Research progress of cathode materials for lithium-ion battery

-

摘要: 锂离子电池(LIB)近年来受到了广泛的关注,与其他可充电电池相比,锂离子电池LIB具有更高的能量密度、功率和效率。正极作为LIB的关键部件,其特性会显著影响LIB的性能。本文分类综述了一些锂离子正极材料,包括一元、二元、三元金属锂氧化物和磷酸亚铁锂正极材料,并对其优缺点进行了介绍。此外,本文还对已商业化的正极材料物性数据和具有商业化应用前景的正极材料进行了系统评价。最后,总结了各类正极材料的优势和缺陷并讨论了未来的发展和挑战。Abstract: Lithium-ion battery (LIB) has received considerable attention in recent years, mainly because LIB has higher energy density, power and efficiency compared with other rechargeable batteries. The cathode material plays an important role in determining the LIB performance (e.g, capacity, thermal stability, and potential) and is the main part of LIB system. This paper presents a systematic classification of LIB cathode materials, including mono-, binary-, and ternary-based lithium metal oxide and lithium iron phosphate cathode materials, and the advantages and disadvantages of these cathode materials are systematically reviewed. The physical properties of commercialized cathode materials are compared and evaluated for potential commercialization. Finally, the advantages and disadvantages of each cathode materials are summarized, and the challenges and prospects of cathode materials for the future application are discussed.

-

图 2 Li+脱出与插入位置(8a和16c)[31] ((a)、(b))、LiMn2O4在1.4~4.4 V的CV曲线(c)、LiMn2O4在1.4~4.4 V的充放电曲线(d)、LiMn2O4在20 mA/g的循环容量曲线(e) [32]

Figure 2. Li+ delocalization and insertion positions (8a and 16c)[31] ((a), (b)), CV curves of LiMn2O4 at 1.4 to 4.4 V (c),charge/discharge curves of LiMn2O4 at 1.4 to 4.4 V (d) and cycle capacity curves of LiMn2O4 at 20 mA/g (e) [32]

图 3 不同温度烧结的LiNi1/3Mn1/3Co1/3O2在0.1 C的充放电循环性能 (a)、930℃烧结的LiNi1/3Mn1/3Co1/3O2的充放电曲线 (b)、930℃烧结的LiNi1/3Mn1/3Co1/3O2的CV曲线 (c)、LiNi0.8Mn0.1Co0.1O2在1 C的充放电循环性能 (d)、LiNi0.8Mn0.1Co0.1O2的充放电曲线 (e)、LiNi0.8Mn0.1Co0.1O2的CV曲线 (f)[47-48]

Figure 3. Cycling performance at 0.1 C ofLiNi1/3Mn1/3Co1/3O2 synthesized in 850, 880, 900, and 930℃ (a), Discharge/charge curves of LiNi1/3Mn1/3Co1/3O2 synthesized in 930℃ (b), CV curves of LiNi1/3Mn1/3Co1/3O2 synthesized in 930℃(c), Cycling performances of LiNi0.8Mn0.1Co0.1O2 at 1 C (d), Discharge/charge curves of LiNi0.8Mn0.1Co0.1O2 (e) and CV curves of LiNi0.8Mn0.1Co0.1O2 (f)[47-48]

图 4 5wt%碳包覆、10wt%碳包覆、15wt%碳包覆的LiFePO4/C的电化学性能:(a) 首次充电/放电曲线;(b)在0.2 C的循环性能;(c) 倍率放电性能[57]

Figure 4. Electrochemical performances of LiFePO4 coated with 5wt% carbon coated, 10wt% carbon, 15wt% carbon: (a) Initial charge/discharge curves; (b) Long-term cycling performance; (c) Rate ccyling performance[57]

图 6 不同碳含量包覆纳米氟化铁的储锂性能(FeF3/C-0、FeF3/C-2、FeF3/C-3、FeF3/C-4的碳含量分别为0wt%、2.1wt%、2.9wt%、3.9wt%):(a) 充放电曲线;(b) 在0.84 C (600 mA/g) 的充放电循环曲线;(c) 倍率循环性能;(d) CV曲线[93]

Figure 6. Lithium storage performances of carbon wrapped nano FeF3 (The carbon content in FeF3/C-0, FeF3/C-2, FeF3/C-3, FeF3/C-4 were 0wt%, 2.1wt%, 2.9wt%,3.9wt%, respectively): (a) Discharge/charge curves; (b) Cycling performance at 0.84 C (600 mA/g); (c) Rate cycling performance; (d) CV curves[93]

表 1 商业化锂离子电池正极材料的部分物性数据对比

Table 1. Performance data of commercial cathode materials

Cathode material LiCoO2 LiNiO2 LiMnO2 LiMn2O4 LiFePO4 NCM NCA Cell types α-NaFeO2 α-NaFeO2 α-NaFeO2 Spinel Peridot α-NaFeO2 α-NaFeO2 Voltage platforms/V Approx. 4.1 Approx. 3.8 Approx. 3.2 Approx. 4.1 Approx. 3.5 Approx. 3.8 Approx. 3.8 Theoretical specific capacity/

(mA·h·g−1)274 275 285 147 170 Approx. 270 275 Actual specific capacity/

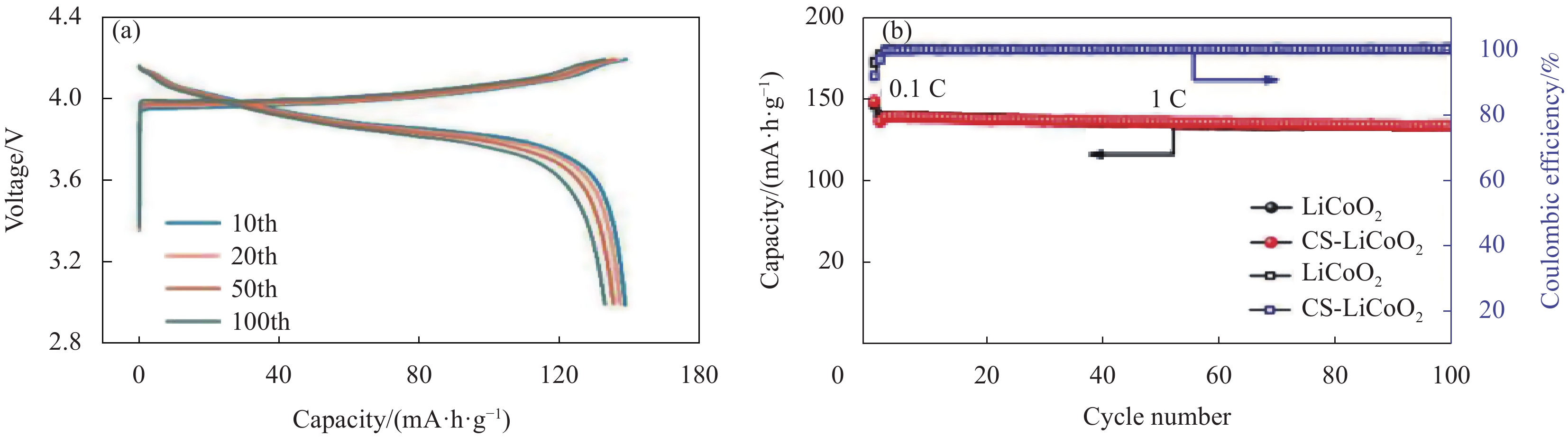

(mA·h·g−1)Approx. 140 Approx. 180 Approx. 150 Approx. 130 Approx. 140 145-190 160-200 Compaction density/

(g·cm−3)4.1-4.3 – – 2.9-3.2 2.2-2.3 3.4-3.7 3.8 Conductivity/(S·cm−1) Approx. 10−3 Approx. 10−1 – Approx. 10−5 10−7−10−9 – – Li+ diffusion coefficient/

(cm2·s−1)10−9 -10−8 10−7 – 10−9 -10−11 10−15 – – Thermal stability Instability Instability – Stability Very stable – – Cost Very high Moderate – Low Minimum – – Whether environmental

protectionToxic Low toxicity Basically

non-toxicBasically

non-toxicBasically

non-toxicToxic Toxic Notes: NCM—LiNixMnyCo1−x−yO2; “–”—Data not available. -

[1] CHENG Q, HE W, ZHANG X, et al. Modification of Li2MnSiO4 cathode materials for lithium-ion batteries: A review[J]. Journal of Materials Chemistry A,2017,5(22):10772-10797. doi: 10.1039/C7TA00034K [2] ZHANG L, WANG H, WANG L, et al. High electrochemical performance of lithium-rich Li1.2Mn0.54NixCoyO2 cathode materials for lithium-ion batteries[J]. Materials Letters,2016,185:100-103. doi: 10.1016/j.matlet.2016.08.118 [3] GANDOMAN F H, JAGUEMONT J, GOUTAM S, et al. Concept of reliability and safety assessment of lithium-ion batteries in electric vehicles: Basics, progress, and challenges[J]. Applied Energy,2019,251:113343. doi: 10.1016/j.apenergy.2019.113343 [4] KHARBACHI A, ZAVOROTYNSKA O, LATROCHE M, et al. Exploits, advances and challenges benefiting beyond Li-ion battery technologies[J]. Journal of Alloys and Compounds,2020,817:153261. doi: 10.1016/j.jallcom.2019.153261 [5] CHEN R, ZHAO T, ZHANG X, et al. Advanced cathode materials for lithium-ion batteries using nanoarchitectonics[J]. Nanoscale Horizons,2016,1(6):423-444. doi: 10.1039/C6NH00016A [6] ZHENG F, YANG C, XIONG X, et al. Nanoscale surface modification of lithium-rich layered-oxide composite cathodes for suppressing voltage fade[J]. Angewandte Chemie International Edition,2015,54(44):13058-13062. doi: 10.1002/anie.201506408 [7] CHENG F, CHEN J. Metal-air batteries: From oxygen reduction electrochemistry to cathode catalysts[J]. Chemical Society Reviews,2012,41(6):2172-2192. doi: 10.1039/c1cs15228a [8] ALABOINA P K, UDDIN M J, CHO S J. Nanoprocess and nanoscale surface functionalization on cathode materials for advanced lithium-ion batteries[J]. Nanoscale,2017,9(41):15736-15752. doi: 10.1039/C7NR02600E [9] GUAN P, ZHOU L, YU Z, et al. Recent progress of surface coating on cathode materials for high-performance lithium-ion batteries[J]. Journal of Energy Chemistry,2020,43:220-235. doi: 10.1016/j.jechem.2019.08.022 [10] ISLAM M. S, FISHER C. A. J. Lithium and sodium battery cathode materials: Computational insights into voltage, diffusion and nanostructural properties[J]. Chemical Society Reviews,2014,43(1):185-204. doi: 10.1039/C3CS60199D [11] ZHU P, GASTOL D, MARSHALL J, et al. A review of current collectors for lithium-ion batteries[J]. Journal of Power Sources,2021,485:229321. doi: 10.1016/j.jpowsour.2020.229321 [12] HUANG B, PAN Z, SU X, et al. Recycling of lithium-ion batteries: Recent advances and perspectives[J]. Journal of Power Sources,2018,399:274-286. doi: 10.1016/j.jpowsour.2018.07.116 [13] HSIEH C, HSU H, HSU J, et al. Infrared-assisted synthesis of lithium nickel cobalt alumina oxide powders as electrode material for lithium-ion batteries[J]. Electrochimica Acta,2016,206:207-216. doi: 10.1016/j.electacta.2016.04.146 [14] LI W. Review—An unpredictable hazard in lithium-ion batteries from transition metal ions: Dissolution from cathodes, deposition on anodes and elimination strategies[J]. Journal of The Electrochemical Society,2020,167:090514. doi: 10.1149/1945-7111/ab847f [15] MIZUSHIMA K, JONES P C, WISEMAN P J, et al. LiXCoO2 "(oless-thanxless-than-or-equal-to1)-A new cathode material for batteries of high-energy density[J]. Materials Research Bulletin,1980,15:783-789. doi: 10.1016/0025-5408(80)90012-4 [16] LIU X, TAN Y, WANG W, et al. Conformal prelithiation nanoshell on LiCoO2 enabling high-energy lithium-ion batteries[J]. Nano Letters,2020,20(6):4558-4565. doi: 10.1021/acs.nanolett.0c01413 [17] LYU Y, WU X, WANG K, et al. An overview on the advances of LiCoO2 cathodes for lithium-ion batteries[J]. Advanced Energy Materials,2021,11:2000982. doi: 10.1002/aenm.202000982 [18] JI X, XIA Q, XU Y, et al. A review on progress of lithium-rich manganese-based cathodes for lithium ion batteries[J]. Journal of Power Sources,2021,487:229362. doi: 10.1016/j.jpowsour.2020.229362 [19] ZHU J, CAO G, LI Y, et al. Efficient utilisation of rod-like nickel oxalate in lithium-ion batteries: A case of NiO for the anode and LiNiO2 for the cathode[J]. Scripta Materialia,2020,178:51-56. doi: 10.1016/j.scriptamat.2019.10.051 [20] KALYANI P, KALAISELVI N. Various aspects of LiNiO2 chemistry: A review[J]. Science and Technology of Advanced Materials,2005,6:689-703. doi: 10.1016/j.stam.2005.06.001 [21] BIANCHINI M, ROCA-AYATS M, HARTMANN P, et al. There and back again-The journey of LiNiO2 as a cathode active material[J]. Angewandte Chemie-International Edition,2019,58:10434-10458. doi: 10.1002/anie.201812472 [22] VLIKANGAS J, LAINE P, HIETANIEMI M, et al. Precipitation and calcination of high-capacity LiNiO2 cathode material for lithium-ion batteries[J]. Applied Sciences,2020,10:8988. doi: 10.3390/app10248988 [23] ZHU X, LIN T, ERIC M, et al. Recent advances on Fe- and Mn-based cathode materials for lithium and sodium ion batteries[J]. Journal of Nanoparticle Research,2018,20:160-200. doi: 10.1007/s11051-018-4235-1 [24] YU R, ZHANG X, LIU T, et al. Spinel/layered heterostructured lithium-rich oxide nanowires as cathode material for high-energy lithium-ion batteries[J]. ACS Applied Materials & Interfaces,2017,9:41210-41223. [25] ZHU X, MENG F, ZHANG Q, et al. LiMnO2 cathode stabilized by interfacial orbital ordering for sustainable lithium-ion batteries[J]. Nature Sustainability,2020,4(5):392-401. [26] TIAN Y, QIU Y, LIU Z, et al. LiMnO2@rGO nanocomposites for high-performance lithium-ion battery cathodes[J]. Nanotechnology,2020,32:015042. [27] SUSAI F A, TALIANKER M, LIU J, et al. Electrochemical activation of Li2MnO3 electrodes at 0 degrees C and its impact on the subsequent performance at higher tempera-tures[J]. Materials,2020,13:4388. doi: 10.3390/ma13194388 [28] VEENA R, DINESH J A, RAMAN S, et al. Li and Mn-rich Li4Mn5O12-Li2MnO3 composite cathode for next generation lithium-ion batteries[J]. Journal of Energy Storage,2019,24:100754. doi: 10.1016/j.est.2019.04.028 [29] SAROHA R, PANWAR A K, GAUR A, et al. Electrochemical studies of novel olivine-layered (LiFePO4-Li2MnO3) dual composite as an alternative cathode material for lithium-ion batteries[J]. Journal of Solid State Electrochemistry,2018,22:2507-2513. doi: 10.1007/s10008-018-3963-6 [30] LIU D, SU Z, WANG L. Pyrometallurgically regenerated LiMn2O4 cathode scrap material and its electrochemical properties[J]. Ceramics International,2021,47:42-47. doi: 10.1016/j.ceramint.2020.06.037 [31] ISHIZAWA N, TATEISHI K. Diffusion of Li atoms in LiMn2O4-A structural point of view[J]. Journal of the Ceramic Society of Japan,2009,117(1361):6-14. doi: 10.2109/jcersj2.117.6 [32] LUO F, WEI C, ZHANG C, et al. Operando X-ray diffraction analysis of the degradation mechanisms of a spinel LiMn2O4 cathode in different voltage windows[J]. Journal of Energy Chemistry,2020,44:138-146. doi: 10.1016/j.jechem.2019.09.011 [33] MARINCAS A, GOGA F, DORNEANU S, et al. Review on synthesis methods to obtain LiMn2O4-based cathode materials for Li-ion batteries[J]. Journal of Solid State Electrochemistry,2020,24:473-497. doi: 10.1007/s10008-019-04467-3 [34] LIU Y, LIU G, XU H, et al. Low-temperature synthesized Li4Mn5O12-like cathode with hybrid cation- and anion-redox capacities[J]. Chemical Communications,2019,55:8118-8121. doi: 10.1039/C9CC02006C [35] ZHANG X, SHI J, LIANG J, et al. Suppressing surface lattice oxygen release of Li-rich cathode materials via heterostructured spinel Li4Mn5O12 coating[J]. Advanced Materials,2018,30:1801751. doi: 10.1002/adma.201801751 [36] PFLEGING W. Recent progress in laser texturing of battery materials: a review of tuning electrochemical performances, related material development, and prospects for large-scale manufacturing[J]. International Journal of Extreme Manufacturing,2020,3(1):012002. doi: 10.1088/2631-7990/abca84 [37] AN Q, SUN X, GUO J, et al. Review-key strategies to increase the rate capacity of cathode materials for high power lithium-ion batteries[J]. Journal of The Electrochemical Society,2020,167:140528. doi: 10.1149/1945-7111/abc4bf [38] BELHAROUAK I, TSUKAMOTO H, AMINE K. LiNi0.5Co0.5O2 as a long-lived positive active material for lithium-ion batteries[J]. Journal of Power Sources,2003,119:175-177. [39] LI B, WU C, HU D, et al. Copper extraction from the ammonia leach liquor of spent lithium ion batteries for regenerating LiNi0.5Co0.5O2 by co-precipitation[J]. Hydrometallurgy,2020,193:105310. doi: 10.1016/j.hydromet.2020.105310 [40] ZHOU Y, LI H. Sol-gel template synthesis of highly ordered LiCo0.5Mn0.5O2 nanowire arrays and their structural properties[J]. Journal of Solid State Chemistry,2002,165:247-253. doi: 10.1006/jssc.2002.9512 [41] MYUNG S T, KOMABA S, KUMAGAI N. Hydrothermal synthesis of orthorhombic LiCoxMn1−xO2 and their structural changes during cycling[J]. Journal of The Electrochemical Society,2002,149:A1349-A1357. doi: 10.1149/1.1504453 [42] WANG H. LiNi0.5Mn1.5O4 cathodes for lithium ion batteries: A review[J]. Journal of Nanoscience and Nanotechnology,2015,15:6883-6890. doi: 10.1166/jnn.2015.10726 [43] GAO C, LIU H, BI S, et al. Insight into the high-temperature cycling stability of a micro-nanostructured LiNi0.5Mn1.5O4/graphene composite cathode for high-voltage lithium-ion batteries[J]. Journal of Physical Chemistry C,2020,124:18847-18858. doi: 10.1021/acs.jpcc.0c02933 [44] EIN-ELI Y, HOWARD W F, LU S H, et al. LiMn2−xCu xO4 spineis - 5 V cathode materials[J]. MRS Online Proceeding Library Archive,1997,496:315. doi: 10.1557/PROC-496-315 [45] YAN W, YANG S, HUANG Y, et al. A review on doping/coating of nickel-rich cathode materials for lithium-ion batteries[J]. Journal of Alloys and Compounds,2019,819:153048. [46] ZHAO X, WANG J, DONG X, et al. Structure design and performance of LiNixCoyMn1−x−yO2 cathode materials for lithium-ion batteries: A review[J]. Journal of the Chinese Chemical Society,2014,61:1071-1083. doi: 10.1002/jccs.201400107 [47] SHUAI H, LI J, HONG W, et al. Electrochemically modulated LiNi1/3Mn1/3Co1/3O2 cathodes for lithium-ion batteries[J]. Small Methods,2019,3:1900065. doi: 10.1002/smtd.201900065 [48] ZENG T, ZHANG C. An effective way of co-precipitating Ni2+, Mn2+ and Co2+ by using ammonium oxalate as precipitant for Ni-rich Li-ion batteries cathode[J]. Journal of Materials Science,2020,55:11535-11544. doi: 10.1007/s10853-020-04753-w [49] WANG Y, CHENG T, YU Z, et al. Study on the effect of Ni and Mn doping on the structural evolution of LiCoO2 under 4.6 V high-voltage cycling[J]. Journal of Alloys and Compounds,2020,842:155827. doi: 10.1016/j.jallcom.2020.155827 [50] KLEINER K, DIXON D, JAKES P, et al. Fatigue of LiNi0.8Co0.15Al0.05O2 in commercial Li ion batteries[J]. Journal of Power Sources,2015,273:70-82. doi: 10.1016/j.jpowsour.2014.08.133 [51] SAITO Y, SHIKANO M, KOBAYASHI H. State of charge (SOC) dependence of lithium carbonate on LiNi0.8Co0.15Al0.05O2 electrode for lithium-ion batteries[J]. Journal of Power Sources,2011,196:6889-6892. doi: 10.1016/j.jpowsour.2010.12.098 [52] WATANABE S, KINOSHITA M, NAKURA K. Capacity fade of LiNi(1− x−y)CoxAlyO2 cathode for lithium-ion batteries during accelerated calendar and cycle life test. I. Comparison analysis between LiNi(1−x−y)CoxAlyO= and Li CoO2 cathodes in cylindrical lithium-ion cells during long term storage test[[J]. Journal of Power Sources,2014,247:412-422. doi: 10.1016/j.jpowsour.2013.08.079 [53] LI W, LIU X, CELIO H, et al. Mn versus Al in layered oxide cathodes in lithium-ion batteries: A comprehensive evaluation on long-term cyclability[J]. Advanced Energy Materials,2018,8:1703154. doi: 10.1002/aenm.201703154 [54] SHODAI T, OKADA S, TOBISHIMA, S, et al. Anode performance of a new layered nitride Li3−xCoxN (x=0.2–0.6)[J]. Journal of Power Sources,1997,68(2):515-518. doi: 10.1016/S0378-7753(97)02597-4 [55] PADHI A K, NANJUNDASWAMY K S, GOODENOUGH J B. Phospho-olivines as positive-electrode materials for rechargeable lithium batteries[J]. Journal of The Electrochemical Society,1997,144:1188-1194. doi: 10.1149/1.1837571 [56] QIN C, LI Y, LV S, et al. Enhancing electrochemical performance of LiFePO4 by vacuum-infiltration into expanded graphite for aqueous Li-ion capacitors[J]. Electrochimica Acta,2017,253:413-421. doi: 10.1016/j.electacta.2017.09.069 [57] SHI M, LI R, LIU Y. In situ preparation of LiFePO4/C with unique copolymer carbon resource for superior perfor-mance lithium-ion batteries[J]. Journal of Alloys and Compounds,2021,854:157162. doi: 10.1016/j.jallcom.2020.157162 [58] WU Y, CHONG S, LIU Y, et al. Review on Li-insertion/extraction mechanisms of LiFePO4 cathode materials[J]. Chinese Journal of Structural Chemistry,2018,37:2011-2023. [59] SUN S, AN Q, TIAN Z, et al. Low-temperature synthesis of LiFePO4 nanoplates/C composite for lithium ion batteries[J]. Energy & Fuels,2020,34:11597-11605. [60] WEN L, HU X, LUO H, et al. Open-pore LiFePO4/C microspheres with high volumetric energy density for lithium ion batteries[J]. Particuology,2015,22:24-29. doi: 10.1016/j.partic.2014.11.002 [61] ZHANG X, HE W, YUE Y, et al. Bio-synthesis participated mechanism of mesoporous LiFePO4/C nanocomposite microspheres for lithium ion battery[J]. Journal of Materials Chemistry,2012,22:19948-19956. doi: 10.1039/c2jm33425a [62] YILMAZ M, RAINA S, HSU S H, et al. Micropatterned arrays of vertically-aligned CNTs grown on aluminum as a new cathode platform for LiFePO4 integration in lithium-ion batteries[J]. Ionics,2019,25:421-427. doi: 10.1007/s11581-018-2651-y [63] FEY G T K, KUMAR P. Long-cycling coated LiCoO2 cathodes for lithium batteries-A review[J]. Journal of Industrial And Engineering Chemistry,2004,10:1090-1103. [64] SHAARI H R, SETHUPRAKHASH V. Review of electrochemical performance of LiNiO2 and their derivatives as cathode material for lithium-ion batteries[J]. Jurnal Teknologi,2014,70:7-13. [65] SASSIN M B, GREENBAUM S G, STALLWORTH P E, et al. Achieving electrochemical capacitor functionality from nanoscale LiMn2O4 coatings on 3-D carbon nanoarchitectures[J]. Journal of Materials Chemistry A,2013,1:2431-2440. doi: 10.1039/c2ta00937d [66] YI T, HAO C, YUE C, et al. A literature review and test: Structure and physicochemical properties of spinel LiMn2O4 synthesized by different temperatures for lithium ion battery[J]. Synthetic Metals,2009,159:1255-1260. doi: 10.1016/j.synthmet.2009.02.026 [67] SHI X, HAN X, SHI X, et al. Synthesis and performance of LiMnO2 as cathodes for Li-ion batteries[J]. Journal of Wuhan University of Technology-Mater. Sci. Ed,2003,18:5-8. doi: 10.1007/BF02838446 [68] WANG J, SUN X. Olivine LiFePO4: The remaining challenges for future energy storage[J]. Energy & Environmental Science,2015,8:1110-1138. [69] MANTHIRAM A, KNIGHT J C, MYUNG S T, et al. Nickel-rich and lithium-rich layered oxide cathodes: Progress and perspectives[J]. Advanced Energy Materials,2016,6:1501010. doi: 10.1002/aenm.201501010 [70] ZHU C, SHU J, WU X, et al. Electrospun V2O5 micro/nano-rods as cathode materials for lithium ion battery[J]. Journal of Electroanalytical Chemistry,2015,759:184-189. doi: 10.1016/j.jelechem.2015.11.013 [71] ZHU L, GE P, XIE L, et al. Doped-Li1+xV3O8 as cathode materials for lithium-ion batteries: A mini review[J]. Electrochemistry Communications,2020,115:106722. doi: 10.1016/j.elecom.2020.106722 [72] QIN R, WEI Y, ZHAI T, et al. LISICON structured Li3V2(PO4)3 with high rate and ultralong life for low-temperature lithium-ion batteries[J]. Journal of Materials Chemistry A,2018,6:9737-9746. doi: 10.1039/C8TA01124A [73] CROY J R, GALLAGHER K G, BALASUBRAMANIAN M, et al. Examining hysteresis in composite xLi2MnO3·(1-x)LiMO2 cathode structures[J]. The Journal of Physical Chemistry C,2013,117:6525-6536. [74] PADHI A K, ARCHIBALD W B, NANJUNDASWAMY K S, et al. Ambient and high-pressure structures of LiMnVO4 and its Mn3+x/Mn2+x redox energy[J]. Journal of Solid State Chemistry,1997,128:267-272. doi: 10.1006/jssc.1996.7217 [75] WAGNER N, SVENSSON A M, VULLUM-BRUER F. Effect of carbon content and annealing atmosphere on phase purity and morphology of Li2MnSiO4 synthesized by a PVA assisted sol–gel method[J]. Solid State Ionics,2015,276:26-32. doi: 10.1016/j.ssi.2015.03.029 [76] TAN H, YU X, HUANG K, et al. Large-scale carambola-like V2O5 nanoflowers arrays on microporous reed carbon as improved electrochemical performances lithium-ion batteries cathode[J]. Journal of Energy Chemistry,2020,51:388-395. doi: 10.1016/j.jechem.2020.03.053 [77] FENG J, LIU X, ZHANG X, et al. Effects of synthesis methods on Li1+xV3O8 as cathodes in lithium-ion batteries[J]. Journal of The Electrochemical Society,2009,156:A768. doi: 10.1149/1.3174386 [78] BI L, SONG Z, LIU X, et al. Critical roles of RuO2 nano-particles in enhancing cyclic and rate performance of LISICON Li3V2(PO4)3 cathode materials[J]. Journal of Alloys and Compounds,2020,845:156271. doi: 10.1016/j.jallcom.2020.156271 [79] YUAN Z, CUI Y, SHEN M, et al. Preparation and electrochemical performance of LiTi2(PO4)3/C composite cathode for lithium ion batteries[J]. Acta Physico-Chimica Sinica,2012,28:1169-1176. doi: 10.3866/PKU.WHXB201203012 [80] ZHOU J, SUN X, WANG K. Preparation of high-voltage Li3V2(PO4)3 co-coated by carbon and Li7La3Zr2O12 as a stable cathode for lithium-ion batteries[J]. Ceramics International,2016,42:10228-10236. doi: 10.1016/j.ceramint.2016.03.144 [81] NAYAK P K, ERICKSON E M, SCHIPPER F, et al. Review on challenges and recent advances in the electrochemical performance of high capacity Li- and Mn-rich cathode materials for Li-ion batteries[J]. Advanced Energy Materials,2018,8:1702397. doi: 10.1002/aenm.201702397 [82] KIM D, SANDI G, CROY J R, et al. Composite 'layered-layered-spinel' cathode structures for lithium-ion batteries[J]. Journal of The Electrochemical Society,2013,160:A31-A38. doi: 10.1149/2.049301jes [83] ATES M N, MUKERJEE S, ABRAHAM K M. A search for the optimum lithium rich layered metal oxide cathode material for Li-ion batteries[J]. Journal of The Electrochemical Society,2015,162:A1236-A1245. doi: 10.1149/2.0481507jes [84] LI J, LI M, ZHANG L, et al. General synthesis of xLi2MnO3(1−x)LiNi1/3-Co1/3Mn1/3O2(x=1/4, 1/3, and 1/2) hollow microspheres towards enhancing the performance of rechargeable lithium ion batteries[J]. Journal of Materials Chemistry A,2016,4:12442-12450. doi: 10.1039/C6TA04219H [85] FEY G T K, LI W, DAHN J R. LiNiVo4-A 4.8 volt electrode material for lithium cells[J]. Journal of The Electrochemical Society,1994,141:2279-2282. doi: 10.1149/1.2055111 [86] HAREENDRAKRISHNAKUMAR H, CHULLIYOTE R, JOSEPH M G. Micro- and nanocrystalline inverse spinel LiCoVO4 for intercalation pseudocapacitive Li+ storage with ultrahigh energy density and long-term cycling[J]. ACS Applied Energy Materials,2018,1:393-401. doi: 10.1021/acsaem.7b00070 [87] PRAKASH D, MASUDA Y, SANJEEVIRAJA C. Structural, electrical and electrochemical studies of LiCoVO4 cathode material for lithium rechargeable batteries[J]. Powder Technology,2013,235:454-459. doi: 10.1016/j.powtec.2012.10.042 [88] VAJEESTON P, BIANCHINI F, FJELLVAG H. First-principles study of the structural stability and dynamic properties of Li2MSiO4(M=Mn, Co, Ni) Polymorphs[J]. Energies,2019,12(2):224. doi: 10.3390/en12020224 [89] GONG Z, LI Y, YANG Y. Synthesis and electrochemical performance of Li2CoSiO4 as cathode material for lithium ion batteries[J]. Journal of Power Sources,2007,174:524-527. doi: 10.1016/j.jpowsour.2007.06.250 [90] TSUBAKIYAMA K, KUDO Y, YAMASHITA K. First-principles study on Li2MSiO4(M=Mn, Fe, Co, Ni) as cathode materials of lithium ion battery[J]. ECS Transactions,2013,53:25-34. [91] HU Z, ZHANG K, GAO H, et al. Li2MnSiO4@C nanocomposite as a high-capacity cathode material for Li-ion batteries[J]. Journal of Materials Chemistry A,2013,1:12650-12656. doi: 10.1039/c3ta12106b [92] WANG L, WU Z, ZOU J, et al. Li-free cathode materials for high energy density lithium batteries[J]. Joule,2019,3:2086-2102. doi: 10.1016/j.joule.2019.07.011 [93] LI J, FU L, XU Z, et al. Electrochemical properties of carbon-wrapped FeF3 nanocomposite as cathode material for lithium ion battery[J]. Electrochimica Acta,2018,281:88-98. doi: 10.1016/j.electacta.2018.05.158 -

下载:

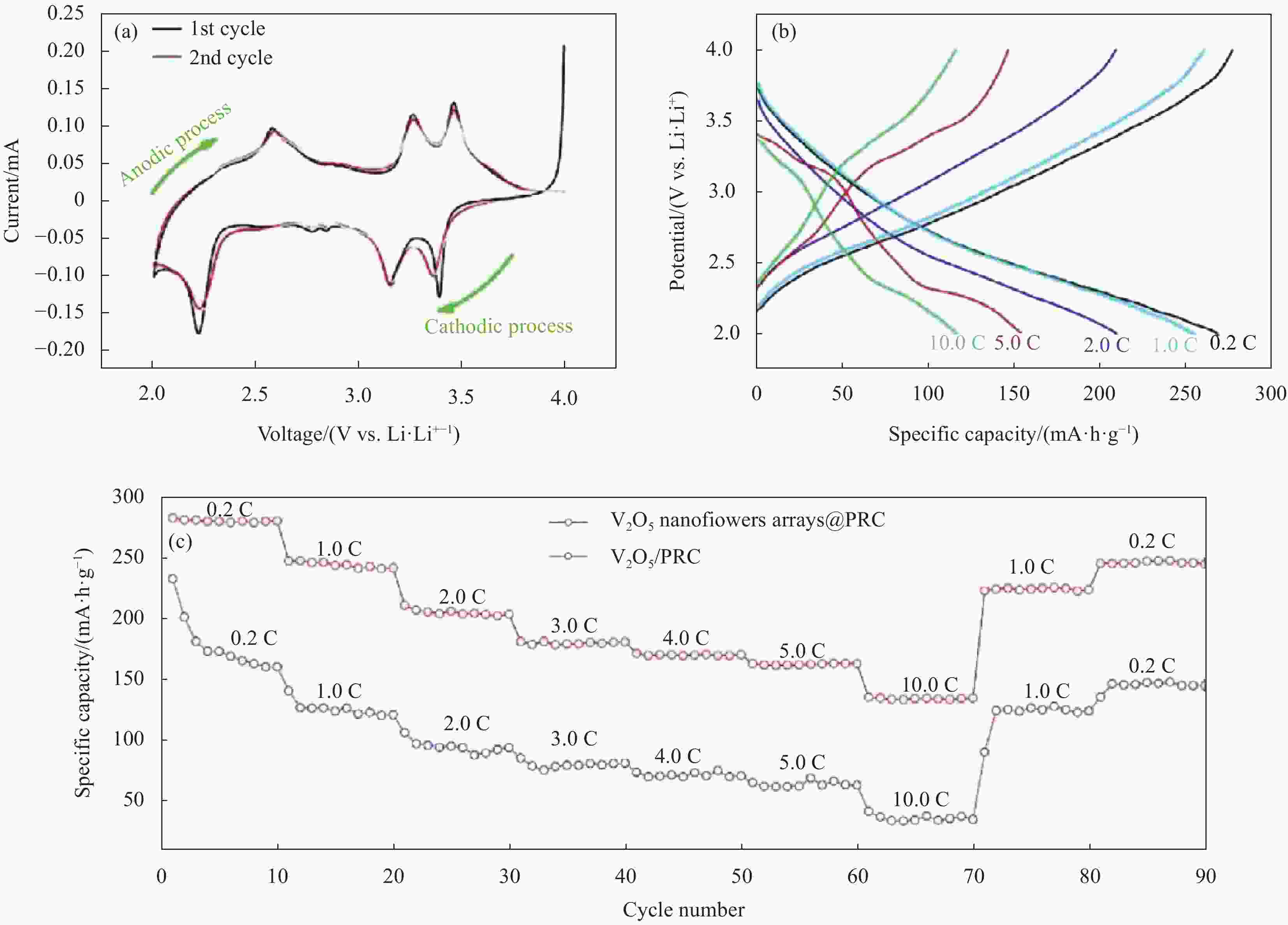

下载: