Shear thickening characteristics and mechanism of nano-SiO2/polyethylene glycol composite system

-

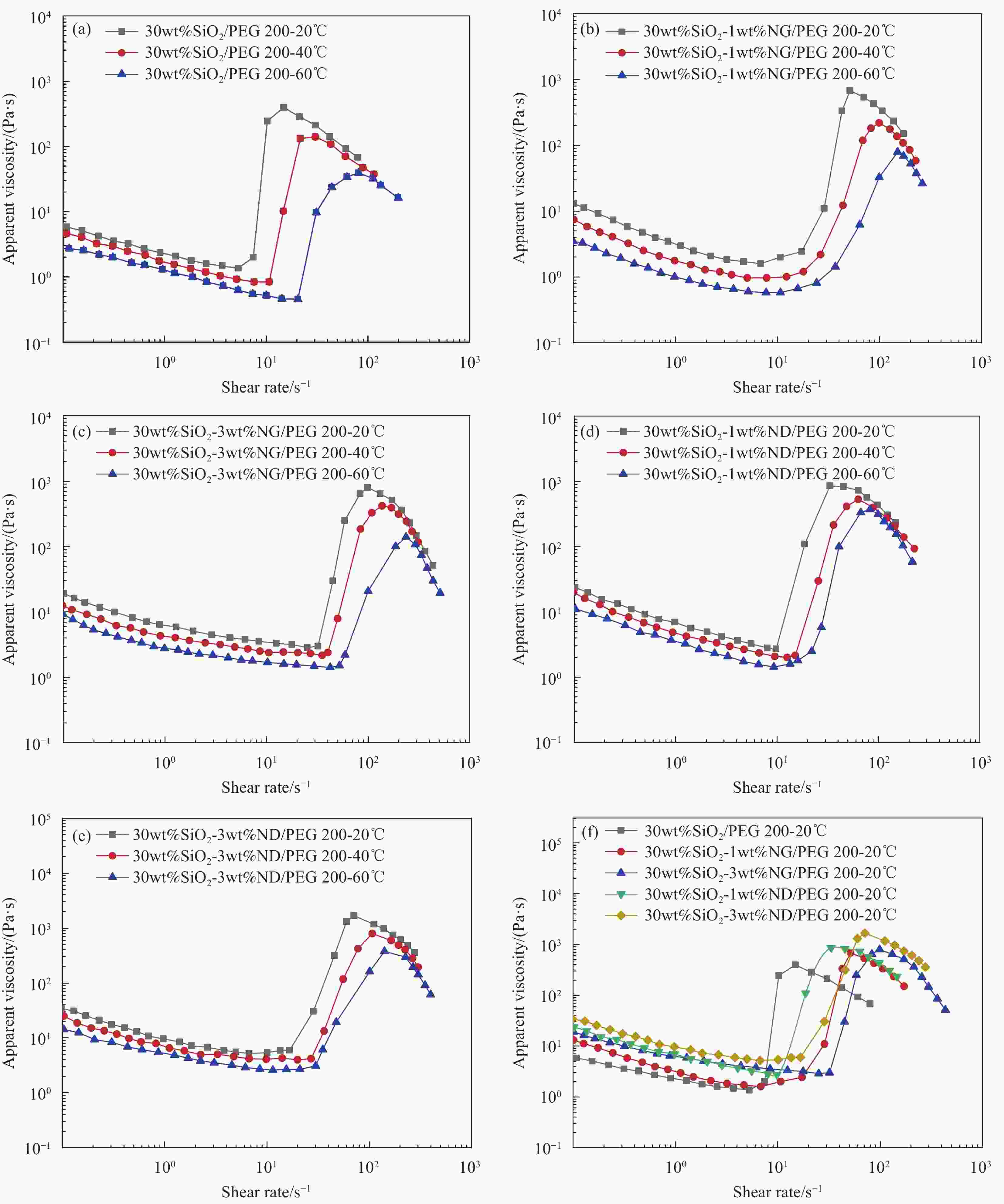

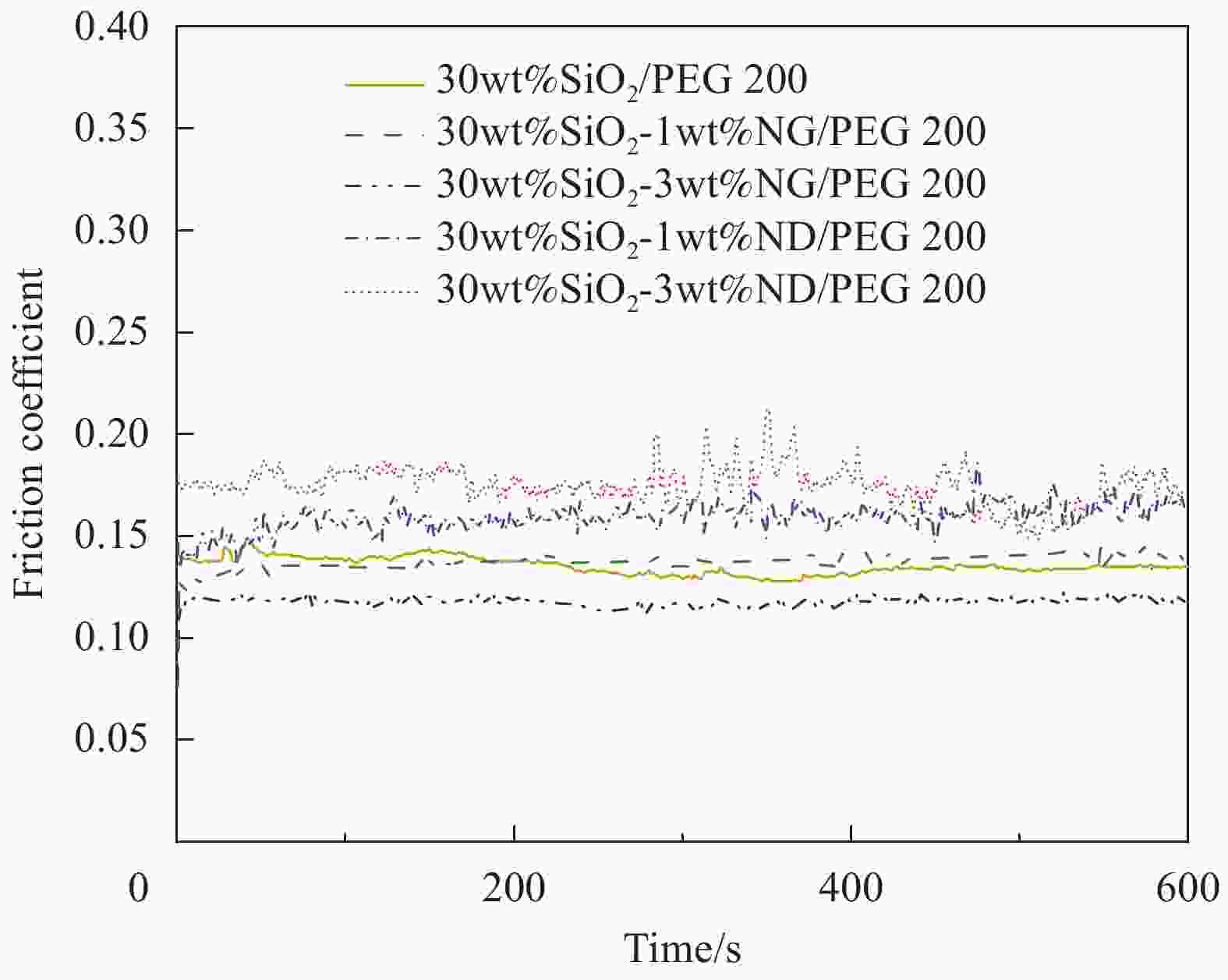

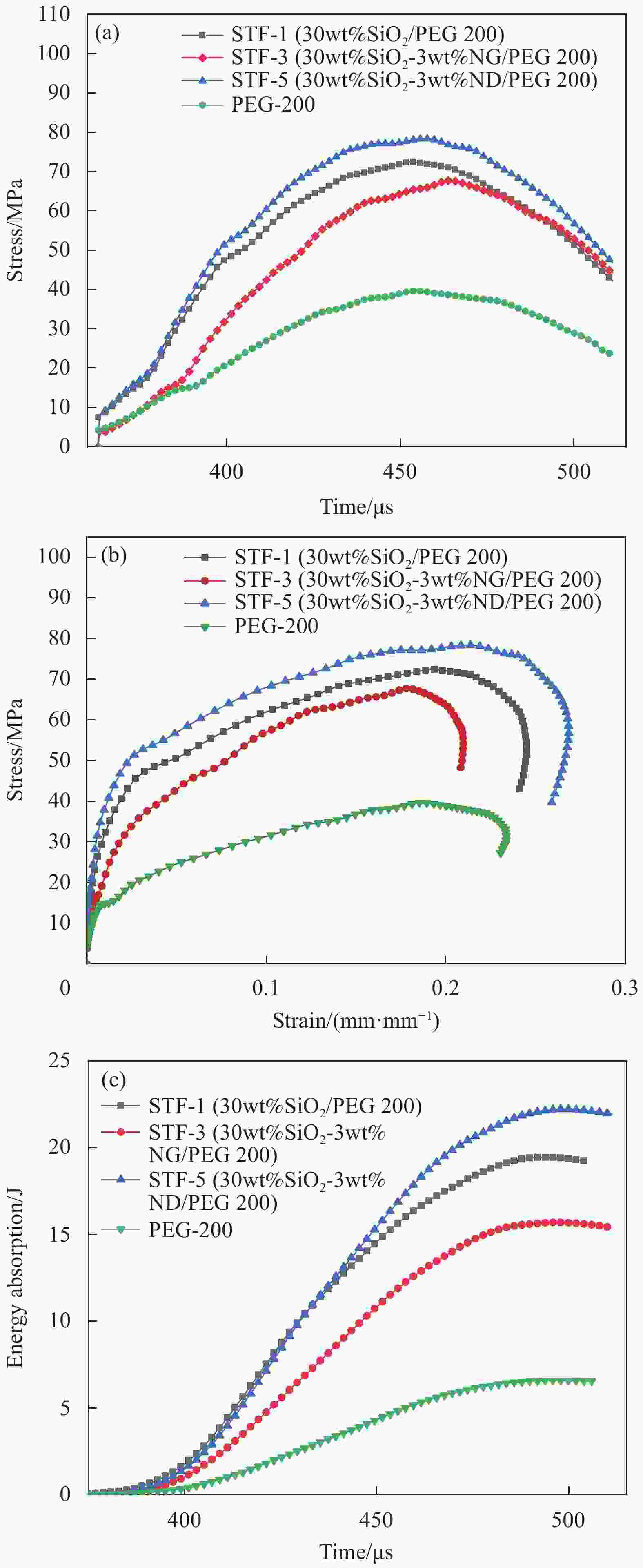

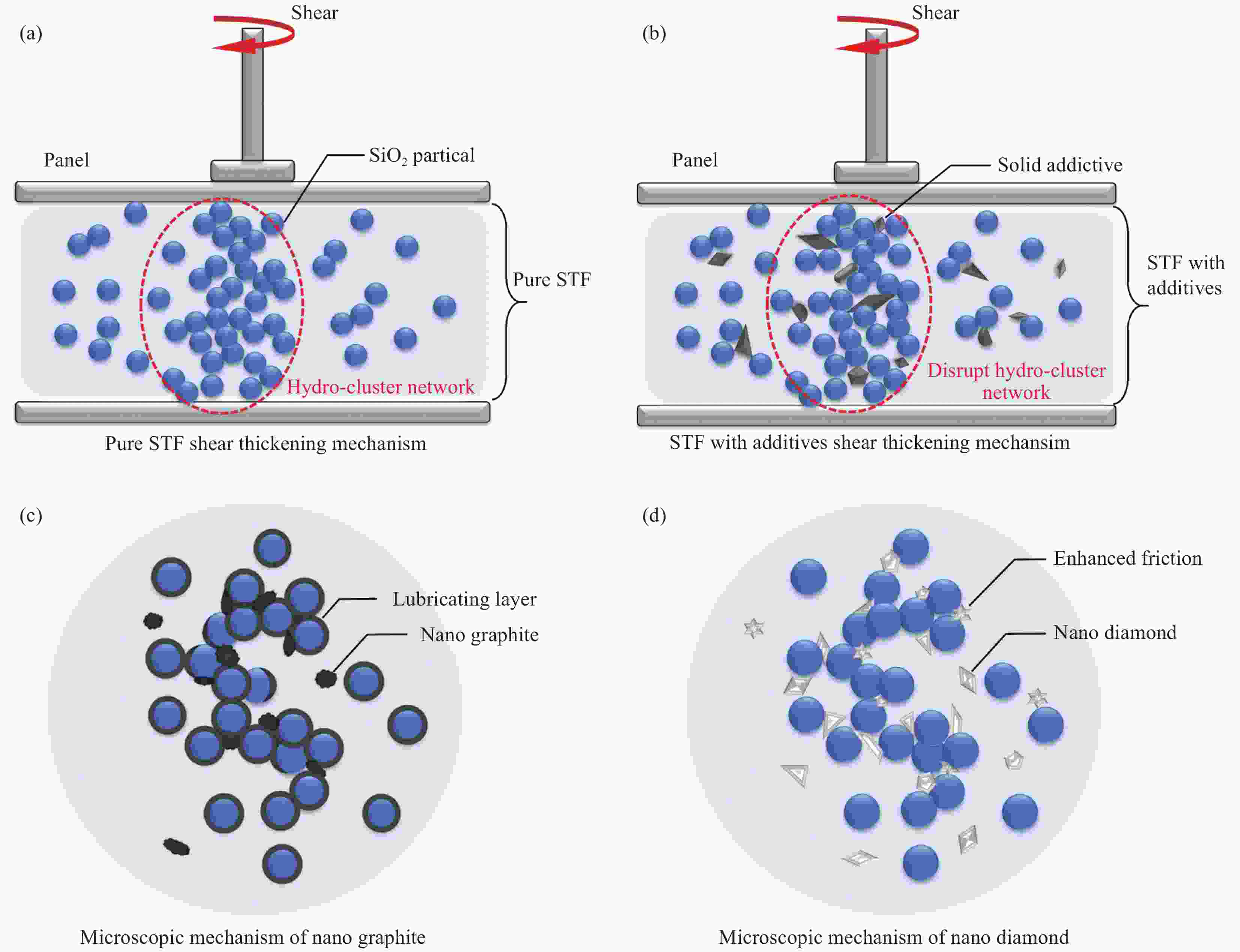

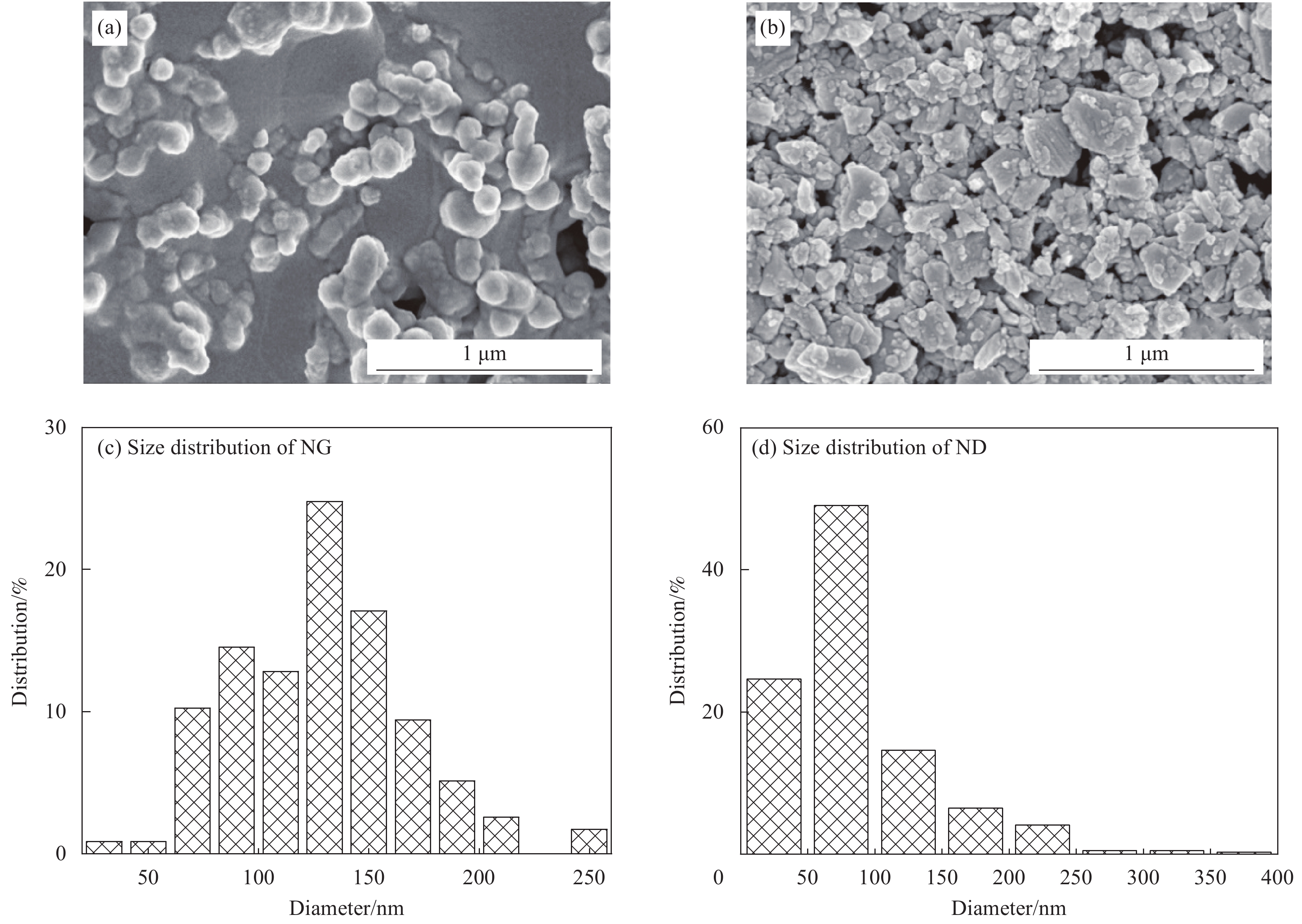

摘要: 为分析纳米固体颗粒在剪切增稠液体(STF)稠化过程中的影响及其在中低速稳态剪切和高速动态冲击环境下发挥的作用,以纳米SiO2和聚乙二醇(PEG 200)作为分散相和连续相,以不同含量的纳米石墨和纳米金刚石颗粒为添加剂,制备STF。研究样品的摩擦系数曲线和不同温度下的流变特性,以临界剪切速率、稠化区间长度和增稠比为指标依托,分析不同温度环境和不同纳米固体添加剂含量下剪切增稠机制的变化。并通过分离式霍普金森压杆(SHPB)实验探究瞬态高速冲击条件下STF的力学响应。流变特性实验结果表明:高温环境下分子间排斥力增强,粒子簇的形成需更强的分子间动力接触,因此稠化区间长度延长。纳米金刚石颗粒加强了粒子簇之间的接触耦合力和接触概率,使体系最大黏度达1679 Pa·s,增稠比值高达318倍,提升了STF的流变特性。SHPB实验的结果表明:在受到瞬时冲击后,STF可在50~75 μs时间范围内完成动态响应,最大应力可达78 MPa。子弹的入射动能不仅会转变为热能和固液转换的相变能,还能转变为颗粒间的摩擦能。因此,通过改变固体添加剂的参数,能有效控制STF的力学特性和增稠效果,从而制备出适合不同领域应用的STF。Abstract: In order to analyze the influence of nano-solid particles in the thickening process of shear thickening fluid (STF) and its role in the environment of low-speed steady-state shear and high-speed dynamic impact, nano-SiO2 and polyethylene glycol (PEG 200) were used as the dispersed and continuous phases, and different contents of nano-graphite and nano-diamond particles were used as additives to prepare several STF. The friction coefficient curve and the rheological properties at different temperatures were studied. Based on the critical shear rate, the length of the thickening period and the thickening ratio, the changes of shear thickening mechanism under different temperature environments and different nano-solid additive contents were analyzed. And the mechanical response of the STF under transient high-speed impact conditions was explore through the split Hopkinson pressure bar (SHPB) experiment. The experimental results of rheological properties show that the intermolecular repulsive force is enhanced under high temperature environment, and the formation of molecular clusters requires stronger intermolecular dynamic contact, so the length of the thickening interval is extended. Nano-diamond particles strengthen the contact coupling force and contact probability between the particle clusters, so that the maximum viscosity of the system reaches 1679 Pa·s, the thickening ratio is as high as 318 times, and the rheological properties of the STF are improved. The results of the SHPB experiment show that after being impacted, the STF can complete a dynamic response within a 50-75 μs time range, and the maximum stress can reach 78 MPa. The incident kinetic energy of the bullet is not only transformed into thermal energy and phase change energy of solid-liquid conversion, but also into frictional energy between particles. Therefore, by changing the parameters of the solid additive, the mechanical properties and thickening effect of the STF can be effectively controlled, to prepare the STF suitable for applications in different fields.

-

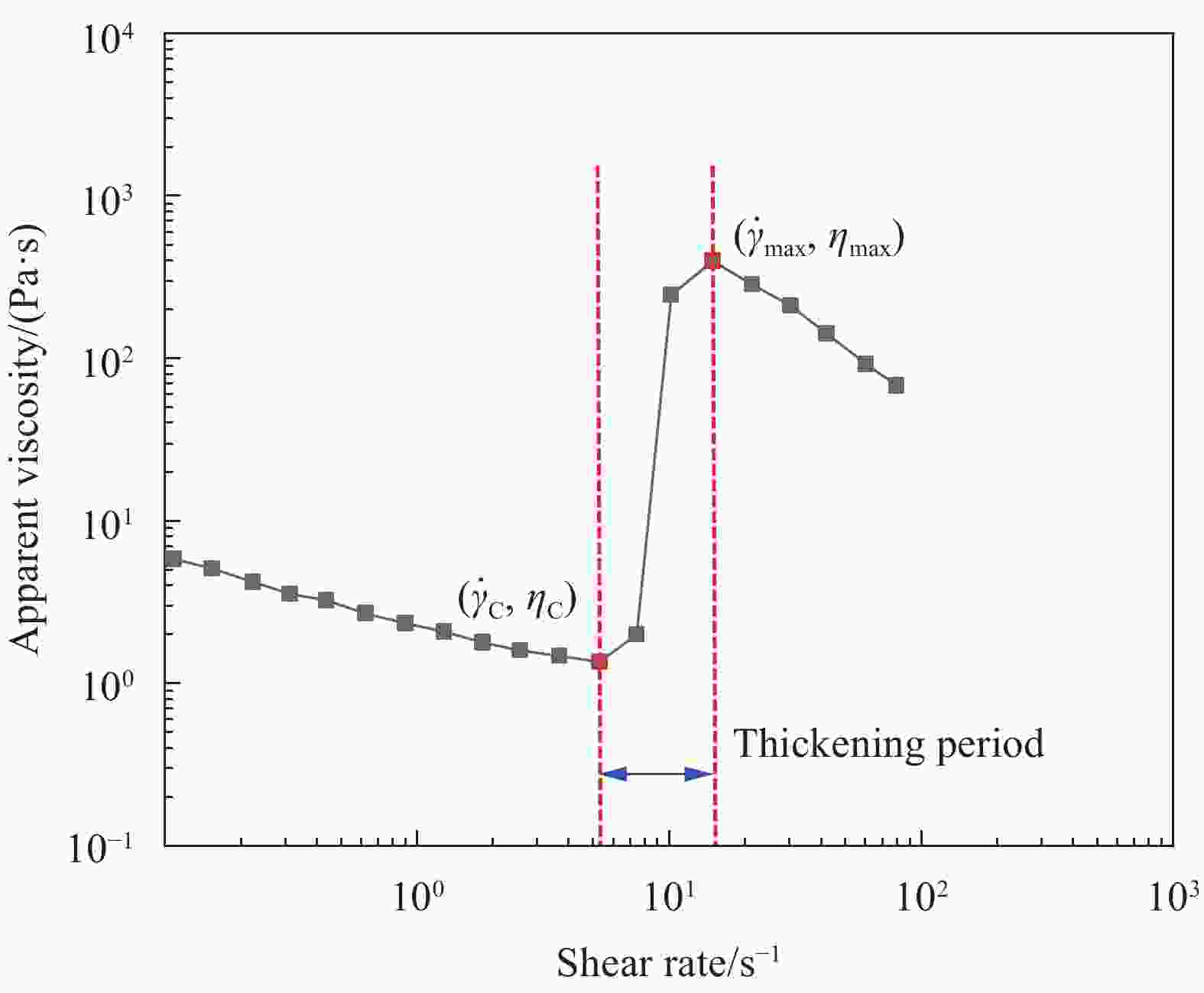

图 7 30wt%SiO2/PEG 200流变曲线参数示意图(20℃)

Figure 7. Schematic diagram of rheological curve parameters of 30wt%SiO2/PEG 200 (20℃)

${\dot \gamma} _{\rm{C}} $—Critical shear rate; ${\dot \gamma} _{\rm{max}} $—Shear rate corresponding to maximum viscosity; ηmax—Maximum viscosity; ηC—Viscosity corresponding to critical shear rate

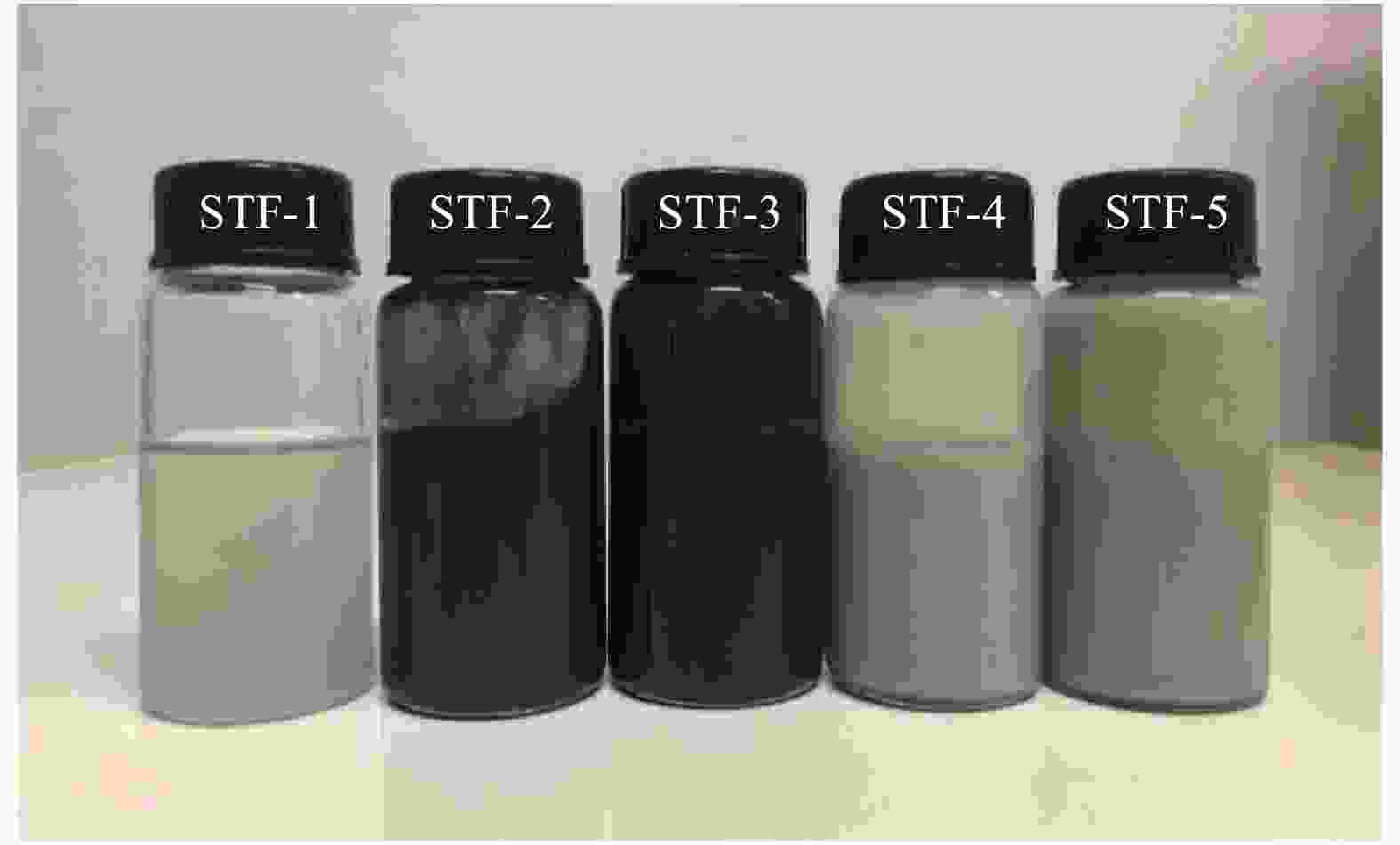

表 1 纳米SiO2/聚乙二醇(PEG 200)复合体系样品设计

Table 1. Sample design of nano-SiO2/polyethylene glycol (PEG 200) composite system

No. Code Dispersed phase Continuous phase Type of additive Additive content/wt% STF-1 30wt%SiO2/PEG 200 30wt%SiO2 PEG 200 — — STF-2 30wt%SiO2-1wt%NG/PEG 200 30wt%SiO2 PEG 200 NG 1 STF-3 30wt%SiO2-3wt%NG/PEG 200 30wt%SiO2 PEG 200 NG 3 STF-4 30wt%SiO2-1wt%ND/PEG 200 30wt%SiO2 PEG 200 ND 1 STF-5 30wt%SiO2-3wt%ND/PEG 200 30wt%SiO2 PEG 200 ND 3 表 2 SHPB设备基本参数

Table 2. Parameters of SHPB equipment

Parameter Value Incident rod length $ {L}_{\mathrm{I}} $/mm 2500 Transmission rod length $ {L}_{\mathrm{T}} $/mm 2500 Incident rod diameter $ {D}_{\mathrm{I}} $/mm 50 Transmission rod diameter $ {D}_{\mathrm{T}} $/mm 50 Distance between incident rod strain gauge and sample $ {L}_{\mathrm{I}\mathrm{S}} $/mm 1300 Distance between transmission rod strain gauge and sample $ {L}_{\mathrm{T}\mathrm{S}} $/mm 1300 Elasticity modulus of incident rod $ {E}_{\mathrm{A}} $/GPa 71 Elasticity modulus of transmission rod $ {E}_{\mathrm{B}} $/GPa 71 Rod material aluminum 7075 Rod density $ \rho $/$ (\mathrm{g}\cdot{\mathrm{c}\mathrm{m}}^{-3}) $ 2.81 Rod speed $ \nu $/$ ( $m·s−1) 5100 Bullet diameter $ {D}_{\mathrm{s}} $/mm 50 Bullet length $ {L}_{\mathrm{s}} $/mm 400 Sample thickness $ {T}_{\mathrm{s}} $/mm 10 Aluminum perforated sleeve length $ {L}_{\mathrm{T}\mathrm{U}} $/mm 50 Aluminum perforated sleeve thickness $ {D}_{\mathrm{T}\mathrm{U}} $/mm 15 表 3 纳米SiO2/PEG 200 STF在室温下的摩擦特性参数

Table 3. Friction characteristic parameters of nano-SiO2/PEG 200 STF at room temperature

Code Average friction coefficient Maximum friction coefficient 30wt%SiO2/PEG 200 0.135 0.15 30wt%SiO2-1wt%NG/PEG 200 0.136 0.146 30wt%SiO2-3wt%NG/PEG 200 0.118 0.15 30wt%SiO2-1wt%ND/PEG 200 0.159 0.187 30wt%SiO2-3wt%ND/PEG 200 0.175 0.217 表 4 纳米SiO2/PEG 200 STF流变曲线参数

Table 4. Rheological curve parameters of nano-SiO2/PEG 200 STF

Code Critical shear

rate $ {\dot{\mathrm{\gamma }}}_{\mathrm{C}}/{\rm{s}}^{-1} $Shear rate

corresponding to

maximum viscosity $ {\dot{\mathrm{\gamma }}}_{\mathrm{m}\mathrm{a}\mathrm{x}}/{\rm{s}}^{-1} $Viscosity

corresponding to

critical shear rate ${\mathrm{\eta } }_{\mathrm{C} }/(\mathrm{P}\mathrm{a} \cdot \mathrm{s})$Maximum

viscosity

$ {\eta }_{\mathrm{m}\mathrm{a}\mathrm{x}}/(\mathrm{P}\mathrm{a} \cdot \mathrm{s}) $Thickening

ratio R30wt%SiO2/PEG 200-20℃ 7.4 14.8 2 396.7 198.4 30wt%SiO2/PEG 200-40℃ 10.7 30.3 0.84 140 166.7 30wt%SiO2/PEG 200-60℃ 20.4 80.6 0.45 39.3 87.3 30wt%SiO2-1wt%NG/PEG 200-20℃ 17.3 51.4 2.4 680.8 283.7 30wt%SiO2-1wt%NG/PEG 200-40℃ 17.9 99 1.2 220 183.3 30wt%SiO2-1wt%NG/PEG 200-60℃ 24.1 150.1 0.8 79.5 99.4 30wt%SiO2-3wt%NG/PEG 200-20℃ 32 98.6 3 801 267 30wt%SiO2-3wt%NG/PEG 200-40℃ 40 137 2.4 420.3 175.1 30wt%SiO2-3wt%NG/PEG 200-60℃ 52.1 235.1 1.5 140.1 93.4 30wt%SiO2-1wt%ND/PEG 200-20℃ 9.8 33.2 2.7 858.6 318 30wt%SiO2-1wt%ND/PEG 200-40℃ 15.1 63.2 2.2 531.5 241.6 30wt%SiO2-1wt%ND/PEG 200-60℃ 22 82.4 2.5 372.6 149 30wt%SiO2-3wt%ND/PEG 200-20℃ 16.6 71 6 1679 279.8 30wt%SiO2-3wt%ND/PEG 200-40℃ 27 107 4.2 798 190 30wt%SiO2-3wt%ND/PEG 200-60℃ 30 140.9 3.1 377.7 121.8 -

[1] GÜRGEN S, KUŞHAN M C, LI W. Shear thickening fluids in protective applications: A review[J]. Progress in Polymer Science,2017,75:48-72. doi: 10.1016/j.progpolymsci.2017.07.003 [2] FREUNDLICH H, RÖDER H. Dilatancy and its relation to thixotropy[J]. Transactions of the Faraday Society,1938,34(1):308-316. [3] BARNES H. Shear-thickening (“Dilatancy”) in suspensions of nonaggregating solid particles dispersed in Newtonian liquids[J]. Journal of Rheology,1989,33(2):329-366. doi: 10.1122/1.550017 [4] ZHANG S, WANG S, WANG Y, et al. Conductive shear thickening gel/polyurethane sponge: A flexible human motion detection sensor with excellent safeguarding perfor-mance[J]. Composites Part A: Applied Science and Manufacturing,2018,112:197-206. doi: 10.1016/j.compositesa.2018.06.007 [5] SEN S, JAMAL M N B, SHAW A, et al. Numerical investigation of ballistic performance of shear thickening fluid (STF)-Kevlar composite[J]. International Journal of Mechanical Sciences,2019,164:105174. doi: 10.1016/j.ijmecsci.2019.105174 [6] SANTOS T F, SANTOS C M S, AQUINO M S, et al. Influence of silane coupling agent on shear thickening fluids (STF) for personal protection[J]. Journal of Materials Research and Technology,2019,8(5):4032-4039. doi: 10.1016/j.jmrt.2019.07.013 [7] MAWKHLIENG U, MAJUMDAR A. Deconstructing the role of shear thickening fluid in enhancing the impact resistance of high-performance fabrics[J]. Composites Part B: Engineering,2019,175:107167. [8] CAO S, HE Q, PANG H, et al. Stress relaxation in the transition from shear thinning to shear jamming in shear thickening fluid[J]. Smart Materials and Structures,2018,27(8):085013. doi: 10.1088/1361-665X/aacbf8 [9] HADDE E K, CHEN J. Shear and extensional rheological characterization of thickened fluid for dysphagia management[J]. Journal of Food Engineering,2019,245:18-23. doi: 10.1016/j.jfoodeng.2018.10.007 [10] LIU M, JIAN W, WANG S, et al. Shear thickening fluid with tunable structural colors[J]. Smart Materials and Structures,2018,27(9):095012. doi: 10.1088/1361-665X/aad587 [11] CHEN K, WANG Y, XUAN S, et al. A hybrid molecular dynamics study on the non-Newtonian rheological behaviors of shear thickening fluid[J]. Journal of Colloid and Interface Science,2017,497:378-384. doi: 10.1016/j.jcis.2017.03.038 [12] GE J, TAN Z, LI W, et al. The rheological properties of shear thickening fluid reinforced with SiC nanowires[J]. Results in Physics,2017,7:3369-3372. doi: 10.1016/j.rinp.2017.08.065 [13] GONG X, CHEN Q, LIU M, et al. Squeeze flow behavior of shear thickening fluid under constant volume[J]. Smart Materials and Structures,2017,26(6):065017. doi: 10.1088/1361-665X/aa6ef0 [14] GüRGEN S, LI W, KUŞHAN M C. The rheology of shear thickening fluids with various ceramic particle additives[J]. Materials & Design,2016,104:312-319. [15] GÜRGEN S, KUŞHAN M C. The ballistic performance of aramid based fabrics impregnated with multi-phase shear thickening fluids[J]. Polymer Testing,2017,64:296-306. doi: 10.1016/j.polymertesting.2017.11.003 [16] GÜRGEN S, SOFUOĞLU M A. Experimental investigation on vibration characteristics of shear thickening fluid filled CFRP tubes[J]. Composite Structures,2019,226:111236. doi: 10.1016/j.compstruct.2019.111236 [17] LAHA A, MAJUMDAR A. Shear thickening fluids using silica-halloysite nanotubes to improve the impact resistance of p-aramid fabrics[J]. Applied Clay Science,2016,132-133:468-474. doi: 10.1016/j.clay.2016.07.017 [18] LIU M, CHEN Q, WANG S, et al. PVP immobilized SiO2 nanospheres for high-performance shear thickening fluid[J]. Journal of Nanoparticle Research,2017,19(7):234. doi: 10.1007/s11051-017-3911-x [19] LI S, WANG J, CAI W, et al. Effect of acid and temperature on the discontinuous shear thickening phenomenon of silica nanoparticle suspensions[J]. Chemical Physics Letters,2016,658:210-214. doi: 10.1016/j.cplett.2016.06.055 [20] HOFFMAN R L. Discontinuous and dilatant viscosity behavior in concentrated suspensions. i. Observation of a flow instability[J]. Transactions of the Society of Rheology,1972,16(1):155-173. doi: 10.1122/1.549250 [21] BRADY J F, BOSSIS G. The rheology of concentrated suspensions of spheres in simple shear flow by numerical simulation[J]. Journal of Fluid Mechanics,1985,155:105. doi: 10.1017/S0022112085001732 [22] HEAD D A, AJDARI A, CATES M E. Jamming, hysteresis, and oscillation in scalar models for shear thickening[J]. Physical Review E Statistical Nonlinear & Soft Matter Physics,2001,64(6):061509. [23] LOOTENS D, VAN DAMME H, HÉBRAUD P. Giant stress fluctuations at the jamming transition[J]. Physical Review Letters,2003,90(17):178301. doi: 10.1103/PhysRevLett.90.178301 [24] DONEV A, TORQUATO S, STILLINGER F H, et al. Comment on "Jamming at zero temperature and zero applied stress: The epitome of disorder"[J]. Physical Review E Statistical Nonlinear & Soft Matter Physics,2004,70(4):043301. [25] ANDREOTTI B, BARRAT J L, HEUSSINGER C. Shear flow of non-Brownian suspensions close to jamming[J]. Physical Review Letters,2012,109(10):105901. doi: 10.1103/PhysRevLett.109.105901 [26] SETO R, MARI R, MORRIS J F, et al. Discontinuous shear thickening of frictional hard-sphere suspensions[J]. Physical Review Letters,2013,111(21):218301. doi: 10.1103/PhysRevLett.111.218301 [27] MELROSE J R, BALL R C. Continuous shear thickening transitions in model concentrated colloids—The role of interparticle forces[J]. Journal of Rheology,2004,48(5):937. doi: 10.1122/1.1784783 [28] CATHERALL A A, MELROSE J R, BALL R C. Shear thickening and order-disorder effects in concentrated colloids at high shear rates[J]. Journal of Rheology,2000,44(1):1-25. doi: 10.1122/1.551072 -

下载:

下载: