Research progress on the preparation of boron nitride nanosheets and its reinforcement on the thermal conductivity of epoxy resin composites

-

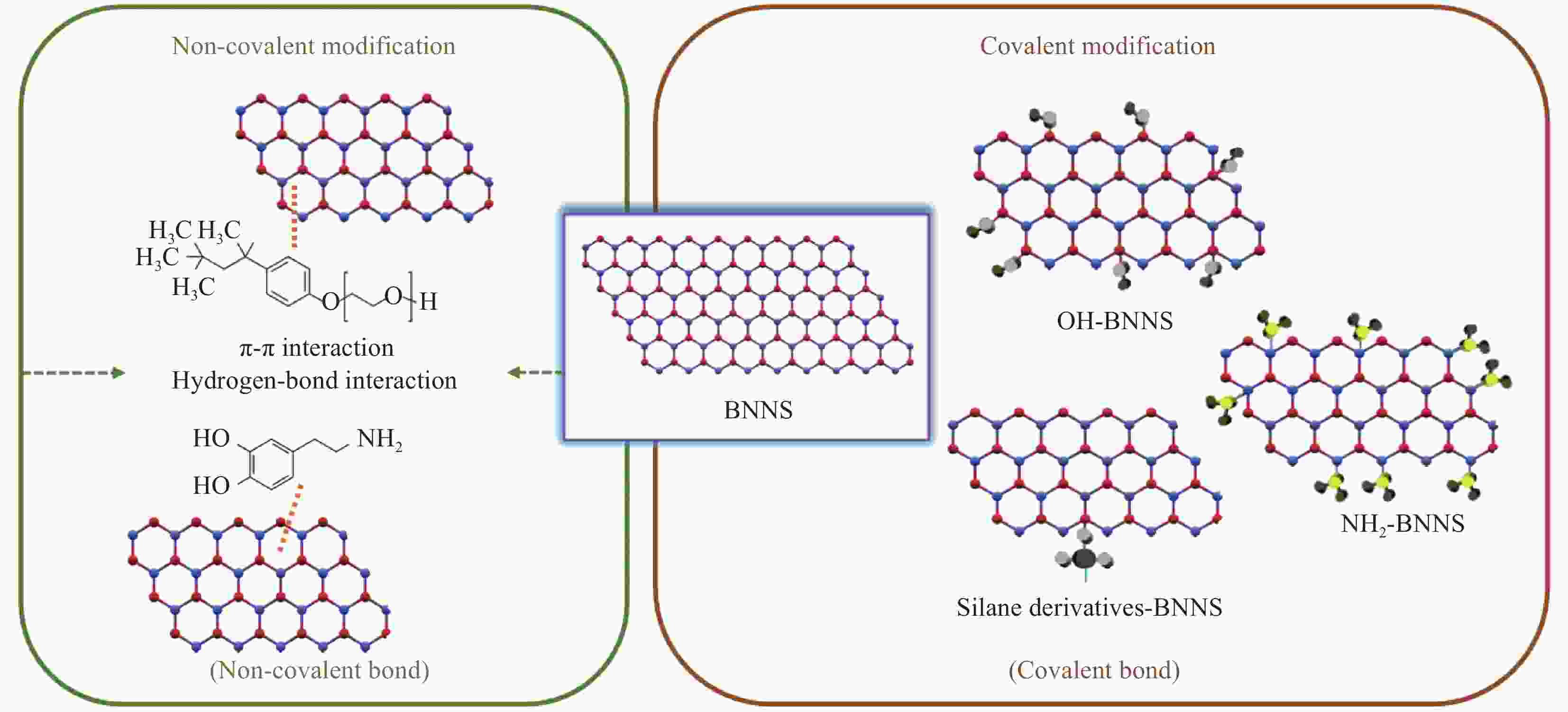

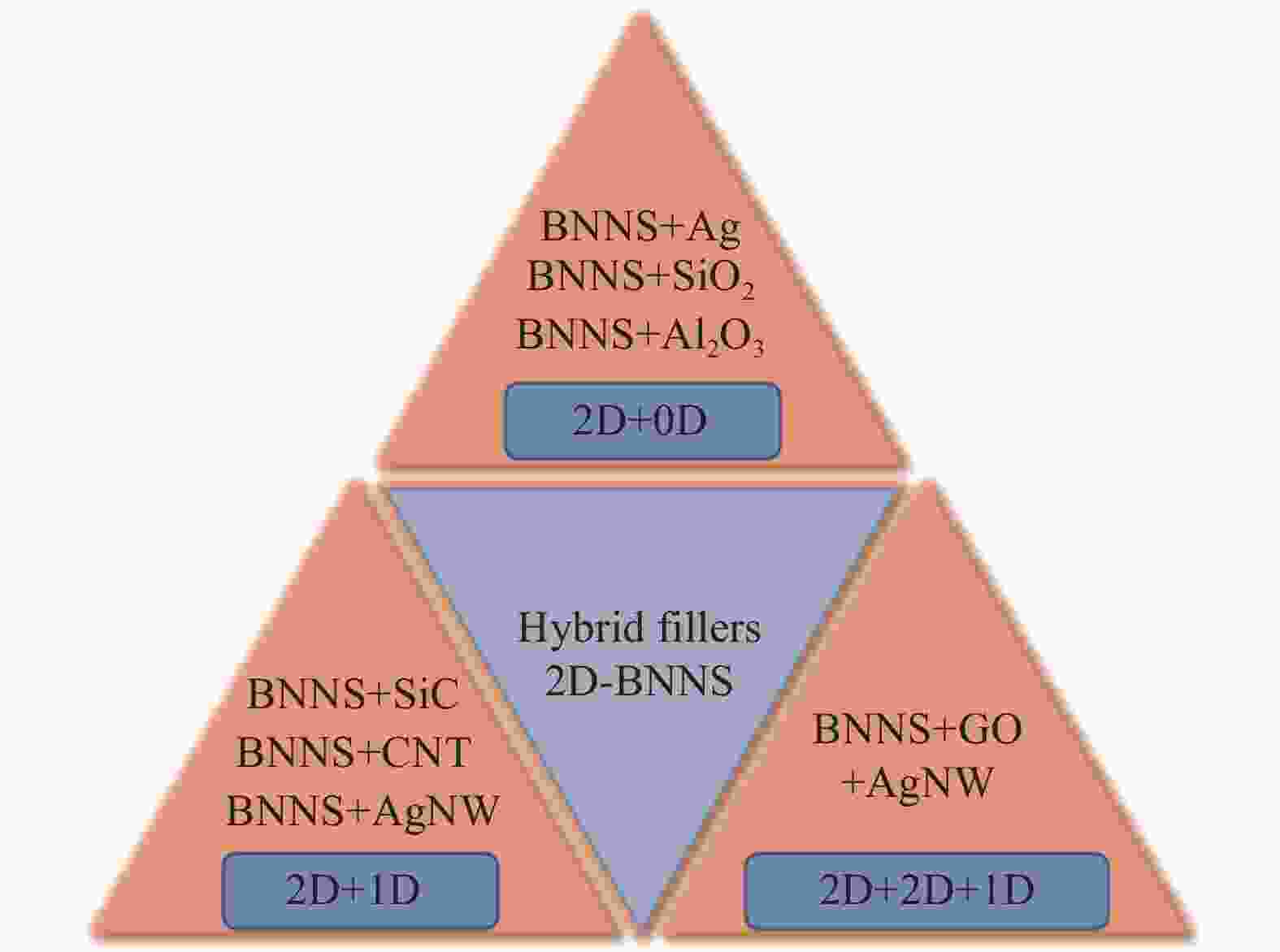

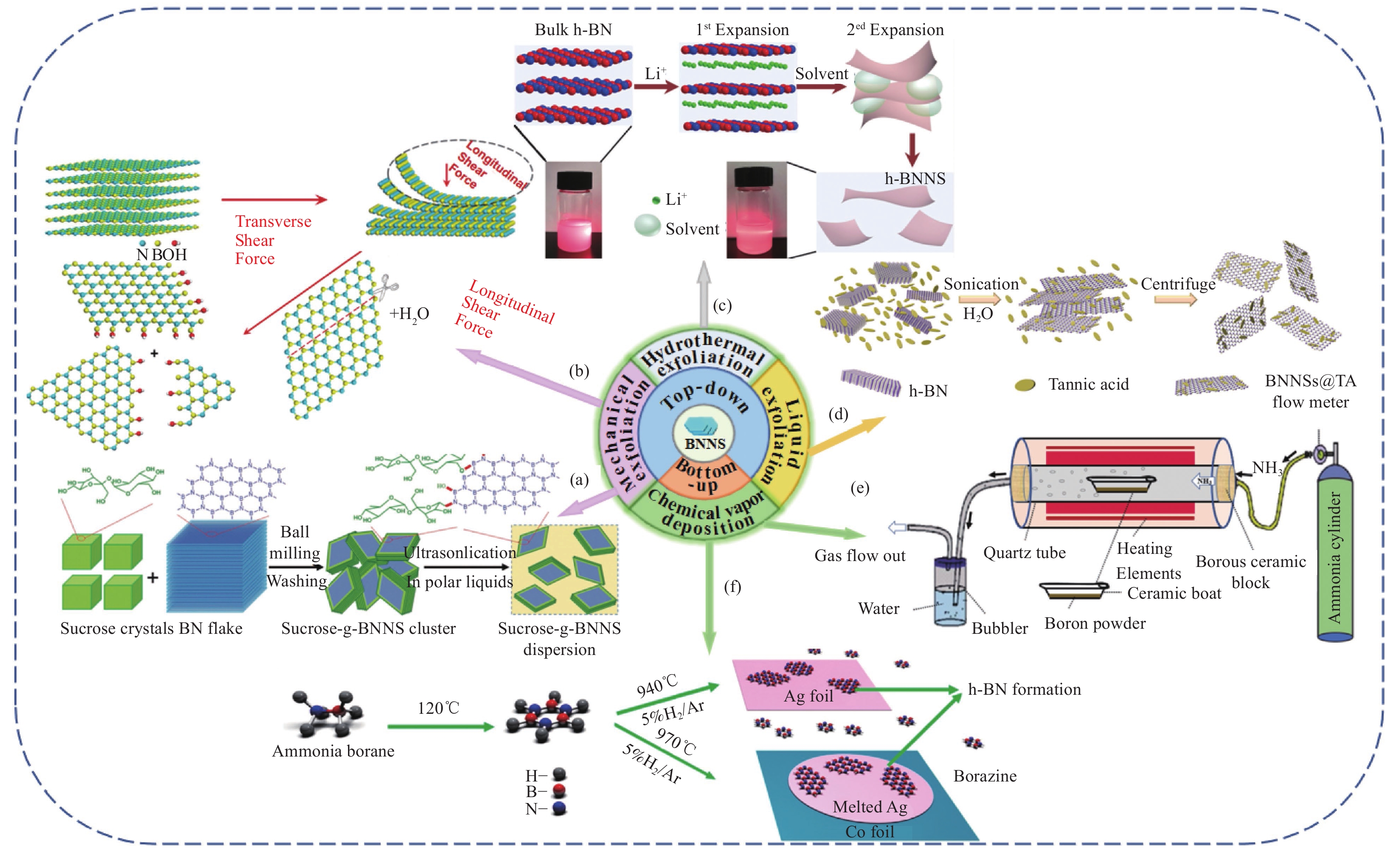

摘要: 随着对新型高导热、高绝缘热界面材料需求的显著增加,具有多种优异性能的环氧树脂(EP)已被广泛用作导热复合材料的基体,然而其固有的低热导率限制了其实际应用。通过向EP中引入具有高导热系数及高绝缘性的氮化硼纳米片(BNNS)可有效弥补EP的缺陷,从而显著提高复合材料的综合性能。基于国内外研究,介绍了BNNS的不同制备方法,并对这些方法的优缺点进行总结;对提高BNNS/EP复合材料导热性能的策略进行了综述,包括BNNS的表面改性、BNNS与不同维度填料之间的复合以及3D-BNNS导热网络的构筑;提出了制备高导热BNNS/EP复合材料所存在的关键问题;最后对BNNS/EP复合材料的发展趋势进行了展望。Abstract: With the significantly increasing demand for new thermal interface materials with high thermal conduc-tivity and high insulation, epoxy resin (EP) with various excellent properties has been widely used as the matrix of thermal conducting composites. However, its practical application is limited by its inherent low thermal conduc-tivity. The incorporation of two-dimensional boron nitride nanosheets (BNNS) with high thermal conductivity and high insulation into epoxy resin can effectively overcome the shortcomings of EP and thereby significantly improve the comprehensive performance. Based on the domestic and foreign research progresses, various preparation methods of BNNS are discussed in this article, and their advantages and disadvantages are summarized. Various strategies for improving the thermal conductivity of BNNS/EP composites is reviewed, including surface modification of BNNS, hybridization between BNNS and multi-dimensional fillers, and construction of 3D-BNNS thermal conductivity network. The key problems in the preparation of BNNS/EP composites with high thermal conductivity are proposed. Finally, the development trend of BNNS/EP composites is prospected.

-

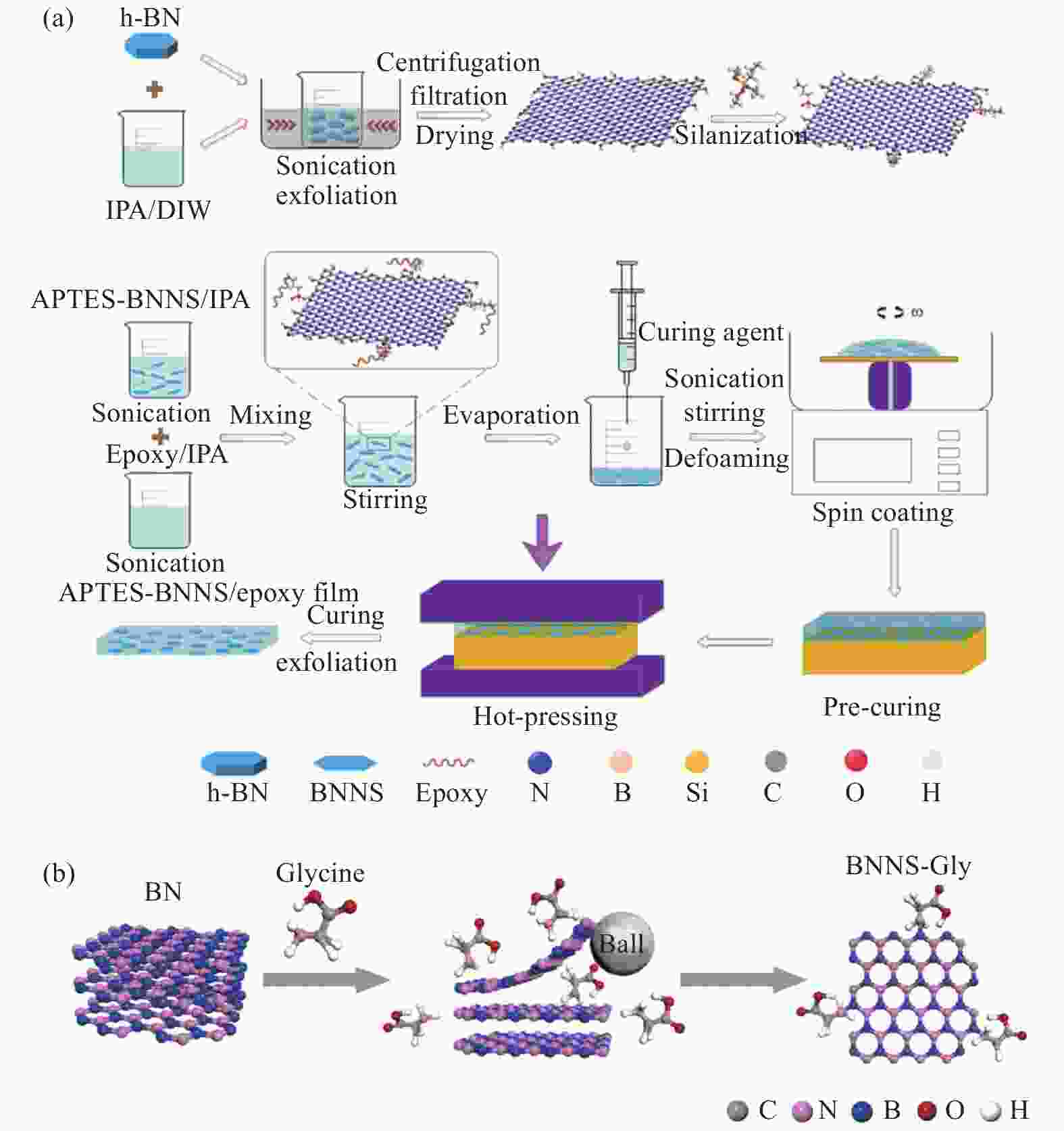

图 3 3-氨丙基三乙氧基硅烷-氮化硼纳米片(APTES-BNNS)与APTES−BNNS/环氧树脂(APTES−BNNS/EP)复合材料(a)[48]及氮化硼纳米片-甘氨酸(BNNS-Gly) (b) 的制备机制示意图[50]

Figure 3. Schematic diagram of the preparation mechanism of (3-aminopropyl)triethoxysilane-boron nitride nanosheets (APTES-BNNS) and APTES-BNNS/epoxy (APTES-BNNS/EP) composite (a)[48]with boron nitride nanosheets-Glycine (BNNS-Gly)(b)[50]

IPA/DIW—Isopropanol/deionized water; Epoxy—Epoxy resin (EP)

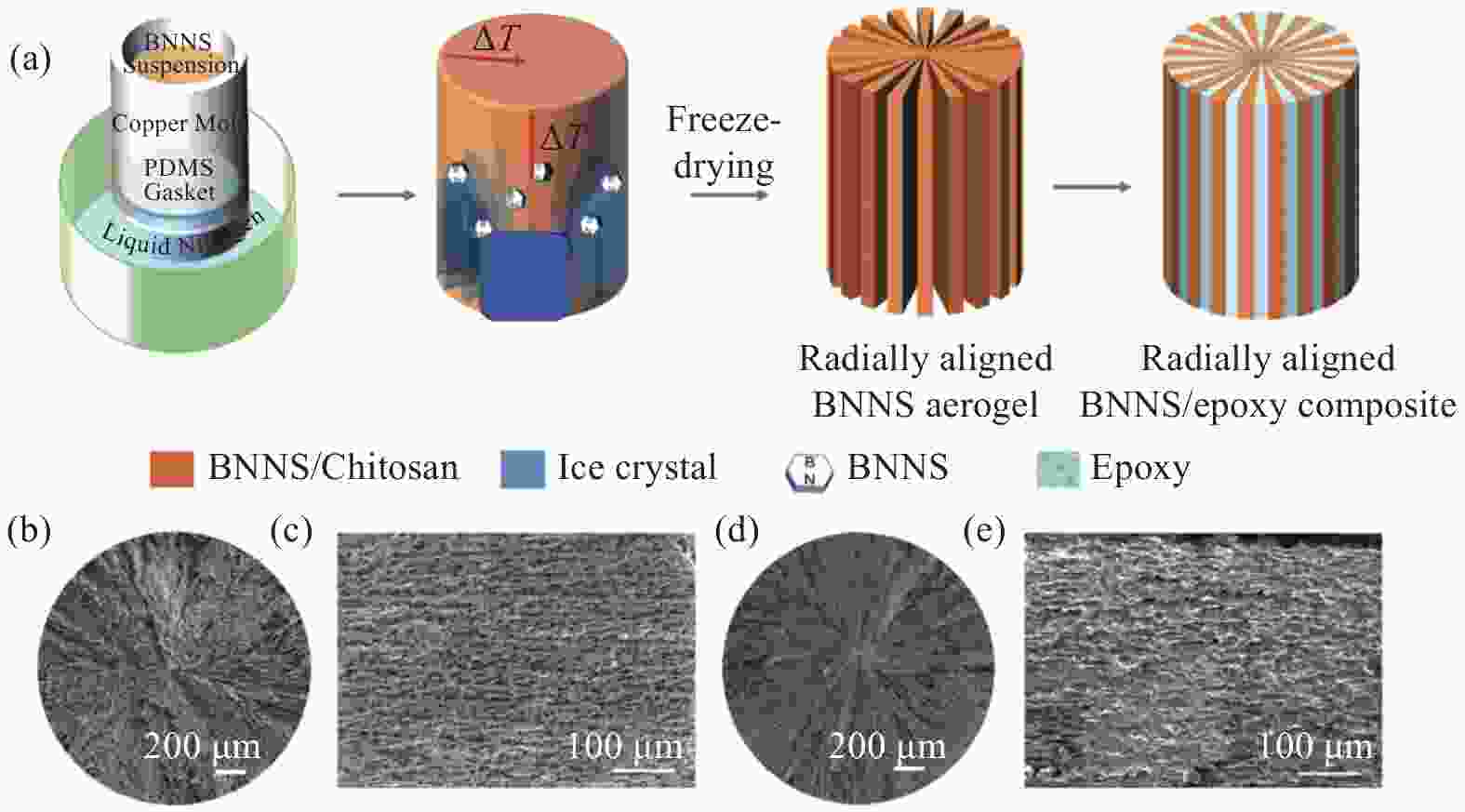

图 8 使用冰模板自组装制造径向排列的3D-BNNS/EP复合材料的制备示意图(a),分别来自径向和垂直方向的BNNS气凝胶((b), (c))及BNNS/EP复合材料((d), (e))的SEM图像[69]

Figure 8. Schematic diagram for the fabrication route of radially aligned 3D-BNNS/EP composite using a ice template self-assembly (a), SEM images of BNNS aerogel ((b), (c)) and BNNS/EP composite ((d), (e)) from radial and vertical directions, respectively[69]

表 1 氮化硼纳米片(BNNS)的主要性能

Table 1. Main properties of boron nitride nanosheets (BNNS)

Characterisation Property Ref. Thermal stability 1000℃ in air and 1400℃ in vacuum [15] Young’s modulus ≈1.0 TPa [16] Specific surface area ≈2600 m2/g [17] Band gap 5-6 eV [18] Thermal expansion coefficient ≈2.72×10−6/K (Axial direction) [19-21] Thermal conductivity 1700-2000 W/(m·K) (Theoretical)

300-360 W/(m·K) (Experimental)[20] Dielectric constant 3-4 [19] -

[1] MOORE A L, LI S. Emerging challenges and materials for thermal management of electronics[J]. Materials Today,2014,17(4):163-174. doi: 10.1016/j.mattod.2014.04.003 [2] 田恐虎, 吴阳, 盛绍顶, 等. 聚合物基绝缘导热复合材料中碳系填料的研究进展[J]. 复合材料学报, 2021, 38(4):1054-1065. doi: 10.13801/j.cnki.fhclxb.20201224.001TIAN Konghu, WU Yang, SHENG Shaoding, et al. Research progress of carbon-based fillers in polymer matrix insulating and thermally conductive composites[J]. Acta Materiae Compositae Sinica,2021,38(4):1054-1065(in Chinese). doi: 10.13801/j.cnki.fhclxb.20201224.001 [3] CHEN H Y, GINZBURG V V, YANG J, et al. Thermal conductivity of polymer-based composites: Fundamentals and applications[J]. Progress in Polymer Science,2016,59:41-85. doi: 10.1016/j.progpolymsci.2016.03.001 [4] MU M L, WAN C Y, MCNALLY T. Thermal conductivity of 2D nano-structured graphitic materials and their compo-sites with epoxy resins[J]. 2D Materials,2017,4(4):042001. doi: 10.1088/2053-1583/aa7cd1 [5] 欧阳泽宇, 王珂珂, 饶琼, 等. 石墨烯纳米片/(酚酞聚芳醚酮-环氧树脂)双逾渗导热复合材料的制备和性能[J]. 复合材料学报, 2021, 38(3):722-731. doi: 10.13801/j.cnki.fhclxb.20200806.003OUYANG Zeyu, WANG Keke, RAO Qiong, et al. Preparation and properties of thermally conductive graphene nanoplates/(polyetherketone cardo-epoxy) composites with double percolation structures[J]. Acta Materiae Compositae Sinica,2021,38(3):722-731(in Chinese). doi: 10.13801/j.cnki.fhclxb.20200806.003 [6] LIN Y, HUANG X Y, CHEN J, et al. Epoxy thermoset resins with high pristine thermal conductivity[J]. High Voltage,2017,2(3):139-146. doi: 10.1049/hve.2017.0120 [7] 刘少刚, 王李波, 王晓龙, 等. 高导热网络聚合物基复合材料的研究进展[J]. 中国塑料, 2019, 33(8):127-135. doi: 10.19491/j.issn.1001-9278.2019.08.021LIU Shaogang, WANG Libo, WANG Xiaolong, et al. Research progress in polymer matrix composites with highly thermal conductivity network[J]. China Plastics,2019,33(8):127-135(in Chinese). doi: 10.19491/j.issn.1001-9278.2019.08.021 [8] HE J, WANG H, QU Q Q, et al. Three-dimensional network constructed by vertically oriented multilayer graphene and SiC nanowires for improving thermal conductivity and operating safety of epoxy composites with ultralow loading[J]. Composites Part A: Applied Science and Manufacturing,2020,139:106062. doi: https://doi.org/10.1016/j.compositesa.2020.106062 [9] CHEN Y, ZOU J, CAMPBELL S J, et al. Boron nitride nano-tubes: Pronounced resistance to oxidation[J]. Applied Physics Letters,2004,84(13):2430-2432. doi: 10.1063/1.1667278 [10] WANG Y X, XU N, LI D Y, et al. Thermal properties of two dimensional layered materials[J]. Advanced Functional Materials,2017,27(19):1604134. doi: 10.1002/adfm.201604134 [11] SHARMA V, KAGDADA H L, JHA P K, et al. Thermal transport properties of boron nitride based materials: A review[J]. Renewable and Sustainable Energy Reviews,2020,120:109622. doi: 10.1016/j.rser.2019.109622 [12] WATANABE K, TANIGUCHI T, KANDA H. Direct-bandgap properties and evidence for ultraviolet lasing of hexagonal boron nitride single crystal[J]. Nature Materials,2004,3(6):404-409. doi: 10.1038/nmat1134 [13] 孙颖颖, 周璐瑶, 韩宇, 等. 气泡和气隙影响六方氮化硼/环氧树脂复合材料导热性能的有限元模拟[J]. 复合材料学报, 2020, 37(10):2482-2488. doi: 10.13801/j.cnki.fhclxb.20200111.004SUN Yinyin, ZHOU Luyao, HAN Yu, et al. Numerical analysis of the effect of air bubbles and gaps on thermal conductivity of hexagonal boron nitride/epoxy composites[J]. Acta Materiae Compositae Sinica,2020,37(10):2482-2488(in Chinese). doi: 10.13801/j.cnki.fhclxb.20200111.004 [14] 张晓星, 胡国雄, 伍云健, 等. 氮化硼纳米片改性环氧树脂导热与介电性能的研究[J]. 高电压技术, 2021, 47(2):645-651. doi: 10.13336/j.1003-6520.hve.20200195ZHANG Xiaoxing, HU Guoxiong, WU Yunjian, et al. Study on the thermal and dielectric properties of epoxy resin modified by boron nitride nanosheets[J]. High Voltage Engineering,2021,47(2):645-651(in Chinese). doi: 10.13336/j.1003-6520.hve.20200195 [15] ZHANG K L, FENG Y L, WANG F, et al. Two dimensional hexagonal boron nitride (2D-hBN): Synthesis, properties and applications[J]. Journal of Materials Chemistry C,2017,5(46):11992-12022. doi: 10.1039/C7TC04300G [16] KUMAR R, RAJASEKARAN G, PARASHAR A. Optimised cut-off function for Tersoff-like potentials for a BN nanosheet: A molecular dynamics study[J]. Nanotechnology,2016,27(8):085706. doi: 10.1088/0957-4484/27/8/085706 [17] WENG Q H, WANG X B, WANG X, et al. Functionalized hexagonal boron nitride nanomaterials: Emerging properties and applications[J]. Chemical Society Reviews,2016,45(14):3989-4012. doi: 10.1039/C5CS00869G [18] GOLBERG D, BANDO Y, HUANG Y, et al. Boron nitride nanotubes and nanosheets[J]. ACS Nano,2010,4(6):2979-2993. doi: 10.1021/nn1006495 [19] YU C P, ZHANG J, TIAN W, et al. Polymer composites based on hexagonal boron nitride and their application in thermally conductive composites[J]. RSC Advances,2018,8(39):21948-21967. doi: 10.1039/C8RA02685H [20] GUERRA V, WAN C Y, MCNALLY T. Thermal conductivity of 2D nano-structured boron nitride (BN) and its compo-sites with polymers[J]. Progress in Materials Science,2019,100:170-186. doi: 10.1016/j.pmatsci.2018.10.002 [21] RASUL M G, KIZILTAS A, ARFAEI B, et al. 2D boron nitride nanosheets for polymer composite materials[J]. npj 2D Materials and Applications,2021,5(1):56. doi: 10.1038/s41699-021-00231-2 [22] JIANG X F, WENG Q H, WANG X B, et al. Recent progress on fabrications and applications of boron nitride nanomaterials: A review[J]. Journal of Materials Science & Technology,2015,31(6):589-598. [23] HAN G J, ZHAO X Y, FENG Y Z, et al. Highly flame-retardant epoxy-based thermal conductive composites with functionalized boron nitride nanosheets exfoliated by one-step ball milling[J]. Chemical Engineering Journal,2021,407:127099. doi: 10.1016/j.cej.2020.127099 [24] CHEN S H, XU R Z, LIU J M, et al. Simultaneous production and functionalization of boron nitride nanosheets by sugar-assisted mechanochemical exfoliation[J]. Advanced Materials,2019,31(10):1804810. doi: 10.1002/adma.201804810 [25] LI H, ZHAO J Z, WANG J F. Total-conversion, high-concentration exfoliation of two-dimensional boron nitride by paste-based sand milling strategy for massively producing high-performance nanocomposites[J]. Composites Science and Technology,2021,201:108545. doi: 10.1016/j.compscitech.2020.108545 [26] SHI X F, WANG K H, TIAN J, et al. Few-layer hydroxyl-functionalized boron nitride nanosheets for nanoscale thermal management[J]. ACS Applied Nano Materials,2020,3(3):2310-2321. doi: 10.1021/acsanm.9b02427 [27] AN L L, YU Y L, BAI C N, et al. Simultaneous production and functionalization of hexagonal boron nitride nanosheets by solvent-free mechanical exfoliation for superlubricant water-based lubricant additives[J]. npj 2D Materials and Applications,2019,3(1):28. doi: 10.1038/s41699-019-0111-9 [28] WANG N, YANG G, WANG H X, et al. A universal method for large-yield and high-concentration exfoliation of two-dimensional hexagonal boron nitride nanosheets[J]. Materials Today,2019,27:33-42. doi: 10.1016/j.mattod.2018.10.039 [29] XIE B S, LI C C, CHEN J, et al. Exfoliated 2D hexagonal boron nitride nanosheet stabilized stearic acid as compo-site phase change materials for thermal energy storage[J]. Solar Energy,2020,204:624-634. doi: 10.1016/j.solener.2020.05.004 [30] MA Z S, DING H L, LIU Z, et al. Preparation and tribolo-gical properties of hydrothermally exfoliated ultrathin hexagonal boron nitride nanosheets (BNNSs) in mixed NaOH/KOH solution[J]. Journal of Alloys and Compounds,2019,784:807-815. doi: 10.1016/j.jallcom.2019.01.108 [31] YOON S I, MA K Y, KIM T Y, et al. Proton conductivity of a hexagonal boron nitride membrane and its energy applications[J]. Journal of Materials Chemistry A,2020,8(6):2898-2912. doi: 10.1039/C9TA12293A [32] CHEN Y, KANG Q, JIANG P K, et al. Rapid, high-efficient and scalable exfoliation of high-quality boron nitride nanosheets and their application in lithium-sulfur batteries[J]. Nano Research,2021,14(7):2424-2431. doi: 10.1007/s12274-020-3245-3 [33] WANG H Y, SU X, SONG T, et al. Scalable exfoliation and dispersion of few-layer hexagonal boron nitride nanosheets in NMP-salt solutions[J]. Applied Surface Science,2019,488:656-661. doi: 10.1016/j.apsusc.2019.05.296 [34] ZHAO L H, YAN L, WEI C M, et al. Aqueous-phase exfoliation and functionalization of boron nitride nanosheets using tannic acid for thermal management applications[J]. Industrial & Engineering Chemistry Research,2020,59(37):16273-16282. [35] DESHMUKH A R, ALOUI H, KIM B S. In situ growth of gold and silver nanoparticles onto phyto-functionalized boron nitride nanosheets: Catalytic, peroxidase mimicking, and antimicrobial activity[J]. Journal of Cleaner Production,2020,270:122339. doi: 10.1016/j.jclepro.2020.122339 [36] ZHAO H R, DING J H, SHAO Z Z, et al. High-quality boron nitride nanosheets and their bioinspired thermally conductive papers[J]. ACS Applied Materials & Interfaces,2019,11(40):37247-37255. [37] NADEEM A, RAZA M A, MAQSOOD M F, et al. Characterization of boron nitride nanosheets synthesized by boron-ammonia reaction[J]. Ceramics International,2020,46(12):20415-20422. doi: 10.1016/j.ceramint.2020.05.132 [38] HAN R, KHAN M H, ANGELOSKI A, et al. Hexagonal boron nitride nanosheets grown via chemical vapor deposition for silver protection[J]. ACS Applied Nano Materials,2019,2(5):2830-2835. doi: 10.1021/acsanm.9b00298 [39] ZHENG Z Y, COX M, LI B. Surface modification of hexagonal boron nitride nanomaterials: A review[J]. Journal of Materials Science,2017,53(1):66-99. [40] HUTCHINSON J M, MORADI S. Thermal conductivity and cure kinetics of epoxy-boron nitride composites-A review[J]. Materials (Basel),2020,13(16):3634. doi: 10.3390/ma13163634 [41] XIAO M, DU B X. Review of high thermal conductivity polymer dielectrics for electrical insulation[J]. High Voltage,2016,1(1):34-42. doi: 10.1049/hve.2016.0008 [42] 张凯, 桂泰江, 吴连锋, 等. 导热绝缘聚合物复合材料的研究进展[J]. 材料导报, 2021, 35(S1):571-575.ZHANG Kai, GUI Taijiang, WU Lianfeng, et al. Research progress of thermal conductive and electrical insulating polymer composites[J]. Materials Reports,2021,35(S1):571-575(in Chinese). [43] MENG Q S, HAN S S, LIU T Q, et al. Noncovalent modification of boron nitrite nanosheets for thermally conductive, mechanically resilient epoxy nanocomposites[J]. Industrial & Engineering Chemistry Research,2020,59(47):20701-20710. [44] LI X W, FENG Y Z, CHEN C, et al. Highly thermally conductive flame retardant epoxy nanocomposites with multifunctional ionic liquid flame retardant-functionalized boron nitride nanosheets[J]. Journal of Materials Chemistry A,2018,6(41):20500-20512. doi: 10.1039/C8TA08008A [45] JUNG D W, KIM J M, YOON H W, et al. Solution-processable thermally conductive polymer composite adhesives of benzyl-alcohol-modified boron nitride two-dimensional nanoplates[J]. Chemical Engineering Journal,2019,361:783-791. doi: 10.1016/j.cej.2018.12.128 [46] JIN X L, LI W Z, LIU Y Y, et al. Self-constructing thermal conductive filler network via reaction-induced phase separation in BNNSs/epoxy/polyetherimide composites[J]. Composites Part A: Applied Science and Manufacturing,2020,130:105727. doi: 10.1016/j.compositesa.2019.105727 [47] WIE J H, KIM M J, KIM J H. Enhanced thermal conductivity of a polysilazane-coated A-BN/epoxy composite following surface treatment with silane coupling agents[J]. Applied Surface Science,2020,529:147091. doi: 10.1016/j.apsusc.2020.147091 [48] LIU Z, LI J H, LIU X H. Novel functionalized BN nanosheets/epoxy composites with advanced thermal conductivity and mechanical properties[J]. ACS Applied Materials Interfaces,2020,12(5):6503-6515. doi: 10.1021/acsami.9b21467 [49] LEE J H, SHIN H, RHEE K Y. Surface functionalization of boron nitride platelets via a catalytic oxidation/silanization process and thermomechanical properties of boron nitride epoxy composites[J]. Composites Part B-Engineering,2019,157:276-282. doi: 10.1016/j.compositesb.2018.08.050 [50] TIAN X J, WU N, ZHANG B, et al. Glycine functionalized boron nitride nanosheets with improved dispersibility and enhanced interaction with matrix for thermal composites[J]. Chemical Engineering Journal,2021,408:127360. doi: 10.1016/j.cej.2020.127360 [51] MA H Q, GAO B, WANG M Y, et al. Strategies for enhancing thermal conductivity of polymer-based thermal interface materials: A review[J]. Journal of Materials Science,2020,56(2):1064-1086. [52] HANSSON J, NILSSON T M J, YE L L, et al. Novel nanostructured thermal interface materials: A review[J]. International Materials Reviews,2018,63(1):22-45. doi: 10.1080/09506608.2017.1301014 [53] HAN Y X, SHI X T, YANG X T, et al. Enhanced thermal conductivities of epoxy nanocomposites via incorporating in-situ fabricated hetero-structured SiC-BNNS fillers[J]. Composites Science and Technology,2020,187:107944. doi: 10.1016/j.compscitech.2019.107944 [54] WU Y J, ZHANG X X, NEGI A, et al. Synergistic effects of boron nitride (BN) nanosheets and silver (Ag) nanoparticles on thermal conductivity and electrical properties of epoxy nanocomposites[J]. Polymers (Basel),2020,12(2):426. doi: 10.3390/polym12020426 [55] YANG L, ZHANG L, LI C Z. Bridging boron nitride nanosheets with oriented carbon nanotubes by electrospinning for the fabrication of thermal conductivity enhanced flexible nanocomposites[J]. Composites Science and Technology,2020,200:108429. doi: 10.1016/j.compscitech.2020.108429 [56] HAN Y X, SHI X T, WANG S S, et al. Nest-like hetero-structured BNNS@SiCnws fillers and significant improvement on thermal conductivities of epoxy composites[J]. Composites Part B: Engineering,2021,210:108666. doi: 10.1016/j.compositesb.2021.108666 [57] AKHTAR M W, KIM J S, MEMON M A, et al. Hybridization of hexagonal boron nitride nanosheets and multilayer graphene: Enhanced thermal properties of epoxy compo-sites[J]. Composites Science and Technology,2020,195:108183. doi: 10.1016/j.compscitech.2020.108183 [58] OWAIS M, ZHAO J, IMANI A, et al. Synergetic effect of hybrid fillers of boron nitride, graphene nanoplatelets, and short carbon fibers for enhanced thermal conductivity and electrical resistivity of epoxy nanocomposites[J]. Composites Part A: Applied Science and Manufacturing,2019,117:11-22. doi: 10.1016/j.compositesa.2018.11.006 [59] LIAN G, TUAN C C, LI L Y, et al. Vertically aligned and interconnected graphene networks for high thermal conductivity of epoxy composites with ultralow loading[J]. Chemistry of Materials,2016,28(17):6096-6104. doi: 10.1021/acs.chemmater.6b01595 [60] LIANG X, DAI F H. Epoxy nanocomposites with reduced graphene oxide-constructed three-dimensional networks of single wall carbon nanotube for enhanced thermal mana-gement capability with low filler loading[J]. ACS Applied Materials & Interfaces, 2020, 12(2): 3051-3058. [61] CHEN J, HUANG X Y, ZHU Y K, et al. Cellulose nanofiber supported 3D interconnected BN nanosheets for epoxy nanocomposites with ultrahigh thermal management capability[J]. Advanced Functional Materials,2017,27(5):1604754. doi: 10.1002/adfm.201604754 [62] ZHAN H F, NIE Y H, CHEN Y N, et al. Thermal transport in 3D nanostructures[J]. Advanced Functional Materials,2020,30(8):1903841. doi: 10.1002/adfm.201903841 [63] ZENG X L, YAO Y M, GONG Z Y, et al. Ice-templated assembly strategy to construct 3D boron nitride nanosheet networks in polymer composites for thermal conductivity improvement[J]. Small,2015,11(46):6205-6213. doi: 10.1002/smll.201502173 [64] HU J T, HUANG Y, YAO Y M, et al. Polymer composite with improved thermal conductivity by constructing a hierarchically ordered three-dimensional interconnected network of BN[J]. ACS Applied Materials & Interfaces,2017,9(15):13544-13553. [65] FU C J, YAN C Z, REN L L, et al. Improving thermal conductivity through welding boron nitride nanosheets onto silver nanowires via silver nanoparticles[J]. Composites Science and Technology,2019,177:118-126. doi: 10.1016/j.compscitech.2019.04.026 [66] LI H T, FU C J, CHEN N, et al. Ice-templated assembly strategy to construct three-dimensional thermally conduc-tive networks of BN nanosheets and silver nanowires in polymer composites[J]. Composites Communications,2021,25:100601. doi: 10.1016/j.coco.2020.100601 [67] WANG X W, WU P Y. 3D vertically aligned BNNS network with long-range continuous channels for achieving a highly thermally conductive composite[J]. ACS Applied Materials Interfaces,2019,11(32):28943-28952. doi: 10.1021/acsami.9b09398 [68] HE S, ZHANG Y S, ZHANG N, et al. Multi-directionally thermal conductive epoxy/boron nitride composites based on circinate vane type network[J]. Composites Communi-cations,2021,25:100744. doi: 10.1016/j.coco.2021.100744 [69] HUANG T Q, LI Y W, CHEN M, et al. Bi-directional high thermal conductive epoxy composites with radially aligned boron nitride nanosheets lamellae[J]. Composites Science and Technology,2020,198:108322. doi: 10.1016/j.compscitech.2020.108322 [70] WANG X W, WU P Y. Melamine foam-supported 3D interconnected boron nitride nanosheets network encapsulated in epoxy to achieve significant thermal conductivity enhancement at an ultralow filler loading[J]. Chemical Engineering Journal,2018,348:723-731. doi: 10.1016/j.cej.2018.04.196 -

下载:

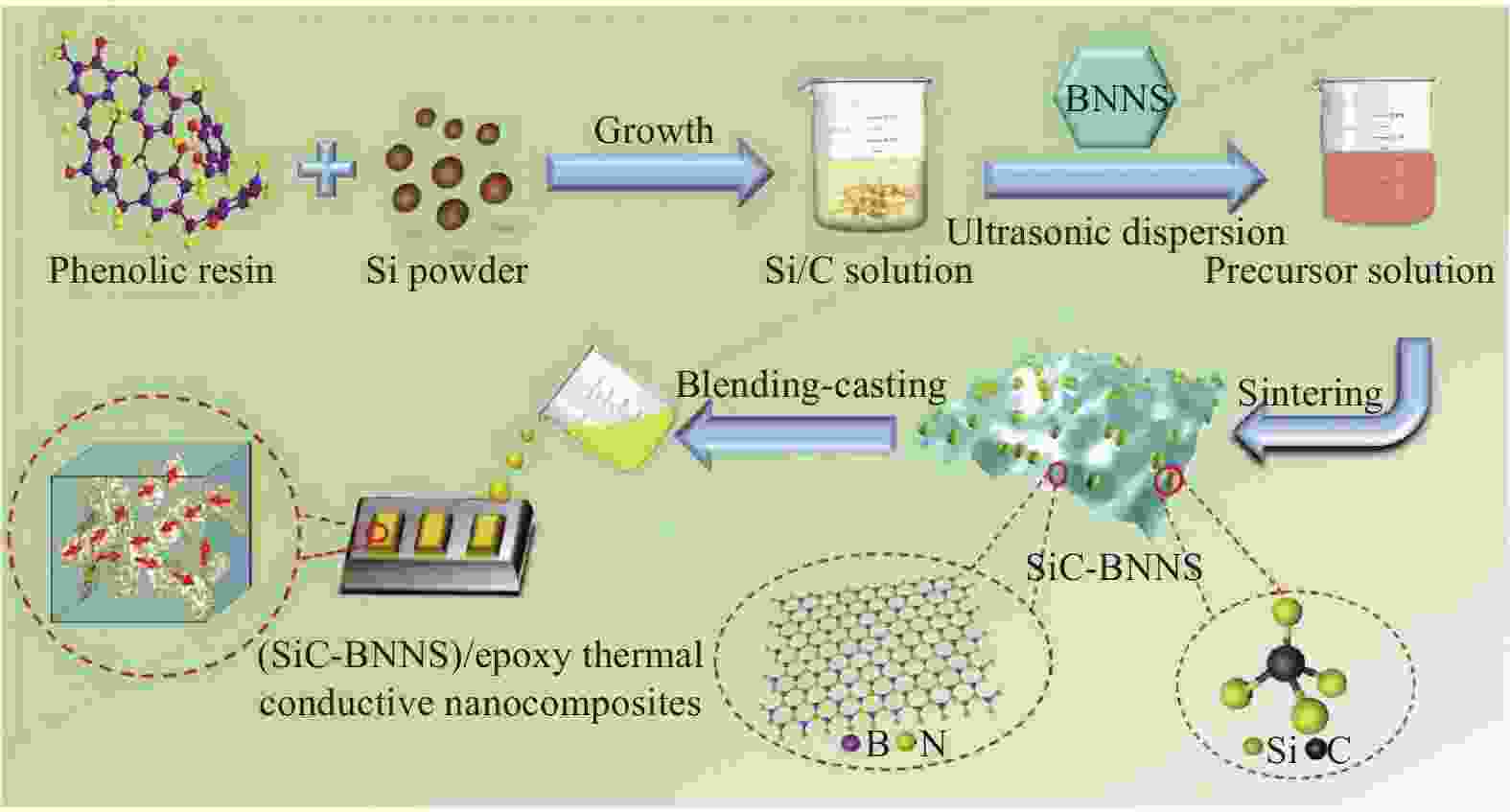

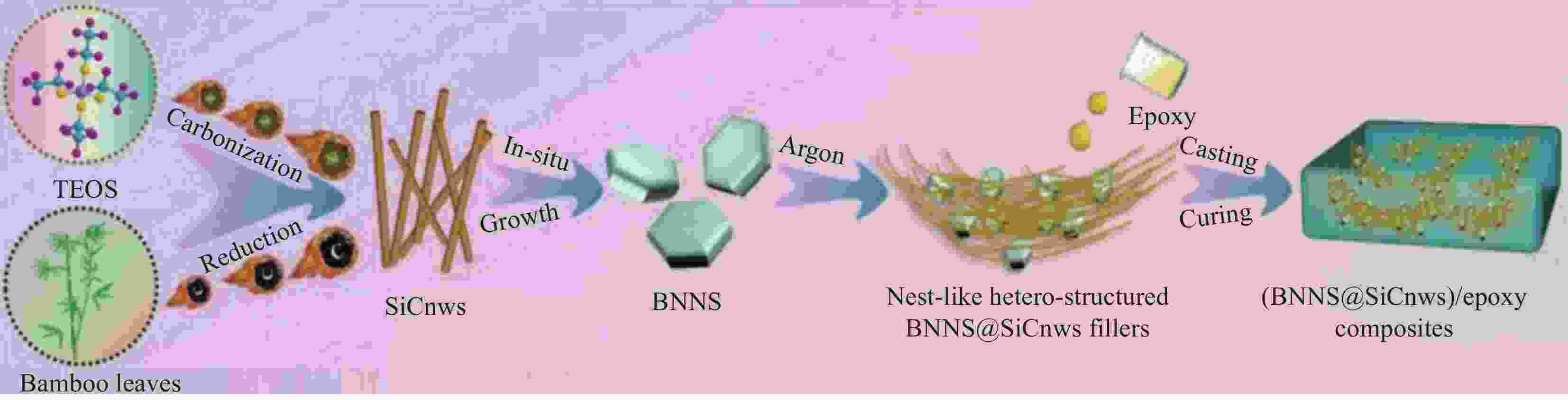

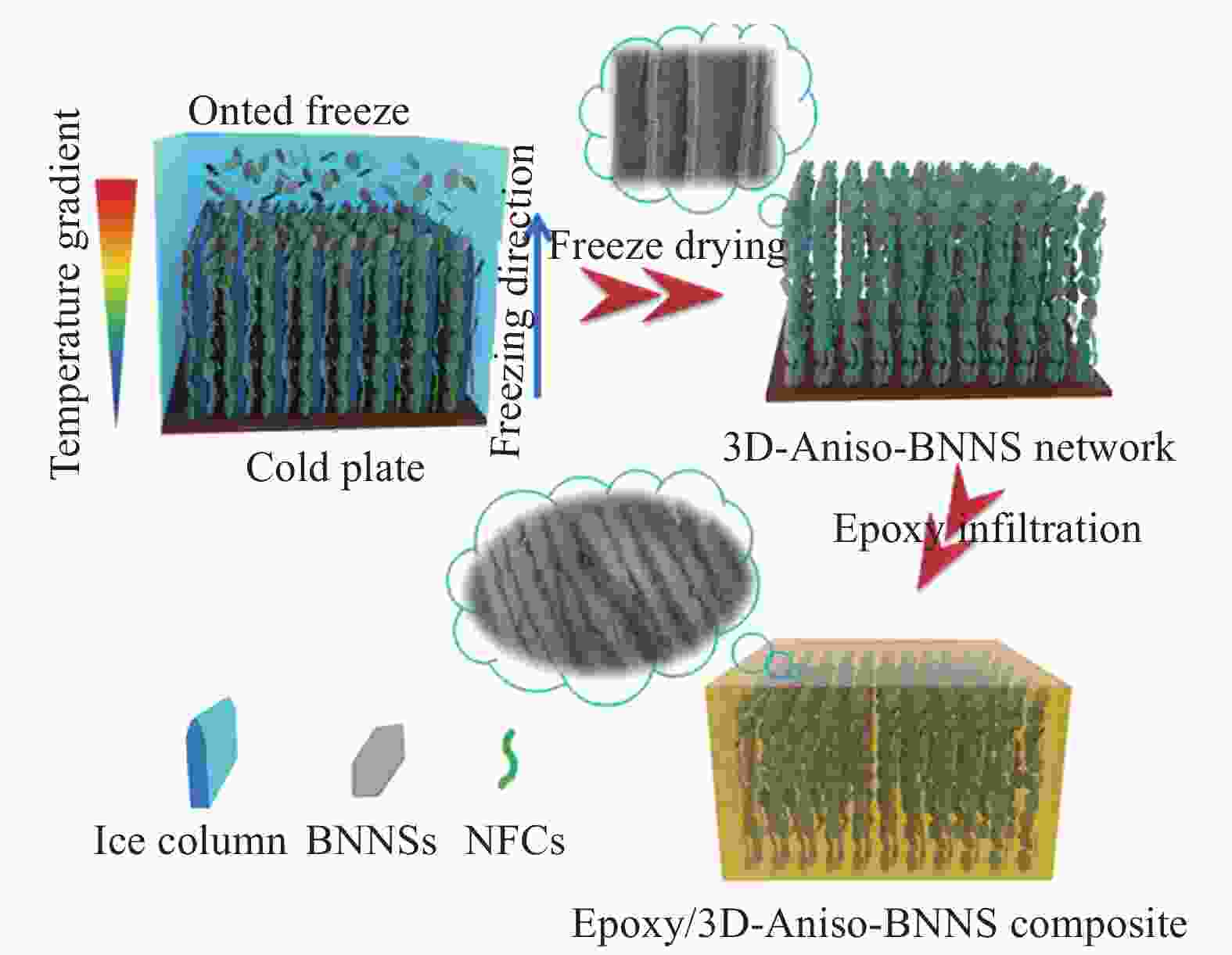

下载: