| [1] |

QIN S B, LEI Y T, BARCH C, et al. A high power density series-stacked energy buffer for power pulsation decoupling in single-phase converters[J]. IEEE Transactions on Power Electronics,2016,32(6):4905-4924.

|

| [2] |

LYU X F, LI Y C, CAO D. A SiC based high power density single-phase inverter with in-series and parallel power decoupling method[J]. IEEE Journal of Emerging Selected Topics in Power Electronics,2017,4(3):893-901.

|

| [3] |

PASSON S, GITIN L, MEISNER J. Investigating the properties of precision resistors for the application in high voltage DC dividers[C]//IEEE International Workshop on Applied Measurements for Power Systems. Aachen, 2016.

|

| [4] |

GUO F, QIAO B B. Corrosion behavior of a steel bar embedded in a cement-based conductive composite[J]. Construction Building Materials,2017,134(1):388-396.

|

| [5] |

MARIA M J, BALANAND S, ANAS S, et al. Zn-dust derived ultrafine grained ZnO non-linear ceramic resistors via in-situ thermal oxidation of cermet reactant mixture[J]. Materials Design,2016,92:387-396.

|

| [6] |

KUMAR R, BHARGAVA P. Fabrication of low specific resistance ceramic carbon composites by colloidal processing using glucose as soluble carbon source[J]. Bulletin of Materials Science,2017,40(6):1197-1202. doi: 10.1007/s12034-017-1463-4

|

| [7] |

KUMER R, CHANDRAPPA C N, APPAIASH S. Synthesis and characteristics of aluminium metal matrix composites using Al2O3 and SiC as reinforcement materials[J]. International Journal of Innovative Research in Advanced Engineering, 2014, 1(7): 247-250.

|

| [8] |

CHENG Y, ZHANG Y, WAN T, et al. Mechanical properties and toughening mechanisms of graphene platelets reinforced Al2O3/TiC composite ceramic tool materials by microwave sintering[J]. Materials Science Engineering: A,2016,680:190-196.

|

| [9] |

曾金珍, 慕玮, 杨建, 等. Al2O3颗粒形貌对注凝成型ZrO2/Al2O3陶瓷性能的影响[J]. 复合材料学报, 2014, 31(2):416-422.ZENG Jinzhen, MU Wei, YANG Jian, et al. Effect of particle morphology of Al2O3 on gelcasting of ZrO2/Al2O3 ceramics[J]. Acta Materiae Compositae Sinica,2014,31(2):416-422(in Chinese).

|

| [10] |

RAJABI A, GHAZALI M J, DAUD A. Chemical composition, microstructure and sintering temperature modifications on mechanical properties of TiC-based cermet—A review[J]. Materials Design,2015,67:95-106. doi: 10.1016/j.matdes.2014.10.081

|

| [11] |

李妤婕, 武志红, 张聪. 保护气氛下反应烧结MoSi2/Al2O3复合陶瓷[J]. 复合材料学报, 2017, 34(5):1034-1039.LI Yujie, WU Zhihong, ZHANG Cong. Fabrication of MoSi2/Al2O3 composites with reaction sintering method under protective atmosphere[J]. Acta Materiae Compositae Sinica,2017,34(5):1034-1039(in Chinese).

|

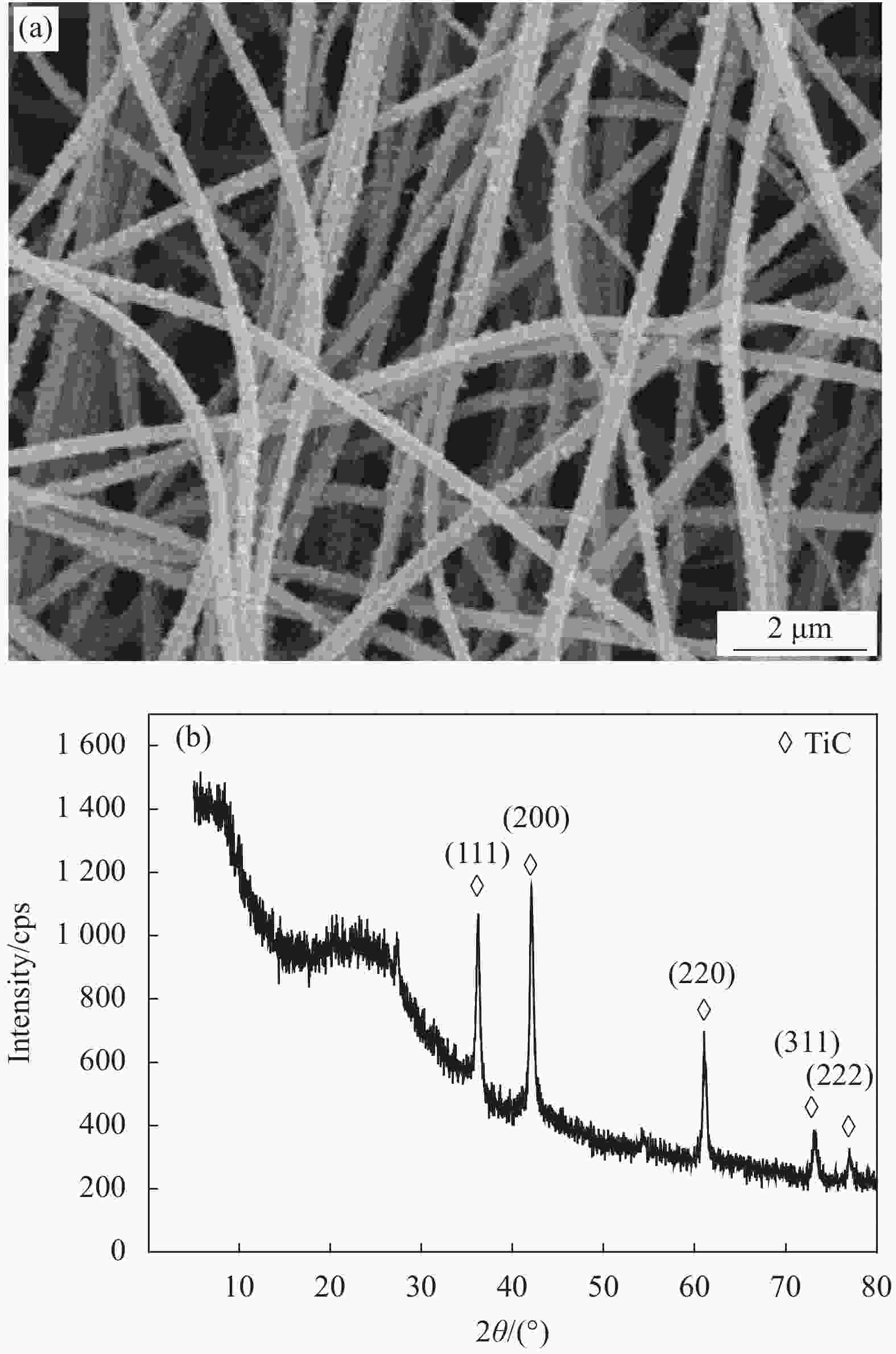

| [12] |

任会兰, 龙波, 宁建国, 等. ZrO2增韧Al2O3陶瓷的力学性能和增韧机制[J]. 复合材料学报, 2015, 32(3):776-781.REN Huilan, LONG Bo, NING Jianguo, et al. Mechanical properties and toughening mechanisms of ZrO2 toughened Al2O3 ceramics[J]. Acta Materiae Compositae Sinica,2015,32(3):776-781(in Chinese).

|

| [13] |

WANG J, LUI Y, YE J W, et al. The fabrication of multi-core structure cermets based on (Ti, W, Ta)CN and TiCN solid-solution powders[J]. International Journal of Refractory Metals Hard Materials,2017,64:294-300. doi: 10.1016/j.ijrmhm.2016.09.011

|

| [14] |

HUSSIUN S, BARBARIOL I, ROITTI S, et al. Electrical conductivity of an insulator matrix (alumina) and conductor particle (molybdenum) composites[J]. Journal of the European Cermiac Society,2003,23(2):315-321. doi: 10.1016/S0955-2219(02)00185-1

|

| [15] |

MIN G J, BAE S, KANG B C, et al. Surface discharge characteristics study on the laminated solid insulator in quasi-uniform electric field with dry air[J]. Journal of Electrical Engineering Technology,2015,10(2):603-609. doi: 10.5370/JEET.2015.10.2.603

|

| [16] |

LI G, LI S, PAN S, et al. Effect of electron irradiation on DC surface flashover of polyimide in vacuum[J]. IEEE Transactions on Dielectrics Electrical Insulation,2016,23(3):1846-1853. doi: 10.1109/TDEI.2016.005429

|

| [17] |

SONG J, SU Y, FAN H, et al. A novel design to produce high-strength and high-toughness alumina self-lubricated composites with enhanced thermal-shock resistance—Part I: Mechanical properties and thermal shock behavior of Al2O3/Mo-Al2O3 laminated composites[J]. Journal of the European Ceramic Society,2017,37(1):213-221. doi: 10.1016/j.jeurceramsoc.2016.08.016

|

| [18] |

ZHOU Y, GAO Y, WEI S, et al. Preparation and characterization of Mo/Al2O3 composites[J]. International Journal of Refractory Metals Hard Materials,2016,54:186-195. doi: 10.1016/j.ijrmhm.2015.07.033

|

| [19] |

张昊, 史忠旗, 胡梦杉, 等. Mo元素掺杂对氧化铝基陶瓷/金属复合材料微观形貌及介电性能的影响[J]. 稀有金属材料与工程, 2016, 45(10):2583-2586.ZHANG H, SHI Z Q, HU M S, et al. Influence of Mo doping on the microstructure and dielectric property of alumina ceramic/metal composites[J]. Rare Metal Materials En-gineering,2016,45(10):2583-2586(in Chinese).

|

| [20] |

ZHANG L, LIU Z, LU X, et al. Nano-clip based composites with a low percolation threshold and high dielectric constant[J]. Nano Energy,2016:550-557.

|

| [21] |

QU M, NILSSON F, QIN Y, et al. Electrical conductivity and mechanical properties of melt-spun ternary composites comprising PMMA, carbon fibers and carbon black[J]. Composites Science Technology,2017,150(29):24-31.

|

| [22] |

WU S, PENG S, WANG C, et al. The effect of dual-scale carbon fibre network on sensitivity and stretchability of wearable sensors[J]. Composites Science Technology,2018(165):138-139.

|

| [23] |

VO N H, DAO T D, JEONG H M. Electrically conductive graphene/poly (methyl methacrylate) composites with ultra-low percolation threshold by electrostatic self-assembly in aqueous medium[J]. Macromolecular Che-mistry and Physics,2015,216(7):770-782. doi: 10.1002/macp.201400560

|

| [24] |

GONG T, PENG S P, BAO R Y. Low percolation threshold and balanced electrical and mechanical performances in polypropylene/carbon black composites with a continuous segregated structure[J]. Composites Part B: Engineering,2016,99:348-357. doi: 10.1016/j.compositesb.2016.06.031

|

| [25] |

DEPLANCKE T, LAME O, BARRAU S. Impact of carbon nanotube prelocalization on the ultra-low electrical percolation threshold and on the mechanical behavior of sintered UHMWPE-based nanocomposites[J]. Polymer,2017,111:204-213. doi: 10.1016/j.polymer.2017.01.040

|

| [26] |

PALAIMIENE E, MACUTKEVIC J, BANYS J. Ultra-low percolation threshold in epoxy resin-onion-like carbon composites[J]. Applied Physics Letters,2018,113(3):033105. doi: 10.1063/1.5030526

|

| [27] |

DEMIRORS A, IMHOF A. BaTiO3, SrTiO3, CaTiO3, and BaxSr1−xTiO3 particles: A general approach for monodisperse colloidal perovskites[J]. Chemistry of Materials,2009,21(13):3002-3007. doi: 10.1021/cm900693r

|

| [28] |

SHI Z C, FAN R H, WANG X A, et al. Radio-frequency permeability and permittivity spectra of copper/yttrium iron garnet cermet prepared at low temperatures[J]. Journal of the European Ceramic Society,2015,35(4):1219-1225. doi: 10.1016/j.jeurceramsoc.2014.10.034

|

| [29] |

WANG L, BAI Y, LU X, et al. Ultra-low percolation threshold in ferrite-metal cofired ceramics brings both high permeability and high permittivity[J]. Scientific Reports,2015,5:7580-7584. doi: 10.1038/srep07580

|

| [30] |

LUX F. Models proposed to explain the electrical conductivity of mixtures made of conductive and insulating materials[J]. Journal of Materials Science,1993,28(2):285-301. doi: 10.1007/BF00357799

|

| [31] |

DIETRICH S. Introduction to percolation theory[M]. London: Taylor & Francis, 1985.

|

| [32] |

SUN Y, BAO H D, GUO Z X, et al. Modeling of the electrical percolation of mixed carbon fillers in polymer-based composites[J]. Macromolecules,2009,42(1):459-463. doi: 10.1021/ma8023188

|

| [33] |

SEN W, XU B Q, YANG B, et al. Preparation of TiC powders by carbothermal reduction method in vacuum[J]. Transactions of Nonferrous Metals Society of China,2011,21(1):185-190. doi: 10.1016/S1003-6326(11)60697-3

|

| [34] |

李瑗茹. RGO/Cu复合材料致密化工艺及电接触特性研究[D]. 哈尔滨: 哈尔滨工业大学, 2017.LI Yuanru. Research on densification process and electrical contact properties of RGO/Cu composites[D]. Harbin: Harbin Institute of Technology, 2017(in Chinese).

|

| [35] |

马婕, 王成国, 于美杰, 等. PAN基碳化纤维的电性能及应用[J]. 功能材料, 2010, 41(3):549-551.MA Jie, WANG Chengguo, YU Meijie, et al. Electrical property and application of PAN-based carbonaceous fibers[J]. Journal of Functional Materials,2010,41(3):549-551(in Chinese).

|

| [36] |

CHEN T, LI M, SONG S, et al. Biotemplate preparation of multilayered TiC nanoflakes for high performance symmetric supercapacitor[J]. Nano Energy,2020,71:337-342.

|

| [37] |

IRVINE J, SINCLAIR D C, WEST A. Electroceramics: Characterization by impedance spectroscopy[J]. Advanced Materials,1990,2(3):132-138. doi: 10.1002/adma.19900020304

|

| [38] |

陈军军. SiC基复相导电陶瓷的制备与性能研究[D]. 上海: 中国科学院大学(中国科学院上海硅酸盐研究所), 2018.CHEN Junjun. Preparation and properties of SiC based electrical conductive ceramics[D]. Shanghai: Shanghai Institute of Ceramics, Chinese Academy of Sciences, 2018(in Chinese).

|

| [39] |

杭晓聪. TiB2-B4C复相陶瓷的制备工艺及力学性能研究[D]. 北京: 北京理工大学, 2016.HANG Xiaocong. Preparation and mechanical properties of TiB2-B4C composite ceramics[D]. Beijing: Beijing Institute of Technology, 2016(in Chinese).

|

| [40] |

YI G, SAGI S, ZHANG L, et al. Electrospun nano-scaled glass fiber reinforcement of bis-GMA/TEGDMA dental composites[J]. Journal of Applied Polymer Science,2010,110(4):2063-2070.

|

| [41] |

康龙昭. 一维填料增强增韧陶瓷基复合树脂材料的研究[D]. 北京: 北京化工大学, 2016.KANG Longzhao. Study on one-dimensional filler reinforced and toughened ceramic matrix composite resin material[D]. Beijing: Beijing University of Chemical Technology, 2016(in Chinese).

|

下载:

下载: