Mechanically stable superhydrophobic surface fabricated by self-growth of ZnO nanoflowers on vulcanized silicone rubber

-

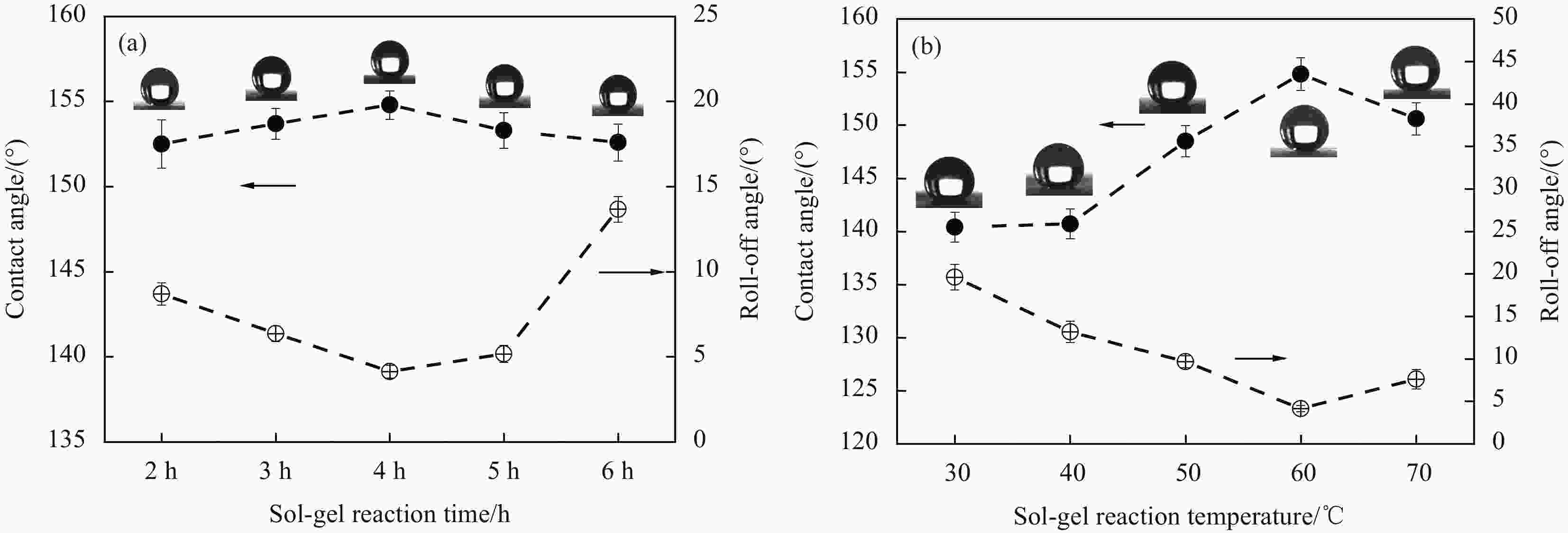

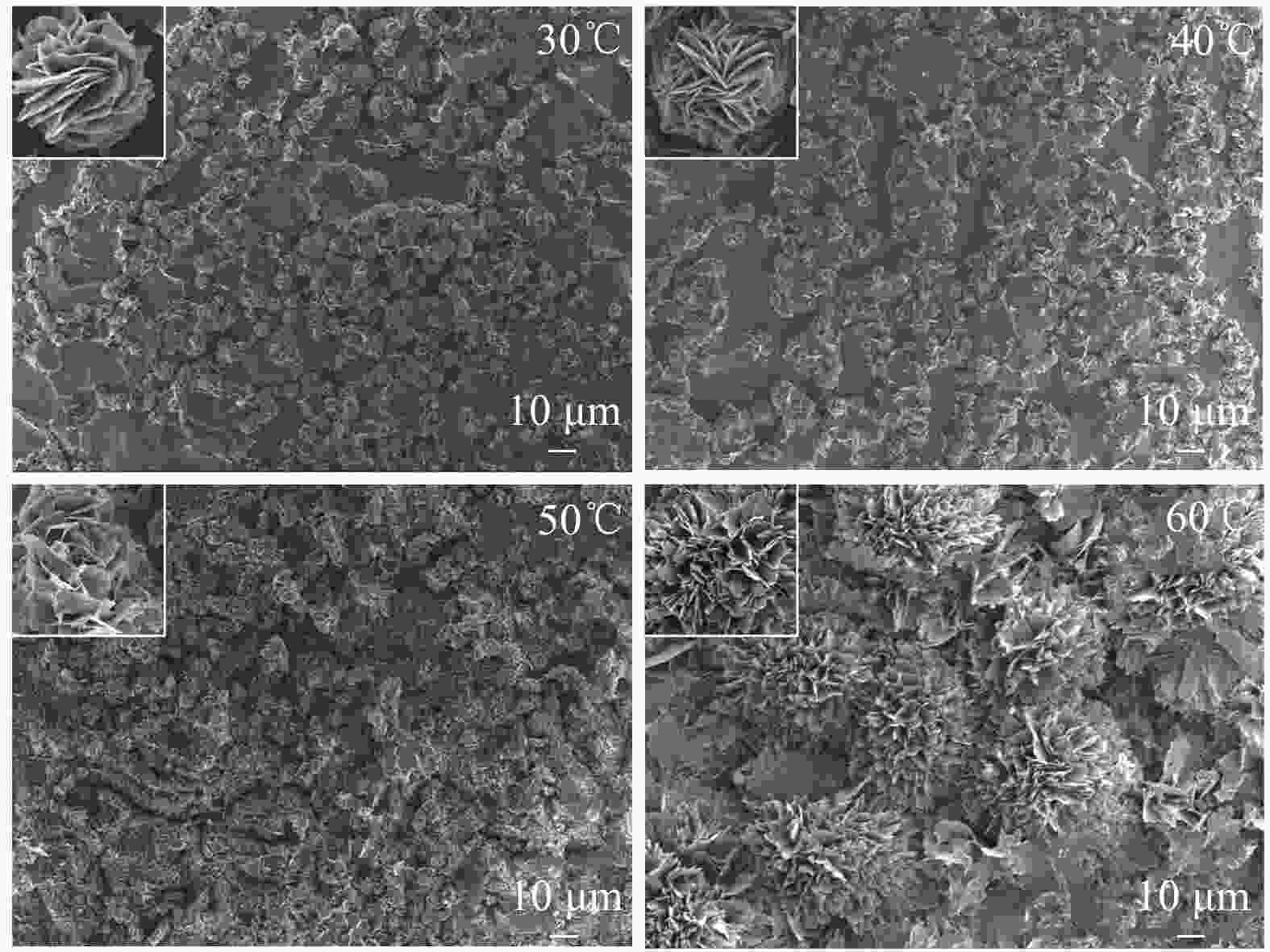

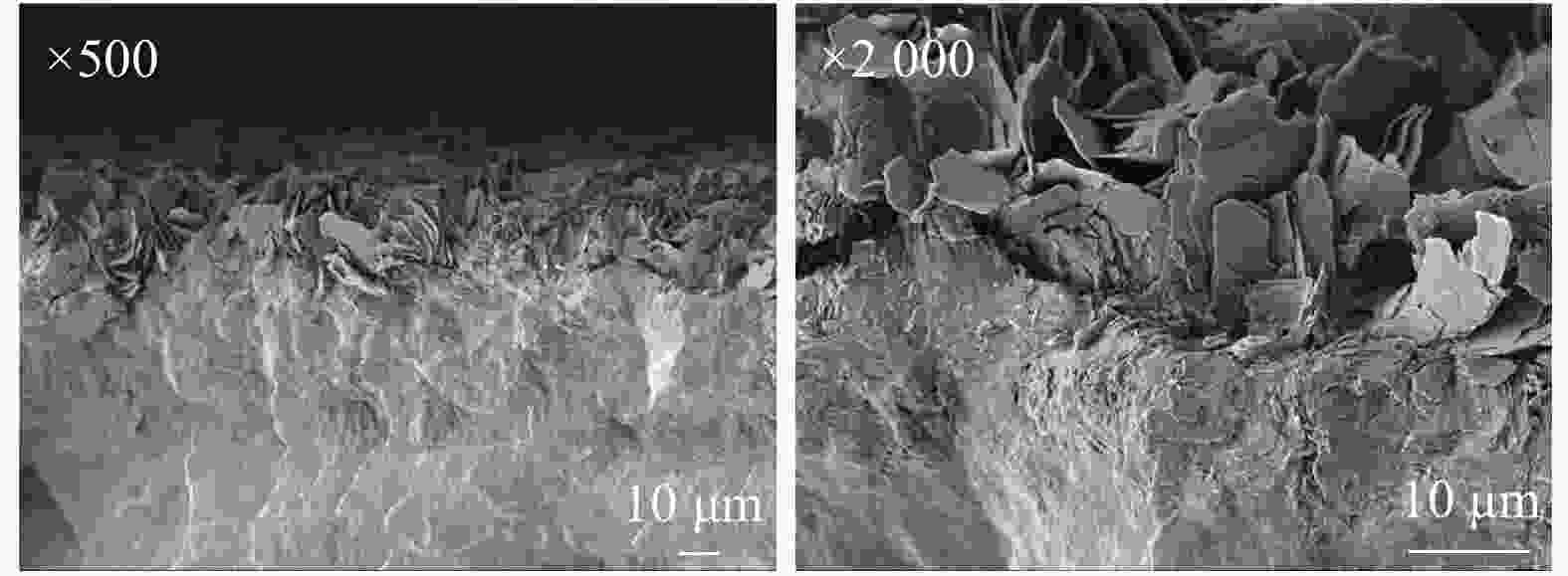

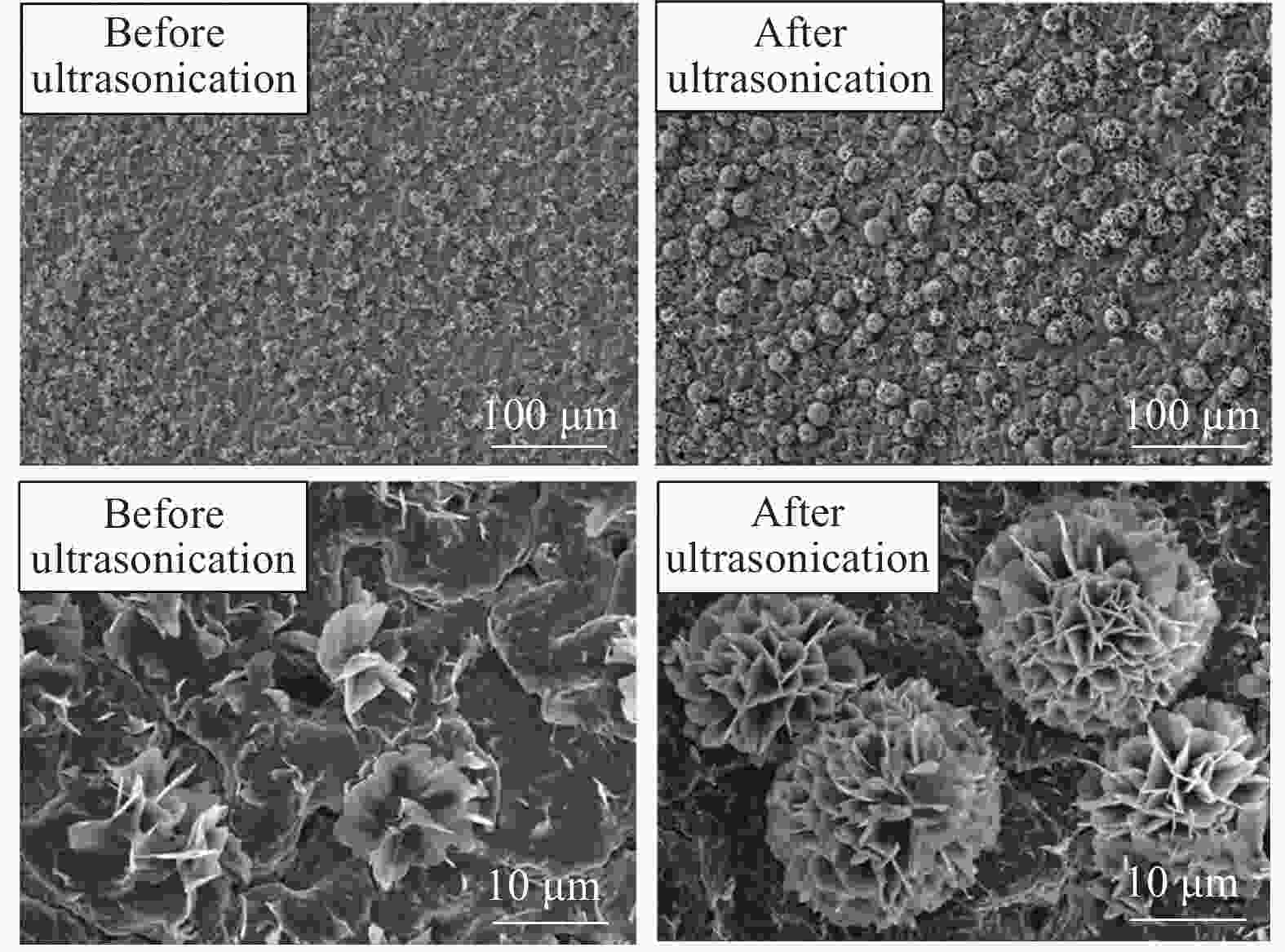

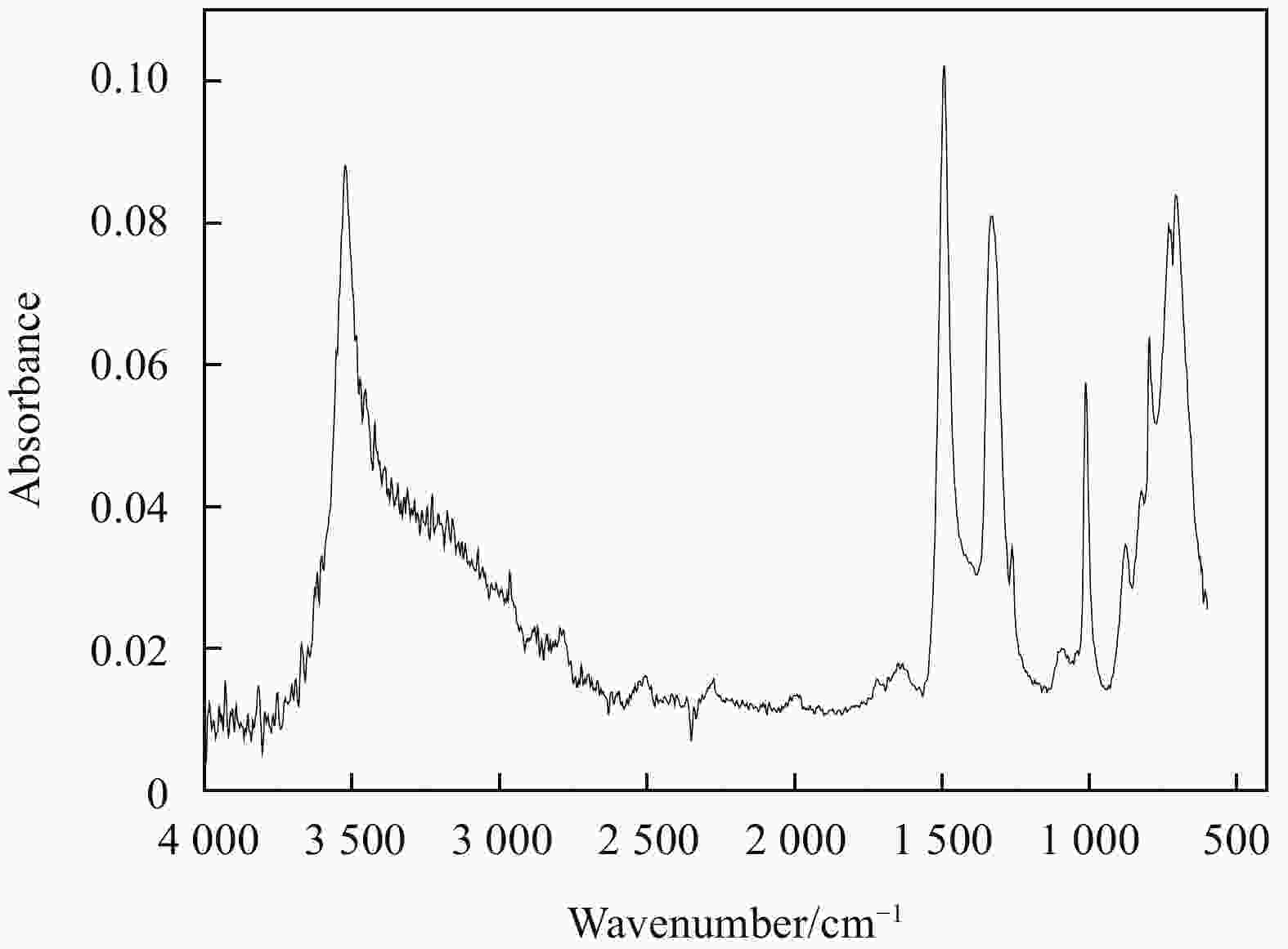

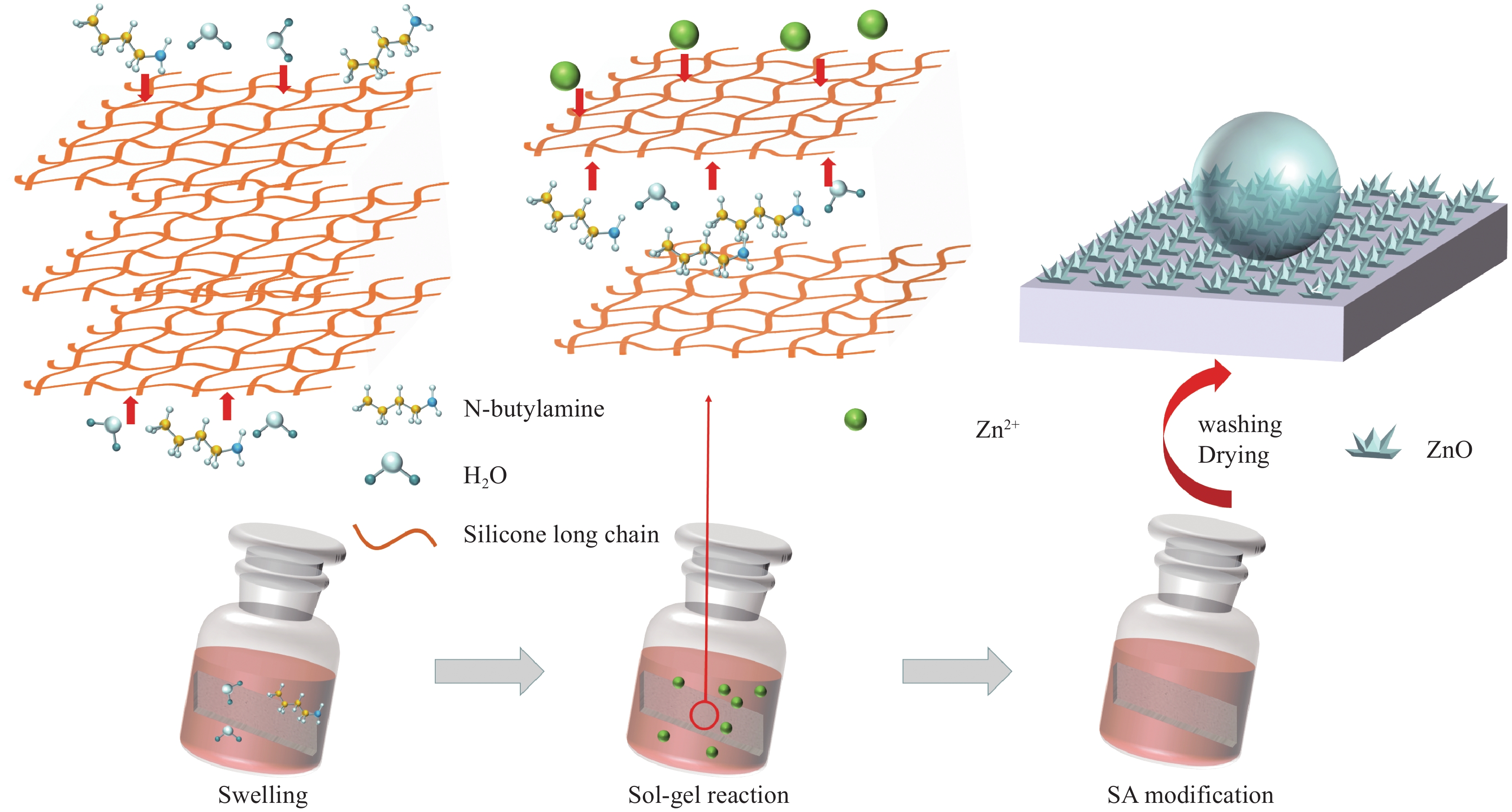

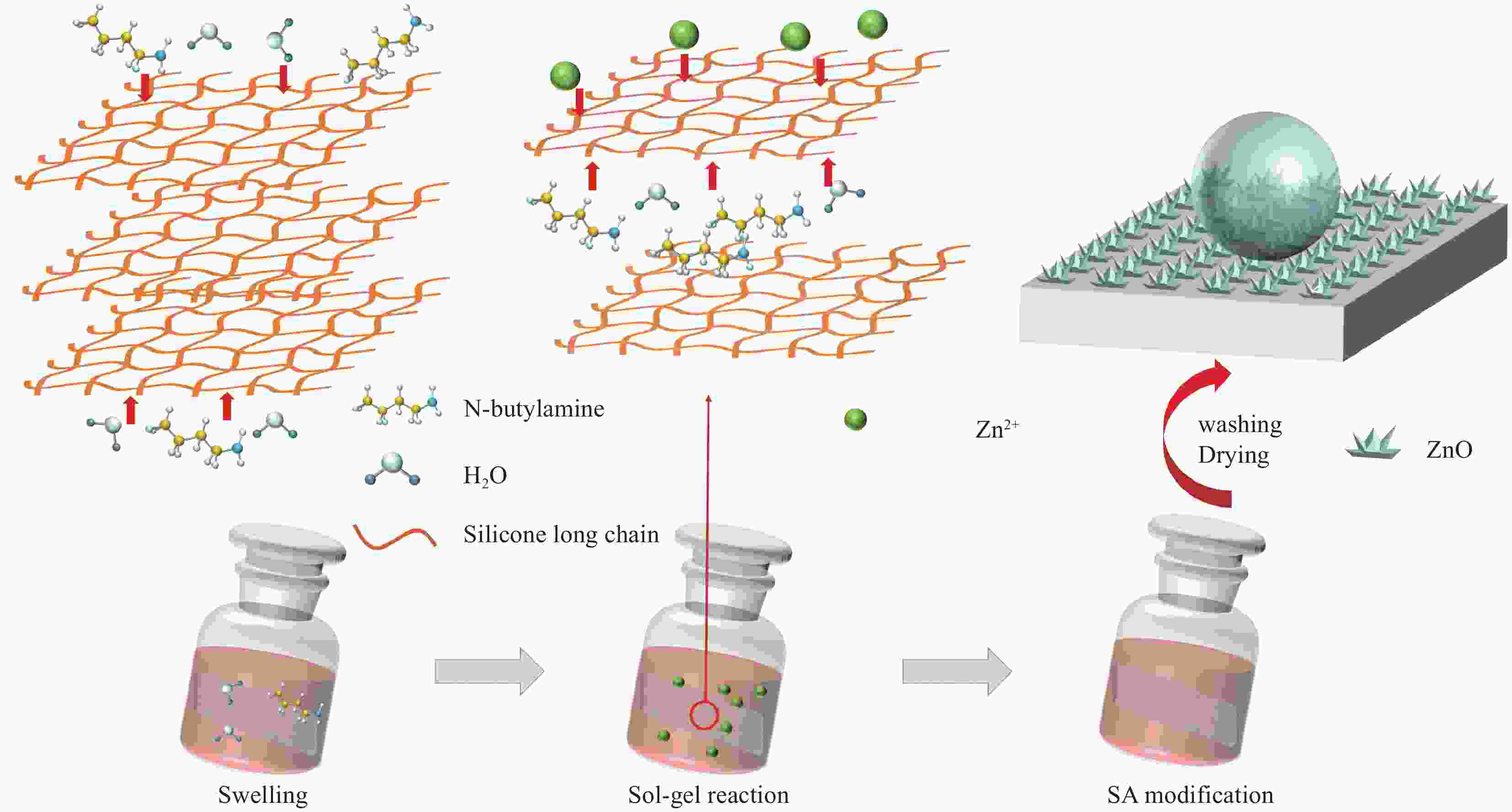

摘要: 制造的复杂性和对机械接触的敏感性严重阻碍了超疏水材料在实际应用的发展。为在柔性基质(硫化的硅橡胶)表面制备机械耐久的柔性超疏水表面,利用硫化硅橡胶溶胀过程可逆的特性,改进溶胶-凝胶法,将硅橡胶片预先用正丁胺水溶液溶胀,然后浸入硝酸锌/乙醇溶液中。利用正丁胺水溶液和硝酸锌/乙醇溶液在硅橡胶表面的交互扩散、反应,使ZnO纳米花在橡胶表面原位生长。超疏水的粗糙结构的构筑来自于硝酸锌与正丁胺的协同作用,其静态接触角(CA)可达(158±1.5)°,滑动角(RA)可达(4.5±0.5)°。SEM图像显示,100~200 nm的ZnO纳米片生长在硅橡胶表面,ZnO纳米片“嵌入”到橡胶表面,而不是沉积在橡胶表面,因此提升了其机械耐久性。而通过向橡胶中添加硅烷偶联剂γ-氨丙基三乙氧基硅烷(KH550),可进一步提升ZnO纳米片与橡胶基体界面相互作用,即使承受300次线性磨损,仍能保持超疏水特性,表现出优异机械稳定性。而且经过500次循环弯曲变形,其疏水性也几乎没有变化,解决了超疏水涂层在基体弯曲变形时的脱落问题。这种超疏水橡胶制备技术简单且适合工业生产,具有极高的实用前景。Abstract: The development of superhydrophobic materials in practical applications has been severely hindered by the complexity of manufacturing and the sensitivity to mechanical contact. In order to prepare a mechanically durable flexible super-hydrophobic surface on the surface of a flexible substrate (vulcanized silicone rubber), using the reversible characteristics of the swelling process of vulcanized silicone rubber and the improved sol-gel method, the silicone rubber sheet was swelled with a n-butylamine aqueous solution in advance, and then immersed in zinc nitrate/ethanol solution. Due to the cross-diffusion, contact and reaction between zinc nitrate and n-butylamine aqueous solution on the surface of silicone rubber, ZnO nanoflowers were grown in-situ on the rubber surface. The construction of the superhydrophobic rough structure came from the synergistic effect of zinc nitrate and n-butylamine, with static contact angle and rolling angle being (158±1.5)° and (4.5±0.5)° respectively. SEM images show that ZnO nanosheets of 100-200 nm in thickness are generated and the ZnO nanosheets are “embedded”, not just “deposited” on the rubber surface, which improves the mechanical durability. By adding a silane coupling agent γ-aminopropyltriethoxysilane (KH550) to the silicone rubber compounds, the interface interaction between the ZnO nanosheets and the rubber matrix is further improved. Even with 300 times of linear wear, it could still maintain superhydrophobic and exhibit excellent mechanical stability. Moreover, after 500 cycles of bending deformation, its hydrophobicity hardly changes, which solves the problem of superhydrophobic coating falling off when the substrate is bent and deformed. High mechanical stability and simple preparation process endow the superhydrophobic rubber a high application prospect.

-

Key words:

- sol-gel method /

- ZnO nanoflower /

- self-growth /

- mechanical stability /

- silicone rubber

-

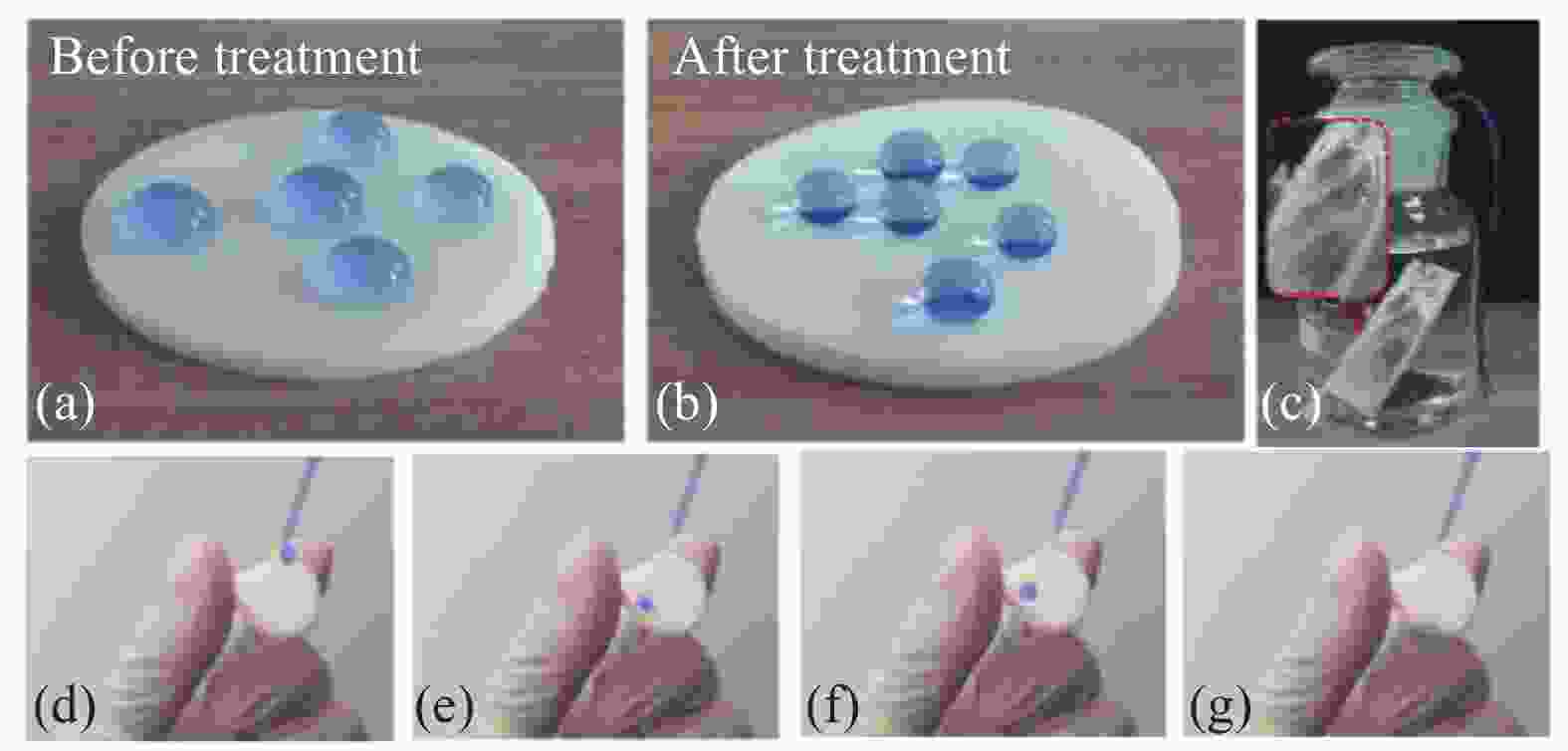

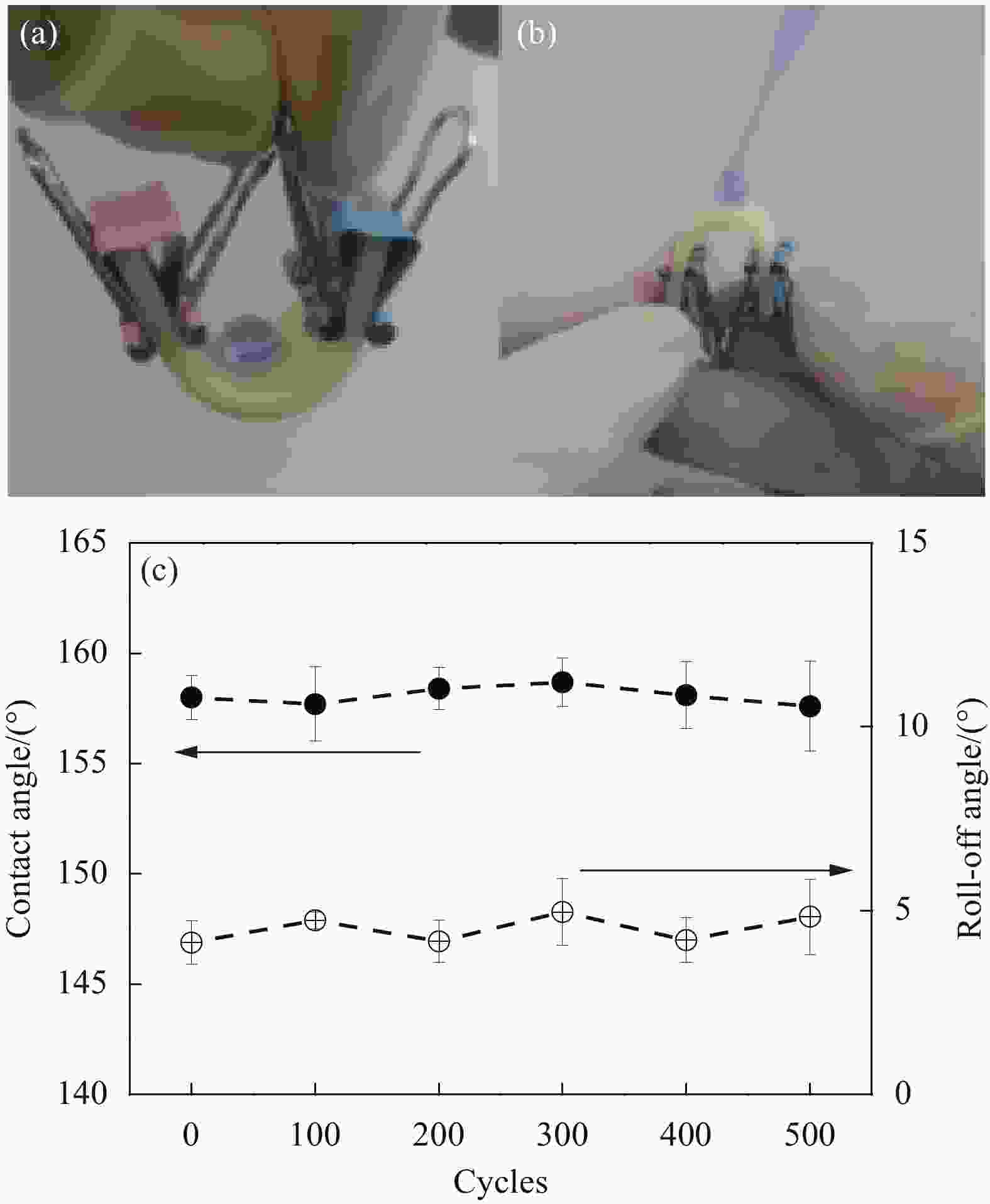

图 7 未处理和处理过的超疏水SR表面上的水滴((a)、(b))、将处理过的膜浸入去离子水中 (c) 和在弯曲过程中处理过的表面上的水滴((d)~(g))照片

Figure 7. Photographs of superhydrophobic SR of water droplet on untreated and treated surface ((a), (b)), treated film was immersed in deionized water (c) and water droplets on the surface treated during the bending process ((d)-(g))

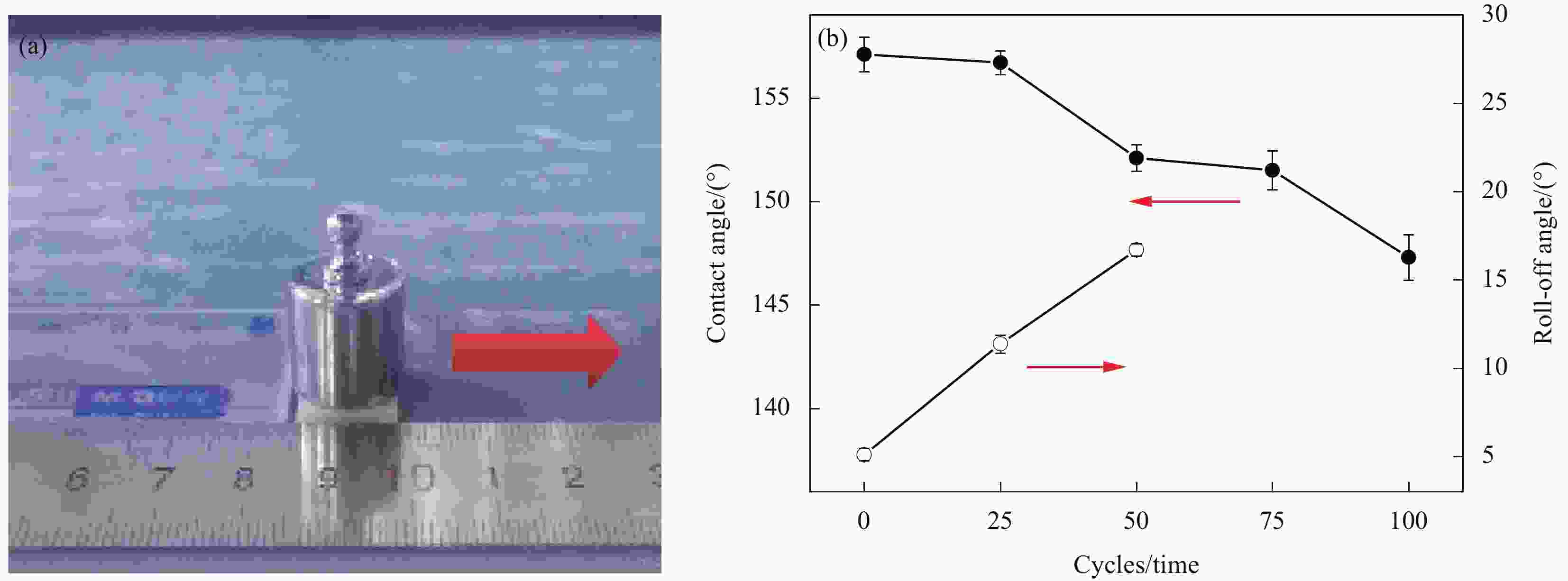

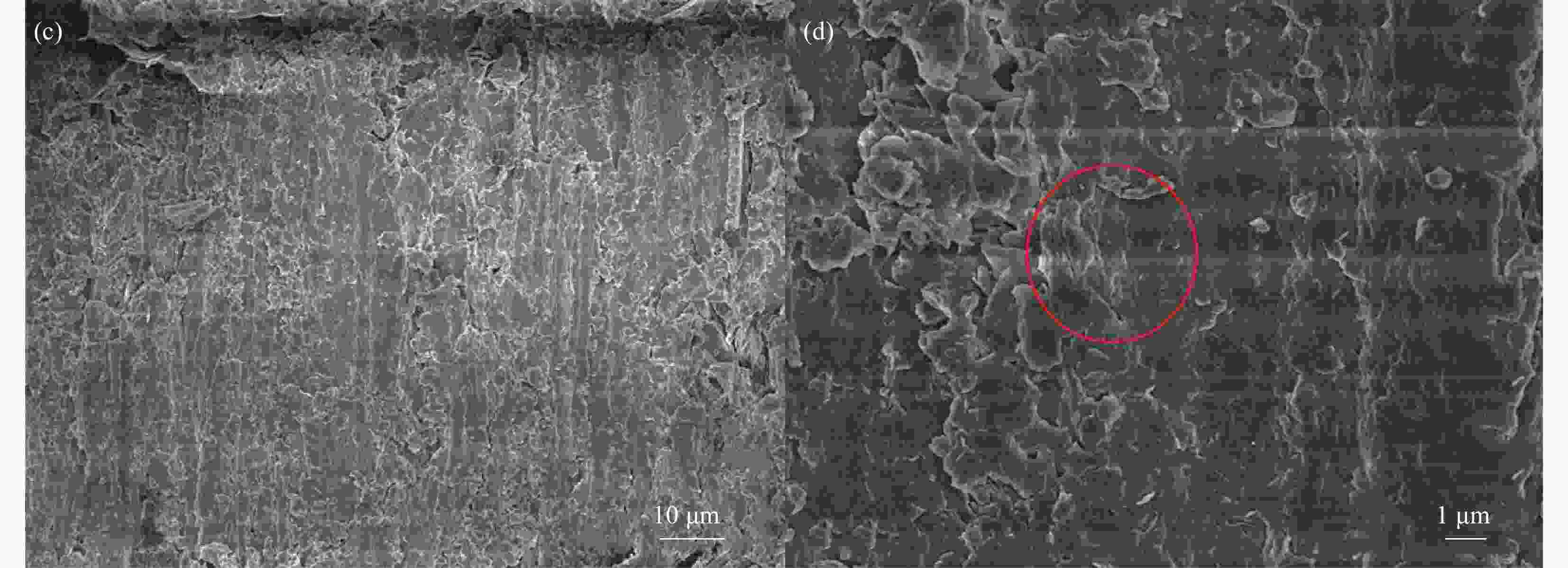

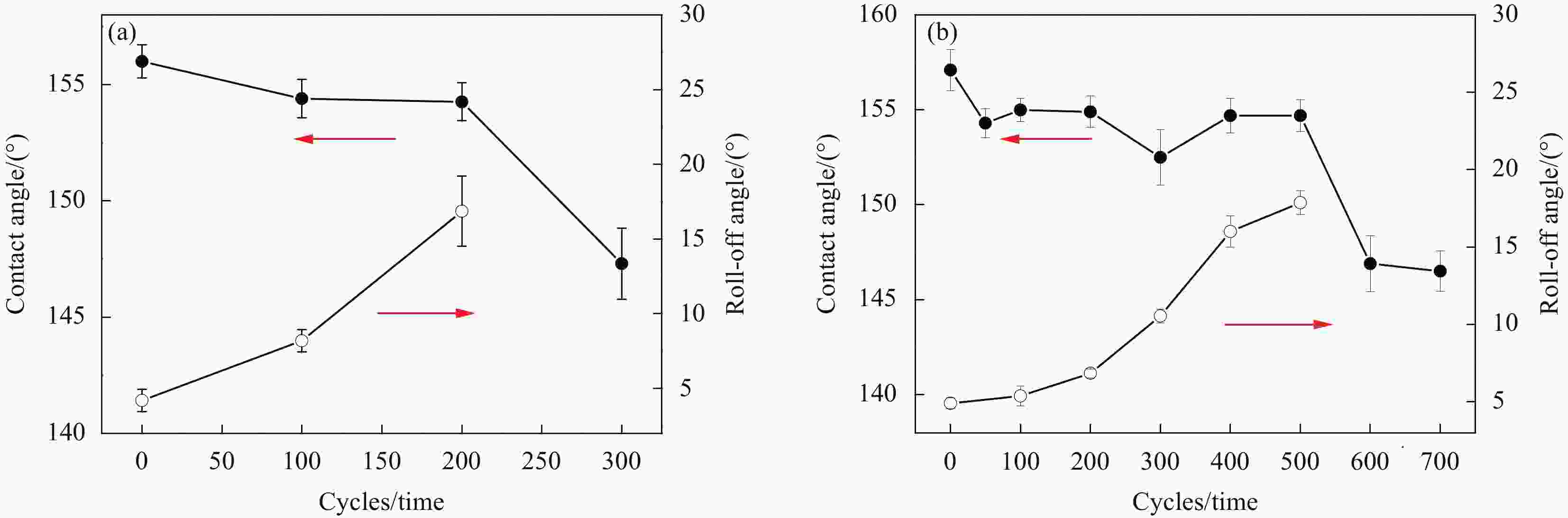

图 9 Si-69填充基体和KH550填充基体在不同的磨损循环后的超疏水SR的CA和RA值 ((a)、(b))、Si-69填充基体的300次磨损循环后的超疏水SR的表面形态的SEM图像 ((c)、(e)) 和KH550填充基体在700次磨损循环后超疏水SR的表面形态的SEM图像 ((d)、(f))

Figure 9. CA and RA values of superhydrophobic SR of Si-69 filled matrix and KH550 filled matrix after different wear cycles ((a), (b)), SEM images of the superhydrophobic SR surface morphology of the Si-69 filled matrix after 300 cycles of abrasion ((c), (e)) and SEM images of the superhydrophobic SR surface morphology of the KH550 filled matrix after 700 cycles of abrasion ((d), (f))

-

[1] WANG J, KAPLAN J A, COLSON Y L, et al. Stretch-induced drug delivery from superhydrophobic polymer composites: Use of crack propagati on failure modes for controlling release rates[J]. Angewandte Chemie International Edition,2016,55:2796-2800. doi: 10.1002/anie.201511052 [2] ZHOU J C, FRANK M A, YANG Y Y, et al. A novel local drug delivery system: superhydrophobic tita-nium oxide nano-tube arrays serve as the drug reservoir and ultrasonication functions as the drug release trigger[J]. Materials Science and Engineering: C,2018,82:277-283. doi: 10.1016/j.msec.2017.08.066 [3] 胡立琼, 雷鸣, 邱亚群, 等. 仿生超疏水表面在建筑和生物医药领域的研究进展[J]. 广东化工, 2016, 43(17):100-102. doi: 10.3969/j.issn.1007-1865.2016.17.045HU L Q, LEI M, QIU Y Q, et al. Application of biomimetic super-hydrophobic surface in construction and biological medicine field—A review[J]. Guangdong Journal of Che-mical Engineering,2016,43(17):100-102(in Chinese). doi: 10.3969/j.issn.1007-1865.2016.17.045 [4] MALEKIDELARESTAQI M, MANSOURI A, CHINI S F. Electrokinetic energy conversion in a finite length superhydrophobic microchannel[J]. Chemical Physics Letters,2018,703:72-79. doi: 10.1016/j.cplett.2018.05.007 [5] XUE X P, WANG S Q, ZHAN G C, et al. Fabrication of Ni Co coating by electrochemical deposition with high super-hydrophobic properties for corrosion protection[J]. Surface and Coatings Technology,2019,363:352-361. doi: 10.1016/j.surfcoat.2019.02.056 [6] MISHCHENKO L, HATTON B, BAHADUR V, et al. Design of ice-free nanostructured surfaces based on repulsion of impacting water droplets[J]. ACS Nano,2010,4:7699-7707. doi: 10.1021/nn102557p [7] 莫春燕, 郑燕升, 王发龙, 等. TiO2/氟化含氢硅油超疏水防腐涂层的制备及性能[J]. 中国表面工程, 2015, 28(2):132-137. doi: 10.11933/j.issn.1007-9289.2015.02.016MO C Y, ZHENG Y S, WANG F L, et al. Preparation and property of TiO2/PMHS superhydrophobic and anticorrosive coating[J]. New Chemical Materials,2015,28(2):132-137(in Chinese). doi: 10.11933/j.issn.1007-9289.2015.02.016 [8] GALOPIN E, PIRET G, SZUNERITS S, et al. Selective adhesion of bacillus cereus spores on heterogeneously wetted silicon nanowires[J]. Langmuir,2010,26(5):3479-3484. doi: 10.1021/la9030377 [9] 周明, 郑傲然, 杨加宏. 复制模塑法制备超疏水表面及其应用[J]. 物理化学学报, 2007(8):164-168.ZHOU M, ZHENG A R, YANG J H. Superhydrophobic surfaces fabricated by replica molding and its applications[J]. Acta Physico-Chimica Sinica,2007(8):164-168(in Chinese). [10] PENG C Y, CHEN Z Y, TIWARI M K. All-organic superhydrophobic coatings with mechanochemical robustness and liquid impalement resistance[J]. Nature Material,2018,17(4):355-360. doi: 10.1038/s41563-018-0044-2 [11] CHEN F F, YANG Z Y, ZHU Y J, et al. Low-cost and scaled-up production of fluorine-free, sub-strate-independent, large-area superhydrophobic coatings based on hydroxyapatite nanowire bundles[J]. Chemistry-A European Journal,2018,24:416-424. doi: 10.1002/chem.201703894 [12] LEE W K, JUNG W B, RHEE D, et al. Monolithic polymer nanoridges with programmable wetting transitions[J]. Advanced Materials,2018,30(32):1706657. [13] ZHU C, GAO Y, HUANG Y, et al. Controlling states of water droplets on nanostructured surfaces by design[J]. Nanoscale,2017,9(46):18240-18245. doi: 10.1039/C7NR06896D [14] VAZIRINASAB E, JAFARI R, MOMEN G. Application of superhydrophobic coatings as a corrosion barrier: A review[J]. Surface and Coatings Technology,2019,375:100-111. doi: 10.1016/j.surfcoat.2019.07.005 [15] 马宁, 程丹, 张景强, 等. 激光刻蚀法制备GH4169超疏水表面及性能研究[J]. 中国铸造装备与技术, 2020, 55(2):40-45. doi: 10.3969/j.issn.1006-9658.2020.02.010MA N, CHENG D, ZHANG J Q, et al. Preparation and properties of GH4169 super-hydrophobic surface by laser etching[J]. China Foundry Machinery & Technology,2020,55(2):40-45(in Chinese). doi: 10.3969/j.issn.1006-9658.2020.02.010 [16] PENG P P, KE Q P, ZHOU G, et al. Fabrication of microcavity-array superhydrophobic surfaces using an improved template method[J]. Journal of Colloid and Interface Science,2013,395:326-328. doi: 10.1016/j.jcis.2012.12.036 [17] 孙巍, 周雨辰, 陈忠仁. 基于水滴模板法的微纳复合超疏水结构制备的研究[J]. 高分子学报, 2012(12):108-113.SUN W, ZHOU Y C, CHEN Z R. Construction of superhydrophobic surface via secondary processing of honeycomb-patterned substrate[J]. Acta Polymerica Sinica,2012(12):108-113(in Chinese). [18] MAGHSOUDI K, MOMEN G, JAFARI R, et al. Direct replication of micro-nanostructures in the fabrication of superhydrophobic silicone rubber surfaces by compression molding[J]. Applied Surface Science,2018,458:619-628. doi: 10.1016/j.apsusc.2018.07.099 [19] MUNIRASUA S, BANATA F, DURRANI A A, et al. Intrinsically superhydrophobic PVDF mem-brane by phase inversion for membrane distillation[J]. Desalination,2017,417:77-86. doi: 10.1016/j.desal.2017.05.019 [20] WANG D H, SUN Q Q, HOKKANEN M J, et al. Design of robust superhydrophobic surfaces[J]. Nature,2020,582(7810):55-59. doi: 10.1038/s41586-020-2331-8 [21] WU J, DONG J, WANG Y, et al. Thermal oxidation ageing effects on silicone rubber sealing performance[J]. Polymer Degradation and Stability,2017,135:43-53. doi: 10.1016/j.polymdegradstab.2016.11.017 [22] DAVYDOVA M L, SOKOLOVA M D, HALDEEVA A R, et al. Modification of sealing rubber based on nitrile butadiene rubber by thermoexpanded graphite[J]. Journal of Friction & Wear,2015,36(1):23-28. [23] PENG C Y, CHEN Z Y, TIWARI M K. All-organic superhydrophobic coatings with mechanochemical robustness and liquid impalement resistance[J]. Nature Materials,2020,582(7810):355-360. [24] PENG C Y, CHEN Z Y, TIWARI M K, et al. Analysis of wear abrasion resistance of superhydrophobic acrylonitrile butadiene styrene rubber (ABS) nanocomposites[J]. Chemical Engineering Journal,2015,281:730-738. doi: 10.1016/j.cej.2015.06.086 [25] 弯艳玲, 廉中旭, 刘志刚, 等. 高速电火花线切割制备耐用型超疏水铜表面[J]. 材料科学与工程学报, 2014, 32(5):634-637, 642.WAN Y L, LIAN Z X, LIU Z G, et al. Fabrication of robust super-hydrophobic copper surface by HS-WEDM[J]. Journal of Materials Science & Engineering,2014,32(5):634-637, 642(in Chinese). [26] 武志富, 李素娟. 氢氧化锌和氧化锌的红外光谱特征[J]. 光谱实验室, 2012, 29(4):2172-2175.WU Z F, LI S J. Infrared spectra characteristics of zinc hydroxide and zinc oxide[J]. Chinese Journal of Spectroscopy Laboratory,2012,29(4):2172-2175(in Chinese). -

下载:

下载: