Research status and development trend of carbon fiber reinforced polymer hydraulic cylinder

-

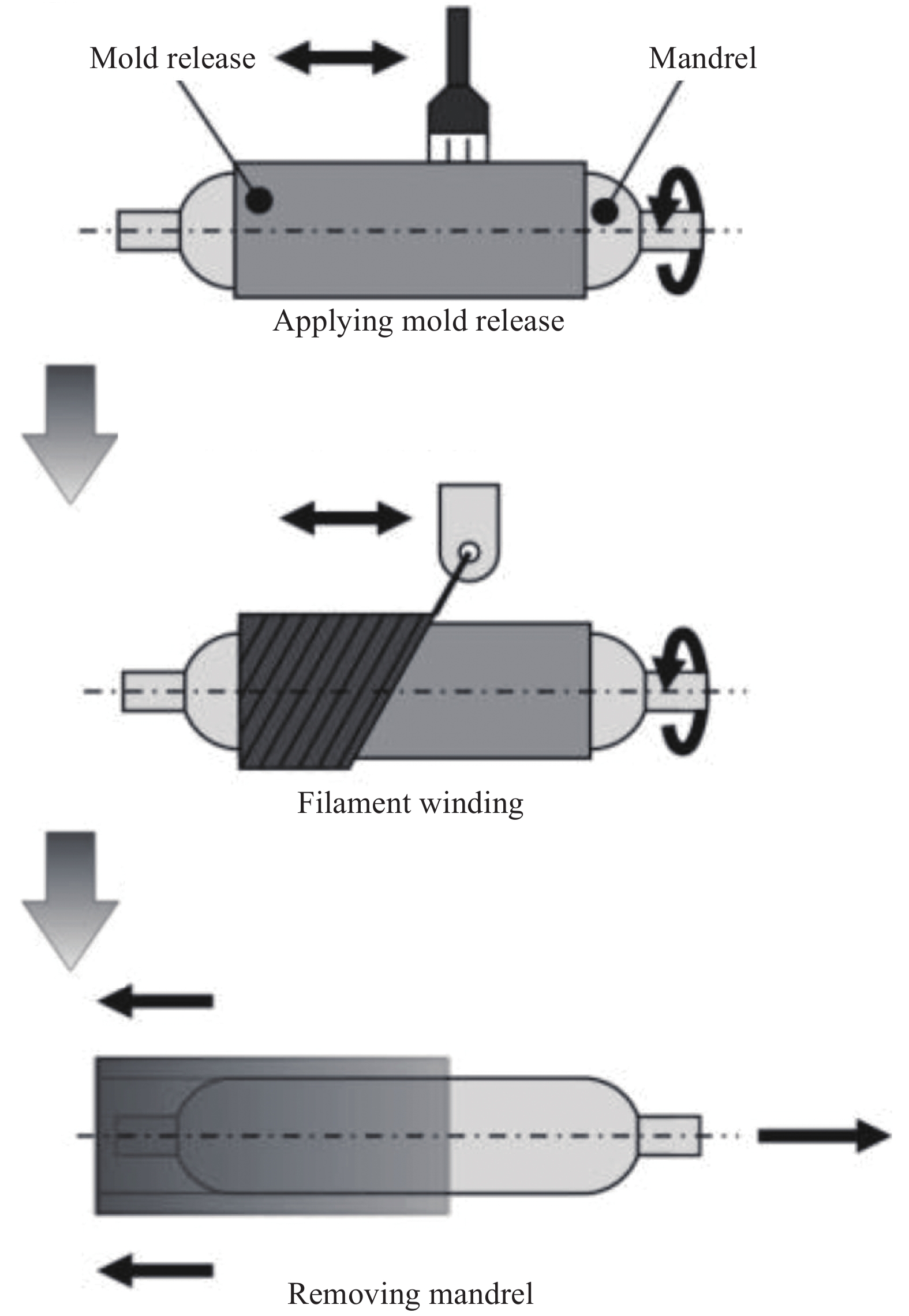

摘要: 碳纤维增强复合材料(CFRP)具有抗热冲击、抗拉强度高、耐腐蚀等优点,已广泛应用在机器人、航空航天、工程装备及其他领域,用CFRP来制备液压缸能够大幅度提升液压系统的轻量化的水平,帮助系统降低能耗。本文从复合材料缸筒、活塞和活塞杆、成型工艺、密封润滑和发展趋势五个方面综述了CFRP液压缸的发展现状,介绍缸筒和活塞中金属与复合材料之间的联接方法及多材料设计的参考准则,并对手糊式、缠绕式、拉挤式、树脂传递模型成型等加工工艺进行介绍,然后讨论了CFRP液压缸存在的密封、摩擦、动态响应等问题,最后从涂层、加工、后处理给出了碳纤维液压缸的发展趋势。Abstract: Carbon fiber reinforced polymer (CFRP) has been widely used in robotics, aerospace, engineering equipment and other fields for its advantages of thermal shock resistance, high tensile strength and corrosion resistance. Producing hydraulic cylinder with CFRP can greatly improve the lightweight level of hydraulic system and reduce energy consumption further. The paper summarizes the development status of CFRP hydraulic cylinder from five aspects: composite cylinder, piston and piston rod, molding process, sealing and lubrication, and development trends. Then the connection methods between metal and composite material in cylinder and piston are introduced, during which the reference criteria of multi-material design is given in detail. The processing technologies of hand lay-up, filament winding, pultrusion, resin transfer model forming are shown, then the problems of sealing, friction and dynamic response of CFRP hydraulic cylinder are discussed. Finally, the development trends of CFRP hydraulic cylinder are given from three aspects: Coating, processing and post-treatment.

-

图 3 四种金属和复合材料的连接方式[33]

Figure 3. Four ways of metal-composite materials connection

表 1 派克缸筒材料与金属的特性对比

Table 1. Characteristics comparison between Parker cylinder material and metal

Characteristic Parker

compositeAluminium

alloysStandard

steelDensity/(g·cm−3) 1.6 2.8 7.85 Fatigue performance *** * ** Corrosion resistance √√√ √√ √ Note: * and √—Approximate values, which stands for the average fatigue performance of Al alloys and the average corrosion resistance of steel, respectively. 表 2 第一代碳纤维复合材料液压缸参数

Table 2. Parameter of the first generation carbon fiber composite hydraulic cylinder

Parameter Value Pressure P/MPa 25 Maximum pressure Pmax/MPa 35 Inner diameter of tube d1/mm 50 Stroke S/mm 500 Diameter of piston rod d2/mm 28 表 3 碳纤维复合材料液压缸参数表

Table 3. Parameter of the third generation carbon fiber compo-site hydraulic cylinder

Parameter Value Pressure P/MPa 21 Diameter of piston d1/mm 25 Diameter of piston rod d/mm 15 Stroke S/mm 57 Mass m/kg 0.89 Output force F/N 10 500 -

[1] 孔祥东, 朱琦歆, 姚静, 等. 高端移动装备液压元件与系统轻量化发展综述[J]. 燕山大学学报, 2020, 44(3):203-217. doi: 10.3969/j.issn.1007-791X.2020.03.003KONG Xiangdong, ZHU Qixin, YAO Jing, etal. Reviews of lightweight development of hydraulic components andsystems for high-level mobile equipment[J]. Journal of Yanshan University,2020,44(3):203-217(in Chinese). doi: 10.3969/j.issn.1007-791X.2020.03.003 [2] 徐宝申, 刘涛. 新型电液伺服系统及其在飞机上的应用[J]. 飞航导弹, 2018(3):90-95.XU Baoshen, LIU Tao. New electro-hydraulic servo system and its application in aircraft[J]. Aerodynamic Missile Journal,2018(3):90-95(in Chinese). [3] 冯耀忠. 机械采油新进展(一)[J]. 国外石油机械, 1999(4):21-27.FENG Yaozhong. New progress of mechanical oil recovery (1)[J]. Foreign Petroleum Machinery,1999(4):21-27(in Chinese). [4] 赖奇暐, 段薇, 向超, 等. 船用液压缸缓冲特性研究[J]. 舰船科学技术, 2019, 41(15):114-117.LAI Qiwei, DUAN Wei, XIANG Chao, et al. Research on cushion characteristics of marine hydraulic cylinder[J]. Ship Science and Technology,2019,41(15):114-117(in Chinese). [5] 侯青. 复合材料在推进系统上的应用综述[J]. 世界导弹与航天, 1989(3):42-47.HOU Qing. Application of composite materials in propulsion system[J]. Missiles and Spacecraft,1989(3):42-47(in Chinese). [6] 张新元, 何碧霞, 李建利, 等. 高性能碳纤维的性能及其应用[J]. 棉纺织技术, 2011, 39(4):65-68. doi: 10.3969/j.issn.1001-7415.2011.04.025ZHANG Xinyuan, HE Bixia, LI Jianli, et al. Property and application of high-performance carbon fiber[J]. Cotton textile technology,2011,39(4):65-68(in Chinese). doi: 10.3969/j.issn.1001-7415.2011.04.025 [7] 何东晓. 先进复合材料在航空航天的应用综述[J]. 高科技纤维与应用, 2006(2):9-11, 19. doi: 10.3969/j.issn.1007-9815.2006.02.003HE Dongxiao. Review of the application of advanced composite in aviation and aerospace[J]. Hi-Tech Fiber & Application,2006(2):9-11, 19(in Chinese). doi: 10.3969/j.issn.1007-9815.2006.02.003 [8] 王军照. 碳纤维复合材料在航空领域中的应用现状及改进[J]. 今日制造与升级, 2020(8):48-49.WANG Junzhao. Application status and improvement of carbon fiber composites in aviation field[J]. Manufacturing and Upgrading Today,2020(8):48-49(in Chinese). [9] 李丰丰, 刘彦菊, 冷劲松. 形状记忆聚合物及其复合材料在航天领域的应用进展[J]. 宇航学报, 2020, 41(6):697-706.LI Fengfeng, LIU Yanju, LENG Jinsong. Progress of shape memory polymers and their composites in aerospace applications[J]. Journal of Astronautics,2020,41(6):697-706(in Chinese). [10] 樊星. 碳纤维复合材料的应用现状与发展趋势[J]. 化学工业, 2019, 37(4):12-16, 25. doi: 10.3969/j.issn.1673-9647.2019.04.004FAN Xing. Application status and development trend of carbon fiber composites[J]. Chemical Industry,2019,37(4):12-16, 25(in Chinese). doi: 10.3969/j.issn.1673-9647.2019.04.004 [11] 李东升. 碳纤维复合材料让飞机结构更轻、更强[J]. 大飞机, 2020(2):76-79. doi: 10.3969/j.issn.2095-3399.2020.02.015LI Dongsheng. Carbon fiber composites make aircraft structure lighter and stronger[J]. Large Aircraft,2020(2):76-79(in Chinese). doi: 10.3969/j.issn.2095-3399.2020.02.015 [12] 李建利, 赵帆, 张元, 等. 碳纤维及其复合材料在军工领域的应用[J]. 合成纤维, 2014, 43(3):33-35, 40.LI Jianli, ZHAO Fan, ZhANG Yuan, et al. Application of carbon fiber and its composites in military industry[J]. Synthetic Fiber,2014,43(3):33-35, 40(in Chinese). [13] 张文栓, 蒋文玲, 吴忠泉, 等. S-2玻纤增强树脂基复合材料弹托的试验研究[J]. 兵工学报, 2000(1):77-79. doi: 10.3321/j.issn:1000-1093.2000.01.022ZHANG Wenshuan, JIANG Wenling, WU Zhongquan, et al. Experimental study on S-2 glass fiber reinforced resin matrix composite sabot[J]. Acta Ordnance Engineering Sinica,2000(1):77-79(in Chinese). doi: 10.3321/j.issn:1000-1093.2000.01.022 [14] 王培源, 肖军, 李勇, 等. 复合材料在常规武器装备中的应用[A]. 中国复合材料学术年会, 2010: 7WANG Peiyuan, XIAO Jun, LI Yong, et al. Application of composite materials in conventional weapons and equipment[A]. China Annual Conference on Composite Materials, 2010: 7(in Chinese). [15] 刘若锦, 王丽, 刘华, 等. 植入性医疗器械用壳聚糖基复合材料的研究进展[J]. 中国医疗器械杂志, 2021, 45(1):52-56. doi: 10.3969/j.issn.1671-7104.2021.01.011LIU Ruojin, WANG Li, LIU Hua, et al. Advances in research of chitosan-based composites for implanted medical devices[J]. Chinese Journal of Medical Instrumentation,2021,45(1):52-56(in Chinese). doi: 10.3969/j.issn.1671-7104.2021.01.011 [16] 朱熠, 滕腾, 王泽庆. 模压型热塑性复合材料在汽车上的应用研究[J]. 汽车工艺与材料, 2015(12):40-43+47. doi: 10.3969/j.issn.1003-8817.2015.12.011ZHU Yi, TENG Teng, Wang Zeqing. Research on Application of molded thermoplastic composites in automobile[J]. Automobile Technology and Materials,2015(12):40-43+47(in Chinese). doi: 10.3969/j.issn.1003-8817.2015.12.011 [17] 于成涛, 张静旖, 吴英彪. 机器人轻量化材料应用的研究进展[J]. 新材料产业, 2019(12):41-45.YU Chengtao, ZHANG Jingyi, WUYingbiao. Research progress in application of robot lightweight materials[J]. New Materials Industry,2019(12):41-45(in Chinese). [18] 王冰佳, 黄强, 呼慧. 复合材料及碳纤维在风力机叶片中的应用现状[J]. 电站系统工程, 2019, 35(3):43-45.WANG Bingjia, HUANG Qiang, HU Hui. Application status and development of wind power blade carbon fiber composites[J]. Power System Engineering,2019,35(3):43-45(in Chinese). [19] 高凌云. 日本用碳纤维制造液压缸[J]. 液压工业, 1988(1):51.GAO Lingyun. Hydraulic cylinder made of carbon fiber in Japan[J]. Hydraulic Industry,1988(1):51(in Chinese). [20] OLAF S, BRUCE O, PETKER J. Composite high pressure hydraulic actuators for lightweight applications[C]. The 9th International Fluid Power Conference (9th IFK). Aachen, 2014. [21] 施虎, 梅雪松. 现代液压传动技术的若干新特点及其发展趋势门[J]. 机床与液压, 2017, 45(23):158-166. doi: 10.3969/j.issn.1001-3881.2017.23.037SHI Hu, MEI Xuesong. New features and development prospect of modem hydraulics drive techniques[J]. Machine Tool Hydraulics,2017,45(23):158-166(in Chinese). doi: 10.3969/j.issn.1001-3881.2017.23.037 [22] 孟玲宇, 陈家正, 纪丹阳. 碳纤维复合材料在液压油缸中的应用[J]. 纤维复合材料, 2018, 35(2):60-62. doi: 10.3969/j.issn.1003-6423.2018.02.014MENG Lingyu, CHEN Jiazheng, JI Danyang. Application of carbon fiber composites in hydraulic cylinder[J]. Fiber Composites,2018,35(2):60-62(in Chinese). doi: 10.3969/j.issn.1003-6423.2018.02.014 [23] 张婷婷. 国外液压研发动态—据中国液压气动密封件工业协会专家委员会特别顾问张海平专家报告整理[J]. 液压气动与密封, 2016, 36(3):92-96.ZHANG Tingting. Foreign hydraulic R d trends-According to Zhang Haiping, expert consultant of the expert ommittee of the expert committee of china hydraulic and pneumatic seals industry association[J]. Hydraulics Pneumatics Seals,2016,36(3):92-96(in Chinese). [24] 习青锋. 混合碳纤维液压缸[J]. 流体传动与控制, 2015(3):63-64. doi: 10.3969/j.issn.1672-8904.2015.03.018XI Qingfeng. Mixed carbon fiber hydraulic cylinder[J]. Fluid Power Transmission and Control,2015(3):63-64(in Chinese). doi: 10.3969/j.issn.1672-8904.2015.03.018 [25] HAENCHEN. Innovation award of Esslingen country-1st prize winner: Hänchen[EB/OL]. (2014-11)[2020-12-15].https://www.haenchen.cn/news/news.html [26] ZHANG J, BAO J, ZHANG D, et al. Inlaid connection of carbon fiber reinforced plastic cylinder [C]//2016 IEEE international Conference on Aircraft Utility Systems. Beijing, 2016: 1024-1029. [27] FAHEY, MARK J, MUELLER, et al. Composite tube with end-fittings: EP, EP2463084 B1[P]. 2014-04-06. [28] PARKER. Lightraulics® composite hydraulic cylinders [EB/OL]. [2020-12-15]https://www.parker.com/litera-ture/Composite Cylinders_1410-UK. [29] ROUHI M, GHAYOOR H, FORTIN-SIMPSON J, et al. Design, manufacturing, and testing of a variable stiffness composite cylinder[J]. Composite Structures,2018,184:146-152. doi: 10.1016/j.compstruct.2017.09.090 [30] ROUHI M, GHAYOOR H, FORTIN-SIMPSON J, et al. Design, Manufacturing and testing of a variable stiffness composite cylinder for improved bending induced buckling performance[C]//Automated Composites Manufacturing-Third International Symposium. Montreal, 2017. [31] ELASSWAD M, TAYBA A, ABDELLATIF A, et al. Development of lightweight hydraulic cylinder for humanoid robots applications[J]. Proceedings of the Institution of Mechanical Engineers, Part C:Journal of Mechanical Engineering Science,2018,232(18):3351-3364. doi: 10.1177/0954406217731794 [32] ELASSWAD M, ALFAYAD S, KHALIL K. Experimental estimation of friction and friction coefficient of a lightweight hydraulic cylinder intended for robotics applications[J]. International Journal of Applied Mechanics,2018,10(8):1850080. doi: 10.1142/S1758825118500801 [33] WERNER H, ANDREAS U, OLAF H, et al. Development of lightweight hydraulic components in innovative fibercomposite design [R]. Germany : Institute of Lightweight Structures and Polymer Technology (ILK), Technical University of Dresden, 2015: 1-11. [34] PARKER. Lightraulics® composite hydraulics ultra-lightweight cylinders for yachting applications [EB/OL]. [2020-12-15]. https://www.parker.com/literature/1404-B-UK Yachting cylinders. [35] SOLAZZI L. Design and experimental tests on hydraulic actuator made of composite material[J]. Composite Structures,2019,232:111544. [36] WERNER H, M. GUDE, ANDREAS U. Lightweight aircraft components in multi-material design for small series production[R]. Stade, Norway: The 6th International CFK—Valley Stade Convention "Productivity and Economic Efficiency", 2012. [37] POLIGON. Composite finished cylinders design guide[Z]. US: Polygon Company Inc, 2012. [38] LUBECKI M. Selected design issues in hydraulic cylinder made of composite materials[C]// 8th Polish National Scientific Conference for Young Scientists-Research and Development. Staniszow, 2018. [39] MANTOVANI S. Feasibility analysis of a double-acting composite cylinder in high-pressure loading conditions for fluid power applications[J]. Applied Sciences,2020,10(3):826. doi: 10.3390/app10030826 [40] LUBECKI M, STOSIAK M, GAZIŃSKA M. Numerical and experimental analysis of the base of a composite hydraulic cylinder made of PET[C]//International Scientific-Technical Conference on Hydraulic and Pneumatic Drives and Control. Staniszow, 2020: 396-405. [41] LI Y, WANG Y, SHANG Y, et al. Design and analysis on light weight carbon fibre-reinforced hydraulic cylinder[C]//The 10th International Conference on Fluid Power Transmission and Control(ICFP 2021). Hangzhou, 2021: S1404. [42] 欧天华. 碳纤维增强液压缸结构设计与力学性能分析[D]. 北京: 北京航空航天大学, 2020OU Tianhua. Structural design and mechanical properties analysis of carbon fiber reinforced hydraulic cylinder[D]. Beijing: Beihang University, 2020(in Chinese). [43] 于天, 尚耀星, 李瑶, 等. 一种轻量化活塞: 中国, ZL 112324743A[P]. 2021-02-05.YU Tian, SHANG Yaoxing, LI Yao, et al. A lightweight piston: China, ZL112324743A. 2021-02-05(in Chinese). [44] 焦宗夏, 李瑶, 于天, 等. 轻量化分瓣式活塞杆结构: 中国, ZL 112797048A[P]. 2021-05-14.JIAO Zongxia, LI Yao, YU Tian, et al. Lightweight split piston rod structure: China, ZL112797048A[P]. 2021-05-14(in Chinese). [45] 尚耀星, 李瑶, 王业硕, 等. 轻量化一体式活塞杆结构: 中国, ZL 113027853A[P]. 2021-06-25.SHANG Yaoxing, LI Yao, WANG Yeshuo, et al. Lightweight integrated piston rod structure: China, ZL113027853A[P]. 2021-06-25(in Chinese). [46] 徐兵, 鲍静涵, 张军辉, 等. 一种采用碳纤维复合材料联接及承载的可拆卸液压缸: 中国, ZL 06151161A[P]. 2016-11-23XU Bing, BAO Jinghan, ZHANG Junhui, et al. Detachable hydraulic cylinder adopting carbon fiber composite material connection and bearing: China, ZL 106151161A[P]. 2016-11-23(in Chinese). [47] 张军辉, 鲍静涵, 徐兵, 等. 一种具有集成联接结构的碳纤维-树脂复合材料液压缸缸筒: 中国, ZL 106523702A[P]. 2017-03-22.ZHANG Junhui, BAO Jinghan, XU Bing, et al. Detachable hydraulic cylinder adopting carbon fiber composite material connection and bearing: China, ZL 106523702A[P]. 2017-03-22(in Chinese). [48] ZONG Huaizhi, ZHANG Junhui, et. al. Investigation on the combination winding technology of carbon fiber reinforced polymer hydraulic cylinder[C]. The 21th International Conference of Fluid Power and Mechatronic Control Engineering (ICFPMCE), Chongqing, 2021. [49] HUANG H, ZHANG J, XU B, et al. Topology optimization design of a lightweight integrated manifold with low pressure loss in a hydraulic quadruped robot actuator[J]. Mechanical Sciences,2021,12(1):249-257. doi: 10.5194/ms-12-249-2021 [50] 汪志南, 陈奎生, 湛从昌, 等. 一种碳纤维复合材料增强的轻量化液压缸: 中国, ZL 1069308A[P]. 2017-07-07.WANG Zhinan, CHEN Kuisheng, ZHAN Congchang, et al. Carbon fiber composite material reinforced lightweight hydraulic cylinder[P]. China, ZL 106930998A[P]. 2017-07-07(in Chinese). [51] 颜磊, 汪东瑶, 於永红, 等. 碳纤维复合材料增强液压油缸: 中国, ZL 202756338U[P]. 2013.02. 27YAN Lei, WANG Dongyao, YU Yonghong, et al. Carbon fi-ber composite reinforced hydraulic cylinder: China, ZL 202756338U[P]. 2013-02-27(in Chinese). [52] 汪东瑶, 陈明新, 颜磊, 等, 轻量化高强度碳纤维复合材料液压油缸: 中国, ZL 103591078A[P]. 2014-02-19.WANG Dongyao, CHEN Mingxin, YAN Lei, et al. Lightweight high-strength carbon fiber composite hydraulic cylinder: China, ZL 103591078A[P]. 2014-02-19(in Chinese). [53] 周祖德, 黄向阳, 胡业发, 等. 一种碳纤维复合材料液压缸: 中国, ZL 103727092[P]. 2014-04-16.ZHOU Zude, HUANG Xiangyang, HU Yefa, et al. A carbon fiber composite hydraulic cylinder: China, ZL 103727092A[P]. 2014-04-16(in Chinese). [54] 曾盛渠, 李韶茂, 李瑶. 一种复合材料筒管及制造方法、液压缸筒、活塞杆: 中国, ZL 103527549A[P]. 2014-01-22.ZENG Shengqu, LI shaomao, LI Yao. A composite material tubewith manufacturing method, cylinder tube and piston rod: China, ZL 103527549A[P]. 2014-01-22(in Chinese). [55] 刘延斌, 郭伦文, 蒋凯歌, 等. 管状件及其制造方法: 中国, ZL 105479823B[P]. 2018-06-22.LIU Yanbin, GUO Lunwen, JIANG Kaige, et al. Tubular parts and manufacturing methods: China, ZL 105479823B[P]. 2018-06-22(in Chinese). [56] 邓创华, 任会礼, 钟懿. 液压缸: 中国, ZL 105587709A[P]. 2016-05-18.DENG Chuanghua, REN Huili, ZHONG Yi. Hydraulic cylinder: China, ZL 105587709A[P]. 2016-05-18(in Chinese). [57] 李晓超, 王佳茜, 李庶. 致动缸的缸体及其制造方法和混凝土泵送设备: 中国, ZL 102705293A[P]. 2012-10-03.LI Xiaochao, WANG Jiaxi, LI Shu. Tube and manufacturing method of Cylinder and concrete pumping equipment: China, ZL 102705293A[P]. 2012-10-03(in Chinese). [58] 高嵩, 杜志全, 朱雷. 驱动缸的缸筒过渡连接头及具有其的驱动缸: 中国, ZL 104832487A[P]. 2015-08-12.GAO Song, DU Zhiquan, ZHU Lei. Tube transition connector of driving cylinder and driving cylinder: China, ZL 104832487a[P]. 2015-08-12(in Chinese). [59] 范华志, 刘帮才, 王伟伟, 等. 一种耐磨涂层轻质复合材料活塞杆及液压缸: 中国, ZL 103398173A[P]. 2013-11-20.FAN Huazhi, LIU Bangcai, WANG Weiwei, et al. A kind of light composite piston rod with wear resistant coating and hydraulic cylinder: China, ZL 103398173A[P]. 2013-11-20(in Chinese). [60] HAENCHEN: Haenchen[EB/OL]. (2014-11)[2020-12-15].https://www.haenchen.cn. [61] SOALAZZI L. Feasibility study of hydraulic cylinder subject to high pressure made of aluminum alloy and compo-site material[J]. Composite Structures,2019,209:739-746. [62] 陈玉辉, 王嵘. 手糊成型工艺生产过程中的质量控制[C]. 玻璃钢/复合材料学术年会. 大连, 2001.CHEN Yuhui, WANG Rong. Quality control in hand lay-up process[C]. Annual Conference of FRP/Composites. Dalian, 2001(in Chinese). [63] TALJSTEN B, ELFGREN L. Strengthening concrete beams for shear using CFRP-materials: Evaluation of different application methods[J]. Composites Part B: Engineering,2000,31(2):87-96. doi: 10.1016/S1359-8368(99)00077-3 [64] ELKINGTON M, BLOOM D, WARD C, et al. Hand layup: Understanding the manual process[J]. Advanced Manufacturing: Polymer & Composites Science,2015,1(3):138-151. [65] KRALL S, ZEMANN R. Investigation of the dynamic behaviour of CFRP leaf springs[J]. Procedia Engineering,2015,100:646-655. doi: 10.1016/j.proeng.2015.01.416 [66] PETERS S, HUMPHREY W, FORAL R. Filament winding composite structure fabrication[C]. Society for the Advancement of Material and Process Engineering. United States, 1991. [67] ROUSSEAU J, PERREUX D, VERDIERE N. The influence of winding patterns on the damage behaviour of filament-wound pipes[J]. Composites Science and Technology,1999,59(9):1439-1449. doi: 10.1016/S0266-3538(98)00184-5 [68] LEE S, SPRINGER G. Filament winding cylinders: I. Process model[J]. Journal of Composite Materials,1990,24(12):1270-1298. doi: 10.1177/002199839002401202 [69] COLOMBO C, VERGANI L. Optimization of filament winding parameters for the design of a composite pipe[J]. Composites Part B: Engineering,2018,148:207-216. doi: 10.1016/j.compositesb.2018.04.056 [70] SORRENTINO L, MARCHETTI M, BELLINI C, et al. Manufacture of high performance isogrid structure by robotic filament winding[J]. Composite Structures,2017,164:43-50. doi: 10.1016/j.compstruct.2016.12.061 [71] 黄家康. 复合材料成型技术[M]. 北京: 化学工业出版社, 1999HUANG Jiakang. Composite molding technology[M]. Beijing: Chemical Industry Press, 1999(in Chinese). [72] KIM B, CHA S, PARK Y. Ultra-high-speed processing of nanomaterial-reinforced woven carbon fiber/polyamide 6 composites using reactive thermoplastic resin transfer molding[J]. Composites Part B: Engineering,2018,143:36-46. doi: 10.1016/j.compositesb.2018.02.002 [73] KIM K, KWAK S, HAN G, et al. Formability evaluation of the vacuum resin transfer molding of a CFRP composite automobile seat cross part[J]. Journal of the Korean Society of Manufacturing Process Engineers,2017,16(3):24-29. doi: 10.14775/ksmpe.2017.16.3.024 [74] SEBASTIAN S, LOTHAR K. Nanocomposite glide surfaces for FRP hydraulic cylinders–Evaluation and test[J]. Composites Part B: Engineering,2014,61:207-213. doi: 10.1016/j.compositesb.2014.01.044 [75] SCHOLZ S, KROLL L, SCHETTLER F. Nanoparticle reinforced epoxy gelcoats for fiber-plastic composites under multiple load[J]. Progress in Organic Coatings, 2014, 77(7): 1129-1136. [76] HAENCHEN: Haenchen[EB/OL]. (2018)[2020-12-15]https://www.haenchen.cn/company/company.html. [77] MEZGHANI S, DEMIRCI I, YOUSFI M, et al. Mutual influence of cross hatch angle and superficial roughness of honed surfaces on friction in ring-pack tribo-system[J]. Tribology International,2013,66(66):54-59. [78] 何凤英. 浅谈液压缸的密封[J]. 中国矿业, 2001(1):88-89.HE Fengying. Seal of hydraulic cylinder[J]. China Mining,2001(1):88-89(in Chinese). [79] 高雨, 傅连东, 湛从昌, 等. 液压缸活塞变间隙密封结构形状研究[J]. 中国机械工程, 2016, 27(24):3345-3350. doi: 10.3969/j.issn.1004-132X.2016.24.014GAO Yu, FU Liandong, ZHAN Congchang, et al. Research on piston variable clearance sealing structures shape in hydraulic cylinders[J]. China Academic Journal Electronic Publishing House,2016,27(24):3345-3350(in Chinese). doi: 10.3969/j.issn.1004-132X.2016.24.014 [80] BURGERS R, EIDT A, FRANKENBERGER R, et al. The anti-adherence activity and bactericidal effect of micro particulate silver additives in composite resin materials[J]. Archives of Oral Biology,2009,54(6):595-601. doi: 10.1016/j.archoralbio.2009.03.004 [81] ZHANG S, WANG R, LIAO Y. A comparative study of two kinds of T800 carbon fibers produced by different spinning methods for the production of filament-wound pressure vessels[J]. New Carbon Materials,2019,34(6):578-586. doi: 10.1016/S1872-5805(19)60033-8 [82] GOH G, YAP Y, AGARWALA S, et al. Recent progress in additive manufacturing of fiber reinforced polymer composite[J]. Advanced Materials Technologies,2019,4(1):1800271. doi: 10.1002/admt.201800271 [83] 谭祥军, 杨庆生. 纤维束分布对复合材料有效性能的影响[J]. 复合材料学报, 2009, 26(3):188-194. doi: 10.3321/j.issn:1000-3851.2009.03.032TAN Xiangjun, YANG Qingsheng. Influence of microstructure on effective properties of fiber bundle reinforced composites[J]. Acta Material Compositae Sinica,2009,26(3):188-194(in Chinese). doi: 10.3321/j.issn:1000-3851.2009.03.032 [84] KOBAYASHI S. Effect of auto-frettage on durability of CFRP composite cylinders subjected to out-of-plane loading[J]. Composites Part B: Engineering,2012,43(4):1720-1726. doi: 10.1016/j.compositesb.2012.01.032 -

下载:

下载: