Research progress of shape memory polymer fibers and reinforced composites

-

摘要: 形状记忆聚合物纤维及增强复合材料是从形状记忆聚合物中发展起来的一种新型智能材料。它除了具有质量轻便、价格低廉、变形能力优异、模量变化可逆、驱动方式多样、设计结构简单等优点,还具备弹性模量较高、回复应力较大等特点,有效地弥补了传统形状记忆聚合物的不足。首先概述了形状记忆聚合物纤维及纤维增强形状记忆聚合物复合材料的驱动方法,并总结了制备形状记忆聚合物纤维的纺丝方法,其次分析了形状记忆聚合物纤维及纤维增强形状记忆聚合物复合材料在多个领域的潜在应用,最后讨论了目前存在的问题并对未来的研究进行了展望。

-

关键词:

- 形状记忆聚合物纤维 /

- 纤维增强形状记忆聚合物复合材料 /

- 驱动方法 /

- 纺丝方法 /

- 潜在应用

Abstract: Shape memory polymer fibers and reinforced composites are novel smart materials developed from shape memory polymers. They have advantages of light weight, low price, excellent deformation capability, reversible modulus, various driving methods and simple structures. Furthermore, they have some characteristics, like high elastic modulus, large recovery stress, etc., that can effectively amend the shortcomings of traditional shape memory polymers. This article first outlines the driving methods of shape memory polymer fibers and fiber reinforced shape memory polymers, and summarizes the spinning methods of shape memory polymer fibers. Then the potential applications of shape memory polymer fibers and fiber reinforced shape memory polymers in various fields are analyzed. Finally, the current problems are discussed and the future research is prospected. -

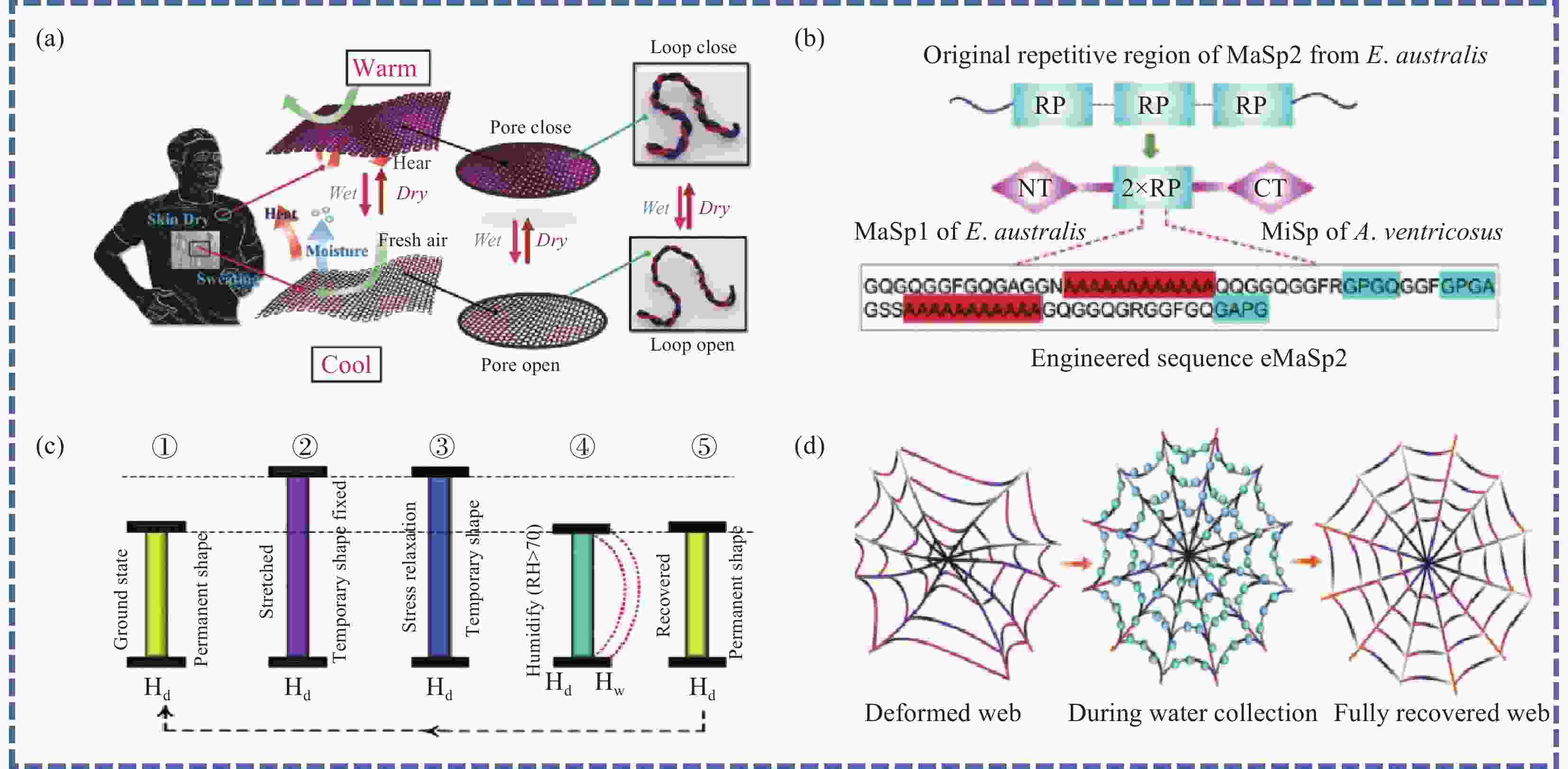

图 1 水驱动:(a) 水驱动调温羊毛针织衫[28];(b) 大壶腹状蛛丝蛋白2(eMaSp2)的基因设计[33];(c) eMaSp2纤维的超牵引能力[33];(d) 蜘蛛丝定向收集水滴的能力[34]

Figure 1. Actuation by water: (a) Water-driven temperature-adjustable wool knitwear[28]; (b) Genetic design of engineered major ampullate spidroin 2 (eMaSp2)[33]; (c) Supercontraction of eMaSp2 fiber[33]; (d) Ability of spider fiber to collect water droplets directionally[34]

Hd—Dry state; Hw—Wet state

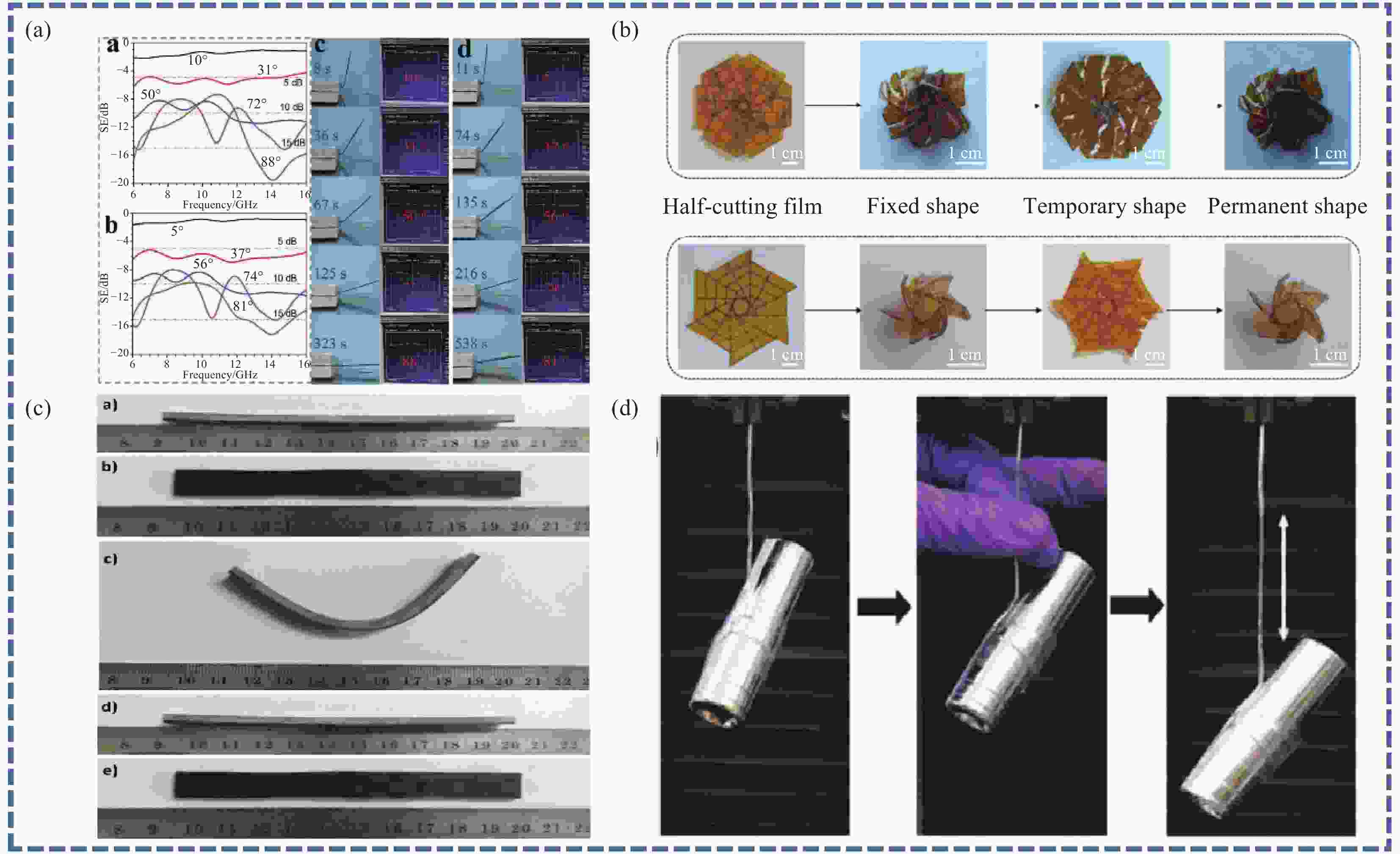

图 2 热驱动:(a) 屏蔽效能与回复角的关系[38];(b) 复杂结构的形状记忆效应[39];(c) 冷编程复合材料的形状记忆效应[40];(d) 体温触发纤维的形状记忆效应[41]

Figure 2. Actuation by heat: (a) Relationship between shielding effect and recovery angle[38]; (b) Shape memory effect of complex structures[39]; (c) Shape memory effect of cold-programming composite[40]; (d) Shape memory effect of fiber by body temperature[41]

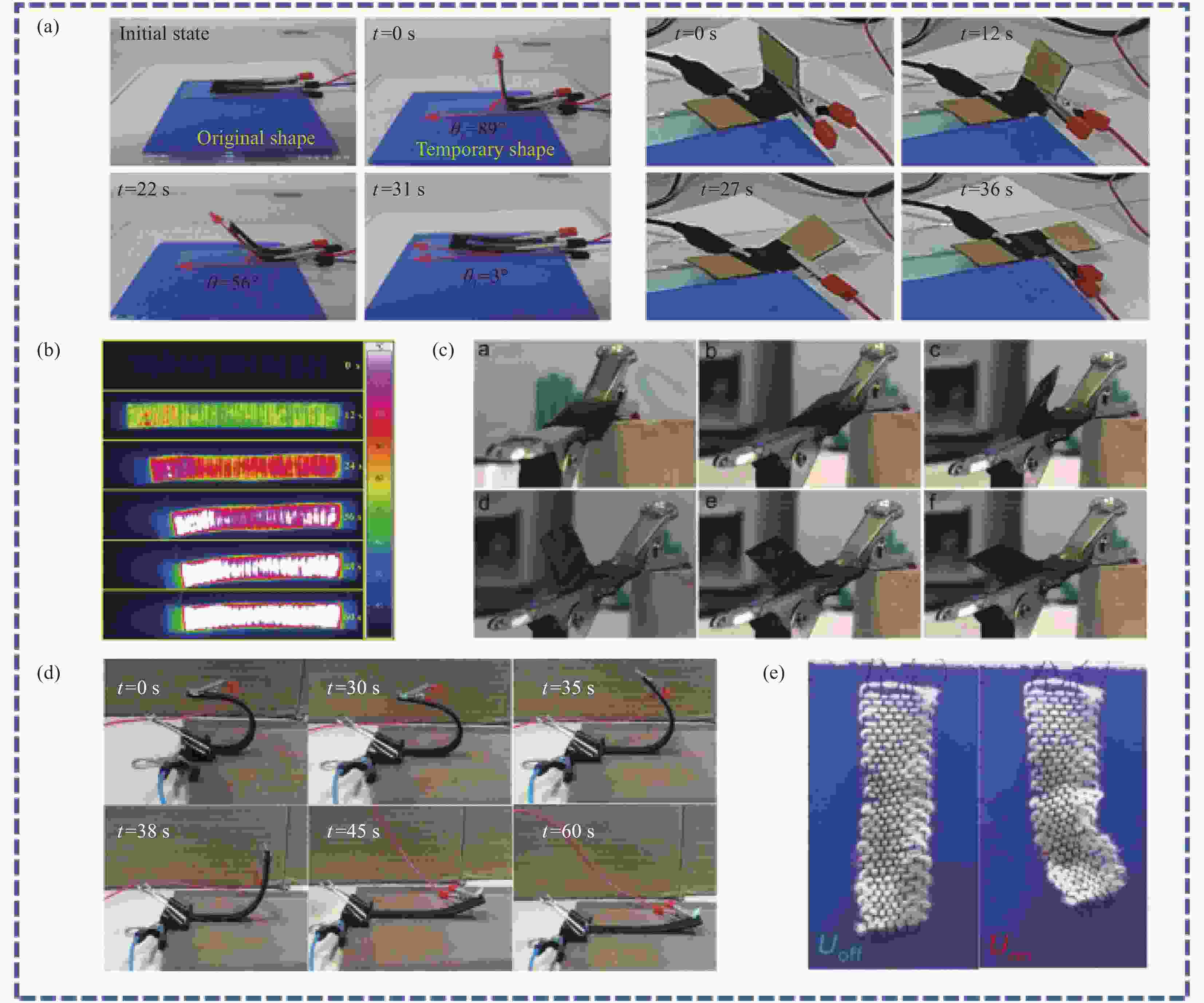

图 3 电驱动: ((a)~(d)) 50 V、35 V、15.87 V、60 V电压下复合材料的形状回复过程[51-54];(e) 电触发纤维的可逆驱动[58]

Figure 3. Actuation by electricity: ((a)-(d)) Shape recovery process of composites under 50 V, 30 V, 15.87 V and 60 V[51-54]; (e) Reversible change of fibers by electricity[58]

Uoff—Voltage source off; Uon—Voltage source on

图 4 光驱动:(a) 光触发界面损伤自修复[62];(b) 不同功率密度的近红外光诱导形状记忆行为[63];(c) 光驱动纤维超大收缩的示意图[64];((d)~(e)) 光驱动精确折纸、回复断裂蜘蛛网、闭合绳袋、筛选不同尺寸的玻璃球[64]

Figure 4. Actuation by light: (a) Self-healing of interface damage by light[62]; (b) Shape memory behavior induced by near infrared light at different power densities[63]; (c) Schematic diagram of ultra large shrinkage of fiber by light[64]; ((d)-(e)) Origami, recover broken spider webs, close rope bags and screen glass balls of different sizes by light[64]

RT—Room temperature

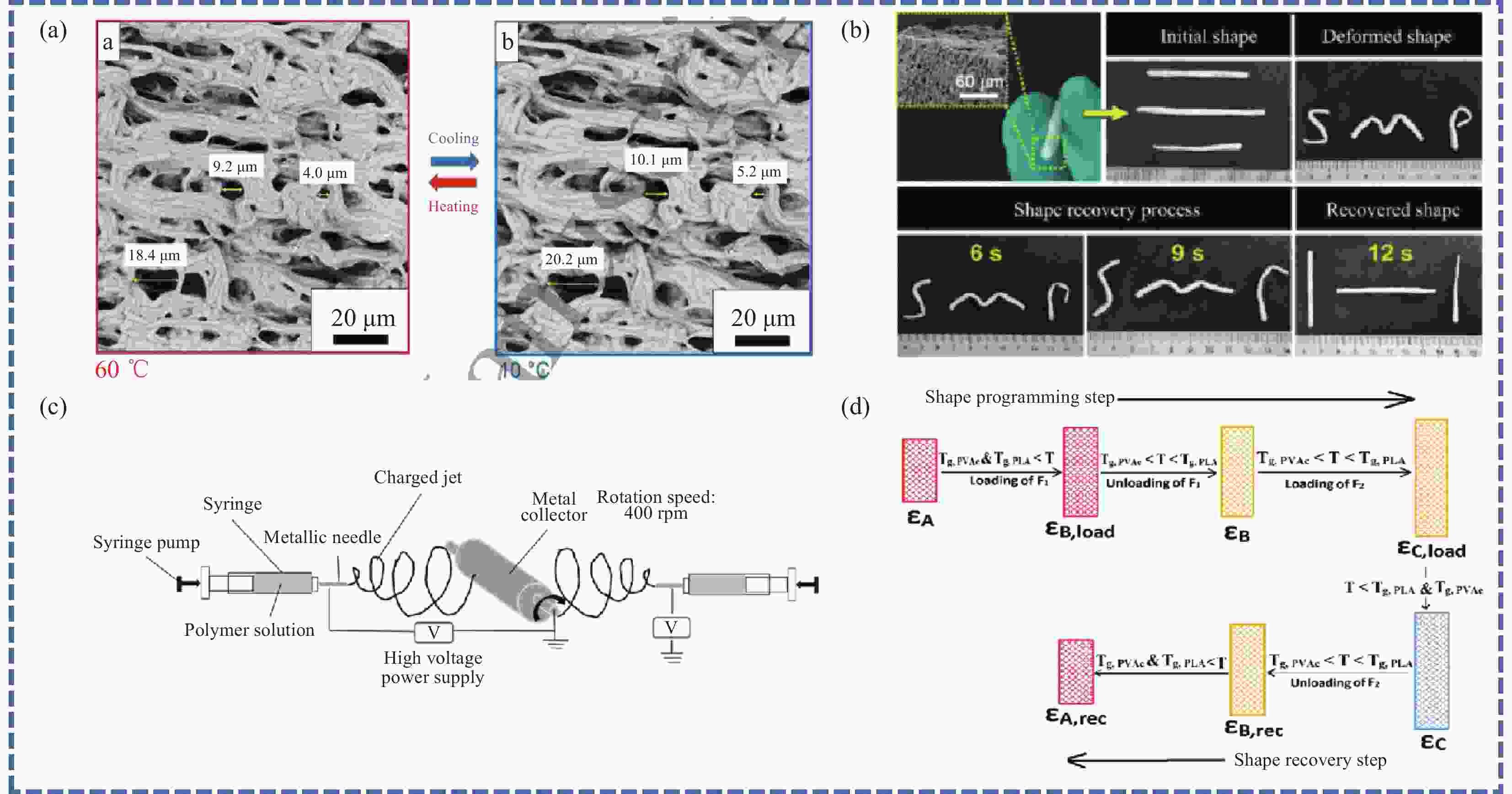

图 5 静电纺丝方法;(a) 纤维网孔径的可逆变化[66];(b) 纤维支架的形状回复过程[67];(c) 双重静电纺丝装置示意图[71];(d) 三重形状记忆效应示意图[72]

Figure 5. Electrospinning method: (a) Reversible change of the pore sizes[66]; (b) Shape recovery process of the fiber scaffolds[67]; (c) Schematic diagram of the double electrospinning device[71]; (d) Schematic diagram of the triple shape memory effect[72]

εA—Permanent shape; εB,load—First temporary shape; εB—First temporary fixed shape; εC,load—Second temporary shape; εC—Second temporary fixed shape; εB,rec—Recovered shape of εB; εA,rec—Recovered shape of εA

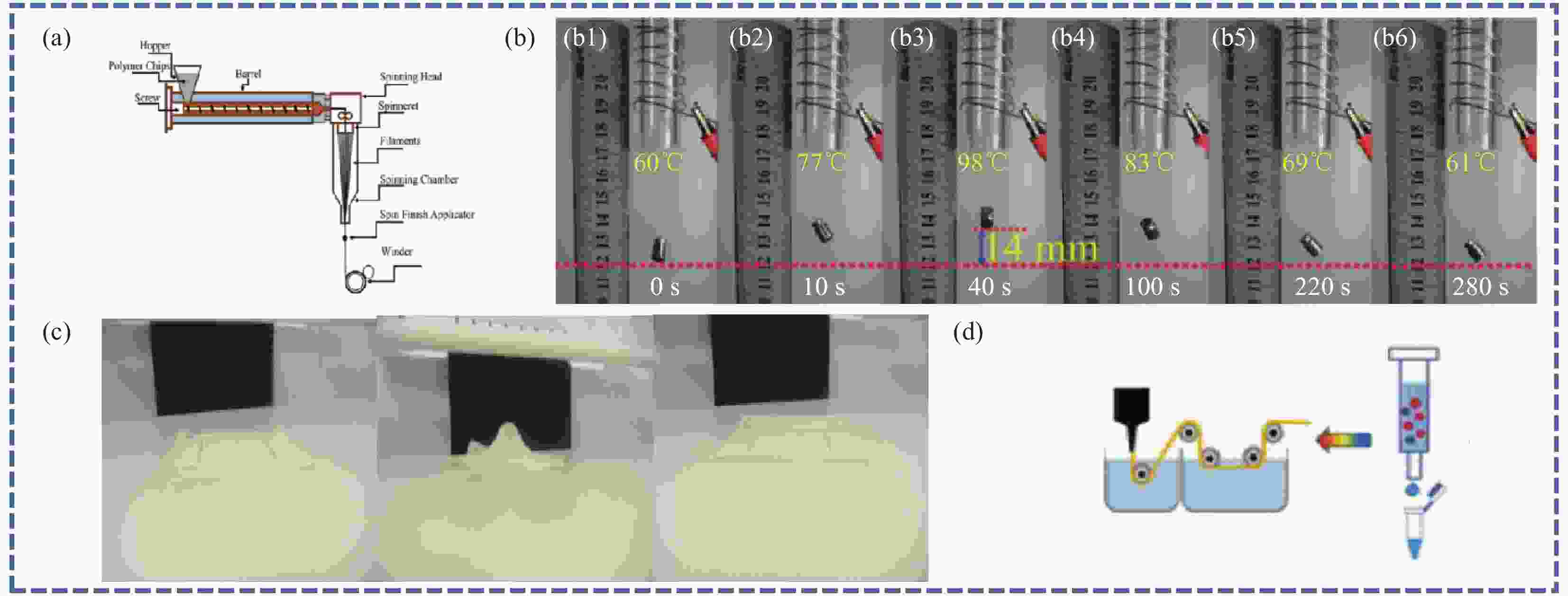

图 6 熔融纺丝方法及湿法纺丝方法:(a) 熔融纺丝装置示意图[75];(b) 恒定应力下纤维的双向形状记忆效应[78];(c) 蒸汽处理后纤维的形状记忆效应[80];(d) 湿法纺丝装置示意图[33]

Figure 6. Melt spinning method and wet spinning method: (a) Schematic diagram of melt spinning device[75]; (b) Two-way shape memory effect of fiber under constant stress[78]; (c)Shape memory effect of fiber after steam treatment[80]; (d) Schematic diagram of wet spinning device[33]

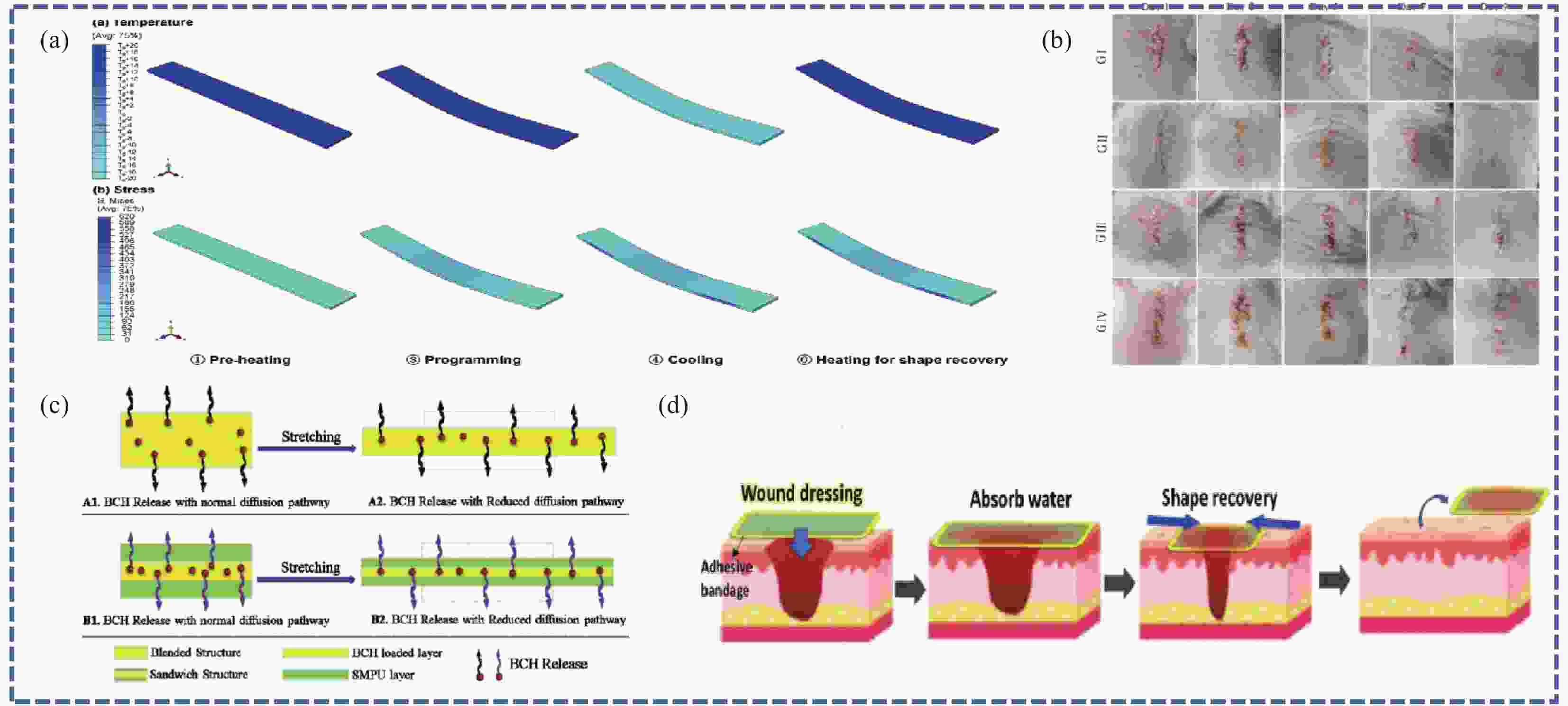

图 7 生物医学应用:(a) 微弯曲回复过程的有限元模拟示意图[87];(b) 外科手术缝合线的应用过程[88];(c) 药物输送系统示意图[89];(d) 伤口敷料示意图[91]

Figure 7. Biomedical applications: (a) Schematic diagram of finite element simulation of microbending recovery process[87]; (b) Process of applying the surgical suture[88]; (c) Schematic diagram of drug delivery system[89]; (d) Schematic diagram of wound dressing[91]

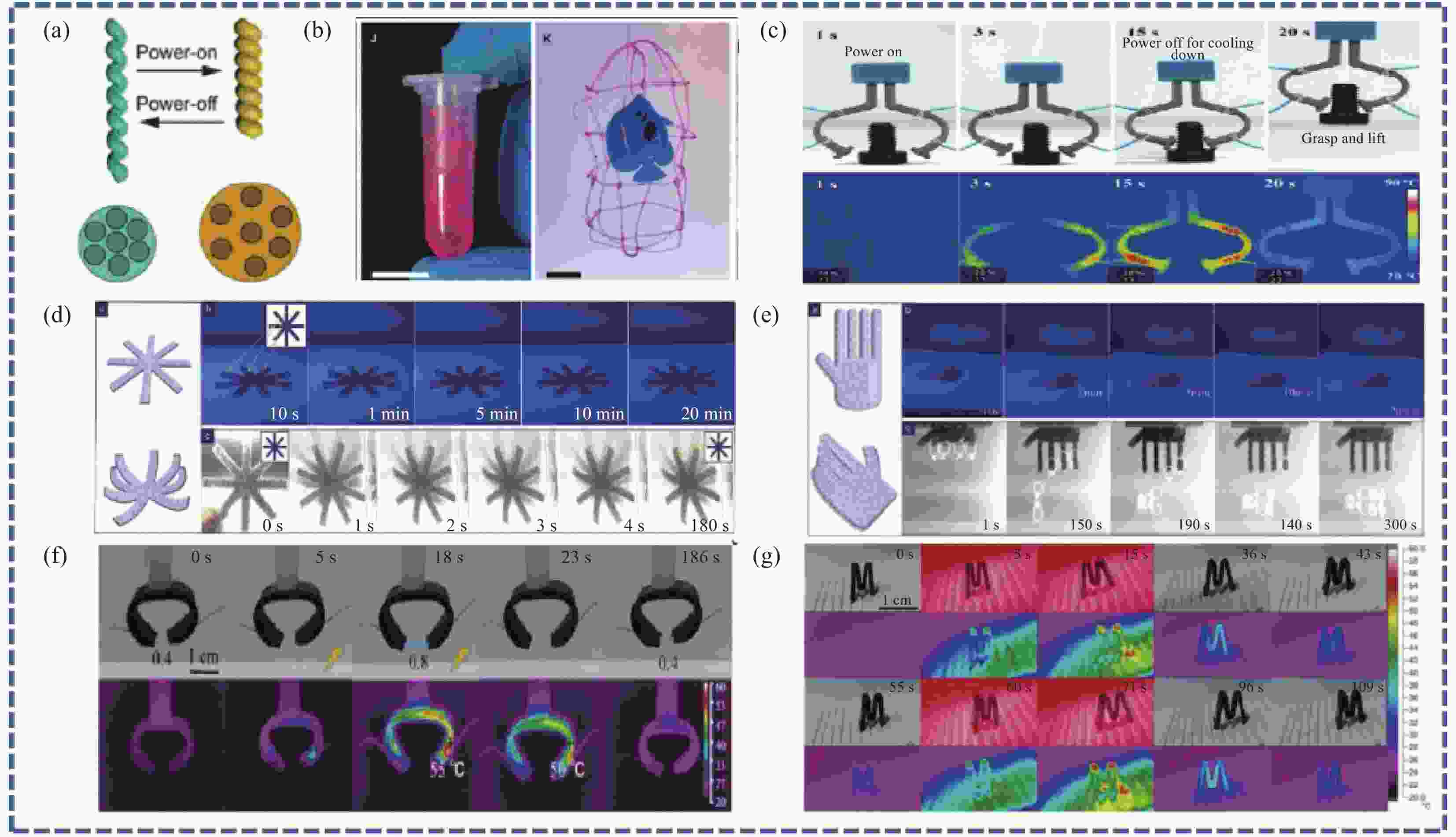

图 8 软机器人应用:(a) 卷绕式复合纱线的收缩机制示意图[94];(b) 捕鱼用形状记忆空心笼[95];(c) 抓取5 g螺栓的电活性抓手[96];((d)~(e)) 热驱动花朵、机械手[97];((f)-(g)) 电致动机械抓手、步行机器人[98]

Figure 8. Applications in soft robotics: (a) Schematic diagram of the shrinkage of coiled yarn[94]; (b) Shape memory cage for fishing[95]; (c) Electricity-driven gripper for grabbing 5 g bolt[96]; ((d)-(e)) Thermally-driven flower and gripper[97]; ((f)-(g)) Electricity-driven gripper and walking robot[98]

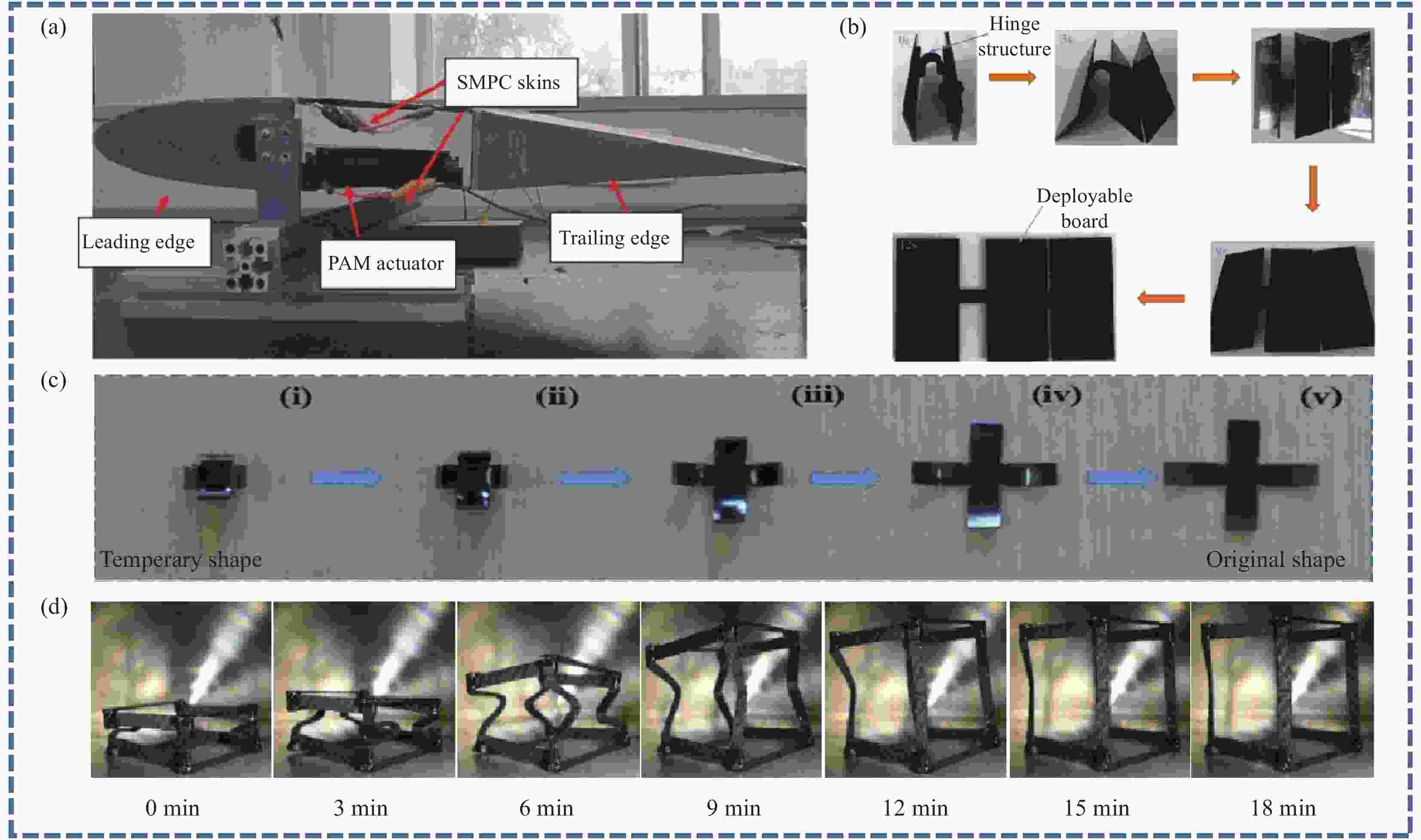

图 9 航空航天应用:(a) 变刚度机翼模型[99];(b) 平板式可展开结构的形状回复过程[100];(c) 箱型结构的形状回复过程[102];(d) 立方体结构的形状回复过程[103]

Figure 9. Aerospace applications: (a) Variable stiffness wing model[99]; (b) Shape recovery process of flat expandable structure[100]; (c) Shape recovery process of box structure[102]; (d) Shape recovery process of cube structure[103]

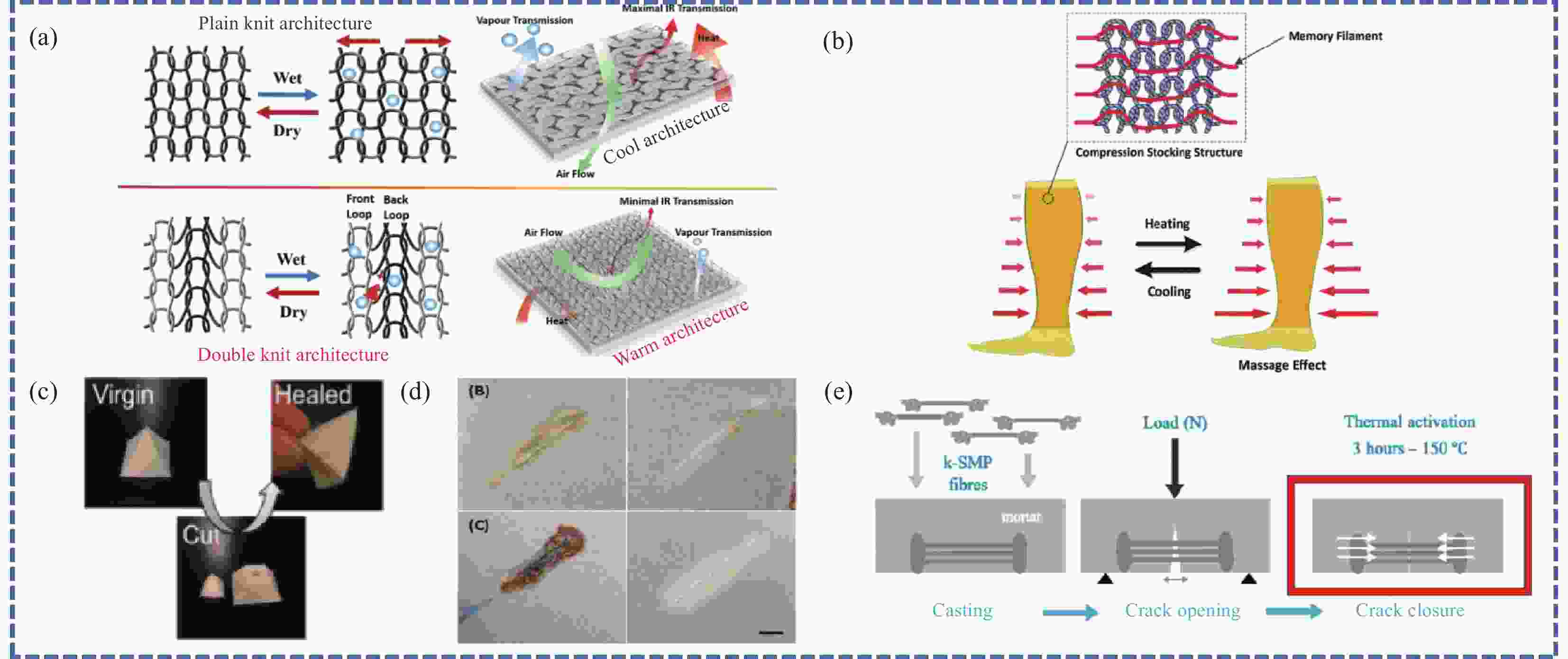

图 10 纺织服装应用及自愈合应用:(a) 针织结构对羊毛针织物形状记忆性能的影响[105];(b) 一体式压力长袜结构示意图[107];(c) 自愈合的空心金字塔[109];(d) 自愈合涂层[110];(e) 水泥裂纹闭合的概念模型[111]

Figure 10. Applications in textile and self-healing: (a) Influence of knitting structure on the shape memory effect of wool fabrics[105]; (b) Structure diagram of one-piece pressured stockings[107]; (c) Self-healing hollow pyramid[109]; (d) Self-healing coating[110]; (e) Conceptual model of closing cement crack[111]

表 1 形状记忆聚合物纤维(SMPFs)和纤维增强形状记忆聚合物复合材料(FRSMPs)的种类、驱动方式和应用前景的总结

Table 1. Summary of the types, driving methods and applications of shape memory polymer fibers (SMPFs) and fiber reinforced shape memory polymers (FRSMPs)

SMPF Types Driving methods Applications Artificial spider silk fiber Water Textile/aerospace[30,33-34] Ga@TPU fiber Heat Textile[41] TPU-Ag-Cu2S-PBO fiber Light Self-healing[62] Linear liquid crystal polymer fiber Light Soft robotics[64] PCL fiber Heat Biomedical [66] poly(D,L-lactide-co-trimethylene carbonate) fiber Heat Biomedical [67] PLA-OLA fiber Heat Biomedical [69] SMPU fiber Heat Textile[73,75,80-82,106-107] EVA fiber Heat Soft robotics/biomedical [78] BCH-SMPU fiber Heat Biomedical [88-89] HA-DEX-SMPU fiber Heat Biomedical [90] PLLA-a-PHB fiber Heat Biomedical [92] UHMWPE fiber Heat Soft robotics[93] CNT/TPU yarn Electricity Soft robotics[94] PCL-SEBS fiber Heat Self-healing[109] FRSMP CF/EP Heat, electricity, light Aerospace[35-36,52,59,101,102-103] CF/PVA Heat, electricity Soft robotics[37,51] CF/SMPU Heat Microwave shielding/biomedical [38,87] GF/EP Heat Aerospace[39] CF-MWCNT/EP Heat Aerospace[40] Ag@CF/EP Electricity Aerospace[54] CNT/SMPU Electricity, light Soft robotics/strain sensors[56-57] PAn/PVA Light Soft robotics[63] Skin collagen fiber/waterborne polyurethane Water Biomedical [91] Ag@CF/PVA Electricity Soft robotics[96] Steel fiber/EP Heat Soft robotics[97] CNT/POE Electricity, light Soft robotics[98] PU fiber-nylon fiber/EP Heat Aerospace[99] CF-CB/EP Electricity Aerospace[100] PCL fiber/EP Heat Self-healing[110] Notes: TPU—Thermoplastic polyurethane; PBO—Poly(p-phenylene benzobisoxazole); PCL—Polycaprolactone; PLA—Polylactic acid; OLA—Oligomer polylactic acid; SMPU—Shape memory polyurethane; EVA—Poly[ethylene-co-(vinyl acetate)]; BCH—Berberine hydrochloride; HA—Hydroxyapatite; DEX—Dexamethasone; PLLA—Poly(L-lactide); a-PHB—Atactic polyhydroxybutyrate; UHMWPE—Ultrahigh molecular weight polyethylene; CNT—Carbon nanotube; SEBS—Styrene ethylene butylene styrene; EP—Epoxy; PVA—Polyvinyl alcohol; MWCNT—Multi-walled carbon nanotubes; PAn—Polyaniline; PU—Polyurethane; CF—Carbon fiber; POE—Poly(ethylene-co-octene). -

[1] HAN Y, HU J, JIANG L. Collagen skin, a water-sensitive shape memory material[J]. Journal of Materials Che-mistry B,2018,6(31):5144-5152. doi: 10.1039/C8TB01346B [2] SONG L, LI Y, XIONG Z, et al. Water-induced shape memory effect of nanocellulose papers from sisal cellulose nanofibers with graphene oxide[J]. Carbohydrate Polymers,2018,179:110-117. doi: 10.1016/j.carbpol.2017.09.078 [3] XIE H, LI L, DENG X Y, et al. Reinforcement of shape-memory poly(ethylene-co-vinyl acetate) by carbon fibre to access robust recovery capability under resistant condition[J]. Composites Science and Technology,2018,157:202-208. doi: 10.1016/j.compscitech.2018.01.031 [4] KAUSAR A. Fabrication of short glass fiber reinforced phenol-formaldehyde-lignin and polyurethane-based composite foam: Mechanical, friability, and shape memory studies[J]. Journal of Polymer Engineering,2018,38(1):33-40. doi: 10.1515/polyeng-2016-0289 [5] QIAN C, ZHU Y, DONG Y, et al. Vapor-grown carbon nanofiber/poly(ethylene-co-vinyl acetate) composites with electrical-active two-way shape memory behavior[J]. Journal of Intelligent Material Systems and Structures,2017,28(19):2749-2756. doi: 10.1177/1045389X17698246 [6] KIM C L, LEE J J, OH Y J, et al. Smart wearable heaters with high durability, flexibility, water-repellent and shape memory characteristics[J]. Composites Science and Technology,2017,152:173-180. doi: 10.1016/j.compscitech.2017.09.023 [7] HERATH H M C M, EPAARACHCHI J A, ISLAM M M, et al. Structural performance and photothermal recovery of carbon fibre reinforced shape memory polymer[J]. Composites Science and Technology,2018,167:206-214. doi: 10.1016/j.compscitech.2018.07.042 [8] GUO Q, BISHOP C J, MEYER R A, et al. Entanglement-ased thermoplastic shape memory polymeric particles with photothermal actuation for biomedical applications[J]. ACS Applied Materials Interfaces,2018,10(16):13333-13341. doi: 10.1021/acsami.8b01582 [9] ZHANG F H, ZHANG Z C, LUO C J, et al. Remote, fast actuation of programmable multiple shape memory composites by magnetic fields[J]. Journal of Materials Chemistry C,2015,3(43):11290-11293. doi: 10.1039/C5TC02464A [10] ZE Q, KUANG X, WU S, et al. Magnetic shape memory polymers with integrated multifunctional shape manipulation[J]. Advanced Materials,2020,32(4):1906657. doi: 10.1002/adma.201906657 [11] KUANG W, MATHER P T. A latent crosslinkable PCL-based polyurethane: Synthesis, shape memory, and enzymatic degradation[J]. Journal of Materials Research,2018,33(17):2463-2476. doi: 10.1557/jmr.2018.220 [12] PAN L, XIONG Z, SONG L, et al. Synthesis and characterization of sisal fibre polyurethane network cross-linked with triple-shape memory properties[J]. New Journal of Chemistry,2018,42(9):7130-7137. doi: 10.1039/C8NJ00181B [13] BUFFINGTON S L, POSNICK B M, PAUL J, et al. Ternary polymeric composites exhibiting bulk and surface quadruple-shape memory properties[J]. Chemphyschem,2018,19(16):2014-2024. doi: 10.1002/cphc.201800389 [14] OMASTOVA M, CIKOVA E, MICUSIK M. Electrospinning of ethylene vinyl acetate/carbon nanotube nanocomposite fibers[J]. Polymers (Basel),2019,11(3):11030550. [15] REDONDO A, CHATTERJEE S, BRODARD P, et al. Melt-spun nanocomposite fibers reinforced with aligned tunicate nanocrystals[J]. Polymers (Basel),2019,11(12):11121912. [16] ANDERSSON M, JIA Q, ABELLA A, et al. Biomimetic spinning of artificial spider silk from a chimeric minispidroin[J]. Nature Chemical Biology,2017,13(3):262-264. doi: 10.1038/nchembio.2269 [17] LIU Y F, WU J L, SONG S L, et al. Thermo-mechanical properties of glass fiber reinforced shape memory polyurethane for orthodontic application[J]. Journal of Materials Science Materials in Medicine,2018,29(9):148-158. doi: 10.1007/s10856-018-6157-y [18] CHEN J, HU J, LEUNG A K L, et al. Shape memory ankle-foot orthoses[J]. ACS Applied Materials Interfaces,2018,10(39):32935-32941. doi: 10.1021/acsami.8b08851 [19] MAKSIMKIN A V, KALOSHKIN S D, ZADOROZHNYY M V, et al. Artificial muscles based on coiled UHMWPE fibers with shape memory effect[J]. Express Polymer Letters,2018,12(12):1072-1080. doi: 10.3144/expresspolymlett.2018.94 [20] ZUBAIR Z, L'HOSTIS G, GODA I. Electrical activation and shape recovery control of 3D multilayer woven shape memory polymer composite incorporating carbon fibers[J]. Materials Letters,2021,291:129511. doi: 10.1016/j.matlet.2021.129511 [21] CHEN S, HU J, YUEN C W, et al. Novel moisture-sensitive shape memory polyurethanes containing pyridine moieties[J]. Polymer,2009,50(19):4424-4428. doi: 10.1016/j.polymer.2009.07.031 [22] LIU R, KUANG X, DENG J, et al. Shape memory polymers for body motion energy harvesting and self-powered mechanosensing[J]. Advanced Materials,2018,30(8):1705195. doi: 10.1002/adma.201705195 [23] LI G, MENG H, HU J. Healable thermoset polymer composite embedded with stimuli-responsive fibres[J]. Journal of the Royal Society Interface,2012,9(77):3279-3287. doi: 10.1098/rsif.2012.0409 [24] XIAO X, HU J. Animal hairs as water-stimulated shape memory materials: Mechanism and structural networks in molecular assemblies[J]. Scientific Reports,2016,6:26393. doi: 10.1038/srep26393 [25] XIAO X, HU J, GUI X, et al. Is biopolymer hair a multi-responsive smart material?[J]. Polymer Chemistry,2017,8(1):283-294. doi: 10.1039/C6PY01283C [26] AGNARSSON I, DHINOJWALA A, SAHNI V, et al. Spider silk as a novel high performance biomimetic muscle driven by humidity[J]. Journal Experimental Biology,2009,212(13):1990-1994. doi: 10.1242/jeb.028282 [27] LIU Z Q, JIAO D, ZHANG Z F. Remarkable shape memory effect of a natural biopolymer in aqueous environment[J]. Biomaterials,2015,65:13-21. doi: 10.1016/j.biomaterials.2015.06.032 [28] HU J, IRFAN I M, SUN F. Wool can be cool: Water-actuating woolen knitwear for both hot and cold[J]. Advanced Functional Materials,2020,30(51):2005033. doi: 10.1002/adfm.202005033 [29] SONG Y X, RONG M Z, ZHANG M Q. Improvement of multiple-responsive shape memory effects of wool through increasing the content of disulfide bonds[J]. Polymer,2020,188:122130. doi: 10.1016/j.polymer.2019.122130 [30] DOU Y, WANG Z P, HE W, et al. Artificial spider silk from ion-doped and twisted core-sheath hydrogel fibres[J]. Nature Communication,2019,10(1):5293. doi: 10.1038/s41467-019-13257-4 [31] HU J, ZHU Y. Spider silk: A smart biopolymer with water switchable shape memory effects-unraveling the mystery of superconraction[J]. Research Journal of Textile and Apparel,2013,17(2):1-9. doi: 10.1108/RJTA-17-02-2013-B001 [32] BLACKLEDGE T A, BOUTRY C, WONG S C, et al. How super is supercontraction persistent versus cyclic responses to humidity in spider dragline silk[J]. Journal Experimental Biology,2009,212(13):1981-1989. doi: 10.1242/jeb.028944 [33] VENKATESAN H, CHEN J, LIU H, et al. Artificial spider silk is smart like natural one: Having humidity-sensitive shape memory with superior recovery stress[J]. Materials Chemistry Frontiers,2019,3(11):2472-2482. doi: 10.1039/C9QM00261H [34] VENKATESAN H, CHEN J, LIU H, et al. A spider-capture-silk-like fiber with extremely high-volume directional water collection[J]. Advanced Functional Materials,2020,30(30):2002437. doi: 10.1002/adfm.202002437 [35] PARK M, KIM Y, HWANG J O, et al. Shape recovery characteristics of shape memory epoxy composites reinforced with chopped carbon fibers[J]. Carbon Letters,2019,29(3):219-224. doi: 10.1007/s42823-019-00031-1 [36] LIU Y, GUO Y, ZHAO J, et al. Carbon fiber reinforced shape memory epoxy composites with superior mechanical performances[J]. Composites Science and Technology,2019,177:49-56. doi: 10.1016/j.compscitech.2019.04.014 [37] LIU L L, ZHOU Q, LI M. Thermal and electroactive shape memory behaviors of polyvinyl alcohol/short carbon fiber composites[J]. Polymer Science, Series A,2020,61(6):913-921. [38] YAN Y, XIA H, QIU Y, et al. Fabrication of gradient vapor grown carbon fiber based polyurethane foam for shape memory driven microwave shielding[J]. RSC Advances,2019,9(17):9401-9409. doi: 10.1039/C9RA00028C [39] ZHU J, FANG G, CAO Z, et al. A self-folding dynamic covalent shape memory epoxy and its continuous glass fiber composite[J]. Industrial & Engineering Chemistry Research,2018,57(15):5276-5281. [40] ABISHERA R, VELMURUGAN R, GOPAL K V N. Shape memory behavior of cold-programmed carbon fiber reinforced CNT/epoxy composites[J]. Materials Research Express,2018,5(8):085603. doi: 10.1088/2053-1591/aaa60c [41] PARK S, BAUGH N, SHAH H K, et al. Ultrastretchable elastic shape memory fibers with electrical conductivity[J]. Advanced Science,2019,6(21):1901579. doi: 10.1002/advs.201901579 [42] XIA Y, HE Y, ZHANG F, et al. A review of shape memory polymers and composites: mechanisms, materials, and applications[J]. Advanced Materials,2021,33(6):2000713. doi: 10.1002/adma.202000713 [43] LI F, SCARPA F, LAN X, et al. Bending shape recovery of unidirectional carbon fiber reinforced epoxy-based shape memory polymer composites[J]. Composites Part A: Applied Science and Manufacturing,2019,116:169-179. doi: 10.1016/j.compositesa.2018.10.037 [44] KWOK N, HAHN H T. Resistance eating for self-healing composites[J]. Journal of Composite Materials,2016,41(13):1635-1654. [45] XU X, FAN P, REN J, et al. Self-healing thermoplastic polyurethane (TPU)/polycaprolactone (PCL) /multi-wall carbon nanotubes (MWCNTs) blend as shape-memory composites[J]. Composites Science and Technology,2018,168:255-262. doi: 10.1016/j.compscitech.2018.10.003 [46] HAN B, ZHANG Y L, CHEN Q D, et al. Carbon-based photothermal actuators[J]. Advanced Functional Materials,2018,28(40):1802235. doi: 10.1002/adfm.201802235 [47] LU H, LIU Y, GOU J, et al. Surface coating of multi-walled carbon nanotube nanopaper on shape-memory polymer for multifunctionalization[J]. Composites Science and Technology,2011,71(11):1427-1434. doi: 10.1016/j.compscitech.2011.05.016 [48] SUN H, LIU H, WU Y. Three-dimensional (3D) crumpled graphene-silver hybrid nanostructures on shape memory polymers for surface-enhanced Raman scattering[J]. Applied Surface Science,2019,467-468:554-560. doi: 10.1016/j.apsusc.2018.09.228 [49] LENG J S, HUANG W M, LAN X, et al. Significantly reducing electrical resistivity by forming conductive Ni chains in a polyurethane shape-memory polymer/carbon-black composite[J]. Applied Physics Letters,2008,92(20):204101. doi: 10.1063/1.2931049 [50] ZHANG F, XIA Y, WANG L, et al. Conductive shape memory microfiber membranes with core-shell structures and electroactive performance[J]. ACS Applied Materials Interfaces,2018,10(41):35526-35532. doi: 10.1021/acsami.8b12743 [51] LIN L, ZHOU Q, LI M. A thermally and electrically shape memory polymer prepared by a novel electro-mixed fusion preparation method[J]. Materials Letters,2019,256:126574. doi: 10.1016/j.matlet.2019.126574 [52] GONG X, XIE F, LIU L, et al. Electro-active variable-stiffness corrugated structure based on shape-memory polymer composite[J]. Polymers (Basel),2020,12(2):12020387. [53] LI X, WANG L, ZHANG Z, et al. Electroactive high-temperature shape memory polymers with high recovery stress induced by ground carbon fibers[J]. Macromolecular Chemistry and Physics,2019,220(17):1900164. doi: 10.1002/macp.201900164 [54] WANG Y, CHEN Z, NIU J, et al. Electrically responsive shape memory composites using silver plated chopped carbon fiber[J]. Frontiers in Chemisty,2020,8:322-352. doi: 10.3389/fchem.2020.00322 [55] DORIGATO A, PEGORETTI A. Shape memory epoxy nanocomposites with carbonaceous fillers and in-situ generated silver nanoparticles[J]. Polymer Engineering and Science,2018,59(4):694-703. [56] KOERNER H, PRICE G, PEARCE N A, et al. Remotely actuated polymer nanocomposites—stress-recovery of carbon-nanotube-filled thermoplastic elastomers[J]. Nature Materials,2004,3(2):115-120. doi: 10.1038/nmat1059 [57] CHO J W, KIM J W, JUNG Y C, et al. Electroactive shape-memory polyurethane composites incorporating carbon nanotubes[J]. Macromolecular Rapid Communications,2005,26(5):412-416. doi: 10.1002/marc.200400492 [58] FARHAN M, CHAUDHARY D, NöCHEL U, et al. Electrical actuation of coated and composite fibers based on poly[ethylene-co-(vinyl acetate)][J]. Macromolecular Materials and Engineering,2020,306(2):200579. [59] YU L, ZHANG T, WANG W, et al. Carbon fiber fabric/epoxy composites with electric- and light-responsive shape memory effect[J]. Pigment & Resin Technology, 2020, ahead-of-print(ahead-of-print). [60] LU H, YAO Y, HUANG W M, et al. Significantly improving infrared light-induced shape recovery behavior of shape memory polymeric nanocomposite via a synergistic effect of carbon nanotube and boron nitride[J]. Composites Part B: Engineering,2014,62:256-261. doi: 10.1016/j.compositesb.2014.03.007 [61] FENG Y, QIN M, GUO H, et al. Infrared-actuated recovery of polyurethane filled by reduced graphene oxide/carbon nanotube hybrids with high energy density[J]. ACS Applied Materials Interfaces,2013,5(21):10882-10888. doi: 10.1021/am403071k [62] HU Z, SHAO Q, HUANG Y, et al. Light triggered interfacial damage self-healing of poly(p-phenylene benzobisoxazole) fiber composites[J]. Nanotechnology,2018,29(18):185602. doi: 10.1088/1361-6528/aab010 [63] BAI Y, ZHANG J, CHEN X. A thermal-, water-, and near-infrared light-induced shape memory composite based on polyvinyl alcohol and polyaniline fibers[J]. ACS Applied Materials Interfaces,2018,10(16):14017-14025. doi: 10.1021/acsami.8b01425 [64] PANG X, QIN L, XU B, et al. Ultralarge contraction directed by light-driven unlocking of prestored strain energy in linear liquid crystal polymer fibers[J]. Advanced Functional Materials,2020,30(32):2002451. doi: 10.1002/adfm.202002451 [65] ZHANG Q, KRATZ K, LENDLEIN A. Shape-memory properties of degradable electrospun scaffolds based on hollow microfibers[J]. Polymers for Advanced Technologies,2015,26(12):1468-1475. doi: 10.1002/pat.3630 [66] ZHANG Q, RUDOLPH T, BENITEZ A J, et al. Temperature-controlled reversible pore size change of electrospun fibrous shape-memory polymer actuator based meshes[J]. Smart Materials and Structures,2019,28(5):14017-14025. [67] BAO M, LOU X, ZHOU Q, et al. Electrospun biomimetic fibrous scaffold from shape memory polymer of PDLLA-co-TMC for bone tissue engineering[J]. ACS Applied Materials Interfaces,2014,6(4):2611-2621. doi: 10.1021/am405101k [68] TIPDUANGTA P, BELTON P, FABIAN L, et al. Electrospun polymer blend nanofibers for tunable drug delivery: The role of transformative phase separation on controlling the release rate[J]. Molecular Pharmaceutics,2016,13(1):25-39. doi: 10.1021/acs.molpharmaceut.5b00359 [69] LEONÉS A, SONSECA A, LÓPEZ D, et al. Shape memory effect on electrospun PLA-based fibers tailoring their thermal response[J]. European Polymer Journal,2019,117:217-226. doi: 10.1016/j.eurpolymj.2019.05.014 [70] IREGUI A, IRUSTA L, MARTIN L, et al. Analysis of the process parameters for obtaining a stable electrospun process in different composition epoxy/poly epsilon-caprolactone blends with shape memory properties[J]. Polymers (Basel),2019,11(3):11030475. [71] ROBERTSON J M, BIRJANDI N H, MATHER P T. Dual-spun shape memory elastomeric composites[J]. ACS Macro Letters,2015,4(4):436-440. doi: 10.1021/acsmacrolett.5b00106 [72] SABZI M, RANJBAR M M, ZHANG Q, et al. Designing triple-shape memory polymers from a miscible polymer pair through dual-electrospinning technique[J]. Journal of Applied Polymer Science,2019,136(19):47471. doi: 10.1002/app.47471 [73] SÁENZ-PÉREZ M, BASHIR T, LAZA J M, et al. Novel shape-memory polyurethane fibers for textile applications[J]. Textile Research Journal,2018,89(6):1027-1037. [74] DEHAGHANI M Z, KAFFASHI B. Shape memory thin films of polyurethane: Synthesis, characterization, and recovery behavior[J]. Journal of Applied Polymer Science,2020,137(47):49547. doi: 10.1002/app.49547 [75] GARCES I T, ASLANZADEH S, BOLUK Y, et al. Effect of moisture on shape memory polyurethane polymers for extrusion-based additive manufacturing[J]. Materials (Basel),2019,12(2):12020244. [76] LIU N, ZHAO Y, KANG M, et al. The effects of the molecular weight and structure of polycarbonatediols on the properties of waterborne polyurethanes[J]. Progress in Organic Coatings,2015,82:46-56. doi: 10.1016/j.porgcoat.2015.01.015 [77] AHMAD M, XU B, PURNAWALI H, et al. High performance shape memory polyurethane synthesized with high molecular weight polyol as the soft segment[J]. Applied Sciences,2012,2(2):535-548. doi: 10.3390/app2020535 [78] QI X, YANG W, YU L, et al. Design of ethylene-vinyl acetate copolymer fiber with two-way shape memory effect[J]. Polymers (Basel),2019,11(10):11101599. [79] QIAN C, DONG Y, ZHU Y, et al. Two-way shape memory behavior of semi-crystalline elastomer under stress-free condition[J]. Smart Materials and Structures,2016,25(8):085023. doi: 10.1088/0964-1726/25/8/085023 [80] MENG Q, HU J, ZHU Y, et al. Biological evaluations of a smart shape memory fabric[J]. Textile Research Journal,2009,79(16):1522-1533. doi: 10.1177/0040517509101789 [81] ZHU Y, HU J, YEUNG L Y, et al. Effect of steaming on shape memory polyurethane fibers with various hard segment contents[J]. Smart Materials and Structures,2007,16(4):969-981. doi: 10.1088/0964-1726/16/4/004 [82] ASLAN S, KAPLAN S. Thermomechanical and shape memory performances of thermo-sensitive polyurethane fibers[J]. Fibers and Polymers,2018,19(2):272-280. doi: 10.1007/s12221-018-7127-6 [83] RISING A, JOHANSSON J. Toward spinning artificial spider silk[J]. Nature Chemical Biology,2015,11(5):309-315. doi: 10.1038/nchembio.1789 [84] MORTIMER B, GUAN J, HOLLAND C, et al. Linking naturally and unnaturally spun silks through the forced reeling of bombyx mori[J]. Acta Biomaterialia,2015,11:247-255. doi: 10.1016/j.actbio.2014.09.021 [85] ZHANG F, LU Q, YUE X, et al. Regeneration of high-quality silk fibroin fiber by wet spinning from CaCl2-formic acid solvent[J]. Acta Biomaterialia,2015,12:139-145. doi: 10.1016/j.actbio.2014.09.045 [86] KOEPPEL A, HOLLAND C. Progress and trends in artificial silk spinning: a systematic eeview[J]. ACS Biomaterials Science and Engineering,2017,3(3):226-237. doi: 10.1021/acsbiomaterials.6b00669 [87] CHENG X, CHEN Y, DAI S, et al. Bending shape memory behaviours of carbon fibre reinforced polyurethane-type shape memory polymer composites under relatively small deformation: characterisation and computational simulation[J]. Journal of the Mechanical Behavior of Biomedical Materials,2019,100:103372. doi: 10.1016/j.jmbbm.2019.103372 [88] ZHOU W C, TAN P F, CHEN X H, et al. Berberine-incorporated shape memory fiber applied as a novel surgical suture[J]. Frontiers in Pharmacology,2019,10:1506. [89] YIN X, TAN P, LUO H, et al. Study on the release behaviors of berberine hydrochloride based on sandwich nanostructure and shape memory effect[J]. Materials Science and Engineering C,2020,109:110541. doi: 10.1016/j.msec.2019.110541 [90] LV H, TANG D, SUN Z, et al. Electrospun PCL-based polyurethane/HA microfibers as drug carrier of dexamethasone with enhanced biodegradability and shape memory performances[J]. Colloid and Polymer Science,2019,298(1):103-111. [91] HAN Y, HU J, CHEN X. A skin inspired bio-smart composite with water responsive shape memory ability[J]. Materials Chemistry Frontiers,2019,3(6):1128-1138. doi: 10.1039/C9QM00114J [92] WALCZAK J, SOBOTA M, CHRZANOWSKI M, et al. Application of the melt-blown technique in the production of shape-memory nonwoven fabrics from a blend of poly(L-lactide) and atactic poly[(R, S)-3-hydroxy butyrate][J]. Textile Research Journal,2017,88(18):2141-2152. [93] MAKSIMKIN A V, LARIN I I, CHUKOV D I, et al. Coiled artificial muscles based on UHMWPE with large muscle stroke[J]. Materials Today Communications,2019,21:100688. doi: 10.1016/j.mtcomm.2019.100688 [94] SONG Y, ZHOU S, JIN K, et al. Hierarchical carbon nanotube composite yarn muscles[J]. Nanoscale,2018,10(8):4077-4084. doi: 10.1039/C7NR08595H [95] DUAN X, YU J, ZHU Y, et al. Large-scale spinning approach to engineering knittable hydrogel fiber for soft robots[J]. ACS Nano,2020,14(11):14929-14938. doi: 10.1021/acsnano.0c04382 [96] WEI H, CAUCHY X, NAVAS I O, et al. Direct 3D printing of hybrid nanofiber-based nanocomposites for highly conductive and shape memory applications[J]. ACS Applied Material Interfaces,2019,11(27):24523-24532. doi: 10.1021/acsami.9b04245 [97] REN L, LI B, SONG Z, et al. Bioinspired fiber-regulated composite with tunable permanent shape and shape memory properties via 3d magnetic printing[J]. Composites Part B: Engineering,2019,164:458-466. doi: 10.1016/j.compositesb.2019.01.061 [98] XU Z, DING C, WEI D W, et al. Electro and light-active actuators based on reversible shape-memory polymer composites with segregated conductive networks[J]. ACS Applied Material Interfaces,2019,11(33):30332-30340. doi: 10.1021/acsami.9b10386 [99] SUN J, LIU Y, LENG J. Mechanical properties of shape memory polymer composites enhanced by elastic fibers and their application in variable stiffness morphing skins[J]. Journal of Intelligent Material Systems and Structures,2014,26(15):2020-2027. [100] REN T, ZHU G, LIU Y, et al. An investigation on electro-induced shape memory performances of CE/EP/CB/SCF composites applied for deployable structure[J]. Journal of Polymer Engineering,2020,40(3):203-210. doi: 10.1515/polyeng-2019-0212 [101] JANG J H, HONG S B, KIM J G, et al. Long-term properties of carbon fiber-reinforced shape memory epoxy/polymer composites exposed to vacuum and ultraviolet radiation[J]. Smart Materials and Structures,2019,28(11):115013. doi: 10.1088/1361-665X/ab3fda [102] WANG L, ZHANG F, LIU Y, et al. γ-rays radiation resistant shape memory cyanate ester resin and its composites with high transition temperature[J]. Smart Materials and Structures,2019,28(7):075039. doi: 10.1088/1361-665X/ab2559 [103] HERATH H M C M, EPAARACHCHI J A, ISLAM M M, et al. Carbon fibre reinforced shape memory polymer composites for deployable space habitats[J]. Engineer,2019,52(1):1-9. doi: 10.4038/engineer.v52i1.7323 [104] MEMIS N K, KAPLAN S. Dual responsive wool fabric by cellulose nanowhisker reinforced shape memory polyurethane[J]. Journal of Applied Polymer Science,2019,137(19):48674. [105] IQBAL M I, SUN F, FEI B, et al. Knit architecture for water-actuating woolen knitwear and its personalized thermal management[J]. ACS Applied Materials Interfaces,2021,13(5):6298-6308. doi: 10.1021/acsami.0c20868 [106] GUPTA P, GARG H, MOHANTY J, et al. Excellent memory performance of poly(1, 6-hexanediol adipate) based shape memory polyurethane filament over a range of thermo-mechanical parameters[J]. Journal of Polymer Research,2020,27(12):382-394. doi: 10.1007/s10965-020-02345-5 [107] NARAYANA H, HU J, KUMAR B, et al. Stress-memory polymeric filaments for advanced compression therapy[J]. Journal of Materials Chemistry B,2017,5(10):1905-1916. doi: 10.1039/C6TB03354G [108] PENG M, LIU C, CHEN S, et al. Development and performance study of a new shrink-proof and non-iron cotton blended fabric[J]. Textile Research Journal,2018,89(16):3269-3279. [109] PENG B, YANG Y, JU T, et al. Fused filament fabrication 4D printing of a highly extensible, self-healing, shape memory elastomer based on thermoplastic polymer blends[J]. ACS Applied Materials Interfaces,2021,13(11):12777-12788. doi: 10.1021/acsami.0c18618 [110] LUO X, MATHER P T. Shape memory assisted self-healing coating[J]. ACS Macro Letters,2013,2(2):152-156. doi: 10.1021/mz400017x [111] MADDALENA R, BONANNO L, BALZANO B, et al. A crack closure system for cementitious composite materials using knotted shape memory polymer (k-SMP) fibres[J]. Cement and Concrete Composites,2020,114:103757. doi: 10.1016/j.cemconcomp.2020.103757 [112] 苏晓斌, 王颖钰, 彭雄奇. 热驱动形状记忆聚合物及其复合材料热力学本构模型[J]. 塑性工程学报, 2020, 27(5):88-102. doi: 10.3969/j.issn.1007-2012.2020.05.011SU Xiaobin, WANG Yingyu, PENG Xiongqi. Thermo-mechanical constitutive models of thermally-induced shape memory polymers and their composites[J]. Journal of Plasticity Engineering,2020,27(5):88-102(in Chinese). doi: 10.3969/j.issn.1007-2012.2020.05.011 [113] 李郑发, 王正道. 形状记忆聚合物热力学本构模型研究进展[J]. 高分子材料科学与工程, 2009, 25(5):171-174. doi: 10.3321/j.issn:1000-7555.2009.05.049LI Zhengfa, WANG Zhengdao. Review on thermomechanical constitutive model of shape memory polymers[J]. Polymer Materials Science and Engineering,2009,25(5):171-174(in Chinese). doi: 10.3321/j.issn:1000-7555.2009.05.049 [114] 张豆, 刘彦菊, 冷劲松. 纤维增强形状记忆聚合物复合材料及其航天应用[J]. 复合材料学报, 2021, 38(3):698-711.ZHANG Dou, LIU Yanju, LENG Jinsong. Fiber reinforced shape memory polymer composites and their applications in aerospace[J]. Acta Materiae Compositae Sinica,2021,38(3):698-711(in Chinese). [115] 王正道, 李郑发, 熊志远, 等. EMC变形机理及在空间展开结构中的应用[J]. 宇航学报, 2009, 30(1):305-309. doi: 10.3873/j.issn.1000-1328.2009.00.055WANG Zhengdao, LI Zhengfa, XIONG Zhiyuan, et al. Deformation mechanism of EMC materials and applications for future deployable space structure[J]. Journal of Astronautics,2009,30(1):305-309(in Chinese). doi: 10.3873/j.issn.1000-1328.2009.00.055 -

下载:

下载: