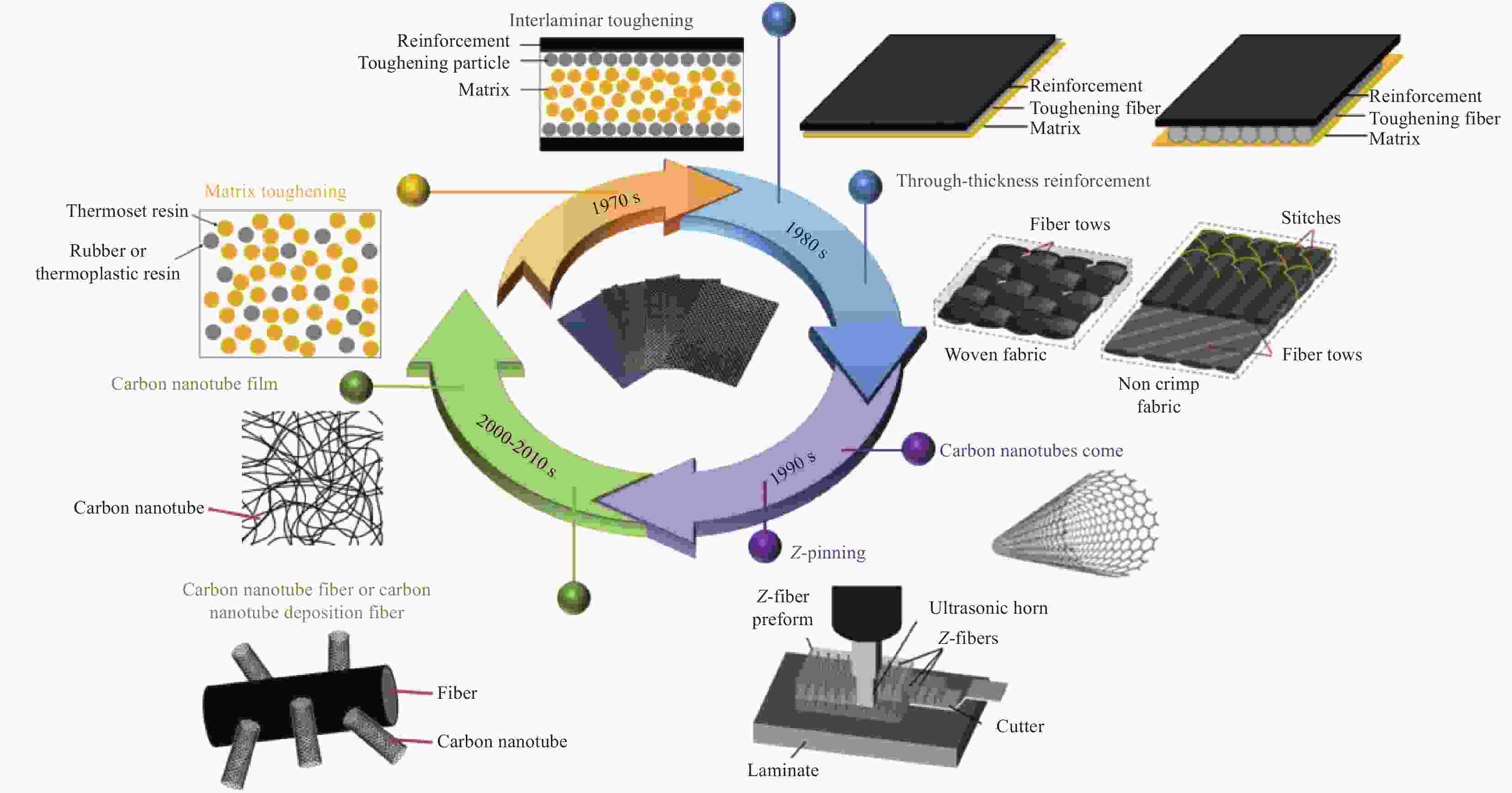

摘要: 碳纳米管(Carbon nanotubes,CNTs)具有优异的力学、热学和电磁学性能,重要用途之一是改性传统的连续纤维增强树脂基复合材料,赋予其更佳的机械强度和多功能性。针对连续纤维增强树脂基复合材料,综述了多种引入CNTs的方法,并就CNTs对连续纤维增强树脂基复合材料性能的影响展开评述,重点介绍了CNTs聚集体改性连续纤维增强树脂基复合材料层间性能的最新研究进展,并展望了未来发展方向。Abstract: Carbon nanotubes (CNTs) has excellent mechanical, thermal and electromagnetic properties. One of its important applications is to modify continuous fiber reinforced resin matrix composites to afford them better mecha-nical and multifunctional properties. For continuous fiber reinforced resin matrix composites, several methods of introducing CNTs are summarized. The interlaminar properties of CNTs-continuous fiber reinforced resin matrix composites are revealed. The latest progress on CNT assemblies-continuous fiber reinforced resin matrix compo-sites is introduced in detail and their future development is also discussed.

-

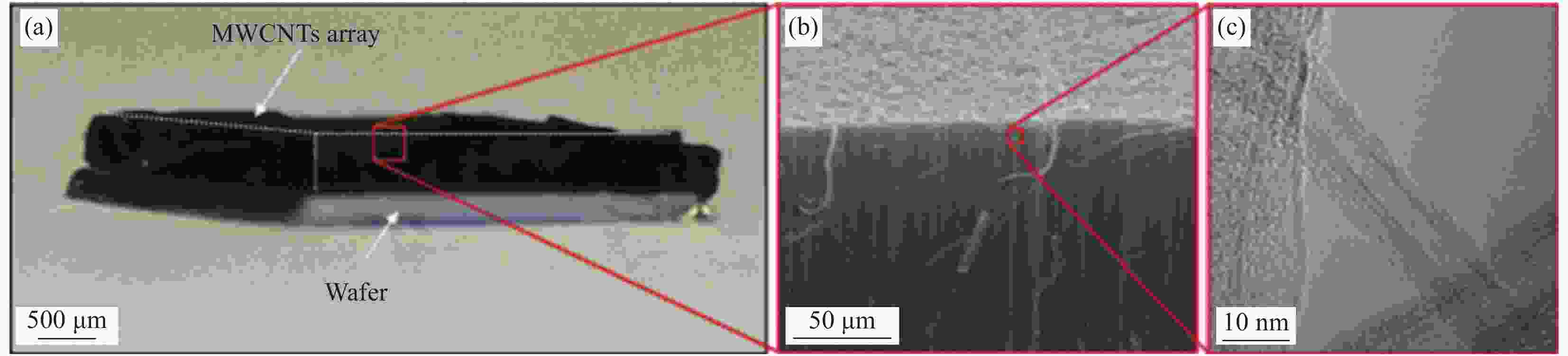

图 4 直径20 nm 间距3倍直径的CNTs组成的VACNTs阵列[18-19]

Figure 4. Aligned CNT array structure comprised of millions of 20 nm-diameter CNTs spaced about 3 diameters apart [18-19]

(a) Optical image of CNTs array-wafer specimen (approx. 5×5×0.5 mm); (b) SEM image of the CNTs array (5 billion MWCNTs/cm2, measured density of 0.022-27 g/cm3 and aspect ratio of 25 000 : 1); (c) HRTEM image of CNTs showing a structure of about 10 walls with an outer diameter of 15 nm and an inner diameter of 4-5 nm

表 1 碳纳米管(CNT)聚集体改性连续纤维增强树脂基复合材料的层间剪切强度(ILSS)

Table 1. Interlaminar shear strength (ILSS) of carbon nanotube (CNT) assemblies modified continuous fiber reinforced resin matrix composites

Fiber/

ResinCNT

contentCNTs

morphologyCNTs

assembliesLay-up CNTs integration

methodFabrication method ILSS/MPa

(Increment)Ref. PWCF/

Epoxy13vol% MWCNTs

(10 walls,

douter=15 nm,

dinner=4-5 nm)Array (h=50-500 μm, 5 billion MWCNT/cm2, ρ=0.022-

0.027 g/cm3)NA ①MWCNTs array removed from wafer and bonded to tape; ②MWCNTs array transferred to carbon fabric Press molding 25.6 (0%) [13] T300-PWCF/

Epoxy18vol% MWCNTs

(d=7-10 nm)Array (h=200 μm,

ρ=0.022-0.027 g/cm3, 5 billion MWCNT/cm2, CNT spacing of

10-20 nm)Separate ply:

9 CNTs array layers +

10 prepregs① Sonication method; ② Adhesive tape method; ③ Mechanical twist method Autoclave 45.8 (80%,

Iosipescu-type shear)[14] UD IM7/

977-3NA MWCNTs Array (h=20 μm) 19 CNTs array layers +

20 prepregs (QI)Place hot iron on substrate and dry ice is applied on back of the substrate Vacuum bag 61.5 (50%, SBS) [15] 47.8 (47%,

Iosipescu-type shear)UD IM7-

G/8552NA MWCNTs Forest (h=5-25 μm) Sharing ply:

15 CNTs forest layers +

16 prepregs (QI)①Press wafer facedown on prepreg and cover with protective film; ②Place on hotplate and heat, apply pressure with roller; ③Peel away film and wafer Autoclave 99.6 (6.5%, SBS) [16] IM7-G/

8552NA MWCNTs

(3-7 walls,

d=8 nm)Forest (h=5-65 μm,

ρ=0.0195 g/cm3, ρaerial≈1vol%, CNTs spacing of ≈60 nm)15 CNTs forest layers +

16 prepregs (QI)①Apply pressure with roller; ②Allow forest to wick into adjacent ply NA 104.6 (8.75%, SBS) [17] Woven IM7/

8552NA MWCNTs Forest (h=75 μm) 11 CNTs forest layers +

12 prepregs (QI)NA Autoclave — (2%, SBS) [18] Forest (h=100 μm) — (−6.3%, SBS) UD AS4/

8552NA MWCNTs Forest (h=20 μm) NA ①Flip wafer onto prepreg and placed on hot plate; ②Take prepreg off the plate and apply pressure Autoclave — (0%) [19] Thick HT-

S40/Q-1112NA MWCNTs

(3-5 walls,

douter≈8 nm)Forest (h=20 μm, ρaerial≈1vol%,

109-1010 MWCNTs/cm2)5 CNTs forest layers +

16 prepregs (QI)Attach prepreg to a rolled cylinder, while pressure is applied, across the Si substrate containing CNT forest to transfer CNTs Autoclave 69.8 (0%, SBS) [20] Thin HTS40/

Q-111215 CNTs forest layers +

48 prepregs (QI)80.6 (5%, SBS) UD AS4/

8552NA MWCNTs

(3-7 walls,

douter≈8 nm,

dinner≈5 nm)Forest (h=20 μm, ρaerial≈1vol%, CNTs spacing of ≈60 nm) 15 CNTs forest layers +

16 prepregs (QI)① Si substrate was positioned with CNTs in contact with prepreg; ② Si substrate/ply assembly was placed on hot plate while pressure was applied Autoclave 96.2 (1.2%, SBS) [21] CF/

EpoxyNanofiber is 2wt% resin MWCNTs

(d=10-20 nm, l=5-15 μm)MWCNTs-EP/PSF hybrid nanofiber (MWCNTs-EP was 20wt% PSF) 16 CNTs veil layers +

16 prepregs①CF/Epoxy prepregs were attached

to drum collector; ②MWCNTs-EP/PSF suspension was directly electrospun onto rotating prepregFlat-plate vulcanizer — (11.9%, 3-point bending) [22] UD Hexcel IM2/Epoxy PR2032 0.016wt% MWCNTs (d=

10 nm)Highly aligned CNTs sheet (drawn from 0.3 mm tall VACNTs forests, t≈100 nm, ρ≈0.025 g/m2) Sharing layer: 15 CNTs

sheet-CF fabrics layers①Place CNT sheets on top and

bottom of CF fabrics; ②15 Layers

CNTs-CF fabrics were stacked

togetherRTM — (30%, SBS) [23] E-glass fabric/Epoxy 0.1wt% MWCNTs Aligned CNTs sheet (drawn out horizontally from VACNTs arrays, 100×50×1.5 mm, ρ=0.354 g/m2) Separate ply: 2 CNTs sheet layers + 32 prepregs (S) Transfer CNTs sheet onto prepreg during ply layup Vacuum bag

and hot press44.4 (0, SBS) [24] PWGF/Aero epoxy NA CNTs Stretched, densified sheet

(l=40 mm, w=2 mm, t=1-2 μm)Sharing layer: 11 CNTs sheet layers + 12 prepregs (S) Insert CNTs sheet in-between GF

plies, epoxy was used as adhesiveHot press 42.7 (9.1%, SBS) [25-26] CF/Un-

known resinNA CNTs Buckypaper NA NA Vacuum-bag — (3.3%, SBS) [27] UD GF/

EpoxyNA Commercially MWCNTs (d=5-

12 nm, l=30-

50 nm)Buckypaper (obtain by spray-vacuum filtration) 1 Buckypaper layer +

16 prepregs (S)Buckypaper was located between the mid-plane layers during the hand lay-up process Vacuum bag

and oven— (83.13%, 3-point bending) [28] PEI grafted UD CF/

Epoxy≈6vol% Commercially MWCNTs (d=20-

30 nm, l=10-

30 μm)Buckypaper (obtain by MWCNTs deposition) NA ① Buckypaper is deposited in situ or stacked on PCF; ② Fully impregnated; ③ Bubble elimination; ④ Stacking and hot pressing Hot press 59 (68.6%, SBS test) [29] MT300 CF/603 NA MWCNTs

(3-7 walls, d=6-

10 nm, acid treated)Randomly oriented film

(t=25 μm)1 CNT film layer +

14 prepregs (S)①Resin impregnation into CNT film; ②CF prepreg and CNT film were layered-up to prepare unidirectional composite laminates Autoclave 108 (Slightly decrease) [30] Randomly oriented film

(t=2 μm)13 CNT film layers +

14 prepregs (S)116 (5%) T700S/Epoxy 0.22wt% MWCNTs

(d=10-20 nm)Film

(CNTs bundles, d=50-60 nm)1 CNTs film layer +

12 prepregs (UD)①CNTs aerogel was deposited onto unidirectional CF fabric which was wrapped on a rotating spindle; ②Infused with epoxy resin;

③Stacked ply-by-ply in the same orientationHot-press molding 43.5 (21.51%, SBS) [31] HS CF/

EpoxyNA NA Randomly oriented commercially CNTs sheets (t=18-23 μm) 14 CNTs sheet layers +

16 prepregs (4S)Insert a CNTs sheet at each fiber/epoxy prepreg 0/90 interface, for a total amount of 14 layers Autoclave 70.51 (−2.6%, SBS) [32] Notes: douter—Outer diameter; dinner—Inner diameter; d—Diameter; h—Height; l—Length; t—Thickness; ρ—Density; ρaerial—Aerial density; MWCNTs—Multi-walled CNTs; SBS—Short beam shear; QI—Quasi-isotropic; S—Symmetry; CF—Carbon fiber; PW—Plain weave; UD—Unidirectional; PEI—Polyethylenimine; GF—Glass fiber; RTM—Resin transfer molding; NA—Not available from the cited studies; Separate and sharing ply—Prepreg of samples is individual or whole; EP—Epoxy resin; PCF—PEI funtionalized CF. 表 2 CNT聚集体改性连续纤维增强树脂基复合材料的层间断裂韧性

Table 2. Interlaminar fracture toughness of continuous fiber reinforced resin matrix composites modified by CNT assemblies

Fiber/

ResinCNTs

contentCNTs

morphologyCNTs assemblies Lay-up CNTs integration method Fabrication method GIC or GIIC/(J·m−2)

(Increment)Ref. Woven SiCf/

Epoxy2wt% MWCNTs Forest (h=60m) 2 CNTs grown-clothes ①CNTs grown on fiber cloth; ②Infiltrated; ③Stacked to yield a "sandwich" structure Autoclave GIC: 4260 (348%)

GIIC: 140 (54%)[33] IM7/977-3 MWCNTs to

forest is 1vol%CNTs (douter=8 nm) Forest (h=60 m, 150 m,

120 m, MWCNTs

spacing of 80 nm)1 CNTs forest layer +

24 prepregs (S)Prepreg is attached to a rolled cylinder, while pressure is applied, across the Si substrate containing

CNTs forest to transfer CNTsAutoclave GIC: 530 (250%) [34] AS4/8552 GIC: 340 (150%)

GIIC: 1100 (300%)T700/M21 MWCNTs to

forest is 1vol%MWCNTs (7 walls, dr=10 nm) Forest (h=100-200 m) 1 CNTs forest layer +

28 prepregs① Heat and pressure applied to Si substrate; ②Removal of substrate

after cool down period; ③Transplanted CNTs forest infused with resinVacuum bag GIC: 435 (31%)

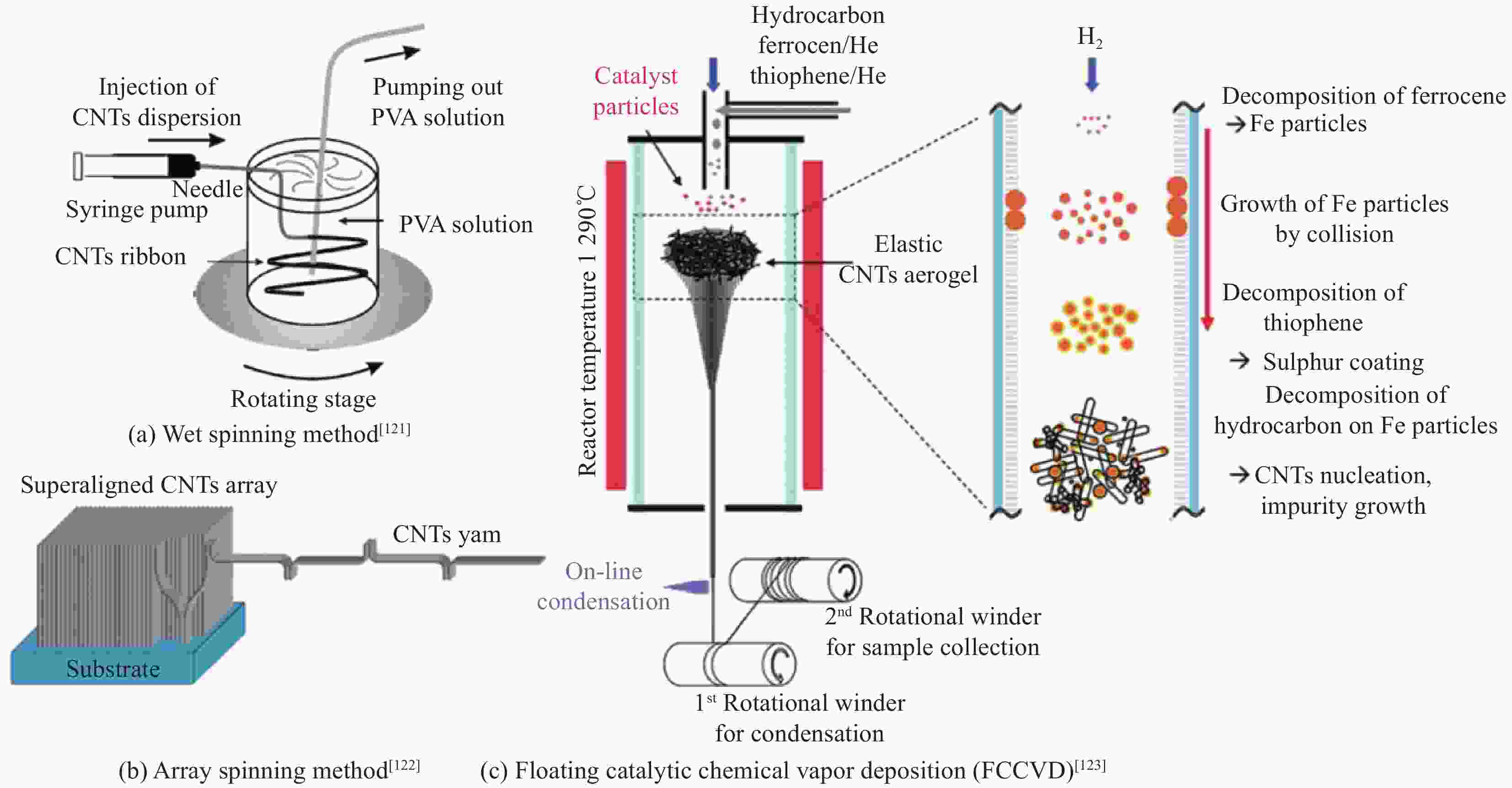

GIIC: 1155 (161%)[35] T700/

SE84LVNA 1 CNTs forest layer +

14 prepregsGIC: 338 (61%) UD AS4/

8552MWCNTs to

forest is 1vol%MWCNTs (3-

7 walls, dinnerr≈5 nm, douter≈8 nm)Forest (h=(20±5) μm,

109-1010 MWCNTs/cm2, MWCNTs spacing of

80 nm)1 CNTs forest layer +

24 prepregsTransfer CNTs forest onto the tacky surface of the composite prepreg before laminate assembly Autoclave GIC, INIT: 300 (0%)

GIC, PROP: 220 (0%)[36] 1 CNTs forest layer+

30 prepregsGIIC, INIT: 1790 (24%)

GIIC, PROP: 580 (0%)CF/Epoxy Nanofiber is 2wt% resin MWCNTs

(d=10-

20 nm, l=5-15 μm)MWCNTs-EP/PSF hybrid nanofiber (MWCNTs-EP

was 20wt% PSF)16 CNTs veil layers +

16 prepregs①CF/Epoxy prepregs were attached

to drum collector; ②MWCNTs-EP/

PSF suspension was directly electrospun onto rotating prepregFlat-plate vulcanizer GIIC: — (48.4%) [27] G0926 WF/Epoxy vinyl ester 1vol% MWCNTs (3-5 walls, d=3-9 nm, l=1 mm) CNTs veil (t=30 m after infusion,

ρaerial=0.8 g/m2)1 CNTs veil layer+

8 prepregs (S)The interleaves were produced by winding continuous fiber of CNTs directly onto CF fabric wrapped around a cylindrical winder VARTM GIC, PROP: — (60%) [37] Densified CNTs veils GIC, PROP: — (–28.4%) T300 fabric/

E-51NA Carboxyl MWCNTs CNTs-decorated Polycaprolactone (PCL) nanofiber (ρaerial=15 g/m2) 1 CNTs-decorated

PCL layer +

16 prepregs①CNTs/PCL interleaf was placed in the mid-plane of the laminate;

②Hand lay-upHot-press GIC: 670 (68%)

GIIC: 2300 (44%)[38] PWCF/

EpoxyCNTs in interleaf is 0.5 and 1.0vol% Carboxyl MWCNTs (d=20-30 nm, l=10-

30 mm, —COOH content is 1.23wt%)CNTs/PSF nanofibrous paper (CNTs is 5wt% and 10wt% of PSF) 1 CNTs/PSF

nanofibrous paper

layer + 16 prepregs①CNTs/PSF nanofibrous paper is placed in the mid-plane;

②Hand lay-upVacuum bag and hot press GIC: 750 (53%)

GIIC: 1 870 (34%)[39] UD Hexcel IM2/Epoxy PR2032 0.016wt% MWCNTs (d=10 nm) Highly aligned CNTs sheet (drawn from

0.3 mm tall VACNT forests, t≈100 nm, ρ≈0.025 g/m2)Sharing layer:

15 CNTs sheet-CF

fabrics layers①Place CNTs sheets on top and bottom of CF fabrics; ②15 CNTs-CF fabrics layers were stacked together RTM GIC, INIT: — (57%);

GIC, PROP: — (30%)[28] E-glass fabric/

Epoxy0.1wt% MWCNTs Aligned CNTs sheet (drawn out horizontally from VACNTs arrays, 100×50×

1.5 mm, ρ=0.354 g/m2)Separate ply: 2 CNTs sheet layers +

32 prepregs (S)Transfer CNTs sheet onto prepreg during ply layup Vacuum bag and hot press GIC: 273 (46.77%, parallel),

225 (20.97%, perpendicular)

GIIC: 438 (−6.2%, parallel),

547 (17.13%, perpendicular)[29] IM7/8552 NA Single walled- and few walled-CNTs Stretched (121%) directional CNTs sheet (ρaerial=9.8 g/m2) 1 CNTs sheet layer +

32 prepregs (UD)①Pre-infused CNTs/epoxy sheet; ②Interleaving aligned, same direction for CNTs sheets and CF Vacuum hot press GIC: 200 (Decrease)

GIIC: 1101.6 (63%)[40] UD GF/

EpoxyNA Commercially MWCNTs (d=5-12 nm,

l=30-50 nm)Buckypaper (obtain

by spray-vacuum filtration)1 Buckypaper layer +

16 prepregs (S)Buckypaper is located between the

mid-plane layers during hand lay-up processVacuum bag and oven GIC, INIT: ≈800 (174.81%),

GIC, PROP: 2500 (179.97%);

GIIC: ≈1050 (55.12%)[33] PEI grafted UD CF/

Epoxy≈6vol% Commercially MWCNTs (d=20-

30 nm, l=10-30 μm)Buckypaper (obtain by MWCNTs deposition) NA ① Buckypaper is deposited in situ or stacked on PCF; ② Fully impregnated; ③ Bubble elimination; ④ Stacking

and hot pressingHot press GIIC: 650 (44.4%) [34] T700 CF/Epoxy NA Commercially MWCNTs (d=8-15 nm, l=5-15 mm) Crosslinked buckypaper (t=18-23 mm,

d=280 mm)1 Buckypaper +

16 prepregs (UD)Buckypaper is directly incorporated into the middle interface of laminates Autoclave GIC: 660 (74%)

GIIC: 2330 (82%)[41] Bi-direction-

al E-glass woven fabric/EpoxyNA MWCNTs Plasma-treated buckypaper (d=70 mm, t=50-75 μm) 1 Buckypaper +

14 prepregs①Attach plasma-treated buckypaper to roller and applied to impregnated GF surface; ②Wet hand lay-up Heat + press GIC: 560 (16%)

GIIC: 1796 (23%)[42] U3160/3266 NA MWCNTs (d=50-

100 nm, l=100-500 μm)CNTs film

(t=30-40 μm)23 CNTs films +

24 prepregs (UD)①CNTs film is laid between CF fabrics; ②Fully impregnated; ③Bubble elimination RTM GIC: 314.8 (0%)

GIIC: 2869 (120%)[43] UD HMC/ SE84LV NA Amino-MWCNTs

(6 walls, d=10 nm,

l=300 m)CNTs webs (10 layers, ρaerial=0.2 g/m2,

w=60 mm)10 CNTs web layers +

12 HMC/SE84LV prepregs (S)①CNTs forests grow; ②CNTs are directly drawn and wound onto Al frames;③Amino functionalization;

④ CNTs webs are laid down perpendicular to fiberHeat under constant vacuum GIC, CNTs: 467 (−9%)

GIC, EDA-CNTs: 580 (13%)

GIC, DAD-CNTs: 428 (−16%)[44] NTPT 402 NA MWCNTs (6 walls, d=10 nm, l=300 m) CNTs webs (10 layers, ρaerial=0.2 g/m2,

70×70 mm2)10 CNTs web layers +

6 NTPT 402 prepregs +

12 SE84LV prepregs (S)①CNTs forests grow; ②CNTs are directly drawn and wound onto Al frames to produce 70×70 mm2 webs; ③CNTs webs were laid down perpendicular to fiber Autoclave GIC, INIT: 140 (−44%);

GIC, PROP: 140 (−68%)[45] TeXtreme/SE84LV 10 CNTs web layers +

2 TeXtreme prepregs +

12 SE84LV prepregs (S)GIC, INIT: 160 (−11%)

GIC, PROP: 250 (0%)T300 fabrics/

EpoxyNA MWCNTs (d=10 nm, l=1 mm) CNTs film (CNTs deposition, ρaerial=0.58-12.48 g/m2) 1 CNTs film +

14 prepregs (UD)①CNTs film is laid between CF fabrics; ②Bubble elimination of epoxy;

③Fully impregnatedVARTM GIC, Quasi-static: 626 (100%)

GIC, Dynamic: 1380 (140%)[46] T300 fabrics/

EpoxyNA NA CNTs belt (100 mm×

5 mm×10 μm, ρaerial=

4.68 g/m2)CNTs belt layers +

12 prepregs (UD)①CNTs belts cut from CNTs film; ②Pre-impregnated CNTs belts; ③CNTs belts stitch UD CF fabrics; ④Impregnated VARTM GIC, VIS: 420.05 (95.2%)

GIC, PROP: 574.57 (62.5%)

GIIC: 1238.56 (94.3%)[47] Notes: EP—Epoxy resin; PSF—Polysulfone; CF—Carbon fiber; VARTM—Vacuum assisted resin transfer molding; GC—Critical energy release rate; HMC/SE84LV—High modulus carbon fibre/toughened epoxy resin prepreg; EDA—Ethylenediamine; DAD—1, 10-Diaminodecane; INIT—Initial; PROP—Propagation; PVA—Polyvinyl alcohol. 表 3 不同高度VACNTs 阵列-碳纤维增强环氧树脂复合材料的力学性能[14]

Table 3. Mechanical properties of VACNTs array-carbon fiber/epoxy composite samples with VACNTs array of different heights [14]

VACNTs height/µm VACNTs content/

vol%ILSS/

MPaTensile strength/MPa 0 0 25.4 189.4 100 16 25.6 204.2 200 18 45.8 155.9 300 15 41 96.6 500 31 32.3 108.6 1000 33 32.2 NA Note: ILSS—Interlaminar shear strength. -

[1] KOLEDNIK O, KASBERGER R, SISTANINIA M, et al. Development of damage-tolerant and fracture-resistant materials by utilizing the material inhomogeneity effect[J]. Journal of Applied Mechanics,2019,86(11):111004. doi: 10.1115/1.4043829 [2] BOON Y D, JOSHI S C. A review of methods for improving interlaminar interfaces and fracture toughness of lami-nated composites[J]. Materials Today Communications,2020,22:100830. doi: 10.1016/j.mtcomm.2019.100830 [3] American Society for Testing and Materials. D5379/5379M Standard test method for shear properties of composite materials by the V-notched beam method[S]. West Conshohocken, US: American Society for Testing and Materials International, 2014. [4] American Society for Testing and Materials. D2344/D2344M Standard test method for short-beam strength of polymer matrix composite materials and their laminates[S]. West Conshohocken, US: American Society for Testing and Materials International, 2000. [5] American Society for Testing and Materials. D7905/D7905M Standard test method for determination of the mode II interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites[S]. West Conshohocken, US: American Society for Testing and Materials International, 2019. [6] American Society for Testing and Materials. D5528/5528M Standard test method for mode I interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites[S]. West Conshohocken, US: American Society for Testing and Materials International, 1994. [7] HUNSTON D L, MOULTON R J, MOULTON R J, et al. Matrix resin effects in composite delamination: Mode I fracture aspects[C]//JOHNSTON N J. West Conshohocken: ASTM International, 1987: 74-94. [8] IIJIMA S. Helical microtubules of graphtic carbon[J]. Nature, 1991, 354(7): 56-58. [9] 沈登雄, 李志生, 刘金刚, 等. 碳/环氧复合材料层间增韧研究进展[J]. 宇航材料工艺, 2013, 43(4):1-7. doi: 10.3969/j.issn.1007-2330.2013.04.002SHEN Dengxiong, LI Zhisheng, LIU Jingang, et al. Recent progress on interlayer toughening of C/E composites[J]. Aerospace Materials & Technology,2013,43(4):1-7(in Chinese). doi: 10.3969/j.issn.1007-2330.2013.04.002 [10] 董慧民, 益小苏, 安学锋, 等. 纤维增强热固性聚合物基复合材料层间增韧研究进展[J]. 复合材料学报, 2014, 31(2):273-285.DONG Huimin, YI Xiaosu, AN Xuefeng, et al. Development of interleaved fibre-reinforced thermoset polymer matrix composites[J]. Acta Materiae Compositae Sinica,2014,31(2):273-285(in Chinese). [11] 卢康逸, 张月义, 杨小平, 等. 碳纤维复合材料层间增强增韧技术研究进展[J]. 航空制造技术, 2020, 63(18):14-23.LU Kangyi, ZHANG Yueyi, YANG Xiaoping, et al. Research development of interlaminar reinforcing and toughening technique of carbon fiber composites[J]. Aeronautical Manufacturing Technology,2020,63(18):14-23(in Chinese). [12] 郑锡涛, 罗贵, 李宇徒. 复合材料层间性能改善方法研究进展[J]. 航空制造技术, 2013, 15:26-29. doi: 10.3969/j.issn.1671-833X.2013.03.002ZHENG Xitao, LUO Gui, LI Yutu. Review of methods on improving interlaminar properties of composites laminate[J]. Aeronautical Manufacturing Technology,2013,15:26-29(in Chinese). doi: 10.3969/j.issn.1671-833X.2013.03.002 [13] ABOT J L, SONG Y, SCHULZ M J, et al. Novel carbon nano-tube array-reinforced laminated composite materials with higher interlaminar elastic properties[J]. Compo-sites Science and Technology,2008,68(13):2755-2760. doi: 10.1016/j.compscitech.2008.05.023 [14] SONG Y. Multifunctional composites using carbon nanotube fiber materials[D]. Cincinnati: University of Cincinnati, 2012. [15] SONG Y, SUBERU B, SHANOV V, et al. Multiscale lami-nated composite materials[M]//SCHULZ M J, SHANOV V N, YIN Z. Nanotube superfiber materials. Boston: William Andrew Publishing, 2014: 627-647. [16] LEWIS D, WARDLE B L. Interlaminar shear strength investigation of aligned carbon nanotube-reinforced prepreg composite interfaces[C]. Florida: 56th AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, 2015. [17] LEWIS D. Interlaminar reinforcement of carbon fiber composites from unidirectional prepreg utilizing aligned carbon nanotubes[D]. Cambrige: Massachusetts Institute of Technology, 2016. [18] KALFON-COHEN E, LEWIS D, RAVINE J, et al. Structure-process-property study of aligned carbon nanotube interlaminar reinforcement in woven carbon fiber prepreg laminate[C]. California: 57th AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, 2016. [19] NI X C, KALFON-COHEN E, FURTADO C, et al. Interlaminar reinforcement of carbon fiber composites using aligned carbon nanotubes[C]. Xi'an: 21st International Conference on Composite Materials, 2017. [20] KALFON-COHEN E, KOPP R, FURTADO C, et al. Synergetic effects of thin plies and aligned carbon nanotube interlaminar reinforcement in composite laminates[J]. Composites Science and Technology,2018,166:160-168. doi: 10.1016/j.compscitech.2018.01.007 [21] NI X, FURTADO C, KALFON-COHEN E, et al. Static and fatigue interlaminar shear reinforcement in aligned carbon nanotube-reinforced hierarchical advanced composites[J]. Composites Part A: Applied Science and Manu-facturing,2019,120:106-115. doi: 10.1016/j.compositesa.2019.02.023 [22] LI P, LIU D, ZHU B, et al. Synchronous effects of multiscale reinforced and toughened CFRP composites by MWNTs-EP/PSF hybrid nanofibers with preferred orientation[J]. Composites Part A: Applied Science & Manufacturing,2015,68:72-80. [23] KOIRALA P, VAN DE WERKEN N, LU H, et al. Using ultra-thin interlaminar carbon nanotube sheets to enhance the mechanical and electrical properties of carbon fiber reinforced polymer composites[J]. Composites Part B: Engi-neering,2021,216:108842. doi: 10.1016/j.compositesb.2021.108842 [24] BHANUSHALI H, BRADFORD P D. Woven glass fiber composites with aligned carbon nanotube sheet interlayers[J]. Journal of Nanomaterials,2016,2016:1-9. [25] SONG Y, CHAUHAN D, HOU G,et al. Carbon nanotube sheet reinforced laminated composites[C]. Williamsburg: American Society for Composites Technical Conference, 2016: 1-7. [26] CHAUHAN D, HOU G, NG V, et al. Multifunctional smart composites with integrated carbon nanotube yarn and sheet[C]. Portland: Proceedings of the SPIE 10172, A Tribute Conference Honoring Daniel Inman, 2017. [27] XIONG X H, WANG H, ZENG Y, et al. Effect of buckypaper on the properties of carbon fiber reinforced hybrid composites[C]. Xi'an: 21st International Conference on Composite Materials, 2017. [28] LI N, WANG G D, MELLY S K, et al. Interlaminar properties of GFRP laminates toughened by CNTs buckypaper interlayer[J]. Composite Structures,2019,208(1):13-22. [29] WU Y, CHENG X, CHEN S, et al. In situ formation of a carbon nanotube buckypaper for improving the interlaminar properties of carbon fiber composites[J]. Materials & Design,2021,202:109535. [30] LI T, LI M, GU Y, et al. Mechanical enhancement effect of the interlayer hybrid CNT film/carbon fiber/epoxy composite[J]. Composites Science and Technology,2018,166:176-182. doi: 10.1016/j.compscitech.2018.02.007 [31] XU H, TONG X, ZHANG Y, et al. Mechanical and electri-cal properties of laminated composites containing continuous carbon nanotube film interleaves[J]. Composites Science & Technology,2016,127:113-118. [32] XIN W, SARASINI F, TIRILLÒ J, et al. Impact and post-impact properties of multiscale carbon fiber composites interleaved with carbon nanotube sheets[J]. Composites Part B: Engineering,2020,183:107711. doi: 10.1016/j.compositesb.2019.107711 [33] VEEDU V P, CAO A, LI X, et al. Multifunctional compo-sites using reinforced laminae with carbon-nanotube forests[J]. Nature Materials,2006,5(6):457-462. doi: 10.1038/nmat1650 [34] GARCIA E J, WARDLE B L, JOHN H A. Joining prepreg composite interfaces with aligned carbon nanotubes[J]. Composites Part A: Applied Science and Manufacturing,2008,39(6):1065-1070. doi: 10.1016/j.compositesa.2008.03.011 [35] FALZON B G, HAWKINS S C, HUYNH C P, et al. An investigation of mode I and mode II fracture toughness enhancement using aligned carbon nanotubes forests at the crack interface[J]. Composite Structures,2013,106:65-73. doi: 10.1016/j.compstruct.2013.05.051 [36] NI X, FURTADO C, FRITZ N K, et al. Interlaminar to intralaminar mode I and II crack bifurcation due to aligned carbon nanotube reinforcement of aerospace-grade advanced composites[J]. Composites Science and Technology,2020,190:108014. doi: 10.1016/j.compscitech.2020.108014 [37] OU Y, GONZÁLEZ C, VILATELA J J. Interlaminar toughening in structural carbon fiber/epoxy composites interleaved with carbon nanotube veils[J]. Composites Part A: Applied Science and Manufacturing,2019,124:105477. doi: 10.1016/j.compositesa.2019.105477 [38] SONG X, GAO J, ZHENG N, et al. Interlaminar toughening in carbon fiber/epoxy composites interleaved with CNT-decorated polycaprolactone nanofibers[J]. Composites Communications,2021,24:100622. doi: 10.1016/j.coco.2020.100622 [39] ZHENG N, HUANG Y, LIU H Y, et al. Improvement of interlaminar fracture toughness in carbon fiber/epoxy composites with carbon nanotubes/polysulfone interleaves[J]. Composites Science and Technology,2017,140:8-15. doi: 10.1016/j.compscitech.2016.12.017 [40] CANO R J, JIN H K, GRIMSLEY B W, et al. Properties of multifunctional hybrid carbon nanotube/carbon fiber polymer matrix composites[C]. Washington DC: National SBIR/STTR Conference, Annual Nanotech Conference and Expo, Annual Tech Connect World Innovation Conference Expo, 2016: 221-224. [41] LIU L, SHEN L, ZHOU Y. Improving the interlaminar fracture toughness of carbon/epoxy laminates by directly incorporating with porous carbon nanotube buckypaper[J]. Journal of Reinforced Plastics and Composites,2016,35(2):165-176. doi: 10.1177/0731684415610919 [42] KRAVCHENKO O G, PEDRAZZOLI D, KOVTUN D, et al. Incorporation of plasma-functionalized carbon nanostructures in composite laminates for interlaminar reinforcement and delamination crack monitoring[J]. Jour-nal of Physics and Chemistry of Solids,2018,112:163-170. doi: 10.1016/j.jpcs.2017.09.018 [43] 刘刚, 胡晓兰, 张朋, 等. 碳纳米管膜层间改性碳纤维/环氧树脂复合材料[J]. 高分子学报, 2013(10):1334-1340.LIU Gang, HU Xiaolan, ZHANG Peng, et al. Carbon nanotube film interlayer toughened carbon fiber reinforced epoxy resin hybrid composites[J]. Acta Polymerica Sinica,2013(10):1334-1340(in Chinese). [44] NISTAL A, FALZON B G, HAWKINS S C, et al. Enhancing the fracture toughness of hierarchical composites through amino‒functionalised carbon nanotube webs[J]. Compo-sites Part B: Engineering,2019,165:537-544. doi: 10.1016/j.compositesb.2019.02.001 [45] DI LEONARDO S, NISTAL A, CATALANOTTI G, et al. Mode I interlaminar fracture toughness of thin-ply lami-nates with CNT webs at the crack interface[J]. Composite Structures,2019,225:111178. doi: 10.1016/j.compstruct.2019.111178 [46] LI Z, WANG Y, CAO J, et al. Effects of loading rates on mode I interlaminar fracture toughness of carbon/epoxy composite toughened by carbon nanotube films[J]. Composites Part B: Engineering,2020,200:108270. doi: 10.1016/j.compositesb.2020.108270 [47] LI H, YU Y, XU X, et al. Enhancing the fracture toughness of laminated composites through carbon nanotube belt stitching[J]. Composites Science and Technology,2021,204:108632. doi: 10.1016/j.compscitech.2020.108632 [48] FAN Z, SANTARE M H, ADVANI S G. Interlaminar shear strength of glass fiber reinforced epoxy composites enhanced with multi-walled carbon nanotubes[J]. Compo-sites Part A: Applied Science & Manufacturing,2008,39(3):540-554. [49] QIAN H, GREENHALGH E S, SHAFFER M S P, et al. Carbon nanotube-based hierarchical composites: A review[J]. Journal of Materials Chemistry,2010,20(23):4751-4762. doi: 10.1039/c000041h [50] SHARMA V. Influence of amine functionalized multi-walled carbonnanotubes on the mechanical properties of carbonfiber/epoxy composites[J]. Materials Today: Proceedings,2021,37:2978-2981. doi: 10.1016/j.matpr.2020.08.710 [51] PARK S J. Effect of ozone-treated single-walled carbon nanotubes on interfacial properties and fracture toughness of carbon fiber-reinforced epoxy composites[J]. Composites Part A: Applied Science and Manufacturing,2020,137:105937. doi: 10.1016/j.compositesa.2020.105937 [52] BAKIS G, WENDEL J F, ZEILER R, et al. Mechanical pro-perties of the carbon nanotube modified epoxy-carbon fiber unidirectional prepreg laminates[J]. Polymers,2021,13(5):770. doi: 10.3390/polym13050770 [53] SRITHARAN R, ASKARI D. Enhancing the short-beam strength of composite laminates using helical carbon nanotubes[J]. Composites Part B: Engineering,2021,221:108999. doi: 10.1016/j.compositesb.2021.108999 [54] ALI A, ANDRIYANA A, HASSAN S B A, et al. Fabrication and thermo-electro and mechanical properties evaluation of helical multiwall carbon nanotube-carbon fiber/epoxy composite laminates[J]. Polymers,2021,13:1437. doi: 10.3390/polym13091437 [55] ZHANG T, CHENG Q, XU Z, et al. Improved interfacial property of carbon fiber composites with carbon nanotube and graphene oxide as multi-scale synergetic reinforcements[J]. Composites Part A: Applied Science and Manufacturing,2019,125:105573. doi: 10.1016/j.compositesa.2019.105573 [56] HE Y, CHEN Q, WU D, et al. Effect of multiscale reinforcement by fiber surface treatment with polyvinyl alcohol/graphene oxide/oxidized carbon nanotubes on the mechanical properties of reinforced hybrid fiber composites[J]. Composites Science and Technology,2021,204:108634. doi: 10.1016/j.compscitech.2020.108634 [57] THOSTENSON E T, LI W Z, WANG D Z, et al. Carbon nanotube/carbon fiber hybrid multiscale composites[J]. Journal of Applied Physics,2002,91(9):6034-6037. doi: 10.1063/1.1466880 [58] ANTHONY D B, SUI X M, ISRAEL K, et al. Continuous carbon nanotube synthesis on charged carbon fibers[J]. Composites Part A: Applied Science and Manufacturing,2018,112:525-538. doi: 10.1016/j.compositesa.2018.05.027 [59] YAO Z, WANG C, LU R, et al. Fracture investigation of functionalized carbon nanotubes-grown carbon fiber fabrics/epoxy composites[J]. Composites Science and Technology,2020,195:108161. doi: 10.1016/j.compscitech.2020.108161 [60] ZHOU J, ZHONG K, ZHAO C, et al. Effect of carbon nanotubes grown temperature on the fracture behavior of carbon fiber reinforced magnesium matrix composites: Interlaminar shear strength and tensile strength[J]. Ceramics International,2021,47(5):6597-6607. doi: 10.1016/j.ceramint.2020.10.249 [61] 张福华. 碳纳米管/碳纤维多尺度增强体及其复合材料界面研究[D]. 哈尔滨: 哈尔滨工业大学, 2008.ZHANG Fuhua. Study on carbon nanotube/carbon fiber multi-scale reinforcement and its composite interfacial properties[D]. Harbin: Harbin Institute of Technology, 2008(in Chinese). [62] 梅蕾, 碳纳米管/碳纤维多尺度结构制备及其界面增强效果研究[D]. 哈尔滨: 哈尔滨工业大学, 2010.MEI Lei. Study on carbon nanotube/carbon fiber multi-scale structure and it's interfacial reinforcing effect[D]. Harbin: Harbin Institute of Technology, 2010(in Chinese). [63] FENG Z, HUANG Y, BAI Y, et al. Formation of a carbon fiber/polyhedral oligomeric silsesquioxane/carbon nanotube hybrid reinforcement and its effect on the interfacial properties of carbon fiber/epoxy composites[J]. Carbon,2011,49:2624-2632. doi: 10.1016/j.carbon.2011.02.026 [64] WANG Y, MENG L, FAN L, et al. Preparation and properties of carbon nanotube/carbon fiber hybrid reinforcement by a two-step aryl diazonium reaction[J]. RSC Advances,2015,5(55):44492-44498. doi: 10.1039/C5RA04117A [65] 王宇威. 重氮反应修饰碳纤维表面及其复合材料界面性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2016.WANG Yuwei. Surface modification of carbon fibers via diazoium reaction and interfacial properties of their composites [D]. Harbin: Harbin Institute of Technology, 2016(in Chinese). [66] LAACHACHI A, VIVET A, NOUET G, et al. A chemical method to graft carbon nanotubes onto a carbon fiber[J]. Materials Letters,2008,62(3):394-397. doi: 10.1016/j.matlet.2007.05.044 [67] KEPPLE K L, SANBORN G P, LACASSE P A, et al. Improved fracture toughness of carbon fiber composite functionalized with multi walled carbon nanotubes[J]. Carbon,2008,46(15):2026-2033. doi: 10.1016/j.carbon.2008.08.010 [68] KIM H, OH E, HAHN H T, et al. Enhancement of fracture toughness of hierarchical carbon fiber composites via improved adhesion between carbon nanotubes and carbon fibers[J]. Composites Part A: Applied Science and Manufacturing,2015,71:72-83. doi: 10.1016/j.compositesa.2014.12.014 [69] GARCIA E J, WARDLE B L, JOHN HART A, et al. Fabrication and multifunctional properties of a hybrid laminate with aligned carbon nanotubes grown in situ[J]. Composites Science and Technology,2008,68(9):2034-2041. doi: 10.1016/j.compscitech.2008.02.028 [70] YAMAMOTO N, WICKS S S, GUZMAN DE VILLORIA R, et al. Mechanical, thermal, and electrical properties of woven laminated advanced composites containing aligned carbon nanotubes[C]. United Kingdom: ICCM International Conferences on Composite Materials, 2009. [71] GARCÍA E J, HART A J, WARDLE B L. Long carbon nano-tubes grown on the surface of fibers for hybrid composites[J]. AIAA Journal,2008,46(6):1405-1412. doi: 10.2514/1.25004 [72] WICKS S S, DE VILLORIA R G, WARDLE B L. Interlaminar and intralaminar reinforcement of composite laminates with aligned carbon nanotubes[J]. Composites Science and Technology,2010,70(1):20-28. doi: 10.1016/j.compscitech.2009.09.001 [73] ZHANG F H, WANG R G, HE X D, et al. Interfacial shearing strength and reinforcing mechanisms of an epoxy composite reinforced using a carbon nanotube/carbon fiber hybrid[J]. Journal of Materials Science,2009,44(13):3574-3577. doi: 10.1007/s10853-009-3484-x [74] ESKIZEYBEK V, AVCI A, GÜLCE A. The mode I interlaminar fracture toughness of chemically carbon nanotube grafted glass fabric/epoxy multi-scale composite structures[J]. Composites Part A: Applied Science and Manufacturing,2014,63:94-102. doi: 10.1016/j.compositesa.2014.04.013 [75] MEI L, LI Y, WANG R, et al. Multiscale carbon nanotube-carbon fiber reinforcement for advanced epoxy compo-sites with high interfacial strength[J]. Polymers and Polymer Composites,2011,19(2-3):107-112. doi: 10.1177/0967391111019002-309 [76] ZHANG R L, WANG C G, LIU L, et al. Polyhedral oligomeric silsesquioxanes/carbon nanotube/carbon fiber multiscale composite: Influence of a novel hierarchical reinforcement on the interfacial properties[J]. Applied Surface Science,2015,353:224-231. doi: 10.1016/j.apsusc.2015.06.156 [77] QIN J, WANG C, WANG Y, et al. Preparation carbon nanotube-decorated carbon fibers under low pressure for epoxy-based unidirectional hierarchical composites with enhanced interlaminar shear strength[J]. Polymer Testing,2021,93:106892. doi: 10.1016/j.polymertesting.2020.106892 [78] QIAN H, BISMARCK A, GREENHALGH E S, et al. Hierarchical composites reinforced with carbon nanotube grafted fibers: The potential assessed at the single fiber level[J]. Chemistry of Materials,2008,20(5):1862-1869. doi: 10.1021/cm702782j [79] SAGER R J, KLEIN P J, LAGOUDAS D C, et al. Effect of carbon nanotubes on the interfacial shear strength of T650 carbon fiber in an epoxy matrix[J]. Composites Science & Technology,2009,69(7-8):898-904. [80] DE LUCA H G, ANTHONY D B, GREENHALGH E S, et al. Piezoresistive structural composites reinforced by carbon nanotube-grafted quartz fibres[J]. Composites Science and Technology,2020,198:108275. doi: 10.1016/j.compscitech.2020.108275 [81] BOCCACCINI A R, CHO J, ROETHER J A, et al. Electrophoretic deposition of carbon nanotubes[J]. Carbon,2006,44(15):3149-3160. doi: 10.1016/j.carbon.2006.06.021 [82] BEKYAROVA E, THOSTENSON E T, YU A, et al. Multiscale carbon nanotube-carbon fiber reinforcement for advanced epoxy composites[J]. Langmuir,2007,23(7):3970-3974. doi: 10.1021/la062743p [83] ATIQ UR REHMAN M, CHEN Q, BRAEM A, et al. Electrophoretic deposition of carbon nanotubes: Recent progress and remaining challenges[J]. International Mater-ials Reviews,2021,66(8):533-562. [84] LI L, LIU W, YANG F, et al. Interfacial reinforcement of hybrid composite by electrophoretic deposition for vertically aligned carbon nanotubes on carbon fiber[J]. Composites Science and Technology,2020,187:107946. doi: 10.1016/j.compscitech.2019.107946 [85] DUONGTHIPTHEWA A, SU Y, ZHOU L. Electrical conductivity and mechanical property improvement by low-temperature carbon nanotube growth on carbon fiber fabric with nanofiller incorporation[J]. Composites Part B: Engineering,2020,182:107581. doi: 10.1016/j.compositesb.2019.107581 [86] WU Y, WANG Z, XU L, et al. Preparation of silver-plated carbon nanotubes/carbon fiber hybrid fibers by combining freeze-drying deposition with a sizing process to enhance the mechanical properties of carbon fiber composites[J]. Composites Part A: Applied Science and Manufacturing,2021,146:106421. doi: 10.1016/j.compositesa.2021.106421 [87] GODARA A, GORBATIKH L, KALINKA G, et al. Interfacial shear strength of a glass fiber/epoxy bonding in compo-sites modified with carbon nanotubes[J]. Composites Science & Technology,2010,70(9):1346-1352. [88] GORBATIKH L, LOMOV S V, VERPOEST I. Nano-engi-neered composites: A multiscale approach for adding toughness to fibre reinforced composites[J]. Procedia Engineering,2011,10:3252-3258. doi: 10.1016/j.proeng.2011.04.537 [89] AN Q, RIDER A N, THOSTENSON E T. Electrophoretic deposition of carbon nanotubes onto carbon-fiber fabric for production of carbon/epoxy composites with improved mechanical properties[J]. Carbon,2012,50(11):4130-4143. doi: 10.1016/j.carbon.2012.04.061 [90] GUO J, LU C, AN F. Effect of electrophoretically deposited carbon nanotubes on the interface of carbon fiber reinforced epoxy composite[J]. Journal of Materials Science,2012,47(6):2831-2836. doi: 10.1007/s10853-011-6112-5 [91] AN Q, RIDER A N, THOSTENSON E T. Hierarchical composite structures prepared by electrophoretic deposition of carbon nanotubes onto glass fibers[J]. ACS Applied Materials and Interfaces,2013,5(6):2022-2032. doi: 10.1021/am3028734 [92] ZHAO Z, TENG K, LI N, et al. Mechanical, thermal and interfacial performances of carbon fiber reinforced compo-sites flavored by carbon nanotube in matrix/interface[J]. Composite Structures,2017,159:761-772. doi: 10.1016/j.compstruct.2016.10.022 [93] LI M, GU Y, LIU Y, et al. Interfacial improvement of carbon fiber/epoxy composites using a simple process for depositing commercially functionalized carbon nanotubes on the fibers[J]. Carbon,2013,52:109-121. doi: 10.1016/j.carbon.2012.09.011 [94] WU Z J, MENG L H, SU H, et al. Interfacial properties improvement of carbon fiber reinforced epoxy composites modified with carbon nanotubes[J]. Materials Science Forum,2015,813:300-306. doi: 10.4028/www.scientific.net/MSF.813.300 [95] YAO H, SUI X, ZHAO Z, et al. Optimization of interfacial microstructure and mechanical properties of carbon fiber/epoxy composites via carbon nanotube sizing[J]. Applied Surface Science,2015,347:583-590. doi: 10.1016/j.apsusc.2015.04.146 [96] XIAO C, TAN Y, WANG X, et al. Study on interfacial and mechanical improvement of carbon fiber/epoxy compo-sites by depositing multi-walled carbon nanotubes on fibers[J]. Chemical Physics Letters,2018,703:8-16. doi: 10.1016/j.cplett.2018.05.012 [97] DU X, LIU H Y, FENG X, et al. Flame synthesis of carbon nanotubes onto carbon fiber woven fabric and improvement of interlaminar toughness of composite laminates[J]. Composites Science & Technology,2014,101:159-166. [98] RODRÍGUEZ-GONZÁLEZ J, RUBIO-GONZÁLEZ C, MENESES-NOCHEBUENA C A, et al. Enhanced interlaminar fracture toughness of unidirectional carbon fiber/epoxy composites modified with sprayed multi-walled carbon nanotubes[J]. Composite Interfaces,2017,24(9):883-896. doi: 10.1080/09276440.2017.1302279 [99] RODRÍGUEZ-GONZÁLEZ J, AANDRUBIO-GONZÁLEZ C. Influence of sprayed multi-walled carbon nanotubes on mode I and mode II interlaminar fracture toughness of carbon fiber/epoxy composites[J]. Advanced Composite Materials,2019,28(S1):19-36. [100] ZAKARIA M R, MD AKIL H, OMAR M F, et al. Enhancement of mechanical and thermal properties of carbon fiber epoxy composite laminates reinforced with carbon nanotubes interlayer using electrospray deposition[J]. Composites Part C: Open Access,2020,3:100075. doi: 10.1016/j.jcomc.2020.100075 [101] ZHU J, IMAM A, CRANE R, et al. Processing a glass fiber reinforced vinyl ester composite with nanotube enhancement of interlaminar shear strength[J]. Composites Science and Technology,2007,67(7):1509-1517. [102] SHAN F L, GU Y Z, LI M, et al. Effect of deposited carbon nanotubes on interlaminar properties of carbon fiber-reinforced epoxy composites using a developed spraying processing[J]. Polymer Composites,2013,34(1):41-50. doi: 10.1002/pc.22375 [103] 邓火英, 王立敏, 冯奕钰, 等. 碳纳米管膜层间增韧对碳纤维复合材料力学性能的影响[J]. 宇航材料工艺, 2015, 45(5):31-35. doi: 10.3969/j.issn.1007-2330.2015.05.006DENG Huoying, WANG Limin, FENG Yiyu, et al. Effect of carbon nanotube film interlayer toughening on mechanical properties of carbon fiber reinforced composite[J]. Aerospace Materials & Technology,2015,45(5):31-35(in Chinese). doi: 10.3969/j.issn.1007-2330.2015.05.006 [104] LU W, ZU M, BYUN J H, et al. State of the art of carbon nanotube fibers: Opportunities and challenges[J]. Advanced Materials,2012,24(14):1805-1833. doi: 10.1002/adma.201104672 [105] BEHABTU N, YOUNG C C, TSENTALOVICH D E, et al. Strong, light, multifunctional fibers of carbon nanotubes with ultrahigh conductivity[J]. Science,2013,339(6116):182-186. doi: 10.1126/science.1228061 [106] BAI Y, ZHANG R, YE X, et al. Carbon nanotube bundles with tensile strength over 80 GPa[J]. Nature Nanotechnology,2018,13:589-595. doi: 10.1038/s41565-018-0141-z [107] 刘长洪, 范守善. 碳纳米管薄膜的制备方法: 中国, CN101597049A[P]. 2009-12-09.LIU Changhong, FAN Shoushan. Fabrication of carbon nanotube films: Chinese Patent, CN101597049A[P]. 2009-12-09(in Chinese). [108] QU S, DAI Y, ZHANG D, et al. Carbon nanotube film based multifunctional composite materials: An overview[J]. Functional Composites and Structures,2020,2(2):022002. doi: 10.1088/2631-6331/ab9752 [109] ZHANG M, FANG S, ZAKHIDOV A A, et al. Strong, transparent, multifunctional, carbon nanotube sheets[J]. Science,2005,309(5738):1215-1219. doi: 10.1126/science.1115311 [110] SUN M, BOO C, SHI W, et al. Carbon nanotube forests: Engineering carbon nanotube forest superstructure for robust thermal desalination membranes[J]. Advanced Functional Materials,2019,29(36):1970245. doi: 10.1002/adfm.201970245 [111] SUBERU B A. Multi-scale composite materials with increased design limits[D]. Cincinnati: University of Cincinnati, 2013. [112] XIA Q, ZHANG Z, LIU Y, et al. Buckypaper and its compo-sites for aeronautic applications[J]. Composites Part B: Engineering,2020,199:108231. doi: 10.1016/j.compositesb.2020.108231 [113] ALY K, LRD P D. Strain sensing in composites using aligned carbon nanotube sheets embedded in the interlaminar region[J]. Composites Part A: Applied Science & Manufacturing,2016,90:536-548. [114] YAO X, FALZON B G, HAWKINS S C. Orthotropic electro-thermal behaviour of highly-aligned carbon nanotube web based composites[J]. Composites Science and Technology,2019,170:157-164. doi: 10.1016/j.compscitech.2018.11.042 [115] YAO X, FALZON B G, HAWKINS S C, et al. Aligned carbon nanotube webs embedded in a composite laminate: A route towards a highly tunable electro-thermal system[J]. Carbon, 2018, 129: 486-494. [116] DZENIS Y A, RENEKER D H. Delamination resistant composites prepared by small diameter fiber reinforcement at ply interfaces: United States Patent, US 6265333 B1[P]. 2001-07-24. [117] ZHANG X, LU W, ZHOU G, et al. Understanding the mechanical and conductive properties of carbon nanotube fibers for smart electronics[J]. Advanced Materials,2019,32(5):1902028. [118] VIGOLO B, PENICAUD A, COULON C, et al. Macroscopic fibers and ribbons of oriented carbon nanotubes[J]. Science,2000,290(5495):1331-1334. doi: 10.1126/science.290.5495.1331 [119] ZHANG X, JIANG K, TENG C, et al. Spinning and processing continuous yarns from 4-inch wafer scale super-aligned carbon nanotube arrays[J]. Advanced Materials,2006,18(12):1505-1510. doi: 10.1002/adma.200502528 [120] GSPANN T S, SMAIL F R, WINDLE A H. Spinning of carbon nanotube fibres using the floating catalyst high temperature route: Purity issues and the critical role of sulphur[J]. Faraday Discuss,2014,173:47-65. doi: 10.1039/C4FD00066H [121] KIM J J, BROWN A D, BAKIS C E, et al. Hybrid carbon nanotube-carbon fiber composites for high damping[J]. Composites Science and Technology,2021,207:108712. doi: 10.1016/j.compscitech.2021.108712 [122] BROWN A D, BAKIS C E, SMITH E C. Interlaminar shear strength of carbon/epoxy composite with aligned carbon nanotube yarn interlayers[C]//POCHIRAJU K, GUPTA N. Virtual, Online: 35th Annual American Society for Composites Technical Conference, 2020: 280-290. [123] KIM J J. Fabrication and characterization of high damping carbon fiber composites with carbon nanotube interlayers[D]. Pennsylvania: Pennsylvania State University, 2019. [124] QIAO J, DI J, ZHOU S, et al. Large-stroke electrochemical carbon nanotube/graphene hybrid yarn muscles[J]. Small,2018,14(38):1801883. doi: 10.1002/smll.201801883 [125] RANA M, OU Y, MENG C, et al. Damage-tolerant, laminated structural supercapacitor composites enabled by integration of carbon nanotube fibres[J]. Multifunctional Materials,2020,3(1):015001. doi: 10.1088/2399-7532/ab686d [126] KOMATSU N, ICHINOSE Y, DEWEY O S, et al. Macroscopic weavable fibers of carbon nanotubes with giant thermoelectric power factor[J]. Nature Communications,2021,12(1):4931. doi: 10.1038/s41467-021-25208-z [127] LI M, SONG Y, ZHANG C, et al. Robust carbon nanotube composite fibers: Strong resistivities to protonation, oxidation, and ultrasonication[J]. Carbon,2019,146:627-635. doi: 10.1016/j.carbon.2019.02.059 -

下载:

下载: