Damage analysis of cold recycled mixture under freeze-thaw environment based on CT technology

-

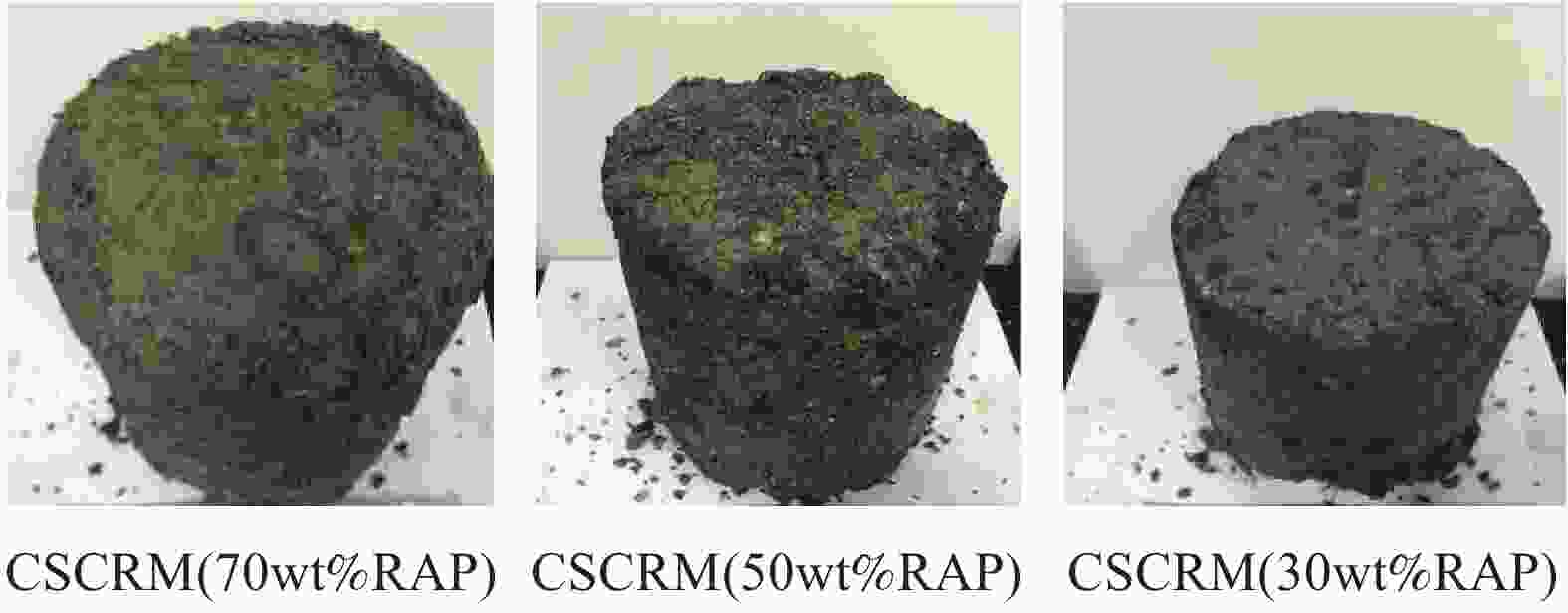

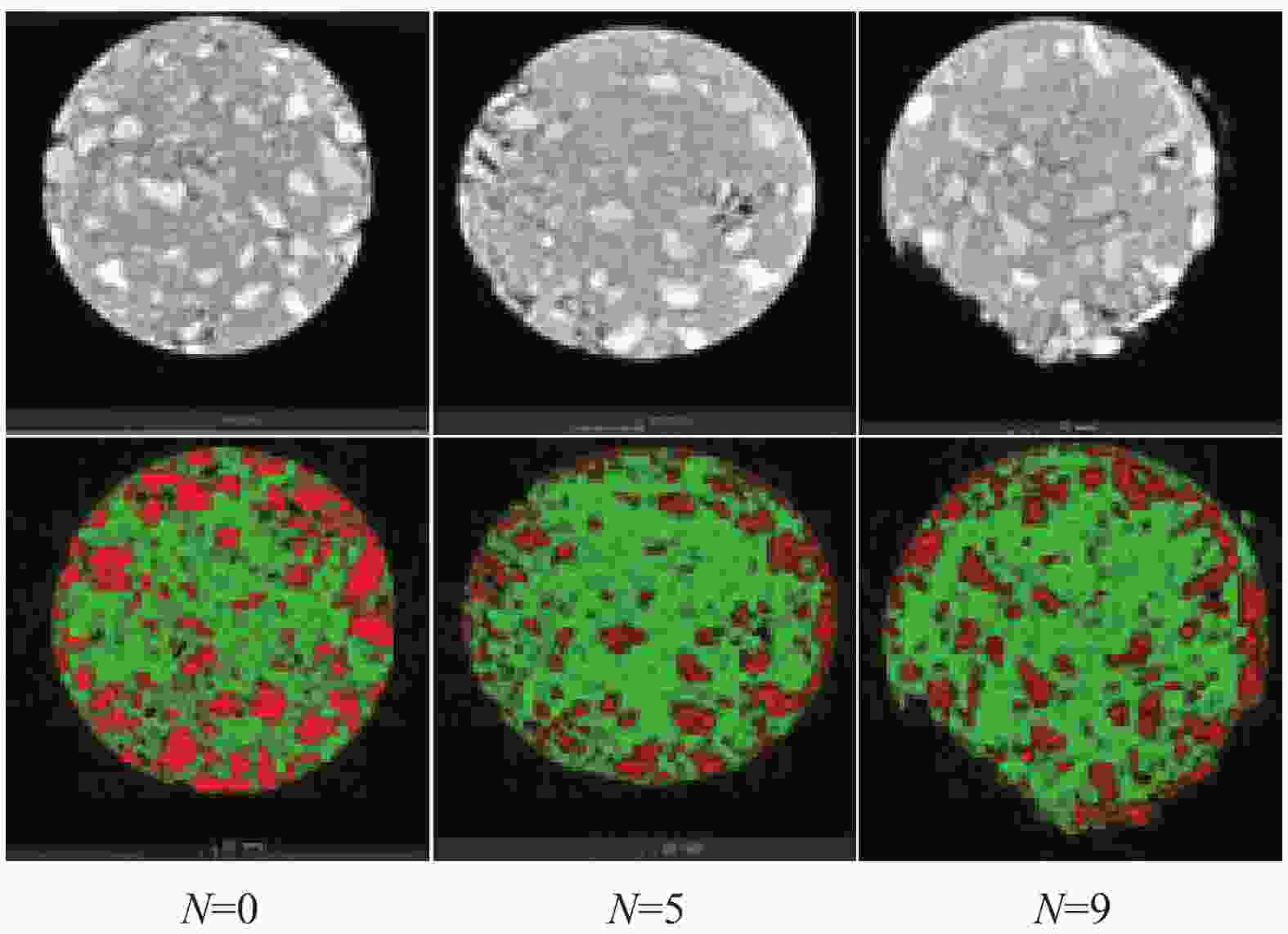

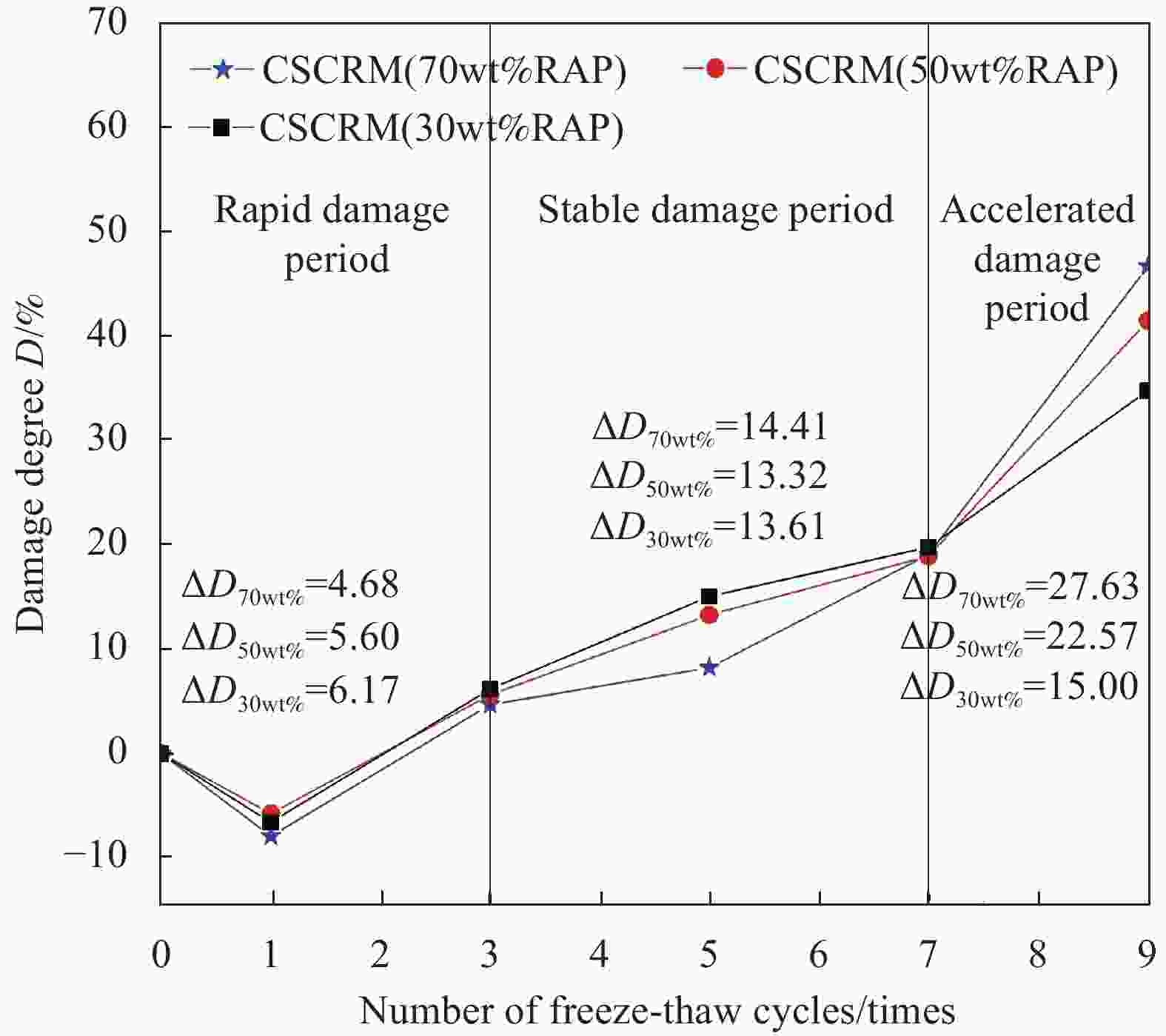

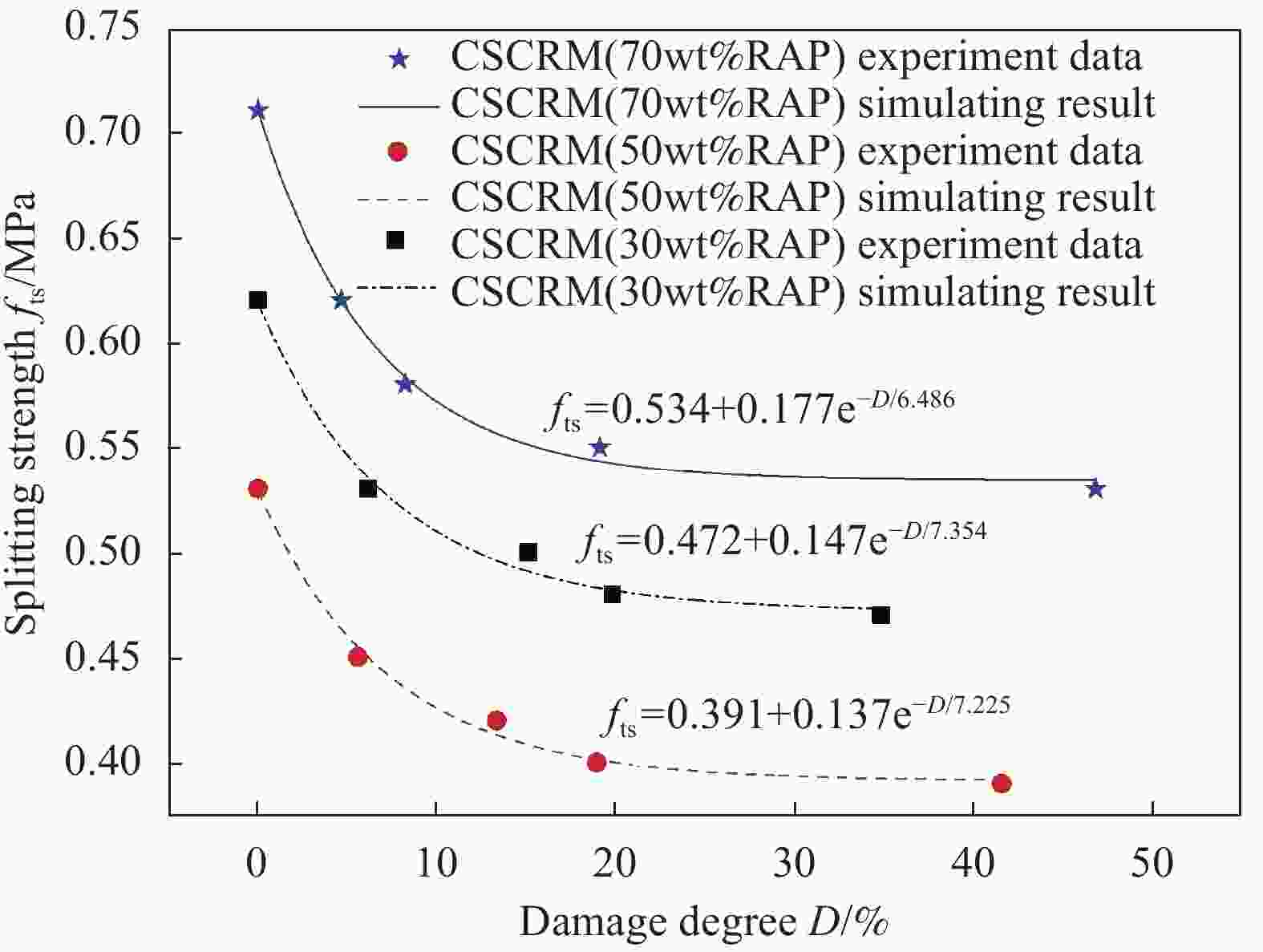

摘要: 通过室内实验揭示冻融环境下水泥稳定冷再生混合料细观结构的损伤演化规律,并分析水泥和旧路面沥青材料(RAP)在不同的冻融循环时期对其损伤的影响。使用CT机对冻融循环后的试件进行扫描,获得二维断层扫描图像。利用图像处理技术对扫描断面进行分析,并以图像中CT均值的变化为基础引入损伤变量。研究结果表明:随着冻融循环次数n的增加,混合料断面的CT均值呈现出先增大后减小的变化规律;损伤变量则表现出先减小后增大的变化趋势,反映出了冻融环境下水泥稳定冷再生混合料从初始细观损伤到宏观破损的全过程,可分为4个阶段:即

$N \leqslant 1$ 、$1 < N \leqslant 3$ 、$3 < N \leqslant 7$ 和$7 < N \leqslant 9$ ,且在N小于7次时水泥含量对试件损伤有显著影响,水泥可提高混合料的粘结性及早期强度;大于7次时试件的损伤主要受到RAP掺量的影响,过高的RAP含量会加剧混合料的损伤。Abstract: The development of meso-damage of cement stabilized cold recycled mixture under freeze-thaw environment was revealed by indoor test, and the effects of cement and recycled asphalt pavement material (RAP) on its damage in different freeze-thaw cycles were analyzed. The specimen after freeze-thaw cycle was scanned by CT machine, and the batch of 2D slice images were obtained. The cross section was analyzed by using the image processing technology, and the damage variable was introduced based on the change of the CT mean value in the image. The results show that with the increase of the number of freeze-thaw cycles, the average CT of mixture cross section increases at first and then decreases. On the other hand, the damage variable first decreases and then increases, which reflects the whole process of cement stable cold recycled mixture from initial meso damage to macroscopic damage in freeze-thaw environment, which can be divided into four stages, i.e.$N \leqslant 1$ ,$1 <N \leqslant 3$ ,$3 < N \leqslant 7$ and$7 < N \leqslant 9$ . When the number of freeze-thaw cycles is less than 7, the cement content has a significant effect on the specimen damage, and the addition of cement can improve the adhesion and early strength of the mixture. When the number of freeze-thaw cycles is more than 7 times, the damage of the specimen is mainly affected by the content of RAP, and the excessive content of RAP will aggravate the damage of the mixture.-

Key words:

- recycled materials /

- freeze thaw cycle /

- CT /

- meso-damage /

- recycled asphalt pavement material

-

表 1 试件材料参数

Table 1. Material property parameters of specimen

Item Apparent density/(kg·m−3) Voidage/% Needle-like particle content/% Mud content/% RAP 2.653 47.3 16.4 0.3 0-5 mm aggregate 2.574 42.3 5.3 15.2 Note: RAP—Recycled asphalt pavement. 表 2 水泥稳定冷再生混合料(CSCRM)级配

Table 2. Gradation of cement stabilized cold recycled mixture (CSCRM)

Specimen Gradation of mixture/% 0.15

/mm0.60

/mm2.36

/mm4.75

/mm9.50

/mm19.0

/mm26.5

/mm31.5

/mmCSCRM(30wt%RAP) 11.1 37.5 53.9 71.5 84.2 96.7 99.8 100 CSCRM(50wt%RAP) 18.1 26.3 40.1 56.5 73.5 94.0 99.4 100 CSCRM(70wt%RAP) 5.0 16.9 26.5 40.7 62.1 91.9 99.2 100 表 3 CSCRM配合比

Table 3. Mix ratio of CSCRM

Specimen RAP test value

/wt%Aggregate/wt% Cement

/wt%Water

/wt%CSCRM(30wt%RAP) 27.65 64.52 2.76 5.07 CSCRM(50wt%RAP) 46.17 46.17 2.76 4.90 CSCRM(70wt%RAP) 63.87 27.37 4.56 4.20 表 4 CT机扫描参数

Table 4. Scanning parameters of CT machine

Voltage

/kVElectric current/mA Layer thickness/mm Reconstruction matrix Magnification 120 185 3 1024×1024 1 表 5 劈裂夹具参数

Table 5. Parameters of splitting fixture

Maximum bracket

block/mmWidth of left and right

gear of bracket/mmLength/

mm50×20 151, 101 305 表 6 3种不同配合比CSCRM的冻融劈裂强度

Table 6. Freeze-thaw splitting strength of CSCRM with three different combinations under different cycles

Freeze-thaw

timeSplitting strength/MPa CSCRM

(30wt%RAP)CSCRM

(50wt%RAP)CSCRM

(70wt%RAP)0 0.62 0.53 0.71 1 0.58 0.49 0.66 3 0.53 0.45 0.62 5 0.50 0.42 0.58 7 0.48 0.40 0.55 9 0.47 0.39 0.53 -

[1] 王宏. 全深式水泥稳定就地冷再生基层应用与耐久性能评价[J]. 公路, 2019, 64(6):1-8.WANG Hong. Application and durability evaluation of full-deep cement stabilized in-situ cold recycled mixture base[J]. Highway,2019,64(6):1-8(in Chinese). [2] 薄雪峰. 冻融循环对泡沫沥青冷再生混合料宏细观结构性能的影响[J]. 公路, 2018, 63(9):47-58.BO Xuefeng. Impact of freeze-thaw cycles on macro and micro structure and properties of foamed asphalt cold recycled asphalt mixtures[J]. Highway,2018,63(9):47-58(in Chinese). [3] GUO L, CARPINTERI A, SUN W, et al. Measurement and analysis of defects in high-performance concrete with three-dimensional micro-computer tomography[J]. Jour-nal of Southeast University (English Edition),2009,25(1):83-88. [4] SUZUKI T, OGATA H, TAKADA R, et al. Use of acoustic emission and X-ray computed tomography for damage evaluation of freeze-thawed concrete[J]. Construction and Building Materials,2010,24(12):2347-2352. doi: 10.1016/j.conbuildmat.2010.05.005 [5] CHEN J, DENG X, LUO Y, et al. Investigation of microstructural damage in shotcrete under a freeze-thaw environment[J]. Construction and Building Materials,2015,83:275-282. doi: 10.1016/j.conbuildmat.2015.02.042 [6] PROMENTILLA M A B, SUGIYAMA T. X-ray microtomography of mortars exposed to freezing-thawing action[J]. Journal of Advanced Concrete Technology,2010,8(2):97-111. doi: 10.3151/jact.8.97 [7] SUZUKI T, NISHIMURA S, SHIMAMOTO Y, et al. Damage estimation of concrete canal due to freeze and thawed effects by acoustic emission and X-ray CT methods[J]. Construction and Building Materials, 2020, 245: 118343. [8] 田威, 张鹏坤, 谢永利, 等. 冻融环境下基于CT技术混凝土孔隙结构的三维分布特征[J]. 长安大学学报(自然科学版), 2016, 36(3):49-55.TIAN Wei, ZHANG Pengkun, XIE Yongli, et al. 3D distribution characteristics on concrete porous structure under freeze-thaw environment based on CT technique[J]. Journal of Chang'an University (Natural Science Edition),2016,36(3):49-55(in Chinese). [9] 田威, 谢永利, 党发宁. 基于CT技术的混凝土冻融环境下细观损伤机理的试验研究[J]. 武汉大学学报(工学版), 2016, 49(3):397-401.TIAN Wei, XIE Yongli, DANG Faning. Experimental study of meso-damage mechanism of concrete under freezing-thawing environment based on CT technology[J]. En-gineering Journal of Wuhan University,2016,49(3):397-401(in Chinese). [10] 田威, 韩女, 张鹏坤. 基于CT技术的混凝土孔隙结构冻融损伤试验[J]. 中南大学学报(自然科学版), 2017, 48(11):3069-3075. doi: 10.11817/j.issn.1672-7207.2017.11.026TIAN Wei, HAN Nv, ZHANG Pengkun. Experiments on the freeze-thaw damage of concrete porous structure based on CT technique[J]. Journal of Central South University (Science and Technology),2017,48(11):3069-3075(in Chinese). doi: 10.11817/j.issn.1672-7207.2017.11.026 [11] 张倩, 李创军. 沥青混合料冻融劈裂微观结构损伤特性分析[J]. 公路交通科技, 2010, 27(2):6-9. doi: 10.3969/j.issn.1002-0268.2010.02.002ZHANG Qian, LI Chuangjun. Analysis of micro structural damage characteristics of freeze-thaw split asphalt mixtures[J]. Journal of Highway and Transportation Research and Development,2010,27(2):6-9(in Chinese). doi: 10.3969/j.issn.1002-0268.2010.02.002 [12] 司伟, 马骉, 汪海年, 等. 沥青混合料在冻融循环作用下的弯拉特性[J]. 吉林大学学报(工学版), 2013, 43(4):885-890.SI Wei, MA Biao, WANG Hainian, et al. Flexural tensile characteristics of asphalt mixture under freeze-thaw cycles[J]. Journal of Jilin University(Engineering and Technology Edition),2013,43(4):885-890(in Chinese). [13] 李兆生, 谭忆秋. 沥青混合料冻融损伤特性研究[J]. 中国科技论文, 2014, 9(11):1279-1281. doi: 10.3969/j.issn.2095-2783.2014.11.015LI Zhaosheng, TAN Yiqiu. Research on asphalt mixture freezing-thawing damage performance[J]. China Sciencepaper,2014,9(11):1279-1281(in Chinese). doi: 10.3969/j.issn.2095-2783.2014.11.015 [14] 徐金枝, 郝培文, 王宏, 等. 两种粘结料对泡沫沥青冷再生混合料性能的影响[J]. 复合材料学报, 2017, 34(4):687-693.XU Jinzhi, HAO Peiwen, WANG hong, et al. Influences of two binder materials on performance of cold recycled mixtures stabilized with foamed asphalt[J]. Acta Materiae Compositae Sinica,2017,34(4):687-693(in Chinese). [15] 魏唐中, 洪锦祥, 林俊涛. 水泥与乳化沥青对冷再生强度的影响及作用机理[J]. 建筑材料学报, 2017, 20(2):310-315. doi: 10.3969/j.issn.1007-9629.2017.02.027WEI Tangzhong, HONG Jinxiang, LIN Juntao. Effect and action mechanism of cement and emulsified asphalt on the strength of cold regeneration[J]. Journal of Building Materials,2017,20(2):310-315(in Chinese). doi: 10.3969/j.issn.1007-9629.2017.02.027 [16] 吴文亮, 卢家志, 涂志先. 基于X-ray CT和离散元法级配离析对沥青混合料骨架结构力学性能的影响[J]. 公路工程, 2020, 45(1):55-61.WU Wenliang, LU Jiazhi, TU Zhixian. Influence of gradation segregation on mechanical properties of asphalt mixture skeleton structure based on X-ray CT and discrete element method[J]. Highway Engineering,2020,45(1):55-61(in Chinese). [17] 彭蕾, 程英伟, 何晓鸣. 基于CT图像的AC-13C型沥青混合料冻融损坏细观结构分析[J]. 武汉轻工大学学报, 2019, 38(6):39-43. doi: 10.3969/j.issn.2095-7386.2019.06.008PENG Lei, CHENG Yingwei, HE Xiaoming. Microstructure analysis of freeze-thaw damage of AC-13C asphalt mixture based on CT image[J]. Journal of Wuhan Polytechnic University,2019,38(6):39-43(in Chinese). doi: 10.3969/j.issn.2095-7386.2019.06.008 [18] 杜少文. 外加材料对乳化沥青再生水泥稳定碎石混合料性能的影响[J]. 建筑材料学报, 2013, 16(2):360-364. doi: 10.3969/j.issn.1007-9629.2013.02.033DU Shaowen. Effect of additive materials on pavement performance of asphalt emulsion recycled cement stabilized aggregate mixture[J]. Journal of Building Materials,2013,16(2):360-364(in Chinese). doi: 10.3969/j.issn.1007-9629.2013.02.033 [19] 侯月琴, 纪小平, 刘陵庆. 水泥稳定再生集料的力学特性及影响因素研究[J]. 公路交通科技, 2016, 33(12):56-61.HOU Yueqin, JI Xiaoping, LIU Lingqing. Study on mechanical property and influencing factors of cement stabilized recycled aggregate[J]. Journal of Highway and Transportation Research and Development,2016,33(12):56-61(in Chinese). [20] 王一琪, 谭忆秋, 王兴隆. 水泥稳定碎石冻融损伤疲劳特性研究[J]. 公路, 2017, 62(4):239-242.WANG Yiqi, TAN Yiqiu, WANG Xinglong. Study on fatigue characteristics of freeze-thaw damage of cement stabilized macadam[J]. Highway,2017,62(4):239-242(in Chinese). [21] 李明欣, 张翼, 王选仓. 水泥掺量对再生混合料力学及干缩性能影响[J]. 河北农业大学学报, 2017, 40(4):119-123.LI Mingxin, ZHANG Yi, WANG Xuancang. Influence analysis of cement content on cement stabilized recycle asphalt mixtures for rural road[J]. Journal of Hebei Agricultural University,2017,40(4):119-123(in Chinese). [22] 王宏. 不同水泥掺量乳化沥青冷再生混合料细微观空隙分布特征[J]. 公路交通科技, 2016, 33(7):27-34. doi: 10.3969/j.issn.1002-0268.2016.07.005WANG Hong. Meso-microscopic void distribution characteristics of emulsified asphalt cold recycled mixture with different cement contents[J]. Journal of Highway and Transportation Research and Development,2016,33(7):27-34(in Chinese). doi: 10.3969/j.issn.1002-0268.2016.07.005 [23] 李国锋, 郝培文, 蒋鹤, 等. 冻融循环对泡沫沥青再生混合料微观结构的影响[J]. 北京工业大学学报, 2017, 43(10):1508-1513.LI Guofeng, HAO Peiwen, JIANG He, et al. Impacts of freeze-thaw cycles on microscopic characteristics of recycled mixture using foamed asphalt[J]. Journal of Beijing University of Technology,2017,43(10):1508-1513(in Chinese). [24] 李志刚, 郝培文, 徐金枝. 冻融循环作用对乳化沥青冷再生混合料抗剪性能的影响[J]. 材料导报, 2016, 30(10):121-125. doi: 10.11896/j.issn.1005-023X.2016.10.027LI Zhigang, HAO Peiwen, XU Jinzhi. Study on impacts of freeze-thaw cycles on the shear performances of emulsified asphalt cold recycle mixture[J]. Materials Reports,2016,30(10):121-125(in Chinese). doi: 10.11896/j.issn.1005-023X.2016.10.027 [25] 杨野, 徐剑, 杨彦海, 等. 冻融循环作用下乳化沥青冷再生混合料损伤分析[J]. 沈阳建筑大学学报(自然科学版), 2020, 36(5):869-876.YANG Ye, XU Jian, YANG Yanhai, et al. Damage analysis of cold recycled mixes using asphalt emulsion under freeze-thaw cycles[J]. Journal of Shenyang Jianzhu University (Natural Science),2020,36(5):869-876(in Chinese). [26] 中华人民共和国交通部(标准制定单位). 公路工程集料试验规程: JTG E42—2005[S]. 北京: 人民交通出版社, 2005.Ministry of Transport of the People’s Republic of China. Test methods of aggregate for highway engineering: JTG E42—2005[S]. Beijing: China Communications Press, 2005(in Chinese). [27] 中华人民共和国交通部. 公路路面基层施工技术细则: JTG/T F20—2015[S]. 北京: 人民交通出版社, 2015.Ministry of Transport of the People’s Republic of China. Technical guidelines for construction of highway roadbases: JTG/T F20—2015[S]. Beijing: China Communications Press, 2015(in Chinese). -

下载:

下载: