Preparation of nano ZIF-8@short carbon fibers and its effects on the flame retardancy, smoke suppression and mechanical properties of epoxy composites

-

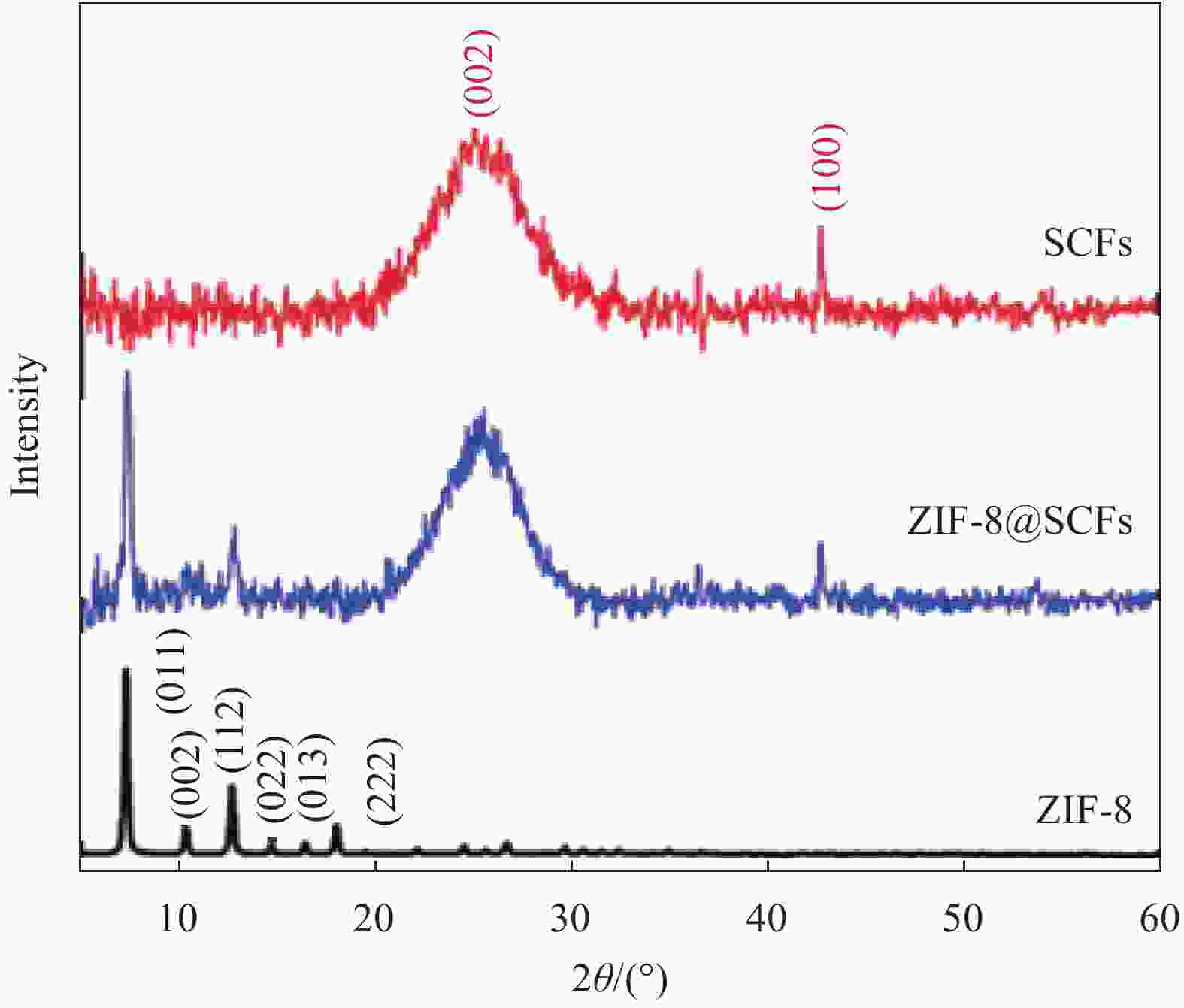

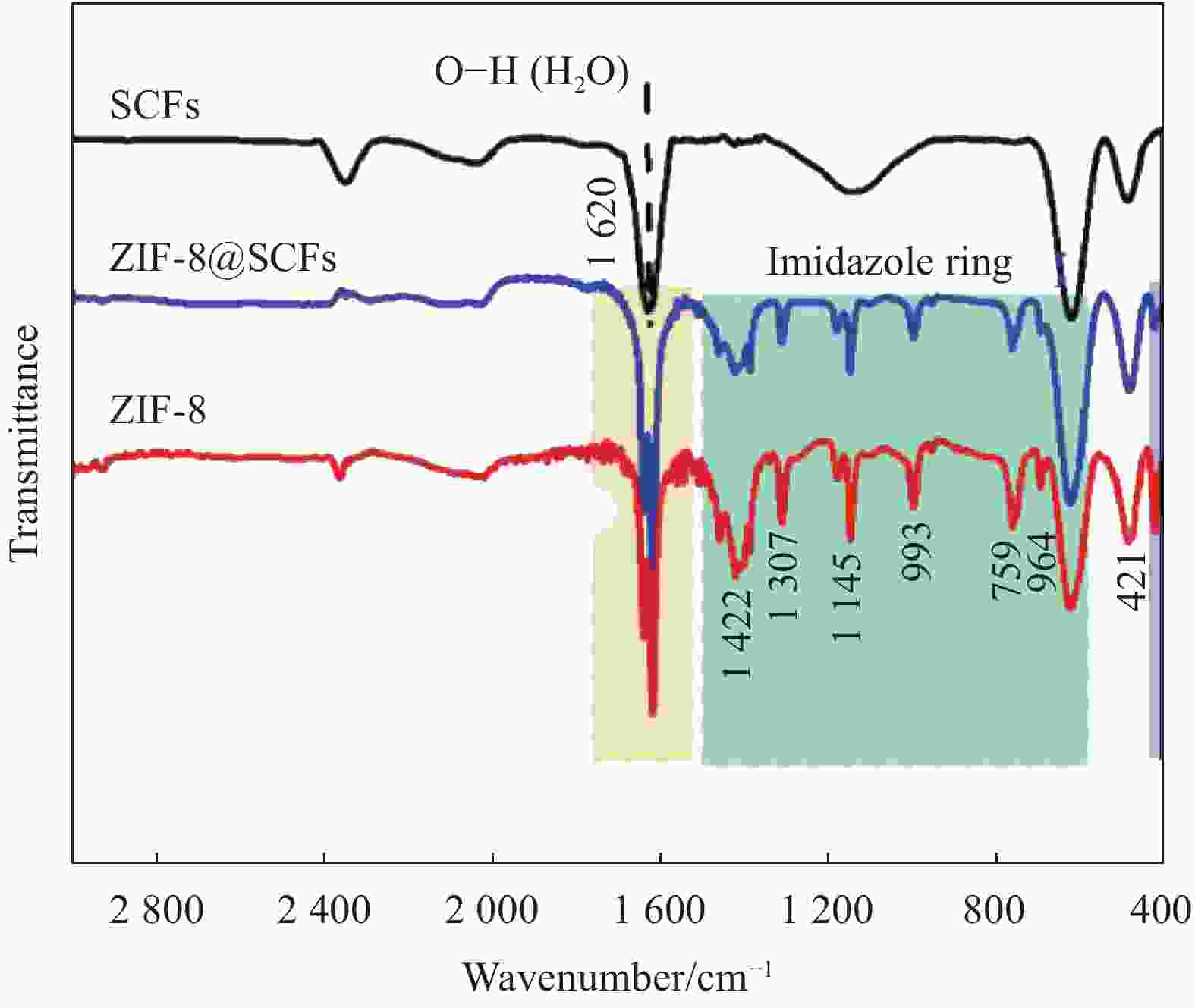

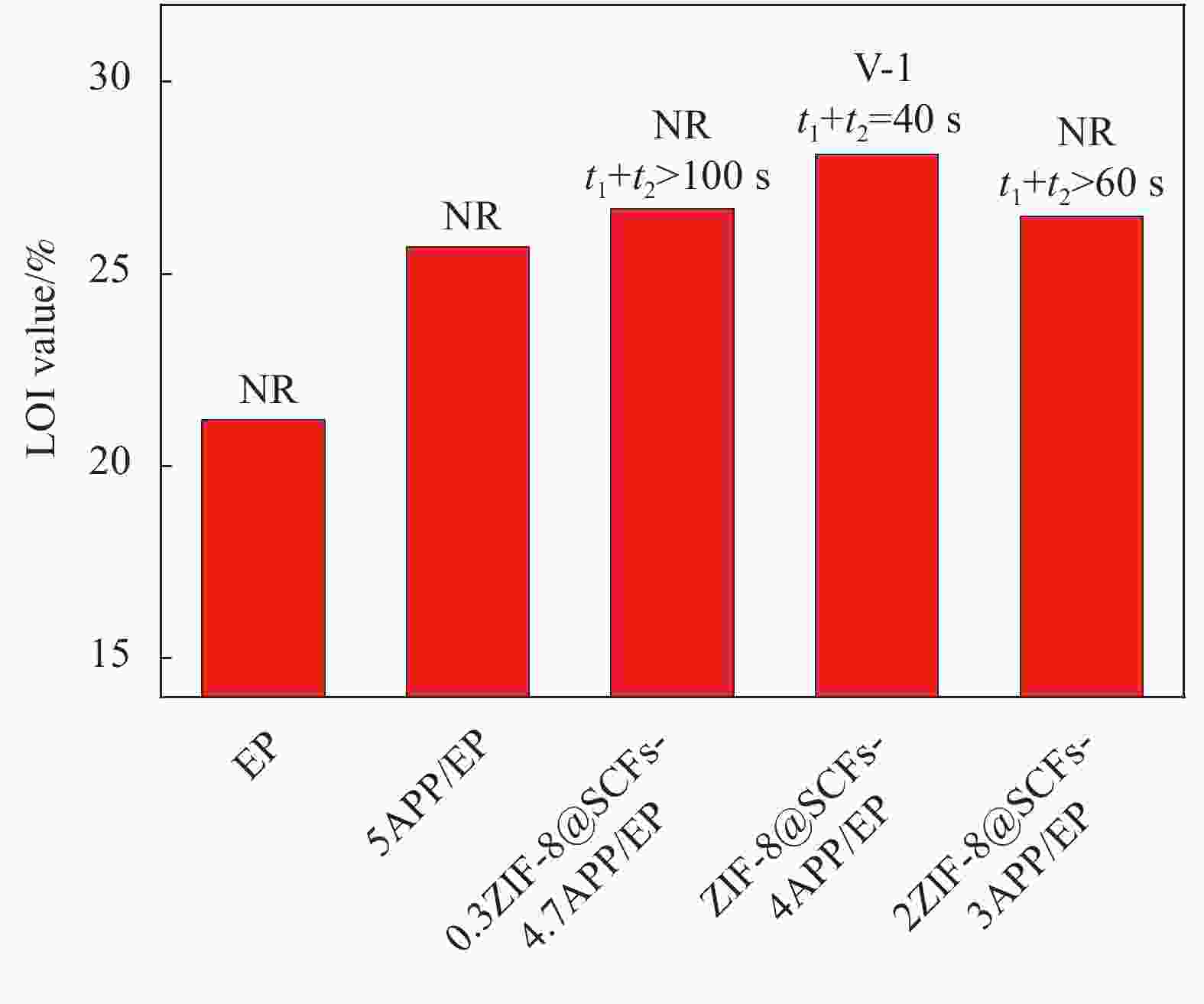

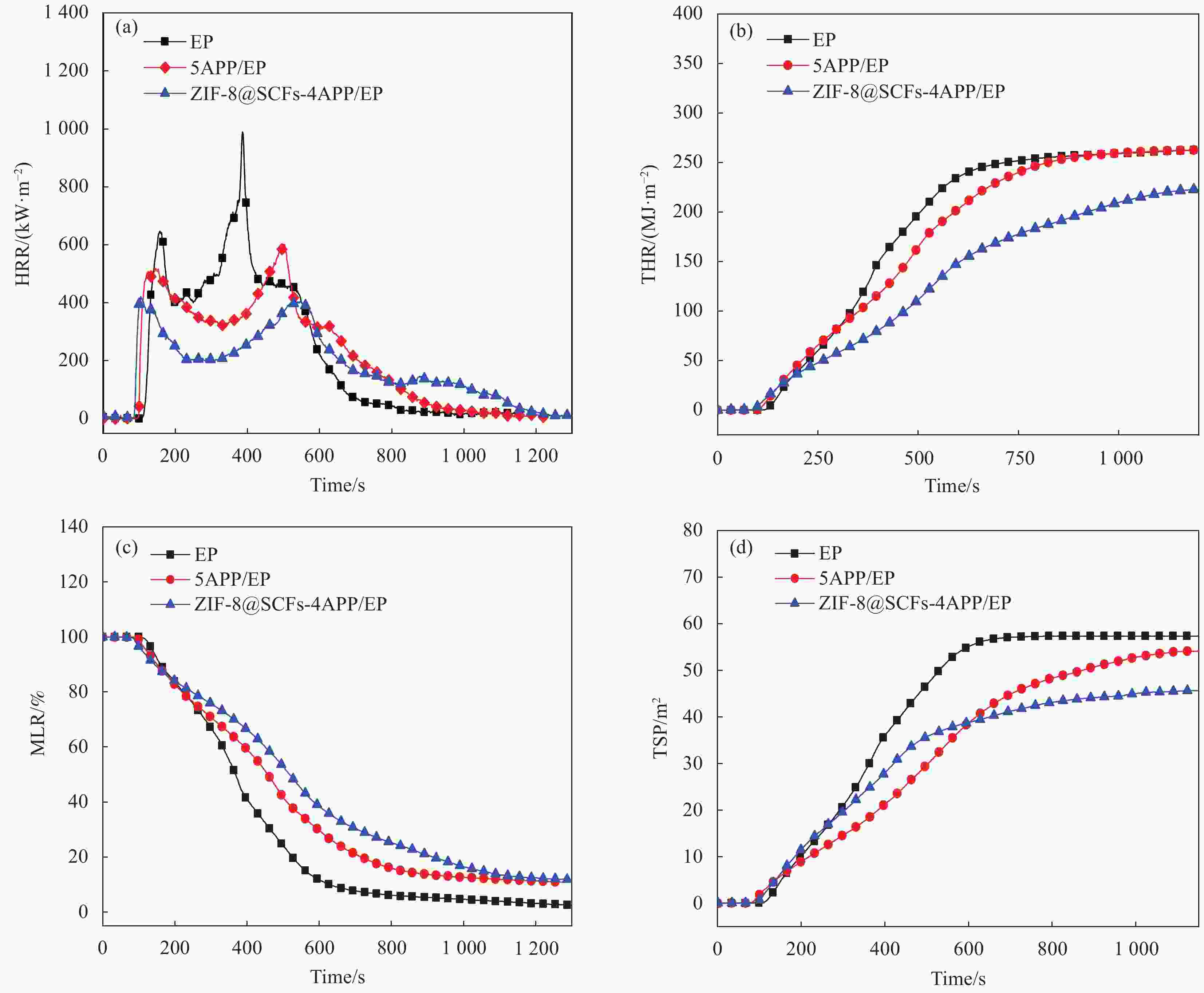

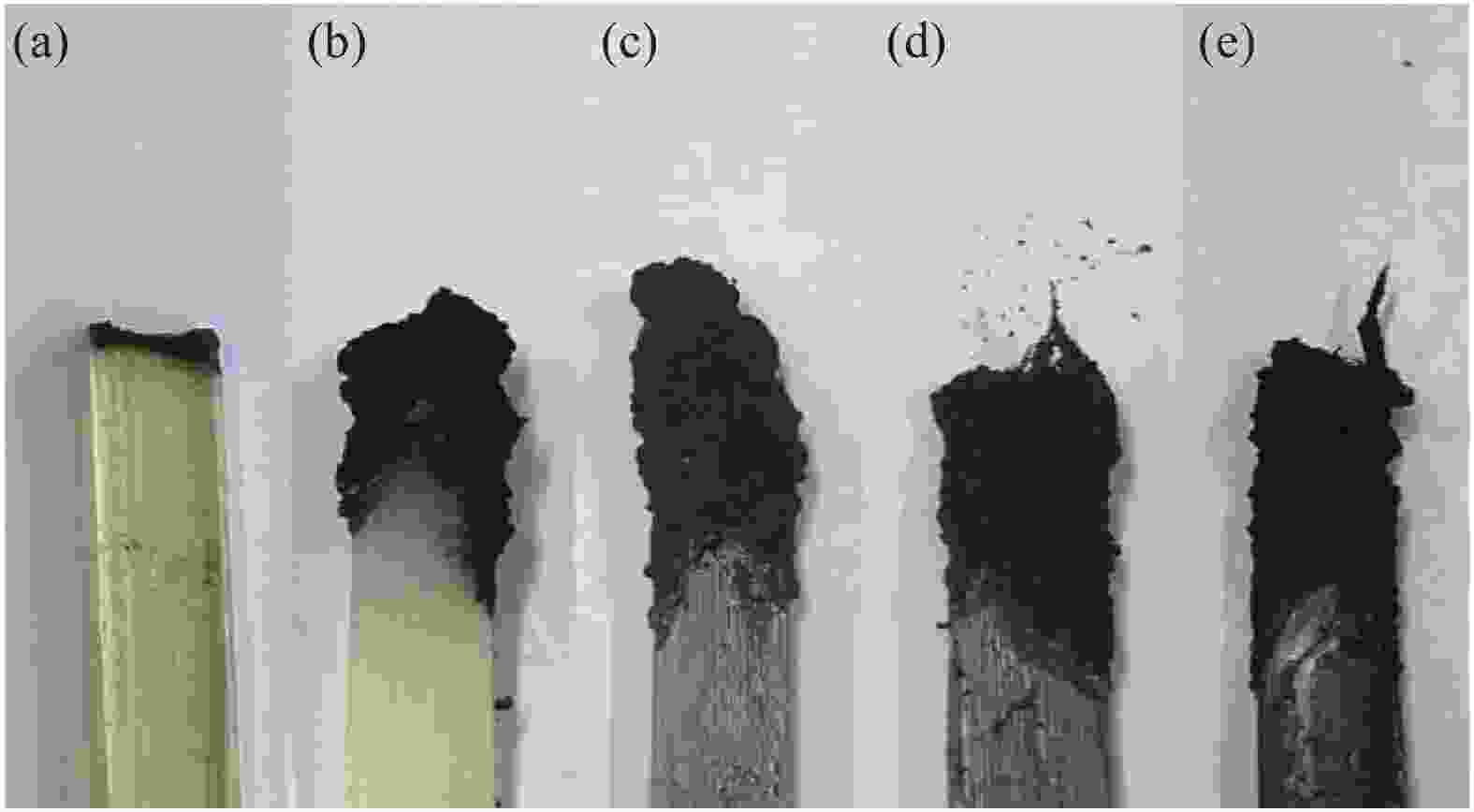

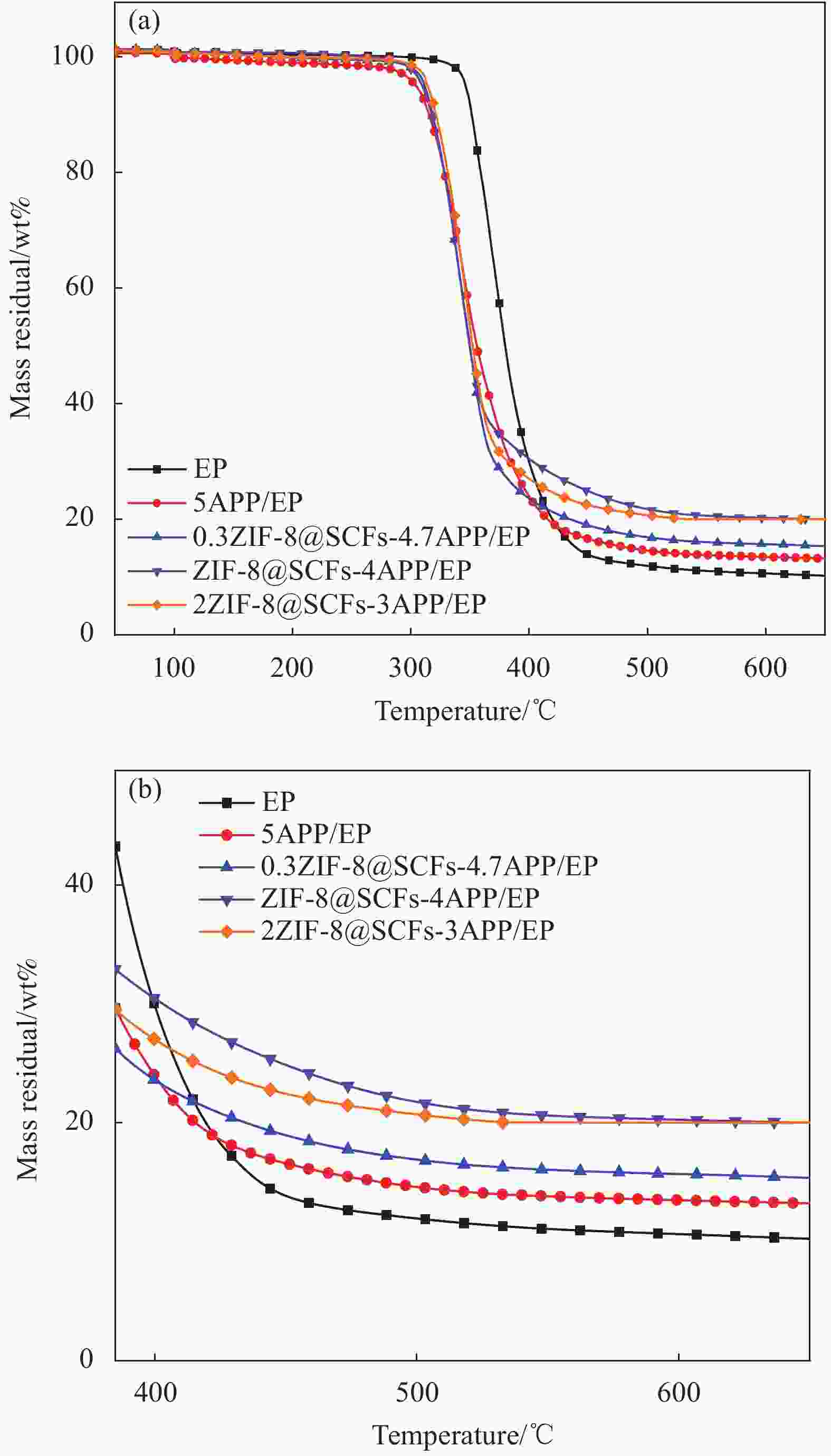

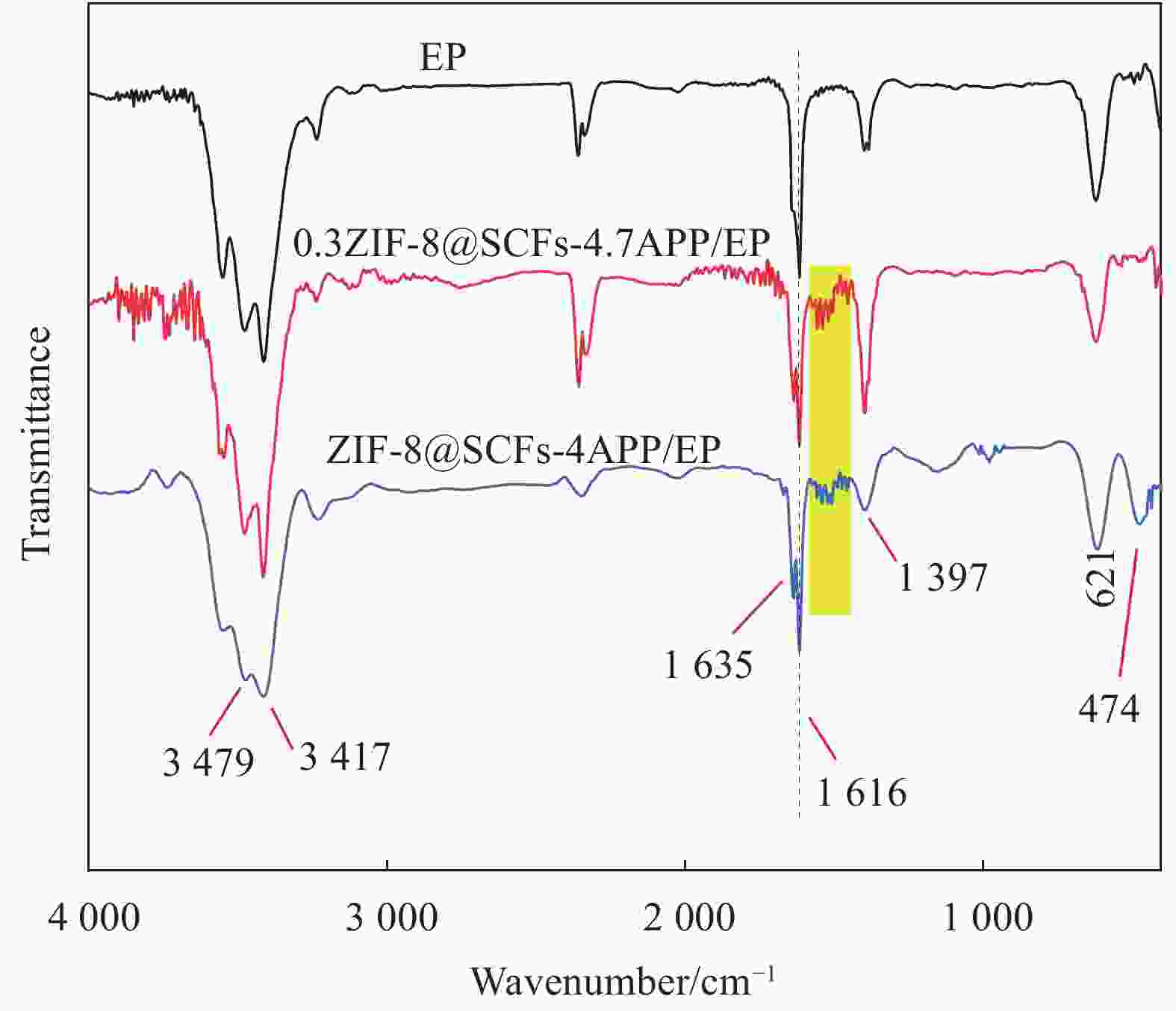

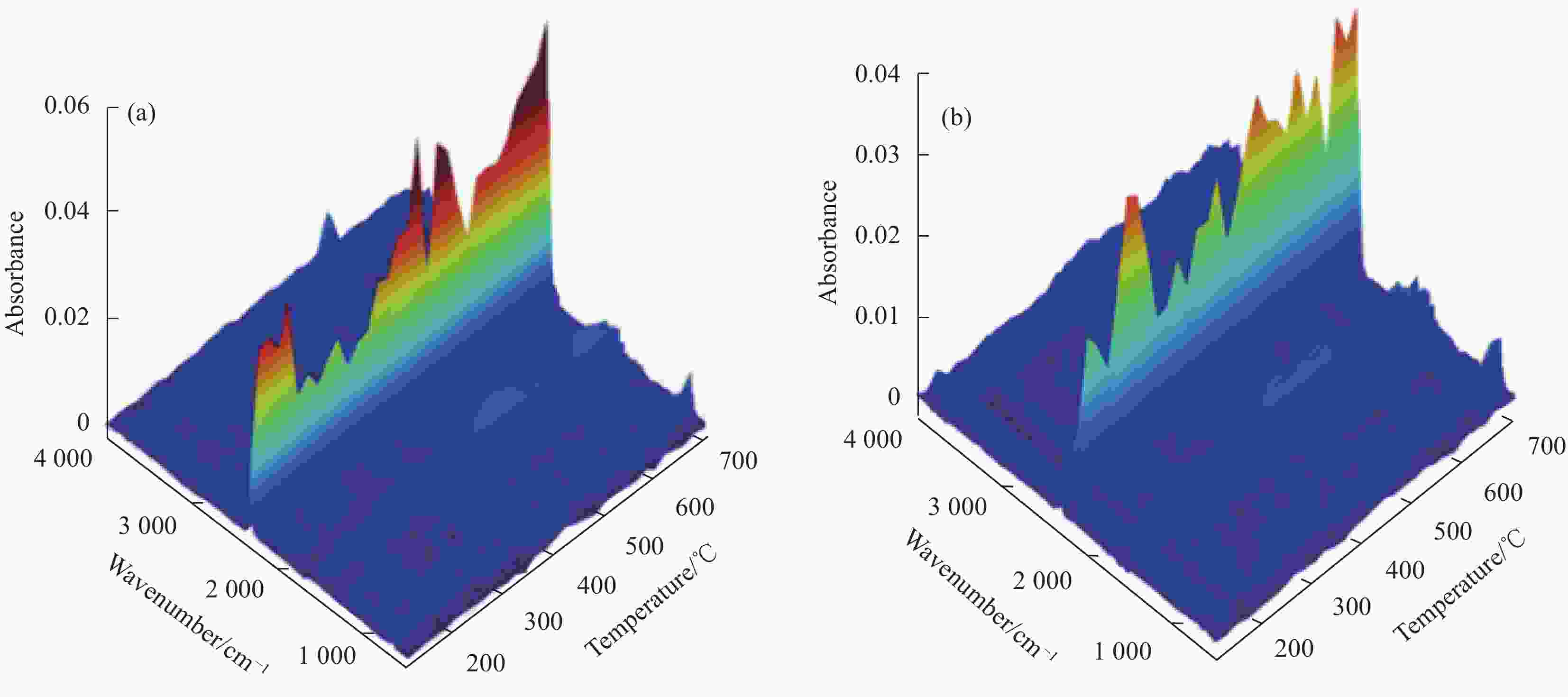

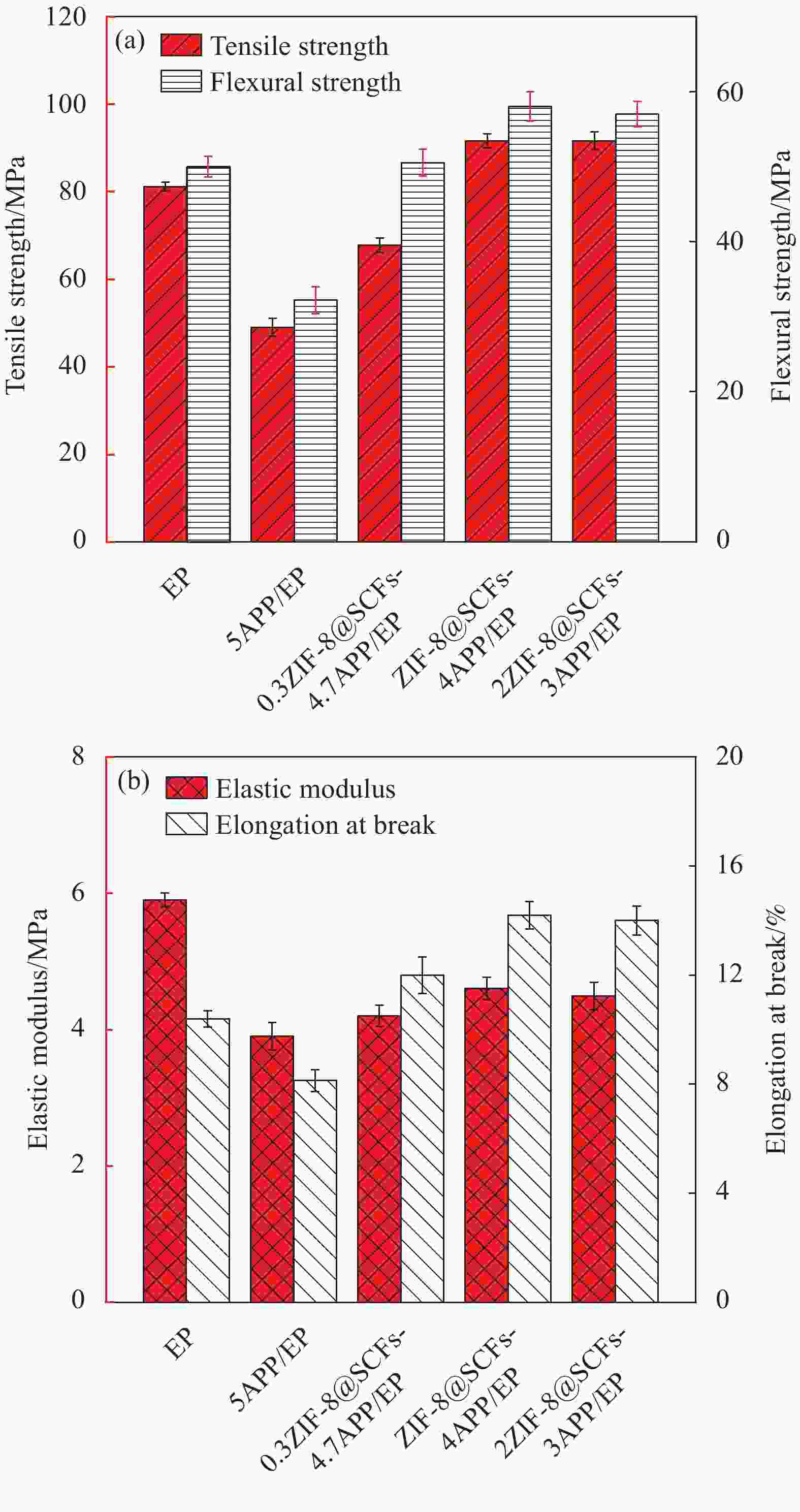

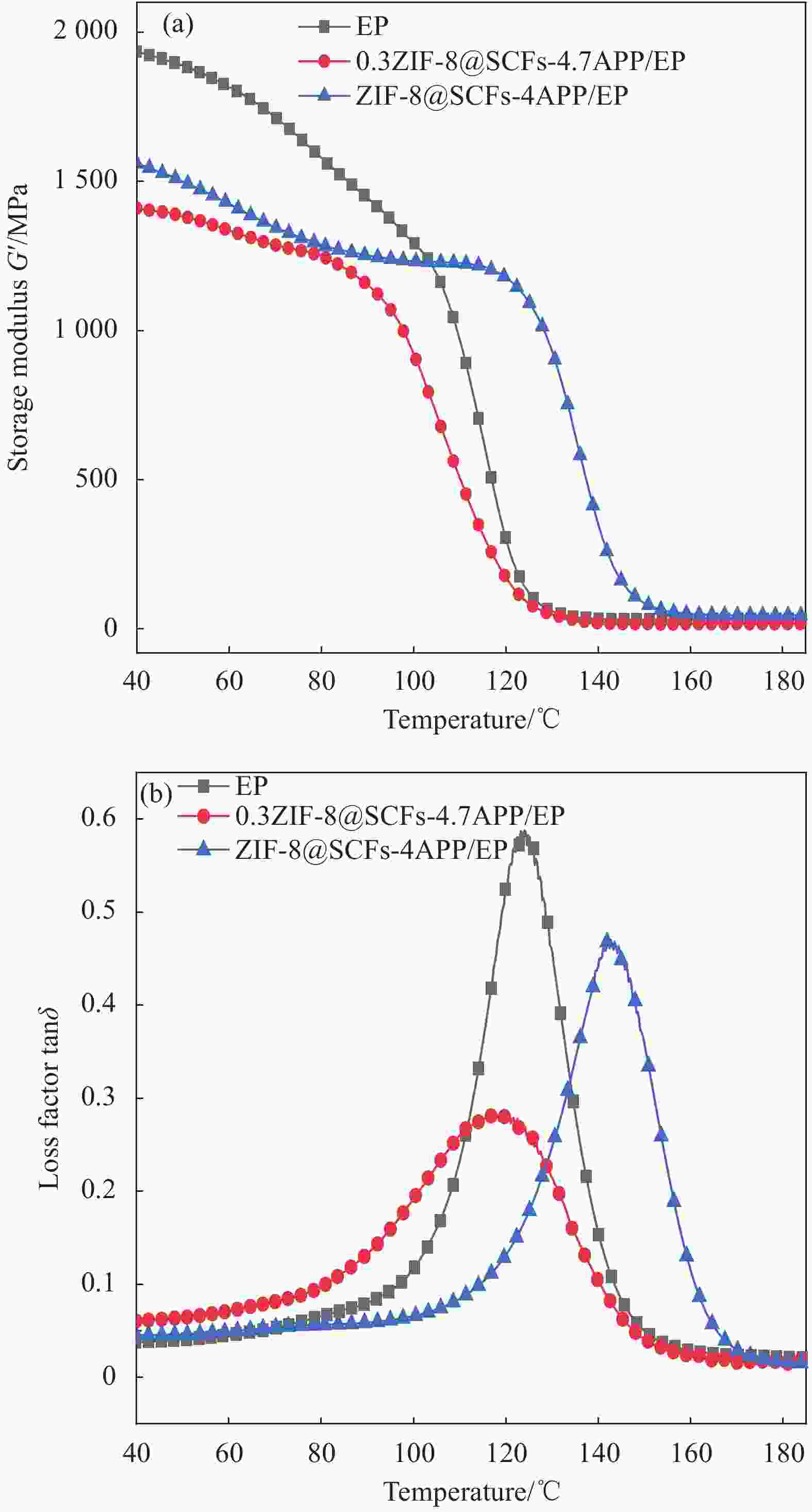

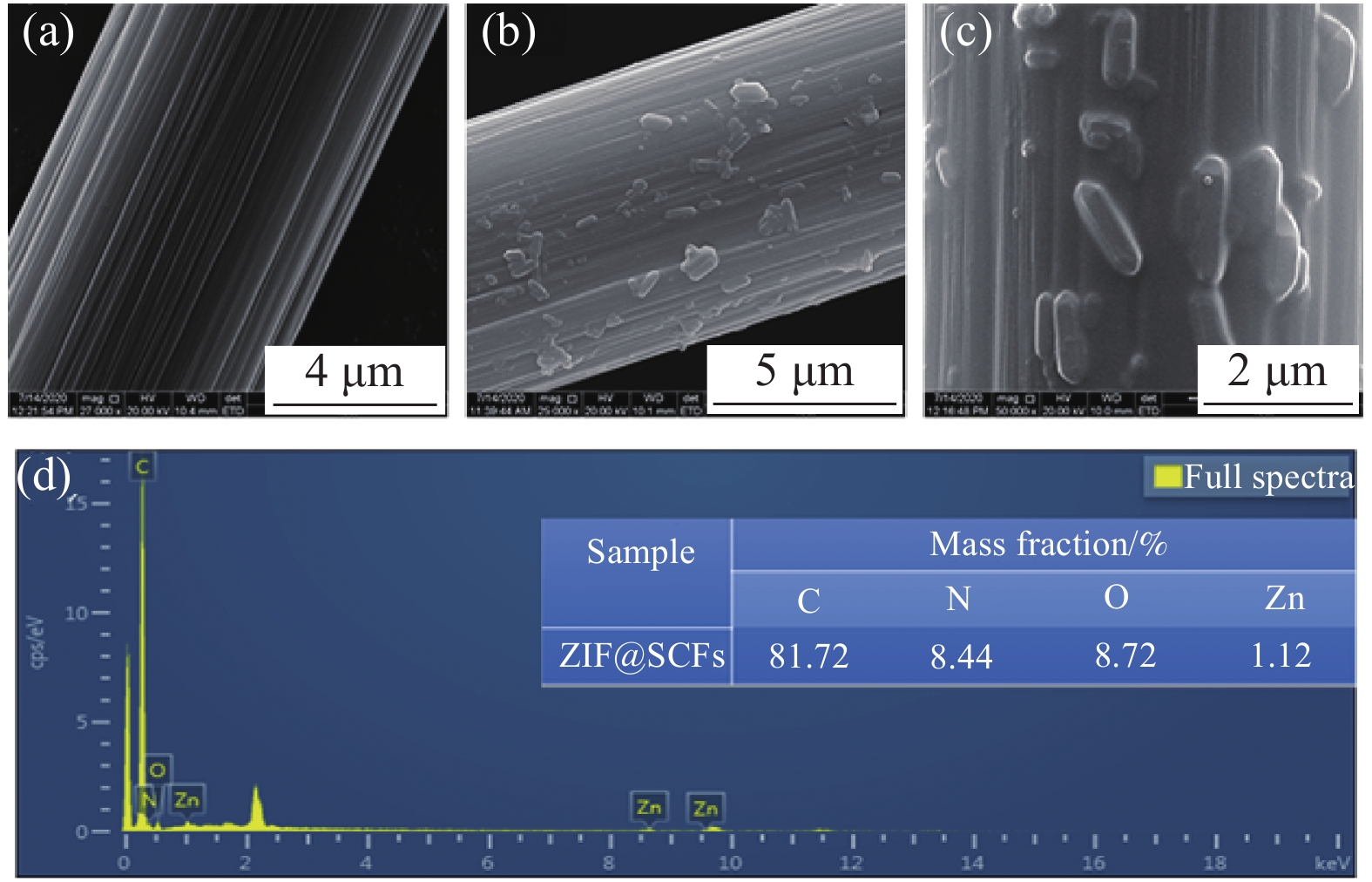

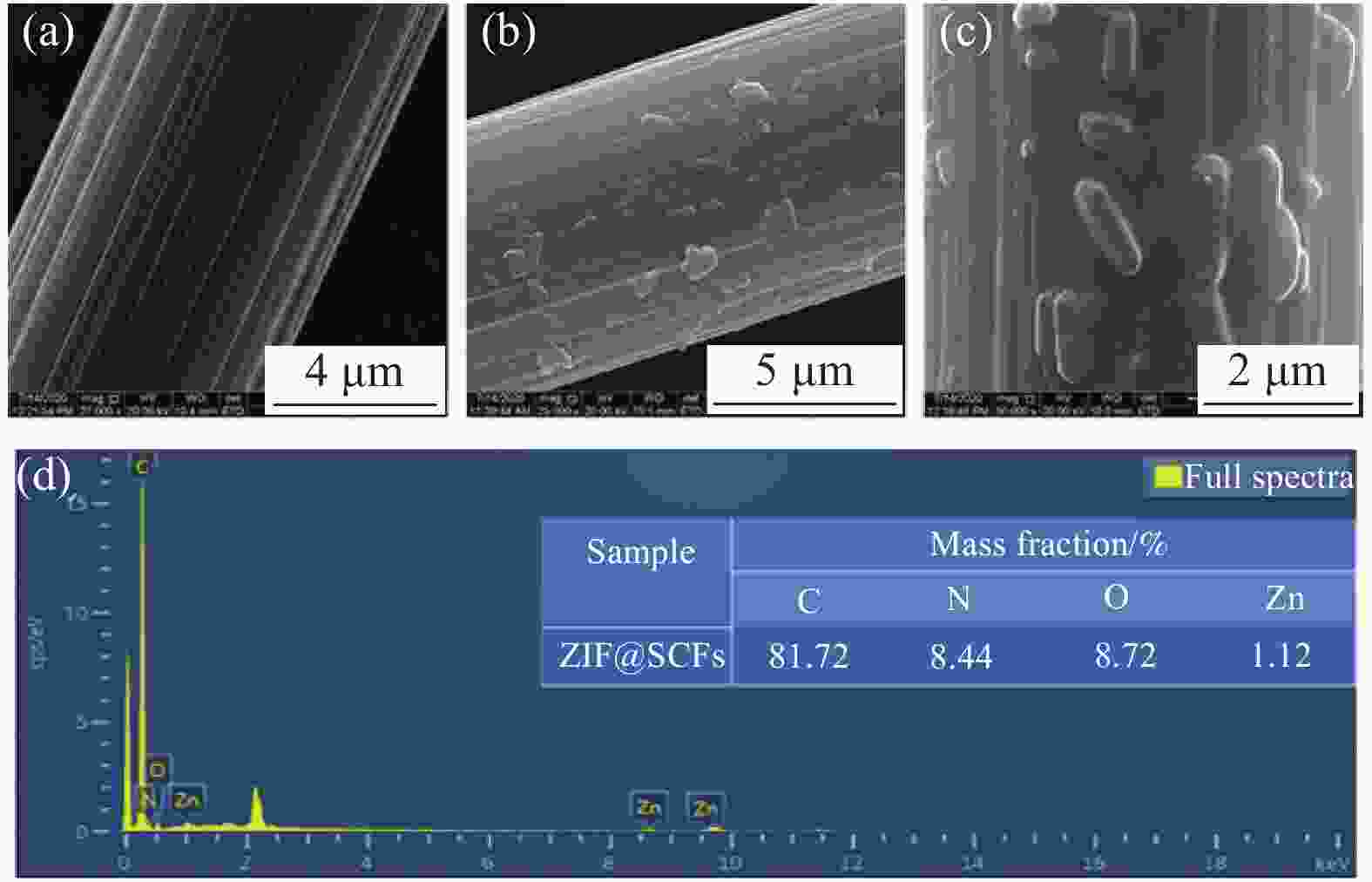

摘要: 通过原位生长的方法制备了ZIF-8@短碳纤维(SCFs)材料,将其与聚磷酸铵(APP)一起加入环氧树脂(EP)制备了阻燃性能和力学性能均有所提高的环氧树脂复合材料。通过氧指数测定仪、水平垂直燃烧测定仪、锥形量热仪及万能电子拉力机对ZIF-8@SCFs-APP/EP复合材料进行了阻燃与力学性能的测试。实验结果表明,与添加5wt%APP阻燃样品相比,当 ZIF-8@SCFs的添加量为1wt% (APP和ZIF-8@SCFs的质量比为4∶1)时,复合材料的极限氧指数从25.7%增加到28.1%,UL-94垂直燃烧试验达到V-1级、热释放率峰值(pHRR)和总烟雾量(TSP)明显降低;复合材料的抗张强度、弯曲强度、弹性模量和断裂伸长率分别提高了86%、81%、20%和75%,解决了无机阻燃填料的添加导致EP力学性能降低的问题,制备的阻燃复合材料具有实际应用价值。Abstract: The nano ZIF-8 on short carbon fibers (ZIF-8@SCFs) were prepared in situ growth. The composites were manufactured using ZIF-8@SCFs, ammonium polyphosphate (APP) and epoxy resin (EP) to improve the flame retardant and mechanical properties. Oxygen index tester, horizontal and vertical combustion tester, cone calorimeter and universal electronic tensile machine were used to investigate the flame retardant and mechanical properties of EP composite materials. The experimental results show that when the addition amount of ZIF-8@SCFs is 1wt% (the mass ratio of APP to ZIF-8@SCFs is 4∶1), the limiting oxygen index of the composite material increases from 25.7% to 28.1%, and UL-94 reaches V-1 level. The peak heat release rate (pHRR) and total smoke production (TSP) are reduced evidently compared with the sample with only 5wt% of APP. Besides, the tensile strength, flexural strength, elastic modulus and elongation at break of the composite material are increased by 86%, 81%, 20% and 75%, respectively, which solves the problem that the addition of inorganic flame-retardant destroys the mechanical properties of EP. The prepared composites could be applied in practice.

-

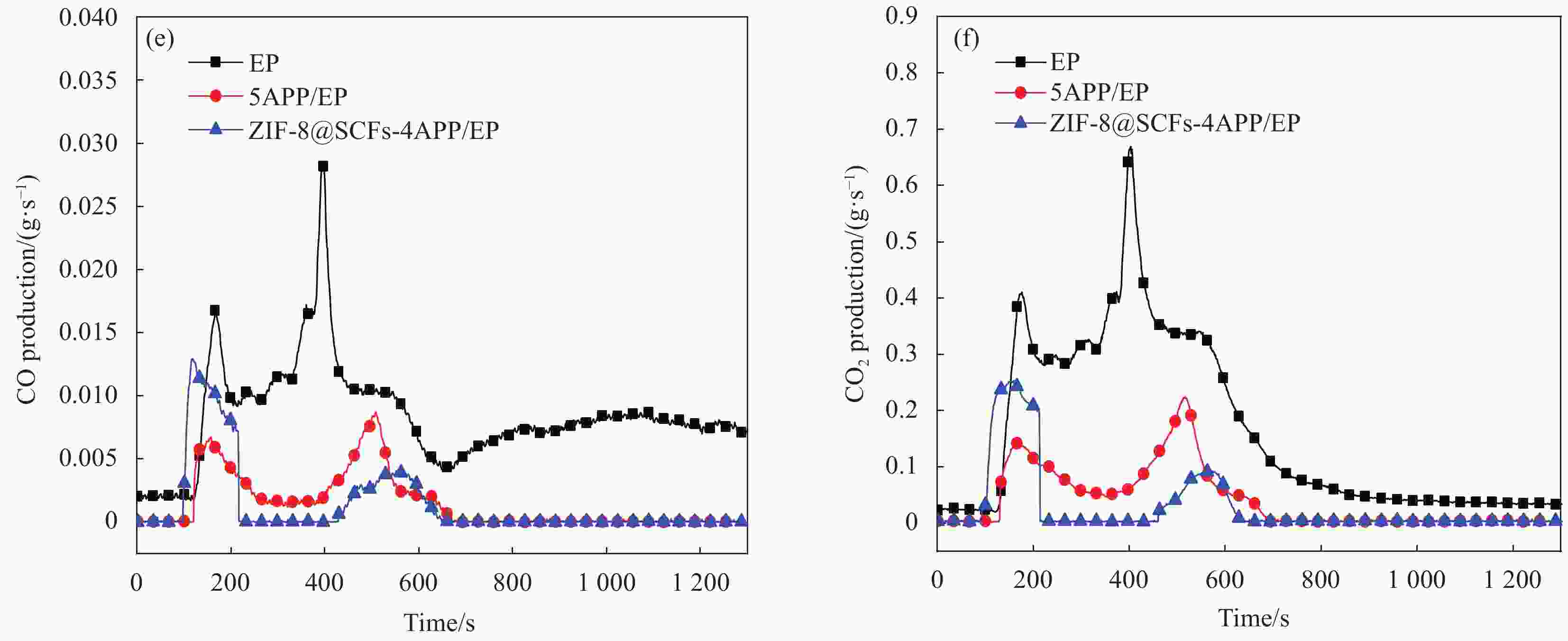

图 5 ZIF-8@SCFs-APP/EP复合材料的热释放率(HRR) (a)、总热释放(THR) (b)、质量损失率(MLR) (c)、总烟雾量(TSP) (d)、平均CO产量(AvCOY) (e) 和平均CO2产量(AvCO2Y) (f) 曲线

Figure 5. Heat release rate (HRR) (a), total heat release (THR) (b), mass loss rate (MLR) (c), total smoke production (TSP) (d), average CO production (AvCOY) (e) and average CO2 production (AvCO2Y) (f) of ZIF-8@SCFs-APP/EP composite materials

表 1 2-甲基咪唑锌盐(ZIF-8)@短碳纤维(SCFs)-聚磷酸铵(APP)/环氧树脂(EP)复合材料的组成配方

Table 1. Formulations of Zinc salt of 2-methylimidazole (ZIF-8)@short carbon fibers (SCFs)-ammonium polyphosphate (APP)/epoxy (EP) composites

Sample EP/

wt%APP/

wt%ZIF-8@SCFs/

wt%EP 100 0 0 5APP/EP 95 5 0 0.3ZIF-8@SCFs-4.7APP/EP 95 4.7 0.3 ZIF-8@SCFs-4APP/EP 95 4 1 2ZIF-8@SCFs-3APP/EP 95 3 2 表 2 EP、5APP/EP和ZIF-8@SCFs-4APP/EP复合材料的锥形量热数据

Table 2. Cone calorimetric data of EP, 5APP/EP and ZIF-8@SCFs-4APP/EP composite materials

Sample pHRR/(kW·m−2) THR/(MJ·m−2) AvMLR/(g·s−1) TSP/m2 AvCOY/% AvCO2Y/% EP 989 265 0.11 57.30 0.05 1.43 5APP/EP 602 263 0.10 54.20 0.01 0.37 ZIF-8@SCFs-4APP/EP 422 225 0.07 45.70 0.01 0.27 Notes: pHRR—Peak heat release rate; AvMLR—Average mass loss rate. -

[1] 全国汽车标准化技术委员会. 汽车内饰材料的燃烧特性: GB 8410—2006[S]. 北京: 中国标准出版社, 2006.COMMITTEE N A S T. Combustion characteristics of automotive interior materials: GB 8410—2006[S]. Beijing: China Standards Press, 2006(in Chinese). [2] WU C S, LIU Y L, CHIU Y S. Epoxy resins possessing flame retardant elements from silicon incorporated epoxy compounds cured with phosphorus or nitrogen containing curing agents[J]. Polymer,2002,43(15):4277-4284. doi: 10.1016/S0032-3861(02)00234-3 [3] KAWAHARA T, YUUKI A, HASHIMOTO K, et al. Immobilization of flame-retardant onto silica nanoparticle surface and properties of epoxy resin filled with the flame-retardant-immobilized silica (2)[J]. Reactive & Functional Polymers,2013,73(3):613-618. [4] LIU Y L, HSIUE G H, CHIU Y S. Synthesis, characterization, thermal, and flame retardant properties of phosphate-based epoxy resins[J]. Journal of Polymerence Part A-Polymer Chemistry,2015,35(3):565-574. [5] 邢云亮, 李云涛, 赵春霞, 等. 功能型核壳微球对环氧树脂燃烧性能和力学性能的影响[J]. 高分子材料科学与工程, 2015, 31(1):57-61.XING Y L, LI Y T, ZHAO C X, et al. Effect of functional core-shell microspheres on the combustion and mechanical properties of epoxy resin[J]. Polymer Materials Science and Engineering,2015,31(1):57-61(in Chinese). [6] BOCCARUSSO L, CARRINO L, DURANTE M, et al. Hemp fabric/epoxy composites manufactured by infusion process: Improvement of fire properties promoted by ammonium polyphosphate[J]. Composites Part B: Engineering,2016,89:117-126. [7] 李娟, 刘青, 曹佳丽, 等. 阻燃环氧树脂研究进展[J]. 合成树脂及塑料, 2016(33):80.LI J, LIU Q, CAO J L, et al. Research progress of flame-retardant epoxy resin[J]. Synthetic Resin and Plastic,2016(33):80(in Chinese). [8] CHEN W, LIU P, LIU Y, et al. Flame-retardant and thermal degradation mechanisms of melamine polyphosphate in combination with aluminum phosphinate in glass fabric-reinforced epoxy resin[J]. Polymer Composites,2018,40(8):3199-3208. [9] 岑浩, 杨洪斌, 傅雅琴. 硅溶胶改性碳纤维对碳纤维/环氧树脂复合材料界面性能影响[J]. 复合材料学报, 2012(6):32-36.CEN H, YANG H B, FU Y Q. Effect of silica sol modified carbon fiber on the interface properties of carbon fiber/epoxy resin composites[J]. Acta Materiae Compositae Sinica,2012(6):32-36(in Chinese). [10] CHEN M, WANG X, LI X, et al. The synergistic effect of cuprous oxide on an intumescent flame-retardant epoxy resin system[J]. RSC Advances,2017,7(57):35619-35628. doi: 10.1039/C7RA05482C [11] DING S, YAN Q, JIANG H, et al. Fabrication of Pd@ZIF-8 catalysts with different Pd spatial distributions and their catalytic properties[J]. Chemical Engineering Journal,2016,296:146-153. doi: 10.1016/j.cej.2016.03.098 [12] ASTM. Standard test method for measuring the comparative burning characteristics of solid plastics in a vertical position: ASTM D3801[S]. West Conshohocken: ASTM, 2013. [13] ASTM. Standard test method for measuring the minimum oxygen concentration to support candle-like combustion of plastics (Oxygen index): ASTM D2863—97[S]. West Conshohocken: ASTM, 1997. [14] ISO. Reaction-to-fire tests—Heat release, smoke production and mass loss rate—Part 1: Heat release rate (cone calorimeter method) and smoke production rate (dynamic measurement): ISO 5660-1:2015[S]. Geneva: ISO, 2015. [15] ASTM. Standard test method for tensile properties of plastics1: ASTM D 638[S]. West Conshohocken: ASTM, 2014. [16] ASTM. Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials: ASTM D 790[S]. West Conshohocken: ASTM, 2017. [17] ZHANG M, SHI X, DAI X, et al. Improving the crystallization and fire resistance of poly(lactic acid) with nano-ZIF-8@GO[J]. Journal of Materials Science,2018,53(9):7083-7093. doi: 10.1007/s10853-018-2049-2 [18] LIU A, YU C, LIN J, et al. Construction of CuInS2@ZIF-8 nanocomposites with enhanced photocatalytic activity and durability[J]. Materials Research Bulletin,2018,112:147-153. [19] BUI T T, CUONG N D, YONG S K, et al. In situ growth of microporous ZIF-8 nanocrystals on a macroporous phyllosilicate mineral[J]. Materials Letters,2017,212:69-72. [20] PAN Y, SUN K, LIU S, et al. Core-shell ZIF-8@ZIF-67-derived CoP nanoparticle-embedded N-doped carbon nanotube hollow polyhedron for efficient overall water splitting[J]. Journal of the American Chemical Society,2018,140(7):2610-2618. doi: 10.1021/jacs.7b12420 [21] LIN L, ZHANG T, LIU H O, et al. In situ fabrication of a perfect Pd/ZnO@ZIF-8 core-shell microsphere as an efficient catalyst by a ZnO support-induced ZIF-8 growth strategy[J]. Nanoscale, 2015, 7(17): 7615. [22] MA L, MENG L, WU G, et al. Improving the interfacial properties of carbon fiber-reinforced epoxy composites by grafting of branched polyethyleneimine on carbon fiber surface in supercritical methanol[J]. Composites Science & Technology,2015,114:64-71. [23] ZHANG, JW, JIANG, et al. Morphology and properties of soy protein and polylactide blends[J]. Biomacromolecules, 2006, 7(5): 1551-1561. [24] XU W, WANG G, LIU Y, et al. Zeolitic imidazolate framework-8 was coated with silica and investigated as a flame retardant to improve the flame retardancy and smoke suppression of epoxy resin[J]. RSC Advances,2018,8(5):2575-2585. doi: 10.1039/C7RA12816A [25] XU W, ZHANG B, WANG X, et al. The flame retardancy and smoke suppression effect of a hybrid containing CuMoO4 modified reduced graphene oxide/layered double hydroxide on epoxy resin[J]. Journal of Hazardous Materials,2018,343:364-375. [26] TAO T, CHEN X, MENG X, et al. Synthesis of multiwalled carbon nanotubes by catalytic combustion of polypropylene[J]. Angewandte Chemie International Edition,2005,44(10):1517-1520. doi: 10.1002/anie.200461506 [27] WANG J, YUAN B, MU X, et al. Two-dimensional metal phenylphosphonates as novel flame retardants for polystyrene[J]. Industrial & Engineering Chemistry Research,2017,56(25):7192-7206. [28] ZHANG W, LI X, YANG R. Blowing-out effect and tempera-ture profile in condensed phase in flame retarding epoxy resins by phosphorus-containing oligomeric silsesquioxane[J]. Polymers for Advanced Technologies,2013,24(11):951-961. doi: 10.1002/pat.3170 [29] LUO Q, YUAN Y, DONG C, et al. Highly effective flame retardancy of a novel DPPA-based curing agent for DGEBA epoxy resin[J]. Industrial& Engineering Chemistry Research,2016,55(41):10880-10888. [30] XIE J, SHI X, ZHANG M, et al. Improving the flame retardancy of polypropylene by nano metal-organic frameworks and bioethanol coproduct[J]. Fire and Materials,2019,43(4):373-380. doi: 10.1002/fam.2709 -

下载:

下载: