| [1] |

王春红, 鹿超, 贾瑞婷, 等. 洋麻纤维-棉纤维混纺织物/环氧树脂复合材料力学及吸湿性能[J]. 复合材料学报, 2020, 37(7):1581-1589.WANG Chunhong, LU Chao, JIA Ruiting, et al. Moisture absorption and mechanical properties of kenaf fiber-cotton fiber blended fabric/epoxy composite[J]. Acta Materiae Compositae Sinica,2020,37(7):1581-1589(in Chinese).

|

| [2] |

DUTTA S D, KIM N K, DAS R, et al. Effects of sample orientation on the fire reaction properties of natural fibre composites[J]. Composites Part B: Engineering,2019,157:195-206. doi: 10.1016/j.compositesb.2018.08.118

|

| [3] |

张安定, 马胜, 丁辛, 等. 黄麻纤维增强聚丙烯的力学性能[J]. 玻璃钢/复合材料, 2004(2):3-5.ZHANG Anding, MA Sheng, DING Xin, et al. Mechanical behaviors of jute fiber reinforced polypropylene compo-site[J]. Fiber Reinforced Plastics/Composites,2004(2):3-5(in Chinese).

|

| [4] |

彭丹. 麻纤维增强聚丙烯的制作及其性能研究[D]. 武汉: 湖北工业大学, 2011.PENG Dan. Fabrication and property investigation of hemp fiber reinforced polypropylene composite[D]. Wuhan: Hubei University of Technology, 2011(in Chinese).

|

| [5] |

张安定. 黄麻纤维增强聚丙烯的制作和性能研究[D]. 上海: 东华大学, 2004.ZHANG Anding. Fabrication and property investigation of jute fiber reinforced polypropylene composite[D]. Shanghai: Donghua University, 2004(in Chinese).

|

| [6] |

倪爱清, 朱坤坤, 王继辉. 纳米SiO2-NaOH-有机硅烷偶联剂表面改性对苎麻纤维/乙烯基酯树脂复合材料性能的影响[J]. 复合材料学报, 2018, 36(11):2579-2586.NI Aiqing, ZHU Kunkun, WANG Jihui. Effects of nano SiO2-NaOH-silane coupling agent surface treatment on beha-vior of ramie fiber/vinyl ester resin composite[J]. Acta Materiae Compositae Sinica,2018,36(11):2579-2586(in Chinese).

|

| [7] |

SANJAY M R, MADHU P, JAWAID M, et al. Characterization and properties of natural fiber polymer composites: A comprehensive review[J]. Journal of Cleaner Production,2018,172:566-581. doi: 10.1016/j.jclepro.2017.10.101

|

| [8] |

胥长龙, 卢德宏, 唐露, 等. 复合区体积分数对氧化锆增韧氧化铝颗粒/40Cr空间结构复合材料冲击磨损性能的影响[J]. 复合材料学报, 2020, 37(9):2223-2229.XU Changlong, LU Dehong, TANG Lu, et al. Effect of composite volume fraction on impact wear properties of zirconium oxide toughened alumina particles/40Cr architecture composites[J]. Acta Materiae Compositae Sinica,2020,37(9):2223-2229(in Chinese).

|

| [9] |

刘新, 陈铎, 何辉永, 等. 热塑性颗粒-无机粒子协同增韧碳纤维增强环氧树脂复合材料[J]. 复合材料学报, 2020, 37(8):1904-1910.LIU Xin, CHEN Duo, HE Huiyong, et al. Synergistic toughening of thermoplastic particles-inorganic particles to carbon fiber reinforced epoxy resin composites[J]. Acta Materiae Compositae Sinica,2020,37(8):1904-1910(in Chinese).

|

| [10] |

KIM B, CHA S, KONG K, et al. Synergistic interfacial reinforcement of carbon fiber/polyamide 6 composites using carbon-nanotube-modified silane coating on ZnO-nanorod grown carbon fiber[J]. Composites Science and Technology,2018,165:362-372. doi: 10.1016/j.compscitech.2018.07.015

|

| [11] |

CHEON J, KIM M. Impact resistance and interlaminar shear strength enhancement of carbon fiber reinforced thermoplastic composites by introducing MWCNT-anchored carbon fiber[J]. Composites Part B: Engineering,2021,217:108872. doi: 10.1016/j.compositesb.2021.108872

|

| [12] |

WANG D, XUAN L, HAN G, et al. Preparation and characterization of foamed wheat straw fiber/polypropylene composites based on modified nano-TiO2 particles[J]. Composites Part A: Applied Science & Manufacturing,2020,128:105674.

|

| [13] |

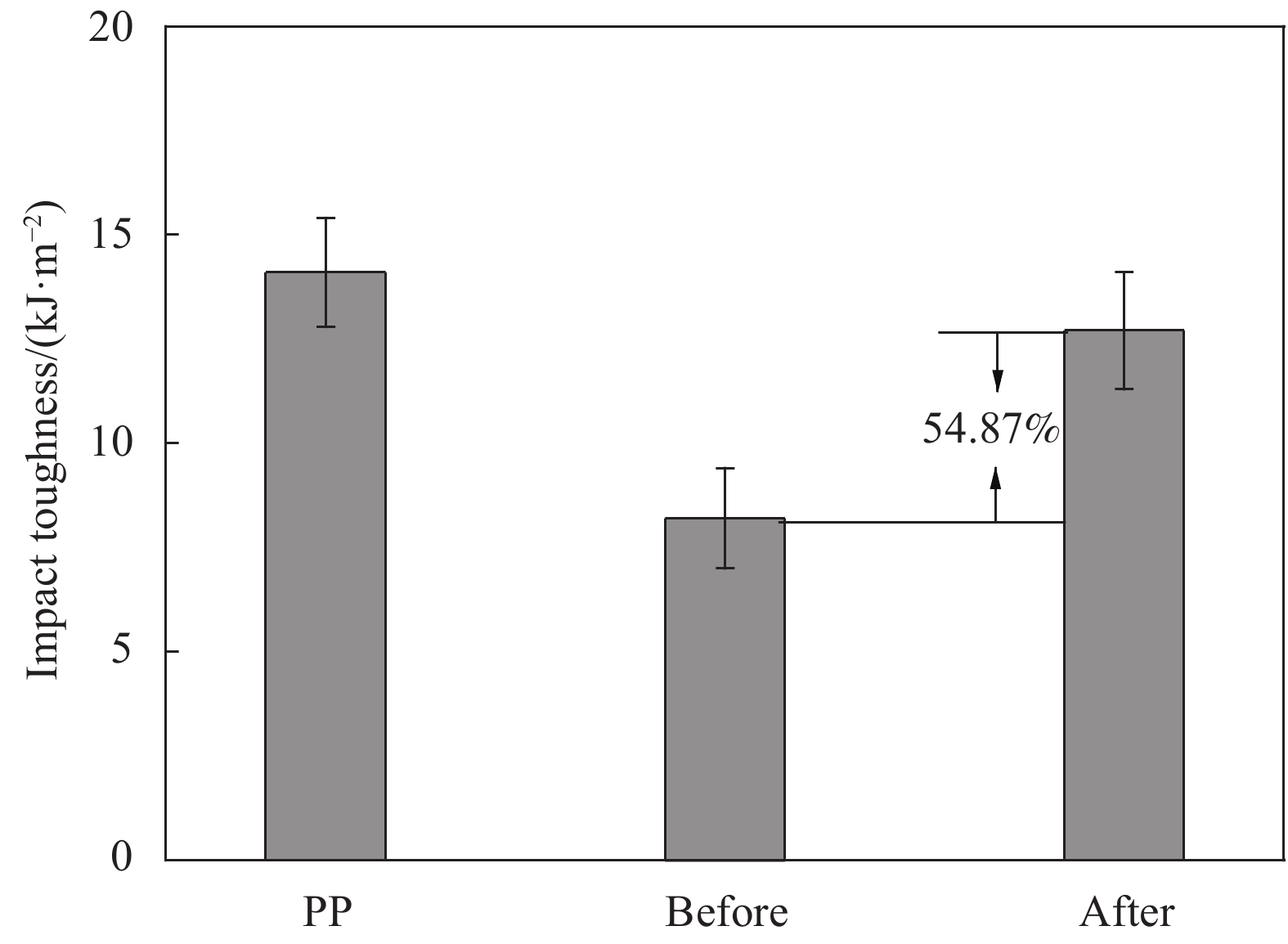

中国国家标准化管理委员会(标准制定单位). GB/T 1451—2005 增强塑料简支梁式冲击韧性试验方法[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. GB/T 1451—2005 Fiber-reinforced plastics compo-sites—Determination of charpy impact properties[S]. Beijing: China Standards Press, 2005(in Chinese).

|

| [14] |

HE L P, LI W J, CHEN D C, et al. Effects of amino silicone oil modification on properties of ramie fiber and ramie fiber/polypropylene composites[J]. Materials and Design,2015,77:142-148. doi: 10.1016/j.matdes.2015.03.051

|

| [15] |

KABIR M M, WANG H, LAU K T, et al. Effects of chemical treatments on hemp fibre structure[J]. Applied Surface Science,2013,276:13-23. doi: 10.1016/j.apsusc.2013.02.086

|

| [16] |

HE L P, LI W J, CHEN D C, et al. Microscopic mechanism of amino silicone oil modification and modification effect with different amino group contents based on molecular dynamics simulation[J]. Applied Surface Science,2018,440:331-340. doi: 10.1016/j.apsusc.2018.01.101

|

| [17] |

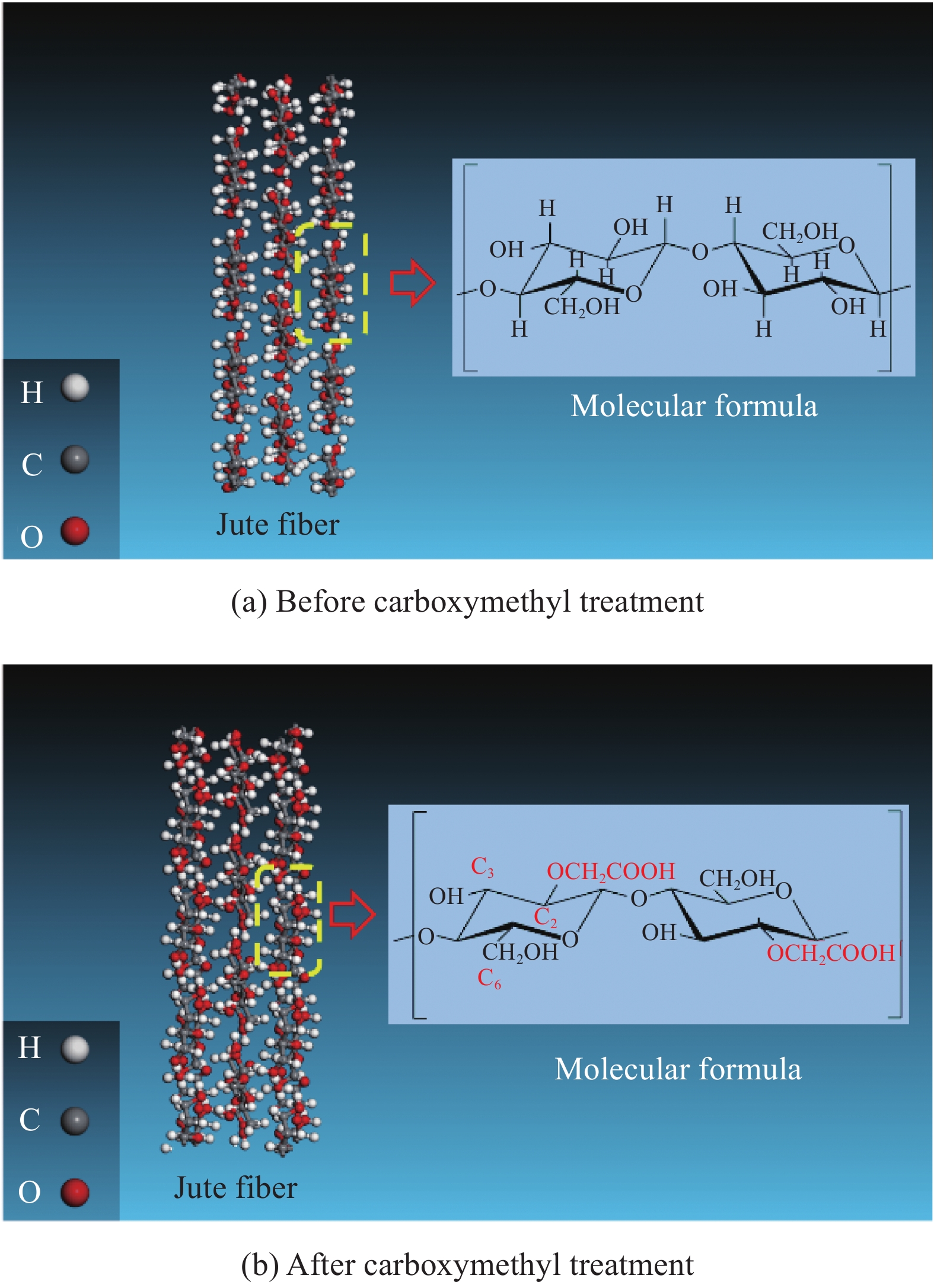

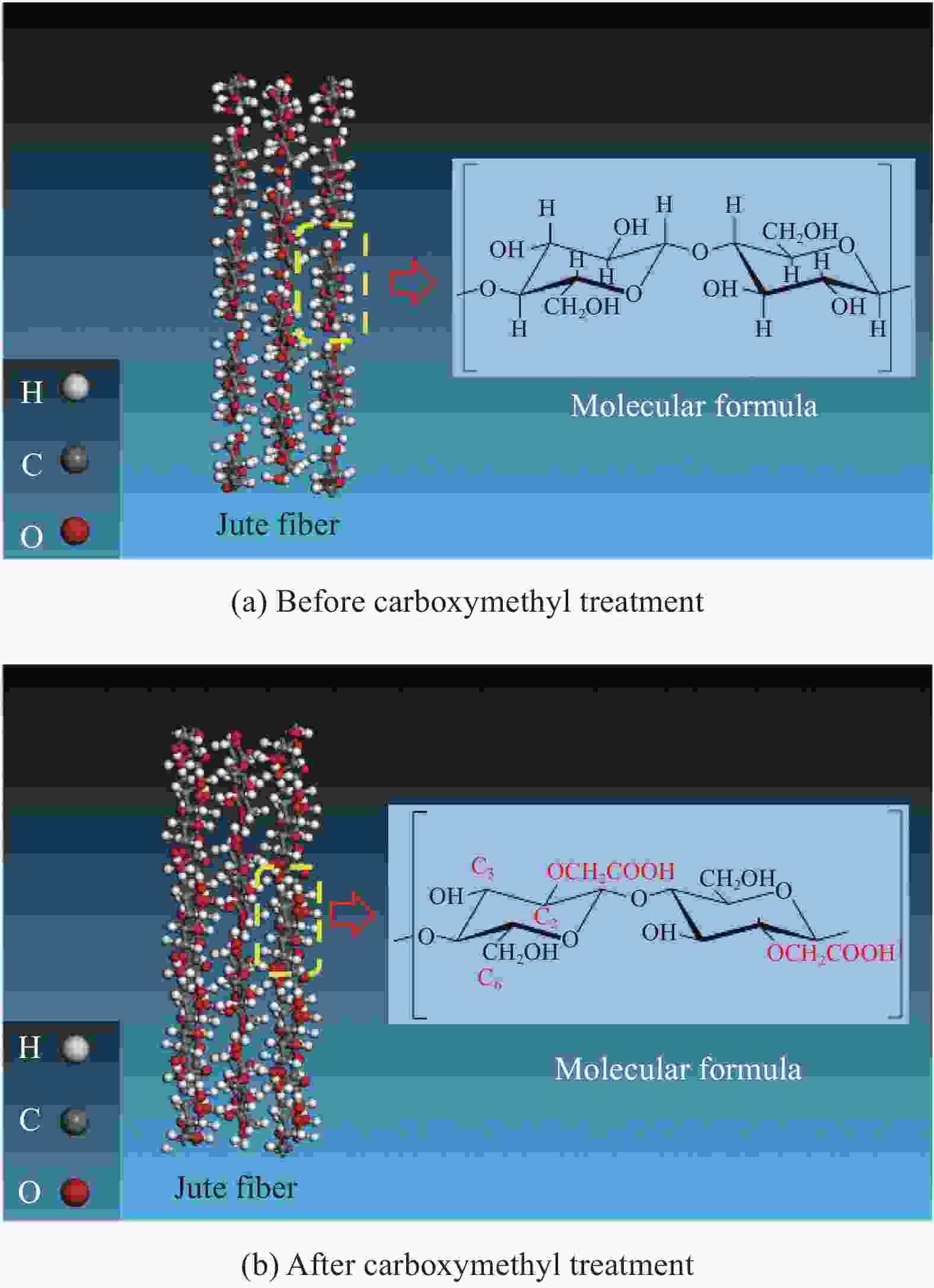

ADINUGRAHA M P, MARSENO D W, HARYADI. Synthesis and characterization of sodium carboxymethylcellulose from cavendish banana pseudo stem (Musa cavendishii LAMBERT)[J]. Carbohydrate Polymers,2005,62:164-169. doi: 10.1016/j.carbpol.2005.07.019

|

| [18] |

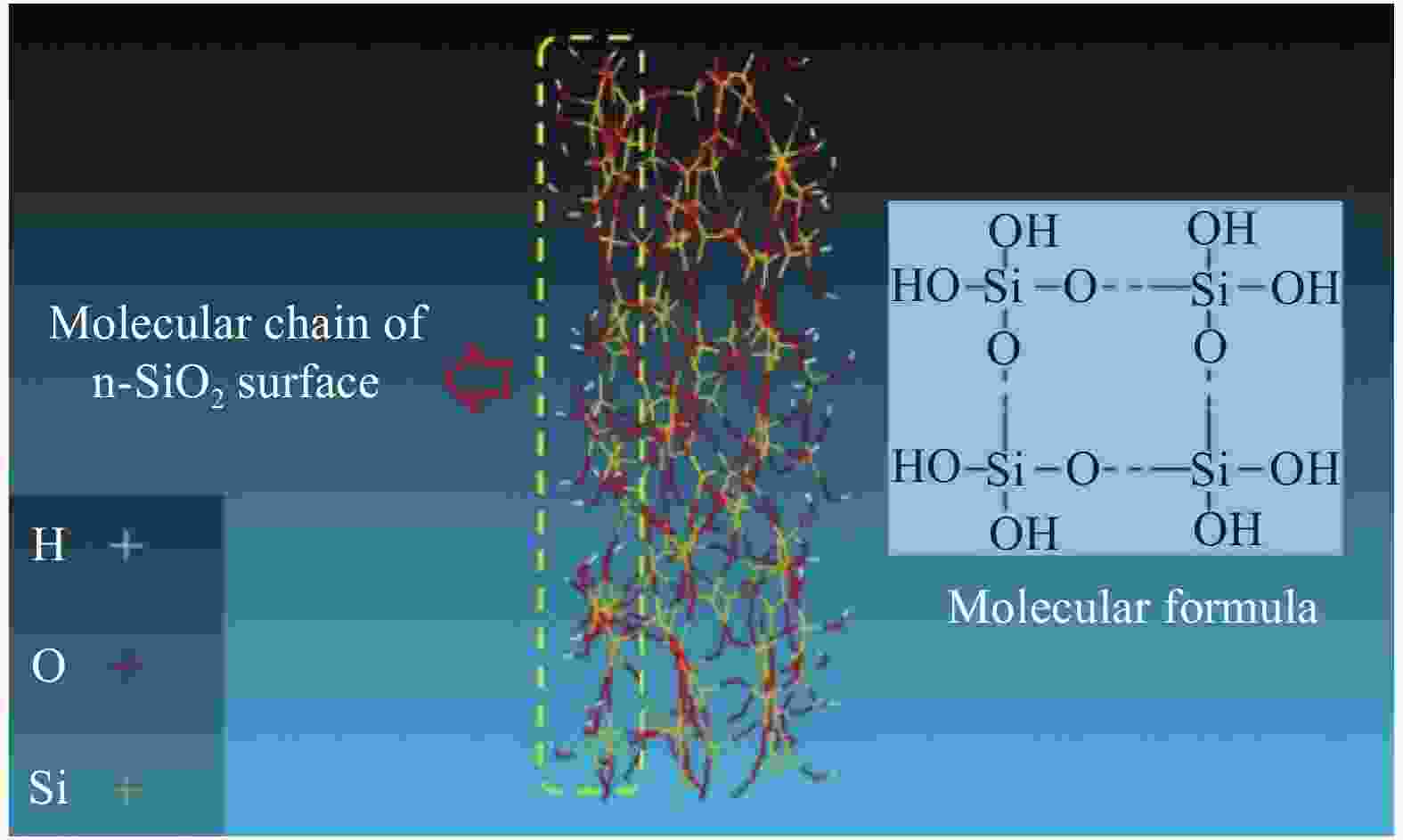

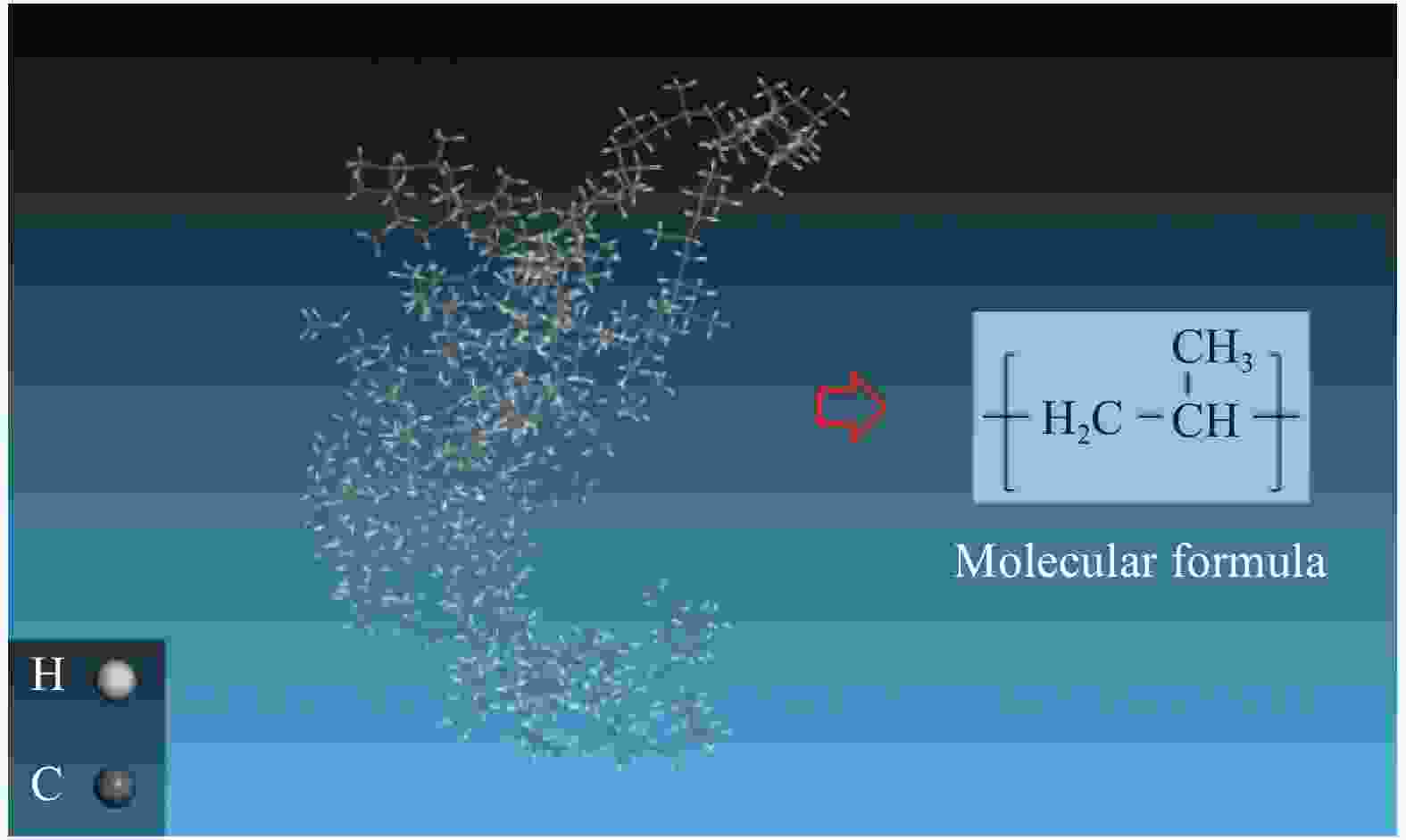

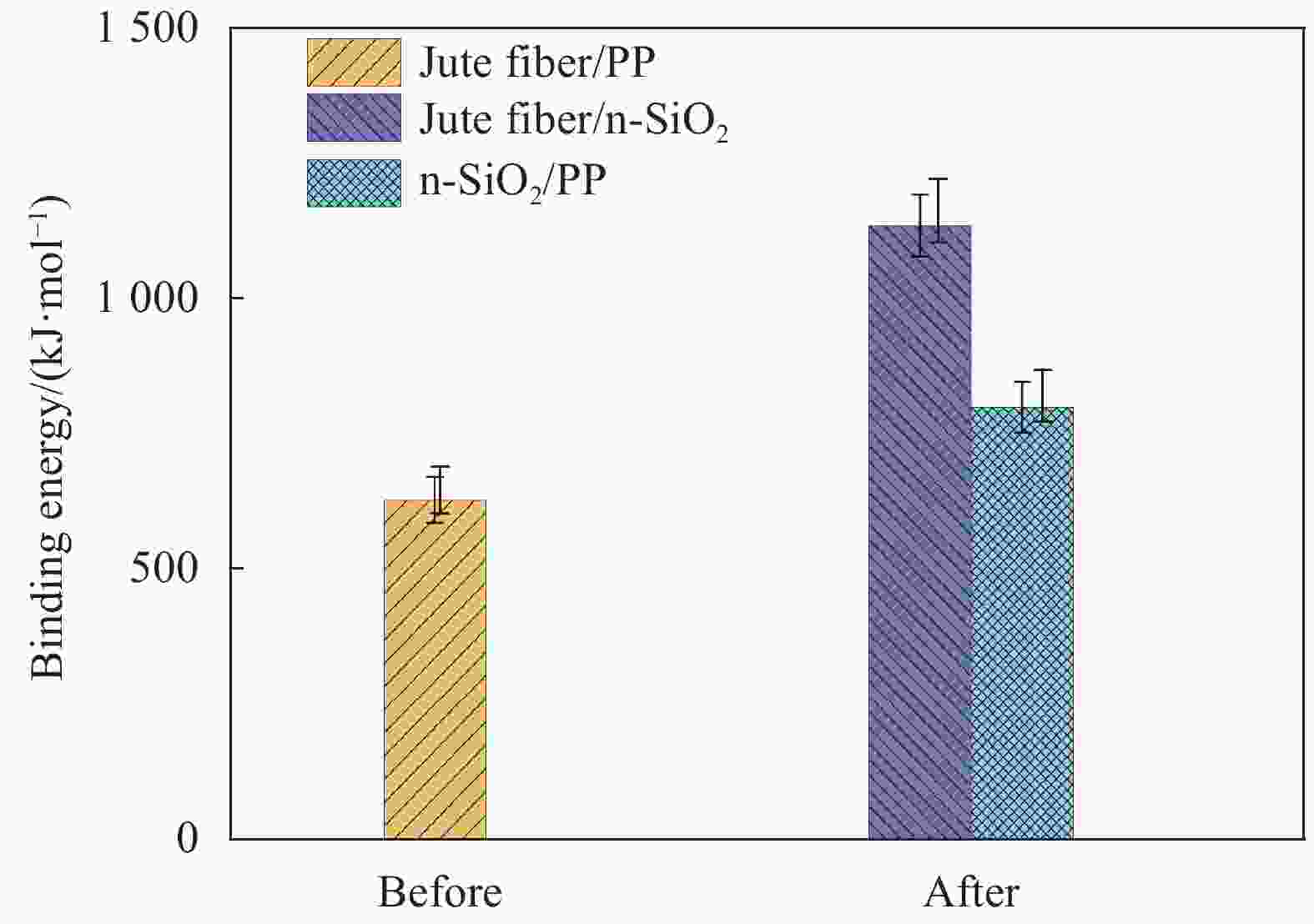

乔丽君. 纤维素-二氧化硅纳米复合材料的分子动力学模拟研究[D]. 兰州: 西北师范大学, 2009.QIAO Lijun. Molecular dynamics simulations of cellulose/SiO2 nanocomposites[D]. Lanzhou: Northwest Normal University, 2009(in Chinese).

|

| [19] |

ZHOU Y, FAN M, CHEN L. Interface and bonding mechanisms of plant fibre composites: An overview[J]. Composites Part B: Engineering,2016,101:31-45. doi: 10.1016/j.compositesb.2016.06.055

|

| [20] |

李文军. 苎麻纤维/聚丙烯车用复合材料的制备及改性机理研究[D]. 长沙: 湖南大学, 2017.LI Wenjun. Preparation and characterization of ramie fiber/polypropylene composites for automobile and study on the mechanism of fiber surface modification[D]. Changsha: Hunan University, 2017(in Chinese).

|

| [21] |

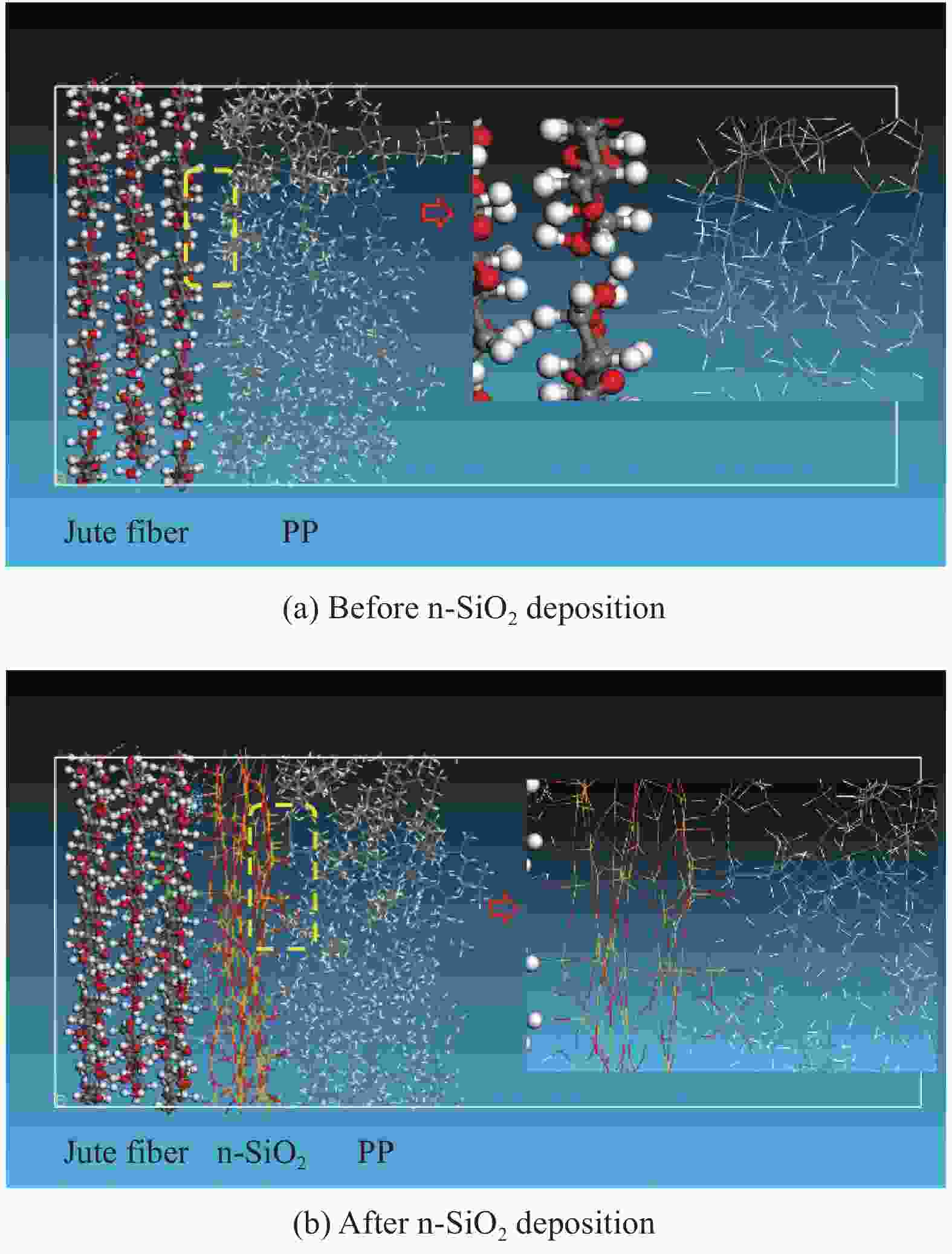

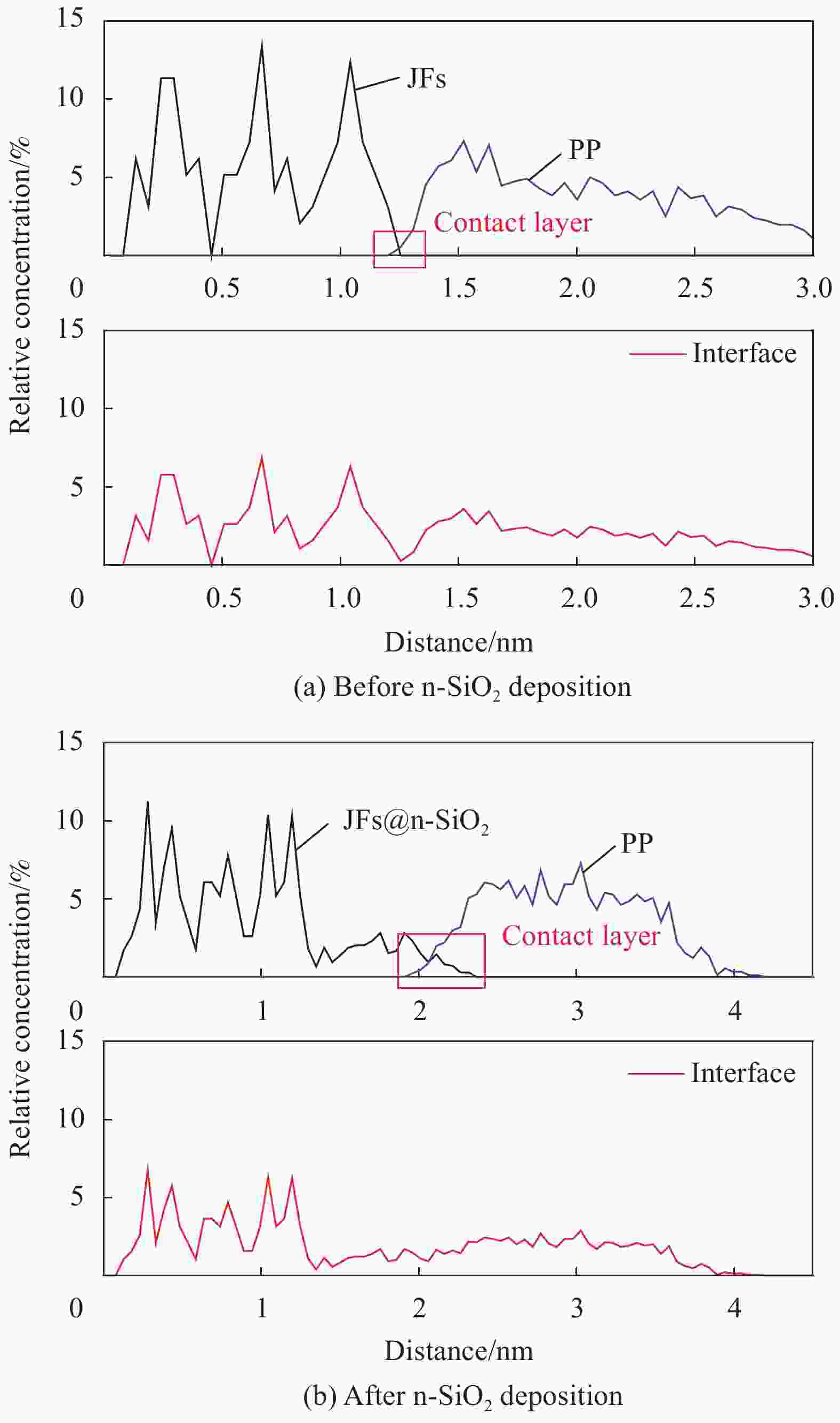

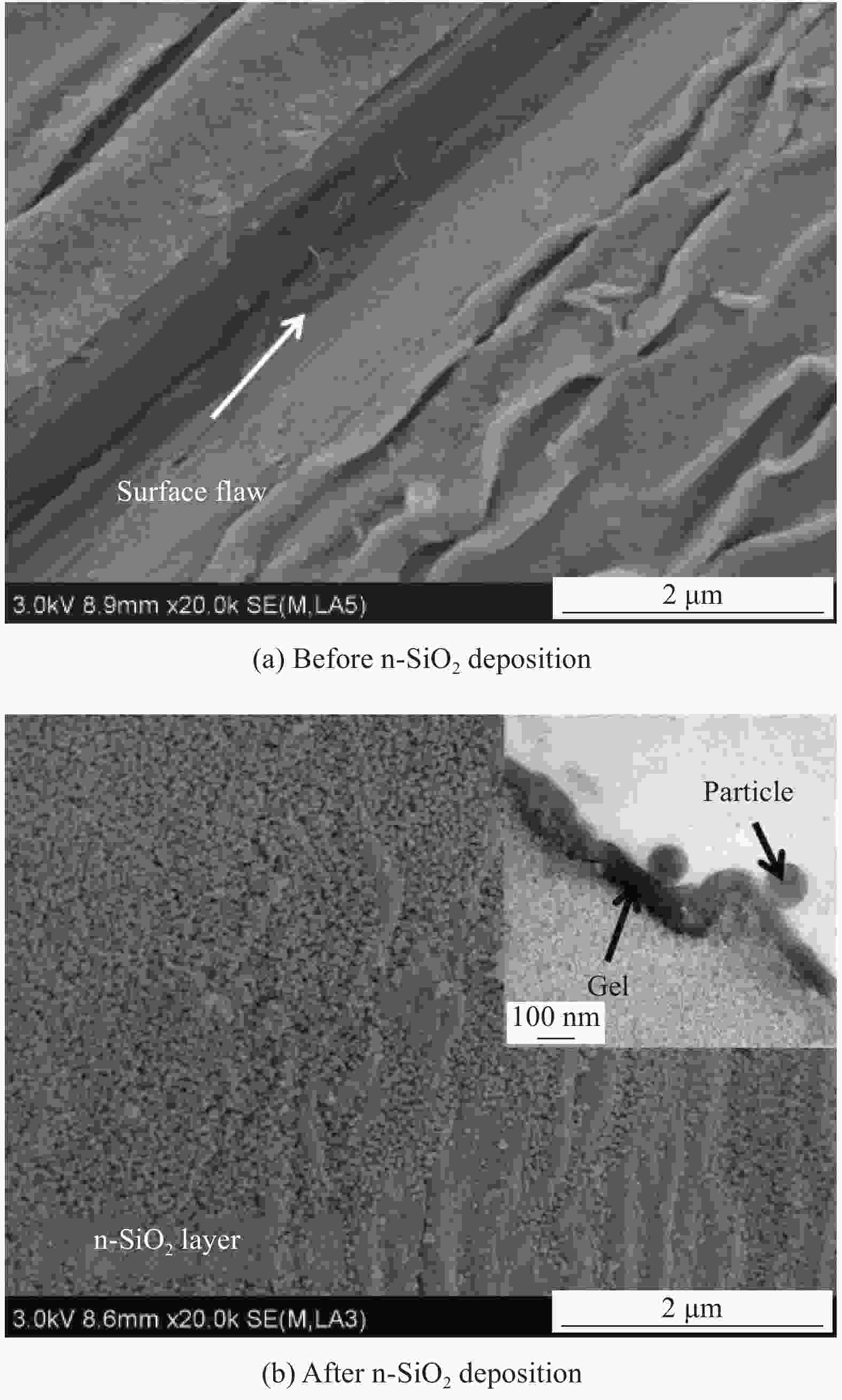

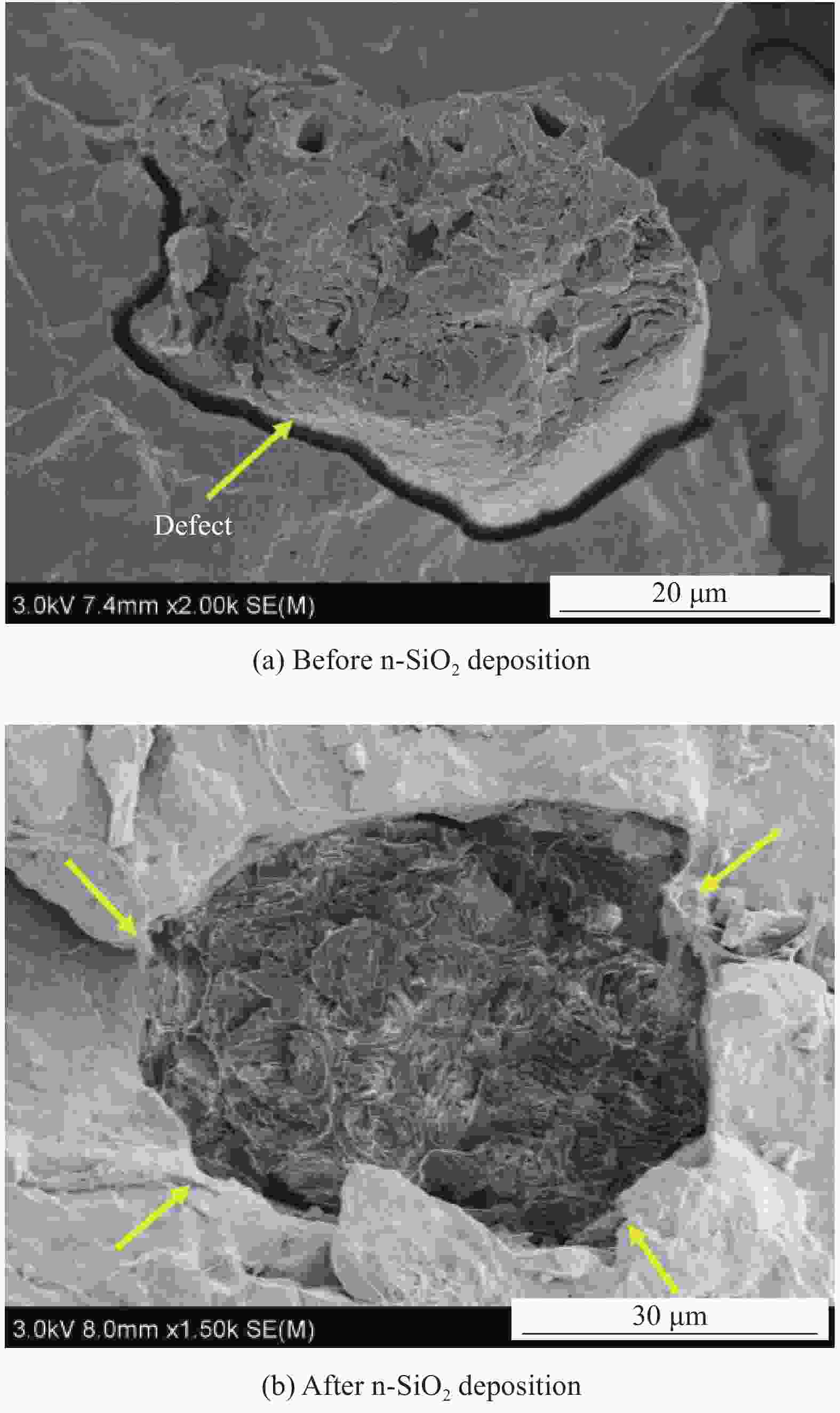

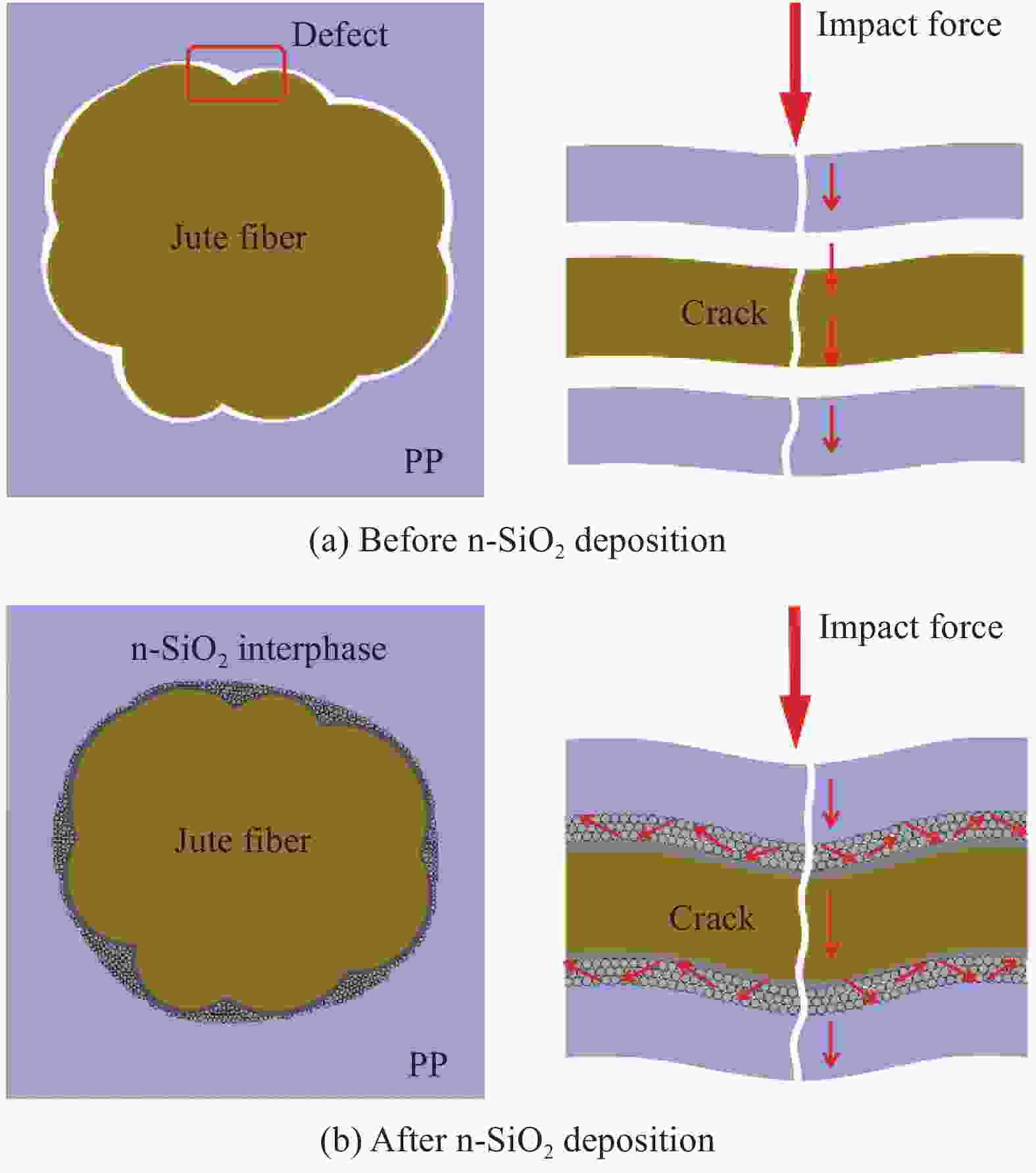

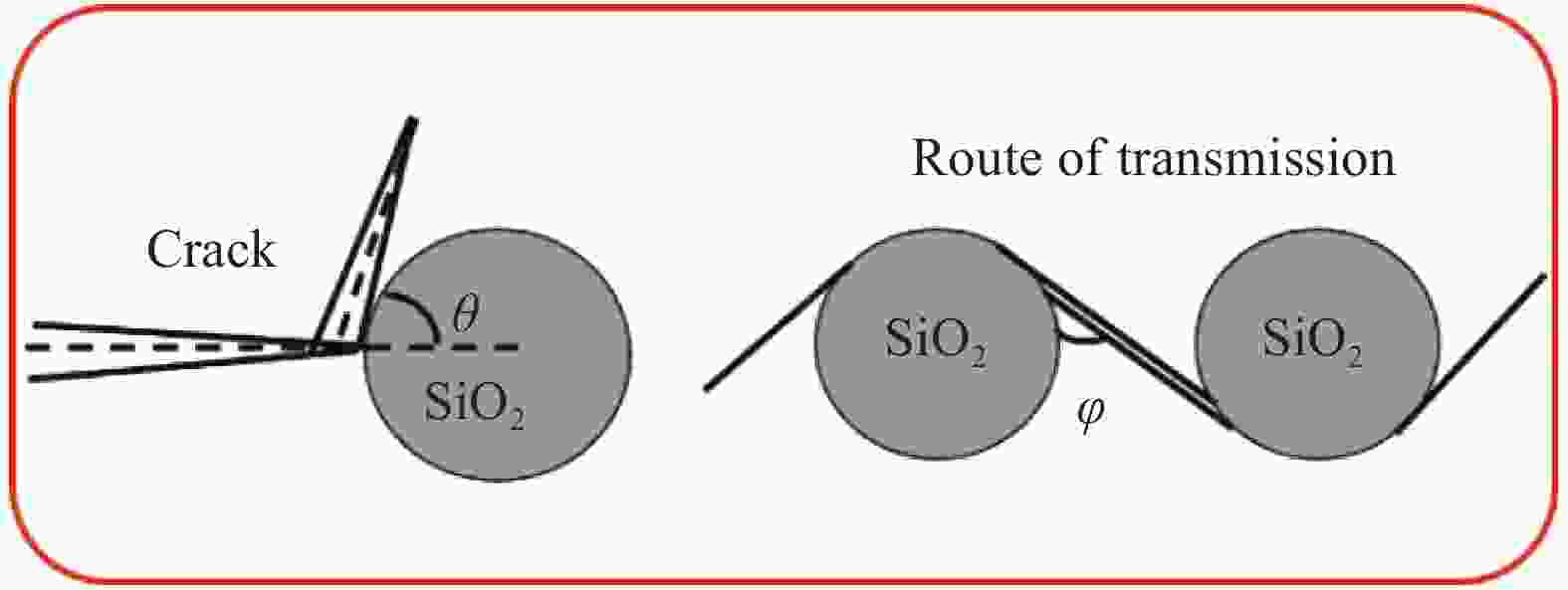

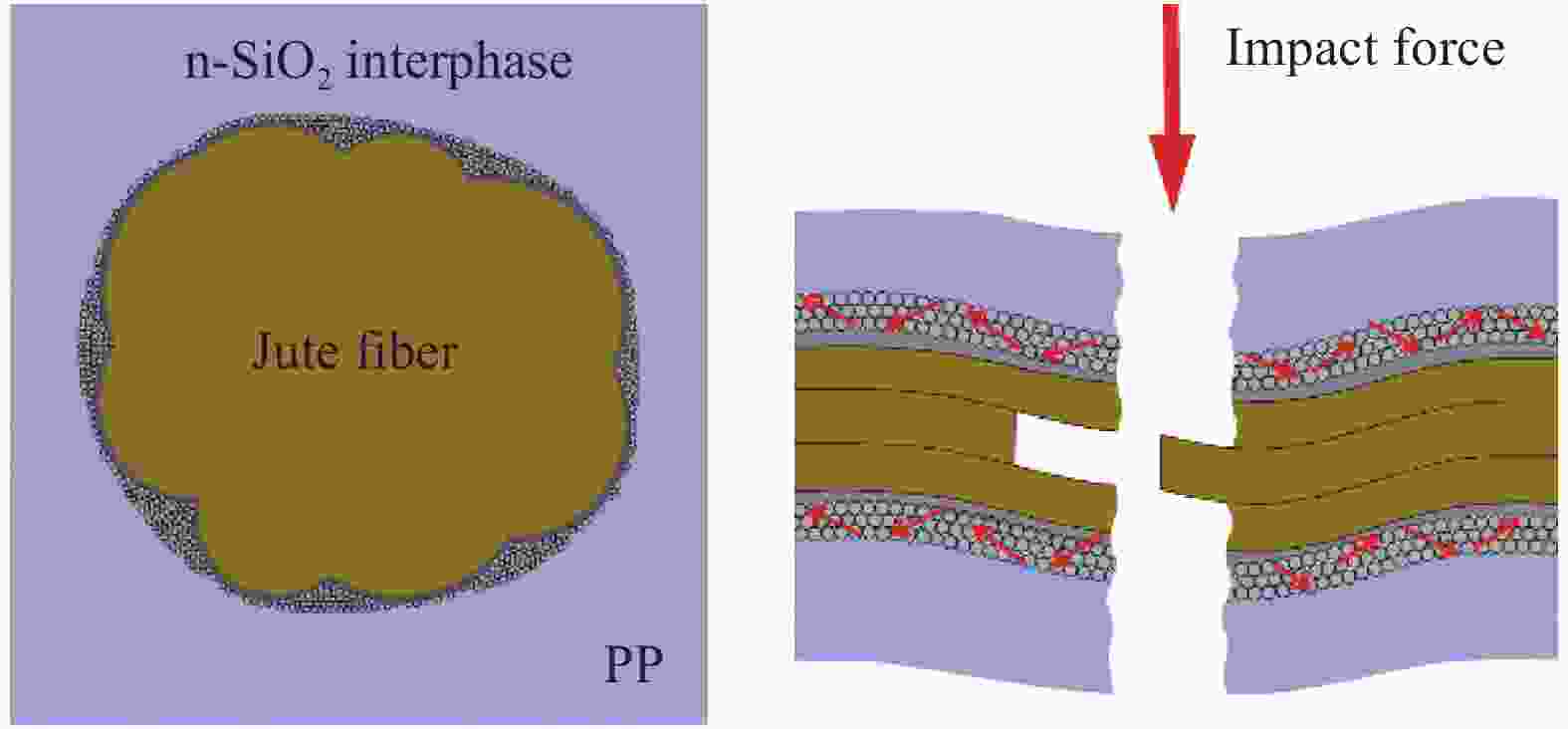

LIU X, CUI Y. Multi-scale analysis of the interface structure and failure behaviors for n-SiO2@jute fiber/PP composites[J]. Composite Structures,2021,267:113865. doi: 10.1016/j.compstruct.2021.113865

|

| [22] |

殷跃洪. 黄麻纤维表面原位沉积纳米SiO2及PP基复合材料的研究[D]. 南京: 南京航空航天大学, 2017.YIN Yuehong. The research of in situ deposited nano-SiO2 on the surface of jute fiber and its polypropylene matrix composites[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2017(in Chinese).

|

| [23] |

JIAO W W, ZHENG T L, LIU W B, et al. Molecular dynamics simulations of the effect of sizing agent on the interface property in carbon fiber reinforced vinyl ester resin composite[J]. Applied Surface Science,2019,479:1192-1199. doi: 10.1016/j.apsusc.2019.02.157

|

| [24] |

陈生辉, 孙霜青, GWALTNEY S R, 等. 碳纳米纤维与环氧树脂单体相互作用的分子动力学模拟[J]. 高分子学报, 2015(10):1158-1164. doi: 10.11777/j.issn1000-3304.2015.15053CHEN Shenghui, SUN Shuangqing, GWALTNEY S R, et al. Molecular dynamics simulations of the interaction between carbon nanofiber and epoxy resin monomers[J]. Acta Polymerica Sinica,2015(10):1158-1164(in Chinese). doi: 10.11777/j.issn1000-3304.2015.15053

|

| [25] |

ZHANG T, XU Y, LI H, et al. Interfacial adhesion between carbon fibers and nylon 6: Effect of fiber surface chemistry and grafting of nano-SiO2[J]. Composites Part A: Applied Science & Manufacturing,2019,121:157-168.

|

| [26] |

LI Q, LI Y, ZHOU L, et al. Nanoscale evaluation of multi-layer interfacial mechanical properties of sisal fiber reinforced composites by nanoindentation technique[J]. Composites Science and Technology,2017,152:211-221.

|

| [27] |

BOS H L, MÜSSIG J, OEVER M J A V D. Mechanical properties of short-flax-fibre reinforced compounds[J]. Compo-sites Part A: Applied Science & Manufacturing,2006,37:1591-1604.

|

下载:

下载: