Preparation and dynamic mechanical properties of boron carbide andorganosilicon two-dimensional laminated composites

-

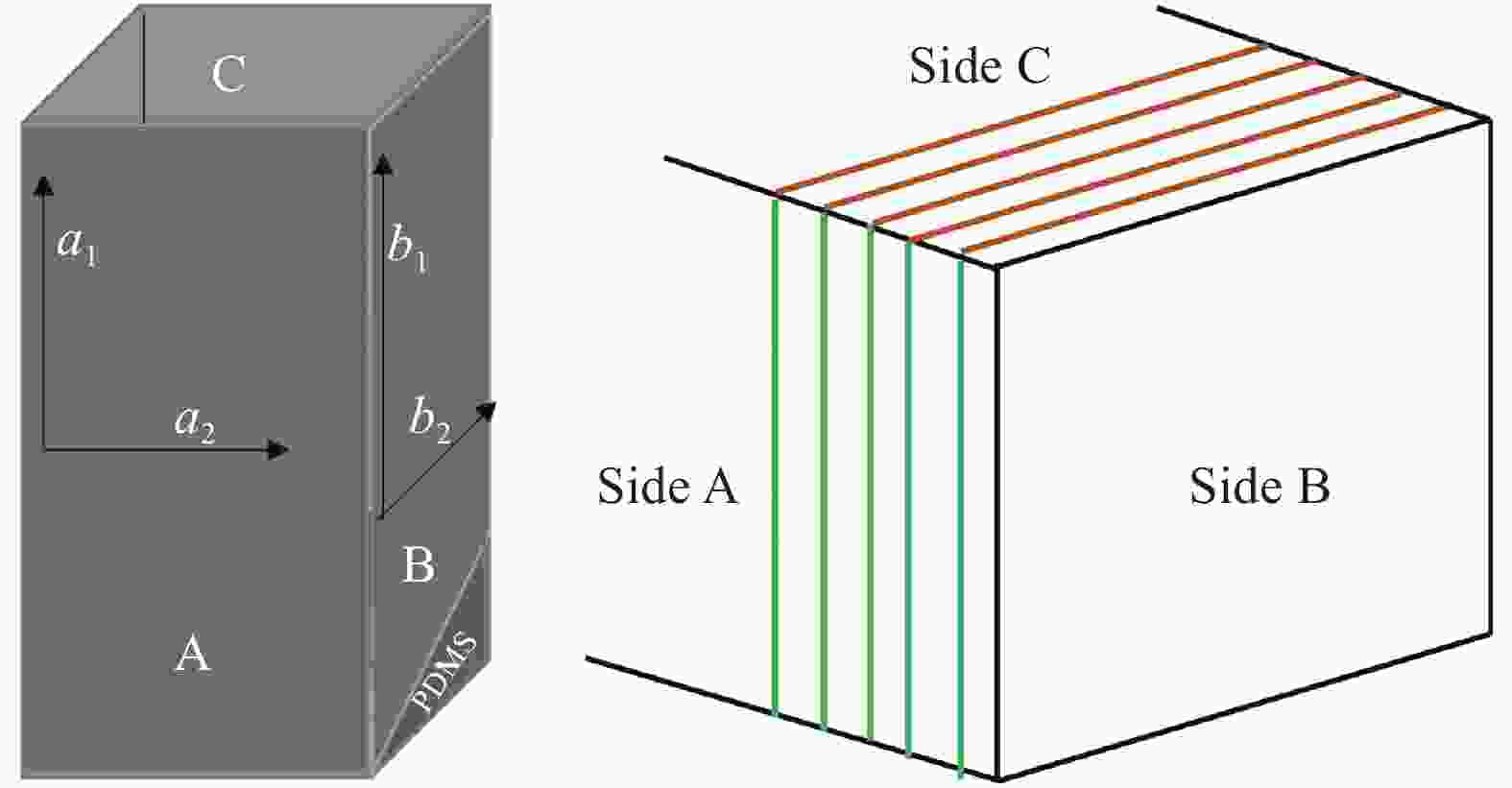

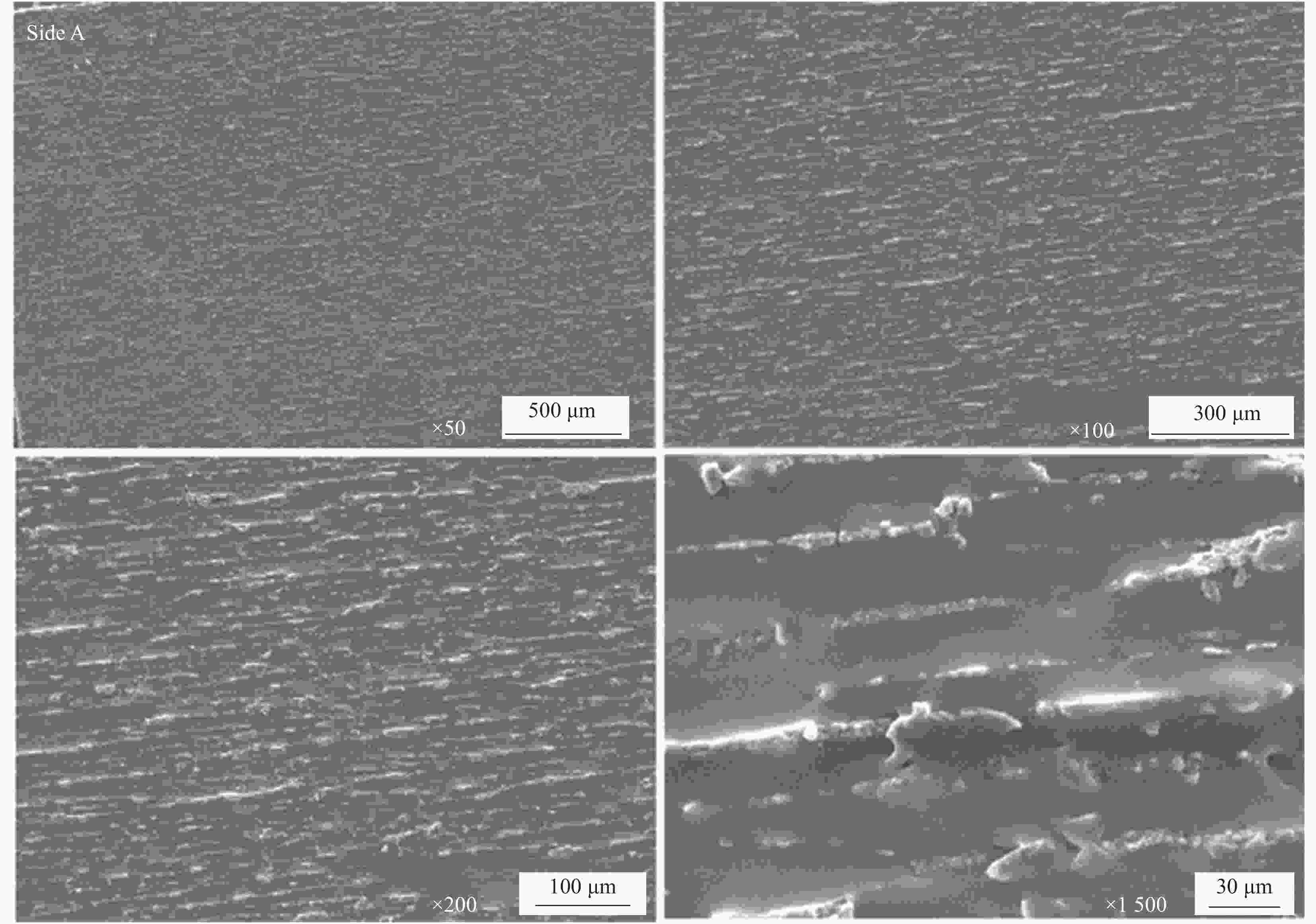

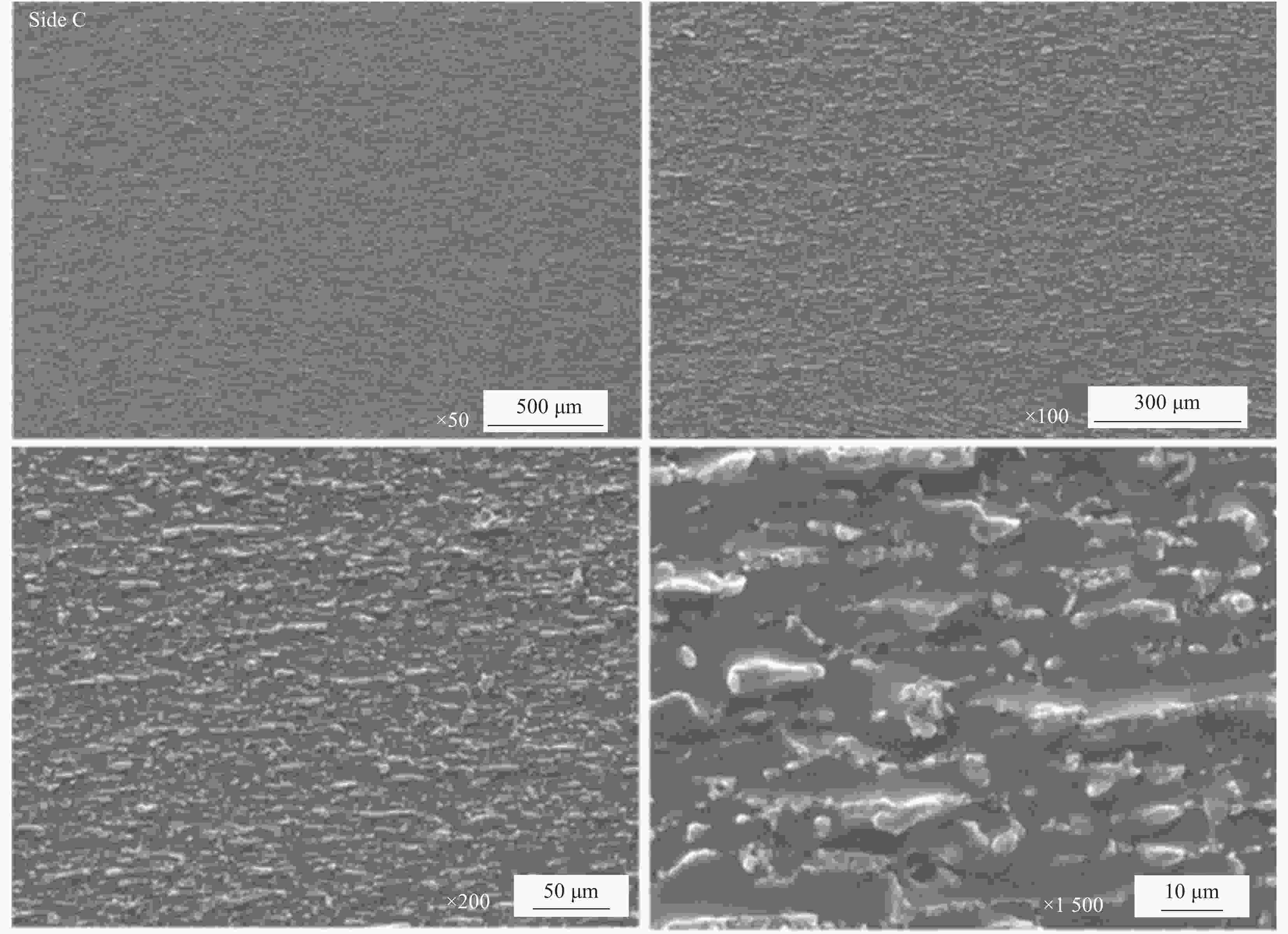

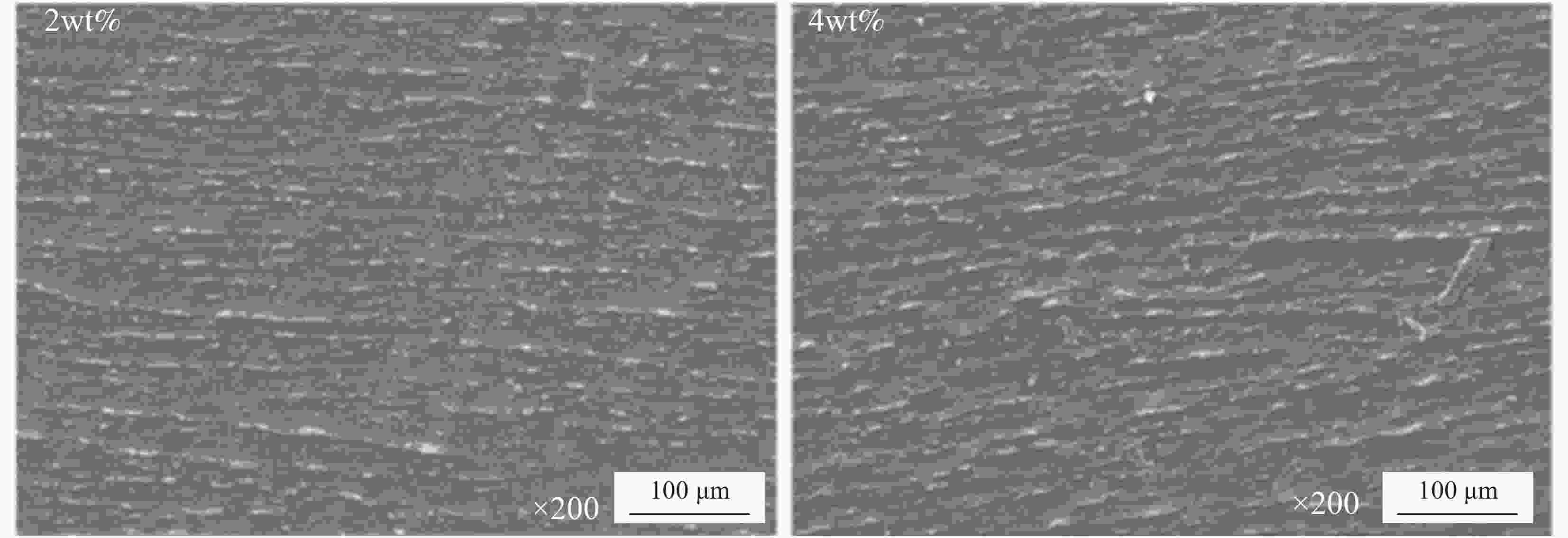

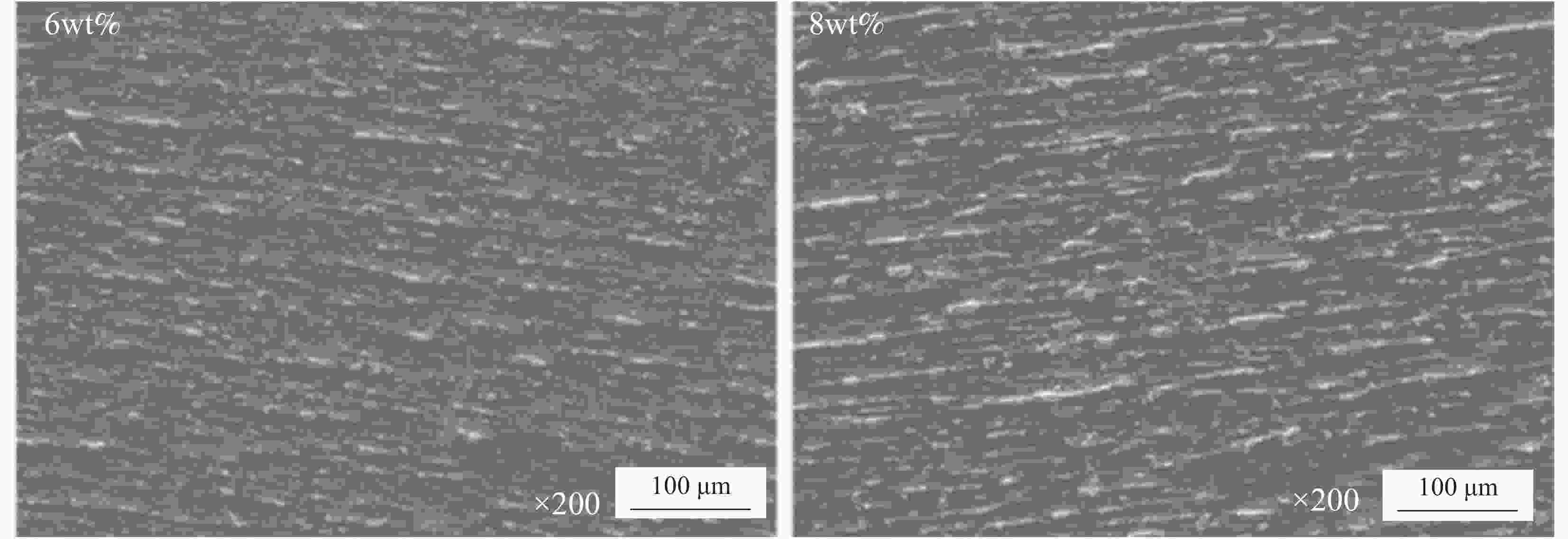

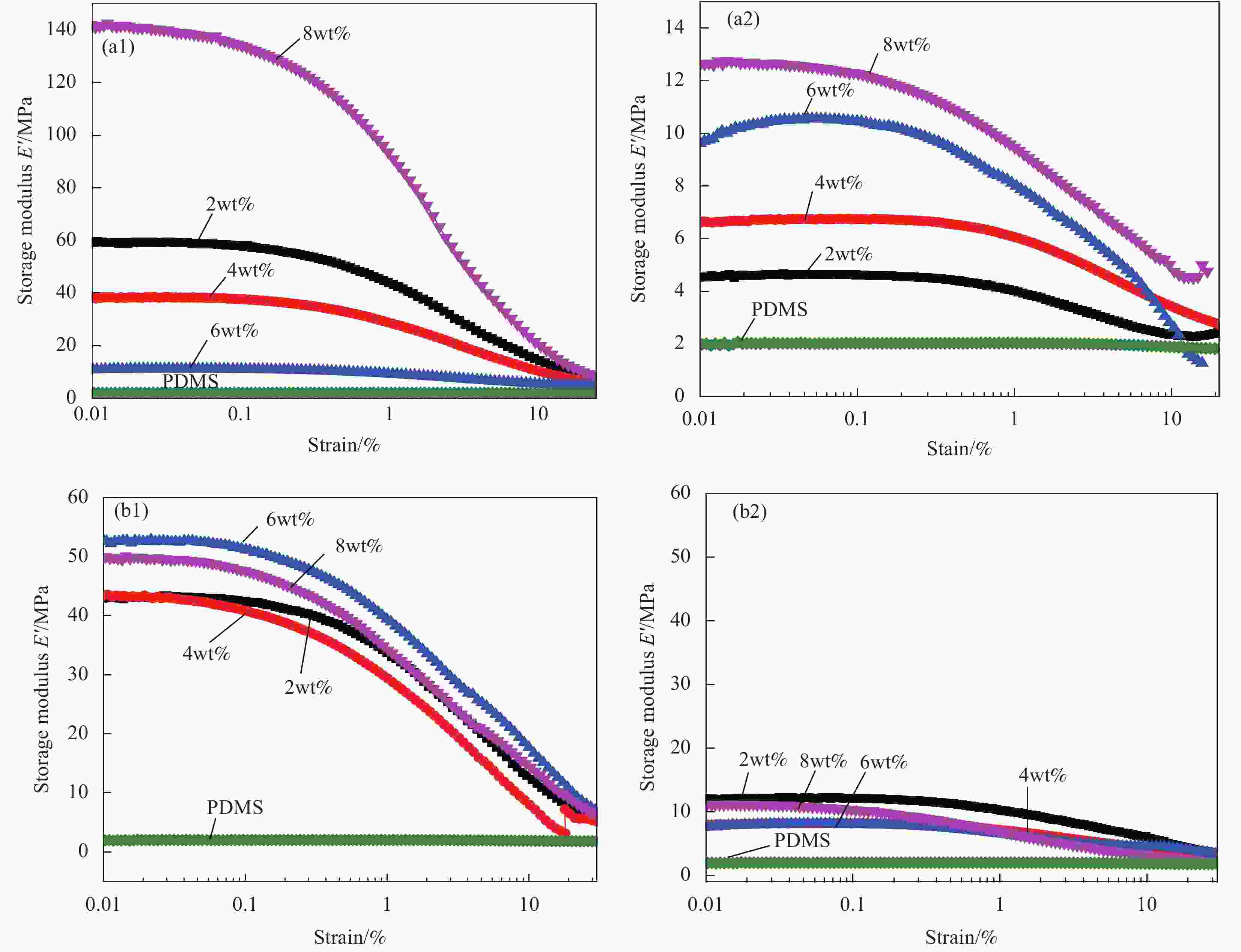

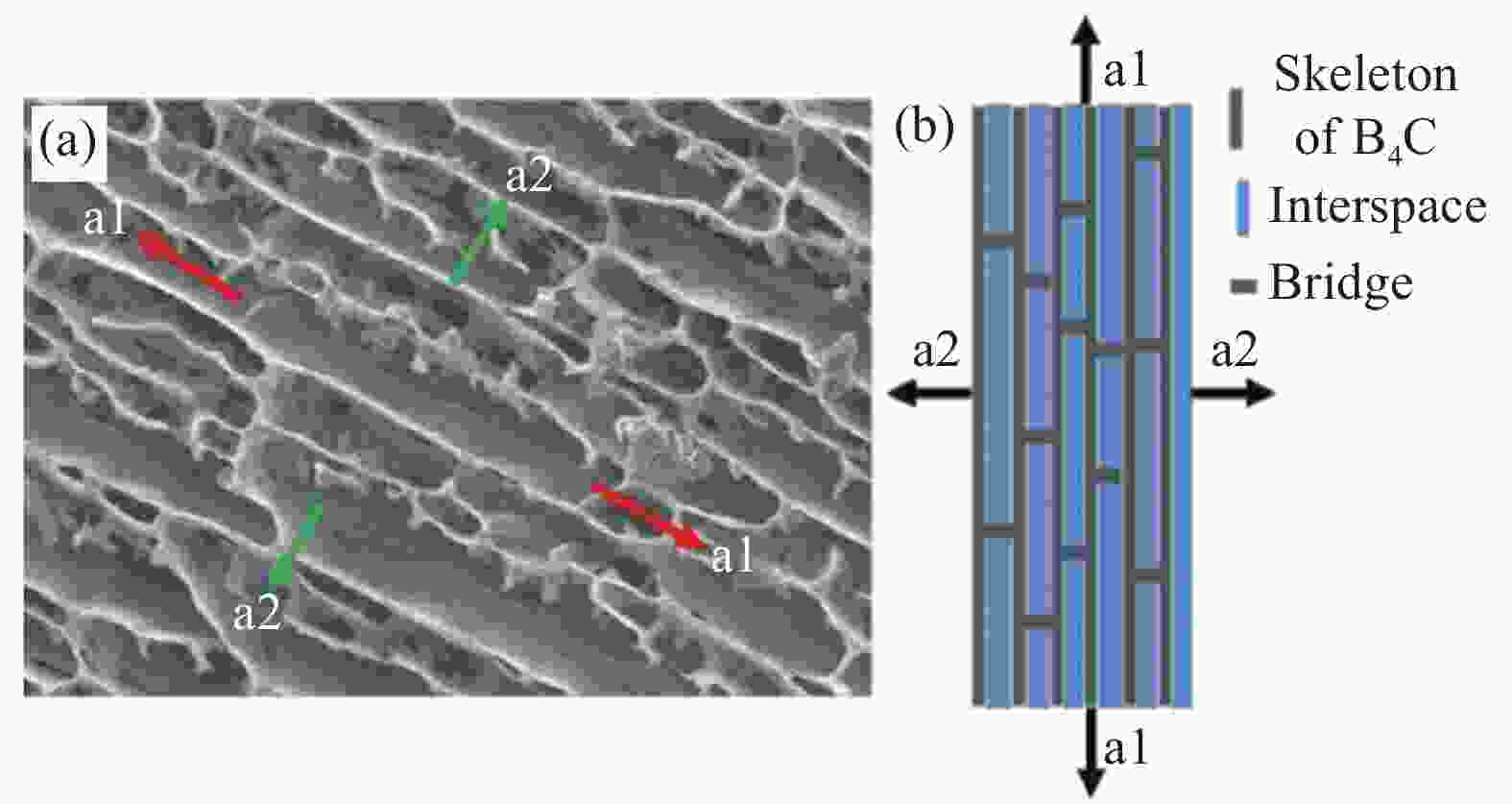

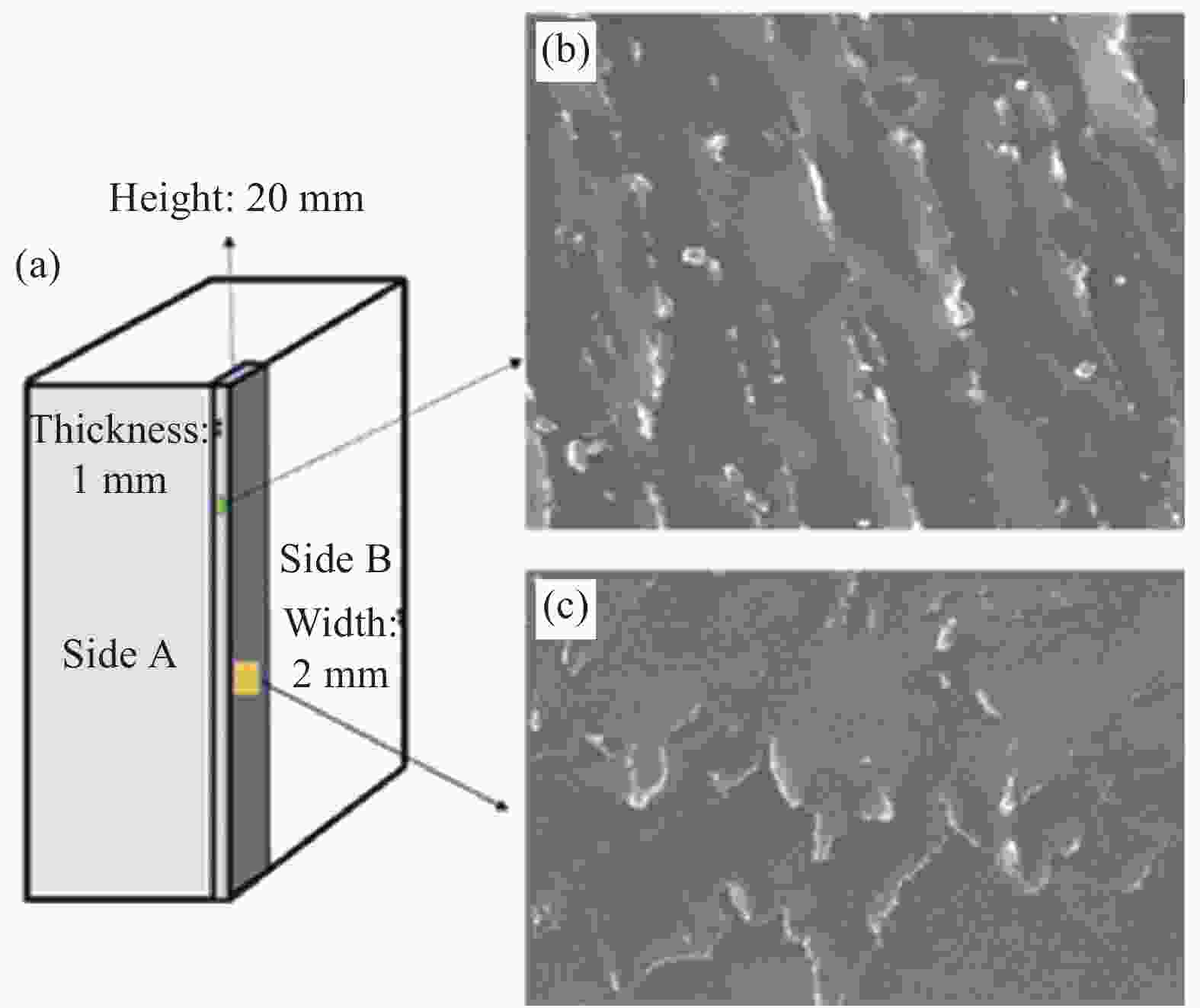

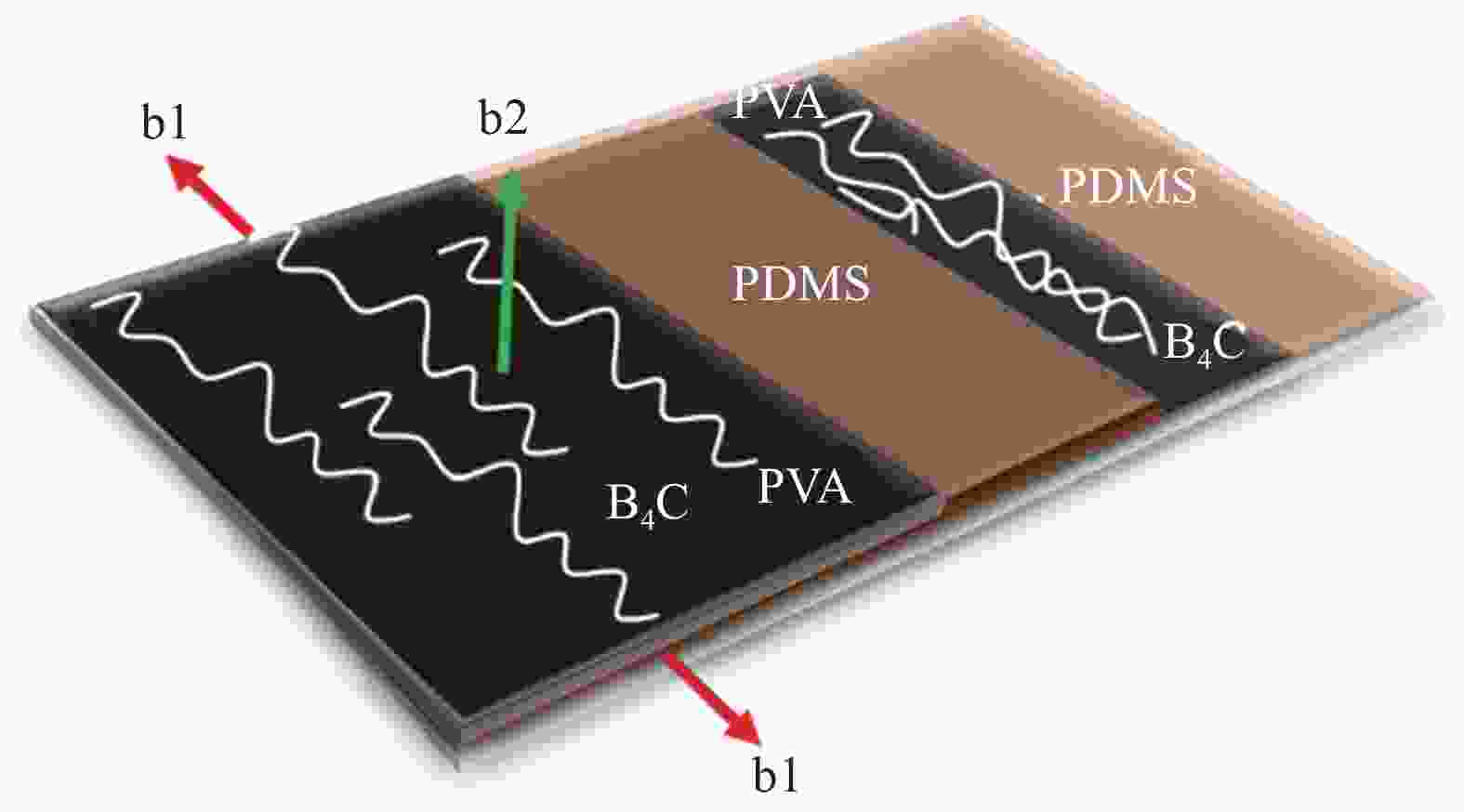

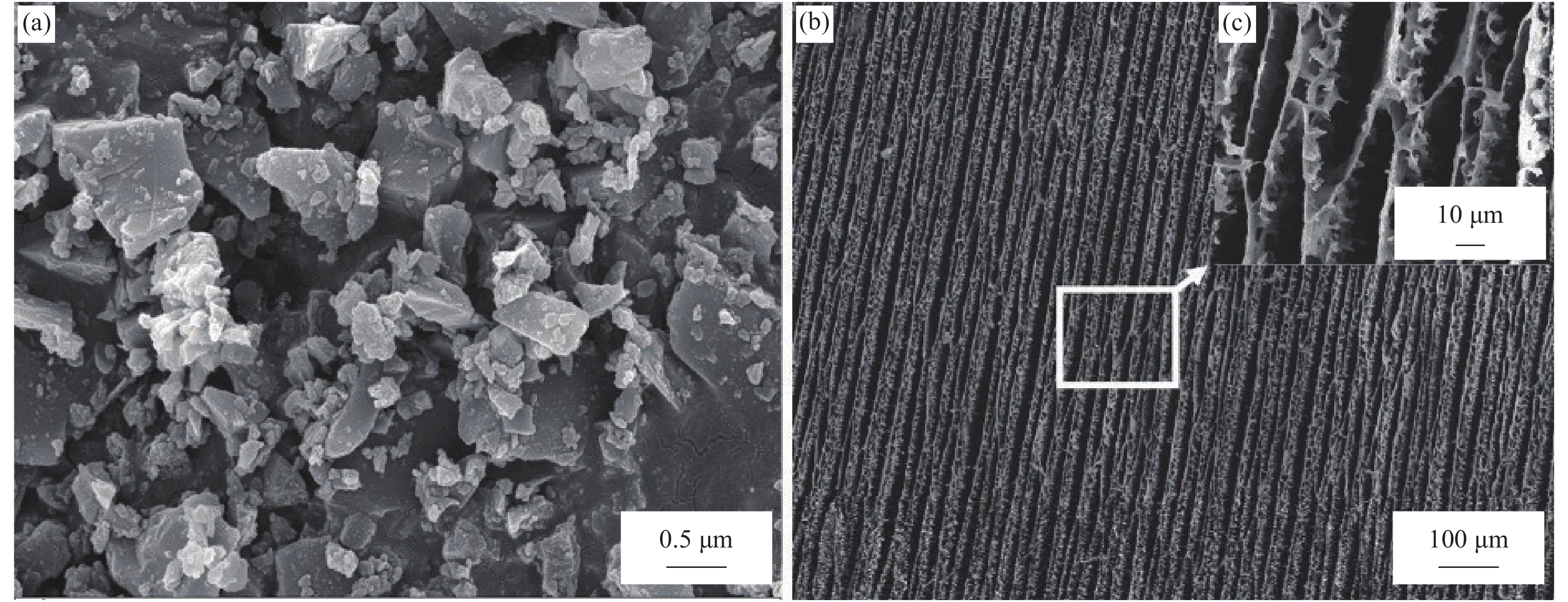

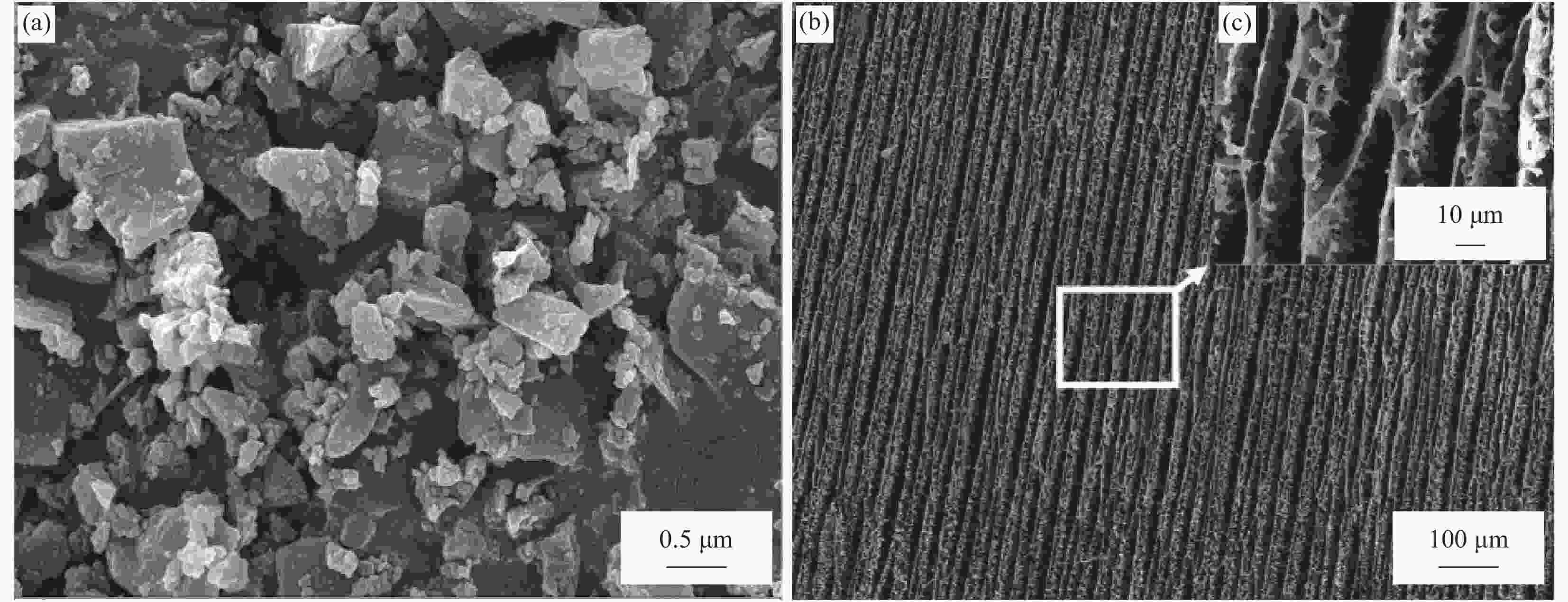

摘要: 科技发展对材料性能提出越来越高的要求,通过对材料内部结构进行有序排列使其在特定方向上实现性能最佳发挥是目前解决高性能应用需求的一个有效的方法。传统单向冷冻技术无法实现二维有序结构的制备。通过双向冷冻方法制备了厘米级的单取向碳化硼(B4C)层状结构支架,在其层间填充聚二甲基硅氧烷(PDMS)制备出具有各向异性的碳化硼-有机硅二维层状复合材料。复合材料的A生长面为PDMS和B4C骨架的交替排列结构,B生长面为海浪状的堆叠结构,且层状支架在复合材料中保持着明显的二维有序层状结构。复合材料面内最大动态模量各向异性比可达12.9,动态模量表现出明显的佩恩效应。这种方法为二维层状有序复合材料的制备提供新思路。Abstract: The development of science and technology has put forward higher and higher requirements for material properties. It is an effective way to achieve the best performance in a specific direction by ordering the internal structure of materials. However, the traditional one-way freezing technology cannot achieve the preparation of two-dimensional ordered structure. B4C layered scaffolds with single orientation were prepared by bidirectional freezing method. The layered scaffolds were filled with polydimethylsiloxane (PDMS) to prepare the two-dimensional layered boron carbide and organosilicate composites with anisotropy. There is an alternate arrangement structure of PDMS and B4C skeleton at the growth plane of A in the composite material. It is a stacked structure like ocean waves at the growth plane of B. The layered scaffold maintains an obvious two-dimensional ordered layered structure in the composite material. The maximum in-plane anisotropy ratio of dynamic modulus of the composite can reach 12.9, and the dynamic modulus shows obvious Payne effect. It provides some new methods and ideas for the preparation of anisotropic composite material systems.

-

Key words:

- B4C /

- bidirectional freeze-cast /

- ice-template /

- two-dimensional ordered structure /

- 3D /

- anisotropy /

- organosilicate /

- PDMS

-

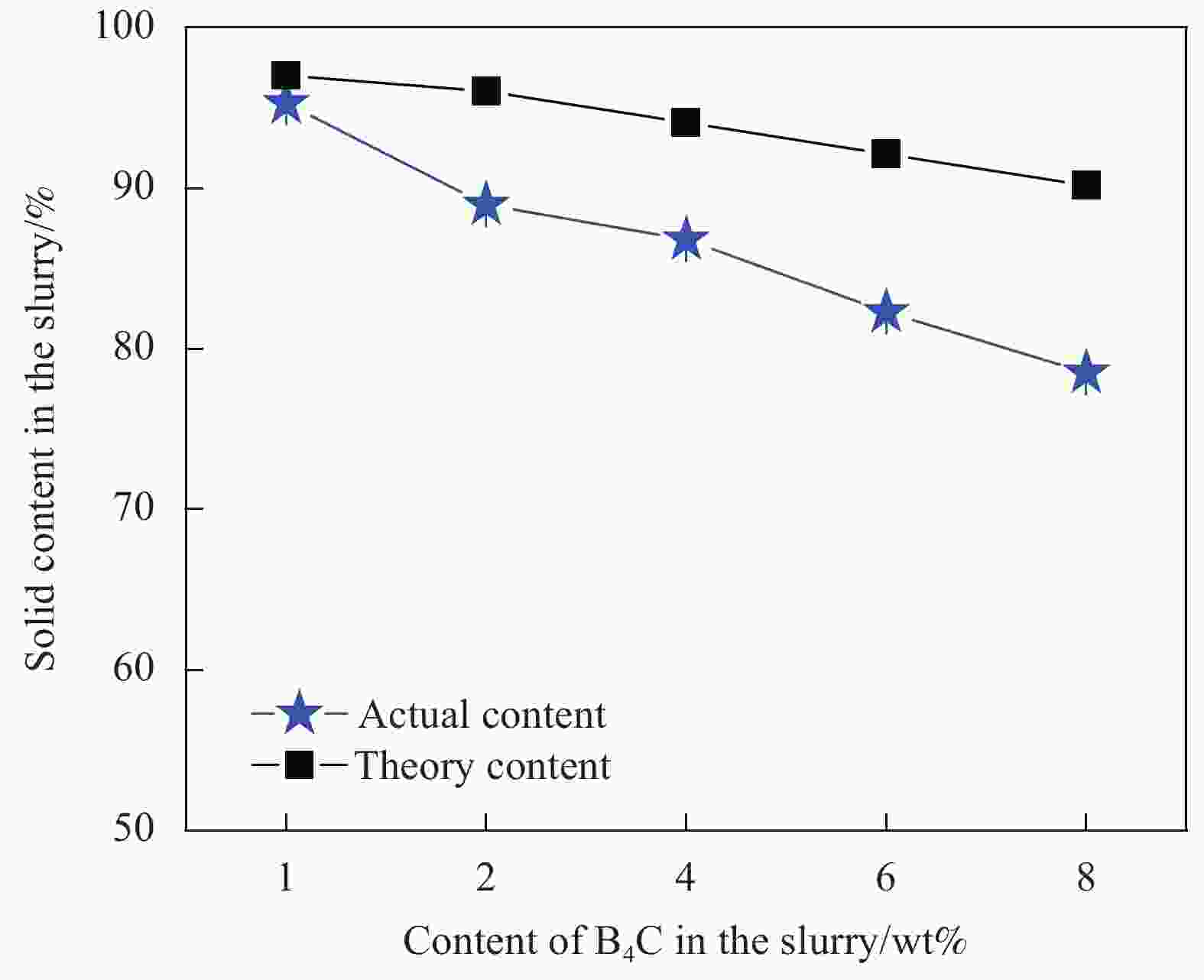

表 1 不同质量分数 B4C 浆料的组成

Table 1. B4C slurry components with different mass fraction

Mass fraction of B4C/wt% 1 2 4 6 8 B4C/g 2 4 8 12 16 PVA/g 198 196 192 188 184 表 2 低应变时B4C层状支架复合硅橡胶材料A面不同方向上储能和耗能模量的比较

Table 2. Comparison of the B4C layered composite silicone rubber material of storage modulus andloss modulus in different direction under low stain at side A

Direction a1 a2 a1 a2 Mass fraction

of B4C/wt%Storage

modulus/MPaStorage

modulus/MPaa1/a2 Loss

modulus/MPaLoss

modulus/MPaa1/a2 0 2.0 2.0 1.0 2.0 2.0 1.0 2 57.9 4.5 12.9 3.7 0.5 7.4 4 38.0 6.6 5.76 2.7 0.7 4.0 6 10.7 9.4 1.14 0.6 0.8 0.75 8 144.5 12.6 11.47 6.3 1.1 6.0 Note: PDMS—Polydimethylsiloxane. 表 3 低应变时B4C层状支架复合硅橡胶材料B面不同方向上储能和耗能模量的比较

Table 3. Comparison of B4C layered composite silicone rubber material of storage modulus and loss modulus in different direction under low stain at side B

Direction b1 b2 b1 b2 Mass fraction

of B4C/wt%Storage

modulus/MPaStorage

modulus/MPab1/b2 Loss

modulus/MPaLoss

modulus/MPab1/b2 0 2.0 2.0 1.0 2.0 2.0 1.00 2 42.3 11.8 3.6 3.5 1.1 3.15 4 42.6 7.7 5.5 3.0 0.8 3.85 6 52.5 7.4 7.0 3.2 0.7 4.85 8 48.4 11.0 4.4 4.5 1.0 4.64 -

[1] WANG L H. Compressive capacitance relaxation of carbon black filled silicone rubber composite[J]. Polymer Composites,2018,39(10):3446-3451. doi: 10.1002/pc.24362 [2] LIN J L, SU S M, HE Y B, et al. Improving thermal and mecha-nical properties of the alumina filled silicone rubber composite by incorporating carbon nanotubes[J]. New Carbon Materials,2020,35(1):66-72. doi: 10.1016/S1872-5805(20)60476-0 [3] YANG D, WEI Q G, LI B Y, et al. High thermal conductive silicone rubber composites constructed by strawberry-structured Al2O3-PCPA-Ag hybrids[J]. Composites Part A: Applied Science and Manufacturing,2021,142:106260. doi: 10.1016/j.compositesa.2020.106260 [4] YADAV S G, GUNTUR N P R, GOPALAN S, et al. Effect of titanium carbide powder as a filler on the mechanical properties of silicone rubber [J]. Materials Today: Proceedings, 2021, 46(1): 665-671 [5] 刘斌, 许春莉, 王许云, 等. 纳米Fe2O3-还原氧化石墨烯复合材料的制备及对双酚A的检测[J]. 复合材料学报, 2020, 37(1):182-190.LIU Bin, XU Chunli, WANG Xuyun, et al. Preparation of nano Fe2O3-reduced graphene oxide composite and its determination of bisphenol A[J]. Acta Materiae Compositae Sinica,2020,37(1):182-190(in Chinese). [6] ZHAO X L, YANG X, LI Q, et al. Synergistic effect of ZnO microspherical varistors and carbon fibers on nonlinear conductivity and mechanical properties of the silicone rubber-based material[J]. Composites Science and Technology,2017,150:187-193. doi: 10.1016/j.compscitech.2017.07.025 [7] SONG P, SONG J N, ZHANG Y. Stretchable conductor based on carbon nanotube/carbon black silicone rubber nanocomposites with highly mechanical, electrical properties and strain sensitivity[J]. Composites Part B: Engineering,2020,191:107979. doi: 10.1016/j.compositesb.2020.107979 [8] 孙晋茹, 姚学玲, 李亚丰, 等. 碳纤维增强树脂复合材料在多重连续雷电流冲击下的损伤特性[J]. 复合材料学报, 2019, 36(12):2764-2771.SUN Jinru, YAO Xueling, LI Yafeng, et al. Damage properties of carbon fiber reinforced epoxy composite subjected to multiple continuous lightning current strikes[J]. Acta Materiae Compositae Sinica,2019,36(12):2764-2771(in Chinese). [9] 高沐, 夏志东, 陈婧晗, 等. 拉伸应变下镍包碳纤维填充导电橡胶取向及电阻响应[J]. 复合材料学报, 2019, 36(12):2756-2763.GAO Mu, XIA Zhidong, CHEN Jinghan, et al. Orientation and resistivity response of nickel coated carbon fiber filled conductive rubber at tensile strain[J]. Acta Materiae Compositae Sinica,2019,36(12):2756-2763(in Chinese). [10] LU Y, WANG J C, WANG L, et al. Construction of 3D carbon fiber/carbon nanotube/silicone rubber nanocomposites for stretchable conductors through interface host-guest dendrimers[J]. Composites Science and Technology,2021,205:108692. doi: 10.1016/j.compscitech.2021.108692 [11] LIU P Y, LI L C, WANG L M. Effects of 2D boron nitride (BN) nanoplates filler on the thermal, electrical, mechani-cal and dielectric properties of high temperature vulca-nized silicone rubber for composite insulators[J]. Journal of Alloys and Compounds,2019,774:396-404. doi: 10.1016/j.jallcom.2018.10.002 [12] SARATH P S, SAMSON S V, REGHUNATH R, et al. Fabrication of exfoliated graphite reinforced silicone rubber composites-Mechanical, tribological and dielectric properties[J]. Polymer Testing,2020,89:106601. doi: 10.1016/j.polymertesting.2020.106601 [13] SONG Y Z, YU J H, YU L H, et al. Enhancing the thermal, electrical, and mechanical properties of silicone rubber by addition of graphene nanoplatelets [J]. Materials & Design, 2015, 88: 950-957. [14] ZHANG P, ZHU Q Z, SOOMRO R A, et al. In situ ice template approach to fabricate 3D flexible MXene film-based electrode for high performance supercapacitors[J]. Advanced Functional Materials,2020,30(47):2000922. doi: 10.1002/adfm.202000922 [15] DU G L, MAO A R, YU J H, et al. Nacre-mimetic composite with intrinsic self-healing and shape-programming capability[J]. Nature Communications,2019,10(1):1-8. doi: 10.1038/s41467-018-07882-8 [16] FERNANDEZ F, LEWICKI J P, TORTORELLI, D A. Optimal toolpath design of additive manufactured composite cylindrical structures[J]. Computer Methods in Applied Mechanics and Engineering,2021,376:113673. doi: 10.1016/j.cma.2021.113673 [17] THAKUR A, DONG X Y. Additive manufacturing of 3D structural battery composites with coextrusion deposition of continuous carbon fibers[J]. Manufacturing Letters,2020,26:42-47. doi: 10.1016/j.mfglet.2020.09.007 [18] TIAN J, ZHANG R, WU Y H, et al. Additive manufacturing of wood flour/polyhydroxyalkanoates (PHA) fully bio-based composites based on micro-screw extrusion system[J]. Materials & Design,2021,199:109418. [19] BHARDWAJ P, GRANCE A N. Antistatic and microwave shielding performance of polythiophene-graphene grafted 3-dimensional carbon fibre composite[J]. Diamond and Related Materials,2020,106:107871. doi: 10.1016/j.diamond.2020.107871 [20] BAI H B, CHEN Y, DELATTRE B. Bidirectional freeze casting for fabricationg lamellar structures: US Patent, 20170100857A1 [P]. 2015-10-13. [21] HAN J K, DU G L, GAO W W, et al. An anisotropically high thermal conductive boron nitride/epoxy composite based on nacre-mimetic 3D network[J]. Advanced Functional Materials,2019,29(13):1900412-1900421. doi: 10.1002/adfm.201900412 [22] BAI H, WALSH F, GLUDOVATZ B, et al. Bioinspired hydroxyapatite/poly(methylmethacrylate) composite with a nacre-mimetic architecture by a bidirectional freezing method[J]. Advanced Materials,2016,28(1):50-56. doi: 10.1002/adma.201504313 [23] SHAMONIN M, KRAMARENKO E. Highly responsive magnetoactive elastomers: In novel magnetic nanostructures [M]. Amsterdam: Elsevier, 2018: 221-245. [24] WHITE J, MARK J, ERMAN B. Rheological behavior and processing of unvulcanized rubber. In science and technology of rubber [M]. San Diego: Academic Press, 1994: 257-338. [25] WANG X R, ROBERTSON C G. Strain-induced nonlinearity of filled rubbers[J]. Physical Review E :Statistical, Nonlinear, and Soft Matter Physics,2005,72(3):031406-031415. [26] ROBERTSON C G, WANG X R. Isoenergetic jamming tran-sition in particle-filled systems[J]. Physical Review Letters,2005,95(7):075703-075707. doi: 10.1103/PhysRevLett.95.075703 -

下载:

下载: