Preparation and compression properties of negative stiffness honeycomb cell structure

-

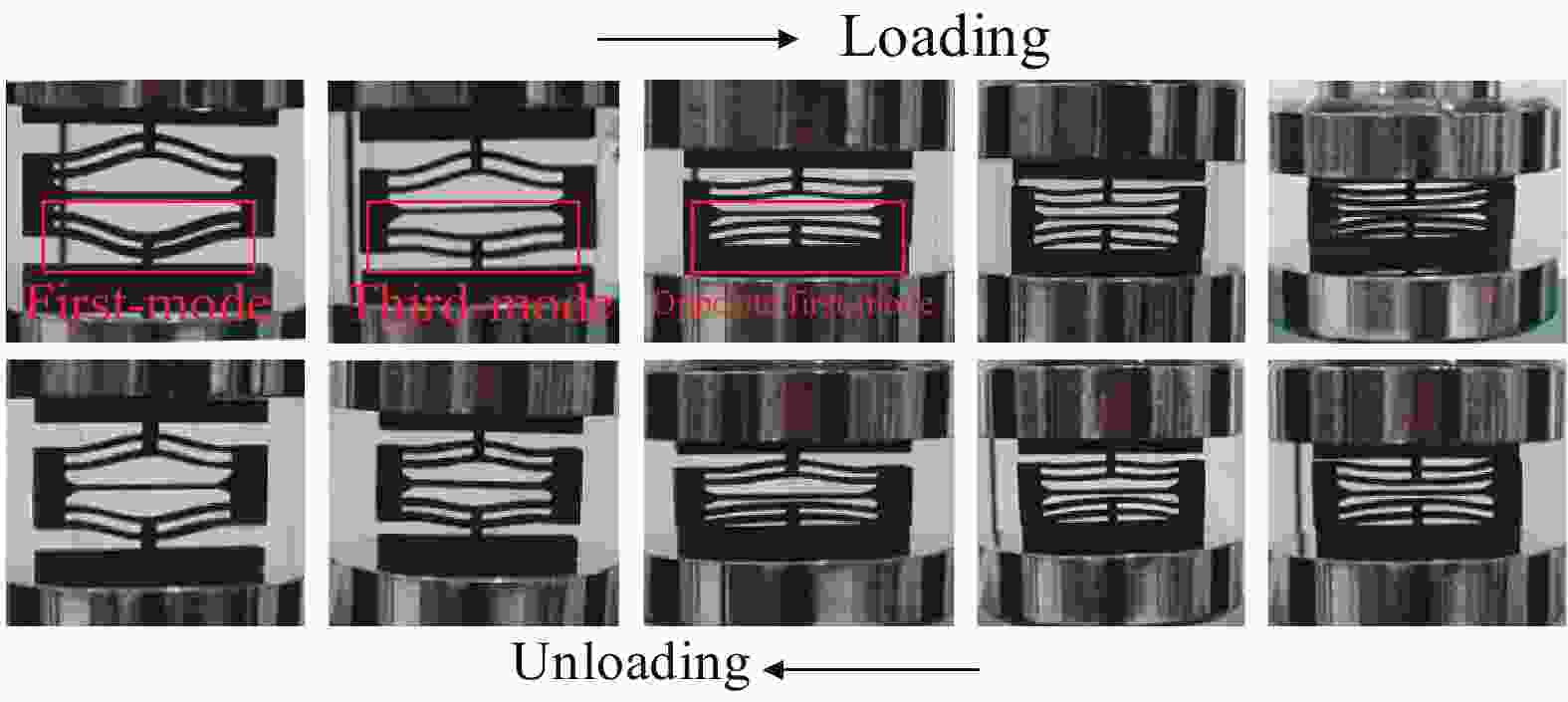

摘要: 基于短切碳纤维增强尼龙复合材料(MarkForged Onyx),采用熔融丝制造工艺(FFF)制备了负刚度蜂窝单胞结构。为分析其打印性能和压缩性能,进行负刚度蜂窝单胞结构试样压缩试验,试验分析了堆叠方式、填充图案及壁厚层数三种打印工艺参数对该结构打印性能和压缩性能的影响机制。结果表明:水平堆叠方式、六边形填充图案、一层壁厚打印工艺参数组合有效减少结构的打印时间、打印成本。水平堆叠方式结构的压缩性能优于侧立和正立方向;与四边形、六边形填充图案相比,三角形填充图案明显提高结构的吸能能力;二层的壁厚层数对结构抗压强度的提高最显著。在加载过程中,单胞结构呈现出显著的负刚度特性,能量吸收效率约达70%,力阈值约为185 N;循环试验后,仅存在6%的压缩变形量,实现了基于MarkForged Onyx短切碳纤维增强尼龙复合材料负刚度蜂窝芯结构的可恢复能量吸收。

-

关键词:

- 纤维增强热塑性复合材料 /

- 负刚度蜂窝结构 /

- 压缩性能 /

- 能量吸收 /

- 堆叠方式

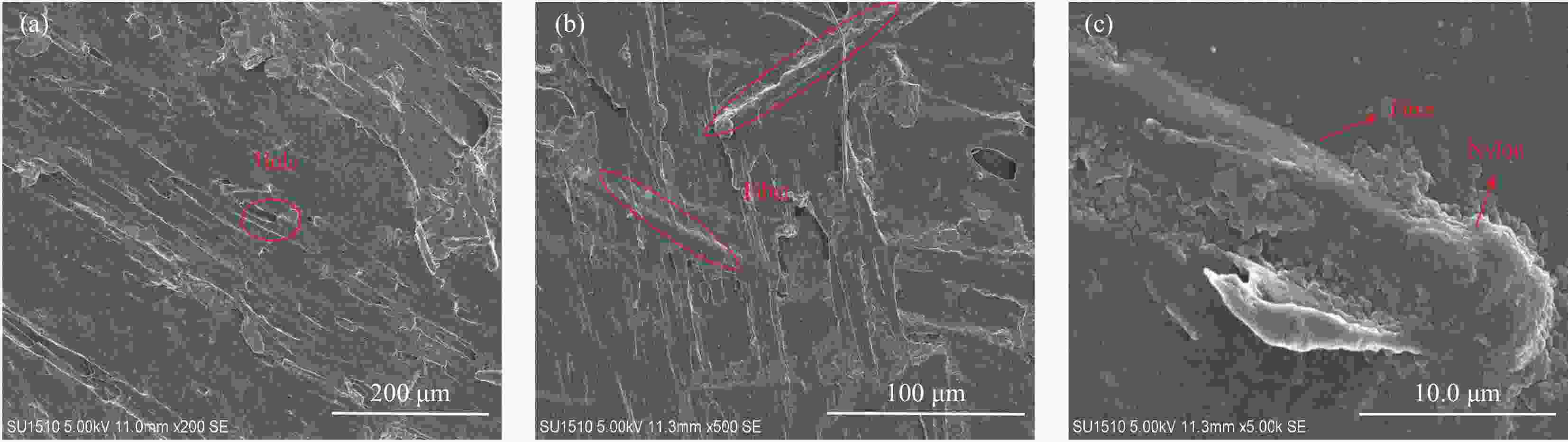

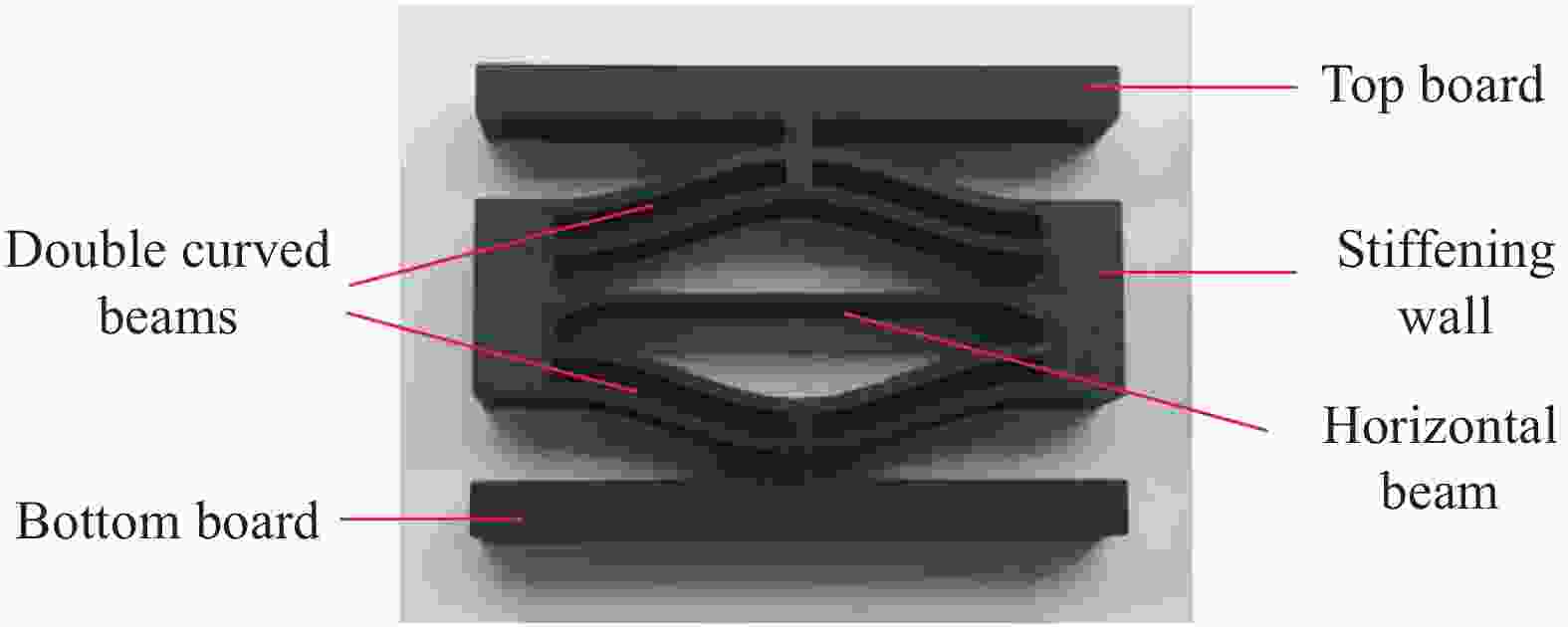

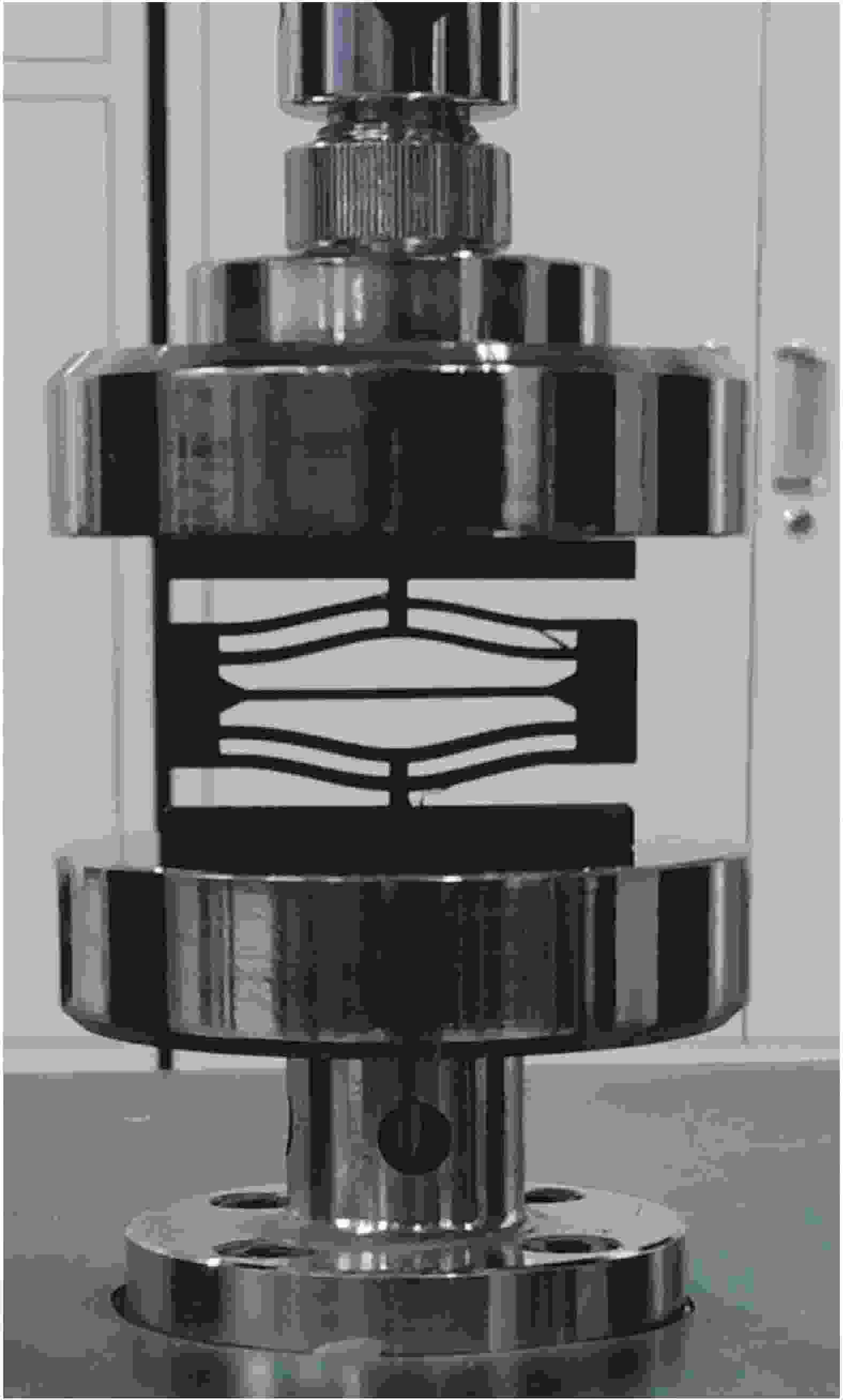

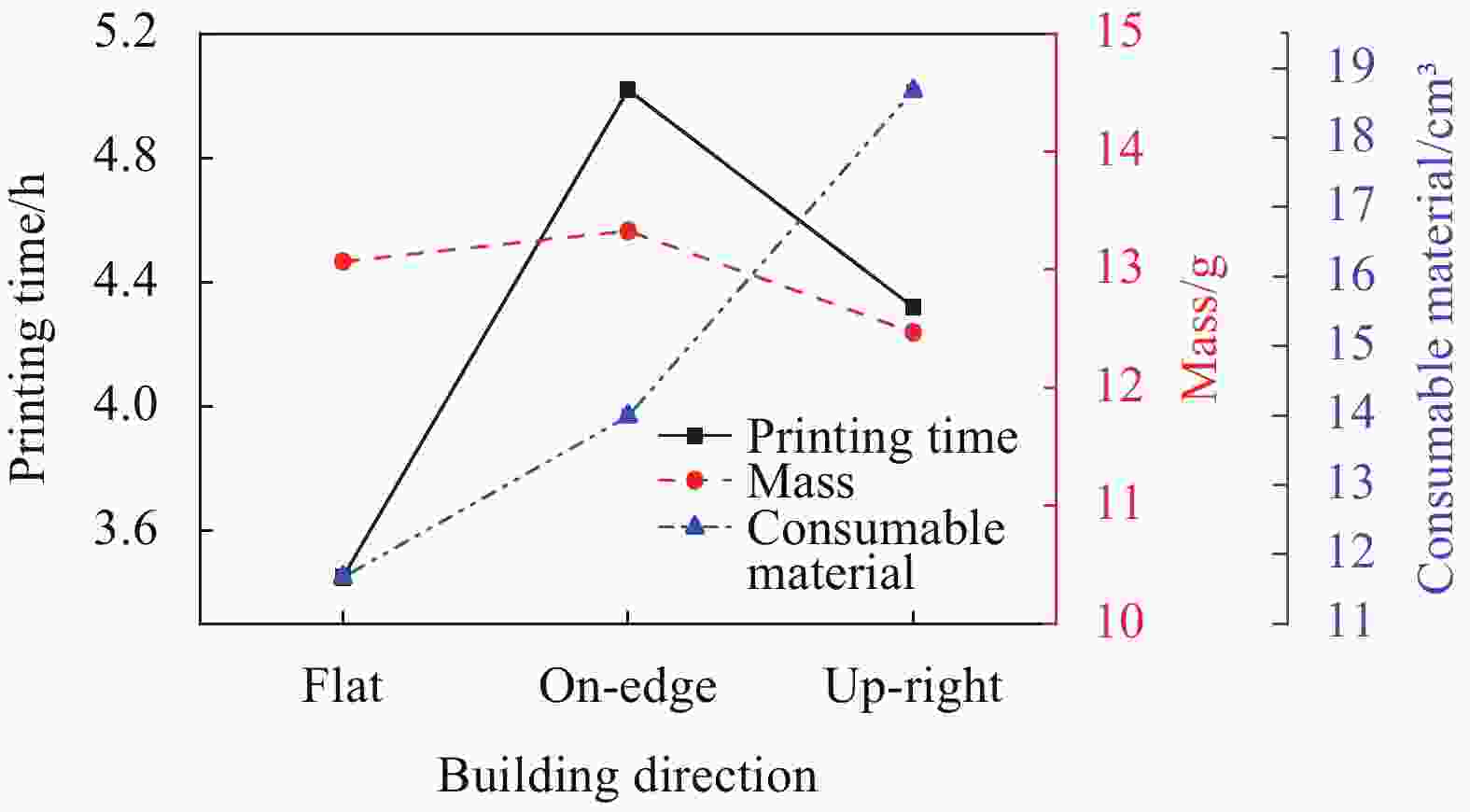

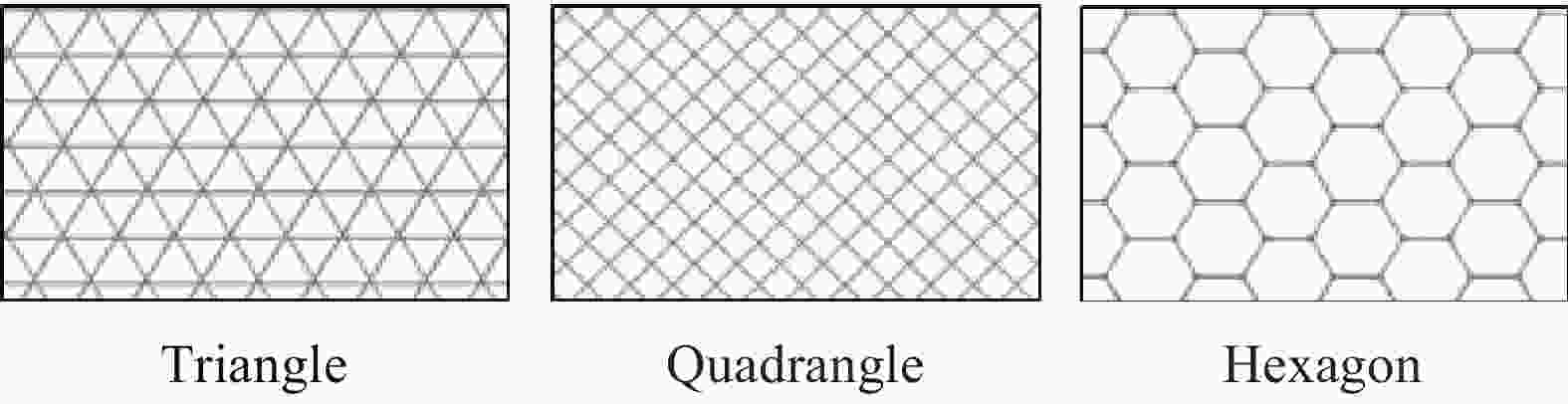

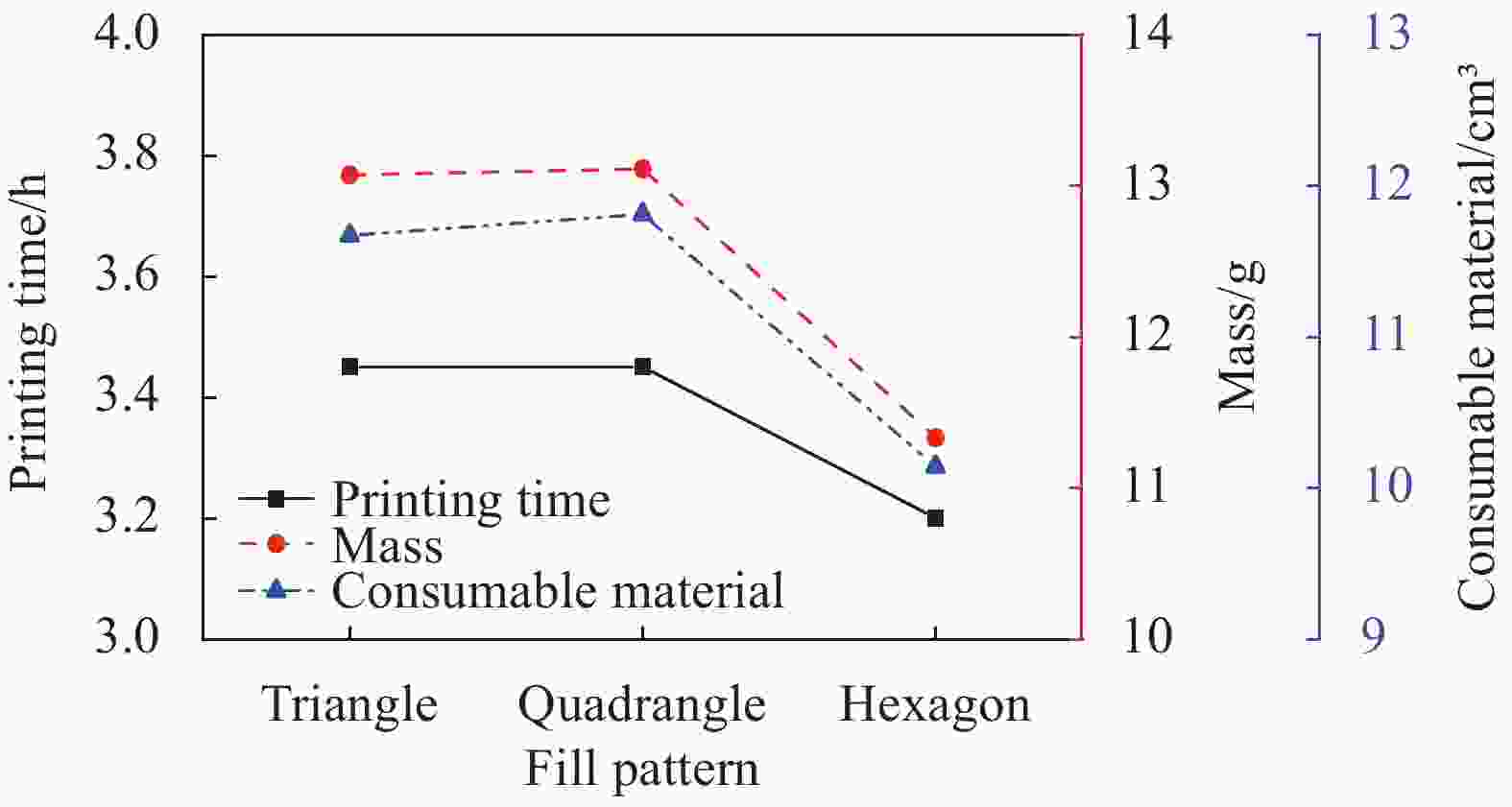

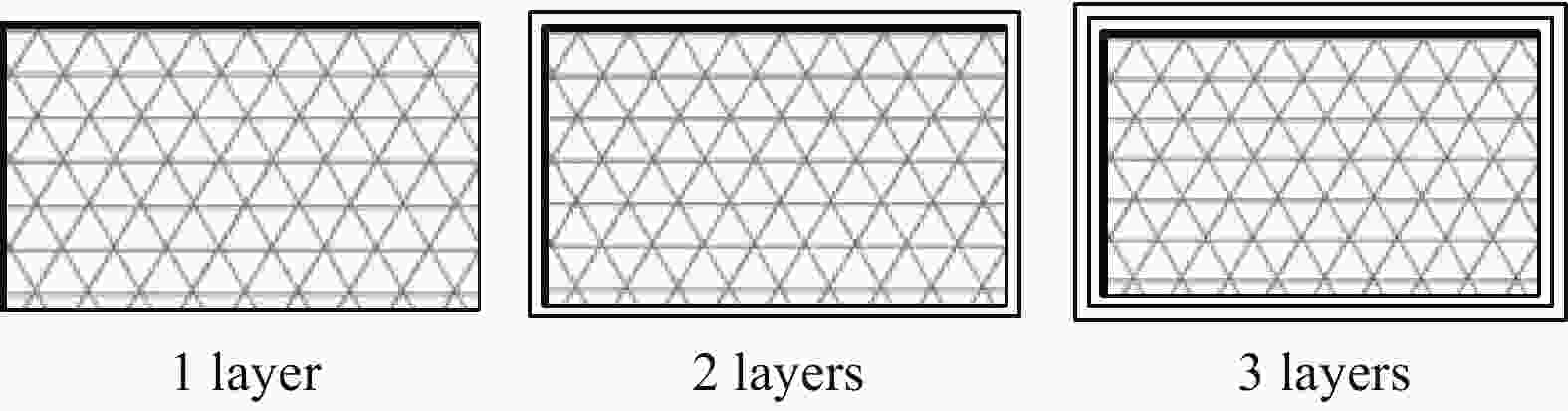

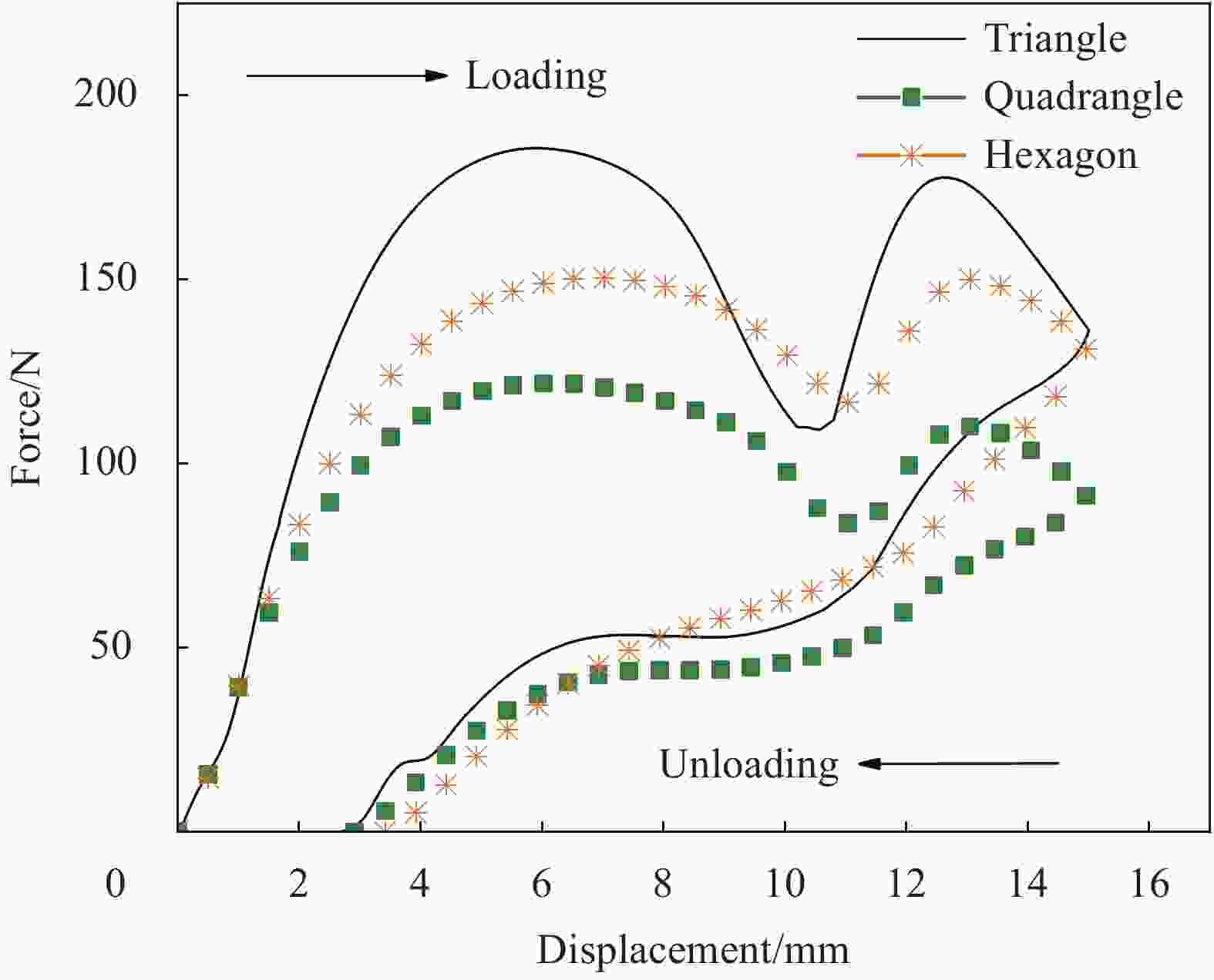

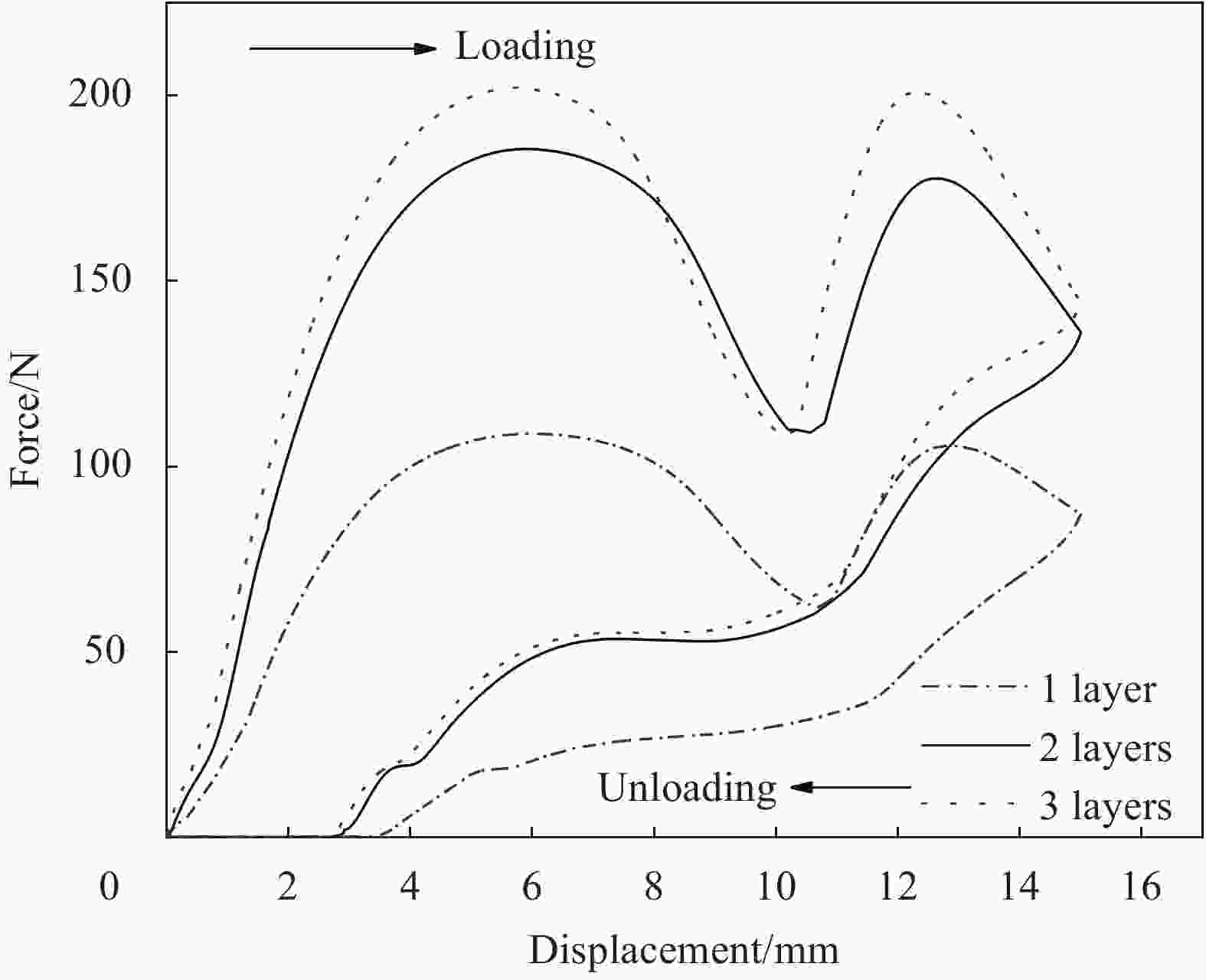

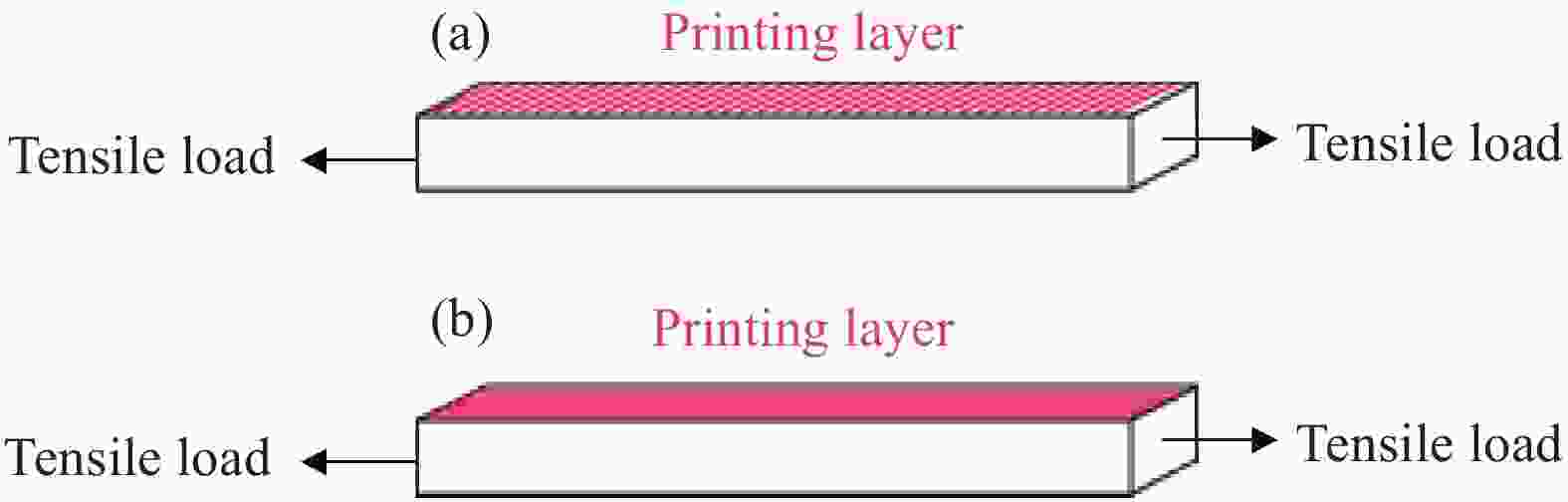

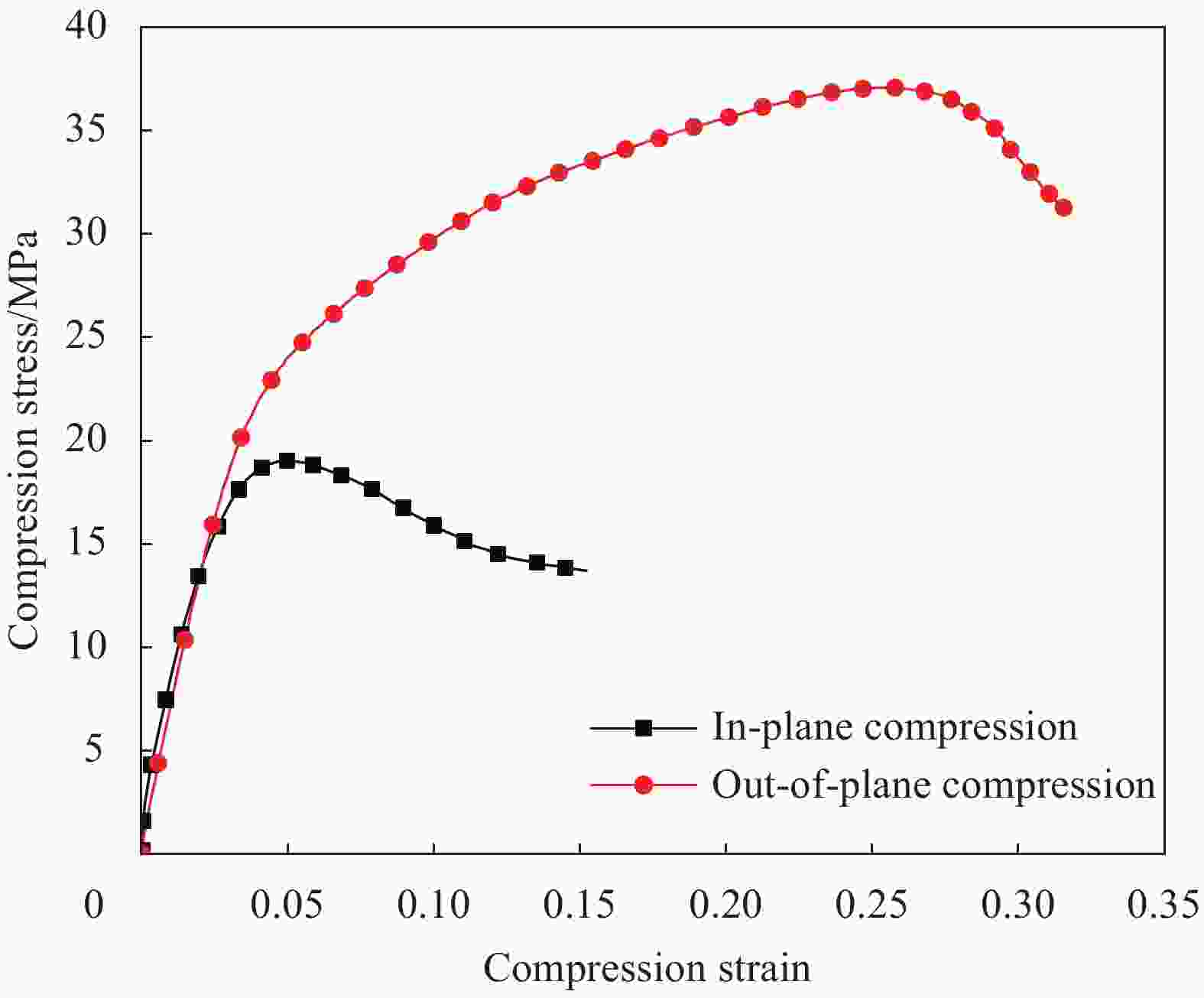

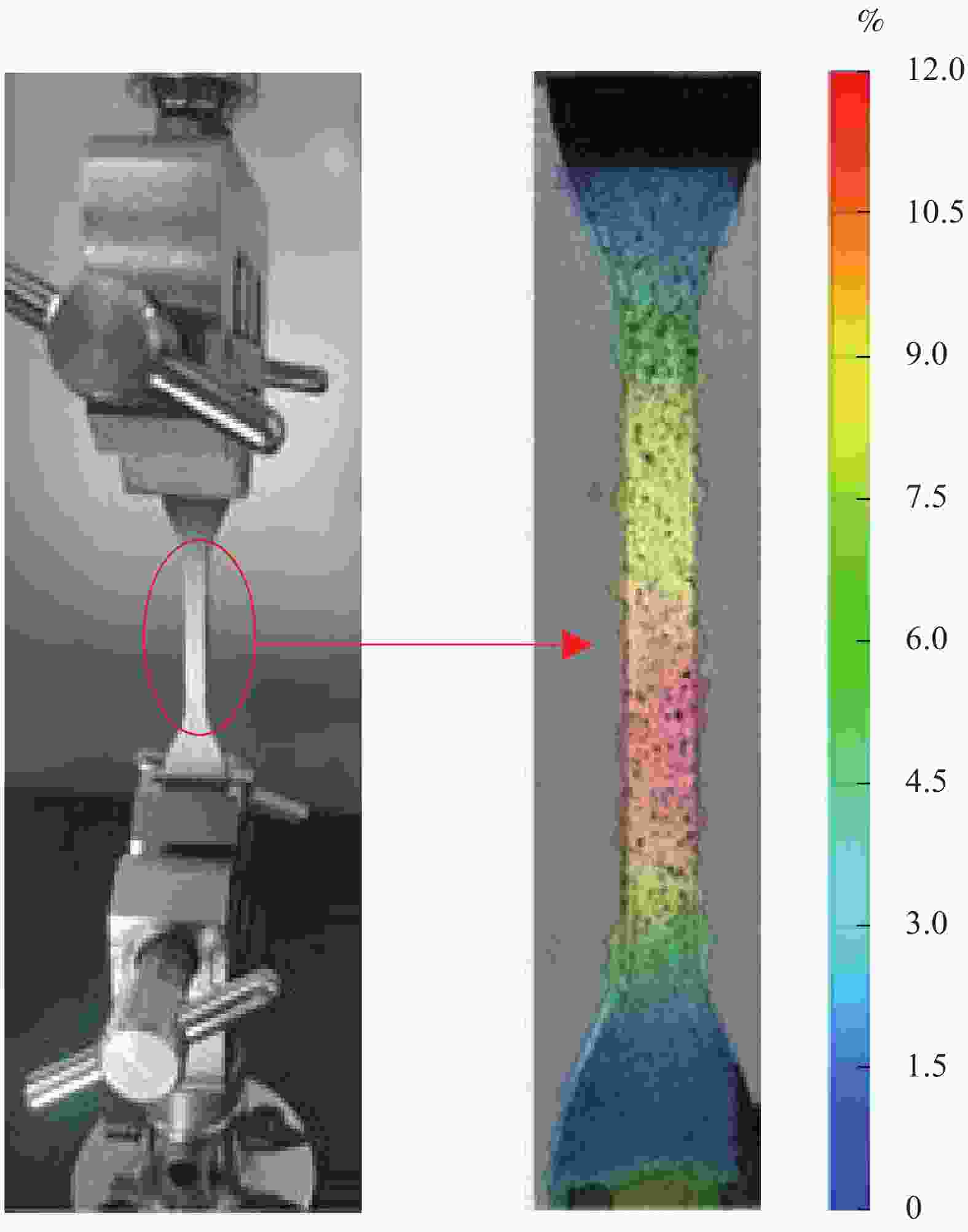

Abstract: Negative stiffness honeycomb cell structures were fabricated by fused filament fabrication (FFF) based on chopped carbon fiber reinforced nylon composites (MarkForged Onyx). In order to analyze the printing properties and compression properties, compression tests for negative stiffness honeycomb cell structure specimens were carried out. The influence mechanism of three process parameters, including building directions, fill patterns and wall layers, on the printing properties and compression properties of the structure was analyzed. The results show that the combination of flat building directions, hexagonal fill pattern and one wall layer can effectively reduce the printing time and cost of the structure. The compression properties of the flat building directions are superior to that of the on-edge and up-right. Compared with quadrilateral and hexagonal fill pattern, triangular fill pattern improves the energy absorption capacity of the structure significantly. Two wall layers have a great impact on the compressive strength of the structure. Cell structures show pronounced negative stiffness behavior during the loading process with percent energy absorbed up to 70%, and force threshold of about 185 N. Through the cycle tests, there is only 6% of the compression deformation, realizing the recoverable energy absorption of negative stiffness honeycomb core structures based on Markforged Onyx chopped carbon fiber reinforced nylon composites. -

表 1 MarkForged Onyx短切碳纤维增强尼龙复合材料及常见的打印原材料的基本力学参数

Table 1. Properties of Markforged Onyx chopped carbon fiber reinforced nylon composites and common printing raw materials

Property MarkForged Onyx Common printing raw materials Nylon TPU PLA ABS Young’s modulus/MPa 1850 570 26 2346.5 1681.5 Yield stress/MPa 20 27.8 8.6 49.5 39 Elongation at break/% 25 210 580 5.2 4.8 Notes: TPU—Thermoplastic polyurethane; PLA—Polylactic acid; ABS—Acrylonitrile-butadiene-styrene. 表 2 负刚度蜂窝单胞结构的打印工艺参数

Table 2. Process parameters of negative stiffness honeycomb cell structures

Specimen Building direction Fill pattern Number of wall layer S1 Flat Triangle 2 S2 On-edge Triangle 2 S3 Up-right Triangle 2 S4 Flat Quadrangle 2 S5 Flat Hexagon 2 S6 Flat Triangle 1 S7 Flat Triangle 3 Notes: Nozzle temperature 273℃; Fill density 40%; Layer height 0.1 mm. 表 3 不同打印工艺参数负刚度蜂窝单胞结构的能量吸收及力阈值

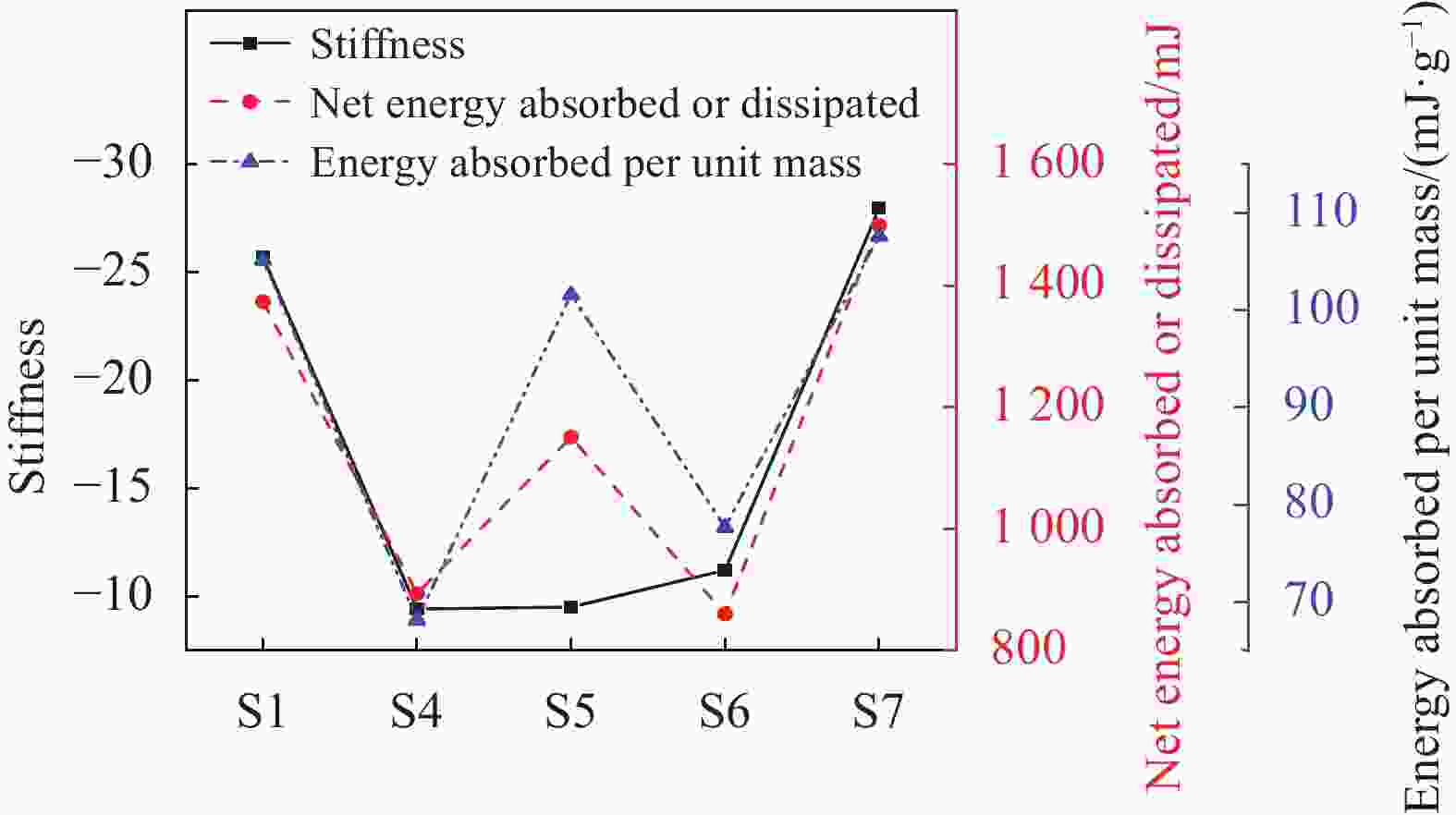

Table 3. Energy absorption and force threshold of negative stiffness honeycomb cell structures with different process parameters

Performance parameter S1 S4 S5 S6 S7 Force threshold/N 185 122 151 109 202 Energy absorbed during loading/mJ 1997.09 1461.47 1847.38 1257.81 2338.35 Energy recovered during unloading/mJ 623.09 567.82 696.17 397.72 838.76 Net energy absorbed or dissipated/mJ 1374.01 893.64 1151.21 860.09 1499.57 Percent energy absorbed/% 68.8 61.1 62.3 68.4 64.1 Mass/g 13.07 13.11 11.33 11.07 13.93 Energy absorbed per unit mass/(mJ·g-1) 105.18 68.16 101.61 77.69 107.65 -

[1] VANAEI H, SHIRINBAYAN M, DELIGANT M, et al. Influence of process parameters on thermal and mechanical properties of polylactic acid fabricated by fused filament fabrication[J]. Polymer Engineering and Science,2020,60(8):1822-1831. doi: 10.1002/pen.25419 [2] 陈向明, 姚辽军, 果立成, 等. 3D打印连续纤维增强复合材料研究现状综述[J]. 航空学报, 2021, 42(10):167-191. doi: 10.7527/S1000-6893.2020.23844CHEN Xiangming, YAO Liaojun, GUO Licheng, et al. 3D printed continuous fiber-reinforced composites: State of art and perspective[J]. Acta Aeronautica et Astronautica Sinica,2021,42(10):167-191(in Chinese). doi: 10.7527/S1000-6893.2020.23844 [3] JUSTO J, TAVARA L, GARCIA-GUZMAN L, et al. Characterization of 3D printed long fibre reinforced composites[J]. Composite Structures,2018,185:537-548. doi: 10.1016/j.compstruct.2017.11.052 [4] LIU Y, ZHUANG W. Self-piercing riveted-bonded hybrid joining of carbon fibre reinforced polymers and aluminium alloy sheets[J]. Thin-Walled Structures,2019,144:1-11. [5] LIANG J S, JIANG H, ZHANG J S, et al. Investigations on mechanical properties and microtopography of electromagnetic self-piercing riveted joints with carbon fiber reinforced plastics/aluminum alloy 5052[J]. Archives of Civil and Mechanical Engineering,2019,19(1):240-250. doi: 10.1016/j.acme.2018.11.001 [6] TEKINALP H L, KUNC V, VELEZ-GARCIA G M, et al. Highly oriented carbon fiber-polymer composites via additive manufacturing[J]. Composites Science and Technology,2014,105:144-150. doi: 10.1016/j.compscitech.2014.10.009 [7] ZHONG W H, LI F, ZHANG Z G, et al. Short fiber reinforced composites for fused deposition modeling[J]. Materials Science and Engineering: A,2001,301:125-130. doi: 10.1016/S0921-5093(00)01810-4 [8] NING F D, CONG W L, QIU J J, et al. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling[J]. Composites Part B: Engineering,2015,80:369-378. doi: 10.1016/j.compositesb.2015.06.013 [9] FERREIRA R T L, AMATTE I C, DUTRA T A, et al. Experimental characterization and micrography of 3D printed PLA and PLA reinforced with short carbon fibers[J]. Composites Part B: Engineering,2017,124:88-100. doi: 10.1016/j.compositesb.2017.05.013 [10] CAMINERO M A, CHACON J M, GARCIA-MORENO I, et al. Impact damage resistance of 3D printed continuous fibre reinforced thermoplastic composites using fused deposi-tion modelling[J]. Composites Part B: Engineering,2018,148:93-103. doi: 10.1016/j.compositesb.2018.04.054 [11] MOSLEH N, REZADOUST A M, DARIUSHI S. Determining process-window for manufacturing of continuous carbon fiber-reinforced composite Using 3D-printing[J]. Materials and Manufacturing Processes,2021,36(4):409-418. doi: 10.1080/10426914.2020.1843664 [12] TIAN X, LIU T, YANG C, et al. Interface and performance of 3D printed continuous carbon fiber reinforced PLA composites[J]. Composites Part A: Applied Science and Manufacturing,2016,88:198-205. doi: 10.1016/j.compositesa.2016.05.032 [13] DAI F H, LI H, DU S Y. A multi-stable lattice structure and its snap-through behavior among multiple states[J]. Composite Structures,2013,97:56-63. doi: 10.1016/j.compstruct.2012.10.016 [14] HA C S, LAKES R S, PLESHA M E. Design, fabrication, and analysis of lattice exhibiting energy absorption via snap-through behavior[J]. Materials & Design,2018,141:426-437. [15] RESTREPO D, MANKAME N D, ZAVATTIERI P D. Phase transforming cellular materials[J]. Extreme Mechanics Letters,2015,4:52-60. doi: 10.1016/j.eml.2015.08.001 [16] TAN X J, CHEN S, WANG B, et al. Design, fabrication, and characterization of multistable mechanical metamaterials for trapping energy[J]. Extreme Mechanics Letters,2019,28:8-21. doi: 10.1016/j.eml.2019.02.002 [17] QIU J, LANG J H, SLOCUM A H. A curved-beam bistable mechanism[J]. Journal of Microelectromechanical Systems,2004,13(2):137-146. doi: 10.1109/JMEMS.2004.825308 [18] CORREA D M, KLATT T, CORTES S, et al. Negative stiffness honeycombs for recoverable shock isolation[J]. Rapid Prototyping Journal,2015,21(2):193-200. doi: 10.1108/RPJ-12-2014-0182 [19] 任晨辉, 杨德庆. 船用新型多层负刚度冲击隔离器性能分析[J]. 振动与冲击, 2018, 37(20):81-87.REN C H, YANG D Q. Characteristics of a novel multilayer negative stiffness shock isolationsystem for a marine structure[J]. Journal of Vibration and Shock,2018,37(20):81-87(in Chinese). [20] 张相闻, 杨德庆. 船用新型抗冲击隔振蜂窝基座[J]. 振动与冲击, 2015, 34(10):40-45.ZHANG X W, YANG D Q. A novel marine impact resistance and vibration isolation cellular base[J]. Journal of Vibration and Shock,2015,34(10):40-45(in Chinese). [21] TAN X J, WANG B, CHEN S, et al. A novel cylindrical nega-tive stiffness structure for shock isolation[J]. Composite Structures,2019,214:397-405. doi: 10.1016/j.compstruct.2019.02.030 [22] WANG B, TAN X J, ZHU S W, et al. Cushion performance of cylindrical negative stiffness structures: Analysis and optimization[J]. Composite Structures,2019,227:1-12. [23] CHEN S, WANG B, ZHU S W, et al. A novel composite nega-tive stiffness structure for recoverable trapping energy[J]. Composites Part A-Applied Science and Manufacturing,2020,129:1-11. [24] GORDELIER T J, THIES P R, TURNER L, et al. Optimising the FDM additive manufacturing process to achieve maximum tensile strength: A state-of-the-art review[J]. Rapid Prototyping Journal,2019,25(6):953-971. doi: 10.1108/RPJ-07-2018-0183 [25] 丁春香, 潘明珠, 杨舒心, 等. 基于数字图像相关技术的木纤维/高密度聚乙烯复合材料界面力学行为[J]. 复合材料学报, 2020, 37(9):2173-2182.DING Chunxiang, PAN Mingzhu, YANG Shuxin, et al. Interfacial mechanical behavior of wood fiber/high density polyethylene compositesbased on digital image correlation[J]. Acta Materiae Compositae Sinica,2020,37(9):2173-2182(in Chinese). [26] ASTM. Standard test method for tensile properties for plastics: ASTM D638-14[S]. West Conshohocken: ASTM International, 2014. [27] TIAN X, LIU T, WANG Q, et al. Recycling and remanufacturing of 3D printed continuous carbon fiber reinforced PLA composites[J]. Journal of Cleaner Production,2017,142:1609-1618. doi: 10.1016/j.jclepro.2016.11.139 [28] 邢开, 徐海兵, 颜春, 等. 碳纤维增强高性能热塑性复合材料界面改性的研究进展[J]. 玻璃钢/复合材料, 2019(5):110-115.XING Kai, XU Haibing, YAN Chun, et al. Research progress of interface modification of carbon fiber reinforced high performance thermoplastic composites[J]. Fiber Reinforced Plastics/Composites,2019(5):110-115(in Chinese). [29] XU C, CHENG K, LIU Y, et al. Effect of processing parame-ters on flexural properties of 3D-printed polyetherketoneketone using fused deposition modeling[J]. Polymer Engineering and Science,2021,61(2):465-476. doi: 10.1002/pen.25590 [30] HUANG B, MENG S, HE H, et al. Study of processing parameters in fused deposition modeling based on mechanical properties of acrylonitrile-butadiene-styrene filament[J]. Polymer Engineering and Science,2019,59(1):120-128. doi: 10.1002/pen.24875 [31] 冯东, 王博, 刘琦, 等. 高分子基功能复合材料的熔融沉积成型研究进展[J]. 复合材料学报, 2021, 38(5):1371-1386.FENG Dong, WANG Bo, LIU Qi, et al. Research progress in manufacturing multifunctional polymer composite materials based on fused deposition modeling technology[J]. Acta Materiae Compositae Sinica,2021,38(5):1371-1386(in Chinese). [32] ASTM. Standard test method for compressive properties of rigid plastics: ASTM D695-02a[S]. West Conshohocken: ASTM International, 2003. -

下载:

下载: