Densification behavior in short carbon fiber reinforced silica-based ceramic cores via atmosphere sintering

-

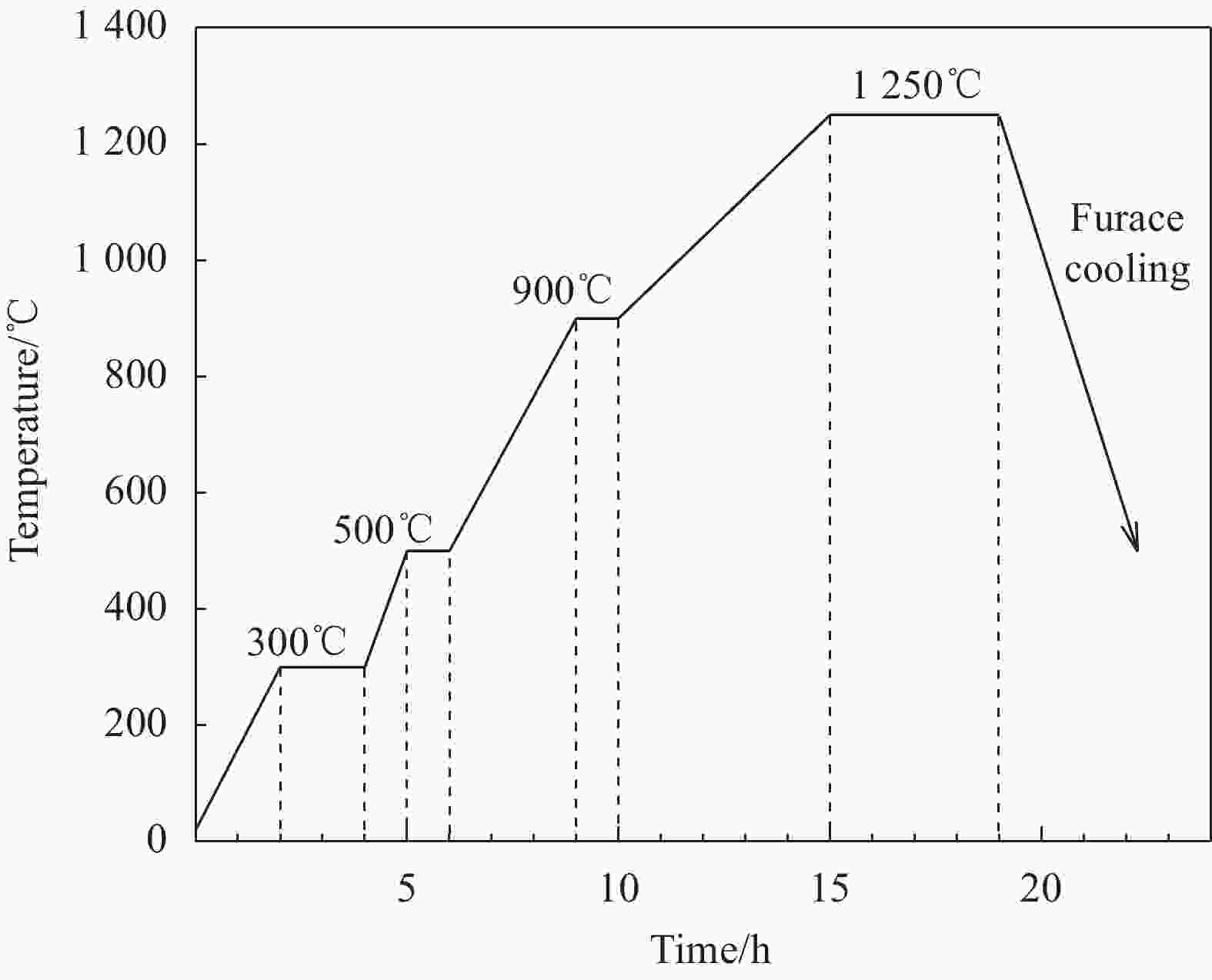

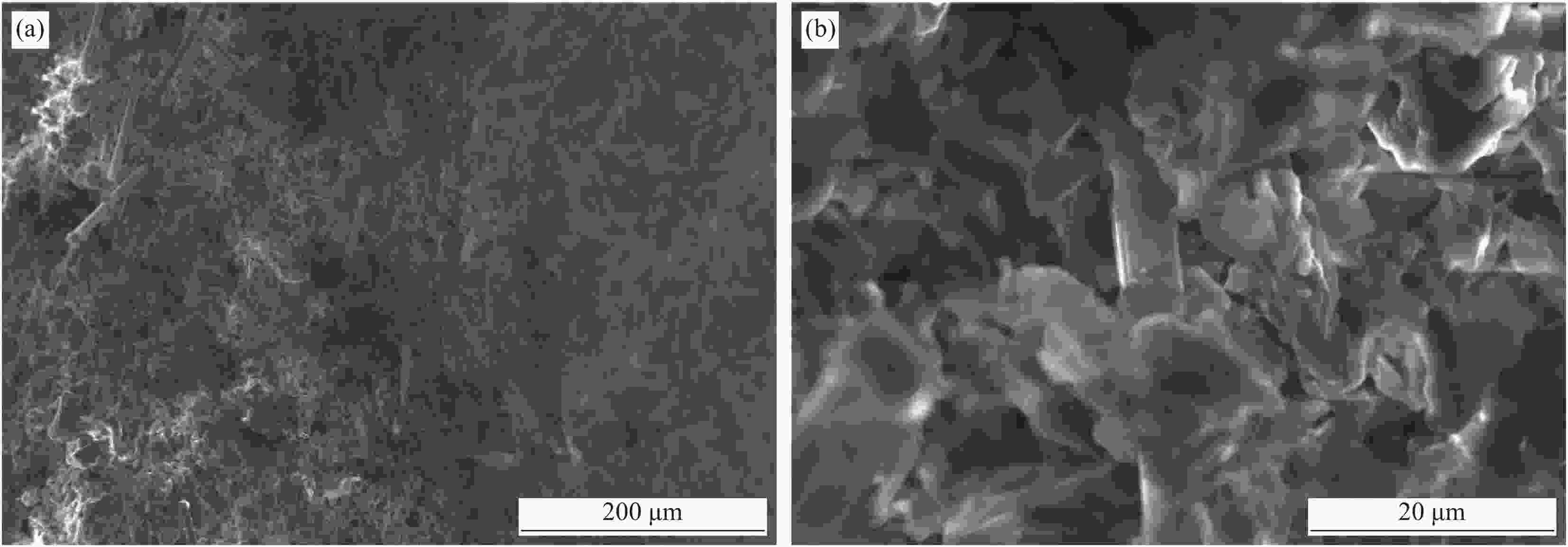

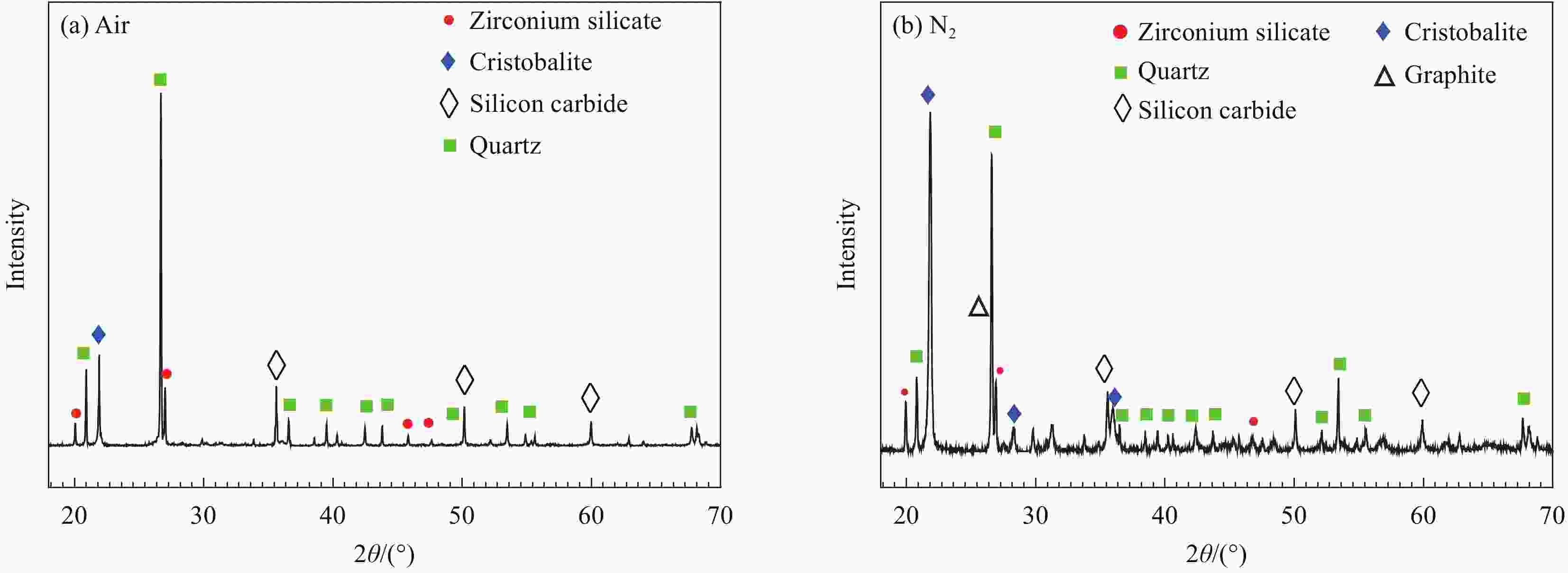

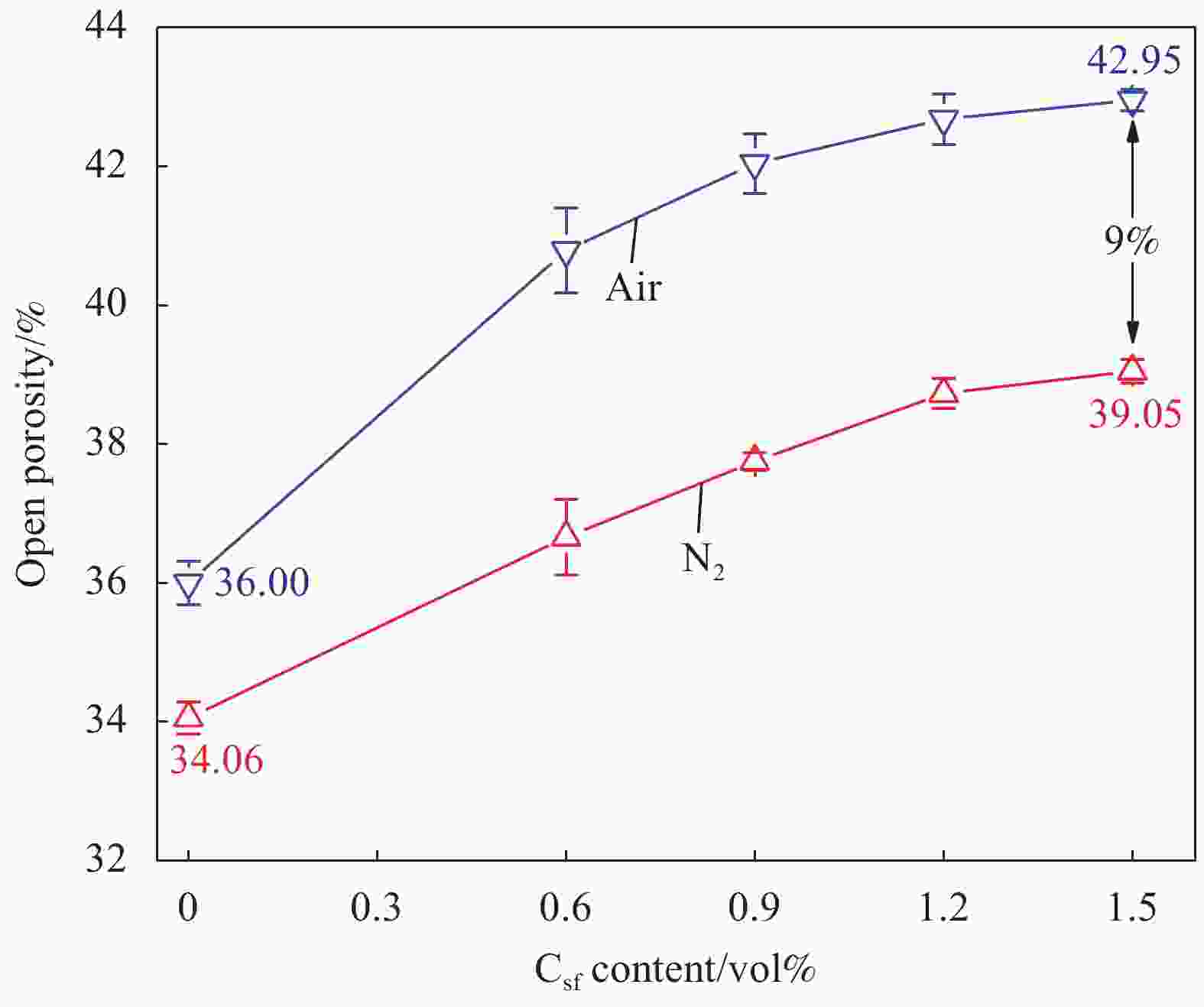

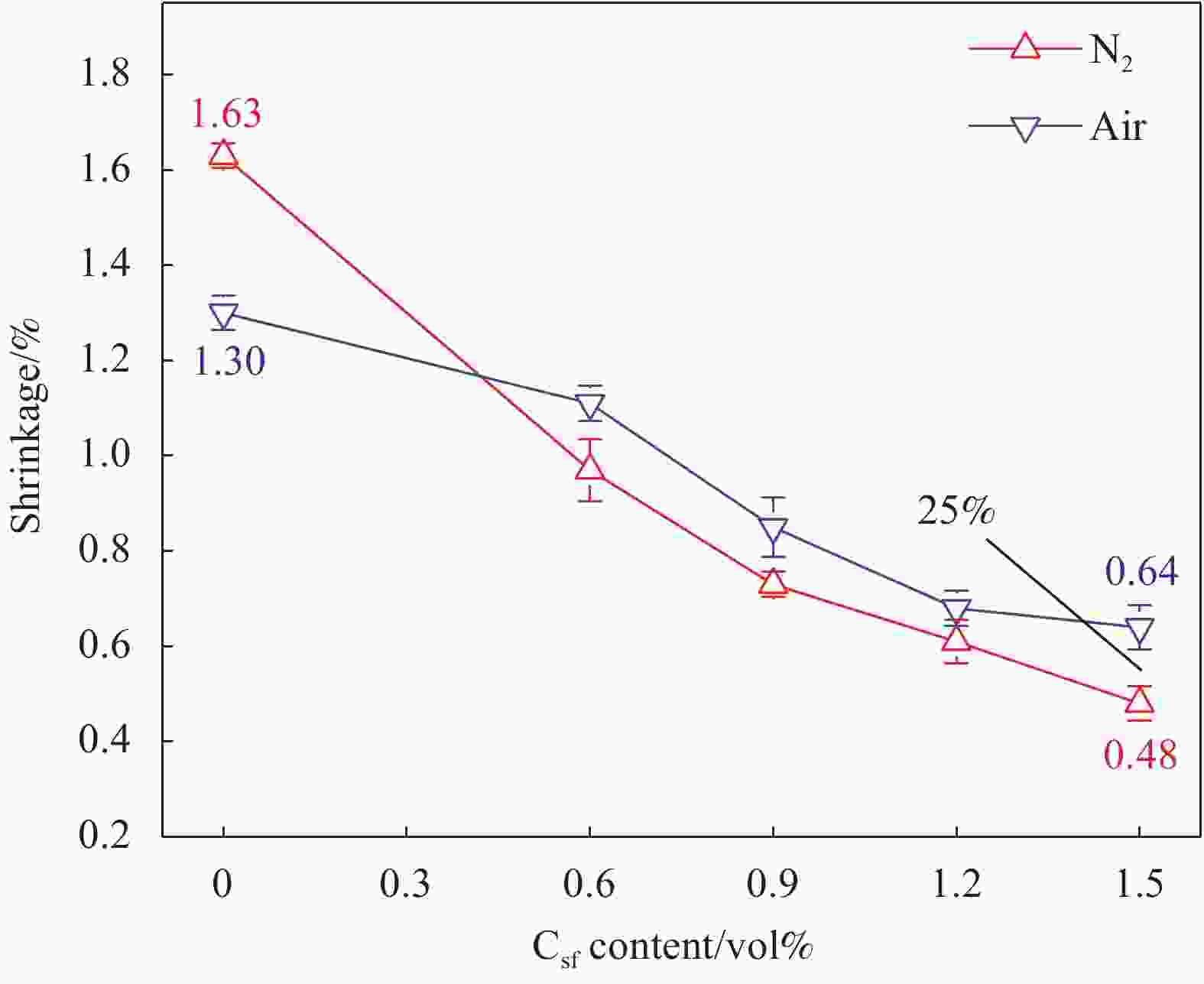

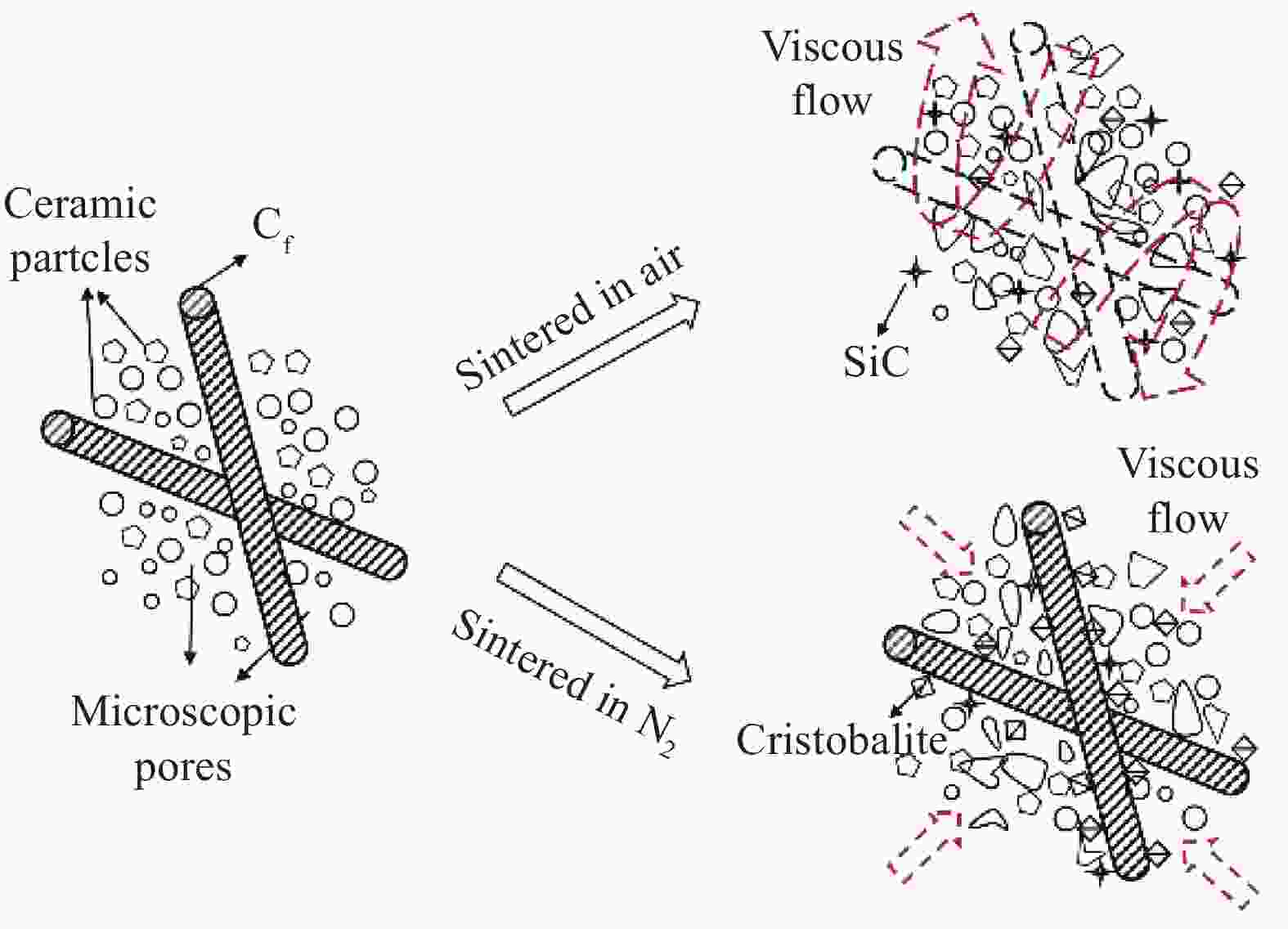

摘要: 为获得满足高温合金单晶叶片熔模精密铸造用高性能陶瓷型芯,本论文采用超声振动和机械搅拌将短切碳纤维(Csf)均匀分散在SiO2基陶瓷浆料中,通过压注法制备型芯生坯并分别在空气和氮气中烧结。观察并分析升温过程中型芯的组织演变及物相转化规律,揭示两种气氛下Csf增强型芯的烧结致密化行为。结果表明,立体互锁Csf网络可以增加陶瓷颗粒之间传质距离,在提供碳源生成原位SiC晶体的同时影响方石英析晶,进而抑制高温下固相的扩散和迁移以及液相的黏性流动。在两种烧结气氛下,随Csf含量的增加,硅基陶瓷型芯的气孔率逐渐上升,收缩率逐渐下降。当Csf含量为1.5vol%时,空气和氮气气氛烧结试样获得的开气孔率最大值为42.95%、39.50%,而最低的收缩率分别为0.64%、0.48%,证实了Csf及高熔点晶体对型芯烧结的致密化行为影响显著。Abstract: In order to obtain high performance ceramic cores for investment casting of superalloy single crystal blade. In this paper, the short carbon fibers (Csf) were uniformly dispersed in silica-based ceramic slurry though synergistic effect of ultrasonic vibration and mechanical stirring, and the green cores were prepared by injection molding method and sintered in air and N2 atmosphere, respectively. The microstructure evolution and phase transformation during heating process were thoroughly observed and analyzed, and further revealed the densification behavior of Csf reinforced silica-based ceramic cores under two sintering atmospheres. The results indicate that the Csf can increase the mass transfer distance between ceramic particles, and provide carbon source to grow in-situ SiC crystals and affect the crystallization of cristobalite in matrix. Therefore, the diffusion and migration of solid phases and viscous flow of liquid phase in ceramic cores are inhibited by the stereo interlocked network of Csf and the high melt point crystalline phases at high temperature. Moreover, the open porosity of silica-based ceramic cores sintered in both air and N2 atmosphere is increased with the increase of Csf content, while the shrinkage is gradually decreased. When the fiber content is 1.5vol%, as for samples sintered in air atmosphere, the highest open porosities in air and N2 sintering atmospheres are about 42.95% and 39.50%, while the least shrinkages are about 0.64% and 0.48%, respectively. It can prove that the Csf and high melting point crystals have significantly influence on the sintering densification behavior of silica-based ceramic cores.

-

Key words:

- ceramic core /

- chopped carbon fiber /

- densification /

- SiC /

- cristobalite /

- shrinkage

-

表 1 石英玻璃化学成分

Table 1. Chemical components of quartz glass

Quartz glass Chemical components SiO2 Al2O3 MgO Fe2O3 K2O N2O CaO TiO2 Different oxide contents/wt% 99.70 0.07 0.03 0.03 0.01 0.01 0.01 0.01 表 2 锆英石粉化学成分

Table 2. Chemical components of zircon powders

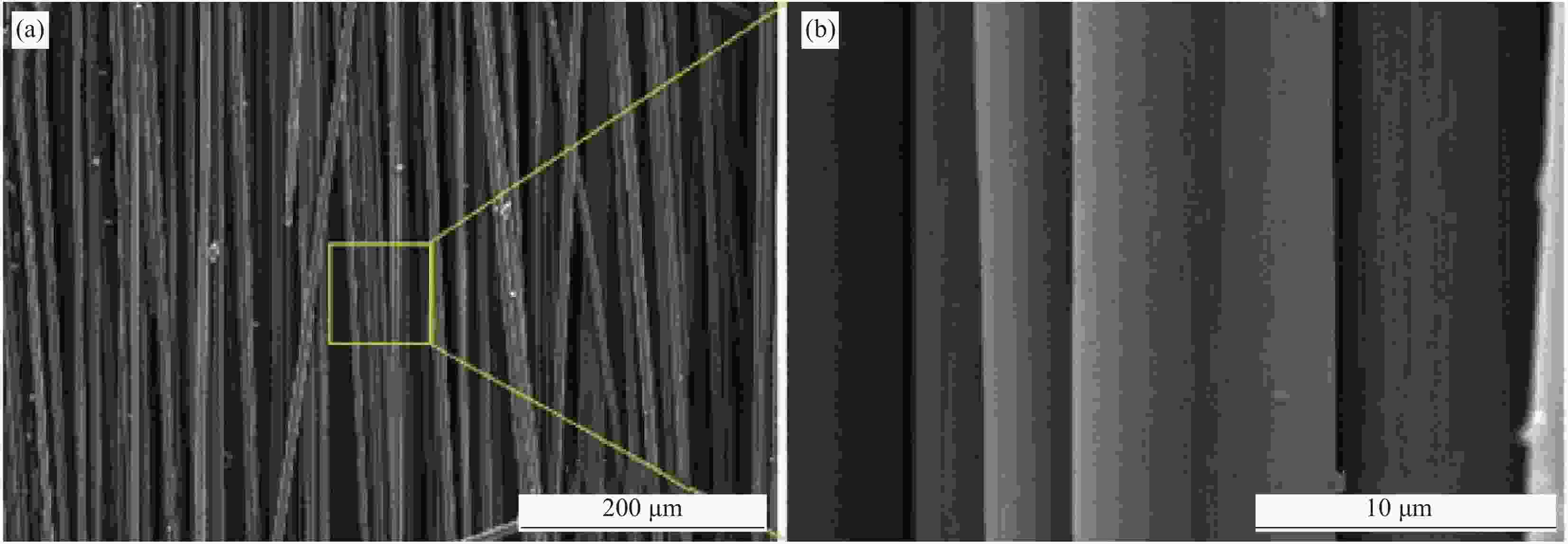

Zircon powders Chemical components (Zr, Hr)O2 SiO2 Fe2O3 TiO2 Different oxide contents/wt% ≥66% ≤32.00 ≤0.12 ≤0.15 表 3 聚丙烯腈(PAN)碳纤维主要特性

Table 3. Typical properties of polyacrylonitrile (PAN)-based carbon fiber

Length/mm Diameter/μm Tensile strength/GPa Young’s modulus/GPa Density/(g·cm−3) 4 5-7 3.28 201.1 1.76 -

[1] PADTURE N P, CELL M, JORDAN E H. Thermal barrier coatings for gas-turbine engine applications[J]. Science,2002,296(5566):280-284. doi: 10.1126/science.1068609 [2] WALALE A, CHAUHAN A S, SATYANARAYNAA A, et al. Analysis of shrinkage & warpage in ceramic injection molding of HPT vane leading edge core of a gas turbine casting[J]. Materials Today: Proceedings,2018(5):19471-19479. [3] KANYO J E, SCHAFFONER S, UWANYUZE R S, et al. An overview of ceramic molds for investment casting of nickel superalloys[J]. Journal of the European Ceramic Society,2020,40(15):4955-4973. doi: 10.1016/j.jeurceramsoc.2020.07.013 [4] WERESZCZAK A A, BREDER K, FERBER M K, et al. Dimensional changes and creep of silica core ceramics used in investment casting of superalloys[J]. Journal of Materials Science,2002(37):4235-4245. [5] YANG Z, ZHAO Z, YU J, et al. Preparation of silica ceramic cores by the preceramic pyrolysis technology using sili-cone resin as precursor and binder[J]. Materials Che-mistry and Physics,2019,223:676-682. doi: 10.1016/j.matchemphys.2018.11.039 [6] 覃业霞, 张睿, 杜爱兵, 等. 粉料粒度对氧化铝基陶瓷型芯材料性能的影响[J]. 复合材料学报, 2007, 36(1):711-713.QIN Yexia, ZHANG Rui, DU Aibing, et al. Effect of particle size on properties of almina-based ceramic cores[J]. Acta Materiae Compositae Sinica,2007,36(1):711-713(in Chinese). [7] KIM Y H, YEO J G, LEE J S, et al. Influence of silicon carbide as a mineralizer on mechanical and thermal properties of silica-based ceramic cores[J]. Ceramics International,2016,42(13):14738-14742. doi: 10.1016/j.ceramint.2016.06.100 [8] JIGNG W, LI K, XIAO J, et al. Effect of silica fiber on the mechanical and chemical behavior of alumina-based ceramic core material[J]. Journal of Asian Ceramic Socie-ties,2018,5(4):410-417. [9] LV K, LIU X, DU Z, et al. Properties of hybrid fibre reinforced shell for investment casting[J]. Ceramics International,2016,42(14):15397-15404. doi: 10.1016/j.ceramint.2016.06.188 [10] 芦刚, 于航, 严青松, 等. Al2O3纤维对SiO2基陶瓷型芯的烧缩阻滞[J]. 复合材料学报, 2018, 35(1):168-172.LU Gang, YU Hang, YAN Qingsong, et al. Effect of Al2O3 fiber on shrinkage blocking of SiO2 matrix ceramic cores[J]. Acta Materiae Compositae Sinica,2018,35(1):168-172(in Chinese). [11] 芦刚, 查军辉, 严青松, 等. PA66纤维含量对多孔铝基陶瓷型芯气孔率的影响[J]. 材料工程, 2020, 48(7):170-175.LU Gang, ZHA Junhui, YAN Qingsong, et al. Influence of PA66 fiber content on porosity of porous aluminum based ceramic core[J]. Journal of Materials Engineering,2020,48(7):170-175(in Chinese). [12] 于航. PA66/Al2O3纤维增强多孔铝基陶瓷型芯的制备及性能研究[D]. 南昌: 南昌航空大学, 2017.YU Hang. Preparation and properties of PA66/Al2O3 fiber reinfoced porous aluminum-based ceramic core[D]. Nanchang: Nanchang Hangkong University, 2017(in Chinese). [13] NEWCOMB B A. Processing, structure, and properties of carbon fibers [J]. Composites Part A: Applied Science and Manufacturing, 2016, 91: 262-282. [14] TANG S, DENG J, WANG S, et al. Ablation behaviors of ultra-high temperature ceramic composites[J]. Materials Science and Engineering: A,2007,465(1/2):1-7. doi: 10.1016/j.msea.2007.02.040 [15] YANG Z, YIN Z, ZHAO Z, et al. Microstructure and properties of SiO2-based ceramic cores with ball-shaped powders by the preceramic polymer technique in N2 atmosphere[J]. Materials Chemistry and Physics,2020,243:122609. doi: 10.1016/j.matchemphys.2019.122609 [16] LI H, LIU Y, LIU Y, et al. Evolution of the microstructure and mechanical properties of stereolithography formed alumina cores sintered in vacuum[J]. Journal of the European Ceramic Society,2020,40(14):4825-4836. doi: 10.1016/j.jeurceramsoc.2019.11.047 [17] WANG X, ZHOU Y, ZHOU L, et al. Microstructure and pro-perties evolution of silicon-based ceramic cores fabricated by 3D printing with stair-stepping effect control[J]. Jour-nal of the European Ceramic Society,2021,41(8):4650-4657. doi: 10.1016/j.jeurceramsoc.2021.03.036 [18] KUCZYNSKI G C. Self-diffusion in sintering of metallic particles[M]. Springer, Dordrecht, 1990: 509-527. [19] TELLE R, GREFFRATH F, PRIELER R. Direct observation of the liquid miscibility gap in the zirconia-silica system[J]. Journal of the European Ceramic Society,2015,35(14):3995-4004. doi: 10.1016/j.jeurceramsoc.2015.07.015 [20] CHEN J P, KONG Q J, LIU Q Q, et al. High yield silicon carbide whiskers from rice husk ash and graphene: Growth method and thermodynamics[J]. ACS Sustainable Che-mistry & Engineering,2019,23(7):19027-19033. [21] ZHANG N L, YANG J F, DENG Y C, et al. Preparation and properties of reaction bonded silicon carbide (RB-SiC) ceramics with high SiC percentage by two-step sintering using compound carbon sources[J]. Ceramics Interna-tional,2019,45(12):15715-15719. doi: 10.1016/j.ceramint.2019.04.224 [22] PAN J, YAN X, CHENG X, et al. In situ synthesis and electrical properties of porous SiOC ceramics decorated with SiC nanowires[J]. Ceramics International,2016,42(10):12345-12351. doi: 10.1016/j.ceramint.2016.05.007 [23] CHU Y, JING S, CHEN J. In situ synthesis of homoge-neously dispersed SiC nanowires in reaction sintered silicon-based ceramic powders[J]. Ceramics International,2018,44(6):6681-6685. doi: 10.1016/j.ceramint.2018.01.080 [24] 占红星, 芦刚, 严青松, 等. 预加方石英含量对SiO2基陶瓷型芯高温蠕变性能的影响[J]. 复合材料学报, 2018, 38(5):1588-1593.ZHAN Hongxing, LU Gang, YAN Qingsong, et al. Effect of pre-added cristobalite content on high temperature creep properties of silicon-based cermaic core[J]. Acta Materiae Compositae Sinica,2018,38(5):1588-1593(in Chinese). [25] KAZEMI A, FAGHIHI S M A, ALIZDEH H R. Investigation on cristobalite crystallization in silica-based ceramic cores for investment casting[J]. Journal of the European Ceramic Society,2013,33(15/16):3397-3402. doi: 10.1016/j.jeurceramsoc.2013.06.025 [26] YOSHIZAWA K, SEMOTO T, HITAOKA S, et al. Synergy of electrostatic and van der waals interactions in the adhesion of epoxy resin with carbon-fiber and glass surfaces[J]. Bulletin of the Chemical Society of Japan,2017,90(5):500-505. doi: 10.1246/bcsj.20160426 [27] SMEACETTO F, FERRARIS M, SALVO M, et al. Protective coatings for carbon bonded carbon fibre composites[J]. Ceramics International,2008,34(5):1297-1301. doi: 10.1016/j.ceramint.2007.03.012 [28] 芦刚, 毛蒲, 严青松, 等. 超声振荡和羟丙基甲基纤维素对短切纤维在精铸硅溶胶浆料中分散性能的影响[J]. 材料工程, 2016, 44(1):71-76. doi: 10.11868/j.issn.1001-4381.2016.01.011LU Gang, MAO Pu, YAN Qingsong, et al. Effect of ultra-sonic vibration and hydroxypropyl methyl cellulose on disperison of short fiber in silica sol slurry for inverstment casting[J]. Journal of Materials Engineering,2016,44(1):71-76(in Chinese). doi: 10.11868/j.issn.1001-4381.2016.01.011 -

下载:

下载: