Fatigue performance of fiber reinforced polymer composites under hygrothermal environment–A review

-

摘要: 纤维增强树脂基复合材料在航空航天航海等领域受到广泛应用,湿热环境下长时间循环载荷的作用是复合材料结构设计必须面对的问题,对复合材料结构的强度和刚度有显著的影响。本文首先简要介绍复合材料的水分扩散机理,阐述湿热环境对其力学性能的退化机制。然后着重介绍了湿热环境下纤维增强树脂基复合材料疲劳性能的研究进展,梳理了影响纤维增强树脂基复合材料疲劳性能的湿热因素,总结归纳了存在的主要问题和挑战,为纤维增强树脂基复合材料未来的发展提供了思路。

-

关键词:

- 纤维增强树脂基复合材料 /

- 疲劳性能 /

- 湿热环境 /

- 水分扩散 /

- 性能退化

Abstract: Fiber reinforced polymer composites are widely used in the fields of aeronautics, astronautics and marine technology engineering. Long-term cyclic load in hygrothermal environment is a critical problem for composite structural design and analysis, which has a significant impact on the strength and stiffness of composite structures. In the present review, by introducing moisture absorption model, performance degeneration of composites under hygrothermal environment was described. Following that, the review focused on the fatigue properties of composites under hygrothermal environment. The hygrothermal factors affecting the fatigue performance of fiber reinforced polymer composites were reviewed. The challenges and the existing problems were summarized. The future development of fiber reinforced polymer composites was finally discussed. -

表 1 纤维和树脂的湿热膨胀系数

Table 1. Coefficient of hygrothermall expansion of fiber and resin

Material Thermal expansion coefficient Moisture expansion coefficient α1/℃−1 α2/℃−1 β Fiber CCF300 0.13×10−6[15] 2.7×10−6[15] — T300 −0.54×10−6[16], −0.7×10−6[17] 10.08×10−6[16],12×10−6[17] — HMS −0.99×10−6[16] 6.84×10−6[16] — P75 −1.35×10−6[16] 6.84×10−6[16] — P100 −1.40×10−6[16] 6.84×10−6[16] — T700-12K −0.52×10−6[18] 10.2×10−6[18] — Resin Urea-formaldehyde 2.5×10−5[19] — 2.01×10−3[19] N5208 11×10−5[20], 6×10−5[17] — 0.6[20] Resin matrix 4.39×10−5[19] — 2.68×10−3[19] Epoxy (solid) 11.0×10−5[21] — 2.68×10−3[21] Epoxy (liquid) 8.8×10−5[21] — 0.35[21] Notes: α1 and α2—Longitudinal and transverse thermal expansion coefficients, respectively; β—Moisture expansion coefficient. 表 2 复合材料吸湿模型

Table 2. Moisture absorption model of composites

Model Mathematical model Scope Characteristic Reference Fick model $\dfrac{{{M_{{t}}}}}{{{M_\infty }}} = \left\{ {1 - {\dfrac{8}{{{\text{π}}^2}}}\displaystyle\sum\limits_{j = 0}^\infty {\dfrac{{\exp \left[ { - {{\left( {2j + 1} \right)}^2}{{\text{π}}^2}\left( {\dfrac{{Dt}}{{{h^2}}}} \right)} \right]}}{{{{\left( {2j + 1} \right)}^2}}}} } \right\}$ Polymers; Single-ply composites Diffusivity is constant [25-26] Non-Fick model $\dfrac{{{M_{{t}}}}}{{{M_\infty }}} = \left( {1 + k\sqrt t } \right)\left\{ {1 - \dfrac{8}{{{{\text{π}}^2}}}\displaystyle\sum\limits_{j = 0}^\infty {\dfrac{{\exp \left[ { - {{\left( {2j + 1} \right)}^2}{{\text{π}}^2}\left( {\dfrac{{{D_{\mathrm{x}}}t}}{{{h^2}}}} \right)} \right]}}{{{{\left( {2j + 1} \right)}^2}}}} } \right\}$ Ambient temperature is below the glass transition temperature of the polymer Diffusivity is constant in the intial stage, while it is changes in the later stage [27] Langmuir type model $\dfrac{{{M_{{t}}}}}{{{M_\infty }}} = \left\{ {\dfrac{\beta }{{\gamma + \beta }}{{\rm{e}}^{ - {{\gamma t}}}}\left[ {1 - \dfrac{8}{{{{\text{π}}^2}}}\displaystyle\sum\limits_{l = 1}^{\infty \left( {odd} \right)} {\dfrac{{{{\rm{e}}^{ - {{k}}{{{l}}^{\mathrm{2}}}{{t}}}}}}{{{l^2}}}} } \right] + \dfrac{\beta }{{\gamma + \beta }}\left( {{{\rm{e}}^{ - {{\beta t}}}} - {{\rm{e}}^{ - {{\gamma t}}}}} \right) + \left( {1 - {{\rm{e}}^{ - {{\beta t}}}}} \right)} \right\}$ An initially dry one dimensional specimen Both the spatial distribution of moisture and total moisture uptake is a function of time. [28] Three-dimensional hindered diffusion model ${M^*} = 1 - \dfrac{{512\mu }}{{{{\text{π}}^6}}}\displaystyle\sum\limits_{P = 0}^\infty {\displaystyle\sum\limits_{Q = 0}^\infty {\displaystyle\sum\limits_{R = 0}^\infty {\dfrac{1}{{{{\left( {2P + 1} \right)}^2}{{\left( {2Q + 1} \right)}^2}{{\left( {2R + 1} \right)}^2}}}{{\rm{e}}^{ - {{\alpha t}}*}} - \left( {1 - \mu } \right){{\rm{e}}^{ - {{t}}*}}} } } $ Polymeric composites Physical or molecular interactions at the microscale lead to hindered diffusion [29] Thickness-dependent non-Fickian model $\dfrac{{{M_{{t}}}}}{{{M_\infty }}} = \phi \left\{ {1 - \exp \left[ { - 7.3{{\left( {\dfrac{{{D_{\mathrm{z}}}t}}{{{h^2}}}} \right)}^{0.75}}} \right]} \right\} + \left( {1 - \phi } \right)\left[ {1 - \left\{ {\exp \left[ {1 - {{\left( {\alpha \left\langle {t - {t_0}} \right\rangle } \right)}^{0.75}}} \right]} \right\}} \right]$ Multi-ply composites Coefficient of the time delay term, α, decrease with thickness [30] Time-varying diffusion coefficient model $\dfrac{{{M_{{t}}} - {M_{\mathrm{i}}}}}{{{M_\infty } - {M_{\mathrm{i}}}}} = 1 - \dfrac{8}{{{{\text{π}}^2}}}\displaystyle\sum\limits_{n = 0}^\infty {\dfrac{1}{{\left( {2n + 1} \right)}}} \exp \left\{ {\dfrac{{ - {{\left( {2n + 1} \right)}^2}{{\text{π}}^2}}}{{{h^2}}} \times \left\{ {{D_0}t + \displaystyle\sum\limits_{r = 1}^R {{D_{{r}}}\left[ {t + {\tau _{{r}}}\left( {{{\rm{e}}^{ - {{t/}}{{\mathrm{\tau }}_{{r}}}}} - 1} \right)} \right]} } \right\}} \right\}$ Polymer Diffusivity and boundary concentration vary continuously with time [31] Dual-diffusivity model $\dfrac{{{M_{{t}}}}}{{{M_\infty }}} = {V_{\mathrm{d}}}\left\{ {1 - \exp \left[ { - 7.3{{\left( {\dfrac{{{D_{\mathrm{d}}}t}}{{{h^2}}}} \right)}^{0.75}}} \right]} \right\} + \left( {{\mathrm{1 - }}{V_{\mathrm{d}}}} \right)\left\{ {{\mathrm{1 - }}\exp \left[ { - 7.3{{\left( {\dfrac{{{D_{\mathrm{l}}}t}}{{{h^2}}}} \right)}^{0.75}}} \right]} \right\}$ Two-phase structure Diffusion process is controlled only by the density of that phase [32] Modified dual-diffusivity model $\dfrac{{{M_{{t}}}}}{{{M_\infty }}} = {M_1}\left\{ {1 - \exp \left[ { - 7.3{{\left( {\dfrac{{{D_1}t}}{{{h^2}}}} \right)}^{0.75}}} \right]} \right\} + {M_2}\left\{ {{\mathrm{1 - }}\exp \left[ { - 7.3{{\left( {\dfrac{{{D_2}t}}{{{h^2}}}} \right)}^{0.75}}} \right]} \right\}$ Two-phase structure Density and hydrophilic character of both phases is different [33] Notes: Mt—Moisture content at the time t; M∞—Saturated moisture content; Mi—Initial moisture content; D—Diffusivity; Dx—Diffusivity in the x direction; t—Time of moisture absorption; h—Thickness of laminates; μ—Dimensionless hindrance coefficient; t*—Dimensionless parameter; φ—Fickian to non-Fickian maximum moisture content ratio; Dz—Moisture diffusivity that exhibits Fickian diffusion behavior; t0—Time of the initiation of non-Fickian moisture diffusion; D0—Unknown temperature-dependent Prony coefficients; τr—Corresponding retardation times; n—Number of terms in the Prony series; Dr, Dd—Diffusion coefficients of the less-dense and the dense phase, respectively; Vd—Volume fraction of the dense phase; M1, M2— Moisture content of the dense matrix and the less dense matrix, respectively; D1, D2—Diffusivity of the dense matrix and the less dense matrix, respectively; j, k, α, β, γ, l, P, Q, R—Parameter. -

[1] ALAM P, MAMALIS D, ROBERT C. The fatigue of carbon fibre reinforced plastics-A review[J]. Composites Part B: Engineering,2019,166:555-579. doi: 10.1016/j.compositesb.2019.02.016 [2] 杜善义, 关志东. 我国大型客机先进复合材料技术应对策略思考[J]. 复合材料学报, 2008, 25(1):1-10. doi: 10.3321/j.issn:1000-3851.2008.01.001DU Shanyi, GUAN Zhidong. Strategic considerations for development of advanced composite technology for large commercial aircraft in China[J]. Acta Materiae Compositae Sinaca,2008,25(1):1-10(in Chinese). doi: 10.3321/j.issn:1000-3851.2008.01.001 [3] 王雪明, 谢富原. 碳纤维/双马树脂复合材料整体成型过程分层扩展行为实验研究[J]. 航空学报, 2021, 42(2):410-418.WANG Xueming, XIE Fuyuan. Experimental study on behavior of delamination propagation of carbon fiber/bismaleimide composites during integral forming process[J]. Acta Aeronautica et Astronautica Sinica,2021,42(2):410-418(in Chinese). [4] 牛一凡, 李璋琪, 朱晓峰. 全湿热场下碳纤维/环氧树脂复合材料弯曲性能及寿命预测[J]. 复合材料学报, 2020, 37(1):104-112.NIU Yifan, LI Zhangqi, ZHU Xiaofeng. Flexural properties and life-time estimation of carbon fiber/epoxy composite under hygrothermal conditions[J]. Acta Materiae Compositae Sinaca,2020,37(1):104-112(in Chinese). [5] VENKATESHA B K, SARAVANAN R, ANAND B K. Effect of moisture absorption on woven bamboo/glass fiber reinforced epoxy hybrid composites[J]. Materials Today: Proceedings,2021,45:216-221. doi: 10.1016/j.matpr.2020.10.421 [6] BACHCHAN A A, DAS P P, CHAUDHARY V. Effect of moisture absorption on the properties of natural fiber reinforced polymer composites: A review[J]. Materials Today: Proceedings,2021, 49 (8) : 3403 - 3408. [7] LI Y, MIRANDA J, SUE H J. Hygrothermal diffusion behavior in bismaleimide resin[J]. Polymer,2001,42(18):7791-7799. doi: 10.1016/S0032-3861(01)00241-5 [8] KHAN L A, NESBITT A, DAY R J. Hygrothermal degradation of 977-2A carbon/epoxy composite laminates cured in autoclave and quickstep[J]. Composites Part A: Applied Science and Manufacturing,2010,41(8):942-953. doi: 10.1016/j.compositesa.2010.03.003 [9] PARKER M J. 5.09 - Test methods for physical properties [M]//KELLY A, ZWEBEN C. Comprehensive Composite Materials. Pergamon: Oxford Press, 2000: 183-226. [10] FAN W, LI J, ZHENG Y, et al. Influence of thermo-oxidative aging on the thermal conductivity of carbon fiber fabric reinforced epoxy composites[J]. Polymer Degradation and Stability,2016,123:162-169. doi: 10.1016/j.polymdegradstab.2015.11.016 [11] 樊威, 李嘉禄. 热氧老化对碳纤维织物增强聚合物基复合材料弯曲性能的影响[J]. 复合材料学报, 2015, 32(5):1260-1270.FAN Wei, LI Jialu. Effects of thermo-oxidative aging on flexural properties of carbon fiber reinforced polymer matrix composites[J]. Acta Materiae Compositae Sinaca,2015,32(5):1260-1270(in Chinese). [12] GUO F, HUANG P, LI Y, et al. Multiscale modeling of mechanical behaviors of carbon fiber reinforced epoxy composites subjected to hygrothermal aging[J]. Composite Structures,2021,256:113098. doi: 10.1016/j.compstruct.2020.113098 [13] GUO F, YAN Y, HONG Y, et al. Prediction and optimization design for thermal expansion coefficients of three-dimensional n-directional-braided composites[J]. Polymer Composites,2019,40(6):2495-2509. doi: 10.1002/pc.25132 [14] RAY B C. Temperature effect during humid ageing on interfaces of glass and carbon fibers reinforced epoxy composites[J]. Journal of Colloid and Interface Science,2006,298(1):111-117. doi: 10.1016/j.jcis.2005.12.023 [15] 李乐坤, 李曙林, 常飞, 等. 碳纤维增强树脂基复合材料的热膨胀行为[J]. 机械工程材料, 2016, 40(7):97-101.LI Lekun, LI Shulin, CHANG Fei, et al. Thermal expansion behavior of carbon fiber reinforced resin composite[J]. Materials for Mechanical Engineering,2016,40(7):97-101(in Chinese). [16] KARADENIZ Z H, KUMLUTAS D. A numerical study on the coefficients of thermal expansion of fiber reinforced composite materials[J]. Composite Structures,2007,78(1):1-10. doi: 10.1016/j.compstruct.2005.11.034 [17] YOUSSEF Z, JACQUEMIN F, GLOAGUEN D, et al. A multi-scale analysis of composite structures: Application to the design of accelerated hygrothermal cycles[J]. Composite Structures,2008,82(2):302-309. doi: 10.1016/j.compstruct.2007.01.008 [18] DONG K, PENG X, ZHANG J, et al. Temperature-dependent thermal expansion behaviors of carbon fiber/epoxy plain woven composites: Experimental and numerical studies[J]. Composite Structures,2017,176:329-341. doi: 10.1016/j.compstruct.2017.05.036 [19] HE Q, DAI H, DENG Q, et al. Buckling analysis of axially compressed CFRR cylindrical shell with damaged porous microcapsule coating in hygrothermal environments[J]. Engineering Structures,2021,236:112116. doi: 10.1016/j.engstruct.2021.112116 [20] ACQUEMIN F, VAUTRIN A. A closed-form solution for the internal stresses in thick composite cylinders induced by cyclical environmental conditions[J]. Composite Structures,2002,58(1):1-9. doi: 10.1016/S0263-8223(02)00051-X [21] HE Q, DAI H, CHENG C, et al. Investigation on dynamic hygro-thermo-elastic response of cylindrical shells with a porous microcapsule coating[J]. Composite Structures,2020,243:112146. doi: 10.1016/j.compstruct.2020.112146 [22] MEHRER H. Diffusion in solids [M]. 1th ed. Heidelberg: Springer, 2007. [23] SUGIMAN S, GOZALI M H, SETYAWAN P D. Hygrothermal effects of glass fiber reinforced unsaturated polyester resin composites aged in steady and fluctuating conditions[J]. Advanced Composite Materials,2019,28(1):87-102. doi: 10.1080/09243046.2017.1405597 [24] SUN P, ZHAO Y, LUO Y, et al. Effect of temperature and cyclic hygrothermal aging on the interlaminar shear strength of carbon fiber/bismaleimide (BMI) composite[J]. Materials & Design,2011,32(8):4341-4347. [25] SANG L, WANG Y, WANG C, et al. Moisture diffusion and damage characteristics of carbon fabric reinforced polyamide 6 laminates under hydrothermal aging[J]. Composites Part A: Applied Science and Manufacturing,2019,123:242-252. doi: 10.1016/j.compositesa.2019.05.023 [26] FICK A. Ueber diffusion[J]. Annalen der Physik,1855,170(1):59-86. doi: 10.1002/andp.18551700105 [27] BAO L, YEE A F, LEE C Y C. Moisture absorption and hygrothermal aging in a bismaleimide resin[J]. Polymer,2001,42(17):7327-7333. doi: 10.1016/S0032-3861(01)00238-5 [28] CARTER H G, KIBLER K G. Langmuir-type model for anomalous moisture diffusion in composite resins[J]. Journal of Composite Materials,1978,12(2):118-131. doi: 10.1177/002199837801200201 [29] GRACE L R, ALTAN M C. Characterization of anisotropic moisture absorption in polymeric composites using hindered diffusion model[J]. Composites Part A: Applied Science and Manufacturing,2012,43(8):1187-1196. doi: 10.1016/j.compositesa.2012.03.016 [30] WONG K J. Moisture absorption characteristics and effects on mechanical behaviour of carbon/epoxy composite: Application to bonded patch repairs of composite structures[D]: Bourgogne: University de Bourgogne, 2013. [31] ROY S, XU W X, PARK S J, et al. Anomalous moisture diffusion in viscoelastic polymers: Modeling and testing[J]. Journal of Applied Mechanics,2000,67(2):391-396. doi: 10.1115/1.1304912 [32] MAGGANA C, PISSIS P. Water sorption and diffusion studies in an epoxy resin system[J]. Journal of Polymer Science Part B: Polymer Physics,1999,37:1165-1182. doi: 10.1002/(SICI)1099-0488(19990601)37:11<1165::AID-POLB11>3.0.CO;2-E [33] JACOBS P M, JONES E R. Diffusion of moisture into two-phase polymers[J]. Journal of Materials Science,1989,24(7):2343-2347. doi: 10.1007/BF01174494 [34] LI D, DANG M, JIANG L. Elevated temperature effect on tension fatigue behavior and failure mechanism of carbon/epoxy 3D angle-interlock woven composites[J]. Composite Structures,2021,268:113897. doi: 10.1016/j.compstruct.2021.113897 [35] SÁPI Z, BUTLER R. Properties of cryogenic and low temperature composite materials-A review[J]. Cryogenics,2020,111:103190. doi: 10.1016/j.cryogenics.2020.103190 [36] KAWAI M, YAJIMA S, HACHINOHE A, et al. High-temperature off-axis fatigue behaviour of unidirectional carbon-fibre-reinforced composites with different resin matrices[J]. Composites Science and Technology,2001,61(9):1285-1302. doi: 10.1016/S0266-3538(01)00027-6 [37] GREGORY J R, SPEARING S M. Constituent and composite quasi-static and fatigue fracture experiments[J]. Composites Part A: Applied Science and Manufacturing,2005,36(5):665-674. doi: 10.1016/j.compositesa.2004.07.007 [38] SJÖGREN A, ASP L E. Effects of temperature on delamination growth in a carbon/epoxy composite under fatigue loading[J]. International Journal of Fatigue,2002,24(2):179-184. [39] KAWAI M, TAKEUCHI H, TAKETA I, et al. Effects of temperature and stress ratio on fatigue life of injection molded short carbon fiber-reinforced polyamide composite[J]. Composites Part A: Applied Science and Manufacturing,2017,98:9-24. doi: 10.1016/j.compositesa.2017.03.008 [40] SONG J, WEN W, CUI H, et al. Weft direction tension-tension fatigue responses of layer-to-layer 3D angle-interlock woven composites at room and elevated temperatures[J]. International Journal of Fatigue,2020,139:105770. doi: 10.1016/j.ijfatigue.2020.105770 [41] JIA N , KAGAN V A. Effects of time and temperature on the tension-tension fatigue behavior of short fiber reinforced polyamides[J]. Polymer Composites,1998,19(4):408-414. doi: 10.1002/pc.10114 [42] YANG L, LI Z, XU H, et al. Prediction on residual stresses of carbon/epoxy composite at cryogenic temperature[J]. Polymer Composites,2019,40:3412-3420. doi: 10.1002/pc.25202 [43] LI D, ZHAO C, GE T, et al. Experimental investigation on the compression properties and failure mechanism of 3D braided composites at room and liquid nitrogen temperature[J]. Composites Part B: Engineering,2014,56:647-659. doi: 10.1016/j.compositesb.2013.08.068 [44] ISLAM M S, E. MELENDEZSOTO E, CASTELLANOS A G, et al. Investigation of woven composites as potential cryogenic tank materials[J]. Cryogenics,2015,72:82-89. doi: 10.1016/j.cryogenics.2015.09.005 [45] MENG J, WANG Y, YANG H, et al. Mechanical properties and internal microdefects evolution of carbon fiber reinforced polymer composites: Cryogenic temperature and thermocycling effects[J]. Composites Science and Technology,2020,191:108083. doi: 10.1016/j.compscitech.2020.108083 [46] SADEGHIAN R, GANGIREDDY S, MINAIE B, et al. Manufacturing carbon nanofibers toughened polyester/glass fiber composites using vacuum assisted resin transfer molding for enhancing the mode-I delamination resistance[J]. Composites Part A: Applied Science and Manufacturing,2006,37(10):1787-1795. doi: 10.1016/j.compositesa.2005.09.010 [47] CORONADO P, ARGüELLES A, VIÑA J, et al. Influence of temperature on a carbon-fibre epoxy composite subjected to static and fatigue loading under mode-I delamination[J]. International Journal of Solids and Structures,2012,49(21):2934-2940. doi: 10.1016/j.ijsolstr.2012.05.018 [48] SAHA S, SULLIVAN R W, BAKER M L. Gas permeability of three-dimensional stitched carbon/epoxy composites for cryogenic applications[J]. Composites Part B: Engineering,2021,216:108847. doi: 10.1016/j.compositesb.2021.108847 [49] ZHANG M, LI K, SHI X, et al. Influence of cryogenic thermal cycling treatment on the thermophysical properties of carbon/carbon composites between room temperature and 1900°C[J]. Journal of Materials Science and Technology,2018,34(2):409-415. doi: 10.1016/j.jmst.2017.03.001 [50] FLANAGAN M, GROGAN D M, GOGGINS J, et al. Permeability of carbon fibre PEEK composites for cryogenic storage tanks of future space launchers[J]. Composites Part A: Applied Science and Manufacturing,2017,101:173-184. doi: 10.1016/j.compositesa.2017.06.013 [51] SHIN K B, KIM C G, HONG C S, et al. Prediction of failure thermal cycles in graphite/epoxy composite materials under simulated low earth orbit environments[J]. Compo-sites Part B: Engineering,2000,31(3):223-235. doi: 10.1016/S1359-8368(99)00073-6 [52] GEORGE P E, DURSCH H W. Low earth orbit effects on organic composites flown on the long duration exposure facility[J]. Journal of Advanced Materials,1994,25(3):10-19. [53] GROGAN D M, LEEN S B, SEMPRIMOSCHNIG C O A, et al. Damage characterisation of cryogenically cycled carbon fibre/PEEK laminates[J]. Composites Part A: Applied Science and Manufacturing,2014,66:237-250. doi: 10.1016/j.compositesa.2014.08.007 [54] HENAFF-GARDINC , LAFARIE-FRENOT M C, GAMBY D. Doubly periodic matrix cracking in composite laminates Part 2: Thermal biaxial loading[J]. Composite Structures,1996,36(1):131-140. [55] KUMAZAWA H, AOKI T, SUSUKI I. Influence of stacking sequence on leakage characteristics through CFRP composite laminates[J]. Composites Science and Technology,2006,66(13):2107-2115. doi: 10.1016/j.compscitech.2005.12.017 [56] BECHEL V T, KIM R Y. Damage trends in cryogenically cycled carbon/polymer composites[J]. Composites Science and Technology,2004,64(12):1773-1784. doi: 10.1016/j.compscitech.2003.12.007 [57] XU J, SANKAR B V. Prediction of stitch crack evolution and gas permeability in multidirectional composite laminates[J]. Composites Part A: Applied Science and Manufacturing,2008,39(10):1625-1631. doi: 10.1016/j.compositesa.2008.07.003 [58] ROY S, BENJAMIN M. Modeling of permeation and damage in graphite/epoxy laminates for cryogenic fuel storage[J]. Composites Science and Technology,2004,64(13):2051-2065. [59] LAUNAY A, MARCO Y, MAITOURNAM M H, et al. Modelling the influence of temperature and relative humidity on the time-dependent mechanical behaviour of a short glass fibre reinforced polyamide[J]. Mechanics of Materials,2013,56:1-10. doi: 10.1016/j.mechmat.2012.08.008 [60] BENAARBIA A, CHRYSOCHOOS A, ROBERT G. Influence of relative humidity and loading frequency on the PA6.6 cyclic thermomechanical behavior: Part I. Mechanical and thermal aspects[J]. Polymer Testing,2014,40:290-298. doi: 10.1016/j.polymertesting.2014.09.019 [61] JIA N, KAGAN V A. Mechanical performance of polyamides with influence of moisture and temperature-accurate evaluation and better understanding [M]//MOALLI J. Plastics failure analysis and prevention. Norwich: William Andrew Publishing, 2001: 95-104. [62] MALPOT A, TOUCHARD F, BERGAMO S. An investigation of the influence of moisture on fatigue damage mechanisms in a woven glass-fibre-reinforced PA66 composite using acoustic emission and infrared thermography[J]. Composites Part B: Engineering,2017,130:11-20. doi: 10.1016/j.compositesb.2017.07.017 [63] PATEL S R, CASE S W. Durability of a graphite/epoxy woven composite under combined hygrothermal conditions[J]. International Journal of Fatigue,2000,22(9):809-820. doi: 10.1016/S0142-1123(00)00041-4 [64] ČERNÝ I, MAYER R M. Evaluation of static and fatigue strength of long fiber GRP composite material considering moisture effects[J]. Composite Structures,2010,92(9):2035-2038. doi: 10.1016/j.compstruct.2009.11.024 [65] MENG M, LE H, GROVE S, et al. Moisture effects on the bending fatigue of laminated composites[J]. Composite Structures,2016,154:49-60. doi: 10.1016/j.compstruct.2016.06.078 [66] BERNASCONI A, KULIN R M. Effect of frequency upon fatigue strength of a short glass fiber reinforced polyamide 6: A superposition method based on cyclic creep parameters[J]. Polymer Composites,2009,30(2):154-161. doi: 10.1002/pc.20543 [67] FARUK O, BLEDZKI A K, FINK H P, et al. Biocomposites reinforced with natural fibers: 2000–2010[J]. Progress in Polymer Science,2012,37(11):1552-1596. doi: 10.1016/j.progpolymsci.2012.04.003 [68] BARBIÈRE R, TOUCHARD F, CHOCINSKI-ARNAULT L, et al. Influence of moisture and drying on fatigue damage mechanisms in a woven hemp/epoxy composite: Acoustic emission and micro-CT analysis[J]. International Journal of Fatigue,2020,136:105593. doi: 10.1016/j.ijfatigue.2020.105593 [69] FOTOUH A, WOLODKO J. Fatigue behavior of natural fiber reinforced thermoplastic composites in dry and wet environments[C]. Proceedings of the ASME 2011 International Mechanical Engineering Congress and Exposition, Colorado, 2011. [70] MA B, FENG Y, HE Y, et al. Effect of hygrothermal environment on the tension-tension fatigue performance and reliable fatigue life of T700/MTM46 composite laminates[J]. Journal of Zhejiang University-Science A,2019,20(7):499-514. doi: 10.1631/jzus.A1900081 [71] GAO Y, LI C, WANG J, et al. Investigation on fatigue behavior and damage mechanism of C/BMI composites under hygrothermal environment[J]. Polymer Degradation and Stability,2019,169:108989. doi: 10.1016/j.polymdegradstab.2019.108989 [72] YAO W X, HIMMEL N. A new cumulative fatigue damage model for fibre-reinforced plastics[J]. Composites Science and Technology,2000,60(1):59-64. doi: 10.1016/S0266-3538(99)00100-1 [73] KO M G, KWEON J H, CHOI J H. Fatigue characteristics of jagged pin-reinforced composite single-lap joints in hygrothermal environments[J]. Composite Structures,2015,119:59-66. doi: 10.1016/j.compstruct.2014.08.025 [74] ATTUKUR NANDAGOPAL R, GIN BOAY C, NARASIMALU S. An empirical model to predict the strength degradation of the hygrothermal aged CFRP material[J]. Composite Structures,2020,236:111876. doi: 10.1016/j.compstruct.2020.111876 [75] GHOLAMI M, AFRASIAB H, BAGHESTANI A M, et al. Hygrothermal degradation of elastic properties of fiber reinforced composites: A micro-scale finite element analysis[J]. Composite Structures,2021,266:113819. doi: 10.1016/j.compstruct.2021.113819 [76] SHAN M, ZHAO L, HONG H, et al. A progressive fatigue damage model for composite structures in hygrothermal environments[J]. International Journal of Fatigue,2018,111:299-307. doi: 10.1016/j.ijfatigue.2018.02.019 [77] TSAI S W. Composites design [M]. 4th ed. Dayton: Think Composites, 1988. [78] ZHAO L, SHAN M, HONG H, et al. A residual strain model for progressive fatigue damage analysis of composite structures[J]. Composite Structures,2017,169:69-78. doi: 10.1016/j.compstruct.2016.10.119 [79] JEDIDIJ , JACQUEMIN F, VAUTRIN A. Design of accelerated hygrothermal cycles on polymer matrix composites in the case of a supersonic aircraft[J]. Composite Structures,2005,68(4):429-437. doi: 10.1016/j.compstruct.2004.04.009 [80] 李野, 陈业标, 盛国柱, 等. 飞机复合材料结构的湿热老化效应[C]. 合肥: 第十一届全国复合材料学术会议, 2000.LI Ye, CHEN Yebiao, SHENG Guozhu, et al. Hygrothermal aging effects for aircraft composite structures[C]. Hefei: National Conference on Composite Materials, 2000(in Chinese). [81] GUO F, AL-SAADI S, SINGH RAMAN R K, et al. Durability of fiber reinforced polymer (FRP) in simulated seawater sea sand concrete (SWSSC) environment[J]. Corrosion Science,2018,141:1-13. doi: 10.1016/j.corsci.2018.06.022 [82] 王登霞, 孙岩, 谢可勇, 等. 碳纤维增强树脂基复合材料模拟海洋环境长期老化及失效行为[J]. 复合材料学报, 2022, 39(3):1369-1378.WANG Dengxia, SUN Yan, XIE Keyong, et al. Long term aging and failure behaviors of carbon fiber reinforced polymer composites in simulated marine environments[J]. Acta Materiae Compositae Sinaca,2022,39(3):1369-1378(in Chinese). [83] HOFER K E, SKAPER G N, BENNETT L C, et al. Effect of moisture on fatigue and residual strength losses for various composites[J]. Journal of Reinforced Plastics and Composites,1987,6(1):53-65. doi: 10.1177/073168448700600105 [84] GHABEZI P, HARRISON N. Mechanical behavior and long-term life prediction of carbon/epoxy and glass/epoxy composite laminates under artificial seawater environment[J]. Materials Letters,2020,261:127091. doi: 10.1016/j.matlet.2019.127091 [85] KIM D, MITTAL G, KIM M, et al. Surface modification of MMT and its effect on fatigue and fracture behavior of basalt/epoxy based composites in a seawater environment[J]. Applied Surface Science,2019,473:55-58. doi: 10.1016/j.apsusc.2018.12.127 [86] TSUDA K. Behavior and mechanisms of degradation of thermosetting plastics in liquid environments[J]. Journal of The Japan Petroleum Institute,2007,50(5):240-248. doi: 10.1627/jpi.50.240 [87] SHARMA B, CHHIBBER R, MEHTA R. Seawater ageing of glass fiber reinforced epoxy nanocomposites based on silylated clays[J]. Polymer Degradation and Stability,2018,147:103-114. doi: 10.1016/j.polymdegradstab.2017.11.017 [88] CAPIEL G, MICCIO L A, MONTEMARTINI P E, et al. Water diffusion and hydrolysis effect on the structure and dynamics of epoxy-anhydride networks[J]. Polymer Degradation and Stability,2017,143:57-63. doi: 10.1016/j.polymdegradstab.2017.06.010 [89] HU Y, LI X, LANG A W W, et al. Water immersion aging of polydicyclopentadiene resin and glass fiber composites[J]. Polymer Degradation and Stability,2016,124:35-42. doi: 10.1016/j.polymdegradstab.2015.12.008 [90] KOTSIKOS G, EVANS J T, GIBSON A G, et al. Environmentally enhanced fatigue damage in glass fibre reinforced composites characterised by acoustic emission[J]. Composites Part A: Applied Science and Manufacturing,2000,31(9):969-977. doi: 10.1016/S1359-835X(00)00014-2 [91] KOSHIMA S, YONEDA S, KAJII N, et al. Evaluation of strength degradation behavior and fatigue life prediction of plain-woven carbon-fiber-reinforced plastic laminates immersed in seawater[J]. Composites Part A: Applied Science and Manufacturing,2019,127:105645. doi: 10.1016/j.compositesa.2019.105645 [92] DENIZ M E, OZEN M, OZDEMIR O, et al. Environmental effect on fatigue life of glass-epoxy composite pipes subjected to impact loading[J]. Composites Part B: Engineering,2013,44(1):304-312. doi: 10.1016/j.compositesb.2012.05.001 [93] PRABHAKAR P, GARCIA R, IMAM M A, et al. Flexural fatigue life of woven carbon/vinyl ester composites under sea water saturation[J]. International Journal of Fatigue,2020,137:105641. doi: 10.1016/j.ijfatigue.2020.105641 [94] HU Y, LANG A W, LI X, et al. Hygrothermal aging effects on fatigue of glass fiber/polydicyclopentadiene composites[J]. Polymer Degradation and Stability,2014,110:464-472. doi: 10.1016/j.polymdegradstab.2014.10.018 [95] ZHAO Y, LIU W, SEAH L K, et al. Delamination growth behavior of a woven E-glass/bismaleimide composite in seawater environment[J]. Composites Part B: Engineering,2016,106:332-343. doi: 10.1016/j.compositesb.2016.09.045 [96] POODTS E, MINAK G, ZUCCHELLI A. Impact of sea-water on the quasi static and fatigue flexural properties of GFRP[J]. Composite Structures,2013,97:222-230. doi: 10.1016/j.compstruct.2012.10.021 -

下载:

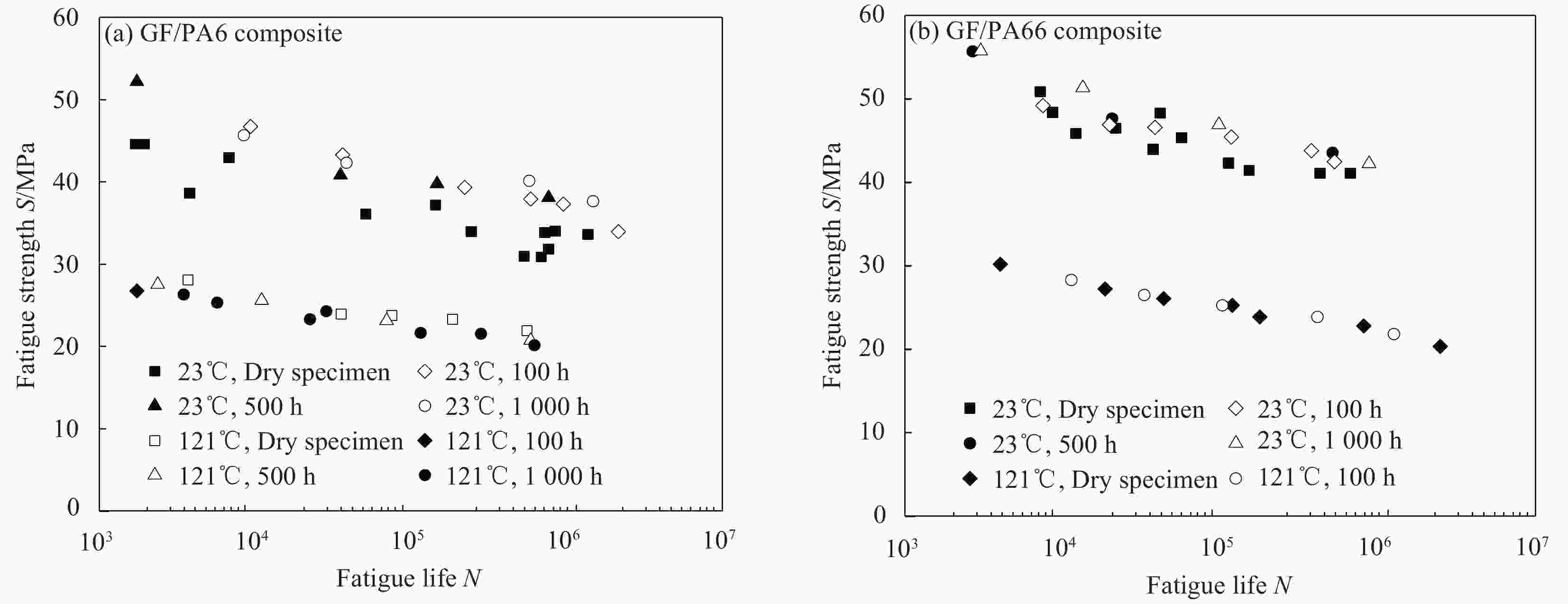

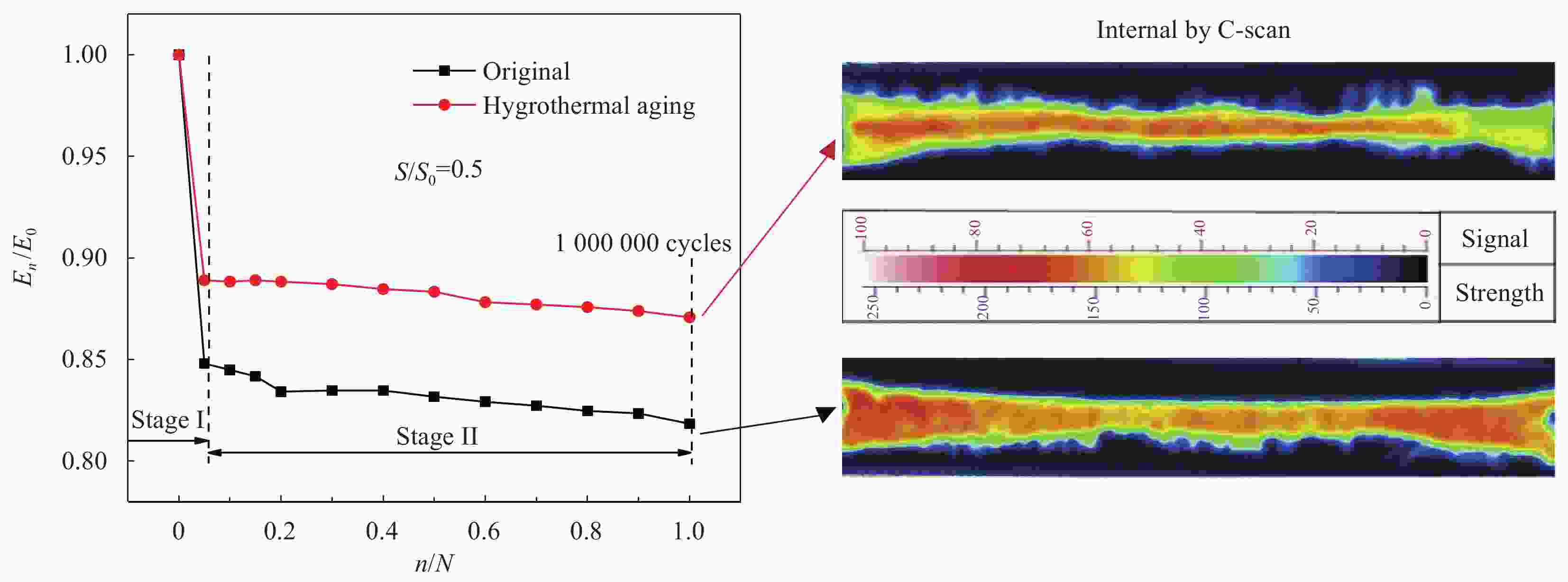

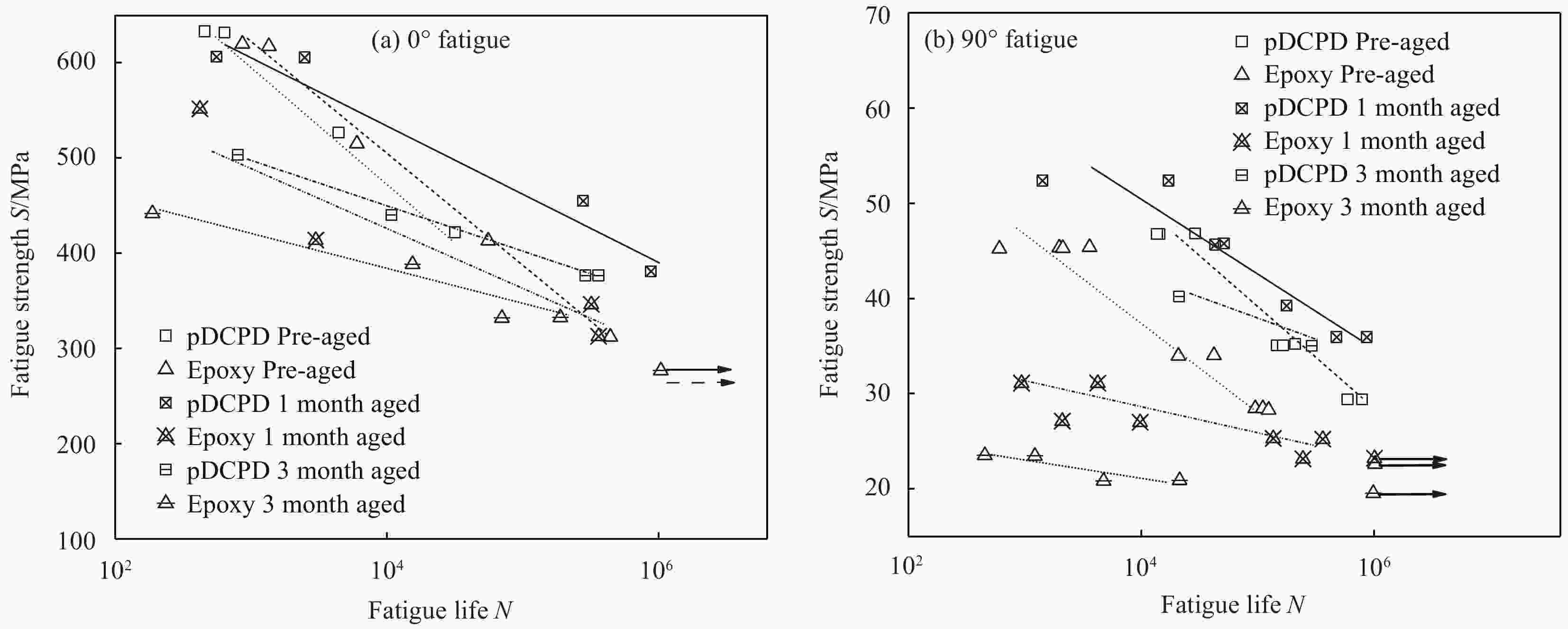

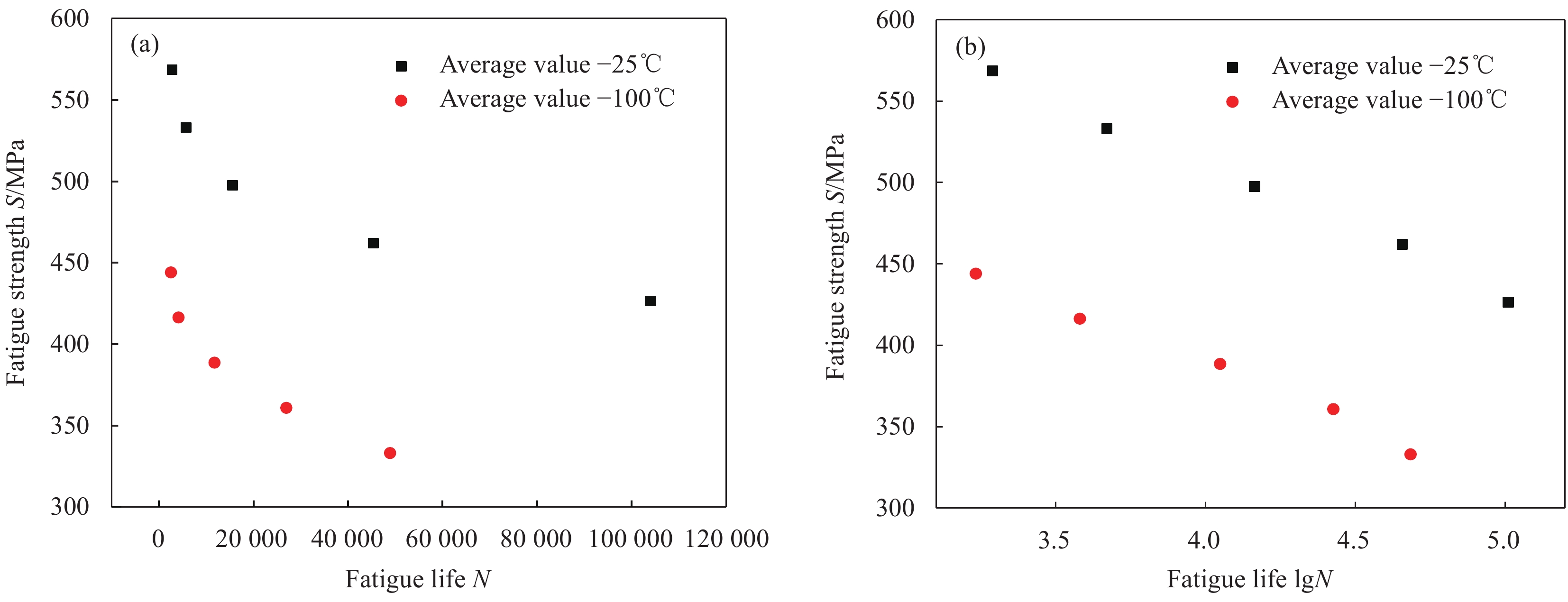

下载: