Three-layer multifunctional vanadium dioxide-fluorescent brightener-organic polymer composite films

-

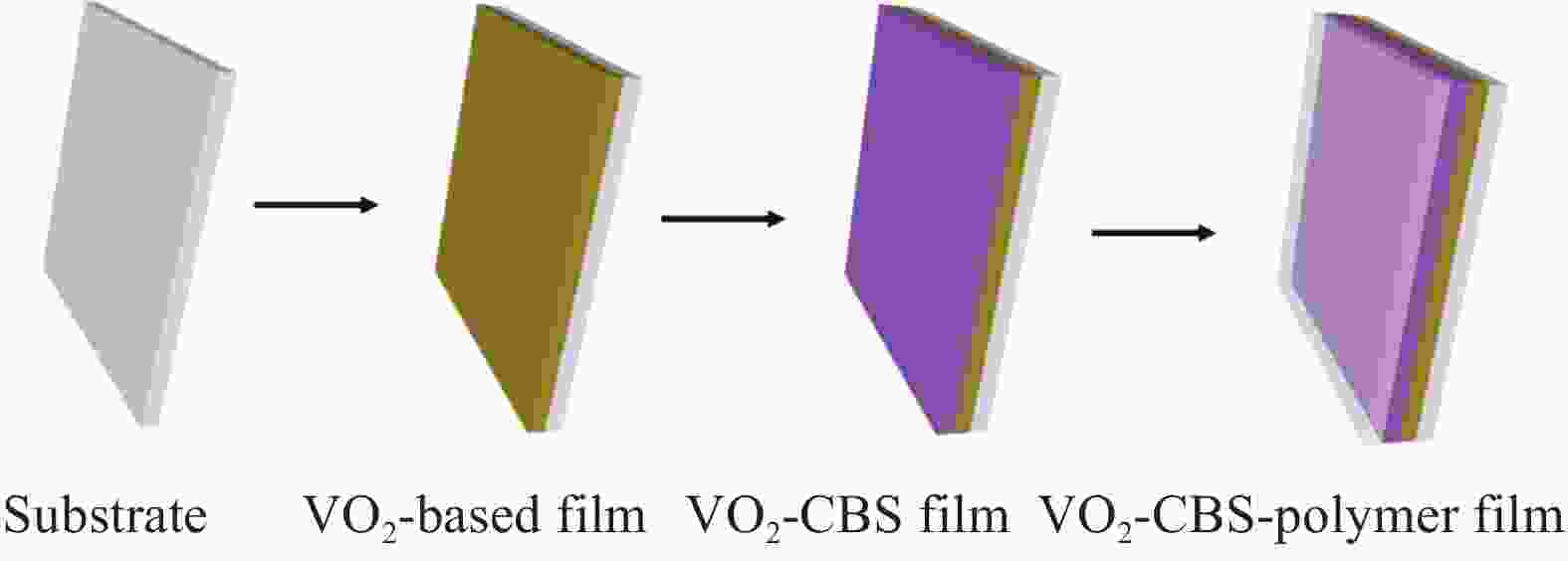

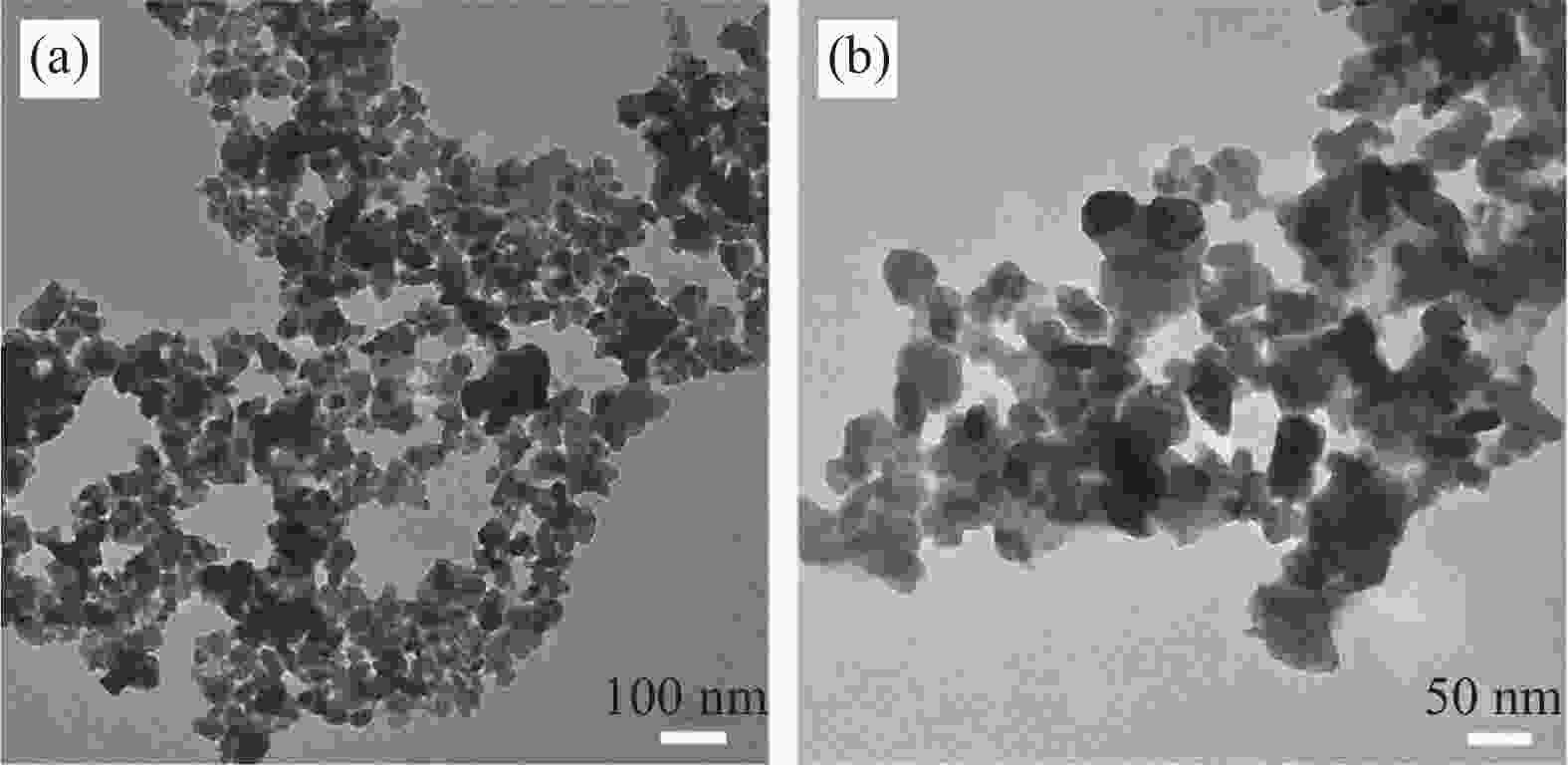

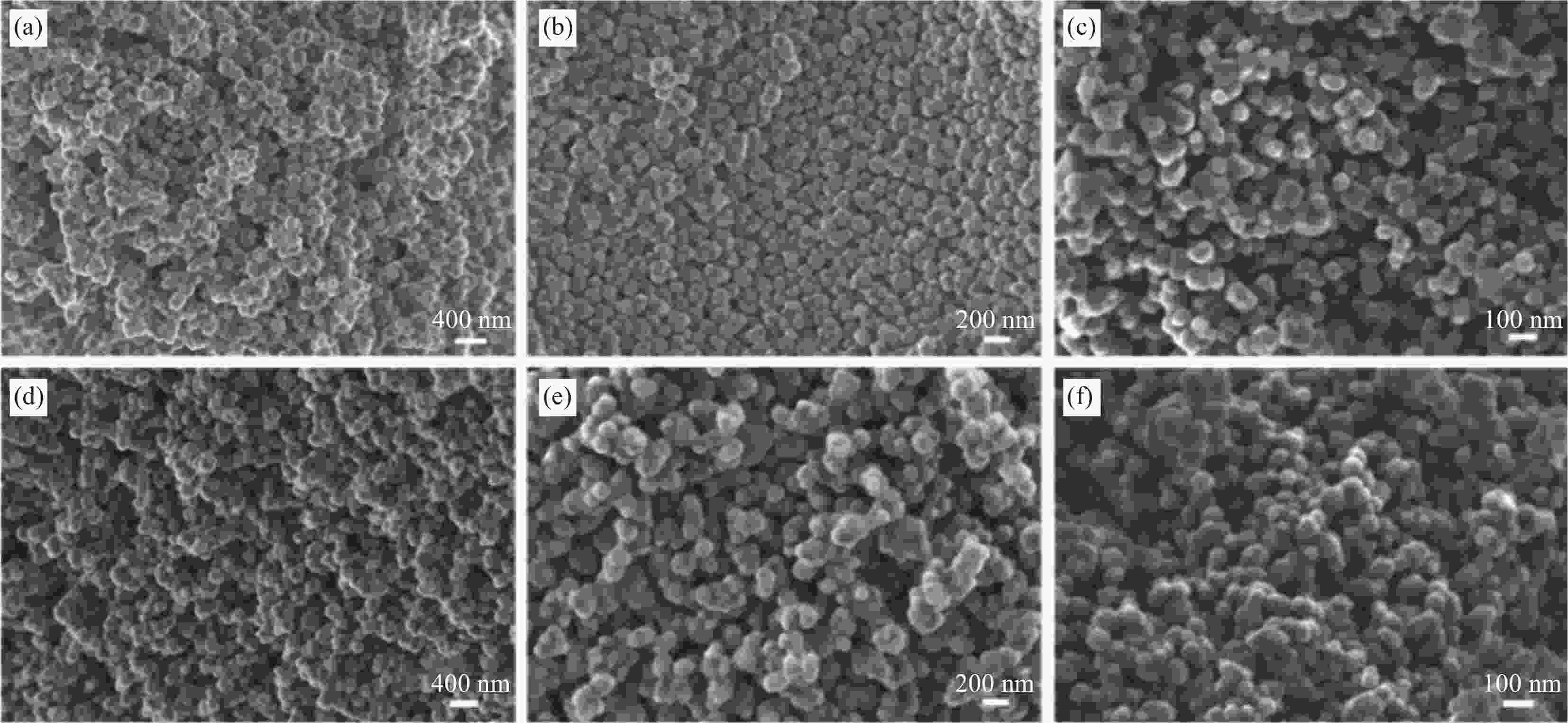

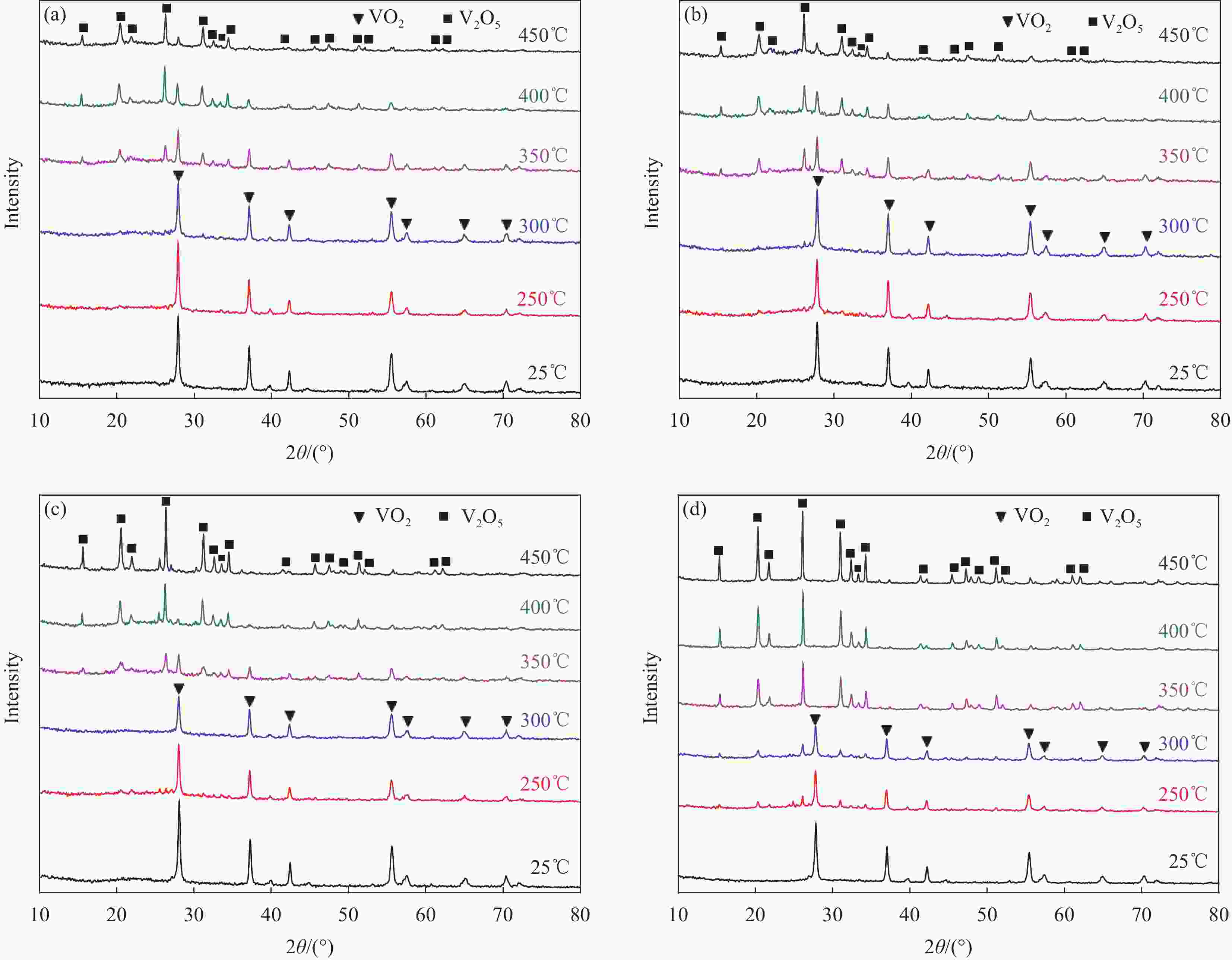

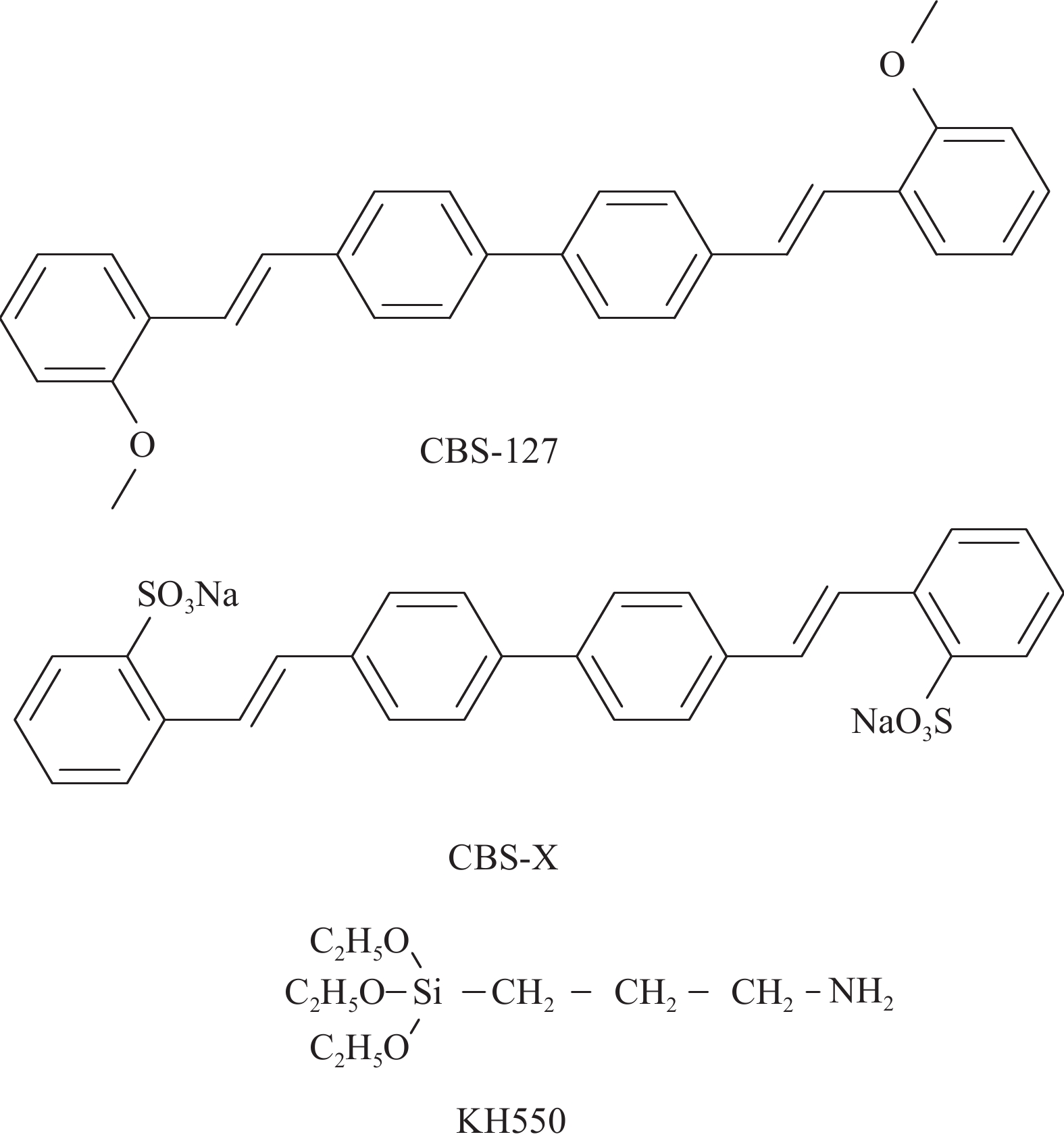

摘要: 二氧化钒(VO2)是一种典型的热致变色材料,用于智能窗可有效降低建筑能耗。然而,VO2智能玻璃的颜色和稳定性问题限制了其大规模应用。本文报道一种VO2基三层荧光复合膜,包括VO2@SiO2热致变色层、荧光增白剂分子层和有机聚合物层。VO2@SiO2层可根据外界温度变化,调控太阳光的摄入量,起到冬暖夏凉的作用,其核壳结构有利于提高VO2的稳定性;荧光分子层在太阳光照射下,吸收紫外光,发射蓝色荧光,从而改善VO2涂层固有的棕黄色;有机聚合物层作为最上层,能有效保护下层的VO2@SiO2层和中间的荧光分子层,增加复合薄膜的稳定性。与纯VO2膜相比,这种复合膜不但保持了较高的可见光透过率和太阳光调制能力,而且在太阳光下颜色可逆地从棕黄色变为蓝色,同时稳定性和紫外阻隔能力明显提升,有利于VO2基智能窗的推广和应用。Abstract: Vanadium dioxide (VO2) is a typical thermochromic material that can be used for smart windows, which can effectively reduce the building energy consumption. However, the issues of the yellow brown color and instabi-lity of VO2 based smart glass restrict its wide application. Herein, a series of VO2 based three-layer fluorescent composite films has been reported. The composite films consist of VO2@SiO2 based thermochromic layer, fluorescent brightener layer and organic polymer layer. The VO2@SiO2 layer can control the sunlight intake with the change of external temperature, regulating the indoor temperature, with the core-shell structure improving the stability of the film. The fluorescent brightener layer absorbs ultraviolet irradiation and emit blue fluorescence, thus improving the color of VO2 coating. As the top layer, the organic polymer layer can effectively protect the lower layers and increase the stability of the whole composite film. Compared with the pure VO2 films, these composite films not only maintain high visible light transmittance and solar modulation ability, but also reversibly change color from yellow-brown to blue under sunlight. Meanwhile, the stability and the UV blocking property are also significantly improved. The properties of this type of composite films are beneficial to the promotion and application of VO2-based smart windows.

-

Key words:

- vanadium dioxide /

- composite films /

- smart windows /

- fluorescent brightener /

- polymer

-

图 9 (a) 每张照片从左到右依次为VO2、VO2-KH550、VO2@SiO2和VO2@SiO2-KH550纳米颗粒分散在0.5 mol/L H2SO4溶液中不同时间的变化情况;(b) 不同时间悬浮液在570 nm处的透射率;(c) 经过30 min 0.5 mol/L H2SO4浸泡后VO2-KH550、VO2@SiO2和VO2@SiO2-KH550纳米颗粒的XRD图谱

Figure 9. (a) In each picture, from left to right: VO2, VO2-KH550, VO2@SiO2 and VO2@SiO2-KH550 particles being dispersed in 0.5 mol/L H2SO4 against time; (b) Transmission spectra of different suspensions at 570 nm; (c) XRD patterns of VO2-KH550, VO2@SiO2 and VO2@SiO2-KH550 particles after being immersed in 0.5 mol/L H2SO4 for 30 min

图 10 (a) 纳米颗粒分散在0.1 mol/L H2O2溶液中不同时间的变化情况,每张照片从左到右依次为VO2、VO2-KH550、VO2@SiO2和VO2@SiO2-KH550;(b) 悬浮液在不同时间570 nm处的透射率;(c) 0.1 mol/L H2O2浸泡30 min后VO2-KH550、VO2@SiO2和VO2@SiO2-KH550纳米颗粒的XRD图谱

Figure 10. (a) In each picture, from left to right: VO2, VO2-KH550, VO2@SiO2 and VO2@SiO2-KH550 particles being dispersed in 0.1 mol/L H2O2 against time; (b) Transmission spectra of different suspensions at 570 nm; (c) XRD patterns of VO2-KH550, VO2@SiO2 and VO2@SiO2-KH550 particles after being immersed in 0.1 mol/L H2O2 for 30 min

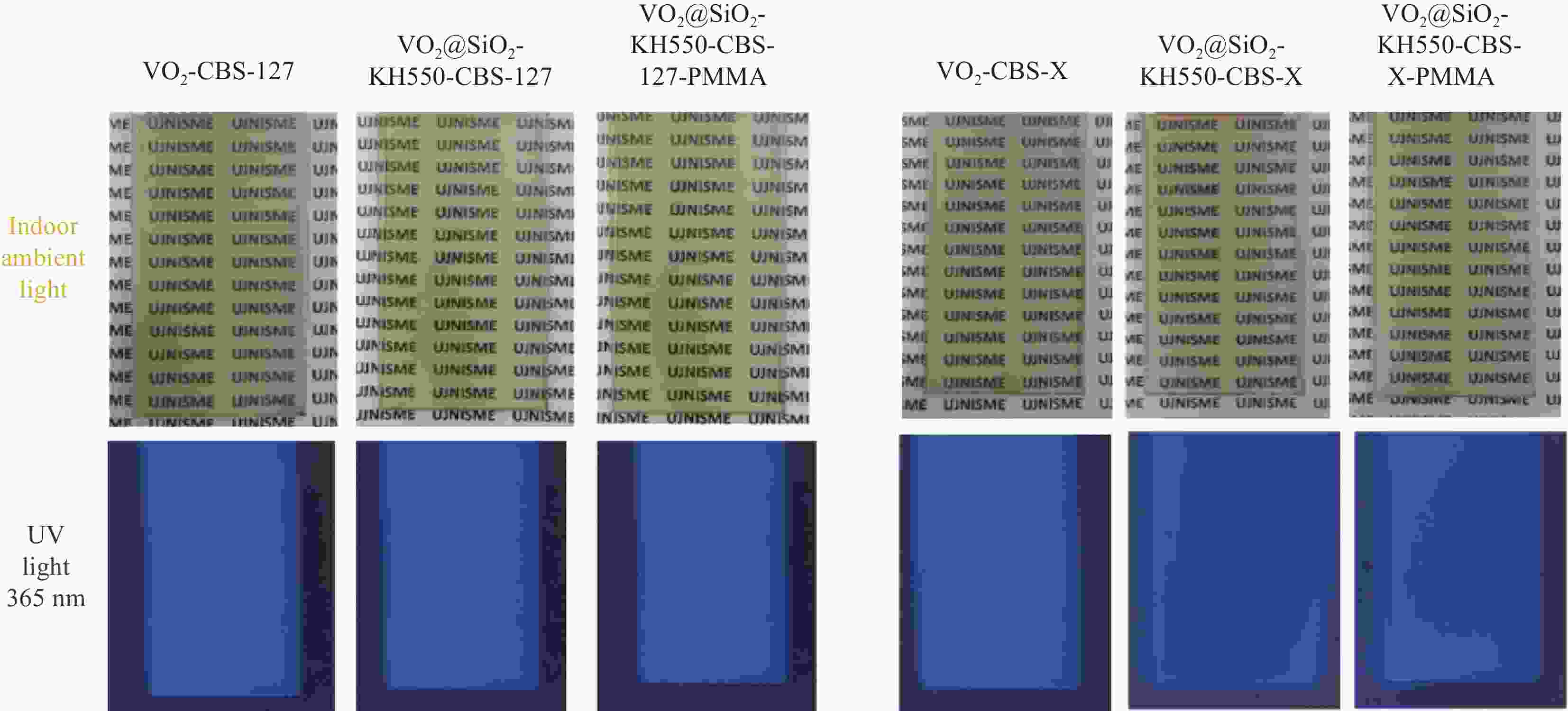

图 16 VO2-CBS-127、VO2@SiO2-KH550-CBS-127和VO2@SiO2-KH550-CBS-127-PMMA薄膜最初(左)及紫外老化24 h(右)在室内自然光、365 nm紫外灯及室外太阳光下的照片

Figure 16. Pictures of films of VO2-CBS-127, VO2@SiO2-KH550-CBS-127 and VO2@SiO2-KH550-CBS-127-PMMA under indoor natural light, UV light of 365 nm and outdoor sunlight after UV irradiation for 24 h

图 17 VO2-CBS-127、VO2@SiO2-KH550-CBS-127和VO2@SiO2-KH550-CBS-127-PMMA薄膜紫外老化前后的荧光光谱(最大激发波长λex= 365 nm)

Figure 17. Fluorescence emission spectra of films of VO2-CBS-127, VO2@SiO2-KH550-CBS-127 and VO2@SiO2-KH550-CBS-127-PMMA before and after UV irradiation for 24 h (Maximum excitation wavelength λex= 365 nm)

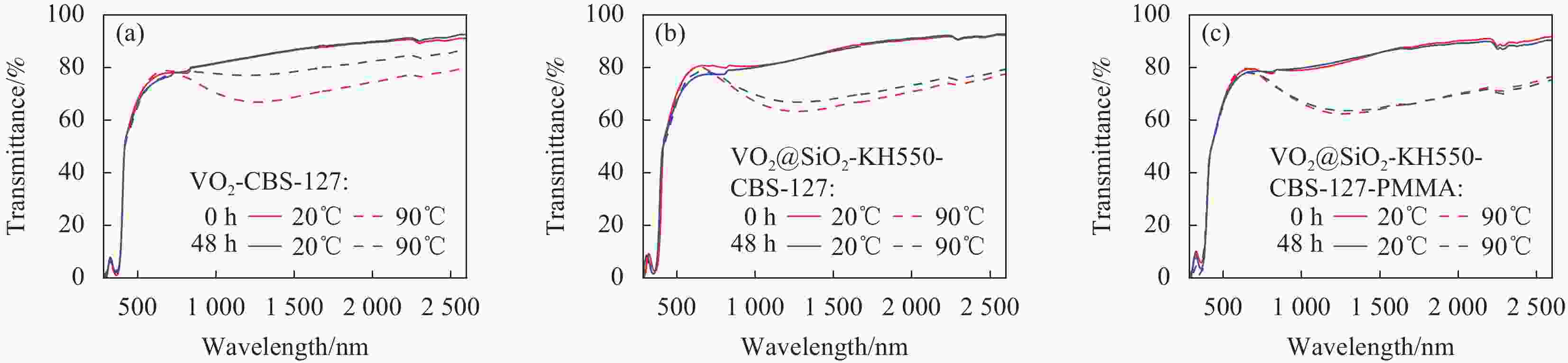

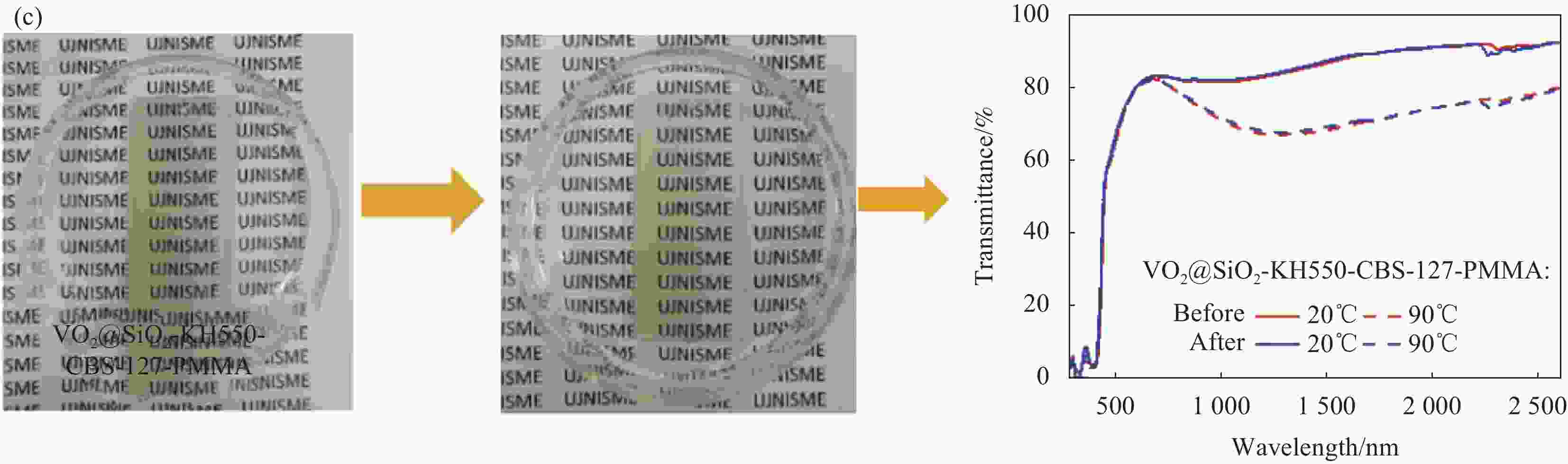

图 18 VO2-CBS-127 (a)、VO2@SiO2-KH550-CBS-127 (b) 和VO2@SiO2-KH550-CBS-127-PMMA (c) 复合薄膜在0.5 mol/L H2SO4溶液浸泡24 h前后的照片及透射光谱

Figure 18. Pictures and transmission spectra of films of VO2-CBS-127 (a), VO2@SiO2-KH550-CBS-127 (b) and VO2@SiO2-KH550-CBS-127-PMMA (c) after being immersed in 0.5 mol/L H2SO4 for 24 h

表 1 VO2-CBS, VO2@SiO2-KH550-CBS和VO2@SiO2-KH550-CBS-polymer复合薄膜的光学性质

Table 1. Optical property of composite films of VO2-CBS, VO2@SiO2-KH550-CBS and VO2@SiO2-KH550-CBS-polymer

Film Tlum/% Tsol/% ΔTsol/% 20℃ 90℃ 20℃ 90℃ VO2-CBS-127 68.80 69.30 71.62 65.11 6.51 VO2@SiO2-KH550-CBS-127 77.86 76.91 79.26 71.84 7.42 VO2@SiO2-KH550-CBS-127-PVB 78.94 78.97 80.24 72.55 7.69 VO2@SiO2-KH550-CBS-127-PVA 79.68 79.63 80.31 72.62 7.69 VO2@SiO2-KH550-CBS-127-PMMA 78.30 78.87 80.04 72.65 7.39 VO2-CBS-X 73.42 73.09 75.36 68.66 6.70 VO2@SiO2-KH550-CBS-X 78.71 78.80 79.32 71.44 7.88 VO2@SiO2-KH550-CBS-127-PVB 78.23 78.85 79.16 71.74 7.42 VO2@SiO2-KH550-CBS-127-PVA 78.32 78.79 79.06 71.38 7.68 VO2@SiO2-KH550-CBS-127-PMMA 78.87 78.65 79.34 72.00 7.34 Notes: Tlum—Visible transmittance; Tsol—Solar transmittance; ΔTsol—Solar modularity. 表 2 湿热实验前后VO2基复合薄膜的光学性质对比

Table 2. Comparison of the optical property of VO2-based composite films before and after the damp heating test

Films Tlum/% Tsol/% ΔTsol/% 20℃ 90℃ 20℃ 90℃ VO2-CBS-127 73.24 73.83 76.89 70.00 6.89 After damp heating test 71.54 71.27 76.59 73.57 3.02 VO2@SiO2-KH550-CBS-127 75.96 75.77 77.78 68.62 9.16 After damp heating test 72.95 73.40 77.02 69.49 7.53 VO2@SiO2-KH550-CBS-127-PMMA 74.07 74.70 76.32 67.86 8.46 After damp heating test 72.82 73.15 76.21 67.73 8.48 VO2-CBS-X 72.86 72.44 74.84 67.73 7.11 After damp heating test 74.21 74.92 75.97 73.27 2.70 VO2@SiO2-KH550-CBS-X 77.15 76.61 78.48 69.39 9.09 After damp heating test 77.41 77.61 79.89 72.18 7.71 VO2@SiO2-KH550-CBS-127-PMMA 78.99 77.64 79.73 70.08 9.65 After damp heating test 78.59 76.79 80.58 71.08 9.50 -

[1] LIU M, SU B, TANG Y, et al. Recent advances in nanostructured vanadium oxides and composites for energy conversion[J]. Advanced Energy Materials,2017,7(23):1700885. doi: 10.1002/aenm.201700885 [2] GAO Y, LUO H, ZHANG Z, et al. Nanoceramic VO2 thermochromic smart glass: A review on progress in solution processing[J]. Nano Energy,2012,1(2):221-246. doi: 10.1016/j.nanoen.2011.12.002 [3] GAO L, BRYAN B A. Finding pathways to national-scale land-sector sustainability[J]. Nature,2017,544(7649):217-222. doi: 10.1038/nature21694 [4] OMER A M. Energy, environment and sustainable development[J]. Renewable and Sustainable Energy Reviews,2008,12(9):2265-2300. doi: 10.1016/j.rser.2007.05.001 [5] TARANTINI M, LOPRIENO A D, PORTA P L. A life cycle approach to Green Public Procurement of building materials and elements: A case study on windows[J]. Energy,2011,36(5):2473-2482. doi: 10.1016/j.energy.2011.01.039 [6] BAETENS R, JELLE B P, GUSTAVSEN A. Properties, requirements and possibilities of smart windows for dynamic daylight and solar energy control in buildings: A state-of-the-art review[J]. Solar Energy Materials and Solar Cells,2010,94(2):87-105. doi: 10.1016/j.solmat.2009.08.021 [7] KAKLAUSKAS A, ZAVADSKAS E K, RASLANAS S, et al. Selection of low-E windows in retrofit of public buildings by applying multiple criteria method COPRAS: A lithuanian case[J]. Energy and Buildings,2006,38(5):454-462. doi: 10.1016/j.enbuild.2005.08.005 [8] 王娜, 白云峰, 孟欣, 等. 浅谈我国Low-E玻璃发展现状及趋势[J]. 建材发展导向, 2016, 14(20):24-27.WANG N, BAI Y F, MENG X, et al. Briefly discuss the deve-lopment status and trend of low-E glass in China[J]. Deve-lopment Guide to Building Materials,2016,14(20):24-27(in Chinese). [9] KAMALISARVESTANI M, SAIDUR R, MEKHILEF S, et al. Performance, materials and coating technologies of thermochromic thin films on smart windows[J]. Renewable and Sustainable Energy Reviews,2013,26:353-364. doi: 10.1016/j.rser.2013.05.038 [10] WANG S, GAN W, HU X, et al. Supramolecular strategy for smart windows[J]. Chemical Communications,2019,55(29):4137-4149. doi: 10.1039/C9CC00273A [11] BABULANAM S M, ERIKSSON T S, NIKLASSON G A, et al. Thermochromic VO2 films for energy-efficient windows[J]. Solar Energy Materials,1987,16(5):347-363. doi: 10.1016/0165-1633(87)90029-3 [12] 陈长, 曹传祥, 罗宏杰, 等. 二氧化钒智能节能窗: 从镀膜玻璃到节能发电一体化窗[J]. 科学通报, 2016, 61(15):1661-1678. doi: 10.1360/N972015-01403CHEN Z, CAO C X, LUO H J, et al. VO2-based thermochromic smart window: From energy savings to generation[J]. Chinese Science Bulletin,2016,61(15):1661-1678(in Chinese). doi: 10.1360/N972015-01403 [13] 孙蕊, 姚琳, 贺军辉, 等. 热致变色材料智能涂层[J]. 化学进展, 2019, 31:1712-1728.SUN R, YAO L, HE J H, et al. Thermochromic smart coatings[J]. Progress in Chemistry,2019,31:1712-1728(in Chinese). [14] WANG S, LIU M, KONG L, et al. Recent progress in VO2 smart coatings: Strategies to improve the thermochromic properties[J]. Progress in Materials Science,2016,81:1-54. doi: 10.1016/j.pmatsci.2016.03.001 [15] CHANG T, CAO X, BAO S, et al. Review on thermochromic vanadium dioxide based smart coatings: From lab to commercial application[J]. Advances in Manufacturing,2018,6(1):1-19. doi: 10.1007/s40436-017-0209-2 [16] XU F, CAO X, LUO H, et al. Recent advances in VO2-based thermochromic composites for smart windows[J]. Journal of Materials Chemistry C,2018,6(8):1903-1919. doi: 10.1039/C7TC05768G [17] CUI Y, KE Y, LIU C, et al. Thermochromic VO2 for energy-efficient smart windows[J]. Joule,2018,2(9):1707-1746. doi: 10.1016/j.joule.2018.06.018 [18] TONG K, LI R, ZHU J, et al. Preparation of VO2/Al-O core-shell structure with enhanced weathering resistance for smart window[J]. Ceramics International,2017,43(5):4055-4061. doi: 10.1016/j.ceramint.2016.11.181 [19] CHEN Y, SHAO Z, YANG Y, et al. Electrons-donating derived dual-resistant crust of VO2 nano-particles via ascorbic acid treatment for highly stable smart windows applications[J]. ACS Applied Materials & Interfaces,2019,11(44):41229-41237. [20] JIANG M, BAO S, CAO X, et al. Improved luminous transmittance and diminished yellow color in VO2 energy efficient smart thin films by Zn doping[J]. Ceramics International,2014,40(4):6331-6334. doi: 10.1016/j.ceramint.2013.10.083 [21] 秦成远, 高迎, 王程, 等. 二氧化钒-1, 4-双(苯并噁唑- 2-基)萘复合薄膜及其热致变色和发光性能[J]. 复合材料学报, 2021, 38(10):3412-3423. doi: 10.13801/j.cnki.fhclxb.20210111.002QIN C Y, GAO Y, WANG C, et al. Vanadium dioxide-1, 4-bis(benzoxazol-2-yl)naphthalene composite films and their thermochromic and photoluminescent property[J]. Acta Materiae Compositae Sinica,2021,38(10):3412-3423(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210111.002 [22] GAO Y, QIN C, NIE Y, et al. Color tunable vanadium dio-xide/fluorescent organic small molecule two-layer composite films with thermochromic property[J]. Thin Solid Films,2021,734:138861. doi: 10.1016/j.tsf.2021.138861 [23] LI Y, JI S, GAO Y, et al. Core-shell VO2@TiO2 nanorods that combine thermochromic and photocatalytic properties for application as energy-saving smart coatings[J]. Scientific Reports,2013,3:1370. doi: 10.1038/srep01370 [24] LAN S D, CHANG C J, HUANG C F, et al. Heteroepitaxial TiO2@W-doped VO2 core/shell nanocrystal films: Preparation, characterization, and application as bifunctional window coatings[J]. RSC Advances,2015,5(90):73742-73751. doi: 10.1039/C5RA11202H [25] YAO L, QU Z, PANG Z, et al. Three-layered hollow nanospheres based coatings with ultrahigh-performance of energy-saving, antireflection, and self-cleaning for smart windows[J]. Small,2018,14(34):1801661. doi: 10.1002/smll.201801661 [26] CHEN Y, ZENG X, ZHU J, et al. High performance and enhanced durability of thermochromic films using VO2@ZnO core-shell nanoparticles[J]. ACS Applied Materials & Interfaces,2017,9(33):27784-27791. [27] GAO Y, WANG S, LUO H, et al. Enhanced chemical stabi-lity of VO2 nanoparticles by the formation of SiO2/VO2 core/shell structures and the application to transparent and flexible VO2-based composite foils with excellent thermochromic properties for solar heat control[J]. Energy & Environmental Science,2012,5(3):6104-6110. [28] WANG M, TIAN J, ZHANG H, et al. Novel synthesis of pure VO2@SiO2 core@shell nanoparticles to improve the optical and anti-oxidant properties of a VO2 film[J]. RSC Advances,2016,6(110):108286-108289. doi: 10.1039/C6RA20636K [29] QU Z, YAO L, LI J, et al. Bifunctional template-induced VO2@SiO2 dual-shelled hollow nanosphere-based coatings for smart windows[J]. ACS Applied Materials & Interfaces,2019,11(17):15960-15968. [30] 建方方, 孙萍萍, 李玉峰, 等. 反式-4, 4'-二(邻甲氧基苯乙烯基)联苯化合物的合成、结构及光物理性能[J]. 化学学报, 2008, 66(17):2006-2010. doi: 10.3321/j.issn:0567-7351.2008.17.013JIAN F F, SUN P P, LI Y F, et al. Synthesis, crystal structure and optic properties of trans-4, 4'-bis(o-methoxylstyryl)biphenyl compound[J]. Acta Chimica Sinica,2008,66(17):2006-2010(in Chinese). doi: 10.3321/j.issn:0567-7351.2008.17.013 [31] JIANG D, CHEN L, FU W, et al. Simultaneous determination of 11 fluorescent whitening agents in food-contact paper and board by ion-pairing high-performance liquid chromatography with fluorescence detection[J]. Journal of Separation Science,2015,38(4):605-611. doi: 10.1002/jssc.201401110 [32] SONG H, LI W, LIU G, et al. Study on the optical properties of 4, 4′-bis-(2-(substituted-styryl))biphenyl and 1, 4-bis-(2-(substituted-styryl))benzene[J]. Spectrochimica Acta Part A: Molecular and Biomolecular Spectroscopy,2003,59(9):2041-2048. doi: 10.1016/S1386-1425(03)00003-9 [33] 冯玉君. 荧光增白剂CBS-127合成工艺研究[J]. 河南化工, 2003(9):18-19. doi: 10.3969/j.issn.1003-3467.2003.01.007FENG Y J. Research of synthetic process of fluorescent whitener CBS-127[J]. Henan Chemical Engineering,2003(9):18-19(in Chinese). doi: 10.3969/j.issn.1003-3467.2003.01.007 [34] KO K Y, LEE C A, CHOI J C, et al. Determination of tinopal CBS-X in rice papers and rice noodles using HPLC with fluorescence detection and LC-MS/MS[J]. Food Additives & Contaminants: Part A,2014,31(9):1451-1459. [35] ZHU J, ZHOU Y, WANG B, et al. Vanadium dioxide nanoparticle-based thermochromic smart coating: High luminous transmittance, excellent solar regulation efficiency, and near room temperature phase transition[J]. ACS Applied Materials & Interfaces,2015,7(50):27796-27803. [36] 董金美, 李颖, 文静, 等. KH550 硅烷偶联剂的水解工艺研究[J]. 盐湖研究, 2020, 28: 29-33.DONG J, LI Y, WEN J, et al. Research on hydrolysis process of KH550 silane coupling agent[J]. Journal of Salt Lake Research, 2020, 28: 29-33(in Chinese). [37] CHANG T, CAO X, LONG Y, et al. How to properly evaluate and compare the thermochromic performance of VO2-based smart coatings[J]. Journal of Materials Chemistry A,2019,7(42):24164-24172. doi: 10.1039/C9TA06681K [38] CHANG T, CAO X, LI N, et al. Facile and low-temperature fabrication of thermochromic Cr2O3/VO2 smart coatings: Enhanced solar modulation ability, high luminous transmittance and UV-shielding function[J]. ACS Applied Materials & Interfaces,2017,9(31):26029-26037. [39] SHAO Z, CAO X, LUO H, et al. Recent progress in the phase-transition mechanism and modulation of vanadium dio-xide materials[J]. NPG Asia Materials,2018,10(7):581-605. doi: 10.1038/s41427-018-0061-2 -

下载:

下载: