Preparation and UV-blocking performance of lignin-cellulose nanofiber composite film

-

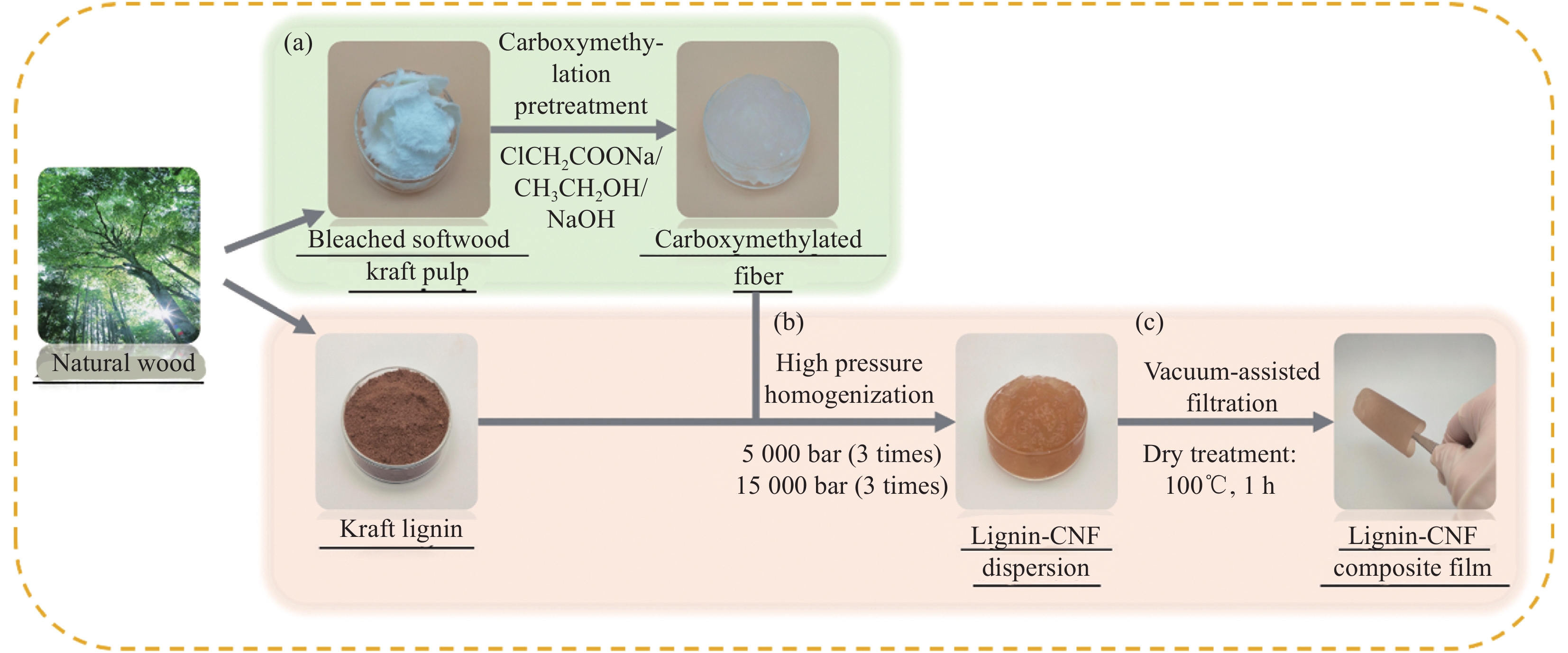

摘要: 由于臭氧层的破坏及塑料污染,研发具有紫外光屏蔽性能的纤维素基薄膜材料引起广泛重视。为实现紫外光屏蔽剂-木质素与纤维素均匀分散,提出了一种利用高压均质法来实现木质素颗粒及羧甲基化纤维均匀混合的方法,随后结合真空抽滤、热压干燥等工艺制得复合薄膜材料。实验中,对木质素-纳米纤维素(Lignin-CNF,L-CNF)复合膜的微观形貌及成形过程进行了深入分析,同时也研究了不同木质素添加量对复合膜透光率、紫外光屏蔽性能及表面色度值(L*a*b*值)的影响规律。结果表明,随木质素添加量的增大,复合膜在600 nm处的透光率有所降低,而在紫外光两个主要波段(UVA:320~400 nm,UVB:280~320 nm)的屏蔽效率显著增加。当木质素添加量达到12wt%时,L-CNF复合膜仍具有40%的透光率,而且在UVA及UVB波段的紫外光屏蔽效率分别达到98%和100%,紫外光屏蔽性能优异。通过合理调控木质素的添加量,L-CNF复合膜有望实现在光敏材料覆膜、食品包装材料等领域的应用价值。Abstract: Due to the current state of ozone layer depletion and plastic pollution, researches on cellulose-based films with ultraviolet (UV) blocking properties has attracted widespread attention. In order to realize the uniform dispersion of UV absorbent (lignin) and cellulose, a method of using high pressure homogenization to achieve mixing of lignin particles and carboxymethylated fibers was proposed. Then lignin-cellulose nanofiber(Lignin-CNF, L-CNF) composite film was fabricated through vacuum filtration and hot pressing process. Moreover, the micro-morphology of the L-CNF composite film was observed and the forming process was determined. At the same time, the influence of different lignin additions on the light transmittance, UV light blocking performance, and surface color value (L*a*b* value) of the composite films was investigated. The results reveal that, with the increase of lignin additions, the light transmittance of the composite films at 600 nm decreases, while the UV-blocking efficiency at the bands of UVA (320-400 nm) and UVB (280-320 nm) increase significantly. Besides, when the amount of lignin reaches 12wt%, the L-CNF composite film still maintains a light transmittance of 40%, and the UV-blocking efficiency in the UVA and UVB bands reaches 98% and 100% respectively, exhibiting an excellent UV shielding performance. Overall, the L-CNF composite film with different performances can be obtained by adjusting the ratio of lignin, which shows high potentials in photosensitive material coating and food packaging materials.

-

Key words:

- lignin /

- cellulose nanofiber /

- high pressure homogenization /

- composite film /

- UV-blocking performance

-

图 3 CNF膜的表面及横截面((a), (a’))和分别对应木质素添加量为4wt%、12wt%、25wt%、50wt%的L-CNF复合膜的表面及横截面((b), (b’))、((c), (c’))、((d), (d’))、((e), (e’)) SEM图像

Figure 3. SEM images of surface and cross-section of CNF film ((a), (a’)) and L-CNF composite film with 4wt%, 12wt%, 25wt%, 50wt% lignin additions ((b), (b’)), ((c), (c’)), ((d), (d’)), ((e), (e’))

-

[1] STRICKLEY J D, MESSERSCHMIDT J L, AWAD M E, et al. Immunity to commensal papillomaviruses protects against skin cancer[J]. Nature,2019,575:519-522. doi: 10.1038/s41586-019-1719-9 [2] GAUSE S, CHAUHAN A. Incorporation of ultraviolet (UV) absorbing nanoparticles in contact lenses for Class 1 UV blocking[J]. Journal of Materials Chemistry B,2016,4:327-339. [3] QU L J, TIAN M W, HU X L, et al. Functionalization of cotton fabric at low graphene nanoplate content for ultrastrong ultraviolet blocking[J]. Carbon,2014,80:565-574. doi: 10.1016/j.carbon.2014.08.097 [4] LEBRETON L C M, ZWET J V D, DAMSTEEG J W, et al. River plastic emissions to the world's oceans[J]. Nature Communications,2017,8:15611. doi: 10.1038/ncomms15611 [5] JAMBECK J R, GEYER R, WILCOX C, et al. Plastic waste inputs from land into the ocean[J]. Science,2015,347:768. doi: 10.1126/science.1260352 [6] KUMAR R, RAI B, GAHLYAN S, et al. A comprehensive review on production, surface modification and characterization of nanocellulose derived from biomass and its commercial applications[J]. Express Polymer Letters,2021,15(2):104-120. doi: 10.3144/expresspolymlett.2021.11 [7] PANG B, JIANG G Y, ZHOU J H, et al. Molecular-scale design of cellulose-based functional materials for flexible electronic devices[J]. Advanced Electronic Materials,2020:1-18. [8] ABITBOL T, AHNIYAZ A, ASENCIO R A, et al. Nanocellulose-based hybrid materials for UV blocking and mechanically robust barriers[J]. ACS Applied BioMaterials,2020,3(4):2245-2254. doi: 10.1021/acsabm.0c00058 [9] HATTORI H, IDE Y, SANO T. Microporous titanate nanofibers for highly efficient UV-protective transparent coating[J]. Journal of Materials Chemistry A,2014,2:16381. doi: 10.1039/C4TA02975E [10] JIANG Y Q, SONG Y Y, MIAO M, et al. Transparent nanocellulose hybrid films functionalized with ZnO nanostructures for UV-blocking[J]. Journal of Materials Chemistry C,2015,3(26):6717-6724. doi: 10.1039/C5TC00812C [11] CORREA B A M, GONCALVES A S, SOUZA A M T D, et al. Molecular modeling studies of the structural, electronic, and UV absorption properties of benzophenone deriva-tives[J]. Journal of Physical Chemistry A,2002,116(45):10927-10933. [12] NIU X, LIU Y T, FANG G G, et al. Highly transparent, strong, and flexible films with modified cellulose nano-fiber bearing UV shielding property[J]. Biomacromolecules,2018,19(12):4565-4575. doi: 10.1021/acs.biomac.8b01252 [13] VISHTAL A G, KRASLAWSKI A. Challenges in industrial applications of technical lignins[J]. BioResources,2011,6:3547-3568. doi: 10.15376/biores.6.3.3547-3568 [14] QIAN Y, QIU X Q, ZHU S P. Lignin: a nature-inspired sun blocker for broadspectrum sunscreens[J]. Green Che-mistry,2015,17(320):6079. [15] SADEGHIFAR H, RAGAUSKAS A. Lignin as a UV light blocker-A review[J]. Polymers,2020,12:1134. doi: 10.3390/polym12051134 [16] BIAN H Y, CHEN L D, DONG M L, et al. Natural lignocellulosic nanofibril film with excellent ultraviolet blocking performance and robust environment resistance[J]. International Journal of Biological Macromolecules,2020,166:1578-1585. [17] SADEGHIFA H, VENDITTI R A, JUR J S, et al. Cellulose-lignin biodegradable and flexible UV protection film[J]. ACS Sustainable Chemistry & Engineering,2017,5:625-631. [18] PARIT M, SAHA P, DAVIS V A, et al. Transparent and homogenous cellulose nanocrystal/lignin UV protection films[J]. ACS Omega,2018,3:10679-10691. doi: 10.1021/acsomega.8b01345 [19] WU R L, WANG X L, LI F, et al. Green composite films prepared from cellulose, starch and lignin in room tempera-ture ionic liquid[J]. Bioresource Technology,2009,100(9):2569-2574. doi: 10.1016/j.biortech.2008.11.044 [20] 中华人民共和国国家质量监督检验验疫总局. GB/T 2410—2008 透明塑料透光率和雾度的测定[S]. 北京: 中国标准出版社, 2008.General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. GB/T 2014—2008 Determi-nation of the luminous transmittance and haze of transpa-rent plastics[S]. Beijing: Standards Press of China, 2008(in Chinese). [21] American Association of Textile Chemists and Colorists. Transmittance or blocking of erythemally weighted ultravio-let radiation through fabrics: AATCC test method 183[S]. United States: American Association of Textile Chemists and Colorists, 2014. [22] 刘浩学, 武兵, 徐艳芳, 等. 印刷色差学[M]. 北京: 中国轻工业出版社, 2008.LIU H X, WU B, XU Y F, et al. Color science and technology[M]. Beijing: China Light Industry Press, 2008(in Chinese). [23] 杨淑蕙, 邱玉桂, 谭国民, 等. 植物纤维化学[M]. 北京: 中国轻工业出版社, 2001: 1.YANG S H, QIU Y G, TAN G M, et al. The chemistry of plant fibers[M]. Beijing: China Light Industry Press, 2001: 1(in Chinese). [24] JIANG B, CHEN C J, LIANG Z Q, et al. Lignin as a wood-inspired binder enabled strong, water stable, and biodegradable paper for plastic replacement[J]. Advanced Functio-nal Materials,2020,30(4):1906307. [25] FAROOQ M, ZOU T, RIVIERE G, et al. Strong, ductile, and waterproof cellulose nanofibril composite films with colloidal lignin particles[J]. Biomacromolecules,2019,20:693-704. doi: 10.1021/acs.biomac.8b01364 [26] GORDOBIL O, MORIANA R, ZHANG L M, et al. Assesment of technical lignins for uses in biofuels and biomaterials: Structure-related properties, proximate analysis and chemi-cal modification[J]. Industrial Crops and Products,2016,83:155-165. doi: 10.1016/j.indcrop.2015.12.048 -

下载:

下载: