Integrated manufacturing and performance study of continuous functionally graded materials-structures based on multi-material 3D printing and constraint sacrifice layer

-

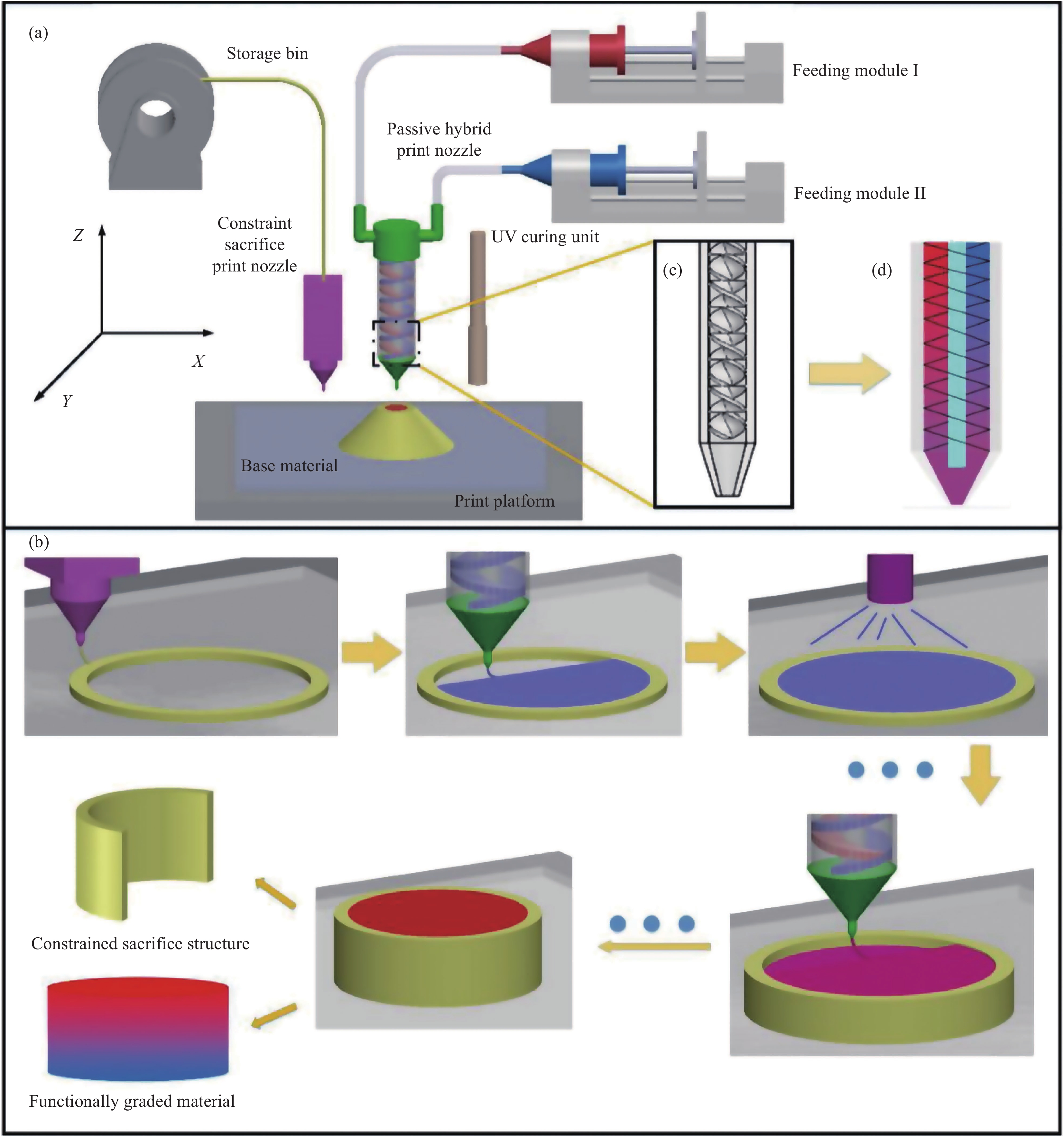

摘要: 针对现有功能梯度材料制备技术存在低黏度液体难以精准控形、层间结合强度差、成形结构单一等方面的不足和局限性,提出了一种基于多材料3D打印和约束牺牲层连续功能梯度材料-结构一体化制造新工艺,实现了聚合物基连续功能梯度材料的全新制备。通过理论分析和实验研究,揭示了挤出速度、打印速度、线间距等主要工艺参数对打印连续功能梯度材料质量和性能的影响规律。利用自主搭建的实验装置制备的石墨烯/光敏树脂介电功能梯度材料(d-FGM),实现了聚合物基连续功能梯度绝缘子的一体化制造,与均质光敏树脂相比,介电常数增加了1倍,电阻率降低了93.3%,沿面电场强度提升幅值超过了14%。Al2O3/聚二甲基硅氧烷(Al2O3/PDMS)连续变刚度功能梯度材料,相较于单一PDMS材料,质量分数为40wt%的Al2O3一侧刚度增加了1倍,实现了Al2O3粉末的连续梯度分布。该3D打印工艺为聚合物基连续功能梯度材料的制备提供了一种低成本、高效率的解决方案。Abstract: An integrated manufacturing of continuous functionally graded materials-structures based on multi-material 3D printing and constrained sacrificial layer was proposed to solve the limitations of the existing functionally graded material preparation methods, such as difficult to control the shape of low-viscosity liquids accurately, poor interlayer bonding strength, and simple forming structure. This technology is capable of realizing the brand-new preparation of polymer-based continuous functionally graded materials. Through theoretical analysis and experimental investigation, the influence law of main process parameters including extrusion speed, printing speed and line spacing, on the forming quality and performance of printing continuous functionally graded materials are revealed. Graphene/UV curable resin dielectric functionally graded material (d-FGM) were prepared by using lab self-developed device, and realizing the integrated manufacturing of polymer-based continuous functionally graded insulators. Compared with the homogeneous UV curable resin, the dielectric constant has doubled, the resistivity has been reduced by 93.3%, and the amplitude of the creeping electric field strength has increased by more than 14%. Besides, the rigidity of the Al2O3 side with 40% content has doubled than a single polydimethylsiloxane (PDMS) material. With the features of realizing the continuous gradient distribution of the Al2O3. The 3D printing process provides a low-cost and high-efficiency solution for the preparation of polymer-based continuous functionally graded materials.

-

表 1 材料组分变化

Table 1. Change of material composition

No. Feeding speed ratio (RI∶RII) 1 RI=15 r/min 2 RI∶RII=4∶1 3 RI∶RII=3∶2 4 RI∶RII=2∶3 5 RI∶RII=1∶4 6 RI=0 r/min Notes: RI—Speed of feeding module I; RII—Speed of feeding module II. 表 2 Al2O3/PDMS功能梯度材料层间拉伸对比实验数据

Table 2. Experimental data of interlayer tensile for Al2O3/PDMS functionally graded material

No. Single-layer one-step curing Single-layer two-step curing Max load/N Interlaminar tensile strength/MPa Max load/N Interlaminar tensile strength/MPa 1 256.8 0.642 462.4 1.156 2 247.2 0.618 456.3 1.141 3 229.2 0.573 451.6 1.129 4 220.4 0.551 445.2 1.113 5 210.4 0.526 438.8 1.097 6 119.2 0.498 432.8 1.082 -

[1] SALEH B, JIANG J H, FATHI R, et al. 30 Years of functionally graded materials: An overview of manufacturing methods, applications and future challenges[J]. Compo-sites Part B,2020,201:108376. doi: 10.1016/j.compositesb.2020.108376 [2] NAEBE M, SHIRVANIMOGHADDAM K. Functionally graded materials: A review of fabrication and properties[J]. Applied Materials Today,2016,5:223-245. doi: 10.1016/j.apmt.2016.10.001 [3] LOH G H, PEI E, HARRISON D, et al. An overview of functionally graded additive manufacturing[J]. Additive Manufacturing,2018,23:34-44. doi: 10.1016/j.addma.2018.06.023 [4] ALMASI D, SADEGHI M, LAU W J, et al. Functionally graded polymeric materials: A brif review of current fabrication methods and introduction of a novel fabrication method[J]. Materials Science & Engineering C,2016,64:102-107. [5] 杨昆, 张广明, 李晓强, 等. 基于电场驱动熔融喷射聚合物基复合材料高分辨率3D打印[J]. 机械工程学报, 2020, 56(23):193-202. doi: 10.3901/JME.2020.23.193YANG Kun, ZHANG Guangming, LI Xiaoqiang, et al. High-resolution 3D printing of polymer matrix composites based on electric-field-driven fusion jetting[J]. Journal of Mecha-nical Engineering,2020,56(23):193-202(in Chinese). doi: 10.3901/JME.2020.23.193 [6] 胡艺伟, 李亚智, 李彪, 等. 纤维增强聚合物基复合材料熔融堆积成型技术的研究进展及产品的力学性能[J]. 复合材料学报, 2021, 38(4): 976-996.HU Yiwei, LI Yazhi, LI Biao, et al. 3D printed fibre-reinforced polymer composites—Review of the fused deposi-tion modeling process and mechanical performance of products [J]. Acta Materiae Compositae Sinica, 2021, 38(4): 976-996(in Chinese). [7] 康泽天, 周博, 薛世峰. 功能梯度形状记忆合金复合梁的力学行为[J]. 复合材料学报, 2019, 36(8):1901-1910.KANG Zetian, ZHOU Bo, XUE Shifeng. Mechanical behaviors of functionally graded shape memory alloy composite beam[J]. Acta Materiae Compositae Sinica,2019,36(8):1901-1910(in Chinese). [8] 徐仙, 陈鹏起, 台运霄, 等. 钨铜梯度材料热震过程中显微组织及热性能[J]. 复合材料学报, 2021, 38(12): 4205-4211.XU Xian, CHEN Pengqi , TAI Yunxiao, et al. Microstructure and thermal properties of W-Cu graded materials during thermal shock test[J]. Acta Materiae Compositae Sinica, 2021, 38(12): 4205-4211(in Chinese). [9] LONG J, NAND A, RAY S. Application of spectroscopy in additive manufacturing[J]. Materials,2021,14(1):203. doi: 10.3390/ma14010203 [10] 李皓鹏, 李宁, 颜家振, 等. 多层陶瓷结构Al2O3-Fe2O3/3Y-TZP 梯度复合陶瓷的制备及性能[J]. 复合材料学报, 2019, 36(3):685-692.LI Haopeng, LI Ning, YAN Jiazhen, et al. Preparation and properties of Al2O3-Fe2O3/3Y-TZP gradient composite ceramics with multilayer ceramic structure[J]. Acta Materiae Compositae Sinica,2019,36(3):685-692(in Chinese). [11] LIM H R, KIM H S, QAZI R, et al. Advanced soft materials, sensor integrations, and applications of wearable flexible hybrid electronics in healthcare, energy, and environment[J]. Advanced Materials,2020,32(15):1901924. doi: 10.1002/adma.201901924 [12] WEHNER M, TRUBY R L, FITZGERALD D J, et al. An integrated design and fabrication strategy for entirely soft, autonomous robots[J]. Nature,2016,536(7617):451-455. doi: 10.1038/nature19100 [13] 时晓梅, 徐对功, 侯代水, 等. 聚合物梯度结构及其梯度功能复合材料研究的最新进展[J]. 高分子通报, 2011(9):71-80.SHI Xiaomei, XU Duigong, HOU Daishui, et al. Research progress in polymer gradient structure and functional gradient composites[J]. Polymer Bulletin,2011(9):71-80(in Chinese). [14] 穆中国, 罗一丁. 聚合物梯度材料的制备及应用研究[J]. 化工新型材料, 2010, 38(5):37-40. doi: 10.3969/j.issn.1006-3536.2010.05.012MU Zhongguo, LUO Yiding. Study on preparation and appli-cation of gradient polymer materials[J]. New Chemical Materials,2010,38(5):37-40(in Chinese). doi: 10.3969/j.issn.1006-3536.2010.05.012 [15] 兰红波, 李涤尘, 卢秉恒. 微纳尺度3D打印[J]. 中国科学: 技术科学, 2015, 45(9):919-940. doi: 10.1360/N092014-00397LAN Hongbo, LI Dichen, LU Bingheng. Micro and nanoscale 3D printing[J]. SCIENTIA SINICA Technologica,2015,45(9):919-940(in Chinese). doi: 10.1360/N092014-00397 [16] WEI C, ZHANG Z Z, CHENG D X, et al. An overview of laser-based multiple metallic material additive manufacturing: From macro-to micro-scales[J]. International Journal of Extreme Manufacturing,2021,3(1):47-70. [17] 程凯, 兰红波, 邹淑亭, 等. 多材料多尺度3D打印主动混合喷头的研究[J]. 中国科学: 技术科学, 2017, 47(2):149-162. doi: 10.1360/N092016-00312CHENG Kai, LAN Hongbo, ZOU Shuting, et al. Research on active mixing printhead for multi-material and multi-scale 3D printing[J]. SCIENTIA SINICA Technologica,2017,47(2):149-162(in Chinese). doi: 10.1360/N092016-00312 [18] 张源值, 杨建军, 高凡, 等. PDMS/SiC功能梯度衬底3D打印制备和性能研究[J]. 中国科学: 技术科学, 2020, 50(5):593-602. doi: 10.1360/SST-2019-0324ZHANG Yuanzhi, YANG Jianjun, GAO Fan, et al. PDMS/SiC functionally gradient substrate fabricated by 3D printing and its performances[J]. SCIENTIA SINICA Technologica,2020,50(5):593-602(in Chinese). doi: 10.1360/SST-2019-0324 [19] GIACHINI P A G S, GUPTA S S, WANG W, et al. Additive manufacturing of cellulose-based materials with continuous, multidirectional stiffness gradients[J]. Science Advances,2020,6(8):0929. doi: 10.1126/sciadv.aay0929 [20] SCHWARTZ J J, BOYDSTON A J. Multimaterial actinic spatial control 3D and 4D printing[J]. Nature Communications,2019,10(1):172-196. doi: 10.1038/s41467-018-08076-y [21] KHATRI B, FREY M, AHMED R F, et al. Development of a multi-material stereolithography 3D printing device[J]. Micromachines,2020,11(5):532-549. doi: 10.3390/mi11050532 [22] Institute of Electrical and Electronics Engineers. ASTM D4496-1987 Test method for DC resistance or conductance of moderately conductive materials [S]. United States: American Society for Testing and Materials International, 1987. [23] Institute of Electrical and Electronics Engineers. ASTM D150-1994 Test methods for AC loss characteristics and permittivity (dielectric constant) of solid electrical insulation [S]. United States: American Society for Testing and Materials International, 1994. [24] American Society for Testing and Materials. ASTM D3039/D3039M-2014 Standard test method for tensile properties of polymer matrix composite materials[S]. United States: American Society for Testing and Materials International, 2014. -

下载:

下载: