Self-assembly of montmorillonite-cellulose nanocrystal for enhancing mechanical properties of poly(vinyl alcohol) films

-

摘要: 自然生物体由于多级有序的结构、复杂的有机/无机界面相互作用使其具有优异的力学性能,而合成材料仅通过组分和结构的模拟通常无法实现强度、韧性、断裂伸长率的同步提升。基于此,本文通过静电自组装结合溶剂蒸发获得了蒙脱土-纤维素纳米晶/聚乙烯醇(MMT-PCNC/PVA)层状结构复合膜,利用TEM跟踪组装体的形成过程,结合FTIR图谱结果显示复合膜中存在静电、氢键等多重弱相互作用。系统研究了组装体中MMT与聚乙烯亚胺(PEI)修饰的PCNC之间的质量比例对PVA膜力学性能的影响。结果表明,相较纯的PVA膜,不同MMT、PCNC质量比例的组装体对PVA膜的力学性能均有提升作用。其中二者质量比例为1∶1、1∶2时最为明显,1MMT-1PCNC/PVA复合膜的拉伸强度提升了196%;1MMT-2PCNC/PVA复合膜的断裂伸长率、韧性分别提升了175%和900%。这些均得益于复合膜内部的弱相互作用,给应力的传递提供了有效的途径,同时引起裂纹偏转,达到消耗能量的目的,使其在拉伸强度提高的同时韧性也得到提升。Abstract: Natural organisms exhibit excellent mechanical properties due to hierarchical ordered structure and complex organic/inorganic interface interaction. However, the synthetic materials have proven to be difficult to achieve the synchronous improvement of strength, toughness and elongation at break, by merely mimicking their component and structural. Herein, the hybrid films of montmorillonite-cellulose nanocrystal/poly(vinyl alcohol) (MMT-PCNC/PVA) were prepared by electrostatic self-assembly and solvent evaporation. TEM was used to track the formation process. The results of FTIR spectra show that there are multiple weak interactions such as electrostatic and hydrogen bonds in the composite films. The effect of the proportion of MMT and polyethyleneimine (PEI) modified PCNC on the mechanical properties of the composite films was studied. As a result, it is most obvious when the mass ratio is 1∶1 and 1∶2 of MMT and PCNC can drastically enhance the tensile strength (196% for 1MMT-1PCNC/PVA), elongation at break (175% for 1MMT-2PCNC/PVA), and toughness (900% for 1MMT-2PCNC/PVA), which are superior to the pure PVA film. The multiple types of interactions between nanoscale building blocks improve the efficiency of load transfer and cause crack deflection, which result in a highly energy consumption and excellent mechanical properties (such as strength, toughness).

-

强韧、轻质复合多级结构材料在能源储存转化、环境治理、生物医学及航天等战略领域的应用越来越受关注[1-4],其中二维多级层状结构材料独特的电子限域效应赋予这类材料独特的物理、化学性质及丰富的科学内涵,在众多的领域都有重要的应用前景,特别是电子器件、光电器件等方面[5-6]。但人工合成材料不能像天然材料(贝壳、骨骼等)一样通过大量的相互作用对结构基元进行精准的调控,以致各结构基元在受力时应力不能有效传递导致材料断裂,影响力学性质、进而限制材料的应用[7-10]。

受自然界启发,研究工作者发展了大量具有强韧力学性能的二维层状结构材料,通常采取的方案是将高强度的无机纳米片与高柔性的有机聚合物通过层-层(LBL)组装、真空抽滤组装、空气诱导组装、冰模板等方法复合,得到类贝壳珍珠层的“砖-泥”结构[11-13]。如Shin等[14]将还原石墨烯氧化物(RGOF)与碳纳米管(SWNT)复合,用RGOF-SWNT复合体填充聚乙烯醇(PVA),获得了具有强韧性的RGOF-SWNT-PVA复合膜材料。Cao等[15]鉴于电磁屏蔽材料对厚度与力学性能的需要,选择Ti3C2Tx (MXene)与纤维素纳米纤维(CNF)为功能基元通过真空抽滤自组装的方法得到了高电磁屏蔽效率的复合膜材料,同时保证了材料的强度和韧性。Yoo等[16]通过静电组装氮化硼(BNNS)与明胶获得机械强度媲美人体骨密质的复合膜,且表现出优异的生物相容性,有望应用于组织工程与骨内植入领域。Woo等[17]利用交联剂(CA) 将片层氧化石墨烯(GO)通过化学键相连,形成仿贝壳结构的GO/CA层状复合薄膜,由于GO之间强大的共价键网络,复合薄膜表现出优异的力学性能,在航空航天、电子保护器、渗透膜等领域有潜在应用。过去研究者们采用纳米填充质增强聚合物薄膜的工作在拉伸强度上都有明显的提升,但断裂伸长率却变化不大甚至有所降低,导致复合薄膜的韧性提升被限制。究其原因在于结构基元之间可作为牺牲性成键的相互作用力较少,也将其归结为应力传递效率较低。综上所述,发展一种普适性的复合膜增强增韧方法仍然具有一定的挑战性[18-20]。

利用聚乙烯亚胺(PEI)修饰过后的纤维素纳米晶(PCNC)与蒙脱土纳米片(MMT)静电自组装得到MMT-PCNC组装体,将其分散到PVA水溶液中并搅拌均匀,随后倒入培养皿中利用溶剂蒸发法成膜。得到的MMT-PCNC/PVA复合膜拉伸强度与断裂伸长率同步增加,性能平衡。此法提高了材料的应力传递效率,有效增加了复合膜的拉伸强度;同时利用多重弱相互作用实现了断裂强度、断裂伸长率以及韧性的同步提升。

1. 实验材料及方法

1.1 原材料

蒙脱土粉末购买于浙江丰虹新材料有限公司,棉浆浆板购买于河北中国纸业公司,浓硫酸(98%)购买于北京化学试剂厂,聚乙烯醇(PVA,醇解度为87%~89%,AR)在阿拉丁上海有限公司购买,聚乙烯亚胺(PEI,Mw=10000,AR)购买于阿达玛斯试剂有限公司。实验过程中所用到的试剂都未经任何处理。

1.2 PCNC的制备

晶态纳米纤维素(Cellulose nanocrystals, CNC)悬浮液制备方法参考文献[21]制得,PEI修饰的CNC具体制备过程如下:取10 mL PEI水溶液(3.0wt%)加入到5 mL CNC悬浮液(3.0wt%)中,室温下连续搅拌1 h,随后用浓盐酸将混合溶液pH调到1.3以增强CNC与PEI之间的离子相互作用。继续搅拌十分钟后,将混合溶液高速离心20 min(13000 r/min),弃去上层清液,将沉淀用超纯水(18.2 MΩ·cm,Mill-Q Corp)洗涤三次,去掉未发生相互作用的游离PEI聚合物。最后再将沉淀加入水中,超声30 min重新分散,8000 r/min低速离心8 min,去掉CNC聚集体,收集上层清液得到单分散的CNC悬浮液,浓度为1.0wt%,命名为PCNC。

1.3 MMT悬浮液的制备

将2 g MMT粉末加入到500 mL超纯水中,连续溶解搅拌一周后静置72 h,收集上层清液得到剥离充分的MMT纳米片备用,浓度为0.2wt%。

1.4 MMT-PCNC组装体的制备

将MMT (0.2wt%)悬浮溶液逐滴加入到PCNC (1.0wt%)悬浮溶液中,持续搅拌24 h,得到MMT-PCNC组装体悬浮液,控制MMT与PCNC的质量比分别为1∶1、1∶2、1∶4。得到不同MMT、PCNC质量比的组装体,分别命名为1MMT-1PCNC、1MMT-2PCNC、1MMT-4PCNC,具体组成见表1。

1.5 MMT-PCNC/PVA复合膜的制备

将上述组装体悬浮液加入到PVA水溶液中,搅拌过夜,使组装体分散均匀,组装体含量控制为PVA质量的20%。将混合液置于直径为60 mm的聚乙烯塑料培养皿中室温干燥2天,得到柔性MMT-PCNC/PVA复合膜。

表 1 蒙脱土-纤维素纳米晶(MMT-PCNC)组装体的组成Table 1. Compositions of the montmorillonite-cellulose nanocrystal (MMT-PCNC) assembliesSample 1MMT-1PCNC 1MMT-2PCNC 1MMT-4PCNC Composition Mass fraction Mass ratio Mass ratio Mass ratio MMT 0.2% 1 1 1 PCNC 1.0% 1 2 4 1.6 样品性能及表征

SEM结果在JSM-6510A上获得,样品用导电胶粘贴于样品台表面,喷金60 s,电压设置为20 kV,电流设置为86 μA[22]。TEM结果在FEI Tecnai G2S-Twin上获得,样品滴于200 mm铜网上,室温晾干,加速电压为200 kV。溶液的Zeta电势常温下在Malvern Zetasizer Nano-ZS90上获得,样品浓度为0.1wt%[23]。傅立叶红外光谱(FTIR)测试在Bruker IFS 66v/S红外光谱仪上进行,扫描范围为 400~4000 cm−1,扫描速度为4 cm−1,制样过程参考文献[24],样品采用KBr压片,测试前置于60℃烘箱干燥1 h。力学性能测试在万能材料测试机(Instron 5944, UK)上进行,所用传感器为2000 N,拉伸速率为5 mm·min−1,夹距为10 mm。所有的样品测试均在常温下进行,样品长度约为50 mm、宽度约为5 mm、厚度约为0.3 mm,每组样品重复测量3次。

2. 结果与讨论

2.1 MMT-PCNC组装体的形成过程

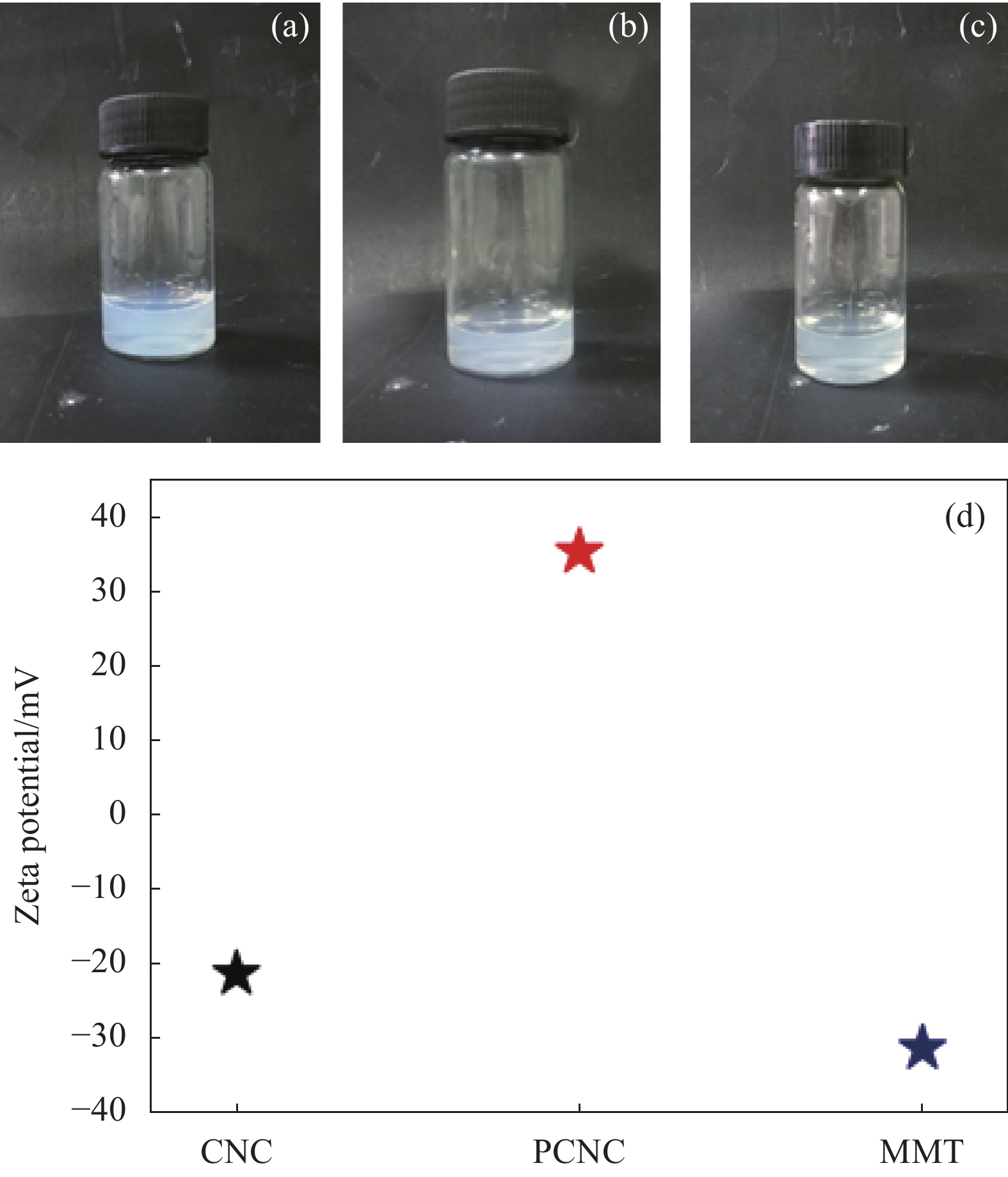

图1(a)~1(c)分别为CNC、PCNC、MMT悬浮溶液置于室温下一个月之后的光学照片,从图中可以看到溶液基本都呈乳白色,无沉淀产生,说明所有的溶液均非常稳定。CNC由硫酸水解制得,表面含有磺酸基,带负电,Zeta电势分析得到CNC的电势值为−21.3 mV。加入PEI对其进行修饰后,在其表面引入了氨基,带正电,Zeta电势分析显示,PEI修饰过后的CNC (PCNC)电势值由−21.3 mV增加到35.4 mV。对MMT进行Zeta电势表征得到,其电势值为−31.3 mV,与PCNC所带电荷相反,数值匹配,为静电相互作用驱动形成MMT-PCNC组装体提供了必要的条件(图1(d))。

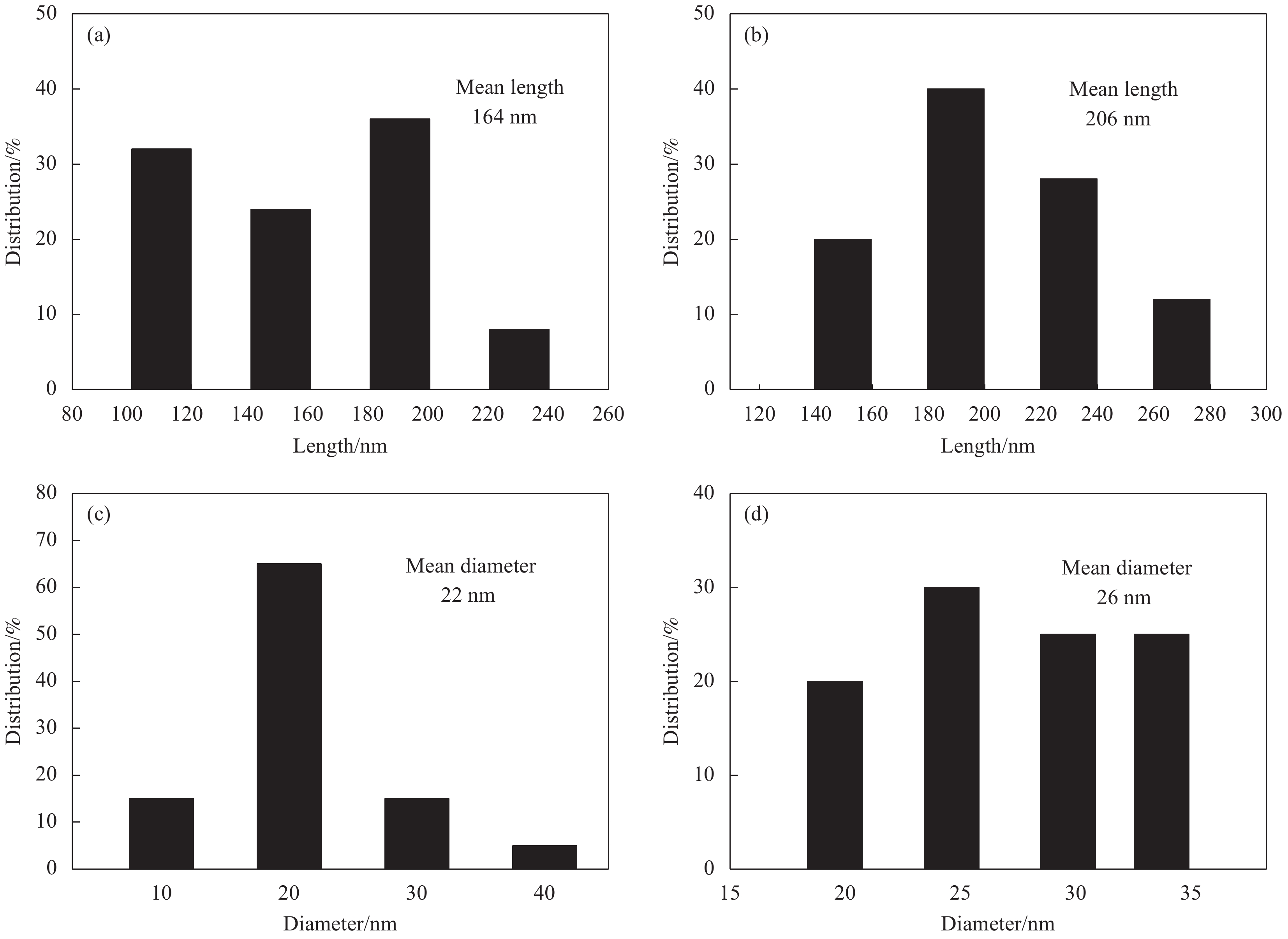

对修饰前后的CNC进行TEM表征,可以看到PCNC仍为棒状结构,长度与直径相比较CNC有明显的增加(图2)。经过统计,平均长度由164 nm增加到206 nm,平均直径由22 nm增加到26 nm (图3),说明PEI聚电解质已成功包覆于CNC的表面,形成PCNC。

将不同质量比的PCNC与MMT悬浮液混合,得到不同质量比的MMT-PCNC组装体悬浮液(1MMT-2PCNC、1MMT-1PCNC、1MMT-4PCNC),组装后发现三组不同配比的溶液均不同程度的发生聚沉,出现明显颗粒感,说明两种结构基元发生相互作用,且组装以后尺寸变大。以1MMT-2PCNC组装体为例,分别对组装前后的结构基元(MMT纳米片、PCNC纳米棒和1MMT-2PCNC组装体)进行TEM表征(图4)。如图4(a)所示,MMT呈分散、不规则片层结构,横向尺寸大约有100~1000 nm。在1MMT-2PCNC组装体的TEM图像中可以看到PCNC纳米棒附着于MMT纳米片的表面及边缘上,取向各异,在MMT表面上形成一层稠密的PCNC层(图4(c)及插图)。组装体的尺寸取决于原始MMT与PCNC的尺寸。

2.2 MMT-PCNC/PVA复合膜的形貌

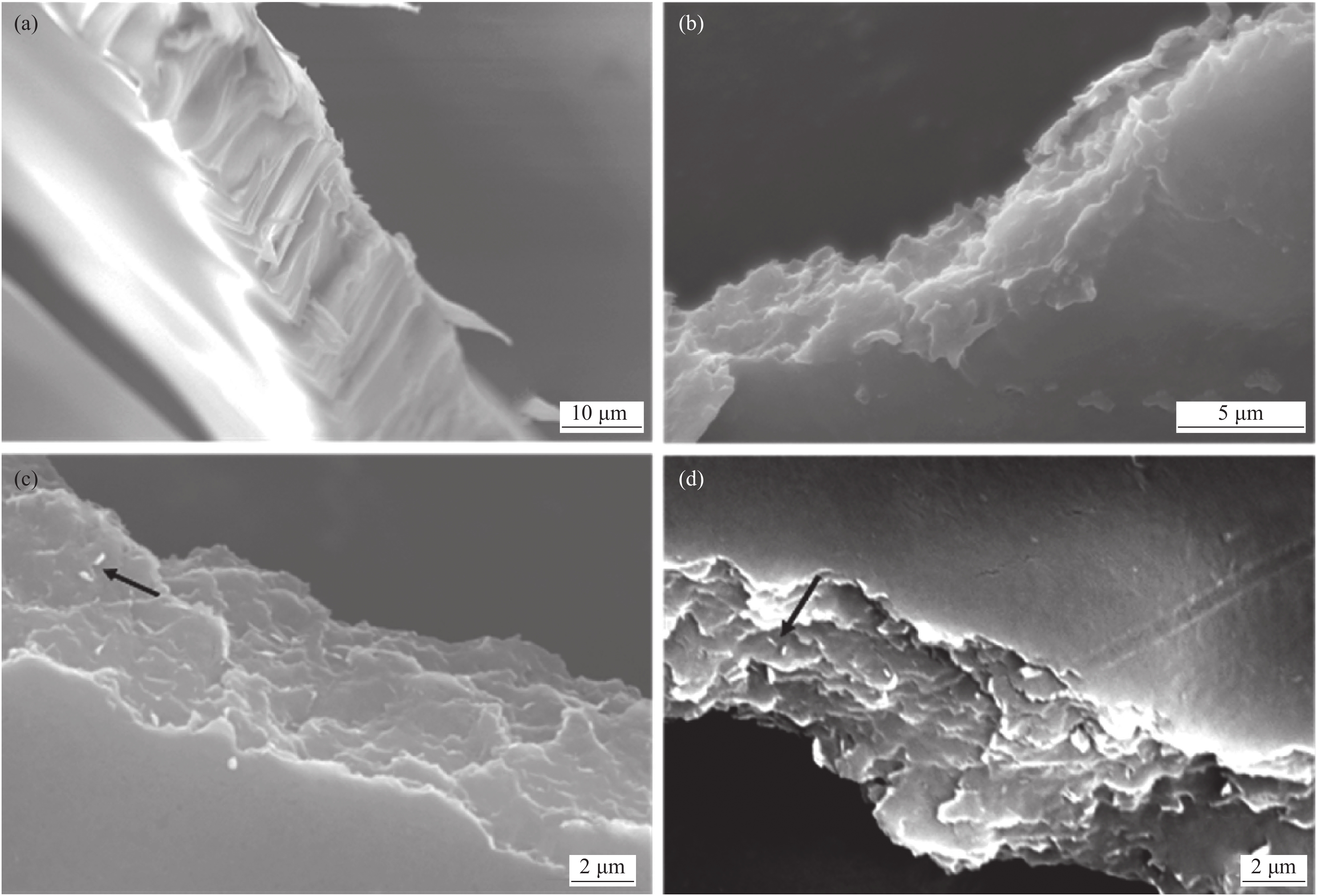

图5为不同MMT-PCNC/PVA复合膜的SEM图像。如图所示,纯PVA薄膜截面致密,无有序结构。而由不同MMT、PCNC质量比的组装体所构成的复合膜均具有明显层状结构,为干燥成膜过程中MMT纳米片组装而成,由图5(c)、5(d)可见,层间具有明显PCNC附着(图中箭头所指),表明由于较强的静电相互作用,使MMT-PCNC组装体在成膜过程中得以有效保存,但由于层间还存在PVA分子,使得PCNC被部分覆盖,电镜下只观察到棒状尖端。图5(b)中,由于PCNC含量相对较少,未在截面处观察到明显PCNC结构。

2.3 MMT-PCNC/PVA复合膜的力学性能

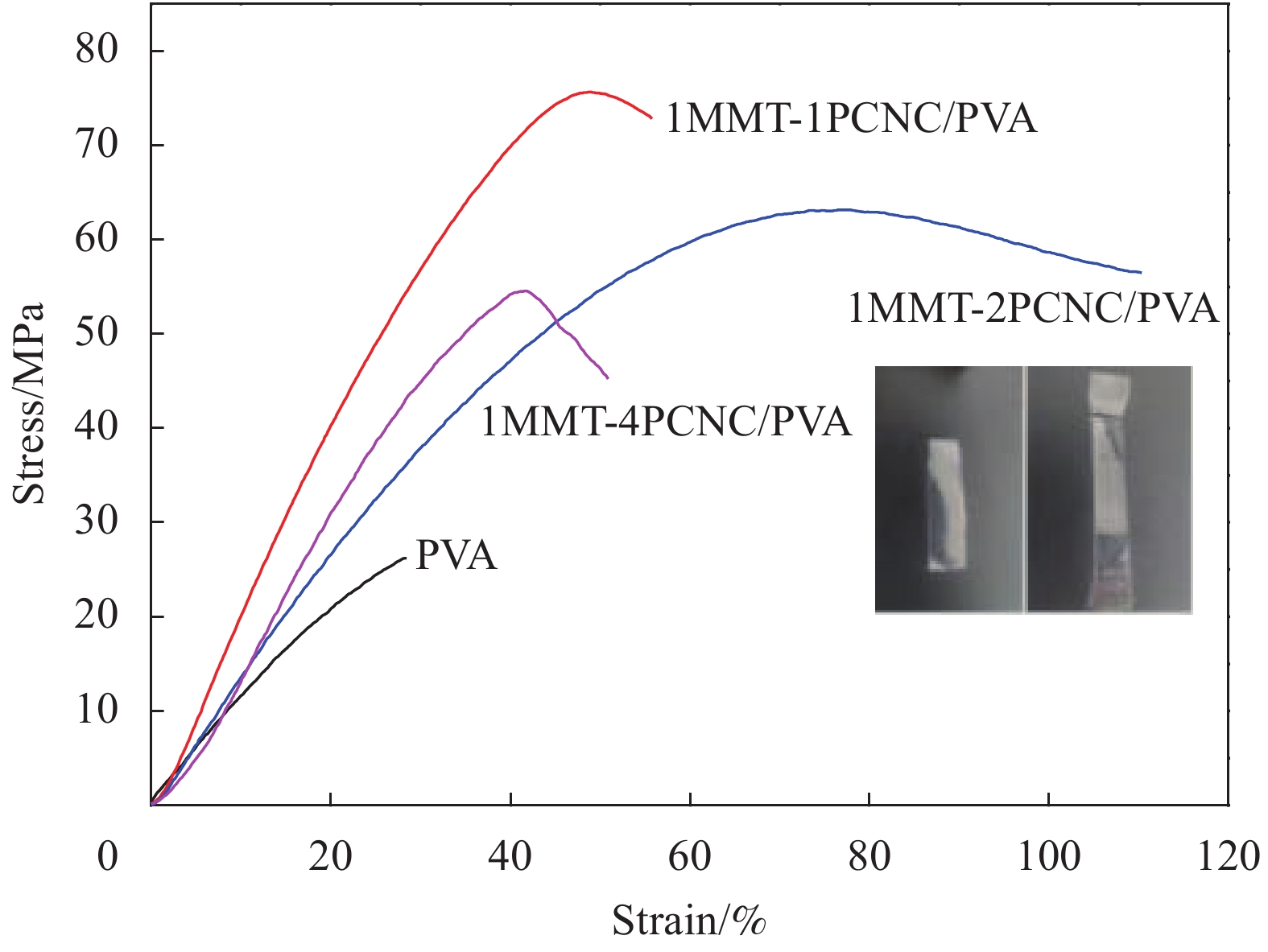

对复合膜及纯PVA膜进行力学性能的测试(图6),测试结果总结于表2中。如图6所示,相比较纯PVA膜,MMT-PCNC作为增强质对复合膜的力学性能产生正影响,拉伸强度、断裂伸长率、韧性都不同程度的增加,杨氏模量均略有下降;其中,1MMT-1PCNC/PVA复合膜拉伸强度增长最为明显,为196%;1MMT-2PCNC/PVA复合膜的断裂伸长率、韧性增加最为明显(图6插图),分别为175%和900%。这些均得益于复合膜内部的弱相互作用[25-26]:MMT与PCNC之间通过静电组装,使组装体内部存在大量静电相互作用;MMT-PCNC组装体表面携带羟基和氨基,易与PVA分子侧基羟基形成氢键,增加了组装体与基体的界面相互作用[27]。这些弱相互作用在复合膜受到拉伸时首先断裂,充当牺牲性成键,使复合膜内部的MMT、PCNC产生滑移,断裂伸长率提高,进而提升韧性[28-29];其次,附着于MMT表面的PCNC通过静电与氢键相互作用将MMT与PVA连接,形成具有砖-泥结构的片层复合膜,当应力作用于膜上时,可在这些刚性结构基元之间有效传递,从而增加复合膜的强度。二者协同作用使材料单位应变时所需的应力减小,即刚性减小。

表 2 MMT-PCNC/PVA复合膜的力学性能Table 2. Mechanical properties of the MMT-PCNC/PVA hybrid filmsHybrid films of filler/PVA Elongation-at-break

/%Tensile strength

/MPaYoung’s modulus

/MPaToughness

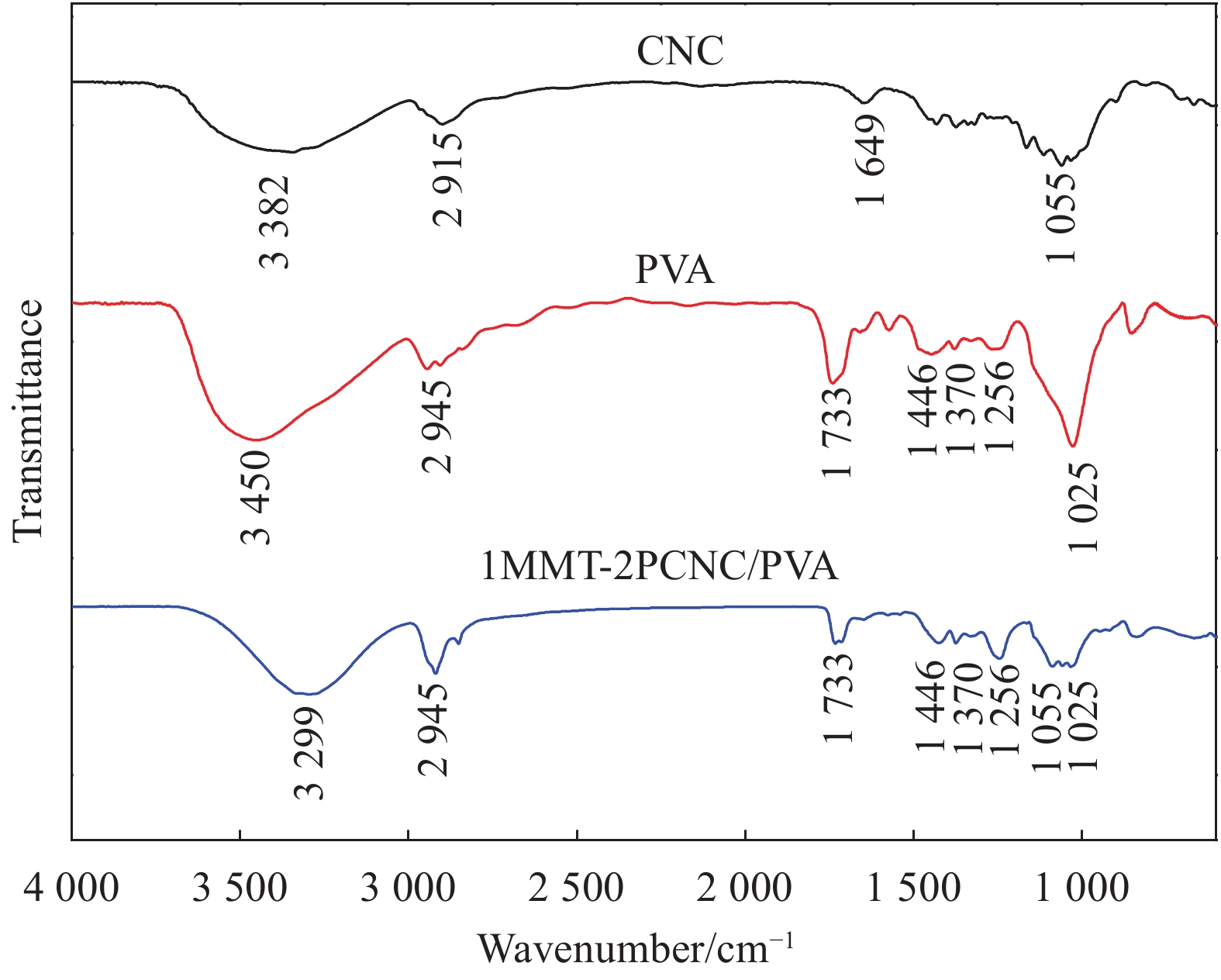

/(MJ·m−3)PVA 28±3 26±3 101±13 3±1 1MMT-1PCNC/PVA 50±4 77±7 97±6 27±6 1MMT-2PCNC/PVA 77±4 63±8 100±3 30±9 1MMT-4PCNC/PVA 42±2 54±9 92±7 13±2 为了证实氢键的存在,对1MMT-2PCNC/PVA复合膜、纯PVA膜以及冷冻干燥的纯CNC进行了红外分析。如图7所示,在3000~3500 cm−1区域内出现的透过峰归属于PVA羟基伸缩振动,对比几个样品—OH的透过峰峰位可以发现,1MMT-2PCNC/PVA复合膜的峰位较纯CNC和PVA向低波数方向移动。过去研究表明[30-33],氢键的形成是导致羟基峰位发生偏移的主要原因。PEI修饰的CNC表面存在大量的氨基,MMT表面也有一定量的羟基,因此组装体1MMT-2PCNC与PVA之间势必会形成氢键,导致羟基峰发生移动。在1025 cm−1、1733 cm−1以及2945 cm−1波数处出现的峰分别归属于PVA的C—OH、C=O以及脂肪质C—H的伸缩振动[34],在1256 cm−1、1370 cm−1以及1446 cm−1处出现的峰分别归属于PVA的C—H、O—H的弯曲振动以及C—H非平面摇摆振动[35-37]。CNC在3382 cm−1、2915 cm−1、1649 cm−1及1055 cm−1处分别出现明显的透过峰,其中3382 cm−1、2915 cm−1归属于CNC的O—H与C—H的伸缩振动,1649 cm−1归属于CNC吡喃糖环的伸缩振动,而1055 cm−1归属于CNC中吸附了水分子的羟基伸缩振动[38]。

为了进一步研究自组装体改善聚合物薄膜力学性能的强韧化机制,人为破坏薄膜表面造成裂纹进行SEM测试。如图8(a)所示,裂纹均非直线传播,而是随着主裂纹的扩展出现了明显的微裂纹偏转(图8(a)中白色折线),说明MMT、PCNC、PVA之间存在强烈的相互作用,与之前分析一致。存在于片层之间的PCNC通过静电以及氢键作用将PVA和MMT相互连接,当应力施加时充当桥连剂,阻止裂纹扩展,随着应力增大,裂纹将沿着纳米纤维发生偏转,直至最终断裂,这一过程将导致裂纹路径增大,消耗更多的能量,实现复合材料的强韧化[26, 39]。

![]() 图 8 1MMT-2PCNC/PVA复合膜断裂形态的SEM图像和断裂示意图:(a) 断裂过程中裂纹扩展的SEM图像(白色折线表示裂纹偏转);(b) 断裂模型示意图Figure 8. SEM image of fracture morphologies of 1MMT-2PCNC/PVA hybrid films and the proposed fracture model: (a) SEM image of crack propagation occurred during fracture (White line indicate crack propagation); (b) Schematic illustration of the fracture model

图 8 1MMT-2PCNC/PVA复合膜断裂形态的SEM图像和断裂示意图:(a) 断裂过程中裂纹扩展的SEM图像(白色折线表示裂纹偏转);(b) 断裂模型示意图Figure 8. SEM image of fracture morphologies of 1MMT-2PCNC/PVA hybrid films and the proposed fracture model: (a) SEM image of crack propagation occurred during fracture (White line indicate crack propagation); (b) Schematic illustration of the fracture model通过观察组装体中MMT与PCNC的不同比例组装体对薄膜力学性能的影响发现,随着组装体中PCNC含量的增加,拉伸强度逐渐减弱,当MMT与PCNC比例为1∶4时,断裂伸长率也明显下降(图6),原因可能是随着PCNC含量的增加,组装体质量加重,更易发生聚沉,且当其分布于聚合物基体中时,不易分散均匀,导致复合膜力学性能下降[40-41]。

3. 结 论

(1) 组装体1MMT(蒙脱土)-1PCNC(纤维素纳米晶)和1MMT-2PCNC对PVA(聚乙烯醇)力学性能增强较为明显,拉伸强度分别增加196%、142%;断裂伸长率增幅分别为79%、175%;韧性增幅分别为800%、900%;复合膜杨氏模量略有下降。

(2) MMT-PCNC/PVA复合膜中存在多种弱相互作用(静电相互作用、氢键),给应力的传递提供了有效的途径,同时引起裂纹偏转,达到消耗能量的目的,使其在拉伸强度提高的同时断裂伸长率也得到提升。本文提出了一种新的合理设计构筑先进复合纳米材料的思路,即用自组装的方法制备组装体,并利用组装体中存在的大量弱相互作用提升聚合物薄膜的力学性质,从而拓展其应用。

-

图 8 1MMT-2PCNC/PVA复合膜断裂形态的SEM图像和断裂示意图:(a) 断裂过程中裂纹扩展的SEM图像(白色折线表示裂纹偏转);(b) 断裂模型示意图

Figure 8. SEM image of fracture morphologies of 1MMT-2PCNC/PVA hybrid films and the proposed fracture model: (a) SEM image of crack propagation occurred during fracture (White line indicate crack propagation); (b) Schematic illustration of the fracture model

表 1 蒙脱土-纤维素纳米晶(MMT-PCNC)组装体的组成

Table 1 Compositions of the montmorillonite-cellulose nanocrystal (MMT-PCNC) assemblies

Sample 1MMT-1PCNC 1MMT-2PCNC 1MMT-4PCNC Composition Mass fraction Mass ratio Mass ratio Mass ratio MMT 0.2% 1 1 1 PCNC 1.0% 1 2 4 表 2 MMT-PCNC/PVA复合膜的力学性能

Table 2 Mechanical properties of the MMT-PCNC/PVA hybrid films

Hybrid films of filler/PVA Elongation-at-break

/%Tensile strength

/MPaYoung’s modulus

/MPaToughness

/(MJ·m−3)PVA 28±3 26±3 101±13 3±1 1MMT-1PCNC/PVA 50±4 77±7 97±6 27±6 1MMT-2PCNC/PVA 77±4 63±8 100±3 30±9 1MMT-4PCNC/PVA 42±2 54±9 92±7 13±2 -

[1] ZHANG G, YU L, HOSTER H E, et al. Synthesis of one-dimensional hierarchical NiO hollow nanostructures with enhanced supercapacitive performance[J]. Nanoscale,2013,5(3):877-881. DOI: 10.1039/C2NR33326K

[2] 张梦辉, 马忠雷, 马建中, 等. 聚合物基电磁屏蔽复合材料的结构设计与性能研究进展[J]. 复合材料学报, 2021, 38(5):1358-1370. ZHANG Menghui, MA Zhonglei, MA Jianzhong, et. al. Research progress of structure design and performance of polymer-based electromagnetic shielding composite materials[J]. Acta Materiae Compositae Sinica,2021,38(5):1358-1370(in Chinese).

[3] SAJI V S, CHOE H C, BRANTLEY W A. An electrochemical study on self-ordered nanoporous and nanotubular oxide on Ti–35Nb–5Ta–7Zr alloy for biomedical applications[J]. Acta Biomaterialia,2009,5(6):2303-2310. DOI: 10.1016/j.actbio.2009.02.017

[4] WEINTRAUB B, ZHOU Z, LI Y, et al. Solution synthesis of one-dimensional ZnO nanomaterials and their applications[J]. Nanoscale,2010,2(9):1573-1587. DOI: 10.1039/c0nr00047g

[5] ZENG M G, XIAO Y, LIU J X, et al. Exploring two-dimensional materials toward the next-generation circuits: From monomer design to assembly control[J]. Chemical Reviews,2018,118(13):6236-6296. DOI: 10.1021/acs.chemrev.7b00633

[6] WU B, GUO Y, HOU C Y, et al. High-performance flexible thermoelectric devices based on all-inorganic hybrid films for harvesting low-grade heat[J]. Advanced Functional Materials,2019,29(25):1900304.1-1900304.11.

[7] RITCHIE R O. The conflicts between strength and toughness[J]. Nature Materials,2011,10(11):817-822. DOI: 10.1038/nmat3115

[8] HING K A. Bone repair in the twenty–first century: Biology, chemistry or engineering?[J]. Philosophical Transactions of the Royal Society of London Series A: Mathematical, Physi-cal and Engineering Sciences,2004,362(1825):2821-2850. DOI: 10.1098/rsta.2004.1466

[9] WEGST U G K, BAI H, SAIZ E, et al. Bioinspired structural materials[J]. Nature Materials,2015,14(1):23-36. DOI: 10.1038/nmat4089

[10] LI S, TUO P, XIE J F, et al. Ultrathin MXene nanosheets with rich fluorine termination groups realizing efficient electrocatalytic hydrogen evolution[J]. Nano Energy,2018,47:512-518. DOI: 10.1016/j.nanoen.2018.03.022

[11] CHEN S M, GAO H L, SUNX H, et al. Superior biomimetic nacreous bulk nanocomposites by a multiscale soft-rigid dual-network interfacial design strategy[J]. Matter,2019,1(2):1-16.

[12] YAO H B, TAN Z H, FANG H Y, et al. Artificial nacre-like bio-nanocomposite films from the self-assembly of chitosan–montmorillonite hybrid building blocks[J]. Angew-andte Chemie International Edition,2011,122(52):10325-10329.

[13] WU Q, YANG X, WAN Q, et al. Layer-by-layer assembled nacre-like polyether amine/GO hierarchical structure on carbon fiber surface toward composites with excellent interfacial strength and toughness[J]. Composites Science and Technology,2020,198:108296. DOI: 10.1016/j.compscitech.2020.108296

[14] SHIN M K, LEE B, KIM S H, et al. Synergistic toughening of composite fibres by self alignment of reduced graphene oxide and carbon nanotubes[J]. Nature Communications,2012,3:650. DOI: 10.1038/ncomms1661

[15] CAO W T, CHEN F F, ZHU Y J, et al. Binary strengthening and toughening of MXene/cellulose nanofiber composite paper with nacre-inspired structure and superior electromagnetic interference shielding properties[J]. ACS Nano,2018,12(5):4583-4593. DOI: 10.1021/acsnano.8b00997

[16] YOO S C, PARK Y K, Park C, et al. Biomimetic artificial nacre: Boron nitride nanosheets/ gelatin nanocomposites for biomedical applications[J]. Advanced Functional Materials,2018,28(51):1805948. DOI: 10.1002/adfm.201805948

[17] WOO Y J, OH J H, JO S H, et al. Nacre-Mimetic graphene oxide/cross-linking agent composite films with superior mechanical properties[J]. ACS nano,2019,13(4):4522-4529. DOI: 10.1021/acsnano.9b00158

[18] ZHU W K, CONG H P, YAO H B, et al. Bioinspired, ultrastrong, highly biocompatible, and bioactive natural polymer/graphene oxide nanocomposite films[J]. Small,2015,11(34):4298-4302. DOI: 10.1002/smll.201500486

[19] CHEN K, ZHANG S, LI A, et al. A bioinspired interfacial chelating-like reinforcement strategy toward mechani-cally enhanced lamellar materials[J]. ACS Nano,2018,12(5):4269-4279. DOI: 10.1021/acsnano.7b08671

[20] MING P, SONG Z F, GONG S S, et al. Nacre-inspired inte-grated nanocomposites with fire retardant properties by graphene oxide and montmorillonite[J]. Journal of Mate-rials Chemistry A,2015,3(42):21194-21200. DOI: 10.1039/C5TA05742F

[21] CHU G, WANG X, YIN H, et al. Free-standing optically switchable chiral plasmonic photonic crystal based on self-assembled cellulose nanorods and gold nanoparticles[J]. ACS Applied Materials & Interfaces,2015,7(39):21797-21806.

[22] XU S, LI J, YE Q, et al. Flame-retardant ethylene vinyl ace-tate composite materials by combining additions of alumi-num hydroxide and melamine cyanurate: Preparation and characteristic evaluations[J]. Journal of Colloid and Interface Science,2021,589:525-531. DOI: 10.1016/j.jcis.2021.01.026

[23] HUANG Z, LIU J, LIU Y, et al. Enhanced permeability and antifouling performance of polyether sulfone (PES) membrane via elevating magnetic Ni@MXene nanoparticles to upper layer in phase inversion process[J]. Journal of Membrane Science,2021,623:119080. DOI: 10.1016/j.memsci.2021.119080

[24] WU M, CHEN Y, LIN H, et al. Membrane fouling caused by biological foams in a submerged membrane bioreactor: Mechanism insights[J]. Water Research,2020,181:115932.

[25] 司联蒙, 陆赵情, 赵永生, 等. 基于真空辅助层层自组装的透明柔性纳米芳纶薄膜的制备[J]. 复合材料学报, 2019, 36(08):1847-1853. SI Lianmeng, LU Zhaoqing, ZHAO Yongsheng, et al. preparation of transparent and flexible nano-aramid film based on vacuum-assisted layer-by-layer self-assembly[J]. Acta Materiae Compositae Sinica,2019,36(08):1847-1853(in Chinese).

[26] ZENG H, WU J, PEI H, et al. Highly thermally conductive yet mechanically robust composites with nacre-mimetic structure prepared by evaporation-induced self-assembly approach[J]. Chemical Engineering Journal,2021,405(3):126865.

[27] ZHU B, WANG Y, LIU H, et al. Effects of interface interaction and microphase dispersion on the mechanical properties of PCL/PLA/MMT nanocomposites visualized by nanomechanical mapping[J]. Composites Science and Technology,2020,190:108048. DOI: 10.1016/j.compscitech.2020.108048

[28] XU D, WANG S, BERGLUND L A, et al. Surface charges control the structure and properties of layered nanocomposite of cellulose nanofibrils and clay platelets[J]. ACS Applied Materials & Interfaces,2021,13(3):4463-4472.

[29] CHEN L, QIANG T, CHEN X, et al. Fabrication and evaluation of biodegradable multi-cross-linked mulch film based on waste gelatin[J]. Chemical Engineering Journal,2021,419(11):129639.

[30] DONG L, XU C, LI Y, et al. Simultaneous production of high-performance flexible textile electrodes and fiber electrodes for wearable energy storage[J]. Advanced Materials,2016,28(8):1675-1681. DOI: 10.1002/adma.201504747

[31] SUKHISHVILI S A, GRANICK S. Layered, eras able polymer multilayers formed by hydrogen-bonded sequential self-assembly[J]. Macromolecules,2002,35(1):301-310. DOI: 10.1021/ma011346c

[32] YUZ R, MAO M, LI S N, et al. Facile and green synthesis of mechanically flexible and flame-retardant clay/graphene oxide nanoribbion interconnected networks for fire safety and prevention[J]. Chemical Engineering Journal,2020,405(6454):126620.

[33] 曾春芽, 单慧媚, 赵超然, 等. 纳米铁-氧化石墨烯/壳聚糖复合材料的制备及其力学性能[J]. 复合材料学报, 2022, 39(4):1739-1747. ZENG Chunya, SHAN Huimei, ZHAO Chaoran, et al. Preparation and mechanical properties of nano-iron-graphene oxide/chitosan composites[J]. Acta Materiae Compositae Sinica,2022,39(4):1739-1747(in Chinese).

[34] COSTA V C, COSTA H S, VASCONCELOS W L, et al. Prepa-ration of hybrid biomaterials for bone tissue engineering[J]. Materials Research,2007,10(1):21-26. DOI: 10.1590/S1516-14392007000100006

[35] HABIBA U, SIDDIQUE T A, TALEBIAN S, et al. Effect of deacetylation on property of electrospun chitosan/PVA nanofibrous membrane and removal of methyl orange, Fe(III) and Cr(VI) ions[J]. Carbohydrate Polymers,2017,177:32-39. DOI: 10.1016/j.carbpol.2017.08.115

[36] JIA Y T, GONG J, GU X H, et al. Fabrication and characteri-zation of poly(vinyl alcohol)/chitosan blend nanofibers produced by electrospinning method[J]. Carbohydrate Polymers,2007,67(3):403-409. DOI: 10.1016/j.carbpol.2006.06.010

[37] KHANNA P K, SINGH N, CHARAN S, et al. Syn thesis and characterization of Ag/PVA nanocomposite by chemical reduction method[J]. Materials Chemistry and Physics,2005,93(1):117-121. DOI: 10.1016/j.matchemphys.2005.02.029

[38] BAI L, BOSSA N, QU F, et al. Comparison of hydrophilicity and mechanical properties of nanocomposite membranes with cellulose nanocrystals and carbon nanotubes[J]. Environmental Science & Technology,2017,51(1):253-262.

[39] YAN Y X, YAO H B, YU S H. Nacre-like ternary hybrid films with enhanced mechanical properties by interlocked nano-fiber design[J]. Advanced Materials Interfaces,2016,3(17):1600296. DOI: 10.1002/admi.201600296

[40] WANG J, JIN X, WU H, et al. Polyimide reinforced with hybrid graphene oxide@carbon nanotube: Toward high strength, toughness, electrical conductivity[J]. Carbon,2017,123:502-513. DOI: 10.1016/j.carbon.2017.07.055

[41] HOU H, GE J J, ZENG J, et al. Electrospun polyacrylonitrile nanofibers containing a high concentration of well-aligned multiwall carbon nanotubes[J]. Chemistry of Materials,2005,17(5):967-973. DOI: 10.1021/cm0484955

-

下载:

下载: