Effect of graphene coating on indentation properties of aluminum matrix

-

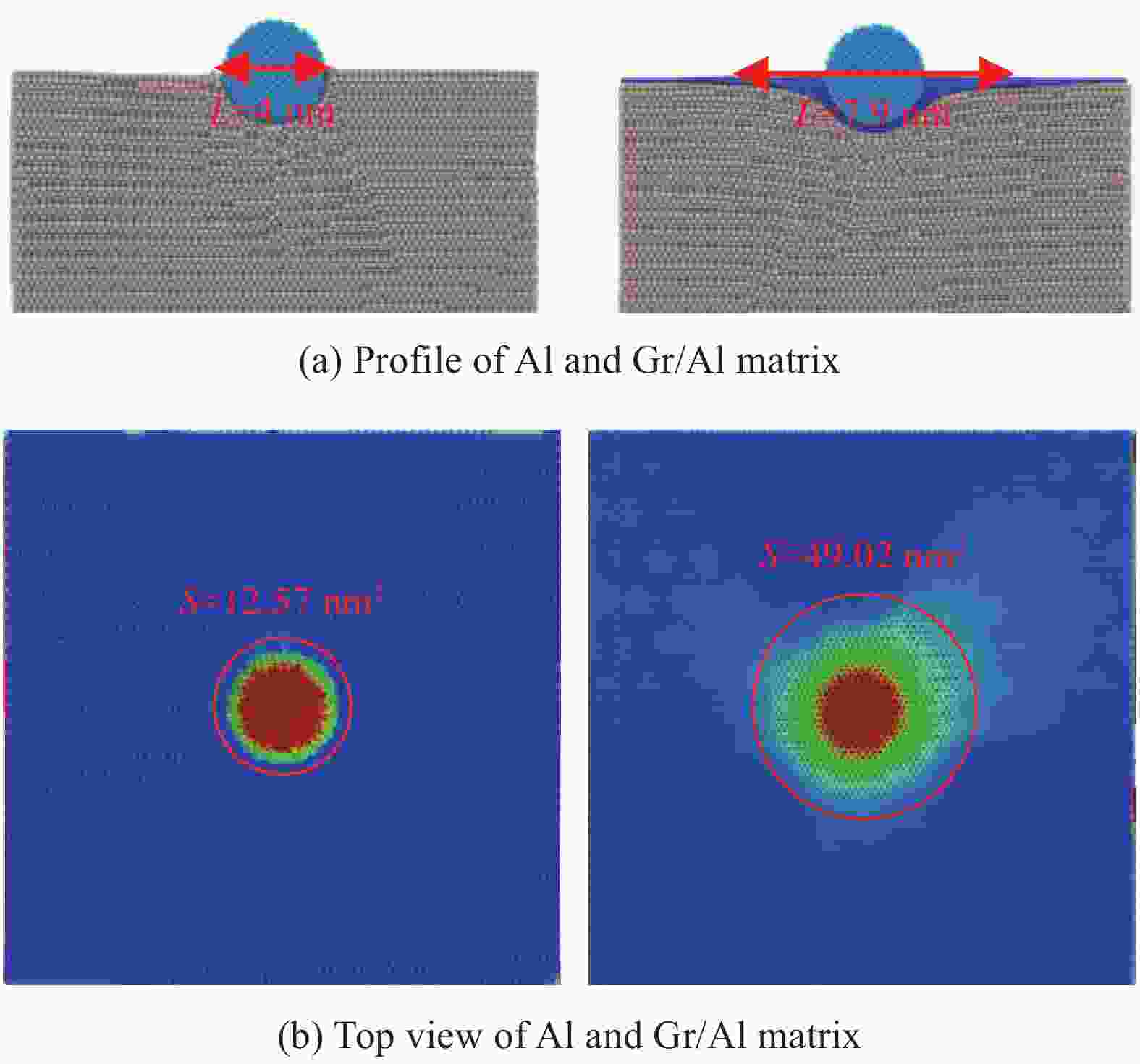

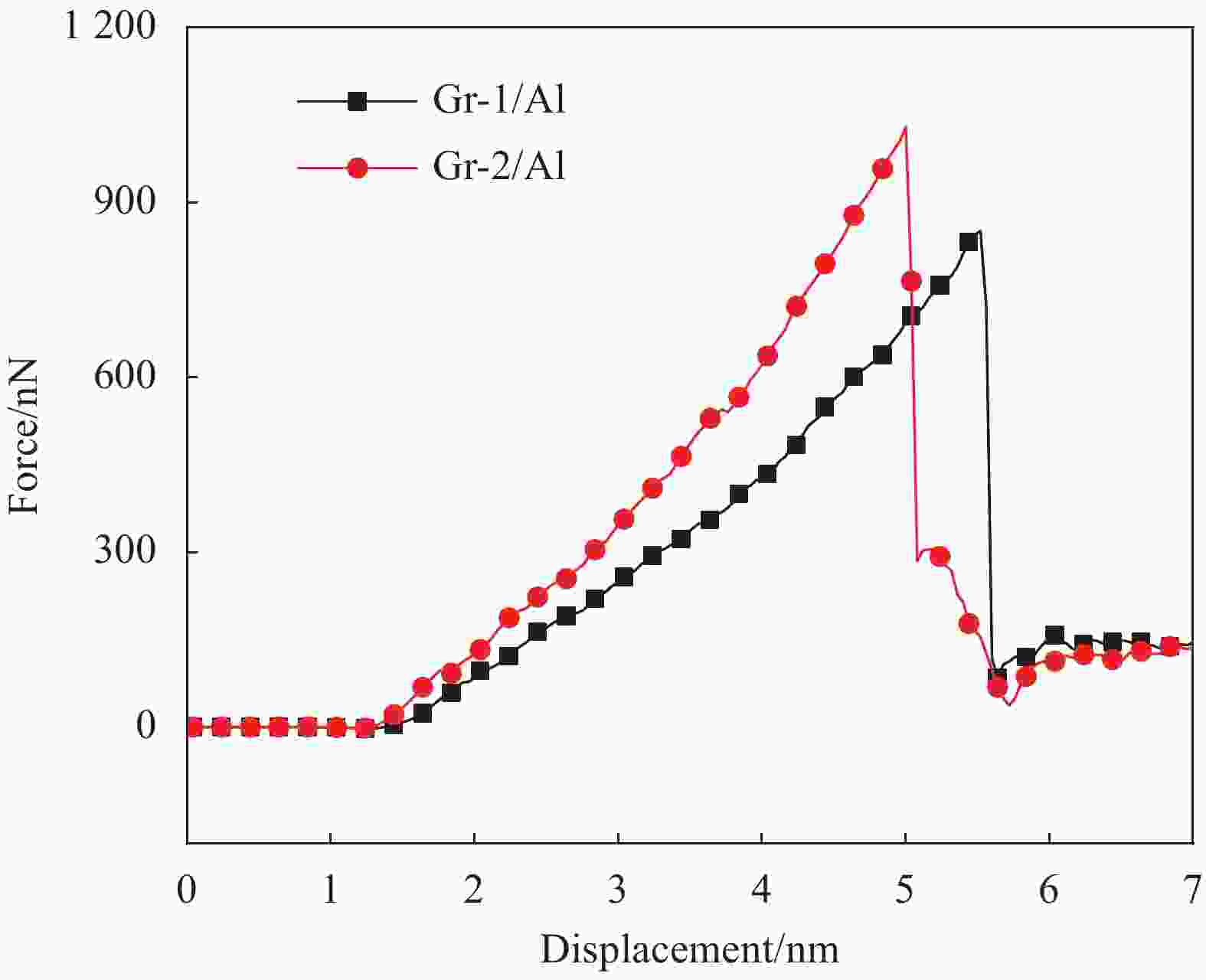

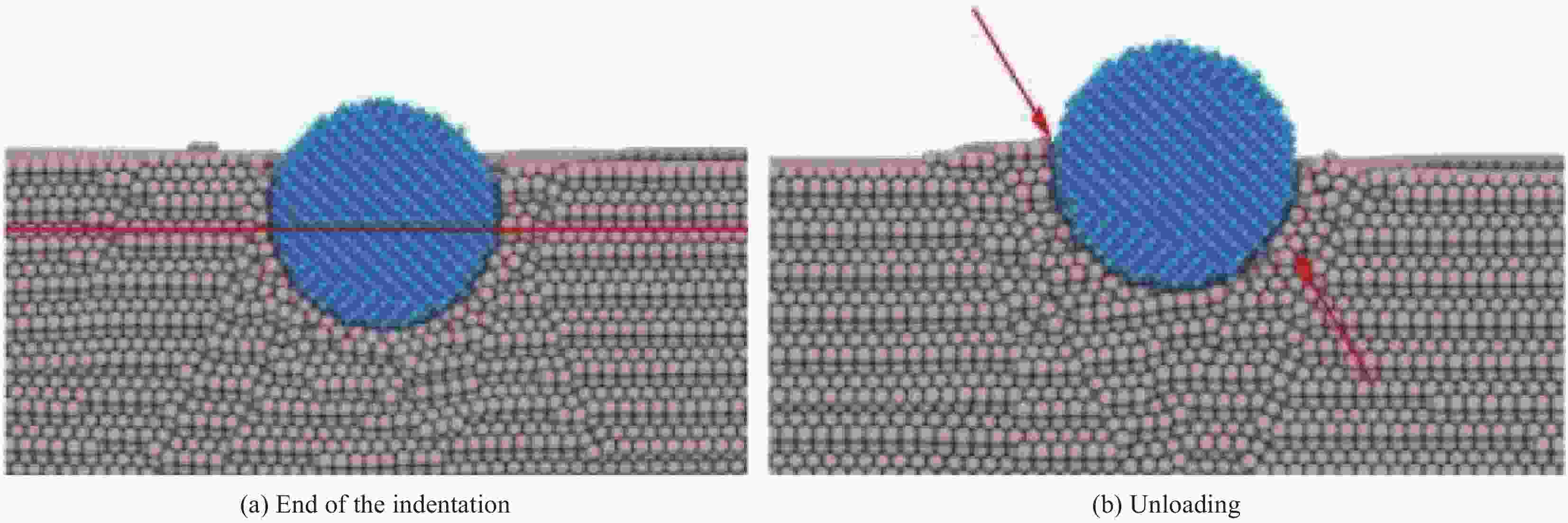

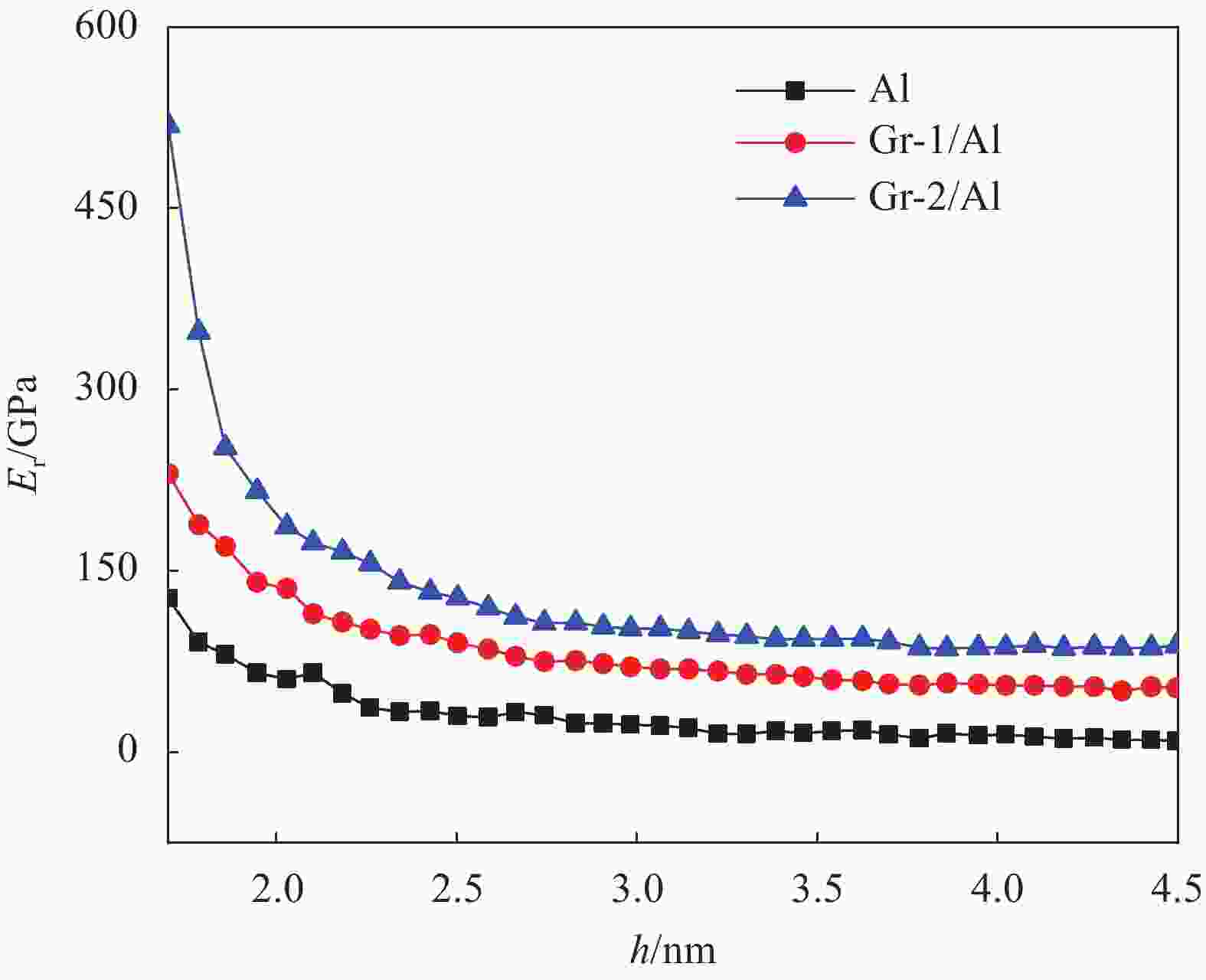

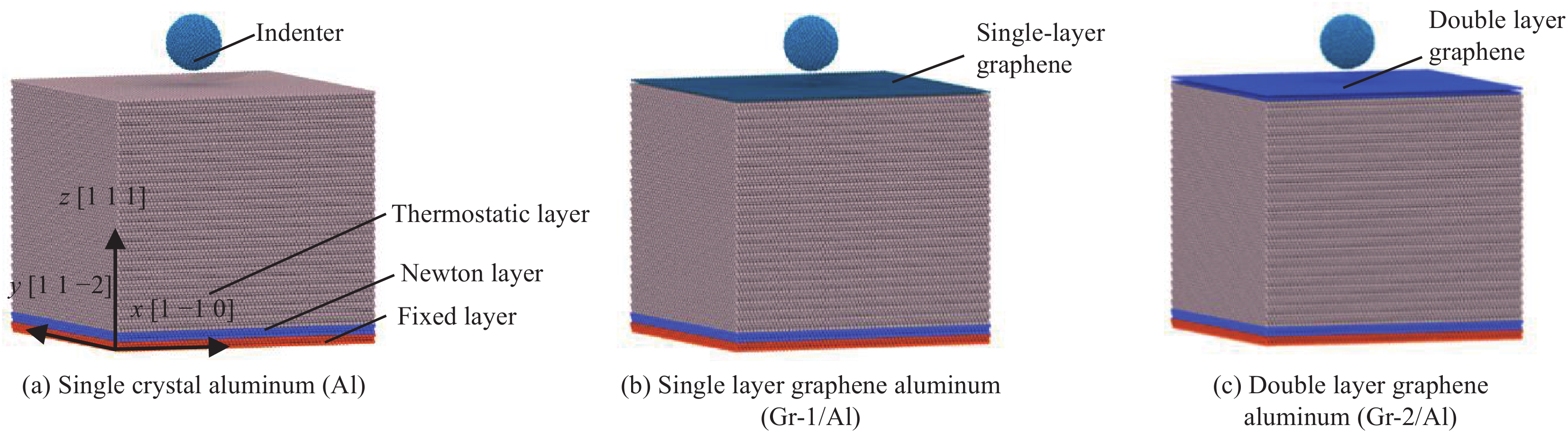

摘要: 石墨烯作为一种新型增强材料,在增强金属的力学性能方面有广阔的应用前景。利用分子动力学模拟,计算了单晶铝(Al)及单、双层石墨烯涂层铝(Gr/Al)的纳米压痕响应。研究了Al和Gr/Al在球形压头下的压痕性能,并对其压痕力学行为进行分析,以探究压痕作用下Gr涂层对Al基体性能的影响。结果表明,Gr涂层显著增强了Al基体的承载能力,并且提高了其硬度和折合弹性模量。通过分析材料变形行为、内部应力及位错扩展发现,Gr提高Al基体压痕性能的原因主要有两个:一是Al基体在Gr涂层的“托举作用”下承载面积的大幅增加;二是Gr涂层改变了Al基体中位错的扩展。通过对比单、双层Gr涂层下Al基体的压痕性能,发现增加Gr层数可以提高整个系统的承载能力,但减小了系统的临界压深。Abstract: Graphene, as a new type of reinforcement material, has a wide application prospect in strengthening the mechanical properties of metals. The indentation response of single crystal aluminum (Al) and aluminum coated by single or double-layer graphene (Gr/Al) was calculated by molecular dynamics method. The indentation properties of Al and Gr/Al under the spherical indenter were studied, and the indentation mechanical behaviors were analyzed to investigate the influence of Gr coating on Al matrix properties under indentation. The results show that the Gr coating can significantly enhance the bearing capacity of Al matrix, and improve the hardness and reduced elastic modulus of Al matrix. Through the analysis of deformation behavior, internal stress and dislocation expansion, it is found that there are two main reasons for Gr to improve the indentation performance of Al matrix: one is the increase of bearing area of Al matrix under the "lifting action" of Gr coating. The second is that Gr coating changes the dislocation expansion in Al matrix. By comparing the indentation properties of Al matrix under single and double Gr coating, it is found that increasing Gr layer number can improve the bearing capacity of the whole system, but reduce the critical depth of the system.

-

Key words:

- graphene/aluminum composites /

- molecular dynamics /

- indentation /

- coating /

- dislocation

-

表 1 Fmax、dP/dh、hc、A、H和Er的数值

Table 1. Values of Fmax、dP/dh、hc、A、H and Er

Type Fmax/nN dP/dh/(nN·nm−1) hc/nm A/nm2 H/GPa Er/GPa Al 94.64 108.27 2.34 29.46 3.21 17.68 Gr-1/Al 533.09 325.53 1.77 22.27 23.94 61.14 Gr-2/Al 781.42 448.42 1.69 21.28 36.73 86.16 Notes:Fmax—Maximum indenter load in indentation stage; dP/dh—Contact stiffness of the material; hc—Catual indentation contact depth; A—Indentation contact area; H—Hardness of material; Er—Modulus of elasticity of the material. -

[1] KOMANDURI R, CHANDRASEKARAN N, RAFF L M. MD simulation of indentation and scratching of single crystal aluminum[J]. Wear,2000,240(1-2):113-143. doi: 10.1016/S0043-1648(00)00358-6 [2] OTIENO T, ABOU-EL-HOSSEIN K. Molecular dynamics analysis of nanomachining of rapidly solidified aluminium[J]. The International Journal of Advanced Manufacturing Technology,2018,94:121-131. [3] BALANDIN A A, GHOSH S, BAO W, et al. Superior thermal conductivity of single-layer graphene[J]. Nano Letters,2008,8(3):902. doi: 10.1021/nl0731872 [4] 李坤威, 刘亚伟, 张剑, 等. 石墨烯导热性能及其测试方法[J]. 化学通报, 2017, 80(007):603-610.LI Kunwei, LIU Yawei, ZHANG Jian, et al. Thermal conductivity and measurement of graphene[J]. Chinese Journal of Chemistry,2017,80(007):603-610(in Chinese). [5] 刘海波, 王成辉, 周茜, 等. 石墨烯在金属基复合材料中的应用研究与进展[J]. 热加工工艺, 2020, 49(24):8-14+20.LIU Haibo, WANG Chenghui, ZHOU Qian, et al. Advances in application of graphene in metal matrix composites[J]. Hot Working Technology,2020,49(24):8-14+20(in Chinese). [6] TIWARI S K, SAHOO S, WANG N N, et al. Graphene research and their outputs: Status and prospect [J]. Journal of Science: Advanced Materials and Devices, 2020, 5(1): 10-29. [7] 陈梦艳, 仲兆祥, 邢卫红. 石墨烯功能化纳米纤维空气净化材料研究进展[J]. 南京工业大学学报(自然科学版), 2021, 43(4):411-419.CHEN Mengyan, ZHONG Zhaoxiang, XING Weihong. Advances in graphene functionalized nanofibers for air purification[J]. Journal of Nanjing University of Technology (Natural Science Edition),2021,43(4):411-419(in Chinese). [8] BERMAN D, ERDEMIR A, SUMANT A V. Graphene as a protective coating and superior lubricant for electrical contacts[J]. Applied Physics Letters,2014,105(23):231907. doi: 10.1063/1.4903933 [9] 华军, 宋郴, 段志荣, 等. 石墨烯/铜复合材料剪切性能的分子动力学模拟[J]. 复合材料学报, 2018, 35(3):632-639.HUA Jun, SONG Chen, DUAN Zhirong, et al. Molecular dynamics simulation of shear properties of graphene/copper composites[J]. Acta Materiae Compositae Sinica,2018,35(3):632-639(in Chinese). [10] ZHAO Y, LIU X, ZHU J, et al. Unusually high flexibility of graphene-Cu nanolayered composites under bending[J]. Physical Chemistry Chemical Physics,2019,21(31):17393-17399. [11] WENG S, NING H, TAO F, et al. Molecular dynamics study of strengthening mechanism of nanolaminated graphene/Cu composites under compression[J]. Scientific Reports,2018,8:3089. [12] LIU X T, FANG Q L, HU T W, et al. Thickness dependent raman spectra and interfacial interaction between Ag and epitaxial graphene on 6H-SiC(0001)[J]. Physical Chemistry Chemical Physics,2018,20(8):5964-5974. [13] BERMAN D, ERDEMIR A, SUMANT A V. Few layer graphene to reduce wear and friction on sliding steel surfaces[J]. Carbon,2013,54:454-459. doi: 10.1016/j.carbon.2012.11.061 [14] BERMAN D, ERDEMIR A, SUMANT A V. Reduced wear and friction enabled by graphene layers on sliding steel surfaces in dry nitrogen[J]. Carbon,2013,59:167-175. doi: 10.1016/j.carbon.2013.03.006 [15] SRIVASTAVA A K, PATHAK V K. Elastic properties of graphene-reinforced aluminum nanocomposite: Effects of temperature, stacked, and perforated graphene[J]. Proceedings of the Institution of Mechanical Engineers Part L: Journal of Materials: Design and Applications,2020,234(9):1218-1227. [16] 于伟, 陈立飞, 齐玉, 等. 石墨烯与纳米颗粒协同提高复合体系热导率[J]. 工程热物理学报, 2016, 37(11):2463-2470.YU Wei, CHEN Lifei, QI Yu, et al. Synergistic effects for enhancing composite's thermal conductivity through the hybrid of graphene and spherical nanoparticles[J]. Journal of Engineering Thermophysics,2016,37(11):2463-2470(in Chinese). [17] 赵敬, 彭倚天. 石墨烯表面化学镀铜及铜/石墨烯复合材料的性能研究[J]. 电镀与涂饰, 2020, 39(21):28-32.ZHAO Jing, PENG Yitian. Electroless copper plating on graphene and the properties of copper/graphene composites[J]. Electroplating and Finishing,2020,39(21):28-32(in Chinese). [18] LIN D, LIU C R, CHENG G J. Single-layer graphene oxide reinforced metal matrix composites by laser sintering: Microstructure and mechanical property enhancement[J]. Acta Materialia,2014,80:183-193. doi: 10.1016/j.actamat.2014.07.038 [19] KIM Y, LEE J, YEOM M S, et al. Strengthening effect of single-atomic-layer graphene in metal-graphene nanolayered composites[J]. Nature Communications,2013,4:2114. [20] YAN Y, ZHOU S, LIU S. Atomistic simulation on nanomechanical response of indented graphene/nickel system[J]. Computational Materials Science,2017,130:16-20. doi: 10.1016/j.commatsci.2016.12.028 [21] KLEMENZ A, PASTEWKA L, BA LAKRISHNA S G, et al. Atomic scale mechanisms of friction reduction and wear protection by graphene[J]. Nano Letters,2014,14(12):7145-7152. doi: 10.1021/nl5037403 [22] ZHANG Y, AN Q, LI J, et al. Strengthening mechanisms of graphene in copper matrix nanocomposites: A molecular dynamics study[J]. Journal of Molecular Modeling,2020,26(12):335. [23] ERTURK A, KIRCA M, KIRKAYAK L. Mechanical enhancement of an aluminum layer by graphene coating[J]. Journal of Materials Research,2018,33(18):2741-2751. [24] 吴瑶. 石墨烯涂层/铝界面性能的分子动力学研究[D]. 南昌: 南昌航空大学, 2018.WU Yao. Molecular dynamics of graphene coatings/aluminum interfacial properties [D]. Nanchang: Nanchang Hangkong University, 2018(in Chinese). [25] LIU X H, LI J J, SHA J W, et al. In-situ synthesis of graphene nanosheets coated copper for preparing reinforced aluminum matrix composites[J]. Materials Science and Engineering: A,2018,709:65-71. [26] SHIN S E, CHOI H J, SHIN J H, et al. Strengthening behavior of few-layered graphene/aluminum composites[J]. Carbon,2015,82:143-151. doi: 10.1016/j.carbon.2014.10.044 [27] DAW M S, BASKES M I. Embedded-atom method: Derivation and application to impurities, surfaces, and other defects in metals[J]. Physical Review B Condensed Matter,1984,29(12):6443-6453. doi: 10.1103/PhysRevB.29.6443 [28] STUART S J, TUTEIN A B, HARRISON J A. A reactive potential for hydrocarbons with intermolecular interactions[J]. Journal of Chemical Physics,2000,112(14):6472-6486. doi: 10.1063/1.481208 [29] CHOI B K, YOON G H, LEE S. Molecular dynamics studies of CNT-reinforced aluminum composites under uniaxial tensile loading[J]. Composites Part B: Engineering,2016,91:119-125. [30] SILVESTRE N, FARIA B, LOPES J N C. Compressive behavior of CNT-reinforced aluminum composites using molecular dynamics[J]. Composites Science and Technology,2014,90:16-24. doi: 10.1016/j.compscitech.2013.09.027 [31] CHOI B K, YOON G H, LEE S. Molecular dynamics studies of CNT-reinforced aluminum composites under uniaxial tensile loading[J]. Composites Part B-Engineering,2016,91:119-125. doi: 10.1016/j.compositesb.2015.12.031 [32] 黄跃飞. 纳米压痕过程温度影响的分子动力学研究[J]. 系统仿真学报, 2009, 21(14):4454-4456.HUANG Yuefei. Molecular dynamics study on temperature effect in nanoindentation process[J]. Journal of systems simulation,2009,21(14):4454-4456(in Chinese). [33] 武霞霞. 多层石墨烯纳米压痕和划痕的分子动力学研究[D]. 西安: 西安建筑科技大学, 2016.WU Xiaxia. Molecular dynamics study on Nanoindentation and scratch of multilayer graphene [D]. Xi'an: Xi'an University of Architecture and Technology, 2016(in Chinese). [34] OLIVER W, PHARR G. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments [J]. Journal of Materials Research, 1992, 7 (6): 1564-1583. [35] LILLEODDEN E T, ZIMMERMAN J A. Atomistic simulations of elastic deformation and dislocation nucleation during nanoindentation[J]. Journal of the Mechanics and hysics of Solids,2003,51(5):901-920. doi: 10.1016/S0022-5096(02)00119-9 [36] 杨晓京, 赵彪, 李勇, 等. 利用纳米压痕法研究单晶锗的力学行为[J]. 热加工工艺, 2016, 45(16):80-83.YANG Xiaojing, ZHAO Biao, LI Yong, et al. Study on mechanical behavior of single crystal germanium by nanoindentation method[J]. Hot working technology,2016,45(16):80-83(in Chinese). [37] 周亮, 姚英学. 基于纳米压痕技术和AFM的单晶铝硬度测试实验研究[J]. 机械科学与技术, 2006(1):6-8. doi: 10.3321/j.issn:1003-8728.2006.01.003ZHOU Liang, YAO Yingxue. Experimental study on hardness test of single crystal aluminum based on nano indentation technology and AFM[J]. Mechanical Science and Technology,2006(1):6-8(in Chinese). doi: 10.3321/j.issn:1003-8728.2006.01.003 -

下载:

下载: