Wet orientation technology of recycled short carbon fiber and analysis of its reinforcement performance

-

摘要: 碳纤维/环氧树脂(CF/EP)复合材料具有力学性能优异、质量轻、耐腐蚀等特点,但成本高、废弃物环境影响大等问题制约了其进一步应用。现有方法回收的再生碳纤维(RCF)多为蓬松状的短纤维束,纤维互相缠绕,其优异的力学性能难以得到充分的利用。采用湿法纤维取向技术对不同长度的RCF进行重新取向排布,得到了相应的取向纤维毡,并用模压法制备了RCF/EP复合材料试样。利用二维方向张量对RCF的取向度(DPA)进行评价,采用SEM和力学性能测试表征复合材料的结构与性能。结果表明,RCF长度越长,取向越困难;RCF长度和DPA的增加使复合材料的力学性能得到提高;与2 mm RCF相比,6 mm RCF的DPA降低了约11%,而RCF/EP的拉伸强度和模量、弯曲强度和模量分别提升了63.6%、91.5%、48.8%、43.0%。

-

关键词:

- 纤维取向 /

- 短碳纤维 /

- 碳纤维增强树脂复合材料 /

- 回收再利用 /

- 力学性能

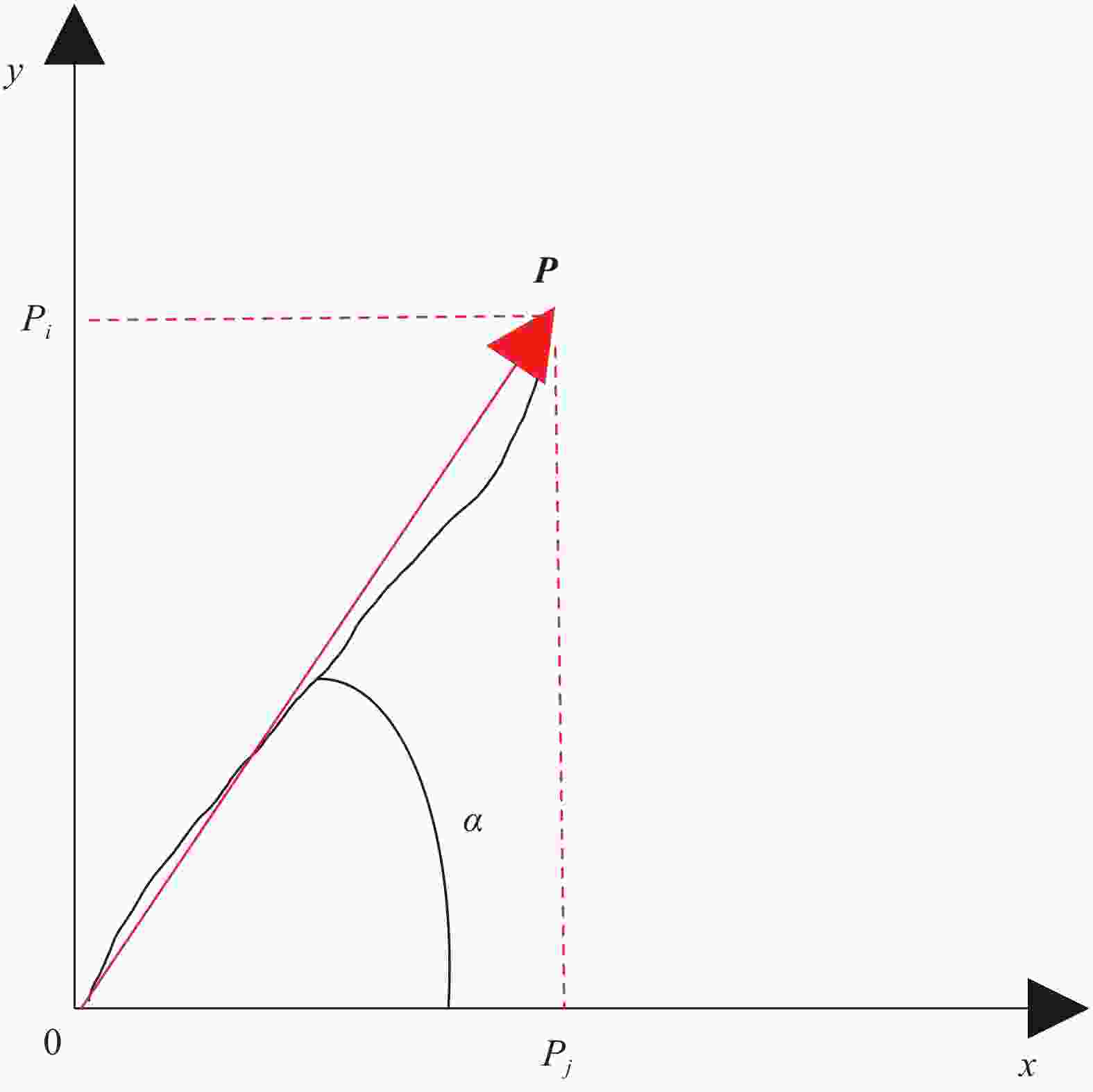

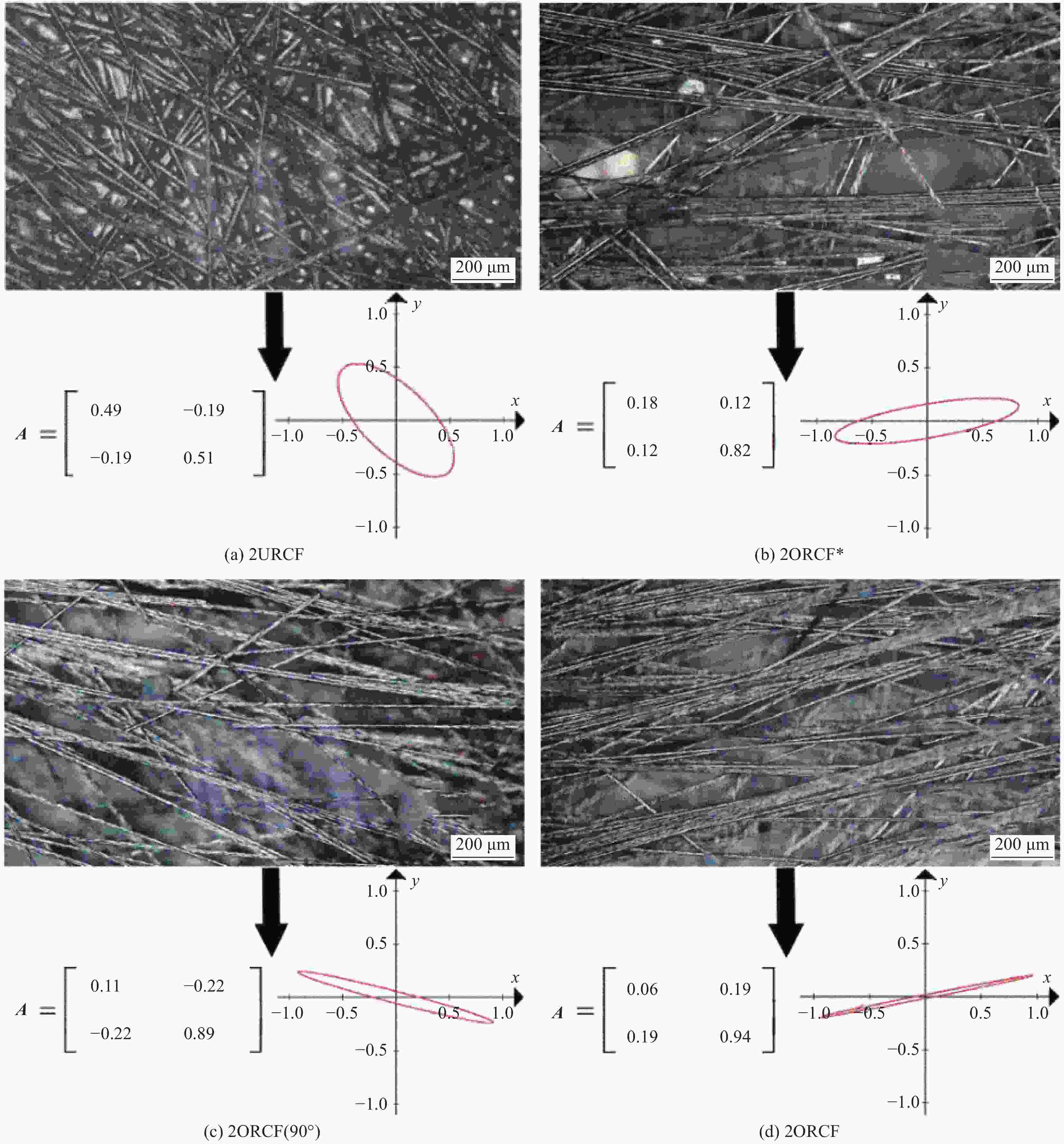

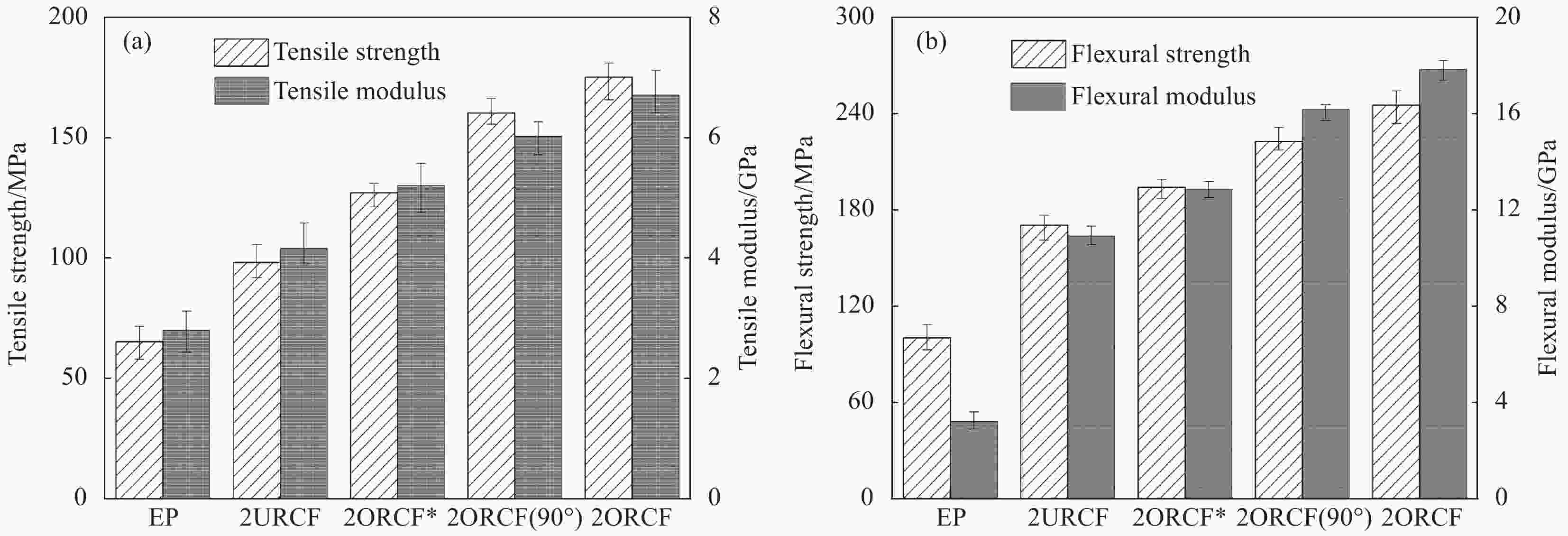

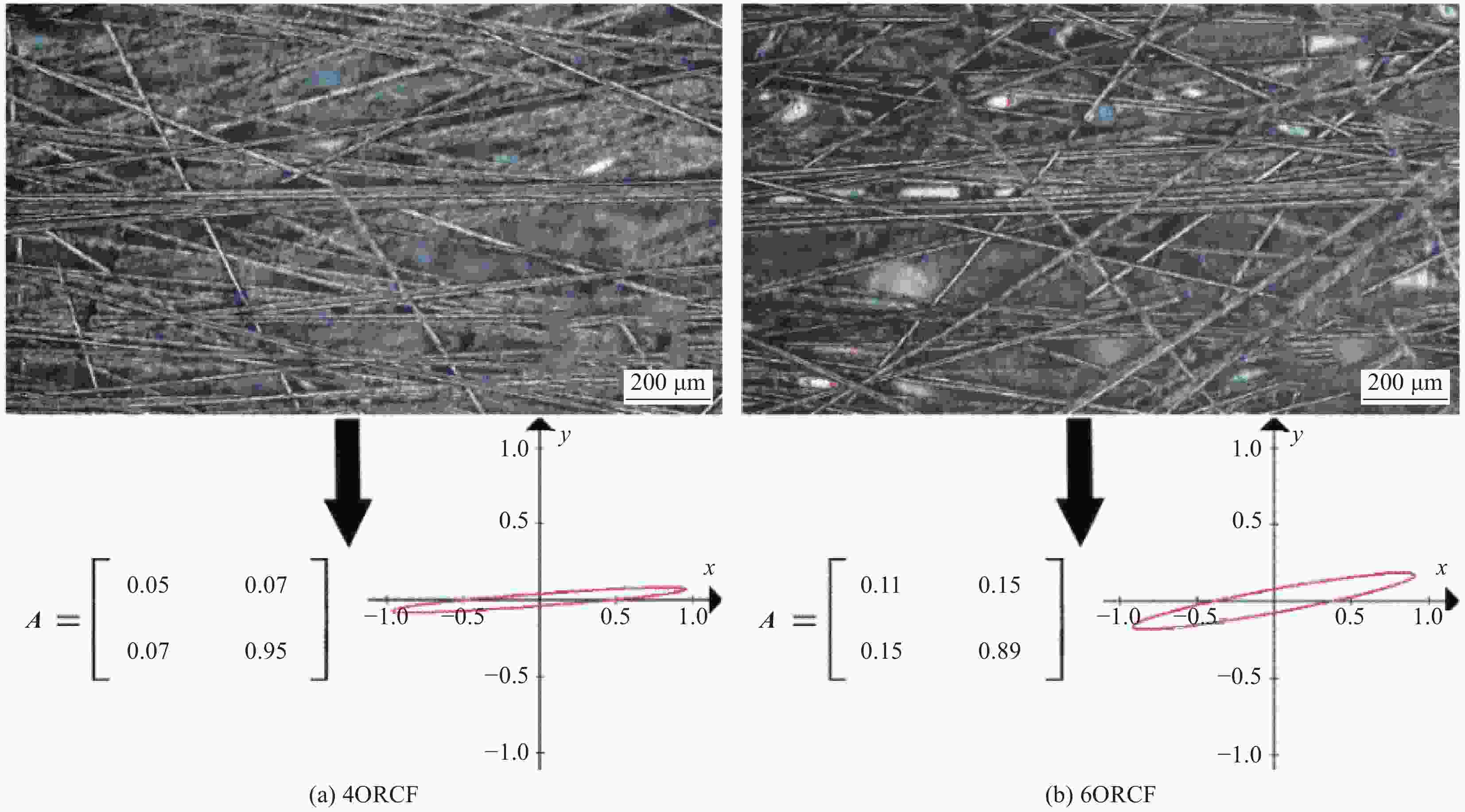

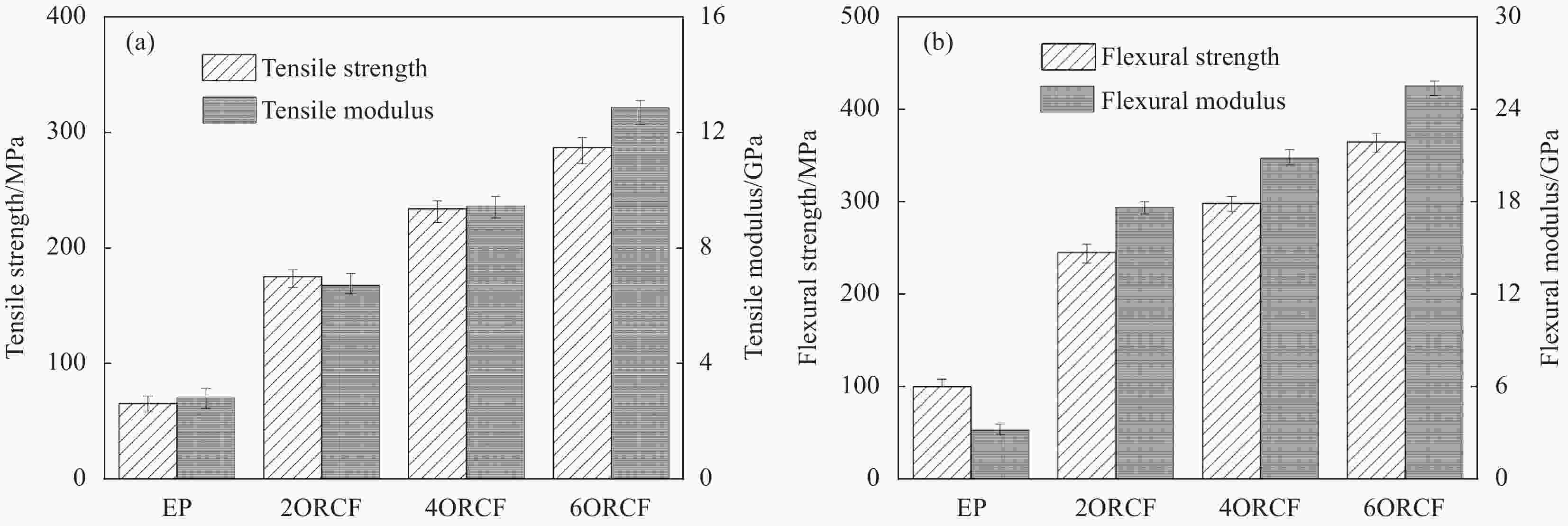

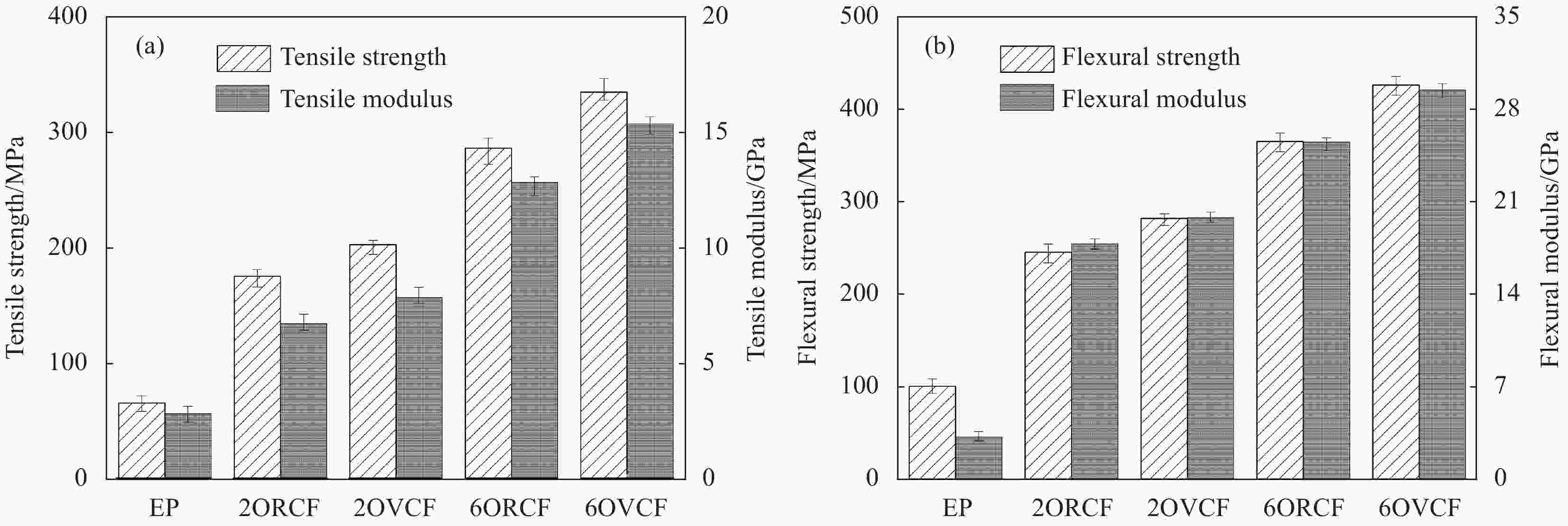

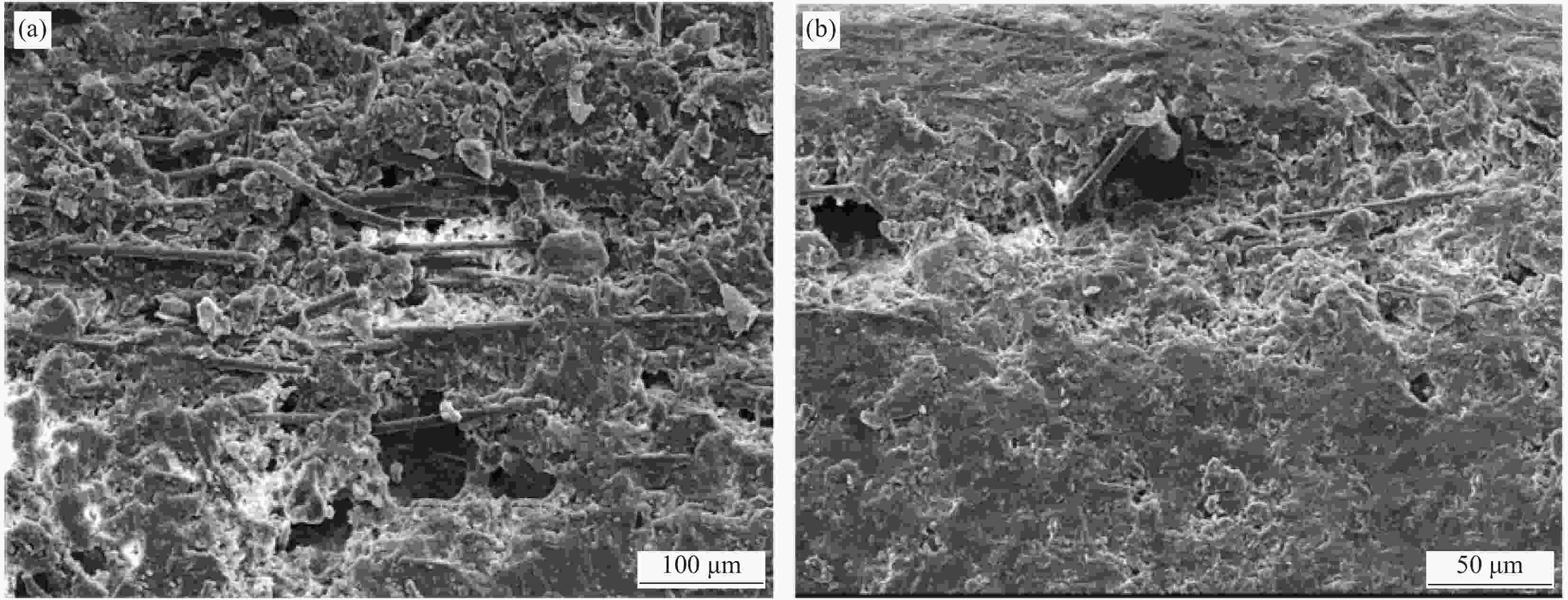

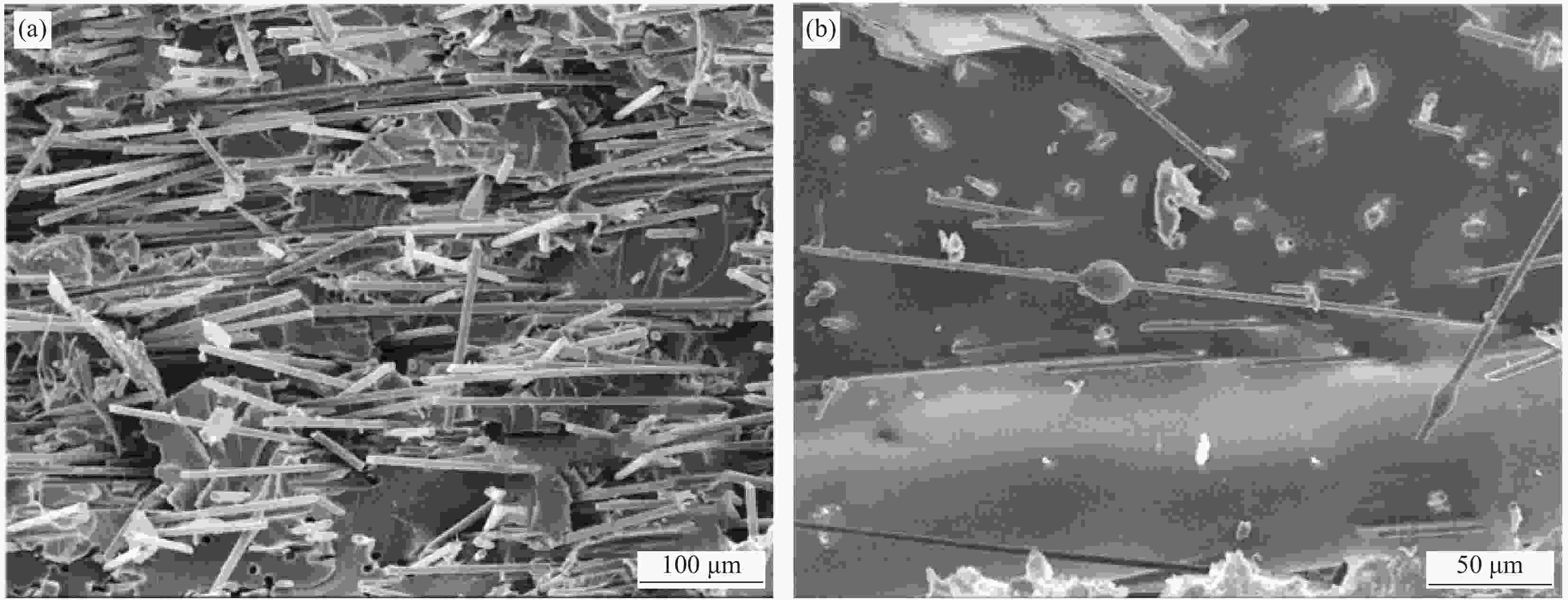

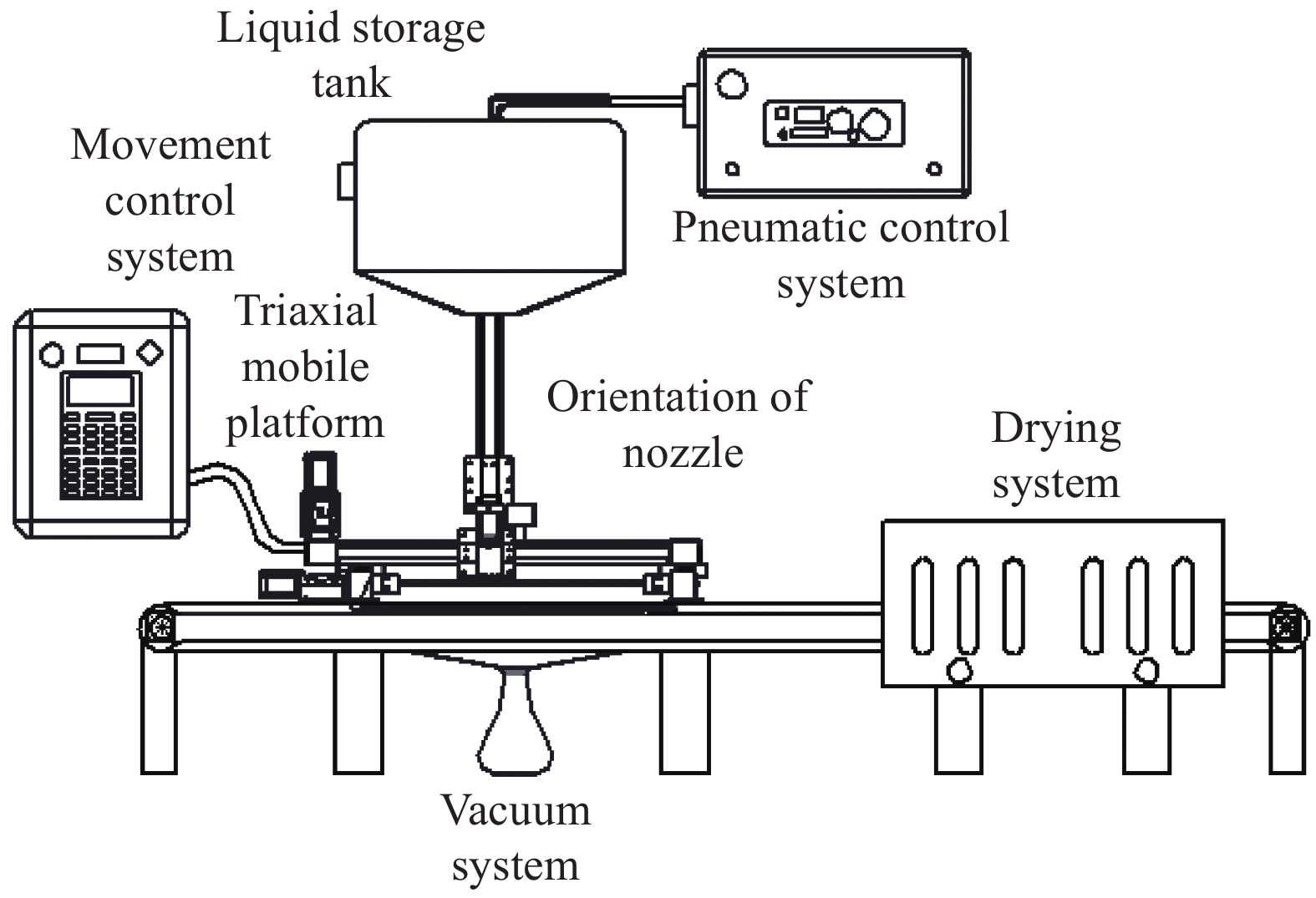

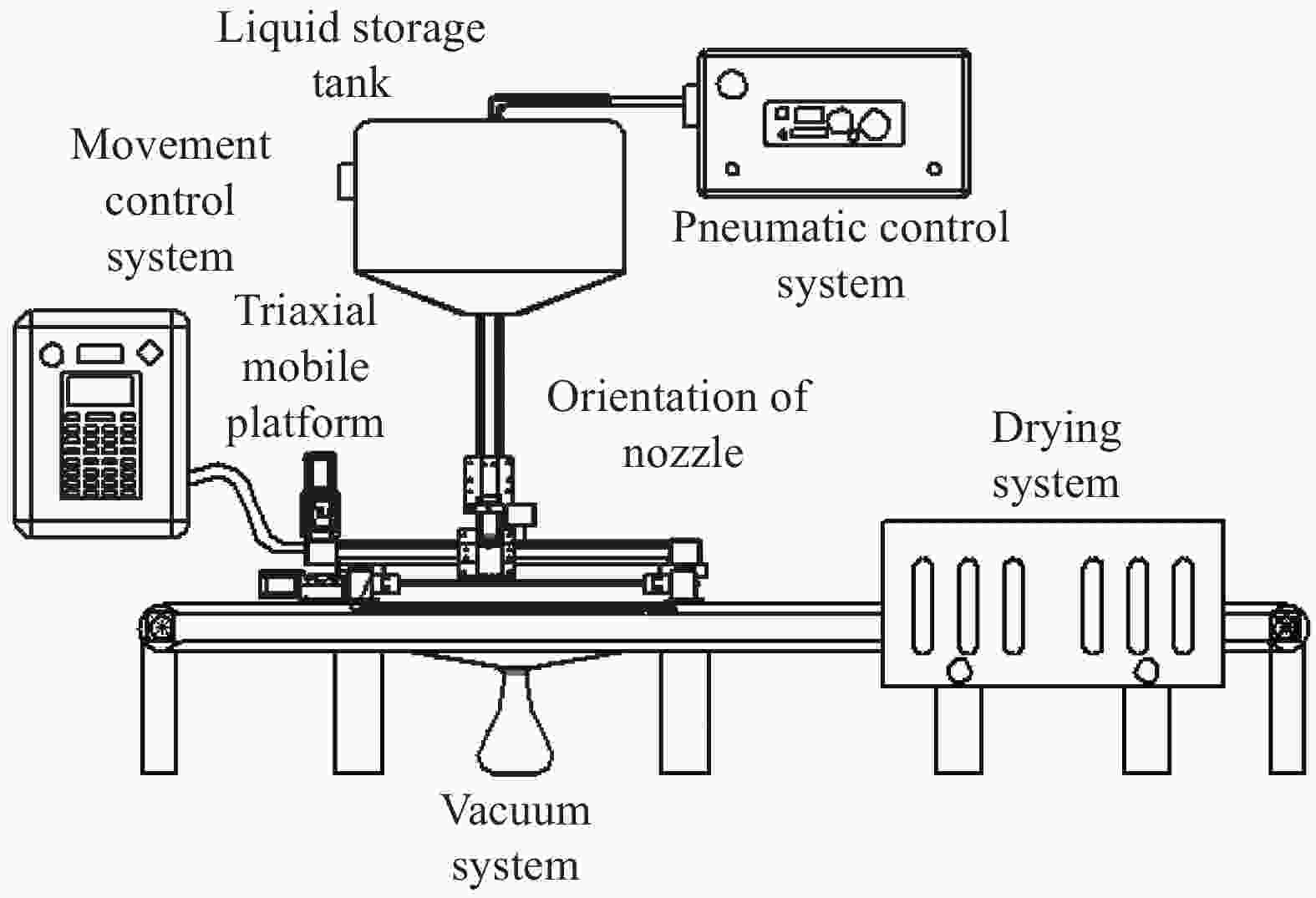

Abstract: Despite carbon fiber/epoxy (CF/EP) composites have the characteristics of excellent mechanical properties, light weight and corrosion resistance, problems such as high cost and severe environmental impact of waste restrict their further applications. Most of the recycled carbon fibers (RCF) recovered by the existing methods are fluffy, short and entangled with each other, which limit its mechanical properties. To address this issue, a wet fiber orientation technology was proposed to reorient and arrange RCF with different lengths. An oriented fiber felt was obtained via this method and RCF/EP fabricate specimens were prepared by compression moulding. The orientation tensor in the 2D plane was applied to evaluate the preferential alignment degree (DPA) of the fiber. The microstructure and properties of the composites were analyzed by SEM and mechanical tests, respectively. The results show that the increasing of RCF length leads to poor fiber orientation. The mechanical properties of the composites are improved with the increase of RCF length and DPA. Compared with 2 mm RCF, the DPA of 6 mm RCF decreases by about 11%, whereas the tensile strength and modulus, flexural strength and modulus of the reinforced resin matrix composites increase by 63.6%, 91.5%, 48.8% and 43.0%, respectively. -

表 1 实验方案

Table 1. Experimental schemes

No. Scheme Abbreviation 1 2 mm Unoriented recycled carbon fiber 2URCF 2 2 mm Oriented recycled carbon fiber 2ORCF 3 2 mm Oriented virgin carbon fiber 2OVCF 4 4 mm Oriented recycled carbon fiber 4ORCF 5 6 mm Unoriented recycled carbon fiber 6URCF 6 6 mm Oriented recycled carbon fiber 6ORCF 7 6 mm Oriented virgin carbon fiber 6OVCF 8 Pure epoxy resin EP 表 2 碳纤维/环氧树脂 (CF/EP)复合材料中各参数的实测值及单项误差

Table 2. Measured values of parameters and the errors of carbon fiber/epoxy (CF/EP) composites

Component Parameter Measured value Single error RCF ρ1/(g·cm−3) 1.78 0.01 w1/wt% 11.5 0.5 EP ρ2/(g·cm−3) 1.12 0.02 w2/wt% 85.5 0.5 HEC ρ3/(g·cm−3) 0.75 0.01 w3/wt% 3.0 0.5 CF/EP composite ρ/(g·cm−3) 1.12 0.01 Notes: RCF—Recycled carbon fiber; HEC—Hydroxyethyl cellulose; ρ—Density; w—Weight fraction. 表 3 2 mm RCF不同实验组的纤维取向度DPA

Table 3. Preferential alignment degree DPA of 2 mm RCF under various experimental conditions

Group Long axes of the ellipse m Short axes of the ellipse n Included angle θ/(°) DPA/% 2URCF 0.691 0.309 135.8 38.1 2ORCF* 0.842 0.158 9.9 68.4 2ORCF(90°) 0.945 0.055 165.5 89.0 2ORCF 0.983 0.017 11.7 96.5 表 4 不同长度RCF实验组的DPA

Table 4. DPA of different length RCF groups

Group Long axes of the ellipse m Short axes of the ellipse n Included angle θ/(°) DPA/% 2ORCF 0.983 0.017 11.7 96.5 4ORCF 0.961 0.039 4.2 91.9 6ORCF 0.924 0.076 10.4 84.9 表 5 RCF与VCF实验组的DPA

Table 5. DPA of the RCF and VCF experimental groups

Group Long axes of the ellipse m Short axes of the ellipse n Included angle θ/(°) DPA/% 2ORCF 0.983 0.017 11.7 96.5 2OVCF 0.986 0.014 10.4 97.2 6ORCF 0.924 0.076 10.4 84.7 6OVCF 0.921 0.079 11.4 84.2 -

[1] JIA X L, ZHU J M, LI W B, et al. Compressive and tensile response of CFRP cylinders induced by multi-walled carbon nanotubes[J]. Composites Science and Technology,2015,110:35-44. doi: 10.1016/j.compscitech.2014.10.023 [2] 杨斌. 碳纤维复合材料回收及再利用研究与产业化进展[R]. 上虞: 2016废塑料及其再生循环利用产业发展交流会, 2016.YANG Bin. Research and industrialization progress of carbon fiber composites recycling and reuse[R]. Shangyu: Waste Plastics and Recycling Industry Development Exchange Conference, 2016(in Chinese). [3] MENG F, ELSA A O, ZHAO Y Y, et al. Comparing life cycle energy and global warming potential of carbon fibre composite recycling technologies and waste management options[J]. ACS Sustainable Chemistry & Engineering,2018,6(8):9854-9865. [4] SOUZA C, OPELT C, CANDIDO G, et al. Reuse of uncured carbon fiber/epoxy resin prepreg scraps: Mechanical behavior and environmental response[J]. ACS Sustainable Chemistry & Engineering,2018,7(2):2200-2206. [5] TAPPER R J, LONGANA M L, YU H N, et al. Development of a closed-loop recycling process for discontinuous carbon fibre polypropylene composites[J]. Composites Part B: Engineering,2018,146:222-231. doi: 10.1016/j.compositesb.2018.03.048 [6] STEPHEN M. Recycled carbon fiber key to mass market applications [EB/OL] (2018-12-7) [2021-03-23]. https://www.plasticstoday.com/recycling/recycled-carbon-fiber-key-mass-market-applications. [7] SONG W, MAGID A, LI D, et al. Application of recycled carbon-fibre-reinforced polymers as reinforcement for epoxy foams[J]. Journal of Environmental Management,2020,269:110766. doi: 10.1016/j.jenvman.2020.110766 [8] AKBAR A, LIEW K M. Assessing recycling potential of carbon fiber reinforced plastic waste in production of eco-efficient cement-based materials[J]. Journal of Cleaner Production,2020,274:123001. doi: 10.1016/j.jclepro.2020.123001 [9] JAGADISH P R, KHALID M, LAU P L, et al. Cost effective thermoelectric composites from recycled carbon fibre: From waste to energy[J]. Journal of Cleaner Production,2018,195:1015-1025. doi: 10.1016/j.jclepro.2018.05.238 [10] BURN D T, HARPER L T, JOHNSON M, et al. The usability of recycled carbon fibres in short fibre thermoplastics: Interfacial properties[J]. Journal of Materials Science,2016,51(16):7699-7715. doi: 10.1007/s10853-016-0053-y [11] LI X, BAI R B, MCKECHNIE J. Environmental and financial performance of mechanical recycling of carbon fibre reinforced polymers and comparison with conventional disposal routes[J]. Journal of Cleaner Production,2016,127:451-460. doi: 10.1016/j.jclepro.2016.03.139 [12] JIANG G, WALKER G S, WONG K H, et al. Surface characterisation of carbon fibre recycled using fluidised bed[J]. Applied Surface Science,2008,254(9):2588-2593. doi: 10.1016/j.apsusc.2007.09.105 [13] 成焕波, 黄海鸿, 刘志峰, 等. 碳纤维复合材料在超临界正丁醇中降解的反应动力学[J]. 复合材料学报, 2016, 33(9):1922-1930.CHENG Huanbo, HUANG Haihong, LIU Zhifeng, et al. Reaction kinetics of degradation of carbon fiber-reinforced plastic in supercritical n-butanol[J]. Acta Materiae Compositae Sinica,2016,33(9):1922-1930(in Chinese). [14] VYAKARNAM M N, DRZAL L T. Composite material of aligned discontinuous fibers: US Patent, 6025285[P]. 2000-02-15. [15] BAGG G E G, EVANS M E N, PRYDE A W H. The glycerine process for the alignment of fibers and whiskers[J]. Composites,1969,1(2):97-100. doi: 10.1016/0010-4361(69)90007-X [16] YU H, POTTER K D, WISNOM M R. A novel manufacturing method for aligned discontinuous fibre composites (high performance-discontinuous fibre method)[J]. Compo-sites Part A: Applied Science and Manufacturing,2014,65:175-185. doi: 10.1016/j.compositesa.2014.06.005 [17] FLEMMING T, KRESS G, FLEMMING M. A new aligned short-carbon-fiber-reinforced thermoplastic prepreg[J]. Advanced Composite Materials,1996,5:151-159. doi: 10.1163/156855196X00068 [18] 黄海鸿, 张保玉, 赵志培. 超临界正丁醇对回收碳纤维复合材料的降解及表征[J]. 高等学校化学学报, 2017, 38(9):1687-1694. doi: 10.7503/cjcu20170037HUANG Haihong, ZHANG Baoyu, ZHAO Zhipei. Degredation and characterization of recycling carbon fiber/epoxy resin composites in supercritical n-butanol[J]. Chemical Journal of Chinese Universities,2017,38(9):1687-1694(in Chinese). doi: 10.7503/cjcu20170037 [19] 全国纤维增强塑料标准化技术委员会. GB/T 1447—2005 纤维增强塑料拉伸性能测试方法 [S]. 北京: 中国标准出版社, 2006.Standardization Administration of the People’s Republic of China. GB/T 1447—2005 Fiber-reinforced plastics compo-sites-determination of flexural properties[S]. Beijing: China Standards Press, 2006(in Chinese). [20] 全国纤维增强塑料标准化技术委员会. GB/T 1449—2005 纤维增强塑料弯曲性能测试方法[S]. 北京: 中国标准出版社, 2006.Standardization Administration of the People’s Republic of China. GB/T 1449—2005 Fiber-reinforced plastics compo-sites-determination of tensile properties[S]. Beijing: China Standards Press, 2006(in Chinese). [21] ADVANI S G, TUCKER C L. The use of tensors to describe and predict fiber orientation in short fiber composites[J]. Journal of Rheology,1987,31(8):751-784. [22] LIU Z, TURNER T A, WONG K H, et al. Development of high performance recycled carbon fibre composites with an advanced hydrodynamic fibre alignment process[J]. Journal of Cleaner Production,2021,278:123785. [23] FAN Z H, ADVANI S G. Characterization of orientation state of carbon nanotubes in shear flow[J]. Polymer,2005,46(14):5232-5240. doi: 10.1016/j.polymer.2005.04.008 [24] YAO S H, YUAN J K, ZHOU T, et al. Stretch-modulated carbon nanotube alignment in ferroelectric polymer composites: Characterization of the orientation state and its influence on the dielectric properties[J]. Journal of Physical Chemistry C,2011,115(40):20011-20017. doi: 10.1021/jp205444x [25] LIU W, HUANG H H, CHENG H B, et al. CFRP reclamation and remanufacturing based on a closed-loop recycling process for carbon fibers using supercritical n-butanol[J]. Fibers and Polymers,2020,21(3):604-618. doi: 10.1007/s12221-020-9575-7 -

下载:

下载: