Application of shape memory alloy in damage repair of composite materials

-

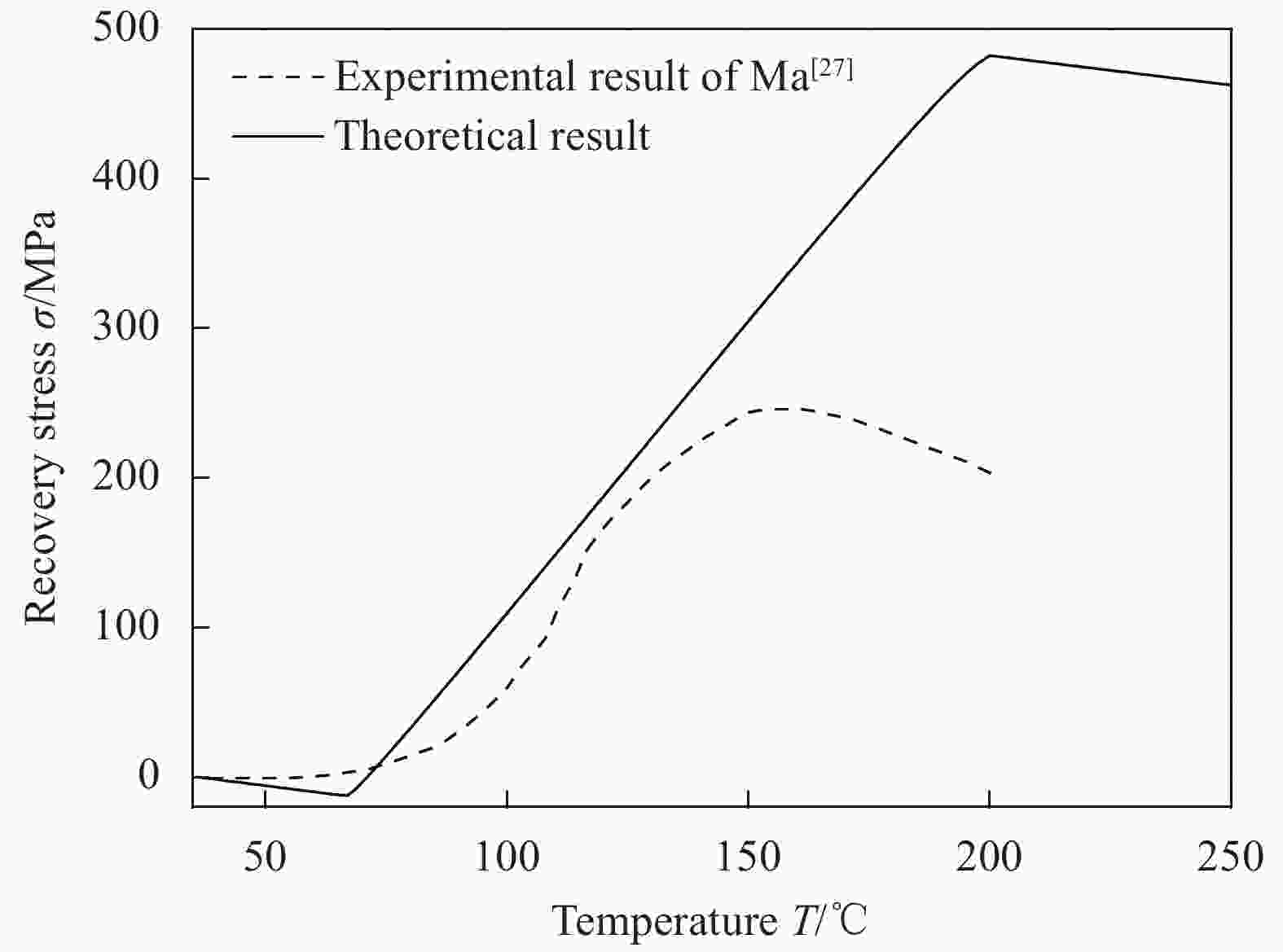

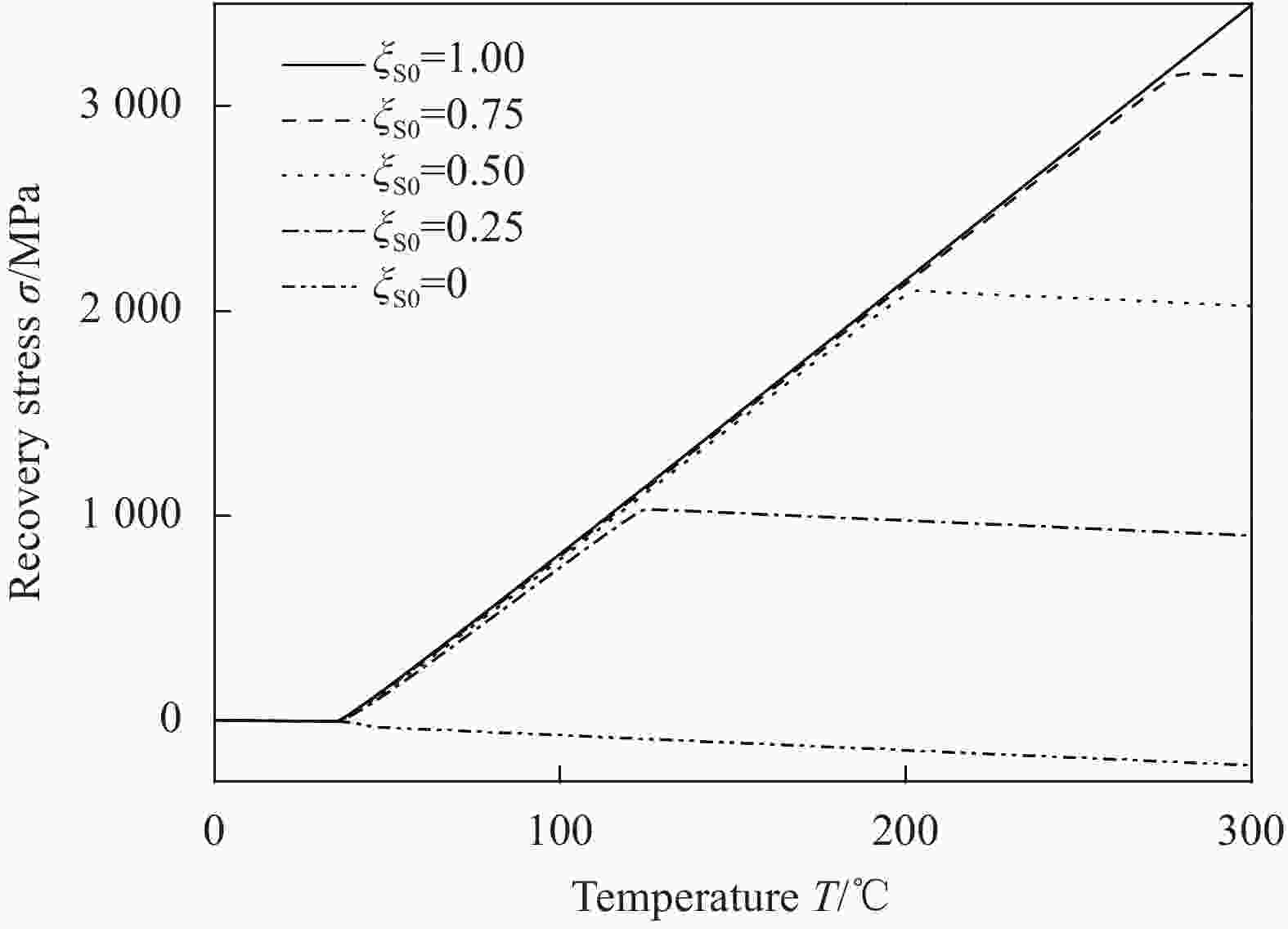

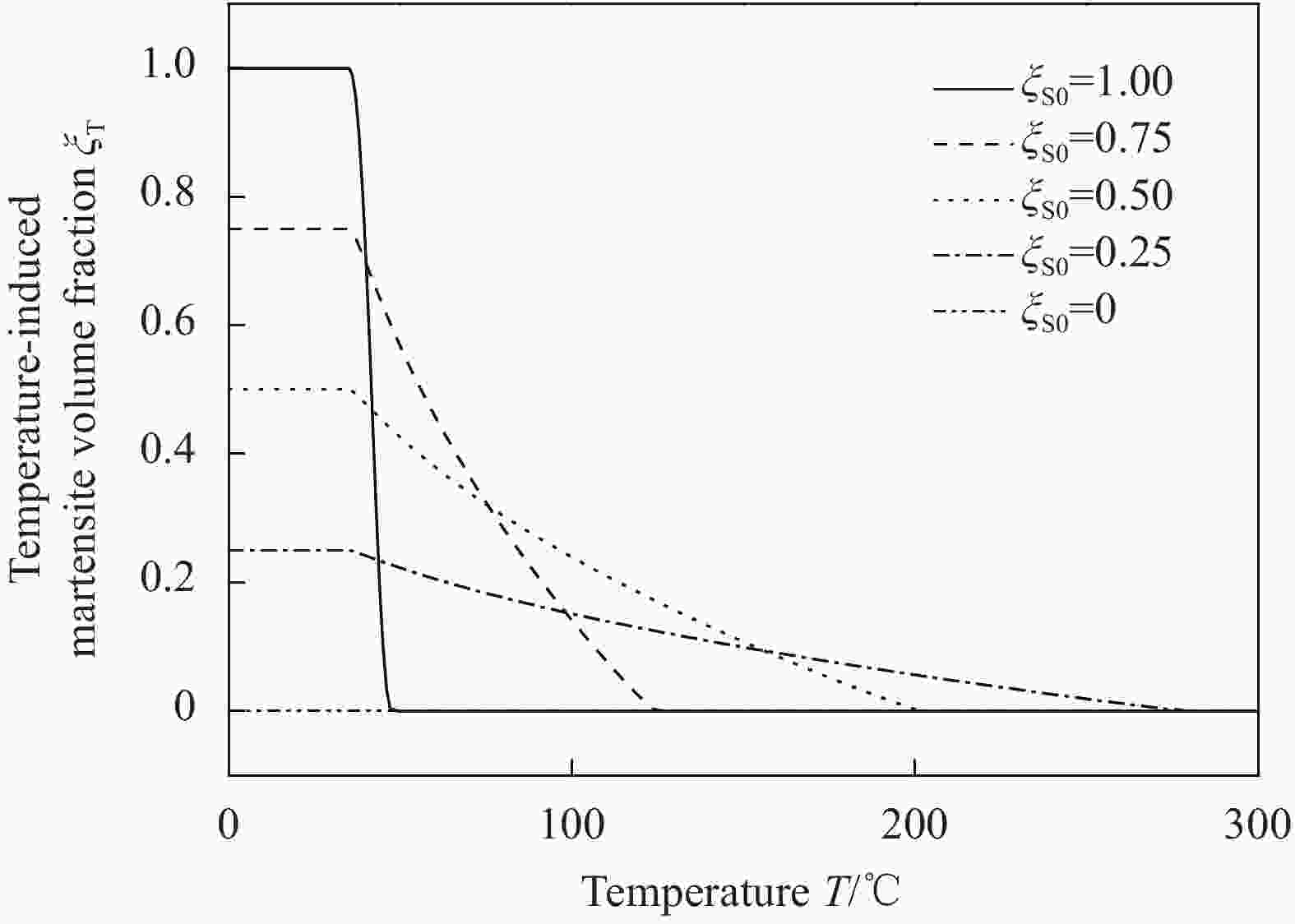

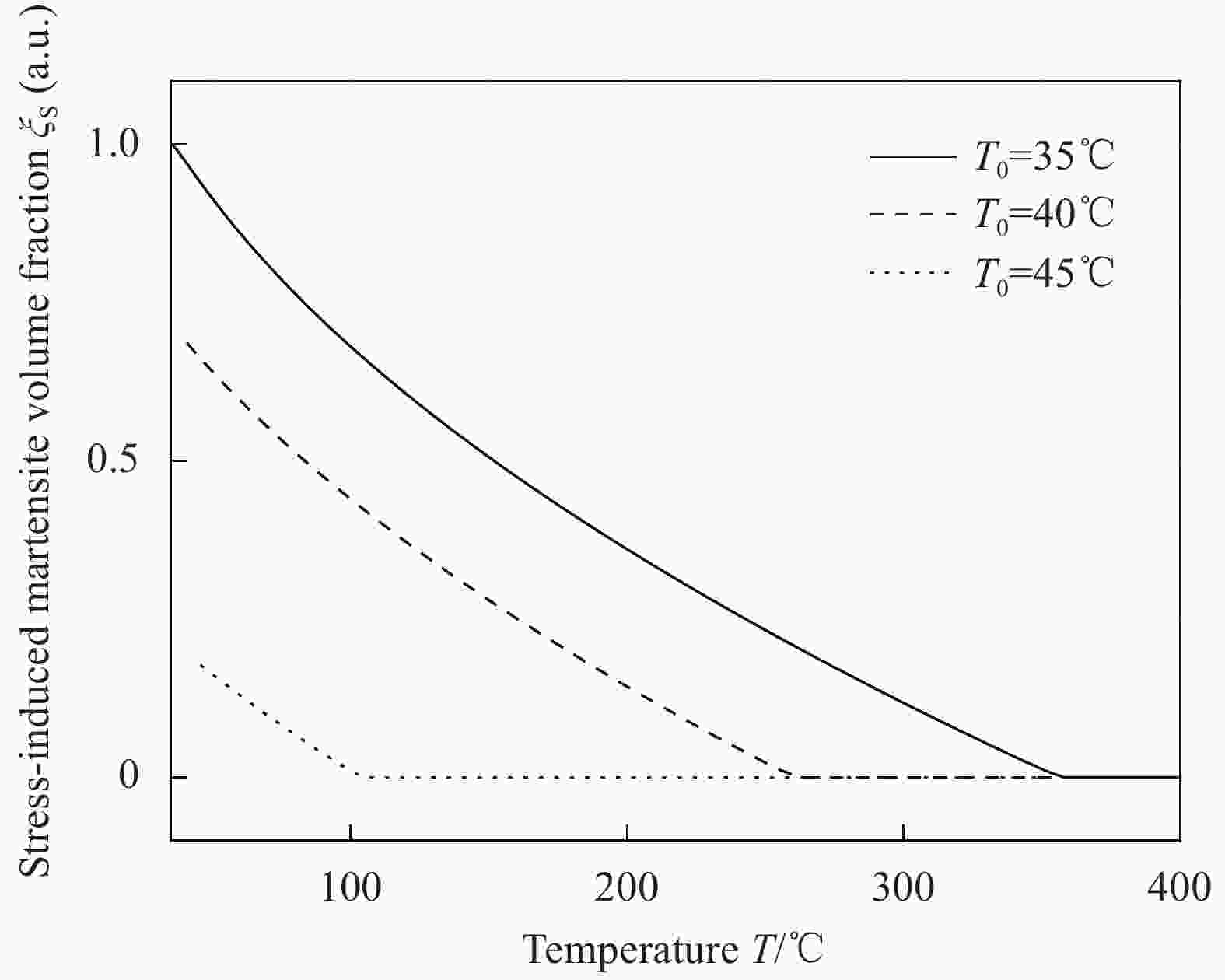

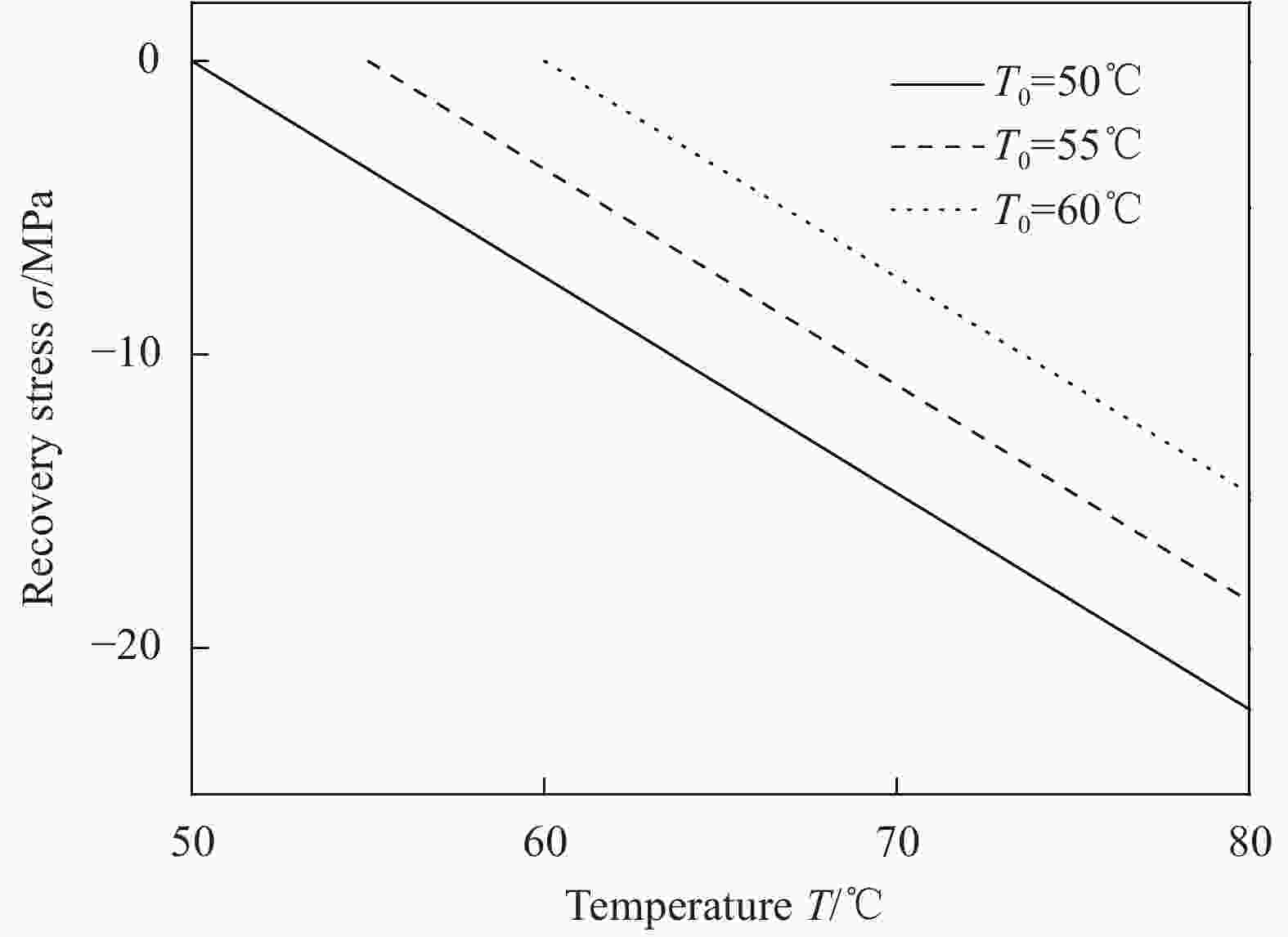

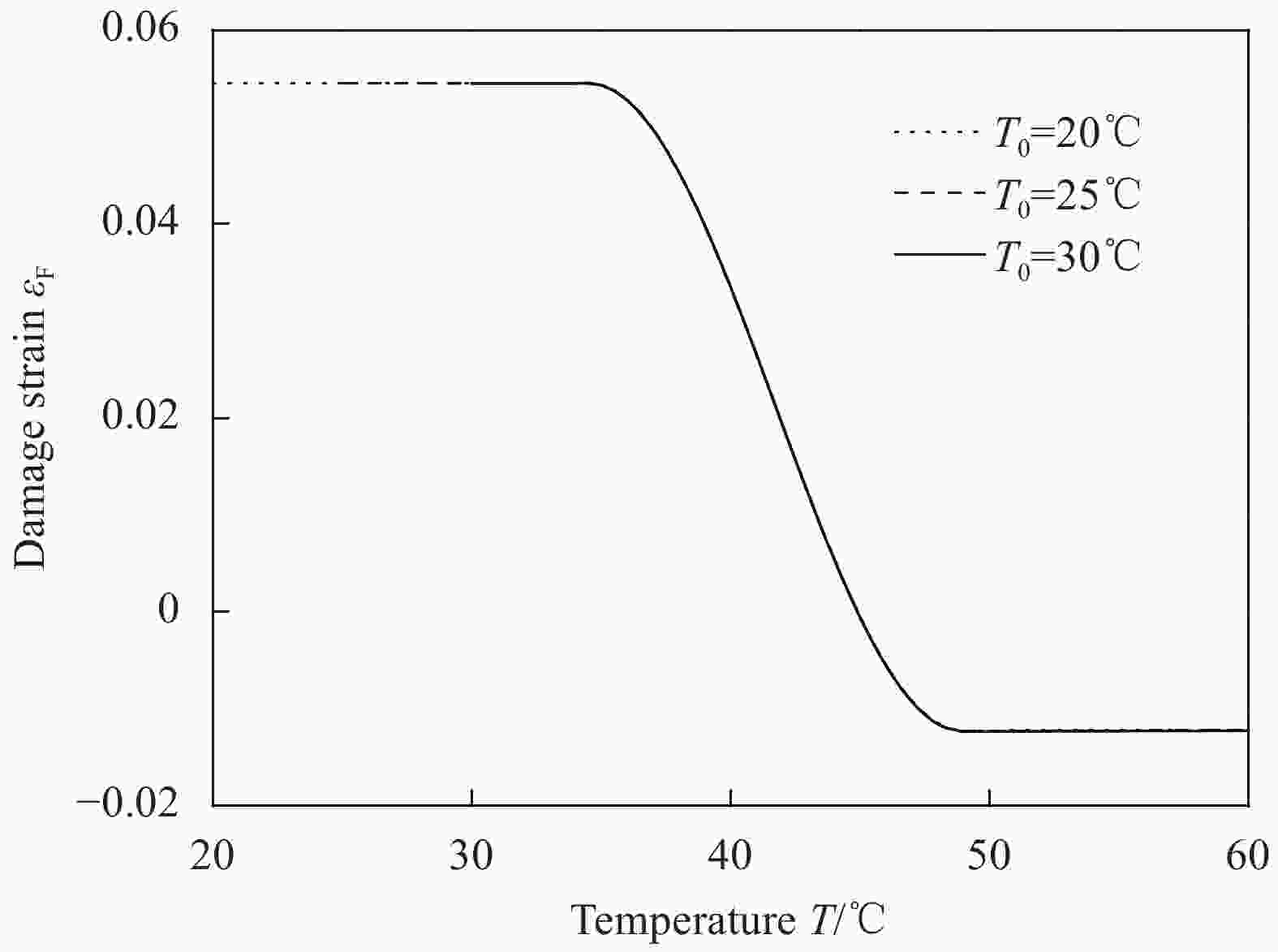

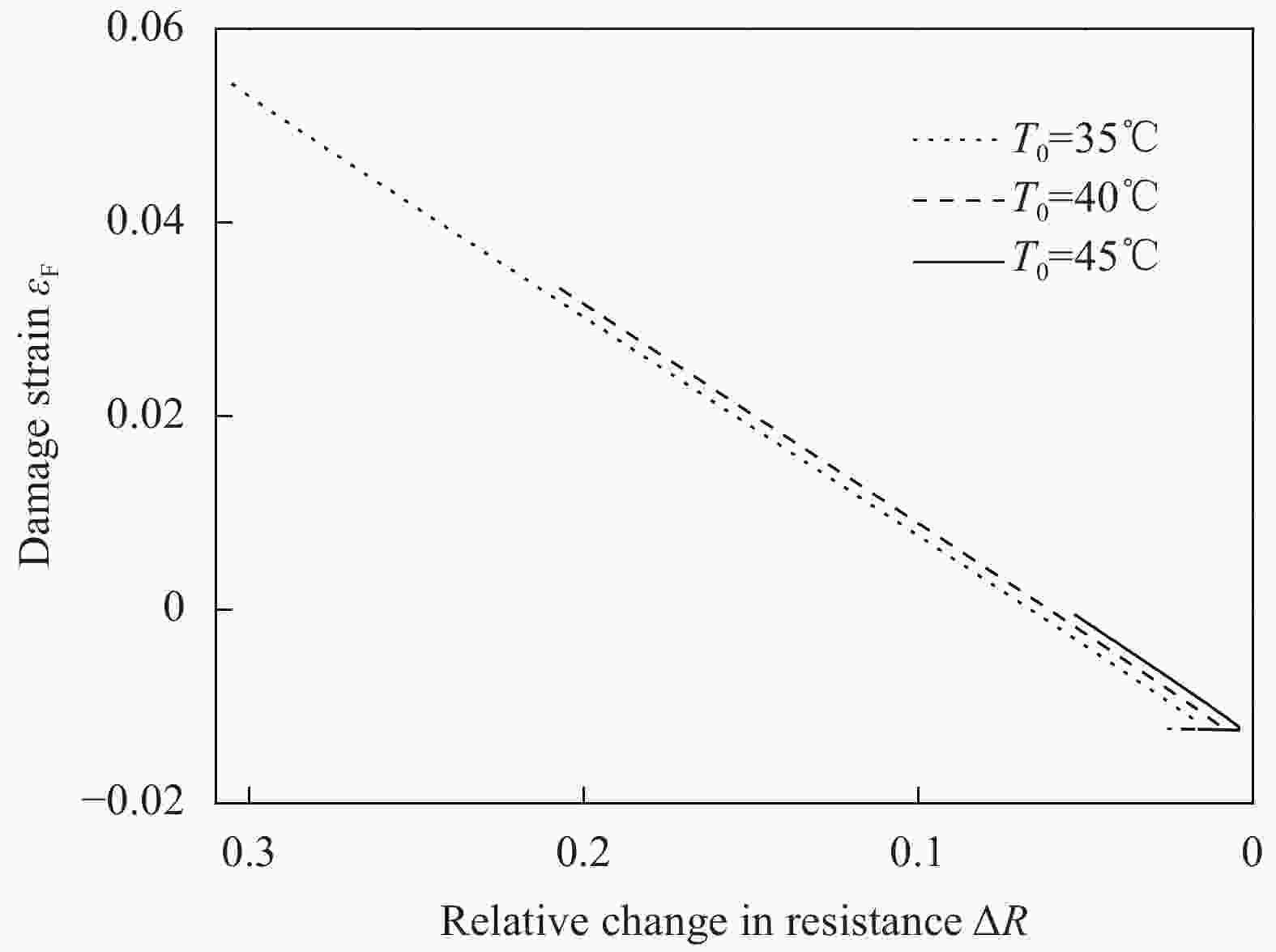

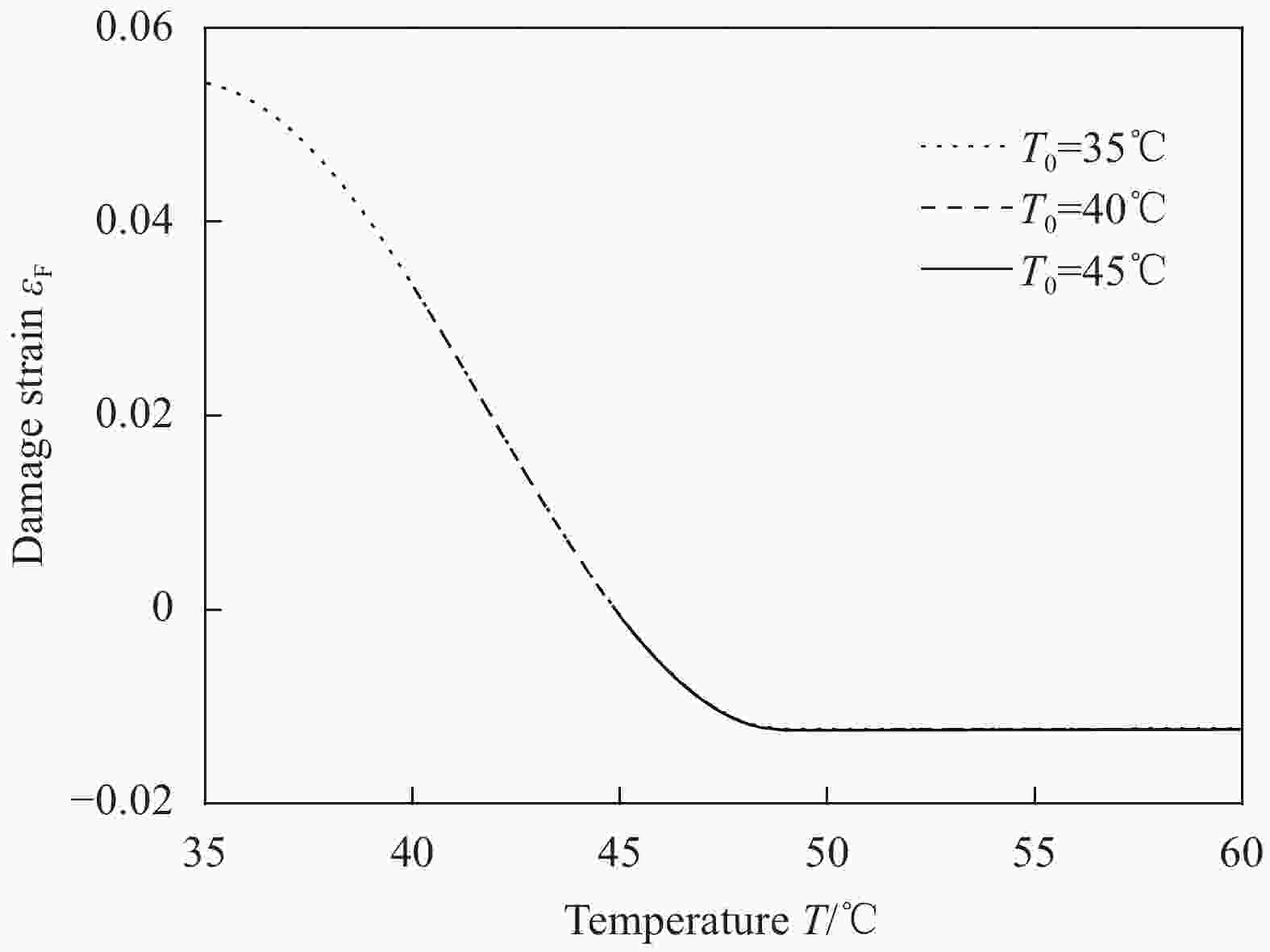

摘要: 复合材料的内部裂纹会使其性能下降甚至失效,为了解决这一问题,本文选择将形状记忆合金(SMA)应用在复合材料中用以实现损伤修复。将SMA埋入复合材料试件中,通过对SMA回复应力、复合材料损伤应变与温度之间的关系进行讨论,建立不同条件下复合材料的损伤修复理论模型。基于该模型讨论了不同初始条件下SMA材料的损伤修复行为。研究结果表明:SMA的回复应力在未发生奥氏体相变时减小,发生奥氏体相变时增大。SMA应力诱发马氏体体积分数越大,升温引起的最大回复应力越大。升温过程中的奥氏体相变可使复合材料的损伤应变减小,进而修复损伤。该研究可为SMA在复合材料损伤修复的工程应用提供理论指导。Abstract: Internal cracks will degrade the performance of composite material and even make it fail. In order to solve such problem, the shape memory alloy (SMA) was chosen to be applicated in composite materials for damage repairing. The SMA was firstly assumed to be embedded in the composite material, by discussing the relationship between SMA recovery stress and temperature, and the relationship between composite damage strain and temperature relatively, a theoretical model of damage repair of composite under different initial conditions was then established. Based on this model, the damage repair behaviors of SMA materials under different initial conditions were discussed. The results show that the recovery stress of SMA decreases with the increasing temperature when there is no austenite transformation happens, while increases with the increasing temperature when the austenite transformation occurs. Moreover, the larger the volume fraction of stress-induced martensite in SMA, the greater the maximum recovery stress occurs in the heating process. The happens of the austenite transformation during the heating process can reduce the damage strain of the composite material, and then achieve the purpose of the damage repair. This article can provide theoretical guidance for the future engineering application of SMA in composite damage repair.

-

Key words:

- shape memory alloy /

- composite materials /

- damage repair /

- recovery stress /

- phase transition /

- application

-

表 1 对初始状态为低温马氏体升温过程中卸载后形状记忆合金(SMA)的可能状态分类

Table 1. Classification of the possible states of shape memory alloy (SMA) after unloading during the heating process of the initial state of high temperature austenite

Temperature section SMA initial state Possible states of SMA after unloading when loaded with different stresses ${T_0} < {M^{\rm{f}}}$ Twinned martensite Twinned martensite Twinned martensite, Detwinned martensite Detwinned martensite ${M^{\rm{f}}} \leqslant {T_0} < {M^{\rm{s}}}$ Twinned martensite Twinned martensite Twinned martensite, Detwinned martensite Detwinned martensite ${M^{\rm{s}}} \leqslant {T_0} < {A^{\rm{s}}}$ Twinned martensite Twinned martensite Twinned martensite, Detwinned martensite Detwinned martensite ${A^{\rm{s}}} \leqslant {T_0} < {A^{\rm{f}}}$ Twinned martensite, Austenite Twinned martensite, Austenite Detwinned martensite, Austenite ${A^{\rm{f}}} \leqslant {T_0}$ Austenite Austenite Notes: Mf—Martensitic transformation completion temperature; Ms— Martensitic transformation start temperature; As— Austenite transfor

mation start temperature; Af—Austenite transformation completion temperature. 表 2 对初始状态为高温奥氏体降温过程中卸载后SMA的可能状态分类

Table 2. Classification of the possible states of SMA after unloading during the cooling process of the initial state of high temperature austenite

Temperature section SMA initial state Possible states of SMA after unloading when

loaded with different stresses${A^{\rm{f}}} \leqslant {T_0}$ Austenite Austenite ${A^{\rm{s}}} \leqslant {T_0} < {A^{\rm{f}}}$ Austenite Austenite Detwinned martensite, Austenite ${M^{\rm{s}}} \leqslant {T_0} < {A^{\rm{s}}}$ Austenite Austenite Detwinned martensite, Austenite Detwinned martensite ${M^{\rm{f}}} \leqslant {T_0} < {M^{\rm{s}}}$ Twinned martensite, Austenite Twinned martensite, Austenite Twinned martensite, Detwinned martensite Detwinned martensite ${T_0} < {M^{\rm{f}}}$ Twinned martensite Twinned martensite Twinned martensite, Detwinned martensite Detwinned martensite 表 3 与SMA和玻璃纤维/不饱和树脂有关的材料参数[23,26]

Table 3. Material parameters related to SMA and glass fiber/unsaturated resin[23,26]

Mf/℃ Ms/℃ As/℃ Af/℃ EA/MPa EM/MPa ${\alpha ^{\rm{A}}}$/10−5℃−1 ${\alpha ^{\rm{M}}}$/10−6℃−1 9 18.4 34.5 49 67000 26300 1.1 6.6 ${\varepsilon _{\rm{L}}}$/% EG/MPa ${\sigma _{\rm{G}}}$/MPa ${\alpha _{\rm{G}}}$/10−6℃−1 CA/(MPa·℃−1) 0.067 33400 417.1 3 13.8 Notes: EA—Elastic modulus of SMA austenite; EM—Elastic modulus of SMA martensite; ${\alpha ^{\rm{A}}}$—Thermal expansion coefficient of SMA austenite; ${\alpha ^{\rm{M}}}$—Thermal expansion coefficient of SMA martensite; ${\varepsilon _{\rm{L}}}$—Maximum recoverable residual strain; EG—Elastic modulus of glass fiber unsaturated resin; ${\sigma _{\rm{G}}}$—Stress on glass fiber unsaturated resin; ${\alpha _{\rm{G}}}$—Thermal expansion coefficient of glass fiber unsaturated resin; CA—Stress influence factor. -

[1] 杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, 24(1):1-12. doi: 10.3321/j.issn:1000-3851.2007.01.001DU S Y. Advanced composite materials and aerospace engineering[J]. Acta Materiae Compositae Sinica,2007,24(1):1-12(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.01.001 [2] 高琳. 智能复合材料在航空、航天领域的研究应用[J]. 纤维复合材料, 2014(1):22-25.GAO L. The study and application of intelligent composite materialsin the aviation and aerospace field[J]. Fiber Composites,2014(1):22-25(in Chinese). [3] WHITE S R, SOTTOS N R, GEUBELLE P H, et al. Autonomic healing of polymer composites.[J]. Nature,2001,409(6822):794-797. doi: 10.1038/35057232 [4] TOOHEY K S, SOTTOS N R, LEWIS J A, et al. Self-healing materials with microvascular networks[J]. Nature Materials,2007,6(8):581-585. doi: 10.1038/nmat1934 [5] YIN T, RONG M Z, ZHANG M Q. Self-healing epoxy composites-Preparation and effect of the healant consisting of microencapsulated epoxy and latent curing agent[J]. Composites Science and Technology,2007,67(2):201-212. doi: 10.1016/j.compscitech.2006.07.028 [6] SUN Y, WAN S, DONG X, et al. Optimized synthesis of isocyanate microcapsules for self-healing application in epoxy composites[J]. High Performance Polymers,2020,32(6):669-680. doi: 10.1177/0954008319897745 [7] NASSHO Y, SANADA K. Microstructure optimizations for improving interlaminar shear strength and self-healing efficiency of spread carbon fiber/epoxy laminates containing microcapsules[J]. Journal of Composite Materials,2021,55(1):27-38. doi: 10.1177/0021998320943941 [8] SHAHABUDIN N, YAHYA R, GAN S N. Microencapsulation of a palm oil-based alkyd by amino resins[J]. Macromolecular Symposia,2015,354(1):305-313. doi: 10.1002/masy.201400085 [9] 王瑞, 刘星, 李婷婷. 自修复微胶囊分散对复合材料拉伸性能的影响[J]. 复合材料学报, 2012, 29(3):90-97.WANG R, LIU X, LI T T. Effect of the dispersion of self-healing microcapsules on tensile properties of microcapsules filled composites[J]. Acta Materiae Compositae Sinica,2012,29(3):90-97(in Chinese). [10] 印明勋, 齐德胜, 云庆文. 航空复合材料自修复研究进展[C]. 北京: 中国航空科学技术大会, 2015: 177-181.YIN M X, QI D S, YUN Q W. Research development of self-healing of aeronautical composite materials[C]. Beijing: China Aviation Science and Technology Conference, 2015: 177-181(in Chinese). [11] JANI J M, LEARY M, SUBIC A, et al. A review of shape memory alloy research, applications and opportunities[J]. Materials & Design,2014,56:1078-1113. [12] TAKAGI T. A concept of intelligent materials[J]. Journal of Intelligent Material Systems and Structures,1990,1(2):149-156. doi: 10.1177/1045389X9000100201 [13] LI P Y, JIA Y F, WANG Y S, et al. Effect of Fe addition on microstructure and mechanical properties of As-cast Ti49Ni51 alloy[J]. Materials,2019,12(19):3114. doi: 10.3390/ma12193114 [14] LI P, WANG Y, MENG F, et al. Effect of heat treatment temperature on martensitic transformation and superelasticity of the Ti49Ni51 shape memory alloy[J]. Materials,2019,12(16):2539-2551. doi: 10.3390/ma12162539 [15] GU X J, SU X Z, WANG J, et al. Improvement of impact resistance of plain-woven composite by embedding superelastic shape memory alloy wires[J]. Frontiers of Mechanical Engineering,2020,15(9):1-11. [16] 薛飞. 形状记忆合金用于锌基合金自修复的研究[D]. 青岛: 中国石油大学(华东). 2016.XUE F. Study on the application of shape memory alloy alloy in self-healing behaviors of Zinc based alloy[D]. Qingdao: China University of Petroleum, 2016(in Chinese). [17] 张亚楠, 刘亚冬, 刘兵飞. 形状记忆合金在复合材料损伤监测中的应用[J]. 复合材料学报, 2021, 38(4):1177-1191.ZHANG Y N, LIU Y D, LIU B F. Research on application of shape memory alloy in damage monitoring of composite materials[J]. Acta Materiae Compositae Sinica,2021,38(4):1177-1191(in Chinese). [18] MAJI A K, NEGRET I. Smart prestressing with shape-memory alloy[J]. Journal of Engineering Mechanics,1998,124(10):1121-1128. doi: 10.1061/(ASCE)0733-9399(1998)124:10(1121) [19] SAKAI Y, KITAGAWA Y, FUKUTA T, et al. Experimental study on enhancement of self-restoration of concrete beams using SMA wire[J]. Proceedings of SPIE-The International Society for Optical Engineering,2003,5057:178-186. [20] LI H, LIU Z Q, OU J P. Behavior of a simple concrete beam driven by shape memory alloy wires[J]. Smart Materials & Structures,2006,15(4):1039-1046. [21] 邓宗才, 李庆斌. 形状记忆合金对混凝土梁驱动效应分析[J]. 土木工程学报, 2002, 35(2):41-47.DENG Z C, LI Q B. Actuating effects of embedded shape memory alloy on concrete beam[J]. China Civil Engineering Journal,2002,35(2):41-47(in Chinese). [22] 王庆菲. SMA智能混凝土的裂缝监测与自修复理论研究[D]. 天津: 中国民航大学. 2020.WANG Q F. Theoretical research on crack monitoring and self-repairing mechanism for SMA intelligent concrete materials[D]. Tianjin: Civil Aviation University of China. 2020(in Chinese). [23] BRINSON L C. One-dimensional constitutive behavior of shape memory alloys: Thermomechanical derivation with non-constant material functions and redefined martensite internal variable[J]. Journal of Intelligent Material Systems and Structures,1993,4(2):229-242. doi: 10.1177/1045389X9300400213 [24] TANAKA K. A thermomechanical sketch of shape memory effect: One-dimensional tensile behavior[J]. Res Mechanica,1986,18:251-263. [25] LIANG C, ROGERS C A. One-dimensional thermomechanical constitutive relations for shape memory materials[J]. Journal of Intelligent Material Systems and Structures,1990,1(2):207-234. doi: 10.1177/1045389X9000100205 [26] 詹瑒. 纤维增强复合材料(FRP)格构柱基本性能研究[D]. 南京: 东南大学. 2016.ZHAN Y. Performance evaluation of lattice columns using pultruded fiber-reinforced polymer(FRP) structurak profiles[D]. Nanjing: Southeast University, 2016(in Chinese). [27] 马奎. NiTi形状记忆合金棒的受限回复与加热试验及分析[D]. 广州: 华南理工大学, 2013.MA K. Tests and analyses of NiTi shape memory alloy bars’ restrained recovery and heating[D]. Guangzhou: South China University of Technology, 2013(in Chinese). -

下载:

下载: