Research progress of flexible nanocomposites for piezoresistive strain sensors

-

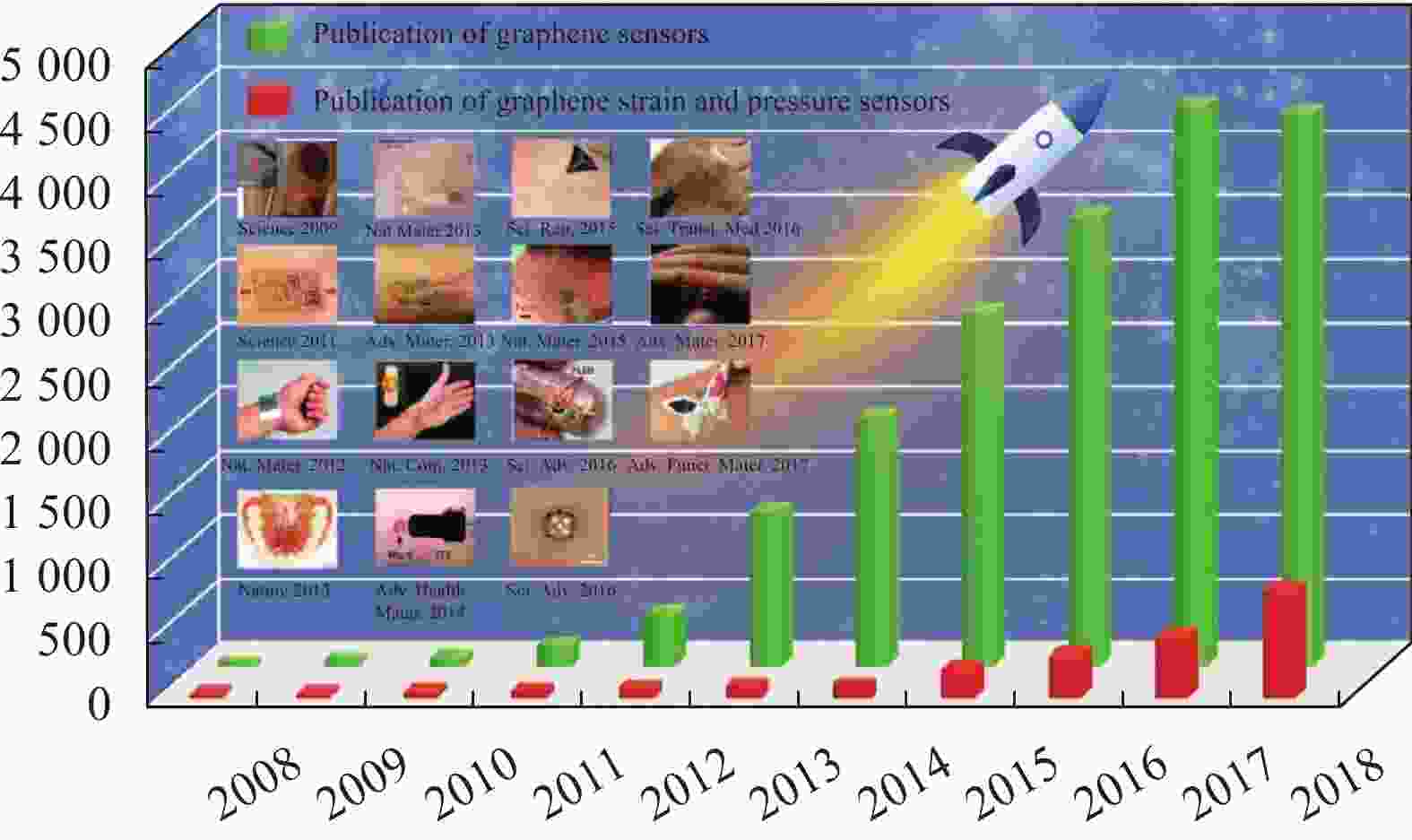

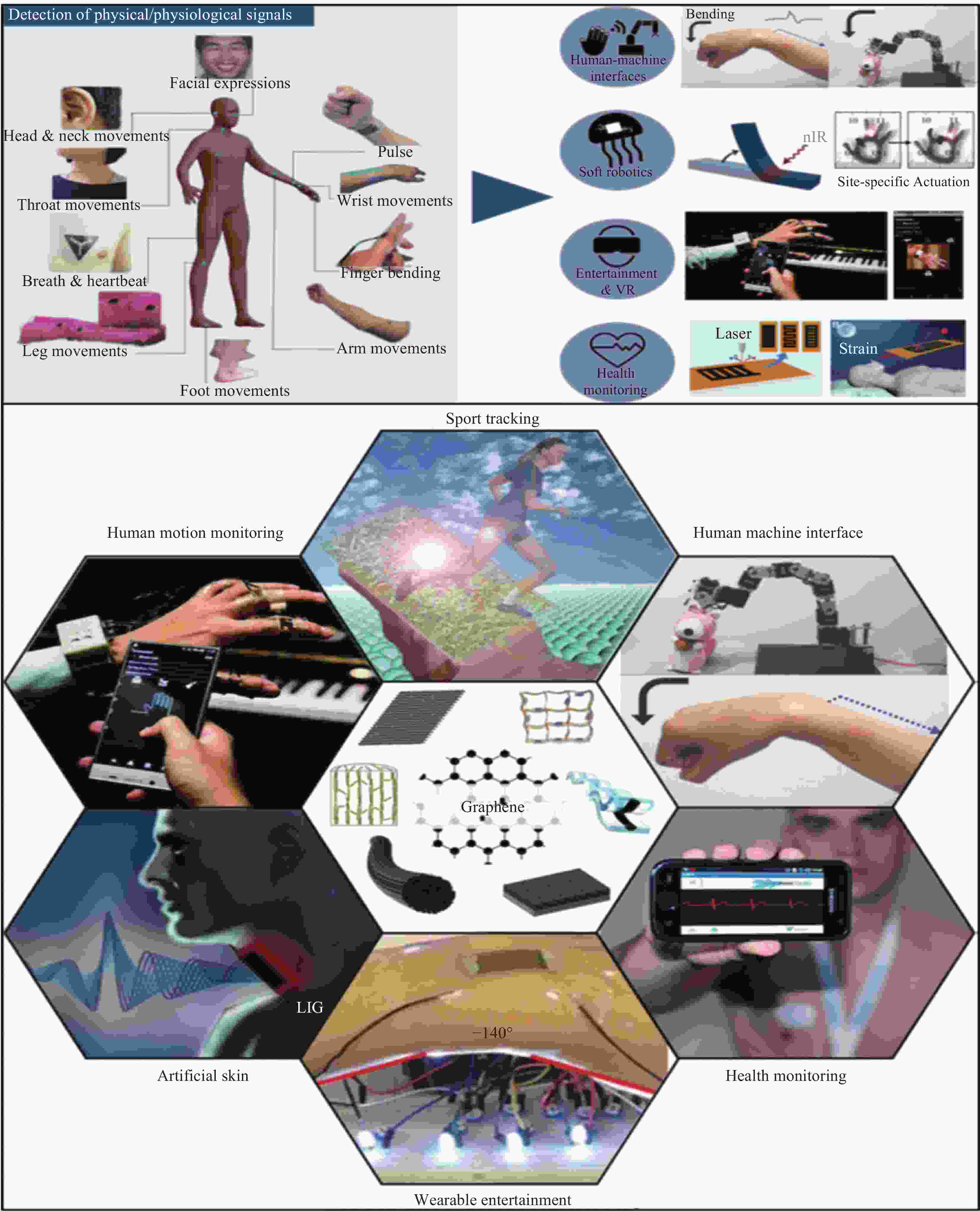

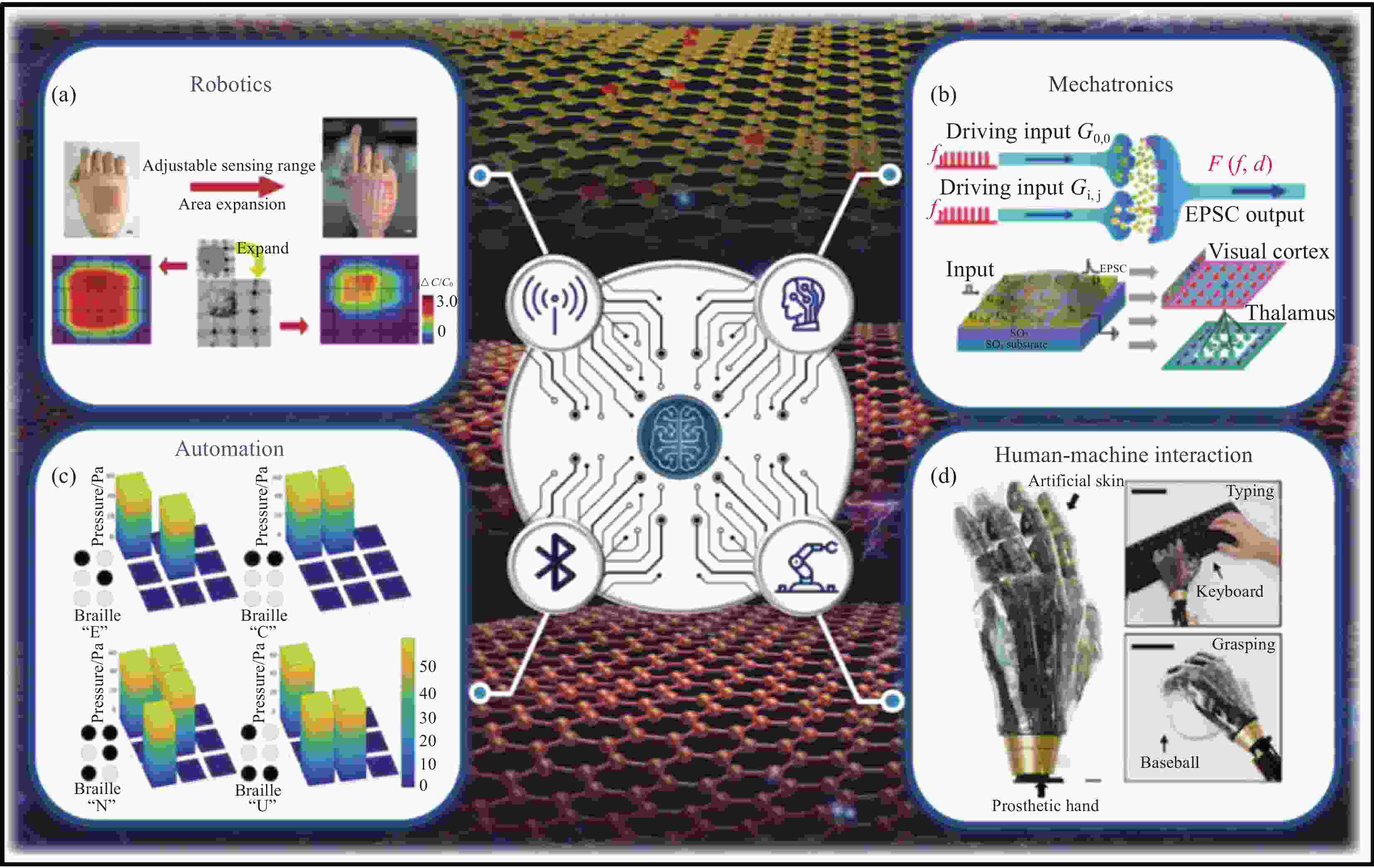

摘要: 柔性纳米复合材料,由于其优异的传感性能、良好的延展性,在压阻式应变传感器方面,受到研究者们不断的关注,主要应用于智能可穿戴,结构健康监测等领域。本文主要从结构设计、制备方法、应用前景三方面,综述了近年来国内外对复合材料压阻式应变传感器在材料选取及结构设计下传感器性能的研究成果及研究进展。首先分析了压阻式传感器的性能参数和传感机制,其次围绕材料优化选取-工艺选择与结构设计-性能与具体应用的主线,进行了深入的讨论与性能分析。由于复合材料传感器的微观导电网络结构与介观层状结构协同主导着传感性能的演变,采用有限元模拟理论与人工智能算法,对传感器的导电网络结构(形成、搭接、演化)、多尺度层状结构设计等方面进行了传感性能的调控与机制分析。最后本文探讨了柔性压阻式传感器的多功能化、信号鉴别与分离、高稳定性与低迟滞性等依然亟需突破与提升的问题,并同时总结了目前复合材料压阻式应变传感器研究工作中的重点及未来的发展方向。Abstract: Flexible nanocomposite piezoresistive strain sensors are becoming more and more attractive owing to their unprecedent merits in sensing performance and stretchability, which can be feasibly employed in the fields of wearable electronics and structural health monitoring.Inthiswork, three aspects including structural design, preparation methods and application prospects are briefly reviewed, where recent progress of composite piezoresistive strain sensors is mainly discussed by centering on materials chosen and structure configuration towards the sensing improvement. Crucial parameters in affecting the sensing performance as well as sensing mechanism have been initially analyzed in composite piezoresistive strain sensors. Subsequently, detailed discussion and analysis were performed on the recent advances of composite strain sensors by focusing on the main guideline of materials optimization-structural design/processing-performance improvement and practical applications. Recent achievements of finite element analysis (FEA) and artificial intelligence algorithm are also introduced to conduct the controlling and mechanism analysis of conductive network design (formation, overlapping and evolution) and multi-scale layered structural configuration in composite strain sensors, where both conductive network and structural configuration are playing a significant role in changing the sensing performance. Consequently, a multi-modality sensor with distinct sensing signal, high stability and low hysteresis is urgently needed to fulfill the demands of flexible nanocomposites for piezoresistive strain sensors, where main points towards future developments and future directions in composites strains sensors are also highlighted.

-

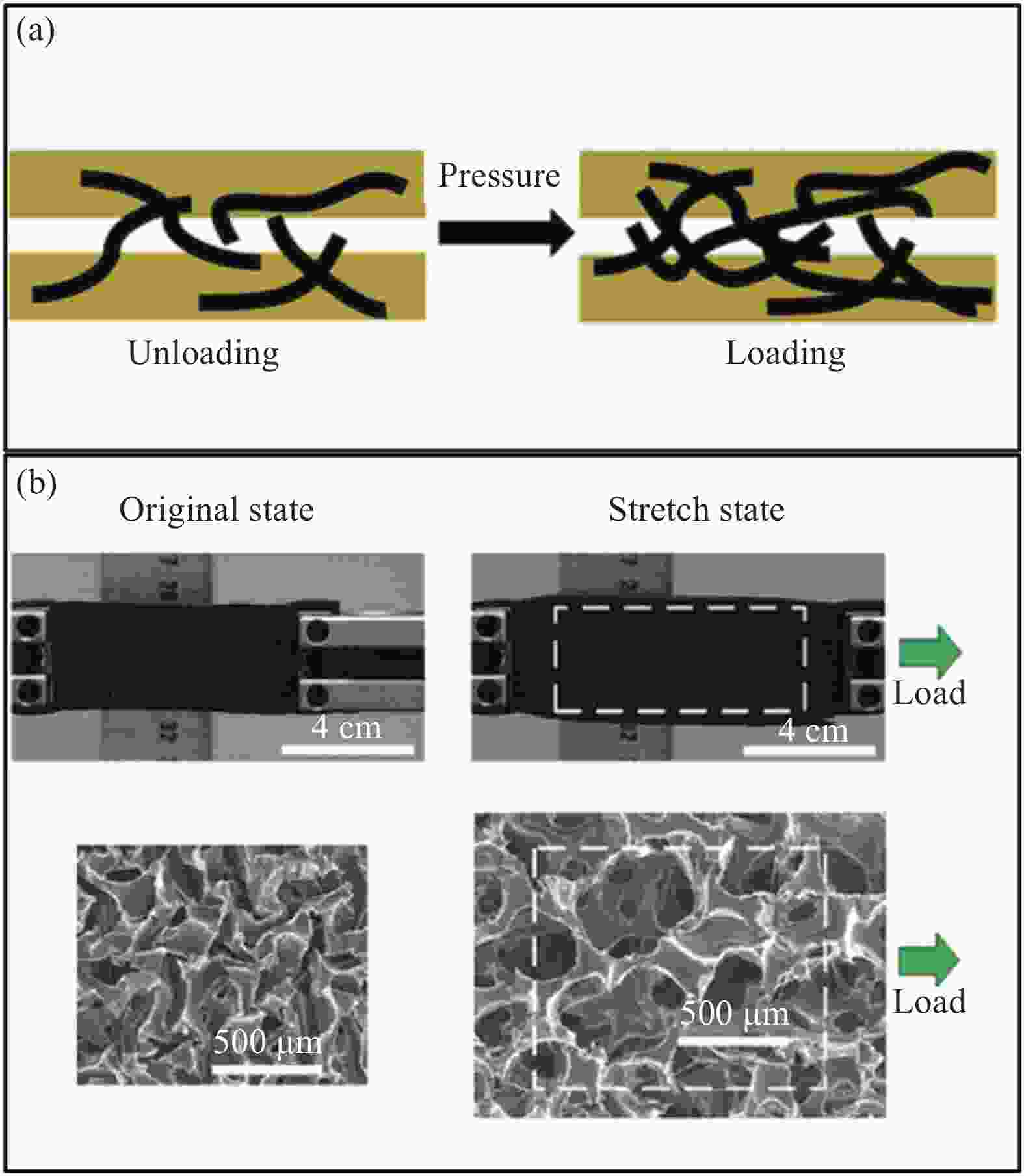

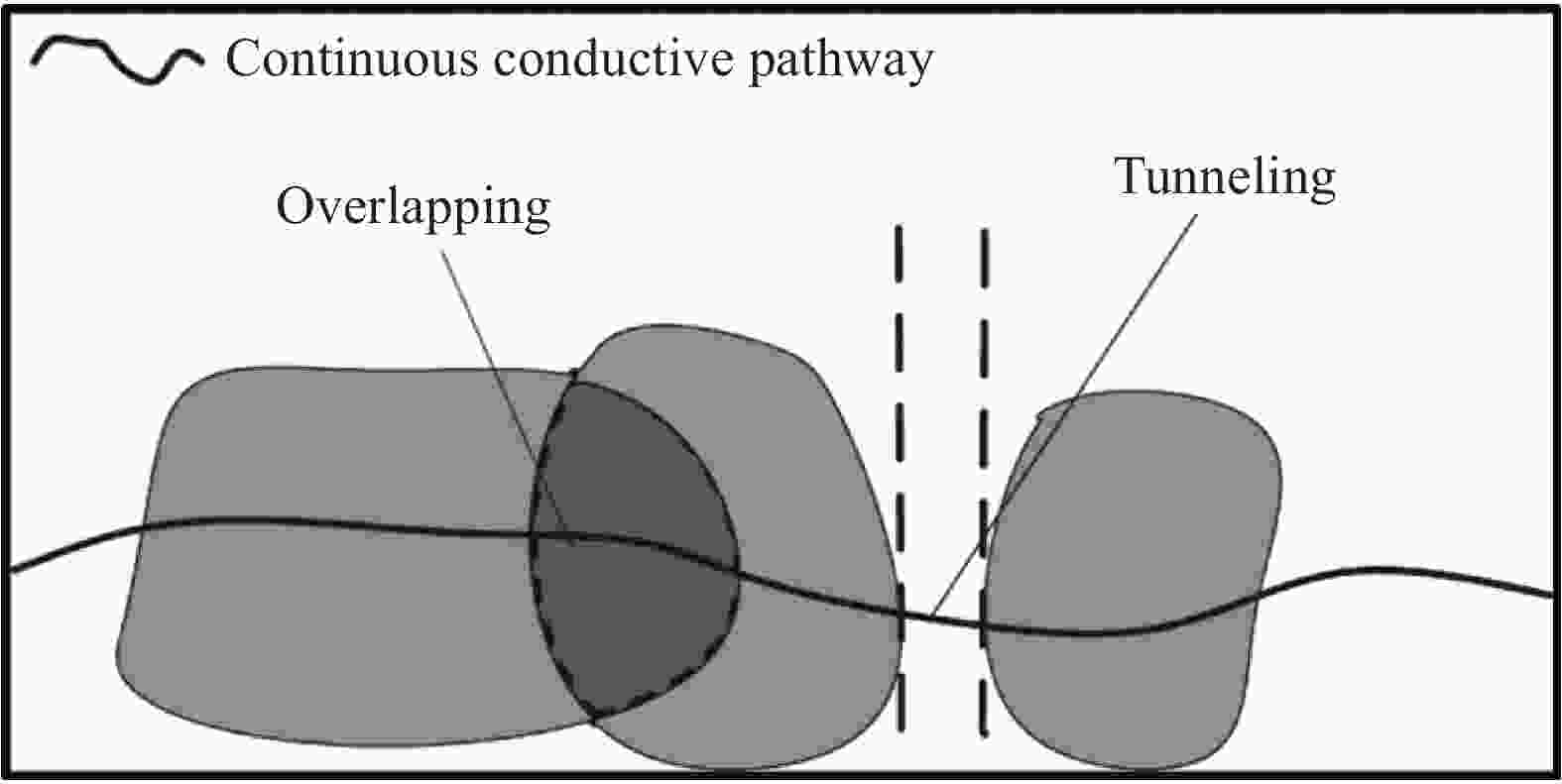

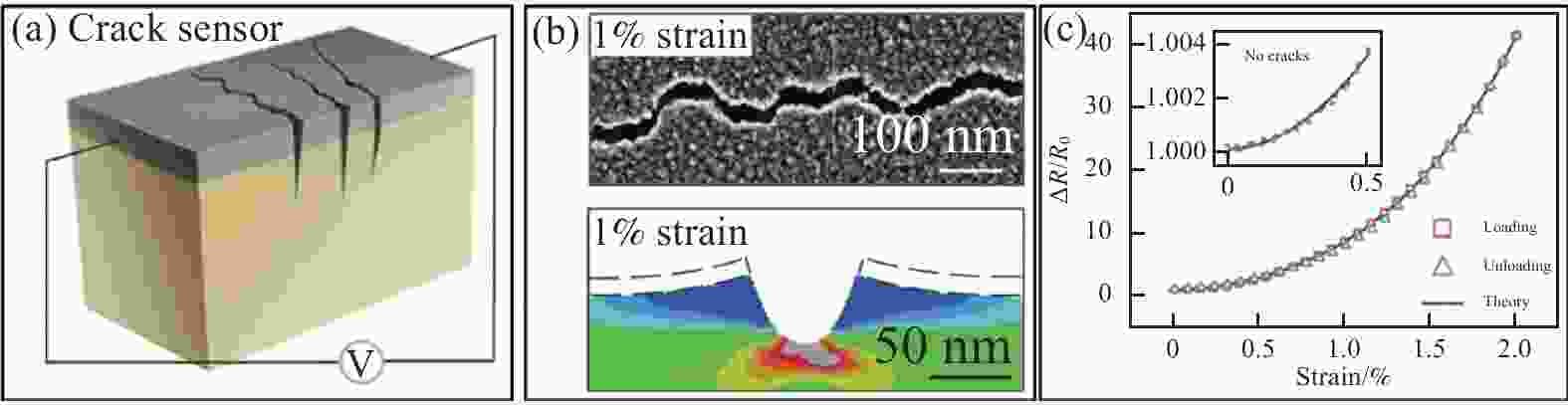

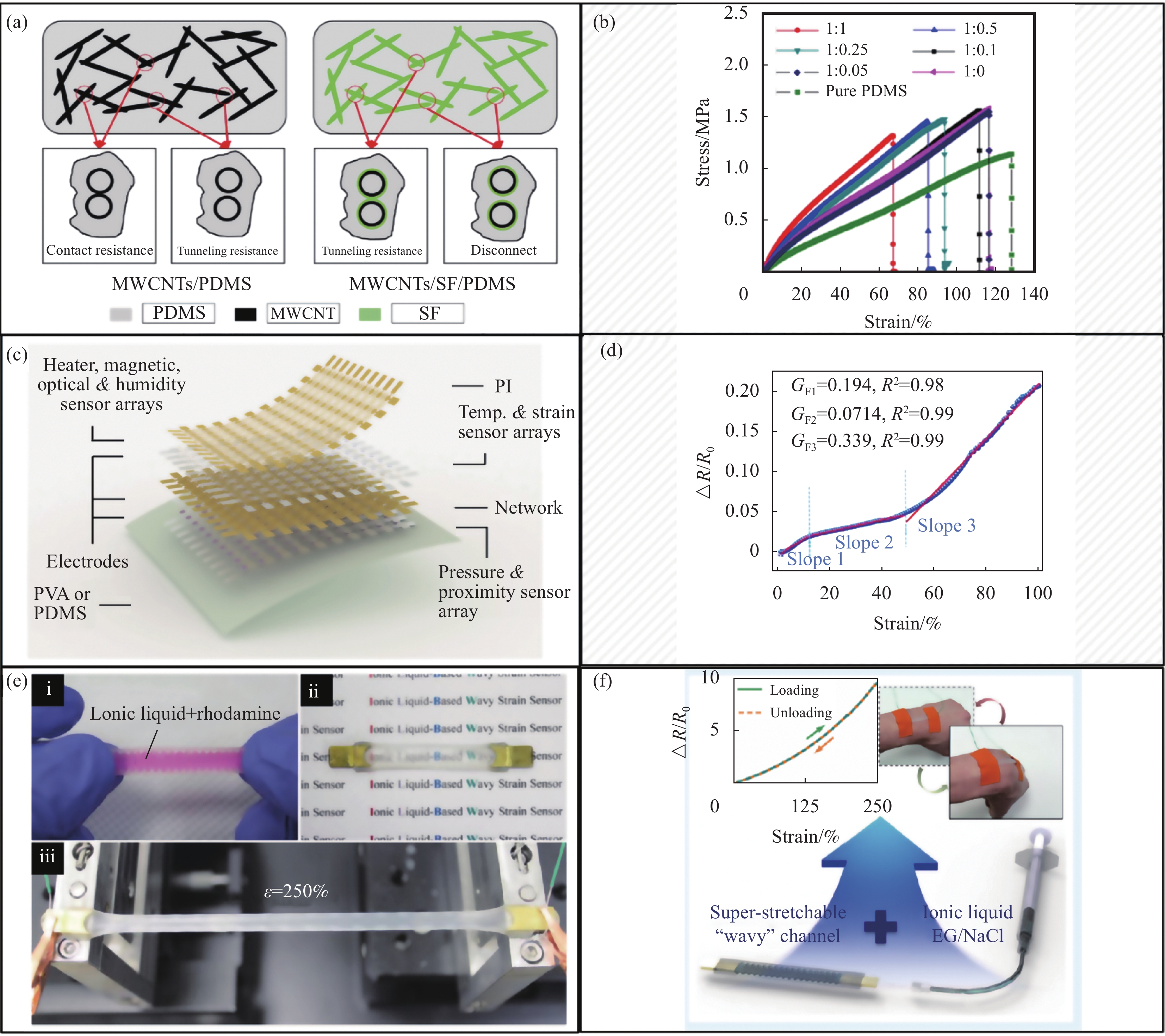

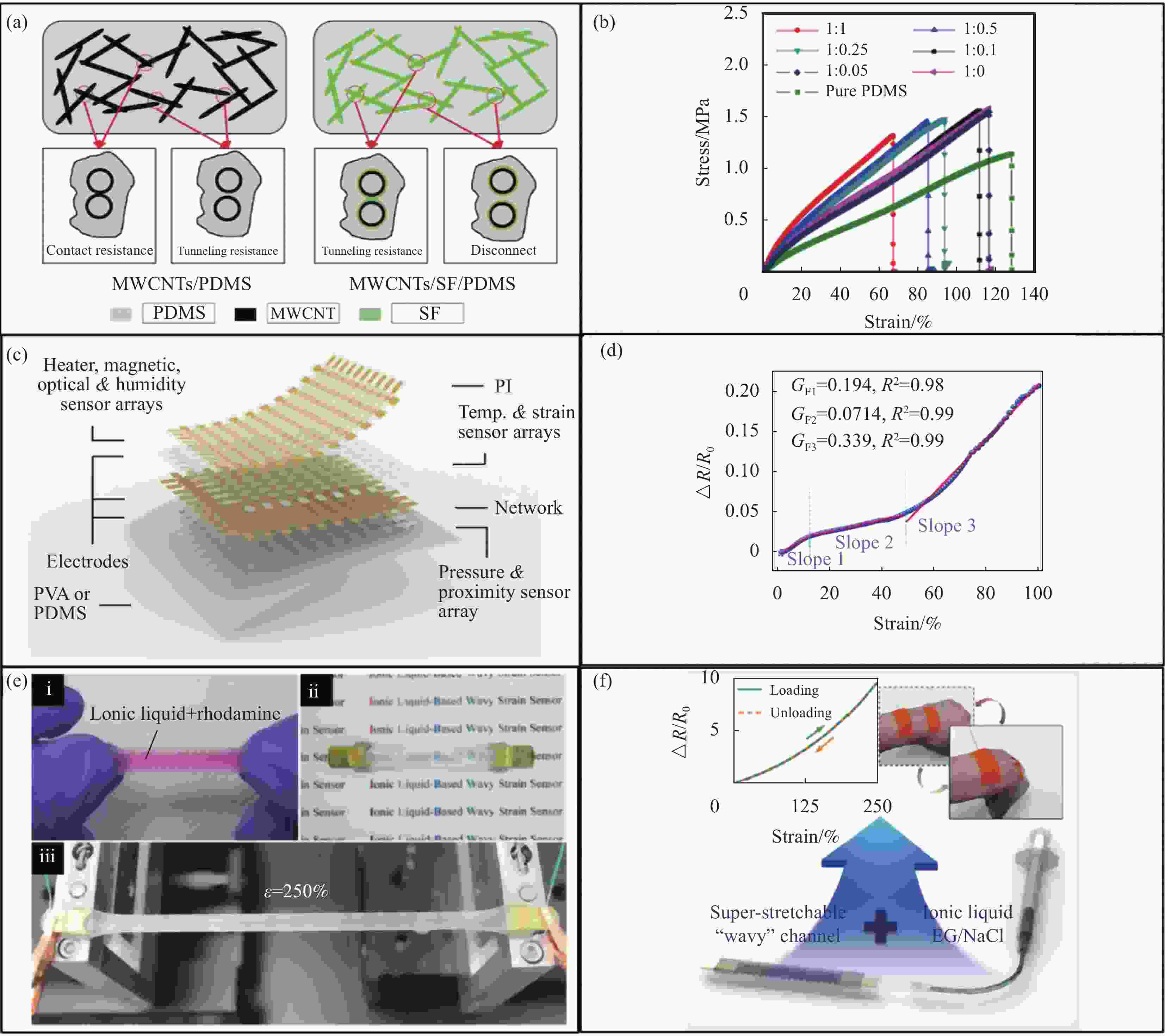

图 1 (a) 初始状态下多壁碳纳米管(MWCNTs)的空间关系和阻力类型的示意性截面图[25];(b) rGO/CNFs/PDM复合物的准静态拉伸应力-应变曲线[28];(c) 一种集成了8种功能的传感器阵列[29];(d)传感器电阻变化(ΔR/R0)vs应变(蓝线表示实验数据,红线表示分段线性拟合)[30];(e) 制备好的离子-液基波(ILBW)应变传感器的照片((i) 波浪形结构,(ii) 良好的透明度,(iii) 超拉伸性);(f) 离子-液基波型传感器的电阻响应具有较强的确定性,且无迟滞现象(图1(f)插图),与理论估计曲线吻合较好,可用于人体检测[16]

Figure 1. (a) Schematic of the initial state of the spatial relationship and resistance of multi-walled carbon nanotubes (MWCNTs) typed strain sensor[25]; (b) Quasi-static tensile stress-strain curves of rGO/CNFs/PDMS composite strain sensors[28]; (c) An integrated sensor array with multifunctionalities[29]; (d) Relative resistance (ΔR/R0) as a function of applied strain[30]; (e) Image of the prepared iron-liquid base wave (ILBW) strainsensor ((i) Wavy structure, (ii) Good transparency, (iii) Hypertension); (f) Resistance response of the ion-liquid based wave sensor has strong determinism and no hysteresis (Fig.1(f) illustration), which is in good agreement with the theoretical estimated curve and can be used for human body detection[16]

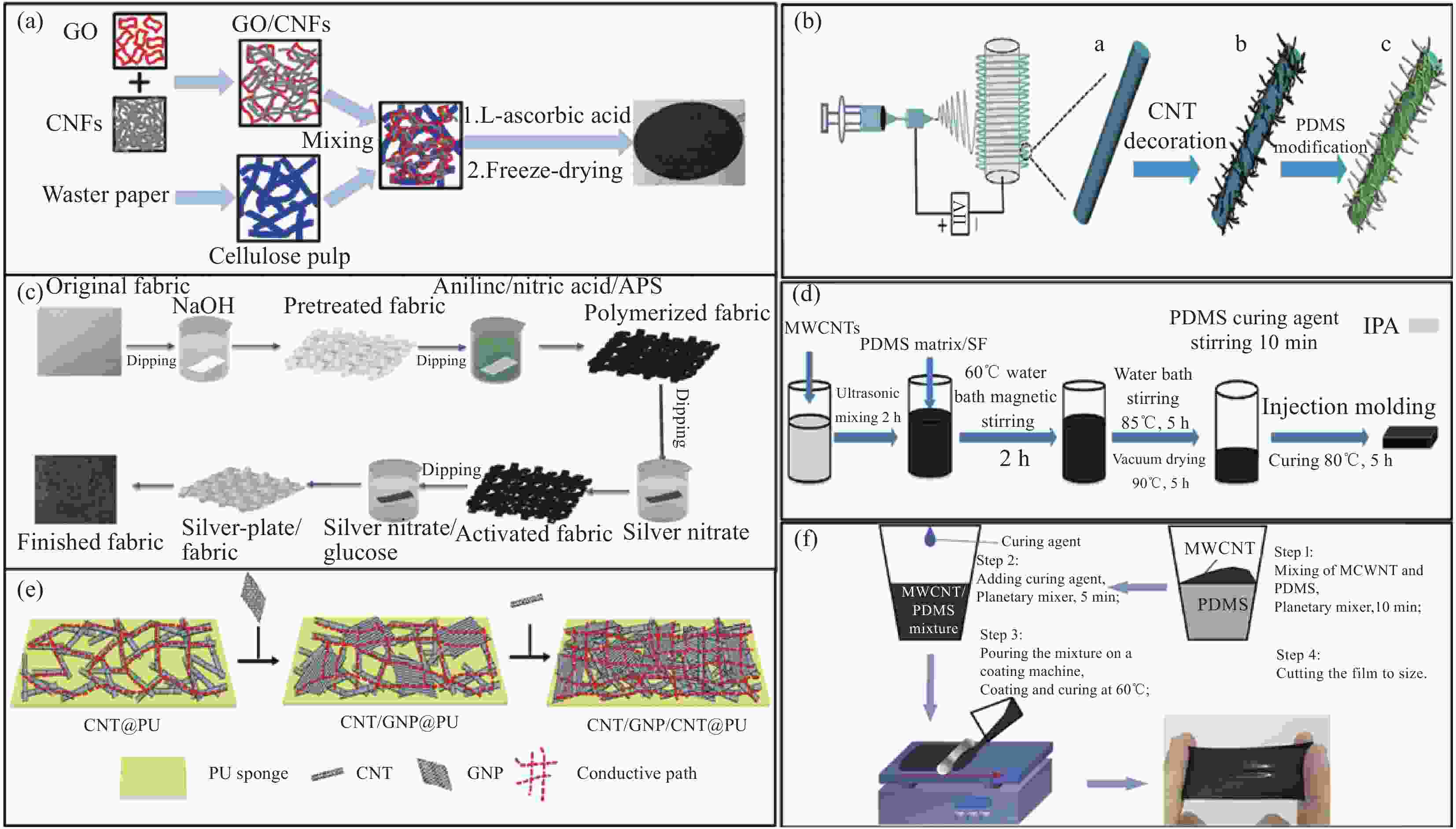

图 6 纳米复合物应变传感器的制备:(a) 氧化石墨烯(GO)与多碳纳米管混合制备纤维素/还原氧化石墨烯(RGO应变传感器的示意图[28];(b) 静电纺丝制备碳纳米管(CNTs)包覆的聚氨酯,接着用聚二甲基硅氧烷(PDMS)进行修饰,得到应变达500%的高应变传感器[30];(c) 基于棉氨纶混纺织物的化学镀银传感器,所得织物具有较高的灵敏度,灵敏因子可达26.11[49];(d) 使用压塑成型法制备的MWCNTs/硅流体(SF)/PDMS传感器示意图[25];(e) 纳米碳素/聚氨酯海绵组装而成的应变传感器结构说明图[50];(f) 通过挤压成型法制备的MWCNTs/PDMS复合薄膜的制备工艺[51]

Figure 6. Fabrication of organic-inorganic nanocomposite strain sensors: (a) Schematic diagram of a cellulose/reduced graphene oxide (RGO) strain sensor made by mixing graphene oxide (GO) with multi-carbon nanotubes[28]; (b) Coating carbon nanotubes (CNTs) with polyurethane through electrostatic spinning, followed by polydimethylsiloxane (PDMS) modification to obtain a 500% high-strain sensor[30]; (c) Electroless silver-plated sensor based on cotton/spandex blended fabric, resulting in a high sensitivity with measured gauge factor up to 26.11[49]; (d) Schematic diagram of MWCNTs/silicon fluid (SF) /PDMS sensor prepared by compression molding method[25]; (e) Diagram to illustrate the structure of the strain sensor assembled from carbon nano/ polyurethane foam[50]; (f) MWCNTs/PDMS composite films prepared by extrusion[51]

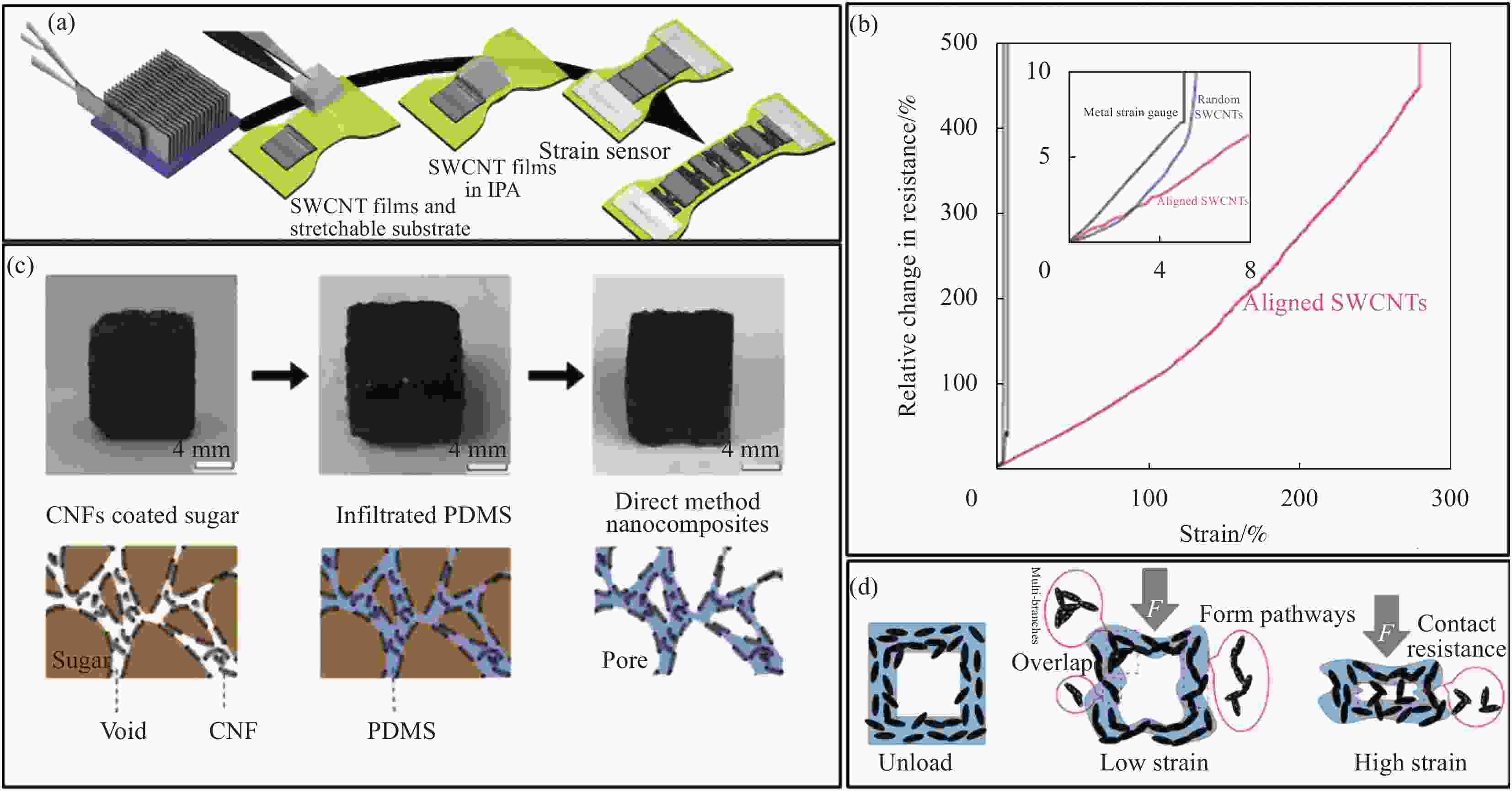

图 7 (a) 制造单壁碳纳米管(SWCNT)应变传感器的关键制备步骤;(b) 应变传感器(定向排布的SWCNTs、随机取向SWCNTs和常规金属薄膜的电阻随应变的变化[53];(c) CNF包覆糖模板制备的多孔纳米复合材料工艺示意图;(d) 低、高压缩应变下纳米复合材料的传感机制[54]

Figure 7. (a) Key preparation steps for fabrication of single-walled carbon nanotube (SWCNT) strain sensors; (b) Resistance of strain sensors (directionally arranged SWCNTs, randomly oriented SWCNTs, and conventional metal films as a function of strain[53]; (c) Process diagram of porous nanocomposites prepared by CNF coated sugar template; (d) Sensing mechanism of nanocomposites under low and high compressive strain[54]

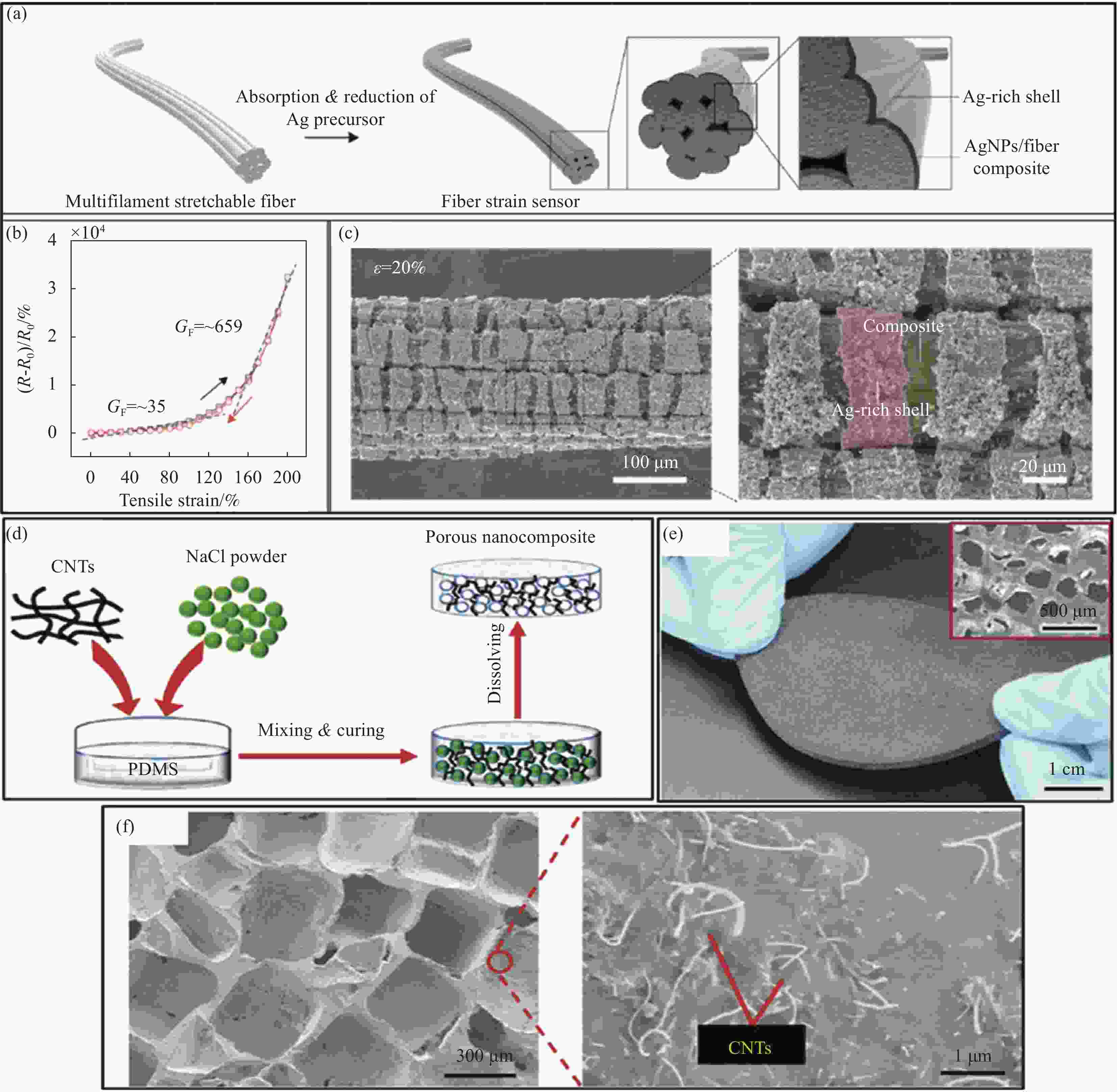

图 8 (a) 多纤维应变传感器制备工艺;(b) 应力应变曲线图;(c) 传感器在20%应变下的SEM图像[79];(d) 多孔纳米复合材料的合成结构示意图;(e) 多孔结构的微观形貌及SEM图像;(f) 多孔纳米复合材料的SEM横截面图像及扫SEM内表面放大图,显示CNTs的分布情况[80]

Figure 8. (a) Preparation process of multi-fiber strain sensor; (b) Stress-strain curves; (c) SEM images of the sensor under 20% strain[79]; (d) Synthesis structure diagram of porous nanocomposites; (e) Micromorphology of the porous structure and SEM image; (f) SEM cross-sectional images and enlarged images of the inner surface of porous nanocomposites, showing the distribution of CNTs[80]

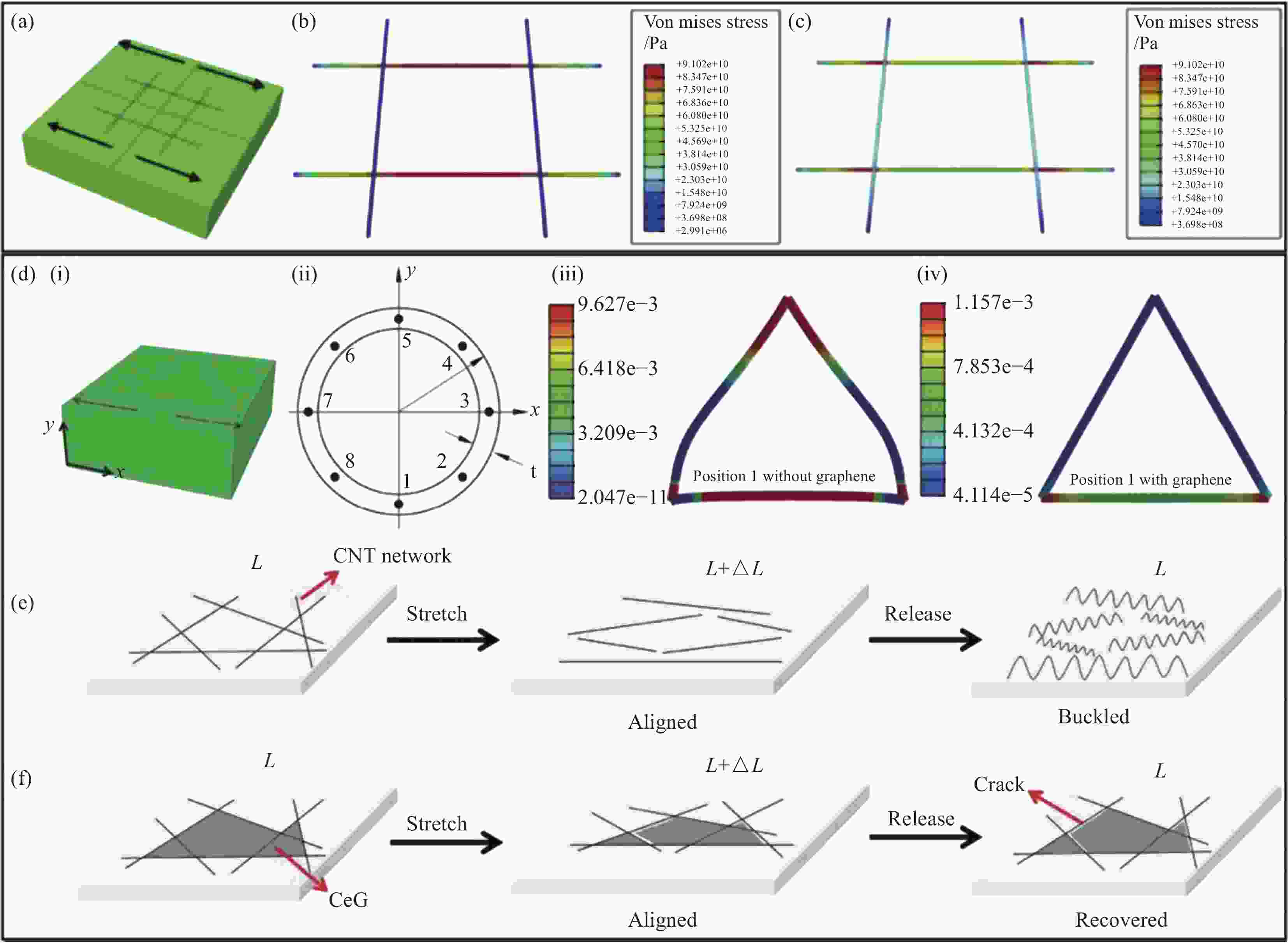

图 10 有限元分析(FEA)揭示了石墨烯与交叉堆叠CNTs阵列杂交后提升了应力传递:(a) 方形CNT网络的代表性模型,以PDMS为支撑基底,拉伸方向用箭头标注,设置与底层平行;((b)~(c)) 在石墨烯掺杂前后,米塞斯应力在方形CNTs网络中的分布。石墨烯耦合杂化CNTs(CeG)于传感器中形成的导电网络机制探究[83];(d) 石墨烯搭接结构的FEA((i) PDMS上等边三角形CNT网络单元的示意图,箭头表示拉伸应变的方向;(ii) CNTs的横截面示意图;(iii) CNTs网络与(iv)石墨烯杂化的CNT搭接在20%应变下,最大主应变在位置1处的空间分布);(e) CNTs网络的微观结构演变示意图;(f) CeG在拉伸和释放下的结构变化[84];((g)~(h)) 表示有限元分析得到单位电阻器拉伸前后I、II、III区域的最大主应变分布情况((i) 通过二维有限元分析,确定了多孔纳米复合材料在相同的应力下,不同的厚度(t=0.5 mm、t=1 mm、t=0.25 mm)最大主应变地分布状况)[82];(j) 无孔纳米复合材料在60%拉伸应变下(箭头表示加载方向)的应力分布示意图[82]

Figure 10. Finite element analysis (FEA) revealed improved stress transfer after hybridization of graphene with cross-forked stacked CNTs arrays: (a) A representative model of a square CNT network, with PDMS as the supporting substrate, stretching direction marked by arrows, set parallel to the bottom layer; ((b)-(c)) Distribution of Mises stress in a square CNTs network before and after graphene hybridization; (c) Research on the mechanism of conductive network formed by graphene-coupled hybrid CNTs (CeG) in sensors[83]; (d) FEA of graphene-bonded structures ((i) Schematic diagram of equilateral triangular CNTs network units on PDMS with arrows indicating the direction of tensile strain; (ii) Schematic diagram of cross section of CNTs; (iii) Spatial distribution of the maximum principal strain at position 1 when the network of CNTs overlaps with the graphene hybrid CNTs at 20% strain); (e) Schematic diagram of microstructure evolution of the CNTs network; (f) Structural changes of CeG under tension and release[84]; ((g)-(h)) Represent the maximum principal strain distribution in regions I, II and III before and after unit resistor stretching obtained by finite element analysis ((i) Distribution of maximum principal strain of porous nanocomposites with different thickness (t=0.5 mm, t=1 mm, t=0.25 mm) under the same stress was determined by two-dimensional finite element analysis)[82]; (j) Schematic diagram of stress distribution of nonporous nanocomposites under 60% tensile strain (arrow indicates loading direction)[82]

L—Pristine length; △L—Elongation length; εmax—Maximum principal strain

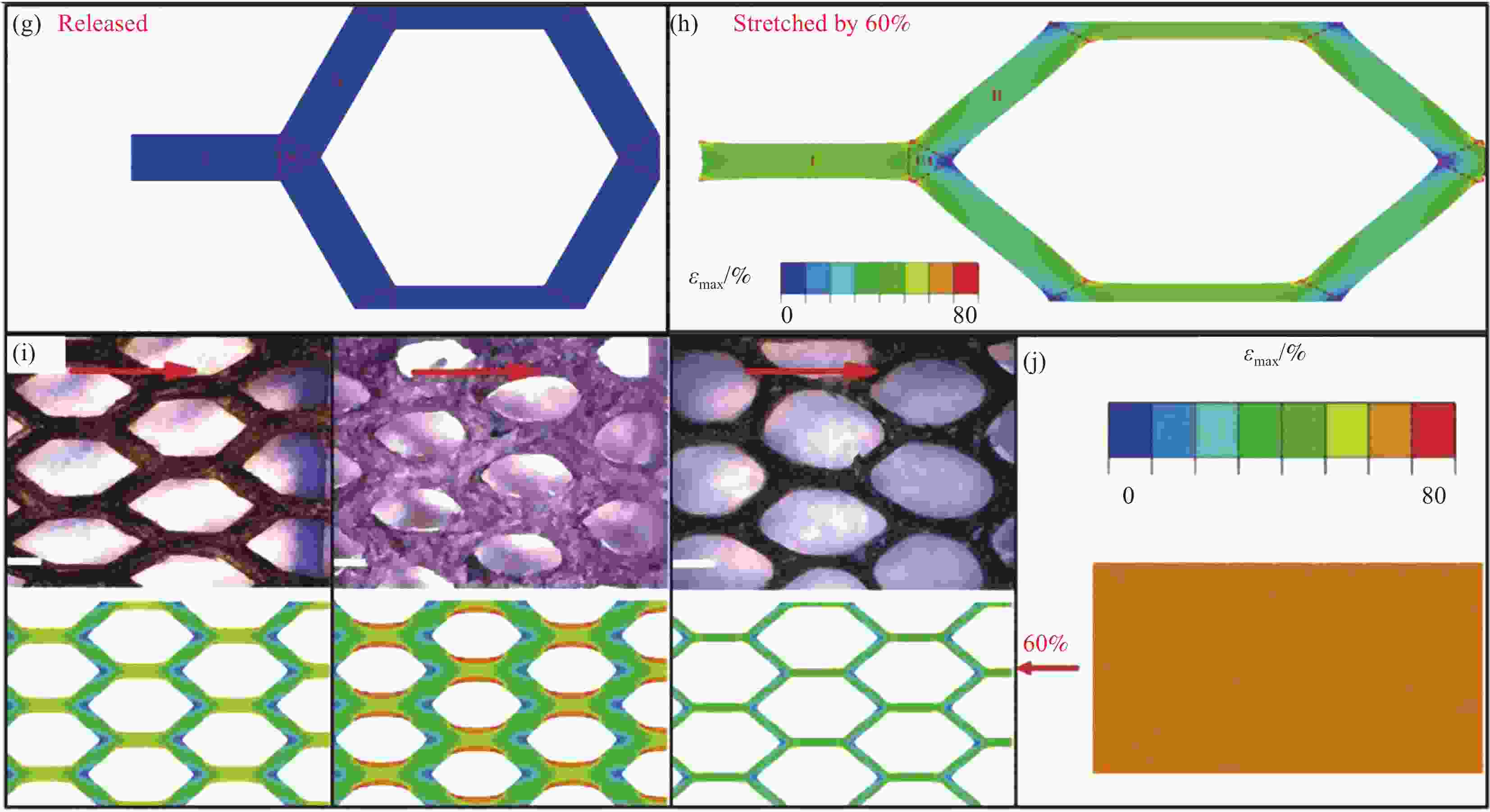

图 11 (a) 智能电子皮肤[85];(b) 人工智能中的机电一体化;(c) 盲文图智能识别交互演示,显示Gr-GO异质结构薄膜压力传感器阵列的点字式压力分布,压力阵列通过蓝牙与外部设备进行无线通信;(d) 智能电子机器手,可用于人机交互[88]

Figure 11. (a) Intelligent skin electronics[85]; (b) Mechatronics in artificial intelligence; (c) Interactive demonstration of intelligent recognition of braille pictures, the right shows the braille pressure distribution of Gr-GO heterogeneous film pressure sensor array, the pressure array communicates wirelessly with an external device via Bluetooth; (d) Intelligent electronic prosthetic hands used for human-computer interaction[88]

表 1 不同种类导电纳米材料的传感器性能传感器材料的种类选择

Table 1. Sensing properties of different sensors with a variety of conductive nanomaterials

Material type Structure characteristics Dimensionality Distribution status Impact on performance Ref Metal nanowire High aspect ratio, easy to lap 1 Most of them exist in the form of overlapping Easy to form a stable conductive network, but its sensitivity is low [41-42] Conducting polymer Light weight, good flexibility, easy to process 1 The conductive network is stable and the bonding with the substrate is general Structure of conductive network is simple and has good linearity, but there is a certain hysteresis [43] CNT/carbon fiber High specific suface area 1 Arrangement is scattered and easy to be wound One-dimensional layered overlapping, low threshold value, good sensor stability [44-45] Graphene Layered structure, good electrical conductivity 2 Not easy to be dispersed, often overlapping in the laminated form/state Composed of lamellar conductive network, good linearity,high seansitivity [46] Note: CNT—Carbon nanotube. 表 2 不同材料制备的柔性纳米复合材料压阻式应变传感器传感性能对比

Table 2. Comparison of sensing behavior in flexible organic-inorganic composite strain sensors prepared via a variety of materials

Composite materials Synthetic method Strain gauge/% Gauge factor Cyclic performance Ref SWCNT/CB/silicone rubber/PDMS Spin coating 120 1.25 1100 [62] CNT/Epoxy resin Ultrasonic dispersion/casting method <2.83 4.45 5 [63] MWCNT/silicone rubber 3D printing 300 1.5 5 [64] MWCNT/TPU 3D printing fusion deposition model/Twin screw extrusion method 100 176 10 [65] Graphene/PTFE Solvent casting 1.5 – – [66] Graphene/TPU Ultrasonic mixing method 300 17.7 20 [67] Graphene/CNT/TPU Coacervation method/

compression molding30 35.78 20 [68] Graphene/rubber Electrostatic assembly 100 82.5 300 [69] CB/

Fluorocarbon elastomerHot melt mixing method 10 14 5 [70] CB/SBS Molding method 15 3.3 6 [71] CNT/spandex Weave 0.4 80 1000 [72] Graphene oxide aerogel Dry spinning 20 5 500 [73] Graphene organic fabric/PDMS CVD/dry −400 13.68 500 [74] Graphene/PI Freeze drying method 50 0.18 2 000 [75] GO/fiber glass Dip-coating method 16400 1 - [76] PU/cotton/CNT Multilayer coating method 40 - 3000 [77] CNT/copolyester CVD 900 64 10000 [78] Notes: CB—Carbon black; PTFE—Polytetrafluoroethylene; PDMS—Polydimethylsiloxane; TPU—Thermoplastic polyurethane; GO—

Graphene oxide; PU—Polyurethane; CVD—Chemical vapor deposition. -

[1] QIU A, LI P, YANG Z, et al. A path beyond metal and silicon: Polymer/nano material composites for stretchable strain sensors[J]. Advanced Functional Materials,2019,29(17):1806306. doi: 10.1002/adfm.201806306 [2] AMJADI M, PICHITPAJONGKIT A, LEE S, et al. Highly stretchable and sensitive strain sensor based on silver nanowire-elastomer nanocomposite[J]. ACS Nano,2014,8(5):5154-5163. doi: 10.1021/nn501204t [3] ARSHAK K, MORRIS D, ARSHAK A, et al. Development of high sensitivity oxide based strain gauges and pressure sensors[J]. Journal of Materials Science-Materials in Electronics,2006,17(9):767-778. doi: 10.1007/s10854-006-0013-4 [4] BAE S H, LEE Y, SHARMA B K, et al. Graphene-based transparent strain sensor[J]. Carbon,2013,51:236-242. doi: 10.1016/j.carbon.2012.08.048 [5] BARLIAN A A, PARK W T, MALLON J R, et al. Review: Semiconductor piezoresistance for microsystems[J]. Proceedings of the IEEE,2009,97(3):513-552. doi: 10.1109/JPROC.2009.2013612 [6] CAI L, SONG L, LUAN P, et al. Super-stretchable, transparent carbon nanotube-based capacitive strain sensors for human motion detection[J]. Scientific Reports,2013,3:3048. doi: 10.1038/srep03048 [7] BUSSE R, BAUER R D, SCHABERT A, et al. Mechanical-properties of exposed human common carotid arteries invivo[J]. Basic Research in Cardiology,1979,74(5):545-554. doi: 10.1007/BF01907647 [8] BOLAND C S, KHAN U, BACKES C, et al. Sensitive, high-strain, high-rate bodily motion sensors based on graphene-rubber composites[J]. ACS Nano,2014,8(9):8819-8830. doi: 10.1021/nn503454h [9] LIN L, LIU S, ZHANG Q, et al. Towards tunable sensitivity of electrical property to strain for conductive polymer composites based on thermoplastic elastomer[J]. ACS Applied Materials & Interfaces,2013,5(12):5815-5824. [10] LU N, LU C, YANG S, et al. Highly sensitive skin-mountable strain gauges based entirely on elastomers[J]. Advanced Functional Materials,2012,22(19):4044-4050. doi: 10.1002/adfm.201200498 [11] LUO S, LIU T. SWCNT/graphite nanoplatelet hybrid thin films for self-temperature- compensated, highly sensitive, and extensible piezoresistive sensors[J]. Advanced Materials,2013,25(39):5650-5657. doi: 10.1002/adma.201301796 [12] FRUTIGER A, MUTH J T, VOGT D M, et al. Capacitive soft strain sensors via multicore-shell fiber printing[J]. Advanced Materials,2015,27(15):2440-2446. doi: 10.1002/adma.201500072 [13] EOM H, LEE J, PICHITPAJONGKIT A, et al. Ag@Ni core-shell nanowire network for robust transparent electrodes against oxidation and sulfurization[J]. Small,2014,10(20):4171-4181. [14] FONSECA M A, ENGLISH J M, VON ARX M, et al. Wireless micromachined ceramic pressure sensor for high-temperature applications[J]. Journal of Microelectromechanical Systems,2002,11(4):337-343. doi: 10.1109/JMEMS.2002.800939 [15] GONG S, LAI D T H, SU B, et al. Highly stretchy black gold e-skin nanopatches as highly sensitive wearable biomedical sensors[J]. Advanced Electronic Materials,2015,1(4):1400063. doi: 10.1002/aelm.201400063 [16] CHOI D Y, KIM M H, OH Y S, et al. Highly stretchable, hysteresis-free ionic liquid-based strain sensor for precise human motion monitoring[J]. ACS Applied Materials & Interfaces,2017,9(2):1770-1780. [17] COHEN D J, MITRA D, PETERSON K, et al. A highly elastic, capacitive strain gauge based on percolating nanotube networks[J]. Nano Letters,2012,12(4):1821-1825. doi: 10.1021/nl204052z [18] CAO C F, ZHANG G D, ZHAO L, et al. Design of mechanically stable, electrically conductive and highly hydrophobic three-dimensional graphene nanoribbon composites by modulating the interconnected network on polymer foam skeleton[J]. Composites Science and Technology,2019,171:162-170. doi: 10.1016/j.compscitech.2018.12.014 [19] DARGAHI J, NAJARIAN S. Analysis of a membrane-type polymeric-based tactile sensor for biomedical and medi-cal robotic applications[J]. Sensors and Materials,2004,16(1):25-41. [20] KONG J H, JANG N S, KIM S H, et al. Simple and rapid micropatterning of conductive carbon composites and its application to elastic strain sensors[J]. Carbon,2014,77:199-207. doi: 10.1016/j.carbon.2014.05.022 [21] KRAMER R K, MAJIDI C, WOOD R J. Masked deposition of gallium-indium alloys for liquid-embedded elastomer conductors[J]. Advanced Functional Materials,2013,23(42):5292-5296. doi: 10.1002/adfm.201203589 [22] LEE J, LIM M, YOON J, et al. Transparent, flexible strain sensor based on a solution-processed carbon nanotube network[J]. ACS Applied Materials & Interfaces,2017,9(31):26279-26285. [23] LEE S, REUVENY A, REEDER J, et al. A transparent bending-insensitive pressure sensor[J]. Nature Nanotechnology,2016,11(5):472. doi: 10.1038/nnano.2015.324 [24] KE D, JING Z. Coherent effect of triple-resonant optical parametric amplification inside a cavity with injection of a squeezed vacuum field[J]. Chinese Physics B,2013,22(9):094205. doi: 10.1088/1674-1056/22/9/094205 [25] GUO D, PAN X, HE H. A simple and cost-effective method for improving the sensitivity of flexible strain sensors based on conductive polymer composites[J]. Sensors and Actuators A: Physical,2019:298. [26] KHANG D Y, JIANG H Q, HUANG Y, et al. A stretchable form of single-crystal silicon for high-performance electronics on rubber substrates[J]. Science,2006,311(5758):208-212. doi: 10.1126/science.1121401 [27] KIM D H, VIVENTI J, AMSDEN J J, et al. Dissolvable films of silk fibroin for ultrathin conformal bio-integrated electronics[J]. Nature Materials,2010,9(6):511-517. doi: 10.1038/nmat2745 [28] WU S, PENG S, WANG C H. WANG. Stretchable strain sensors based on PDMS composites with cellulosesponges containing one and two-dimensional nano carbons[J]. Sensors and Actuators A: Physical,2018,279:90-100. doi: 10.1016/j.sna.2018.06.002 [29] HUA Q, SUN J, LIU H, et al. Skin-inspired highly stretchable and conformable matrix networks for multifunctional sensing[J]. Nature Communications,2018,9(1):244. doi: 10.1038/s41467-017-02685-9 [30] WANG L, CHEN Y, LIN L, et al. Highly stretchable, anti-corrosive and wearable strain sensors based on the PDMS/CNTs decorated elastomer nanofiber composite[J]. Chemical Engineering Journal,2019,362:89-98. doi: 10.1016/j.cej.2019.01.014 [31] LI Y, LUO S, YANG M C, et al. Poisson ratio and piezoresistive sensing: A new route to high-performance 3D flexible and stretchable sensors of multimodal sensing capability[J]. Advanced Functional Materials,2016,26(17):2900-2908. doi: 10.1002/adfm.201505070 [32] GONG S, SCHWALB W, WANG Y W, et al. A wearable and highly sensitive pressure sensor with ultrathin gold nanowires[J]. Nature Communications,2014,5:3132-3138. doi: 10.1038/ncomms4132 [33] LU S, TIAN C, WANG X, et al. Strain sensing behaviors of gnps/epoxy sensor and health monitoring for composite materials under monotonic tensile and cyclic deformation[J]. Composites Science and Technology,2018,158:94-100. doi: 10.1016/j.compscitech.2018.02.017 [34] KANG D, PIKHITSA P V, CHOI Y W, et al. Ultrasensitive mechanical crack-based sensor inspired by the spider sensory system[J]. Nature,2014,516(7530):222-226. doi: 10.1038/nature14002 [35] FATHI A, HATAMI K, GRADY B P. Effect of carbon black structure on low-strain conductivity of polypropylene and low-density polyethylene composites[J]. Polymer Engineering and Science,2012,52(3):549-556. doi: 10.1002/pen.22115 [36] CASTILLO-CASTRO T D, CASTILLO-ORTEGA M M, HERRERA-FRANCO P J. Electrical, mechanical and piezo-resistive behavior of a polyaniline/poly(n-butyl methacrylate) composite[J]. Composites Part A: Applied Science and Manufacturing,2009,40(10):1573-1579. doi: 10.1016/j.compositesa.2009.07.001 [37] XU Zhao, DING Chao, WEI Dunwen. Electro and light-active actuators based on reversible shape memory polymer composites with segregated conductive networks[J]. ACS Applied Materials & Interfaces,2019,33:30332-30340. [38] PYO M, BOHNC C, SMELA E, et al. Direct strain measurement of polypyrrole actuators controlled by the polymer/gold interface[J]. Chemistry of Materials,2003,15(4):916-922. doi: 10.1021/cm020312w [39] PARK Y L, CHEN B R, WOOD R J. Design and fabrication of soft artificial skin using embedded microchannels and liquid conductors[J]. IEEE Sensors Journal,2012,12(8):2711-2718. doi: 10.1109/JSEN.2012.2200790 [40] PARK Y, RYU Y M, WANG T, et al. Colorectal cancer diagnosis using enzyme-sensitive ratiometric fluorescence dye and antibody-quantum dot conjugates for multiplexed detection[J]. Advanced Functional Materials,2018,28(4):1703450. doi: 10.1002/adfm.201703450 [41] KIM S O, HAN C J, LEE C R, et al. Ultrafast photoinduced interconnection of metal-polymer composites for fabrication of transparent and stretchable electronic skins[J]. ACS Applied Materials & Interfaces,2020,12(35):39695-39704. [42] LUAN J, WANG Q, ZHENG X, et al. Flexible strain sensor with good durability and anti-corrosion property based on metal/polymer composite films embedded with silver nanowires[J]. Archives of Civil and Mechanical Engineering,2020,20(4):133. doi: 10.1007/s43452-020-00139-6 [43] HU X Y, JING M X, YANG H, et al. Enhanced ionic conductivity and lithium dendrite suppression of polymer solid electrolytes by alumina nanorods and interfacial graphite modification[J]. Journal of Colloid and Interface Science,2021,590:50-59. doi: 10.1016/j.jcis.2021.01.018 [44] CORTES A, SANCHEZ ROMATE X F, JIMENEZ-SUAREZ A, et al. 3D printed anti-icing and de-icing system based on CNT/GNP doped epoxy composites with self-curing and structural health monitoring capabilities[J]. Smart Materials and Structures,2021,30(2):16-25. [45] ZHANG F, WU S, PENG S, et al. The effects of dual-scale carbon fibre network on sensitivity and stretchability of wearable sensors[J]. Composites Science and Technology, 2018, 165: 131-139. [46] YANG G, FENG X, WANG W, et al. Graphene and carbon nanotube-based high-sensitive film sensors for in-situ monitoring out-of-plane shear damage of epoxy compo-sites[J]. Composites Part B: Engineering,2021,204:108494. doi: 10.1016/j.compositesb.2020.108494 [47] 卫军吴, 董荣珍. 基于石墨烯复合薄膜的应变传感器及性能分析[J]. 中南大学学报(自然科学版), 2020, 51(3):619-627. doi: 10.11817/j.issn.1672-7207.2020.03.006WEI Junwu, DONG Rongzhen. Performance analysis of strain sensor based on graphene composite film[J]. Journal of Central South Universiy,2020,51(3):619-627(in Chinese). doi: 10.11817/j.issn.1672-7207.2020.03.006 [48] LUO Z, HU X, TIAN X, et al. Structure-property relationships in graphene-based strain and pressure sensors for potential artificial intelligence applications[J]. Sensors (Basel),2019,19(5):1250. doi: 10.3390/s19051250 [49] MA Z, XU R, WANG W, et al. A wearable, anti-bacterial strain sensor prepared by silver plated cotton/spandex blended fabric for human motion monitoring[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2019,582:123918. doi: 10.1016/j.colsurfa.2019.123918 [50] ZHANG X, XIANG D, ZHU W, et al. Flexible and high-performance piezoresistive strain sensors based on carbon nanoparticles@polyurethane sponges[J]. Composites Science and Technology,2020,200:108437. doi: 10.1016/j.compscitech.2020.108437 [51] HUANG K, NING H, HU N, et al. Ultrasensitive MWCNT/PDMS composite strain sensor fabricated by laser ablation process[J]. Composites Science and Technology,2020,192:108105. doi: 10.1016/j.compscitech.2020.108105 [52] RAVARY B, POURCELOT P, BORTOLUSSI C, et al. Strain and force transducers used in human and veterinary tendon and ligament biomechanical studies[J]. Clinical Biomechanics,2004,19(5):433-437. doi: 10.1016/j.clinbiomech.2004.01.008 [53] YAMADA T, HAYAMIZU Y, YAMAMOTO Y, et al. A stretchable carbon nanotube strain sensor for human-motion detection[J]. Nature Nanotechnology,2011,6(5):296-301. doi: 10.1038/nnano.2011.36 [54] LUO W, CHARARA M, SAHA M C, et al. Fabrication and characterization of porous CNF/PDMS nanocomposites for sensing applications[J]. Applied Nano Science,2019,9(6):1309-1317. doi: 10.1007/s13204-019-00958-x [55] AZIZKHANI M B, RASTGORDANI S, ANARAKI A P, et al. Highly sensitive and stretchable strain sensors based on chopped carbon fibers sandwiched between silicone rubber layers for human motion detections[J]. Journal of Composite Materials,2020,54(3):423-434. doi: 10.1177/0021998319855758 [56] CHOI W Y, JO H G, KWON S W, et al. Multipoint-detection strain sensor with a single electrode using optical ultrasound generated by carbon nanotubes[J]. Sensors,2019,19(18):3877. doi: 10.3390/s19183877 [57] IRFAN M S, GILL Y Q, ULLAH S, et al. Polyaniline-nbr blends by in situ polymerization: Application as stretchable strain sensors[J]. Smart Materials and Structures,2019,28(9):095024. [58] CHEN J, ZHU Y, JIANG W. A stretchable and transparent strain sensor based on sandwich-like PDNS/CNTs/PDMS composite containing an ultrathin conductive CNT layer[J]. Composites Science and Technology,2020,186:107938. [59] ZHENG Y, JIN Q, CHEN W, et al. High sensitivity and wide sensing range of stretchable sensors with conductive microsphere array structures[J]. Journal of Materials Chemistry C,2019,7(27):8423-8431. doi: 10.1039/C9TC02698C [60] ZHOU C G, SUN W J, JIA L C, et al. Highly stretchable and sensitive strain sensor with porous segregated conductive network[J]. ACS Applied Materials& Interfaces,2019,11(40):37094-37102. [61] SUN H, DAI K, ZHAI W, et al. A highly sensitive and stretchable yarn strain sensor for human motion tracking utilizing a wrinkle-assisted crack structure[J]. ACS Applied Materials & Interfaces,2019,11(39):36052-36062. [62] GUO X, HUANG Y, ZHAO Y, et al. Highly stretchable strain sensor based on SWCNTS/CB synergistic conductive network for wearable human-activity monitoring and recognition[J]. Smart Materials and Structures,2017,26(9):095017. doi: 10.1088/1361-665X/aa79c3 [63] HAN S T, PENG H, SUN Q, et al. An overview of the development of flexible sensors[J]. Advanced Materials,2017,29(33):1700375. doi: 10.1002/adma.201700375 [64] JEONG Y R, PARK H, JIN S W, et al. Highly stretchable and sensitive strain sensors using fragmentized graphene foam[J]. Advanced Functional Materials,2015,25(27):4228-4236. [65] KIM H, AHN J H. Graphene for flexible and wearable device applications[J]. Carbon,2017,120:244-257. doi: 10.1016/j.carbon.2017.05.041 [66] KIM K, PARK J, SUH J H, et al. 3D printing of multiaxial force sensors using carbon nanotube (CNT)/thermoplastic polyurethane (TPU) filaments[J]. Sensors and Actuators A-Physical,2017,263:493-500. doi: 10.1016/j.sna.2017.07.020 [67] LI C Y, LIAO Y C. Adhesive stretchable printed conductive thin film patterns on pdms surface with an atmospheric plasma treatment[J]. ACS Applied Materials & Interfaces,2016,8(18):11868-11874. [68] LIU H, GAO J, HUANG W, et al. Electrically conductive strain sensing polyurethane nanocomposites with synergistic carbon nanotubes and graphene bifillers[J]. Nanoscale,2016,8(26):12977-12989. doi: 10.1039/C6NR02216B [69] LIU H, LI Y, DAI K, et al. Electrically conductive thermoplastic elastomer nanocomposites at ultralow graphene loading levels for strain sensor applications[J]. Journal of Materials Chemistry C,2016,4(1):157-166. [70] NOVOSELOV K S, FAL'KO V I, COLOMBO L, et al. A roadmap for graphene[J]. Nature,2012,490(7419):192-200. doi: 10.1038/nature11458 [71] NANNI F, MAYORAL B L, MADAU F, et al. Effect of mwcnt alignment on mechanical and self-monitoring properties of extruded pet-mwcnt nanocomposites[J]. Composites Science and Technology,2012,72(10):1140-1146. doi: 10.1016/j.compscitech.2012.03.015 [72] FOROUGHI J, SPINKS G M, AZIZ S, et al. Knittedcarbon-nanotube-sheath/spandex-core elastomeric yarns for artificial muscles and strain sensing[J]. ACS Nano,2016,10(10):9129-9135. doi: 10.1021/acsnano.6b04125 [73] LIU Q, ZHANG M, HUANG L, et al. High-quality graphene ribbons prepared from graphene oxide hydrogels and their application for strain sensors[J]. ACS Nano,2015,12(9):12320-12326. [74] TANG Y, ZHAO Z, HU H, et al. Highly stretchable and ultrasensitive strain sensor based on reduced graphene oxide microtubes-elastomer composite[J]. ACS Applied Materials & Interfaces,2015,7(49):27432-27439. doi: 10.1021/acsami.5b09314 [75] QIN Y, PENG Q, DING Y, et al. Lightweight, superelastic, and mechanically flexible graphene/polyimide nanocomposite foam for strain sensor application[J]. ACS Nano,2015,9(9):8933-8941. doi: 10.1021/acsnano.5b02781 [76] MORICHE R, JIMÉNEZ-SUÁREZ A, SÁNCHEZ M, et al. Graphene nanoplatelets coated glass fibre fabrics as strain sensors[J]. Composites Science and Technology,2017,146:59-64. [77] WANG Z, HUANG Y, SUN J, et al. Polyurethane/cotton/carbon nanotubes core-spun yarn as high reliability stretchable strain sensor for human motion detection[J]. ACS Applied Materials & Interfaces,2016,8(37):24837-24843. [78] RYU S, LEE P, CHOU J B, et al. Extremely elastic wearable carbon nanotube fiber strain sensor for monitoring of human motion[J]. ACS Nano,2015,9(6):5929-5936. doi: 10.1021/acsnano.5b00599 [79] LEE J, SHIN S, LEE S, et al. Highly sensitive multifilament fiber strain sensors with ultrabroad sensing range for textile electronics[J]. ACS Nano,2018,12(5):4259-4268. [80] FAN Y J, MENG X S, LI H Y, et al. Stretchable porous carbon nanotube-elastomer hybrid nanocomposite for harvesting mechanical energy[J]. Advance Materials,2017,29(2):1603115. doi: 10.1002/adma.201603115 [81] ZHENG Q, LEE J H, SHEN X, et al. Graphene-based wearable piezoresistive physical sensors[J]. Materials Today,2020,36:158-179. doi: 10.1016/j.mattod.2019.12.004 [82] WANG Z, LIU X, SHEN X, et al. An ultralight graphene honeycomb sandwich for stretchable light-emitting displays[J]. Advanced Functional Materials,2018,28(19):1707043. doi: 10.1002/adfm.201707043 [83] SHI J, HU J, DAI Z, et al. Graphene welded carbon nanotube crossbars for biaxial strain sensors[J]. Carbon,2017,123:786-793. doi: 10.1016/j.carbon.2017.08.006 [84] SHI J, LI X, CHENG H, et al. Graphene reinforced carbon nanotube networks for wearable strain sensors[J]. Advanced Functional Materials,2016,26(13):2078-2084. doi: 10.1002/adfm.201504804 [85] YANG J C, MUN J, KWON S Y, et al. Electronic skin: Recent progress and future prospects for skin-attachable devices for health monitoring, robotics, and prosthetics[J]. Advanced Materials, 2019, 31 (48): 1904765. [86] XIE D J, J HU,W HE, et al . Coplanar multigate mos2 electric-double-layer transistors for neuromorphic visual recognition[J]. ACS Applied Materials & Interfaces, 2018, 10: 25943–25948. [87] ZANG Y P, ZHANG F J, DI C A, et al. Advances of flexible pressure sensors towardartificial intelligence and health care applications[J]. Materials Horizons,2015,2(2):140-156. doi: 10.1039/C4MH00147H [88] KIM J, LEE M, SHIM H J, et al. Stretchable silicon nanoribbon electronics for skin prosthesis[J]. Materials Horizons, 2015, 5: 5747. [89] MANNSFELD S, TEE C K, STOLTENBERG R M, et al. Highly sensitive flexible pressure sensors with microstructured rubber dielectric layers[J]. Nature Materials,2010,9:859-864. doi: 10.1038/nmat2834 [90] ARAKI H, KIM J, ZHANG S, et al. Materials and device designs for an epidermal UV colorimetric dosimeter with near field communication capabilities[J]. Advanced Functional Materials,2017,27(2):1604465. doi: 10.1002/adfm.201604465 [91] CANEVA S, GEHRING P, GARCIA-SUAREZ V M, et al. Mechanically controlled quantum interference in graphene break junctions[J]. Nature Nanotechnology,2018,13(12):1126. doi: 10.1038/s41565-018-0258-0 [92] ZHANG R, HU R, LI X, et al. A bubble-derived strategy to prepare multiple graphene-based porous materials[J]. Advanced Functional Materials,2018,28(23):1705879. doi: 10.1002/adfm.201705879 [93] ZHANG Y, HUANG Y, ZHANG T, et al. Broadband and tunable high-performance microwave absorption of an ultralight and highly compressible graphene foam[J]. Advanced Materials,2015,27(12):2049-2053. doi: 10.1002/adma.201405788 [94] ZHAO H, BAI J. Highly sensitive piezo-resistive graphite nanoplatelet-carbon nanotube hybrids/polydimethylsilicone composites with improved conductive network construction[J]. ACS Applied Materials & Interfaces,2015,7(18):9652-9659. [95] ZHAO S, ZHU R. Electronic skin with multifunction sensors based on thermosensation[J]. Advanced Materials,2017,29(15):1606151. doi: 10.1002/adma.201606151 [96] ZHONG H, XIA J, WANG F, et al. Graphene-piezoelectric material heterostructure for harvesting energy from water flow[J]. Advanced Functional Materials,2017,27(5):1604226. doi: 10.1002/adfm.201604226 [97] ZHANG R, DENG H, VALENCA R, et al. Strain sensing behaviour of elastomeric composite films containing carbon nanotubes under cyclic loading[J]. Composites Science and Technology,2013,74:1-5. [98] 隋少春, 许艾明, 黎小华, 等. 面向航空智能制造的DT与AI融合应用[J]. 航空学报, 2020, 41(7):7-17.SUI S C, XU A M, LI X H, et al. Fusion application of DT and AI for aviation intelligent manufacturing[J]. Acta Aeronautica et Astronautica Sinica,2020,41(7):7-17(in Chinese). [99] LI X, HUA T, XU B. Electromechanical properties of a yarn strain sensor with graphene-sheath/polyurethane-core[J]. Carbon, 2017, 118: 686-698. -

下载:

下载: