A multi-scale prediction model of elastic modulus for ceramic matrix composites considering oxidation damage

-

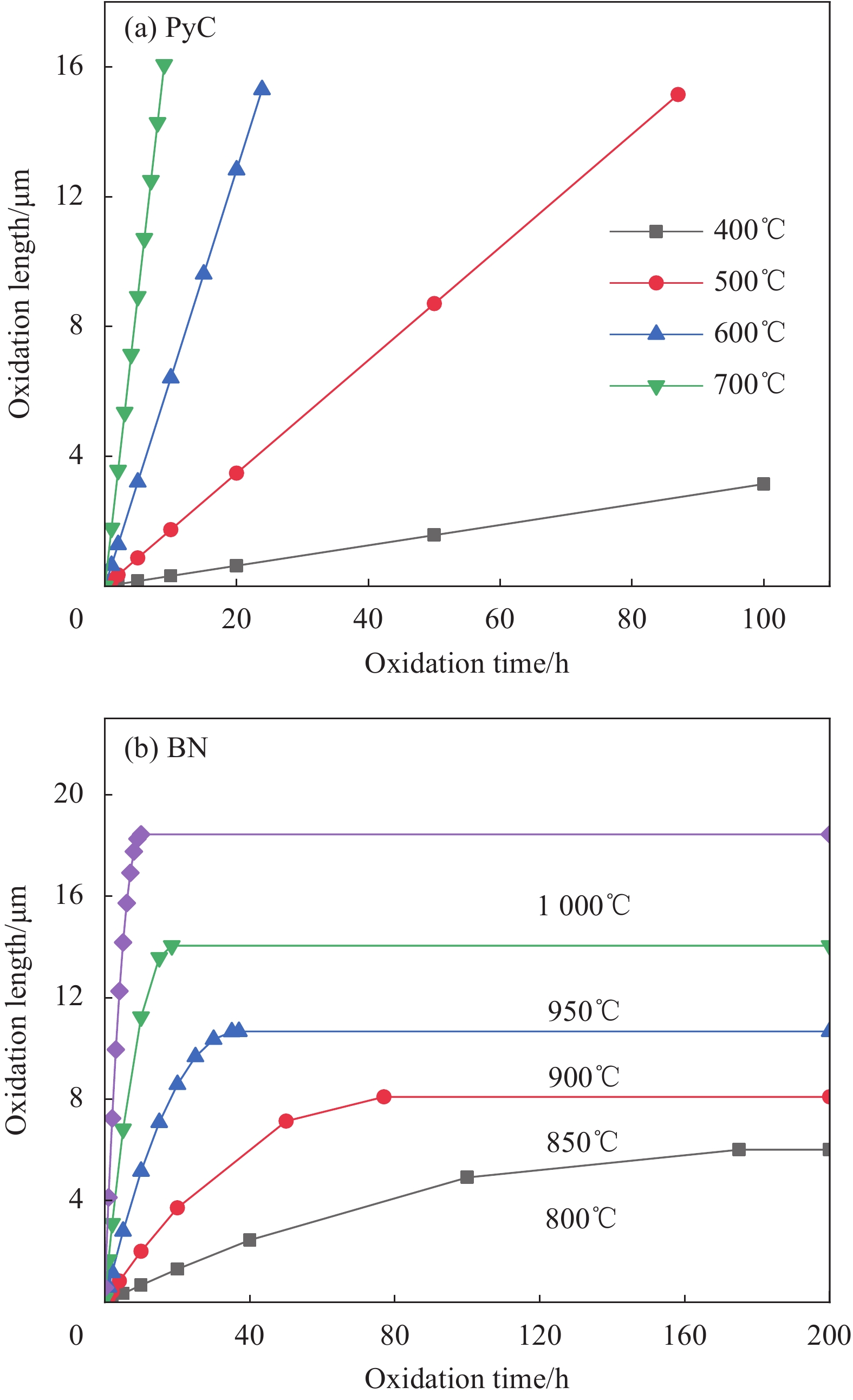

摘要: 分析了化学气相渗透(CVI)工艺制备的陶瓷基复合材料的氧化损伤演化规律,基于基体的微裂纹分布规律及界面、纤维、基体等组分氧化历程,建立了考虑温度、氧化时间影响的纤维和单胞两个尺度的弹性模量预测模型。预测结果表明,碳纤维(Cf)/SiC和SiC纤维(SiCf)/SiC复合材料的拉伸弹性模量随氧化温度升高和氧化时间的增长,下降趋势越明显。通过复合材料高温氧化后的力学性能试验,验证了弹性性能预测模型的正确性:BN界面的SiCf/SiC材料在1000℃不同时间氧化后预测结果与试验结果误差不超过2%;PyC界面的Cf/SiC在700℃不同时间氧化后预测结果与试验结果误差不超过7%。

-

关键词:

- 陶瓷基复合材料 /

- 化学气相渗透(CVI) /

- 氧化 /

- 多尺度 /

- 弹性模量

Abstract: The oxidation damage evolution law of ceramic matrix composites prepared by chemical vapor infiltration (CVI) process was analyzed. Considering the effects of temperature and oxidation time, prediction models of elastic modulus about fiber and cell were established based on the distribution of microcracks in matrix and the oxidation process of interface, fiber and matrix. The prediction results show that the tensile elastic moduli of carbon fiber (Cf)/SiC and SiC fiber (SiCf)/SiC composites decrease more obviously with the increase of temperature and oxidation time. The elastic prediction model was verified by the tensile tests of the composites after high temperature oxidation. The error between the prediction results and the test results of SiCf/SiC composites with BN interphase after oxidation at 1000 ℃ for different time is no more than 2%, and the error between the prediction results and the test results of Cf/SiC composites with PyC interphase after oxidation at 700℃ for different time is no more than 7%. -

表 1 空气中SiC的氧化速率常数[9]

Table 1. Rate constants for oxidation of SiC in air

Parameter Value A/m $A = 1.91 \times {10^{ - 10}}\exp \left( {\dfrac{{75.7{\rm{kJ}}/{\rm{mol}}}}{{RT}}} \right)$ B/(m2·s−1) $B = 3.01 \times {10^{ - 15}}\exp \left( {\dfrac{{ - 94.3{\rm{kJ}}/{\rm{mol}}}}{{RT}}} \right)$ Notes:B—Parabolic rate constant, which indicates the oxidation rate controlled by the rate of oxygen diffusion; B/A—Linear rate constant, which is the growth rate of oxide layer controlled by the rate of reaction. 表 2 陶瓷基复合材料纤维束中组分材料的弹性常数[20, 24-25]

Table 2. Elastic constants of components in the strand of ceramic matrix composites[20, 24-25]

Component Modulus/GPa Possion’s ratio Volume fraction/vol% Coefficient of thermal expansion/(10−6·K−1) EfL EfT GfLT νfLT αL αT C fiber 140 13.8 9.0 0.2 78 −0.3 3.1 SiC fiber 270 270 108 0.25 78 3.5 3.5 SiC matrix 350 350 146 0.2 20 4.6 4.6 Notes: EfL and EfT—axial and radial tensile moduli of fiber; GfLT—Transverse shear moduli of fiber; αL and αT—Coefficients of axial and radial thermal expansion; νfLT—Absolute values of the ratio of radial strain to axial strain. 表 3 陶瓷基复合材料单胞的几何参数

Table 3. Geometric parameters of the unit cell of ceramic matrix composites

Composite gf/mm gw/mm af/mm aw/mm hf/mm hm/mm hw/mm an/mm Cf/SiC 0.18 0.18 0.96 0.96 0.08 0.01 0.08 0.16 SiCf/SiC 0.18 0.18 1.07 1.07 0.20 0.08 0.20 0.40 表 4 BN界面的SiCf/SiC材料氧化前后质量变化

Table 4. Mass changes of SiCf/SiC with BN interphase before oxidation and after oxidation

Oxidation time/h Mass before oxidation/g Mass after oxidation/g Loss-mass rate/% 1 10.2482 10.2363 0.12 2.5 10.2624 10.2468 0.15 4 10.5446 10.5337 0.10 表 5 700℃空气氧化PyC界面的Cf/SiC弹性模量预测结果

Table 5. Prediction of elastic modulus of Cf/SiC with PyC interphase at 700℃ in air

Specimen 1 2, 3 4 Oxidation time/h 0 4 6 Experimental modulus/GPa 103.47 92.3 74.24 Theoretical modulus/GPa 100.43 86.52 78.03 Error/% −2.94 −6.26 5.1 表 6 1000℃空气氧化BN界面的SiCf/SiC弹性模量预测结果

Table 6. Prediction of elastic modulus of SiCf/SiC with BN interphase at 1000℃ in air

Oxidation time/h Experimental modulus/GPa Average modulus/GPa Theoretical modulus/GPa Error/% 0 229.26,233.09,234.43 232.26 229.96 −0.99 1 216.17,219.22,221.14 218.84 222.75 1.79 2.5 213.26,216.81,221.05 217.04 215.78 −0.58 4 207.27,208.30,213.88 209.82 211.02 0.57 -

[1] 陈明伟, 谢巍杰, 邱海鹏. 连续碳化硅纤维增强碳化硅陶瓷基复合材料研究进展[J]. 现代技术陶瓷, 2016, 37(6):393-402.CHEN Mingwei, XIE Weijie, QIU Haipeng. Recent progress in continuous SiC Fiber reinforced SiC ceramic matrix composites[J]. Advanced Ceramics,2016,37(6):393-402(in Chinese). [2] 陈西辉, 孙志刚, 牛序铭, 等. SiC/SiC复合材料氧化退化研究进展[J]. 推进技术, 2020, 41(9):2143-2160.CHEN Xihui, SUN Zhigang, NIU Xuming, et al. Research progress of oxidation degradation of SiC/SiC composites[J]. Journal of Propulsion Technology,2020,41(9):2143-2160(in Chinese). [3] LAMOUROUX F, CAMUS G, THEBAULT J. Kinetics and mechanisms of oxidation of 2D woven C/SiC composites: I, Experimental approach[J]. Journal of the American Ceramic Society,1994,77(8):2049-2057. doi: 10.1111/j.1151-2916.1994.tb07096.x [4] YANG C P, JIAO G Q, WANG B. Modeling oxidation damage of continuous fiber reinforced ceramic matrix compo-sites[J]. Acta Mechanica Sinica,2011,27(3):382-388. doi: 10.1007/s10409-011-0438-8 [5] WING B L, HALLORAN J W. Subsurface oxidation of boron nitride coatings on silicon carbide fibers in SiC/SiC ceramic matrix composites[J]. Ceramics International,2018,44(14):17499-17505. doi: 10.1016/j.ceramint.2018.06.221 [6] National Research Council. Ceramic fibers and coatings: Advanced materials for the twenty-first century[M]. Washington: National Academic Press, 1998: 83-114. [7] 惠新育, 许英杰, 张卫红, 等. 平纹编织SiC/SiC复合材料多尺度建模及强度预测[J]. 复合材料学报, 2019, 36(10):2380-2388.HUI Xinyu, XU Yingjie, ZHANG Weihong, et al. Multi-scale modeling and strength prediction of plain woven SiC/SiC composites[J]. Acta Materiae Compositae Sinica,2019,36(10):2380-2388(in Chinese). [8] LIU X, SHEN X L, GONG L D, et al. Multi-scale thermodynamic analysis method for 2D SiC/SiC composite turbine guide vanes[J]. Chinese Journal of Aeronautics,2018,31(1):117-125. doi: 10.1016/j.cja.2017.08.018 [9] RAMBERG C E, CRUCIANI G, SPEAR K E, et al. Passive-oxidation kinetics of high-purity silicon carbide from 800° to 1100℃[J]. Journal of the American Ceramic Society,1996,79:2897-2911. doi: 10.1111/j.1151-2916.1996.tb08724.x [10] MA X K, YIN X W, FAN X M, et al. Evolution of mechanical and electromagnetic interference shielding properties of C/SiC during oxidation at 700℃[J]. Carbon,2020,157:1-11. doi: 10.1016/j.carbon.2019.09.088 [11] 孙志刚, 王振剑, 宋迎东. 无应力氧化下C/SiC复合材料弹性性能模拟及验证[J]. 复合材料学报, 2013, 30(1):172-179.SUN Zhigang, WANG Zhenjian, SONG Yingdong. Verification and prediction of elastic modulus of C/SiC compo-sites under non-stress oxidation[J]. Acta Materiae Compositae Sinica,2013,30(1):172-179(in Chinese). [12] LAMOUROUX F, BOURRAT X, NASALAIN R, et al. Structure/oxidation behavior relationship in the carbonaceous constituents of 2D-C/PyC/SiC composites[J]. Carbon,1993,31(8):1273-1288. doi: 10.1016/0008-6223(93)90086-P [13] GLIME W H, CAWLEY J D. Oxidation of carbon fibers and films in ceramic matrix composites: A weak link process[J]. Carbon,1995,33(8):1053-1059. doi: 10.1016/0008-6223(95)00034-B [14] 杨成鹏, 矫桂琼, 王波, 等. 2D-C/SiC复合材料的氧化损伤及刚度模型[J]. 复合材料学报, 2009, 26(3):175-181. doi: 10.3321/j.issn:1000-3851.2009.03.030YANG Chengpeng, JIAO Guiqiong, WANG Bo, et al. Oxidation damages and a stiffness model for 2D-C/SiC compo-sites[J]. Acta Materiae Compositae Sinica,2009,26(3):175-181(in Chinese). doi: 10.3321/j.issn:1000-3851.2009.03.030 [15] DEAL B E, GROVE A S. General relationship for the thermal oxidation of silicon[J]. Journal of Applied Physics,1965,36(12):3770-3778. doi: 10.1063/1.1713945 [16] NATHAN J, SERENE F, ARTHUR M, et al. High-temperature oxidation of boron nitride: I, Monolithic boron nitride[J]. Journal of the American Ceramic Society,1999,82(2):393-398. [17] PODOBEDA L G, TSAPUK A K, BURAVOV A D. Oxidation of boron nitride under nonisothermal conditions[J]. Soviet Powder Metallurgy and Metal Ceramics,1976,15(9):696-698. doi: 10.1007/BF01157838 [18] ZHAO D L, FAN X M, YIN X W, et al. Oxidation behavior of tyranno ZMI-SiC Fiber/SiC-SiBC matrix composite from 800 to 1200℃[J]. Materials,2018,11(8):1367. doi: 10.3390/ma11081367 [19] BERNARD B, JOHN W H, ANTHONY G E. Matrix fracture in fiber-reinforced ceramics[J]. Journal of the Mechanics & Physics of Solids,1986,34(2):167-189. [20] 张立同. 纤维增韧碳化硅陶瓷复合材料-模拟、表征与设计[M]. 北京: 化学工业出版社, 2009.ZHANG Litong. Fiber-reinforced silicon carbide ceramic composites-modelling, characterization & design[M]. Beijing: Chemical Industrial Press, 2009(in Chinese) [21] AHN B K, CURTIN W A. Strain and hysteresis by stochastic matrix cracking in ceramic matrix composites[J]. Journal of the Mechanics and Physics of Solids,1997,45(2):177-209. doi: 10.1016/S0022-5096(96)00081-6 [22] UDAYAKUMAR A, SRI GANESH A, RAJA S, et al. Effect of intermediate heat treatment on mechanical properties of SiCf/SiC composites with BN interphase prepared by ICVI[J]. Journal of the European Ceramic Society,2011,31(6):1145-1153. doi: 10.1016/j.jeurceramsoc.2010.12.018 [23] 陶永强, 矫桂琼, 王波, 等. 2D编织陶瓷基复合材料应力-应变行为:分析预测[J]. 工程力学, 2009, 26(10):221-227.TAO Yongqiang, JIAO Guiqiong, WANG Bo, et al. Stress-strain behavior in 2D weave ceramic matrix composite: Analysis predictions[J]. Engineering Mechanics,2009,26(10):221-227(in Chinese). [24] 王西, 王克杰, 柏辉, 等. 化学气相渗透2D-SiCf/SiC复合材料的蠕变性能及损伤机理[J]. 无机材料学报, 2020, 35(7):817-821.WANG Xi, WANG Kejie, BAI Hui, et al. Creep properties and damage mechanisms of 2D-SiCf/SiC composites prepared by CVI[J]. Journal of Inorganic Materials,2020,35(7):817-821(in Chinese). [25] 聂荣华, 矫桂琼, 王波. 二维编织C/SiC复合材料的热膨胀系数预测[J]. 复合材料学报, 2008, 25(2):109-114. doi: 10.3321/j.issn:1000-3851.2008.02.019NIE Ronghua, JIAO Guiqiong, WANG Bo. Prediction on coefficient of thermal expansion for 2-D braided C/SiC composites[J]. Acta Materiae Compositae Sinica,2008,25(2):109-114(in Chinese). doi: 10.3321/j.issn:1000-3851.2008.02.019 [26] 高庆, 康国政. 短纤维复合材料应力传递的修正剪滞理论[J]. 固体力学学报, 2000, 21(3):198-204. doi: 10.3969/j.issn.0254-7805.2000.03.002GAO Qing, KANG Guozheng. The revised shear-lag theory for stress transfer in short fiber composites[J]. Acta Mechanica Solida Sinica,2000,21(3):198-204(in Chinese). doi: 10.3969/j.issn.0254-7805.2000.03.002 [27] 李艳茹, 程忠庆, 姜海波. 利用外方内圆模型预测单向连续纤维增强树脂基复合材料的横向弹性模量[J]. 复合材料学报, 2018, 35(8):2110-2115.LI Yanru, CHENG Zhongqing, JIANG Haibo. Prediction of transverse elastic modulus of unidirectional continuous fiber reinforced resin composites using the model of circle-in-square[J]. Acta Materiae Compositae Sinica,2018,35(8):2110-2115(in Chinese). [28] HASHIN Z. Analysis of composite materials—A survey[J]. Journal of Applied Mechanics,1983,50(3):481-505. doi: 10.1115/1.3167081 [29] NAIK N K, GANESH V K. Prediction of on-axes elastic properties of plain weave fabric composites[J]. Composites Science and Technology,1992,45(2):135-152. doi: 10.1016/0266-3538(92)90036-3 -

下载:

下载: