High-performance flexible piezoresistive strain sensor based on biaxially stretched conductive polymer composite films with reduced graphene oxide-carbon nanotubes

-

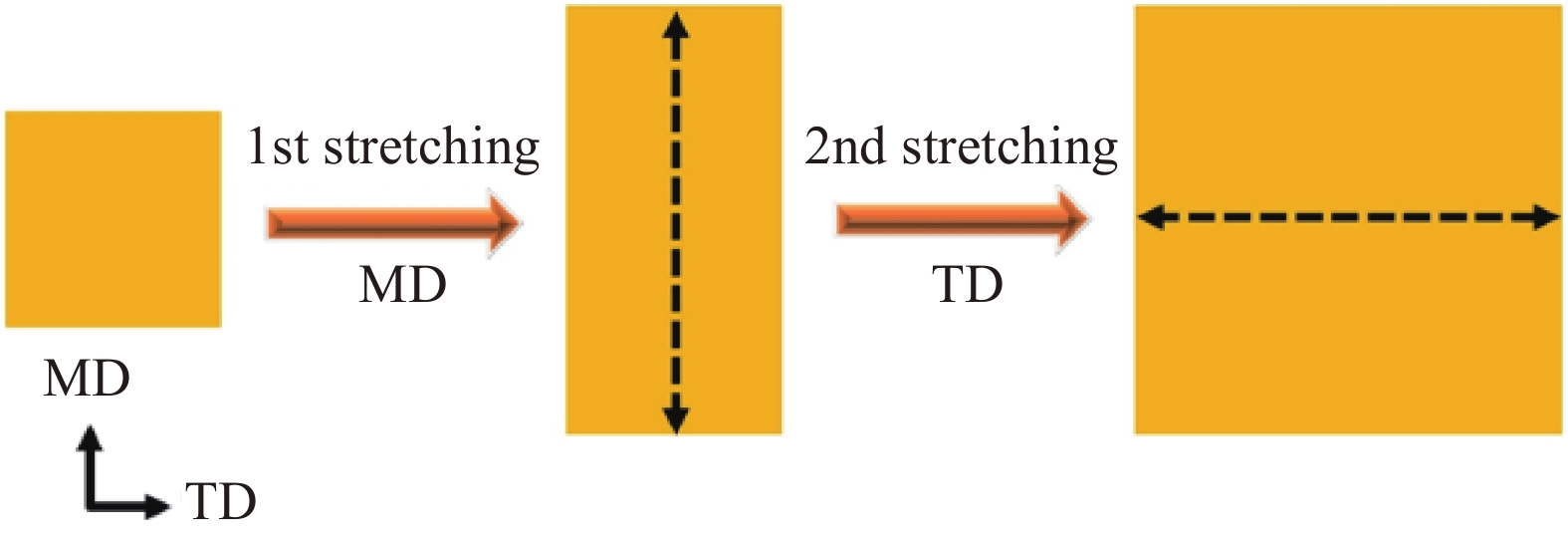

摘要: 随着现代科技的快速发展及人们生活水平的提高,柔性压阻传感器在人体健康监测、智能机器人、可穿戴电子设备和人机交互等方面展现了巨大应用潜力。本文采用Hummer’s法制备了还原氧化石墨烯(rGO),其后通过静电组装将碳纳米管(CNT)负载在rGO的表面上,并将其引入热塑性聚氨酯(TPU)基体中制备成导电纳米复合材料。此外,采用逐次双向拉伸技术实现了基体中纳米填料的进一步分散和平行取向,并基于所获得的复合薄膜研制出了一种可监测微小应变的高性能柔性压阻传感器。研究发现,rGO-CNT/TPU4×4传感器(拉伸比为4×4)在保持高灵敏度(1.5%应变的情况下灵敏度(GF)=46.7)和高线性度(R2=0.98)的同时,能够适用于不同应变和频率变化,并且在循环加载测试中展出优异的稳定性和可重复性。该柔性压阻传感器可以用于识别细微的人体生理活动,包括脉搏和呼气等。此外,还设计制备了一个可压缩的传感器阵列来监测在不同压力下的信号变化情况。本研究对于高性能柔性压阻应变传感器的快速宏量制备及结构与性能调控具有重要的科学指导意义。Abstract: In recent years, flexible piezoresistive sensors have shown great application potential in human health monitoring, smart robots, wearable electronic devices, and human-computer interaction, while it is challenging to efficiently fabricate highly sensitive and low-cost flexible piezoresistive sensor for detecting micro strains. In this work, reduced graphene oxide (rGO) was prepared by Hummer's method, then carbon nanotubes (CNTs) were immobilized on the surface of rGO by electrostatic assembly. Subsequently, the hybrid nanofillers were introduced into thermoplastic polyurethane (TPU) matrix to prepare conductive polymer composite. The further dispersion and parallel orientation of nanofillers in the matrix were achieved by the sequential biaxial stretching process. It is shown that the sensor prepared by biaxially stretched conductive polymer composite exhibits higher sensing performance compared to the sensor without experiencing biaxial stretching. The rGO-CNT/TPU4×4 sensor (with a stretching ratio of 4×4) shows high sensitivity (GF=46.7 at 1.5% strain), high linearity (R2=0.98), responsive capability to different strains and frequencies, excellent stability and repeatability in cyclic loading tests. The flexible piezoresistive sensor can be used to identify subtle human physiological activities, including pulse and exhalation. In addition, a compressible sensor array was fabricated to achieve accurate identification of weight distribution. This study provides an important scientific guidance for the rapid large-scale fabrication and structure and property tuning of high-performance flexible piezoresistive strain sensors.

-

Key words:

- biaxial stretching /

- strain sensor /

- self-assembly /

- reduced graphene oxide /

- carbon nanotube

-

图 6 应变传感器在0.5%应变和不同频率下的相对电阻变化((a), (b));应变传感器在0.1 Hz频率和不同应变下的相对电阻变化((c), (d))

Figure 6. Relative resistance change of strain sensors during a cyclic loading at a strain of 0.5% and different frequency ((a), (b)); Relative resistance of the strain sensors with different nanofillers under cyclic loading at different strain and frequency of 0.1 Hz ((c), (d))

f—Frequency; ε—Strain

-

[1] 张明艳, 杨振华, 吴子剑, 等. 新型三明治结构聚二甲基硅氧烷/聚偏氟乙烯-纳米Ag线/聚二甲基硅氧烷柔性应变传感器的制备与性能[J]. 复合材料学报, 2020, 37(5):1024-1032.ZHANG Mingyan, YANG Zhenhua, WU Zijian, et al. Preparation and performance of a novel sandwich structure polydimethylsiloxane/polyvinylidene fluoride-nanowires/polydimethylsiloxane flexible strain sensor[J]. Acta Materiae Compositae Sinica,2020,37(5):1024-1032(in Chinese). [2] LI B, LUO J, HUANG X, et al. A highly stretchable, super-hydrophobic strain sensor based on polydopamine and graphene reinforced nanofiber composite for human motion monitoring[J]. Composites Part B: Engineering,2020,181:107580-107587. doi: 10.1016/j.compositesb.2019.107580 [3] MA Y, LIU N, LI L, et al. A highly flexible and sensitive piezoresistive sensor based on MXene with greatly changed interlayer distances[J]. Nature Communications,2017,8:1-7. doi: 10.1038/s41467-016-0009-6 [4] MENG Q, LIU Z, HAN S, et al. A facile approach to fabricate highly sensitive, flexible strain sensor based on elastomeric/graphene platelet composite film[J]. Journal of Materials Science,2019,54:10856-108570. doi: 10.1007/s10853-019-03650-1 [5] HERREN B, SAHA MC, ALTAN MC, et al. Development of ultrastretchable and skin attachable nanocomposites for human motion monitoring via embedded 3D printing[J]. Composites Part B: Engineering,2020,200:108224-108235. doi: 10.1016/j.compositesb.2020.108224 [6] WANG Y, HAO J, HUANG Z, et al. Flexible electrically resistive-type strain sensors based on reduced graphene oxide-decorated electrospun polymer fibrous mats for human motion monitoring[J]. Carbon,2018,126:360-371. doi: 10.1016/j.carbon.2017.10.034 [7] KIM H, SIM K, THUKRAL A, et al. Rubbery electronics and sensors from intrinsically stretchable elastomeric composites of semiconductors and conductors[J]. Science Advance,2017,3:1-9. [8] ZHANG X, XIANG D, WU Y, et al. High-performance flexible strain sensors based on biaxially stretched conductive polymer composites with carbon nanotubes immobilized on reduced graphene oxide[J]. Composites Part A: Applied Science Manufacturing, 2021, 151: 106665-106673. [9] ZHANG X, XIANG D, ZHU W, et al. Flexible and high-performance piezoresistive strain sensors based on carbon nanoparticles@polyurethane sponges[J]. Composites Science and Technology,2020,200:108437-108449. doi: 10.1016/j.compscitech.2020.108437 [10] 高沐, 夏志东, 陈婧晗, 等. 拉伸应变下镍包碳纤维填充导电橡胶取向及电阻响应[J]. 复合材料学报, 2019, 36(12):2756-2763.GAO Mu, XIA Zhidong, CHEN Jinghan, et al. Orientation and resistance response of nickel-coated carbon fiber filled conductive rubber under tensile strain[J]. Acta Materiae Compositae Sinica,2019,36(12):2756-2763(in Chinese). [11] 秦红梅, 邓超然, 李明专, 等. 石墨烯纳米薄片-SiO2/天然橡胶复合材料的导电导热性能[J]. 复合材料学报, 2019, 36(11):2683-2691.QIN Hongmei, DENG Chaoran, LI Mingzhuan, et al. Electroconductive and thermal properties of graphene nanosheets-SiO2/natural rubber composites[J]. Acta Materialia Sinica,2019,36(11):2683-2691(in Chinese). [12] ZHANG R, DENG H, VALENCA R, et al. Strain sensing behaviour of elastomeric composite films containing carbon nanotubes under cyclic loading[J]. Composites Science and Technology,2013,74(7):1-5. [13] 林金堂. 基于化学气相沉积石墨烯/PEDOT-PSS共混复合材料的导电薄膜[J]. 复合材料学报, 2018, 35(1):180-184.LIN Jintang. Electroconductive films based on chemical vapor deposition of graphene/PEDOT-PSS blend compo-sites[J]. Acta Materiae Compositae Sinica,2018,35(1):180-184(in Chinese). [14] XIANG D, ZHANG X, HAN Z, et al. 3D printed high-perfor-mance flexible strain sensors based on carbon nanotube and graphene nanoplatelet filled polymer composites [J]. Journal of Materials Science, 2020, 55: 15769–15786. [15] FEI P, CAO S, LI Y, et al. 3D graphene films enable simultaneously high sensitivity and large stretchability for strain sensors[J]. Advanced Functional Material,2018,28(40):1-10. [16] SHEN J, CHAMPANGNE M F, GENDRON R, et al. The development of conductive carbon nanotube network in polypropylene-based composites during simultaneous biaxial stretching[J]. European Polymer Journal,2012,48(5):930-939. doi: 10.1016/j.eurpolymj.2012.03.005 [17] XIANG D, WANG L, ZHANG Q, et al. Comparative study on the deformation behavior, structural evolution, and properties of biaxially stretched high-density polyethylene/carbon nanofiller (carbon nanotubes, graphene nanoplatelets, and carbon black) composites[J]. Polymer Compo-sites,2018,39:909-923. doi: 10.1002/pc.24328 [18] KANAO K, HARADA S, YAMAMOTO Y, et al. Printable flexible tactile pressure and temperature sensors with high selectivity against bending[J]. Proceedings of the IEEE International Conference on Micro Electro Mechanical Systems (MEMS),2015:756-759. [19] 江学良, 郭文文, 张晓宇, 等. 还原氧化石墨烯-SBA/PMMA复合材料的制备及介电性能[J]. 复合材料学报, 2019, 36(3): 578-583.JIANG Xueliang, GUO Wenwen, ZHANG Xiaoyu, et al. Preparation and dielectric properties of reduced graphene-SBA /PMMA composites[J]. Acta Materiae Compositae Sinica, 2019, 36(3): 517-523(in Chinese). [20] JI X, CHEN D, WANG Q, et al. Synergistic effect of flame retardants and carbon nanotubes on flame retarding and electromagnetic shielding properties of thermoplastic polyurethane[J]. Composites Science and Technology,2018,163(28):49-55. [21] ASLAM S, BOKHARI H, ANWAR T, et al. Graphene oxide coated graphene foam based chemical sensor[J]. Materials Letters,2019,235(7):66-70. [22] GUO Q, LUO Y, LIU J, et al. A well-organized graphene nanostructure for versatile strain-sensing application constructed by a covalently bonded graphene/rubber interface[J]. Journal of Materials Chemistry C,2018,6(8):2139-2147. doi: 10.1039/C7TC05758J [23] XIANG D, ZHANG X, LI Y, et al. Enhanced performance of 3D printed highly elastic strain sensors of carbon nanotube/thermoplastic polyurethane nanocomposites via non-covalent interactions[J]. Composites Part B: Engineering,2019,176(5):107250-107263. [24] YE X, YUAN Z, TAI H, et al. A wearable and highly sensitive strain sensor based on a polyethylenimine-rGO layered nanocomposite thin film[J]. Journal of Materials Chemistry C,2017,5(31):7746-7752. doi: 10.1039/C7TC01872J [25] KIM J Y, JI S, JUNG S, et al. 3D printable composite dough for stretchable, ultrasensitive and body-patchable strain sensors[J]. Nanoscale,2017,9(31):11035-11046. doi: 10.1039/C7NR01865G [26] YOU F, LI X, ZHANG L, et al. Polypropylene/poly(methyl methacrylate)/graphene composites with high electrical resistivity anisotropy via sequential biaxial stretching[J]. RSC Advances,2017,7(10):6170-6178. doi: 10.1039/C6RA28486H [27] XIANG D, ZHANG X, HARKIN-JONES E, et al. Synergistic effects of hybrid conductive nanofillers on the perfor-mance of 3D printed highly elastic strain sensors[J]. Composites Part A: Applied Science Manufacturing, 2020, 129: 105730-105742. [28] 黄雅盼, 孙晓刚, 王杰, 等. 羟基化多壁碳纳米管掺杂抑制锂硫电池的穿梭效应[J]. 复合材料学报, 2019, 36(5):1335-1341.HUANG Yapan, SUN Xiaogang, WANG Jie, et al. Inhibitory effects of hydroxylated multi-walled carbon nanotubes on the shuttle-down of lithium-sulfur batteries[J]. Acta Materiae Compositae Sinica,2019,36(5):1335-1341(in Chinese). [29] KIM B, LEE K, KANG S, et al. 2D reentrant auxetic structures of graphene/CNT networks for omnidirectionally stretchable supercapacitors[J]. Nanoscale,2017,9(35):13272-13280. doi: 10.1039/C7NR02869E [30] KHAN A, ASIRI A M, RUB M A, et al. Synthesis, characterization of silver nanoparticle embedded polyaniline tungstophosphate-nanocomposite cation exchanger and its application for heavy metal selective membrane[J]. Compo-sites Part B: Engineering,2013,45(1):1486-1492. doi: 10.1016/j.compositesb.2012.09.023 [31] LOZANO-PREZ, CAUICH-RODRGUEZ JV, AVILS F. Influence of rigid segment and carbon nanotube concentration on the cyclic piezoresistive and hysteretic behavior of multiwall carbon nanotube/segmented polyurethane compo-sites[J]. Composites Science and Technology,2016,128:25-32. doi: 10.1016/j.compscitech.2016.03.010 [32] WANG B, FACCHETTI A. Mechanically flexible conductors for stretchable and wearable E-skin and E-textile devices[J]. Advanced Material,2019,31(28):1901408. [33] ZHEN, YANG, YU, et al. Graphene textile strain sensor with negative resistance variation for human motion detection[J]. ACS Nano,2018,12(9):9134-9141. doi: 10.1021/acsnano.8b03391 [34] CHEN S J, WU R Y, LI P, et al. Acid-interface engineering of carbon nanotube/elastomer with enhanced sensitivity for stretchable strain sensor[J]. ACS Applied Materials & Interfaces,2018,10(43):37760-37766. [35] CHEN Q, XIANG, D, WANG L, et al. Facile fabrication and performance of robust polymer/carbon nanotube coated spandex fibers for strain sensing[J]. Composites Part A: Applied Science and Manufacturing,2018,112:186-196. doi: 10.1016/j.compositesa.2018.06.009 -

下载:

下载: