Mechanical properties and damage failure of carbon fiber reinforced polymer composite sandwich structure with square honeycomb core using the interlocking method

-

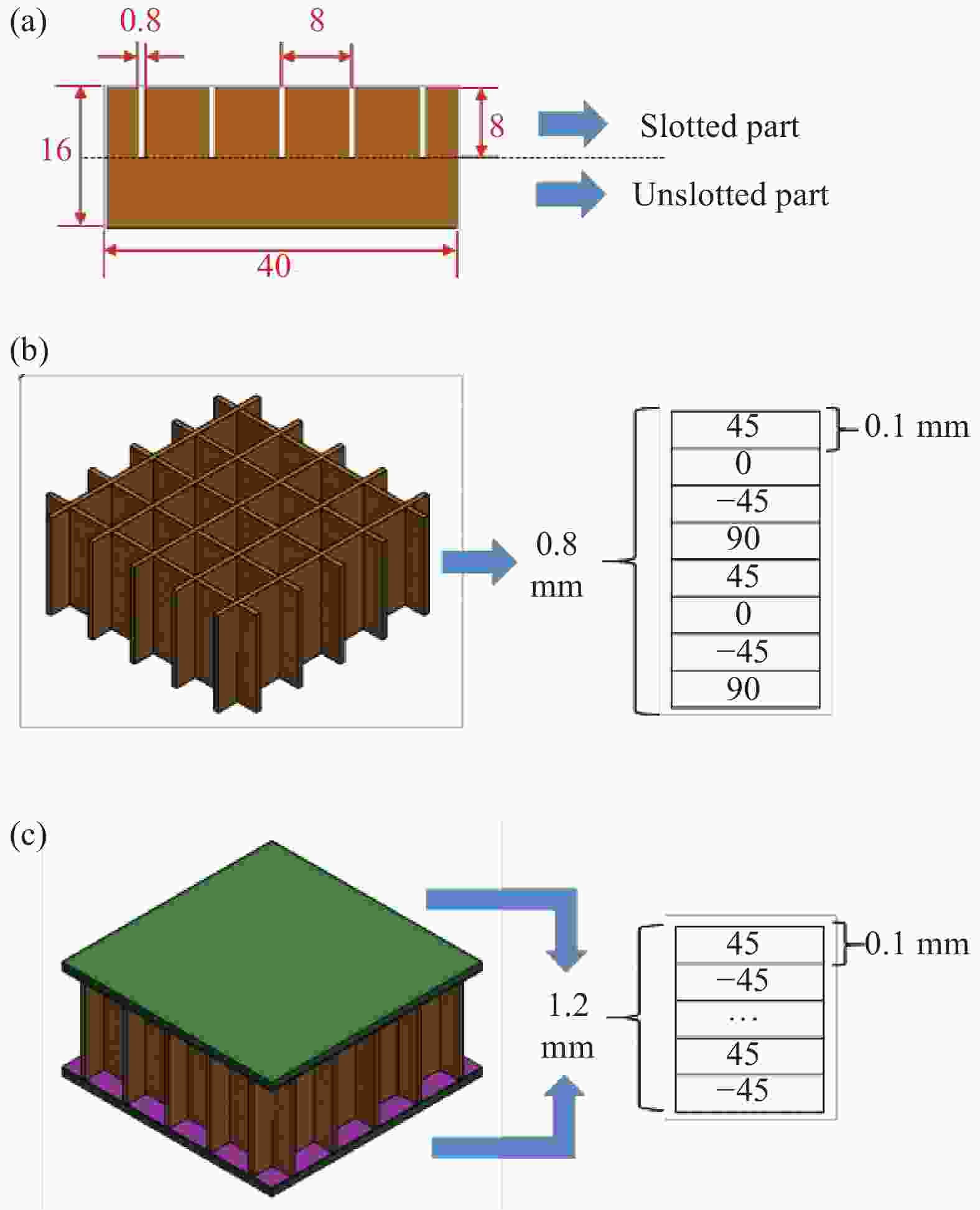

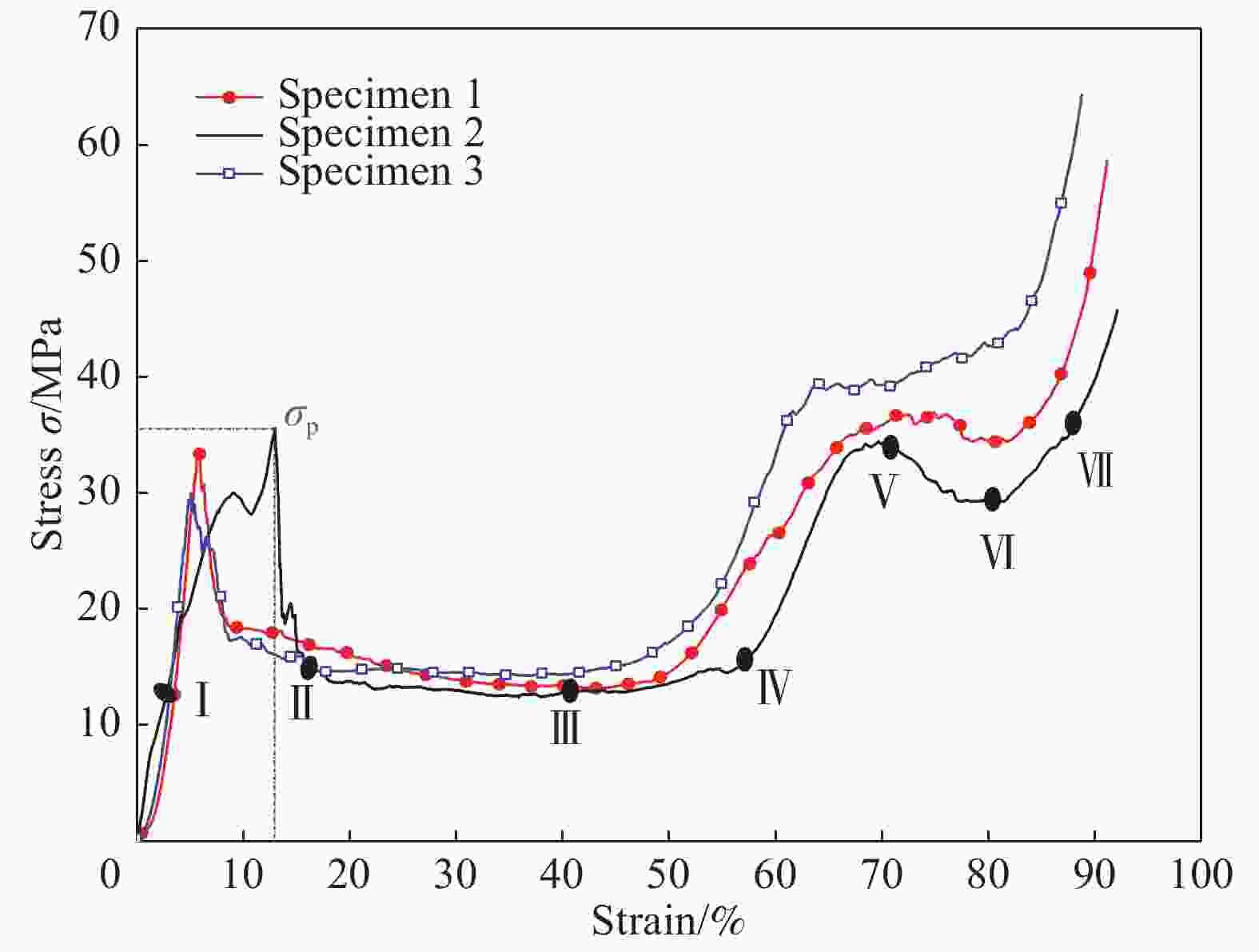

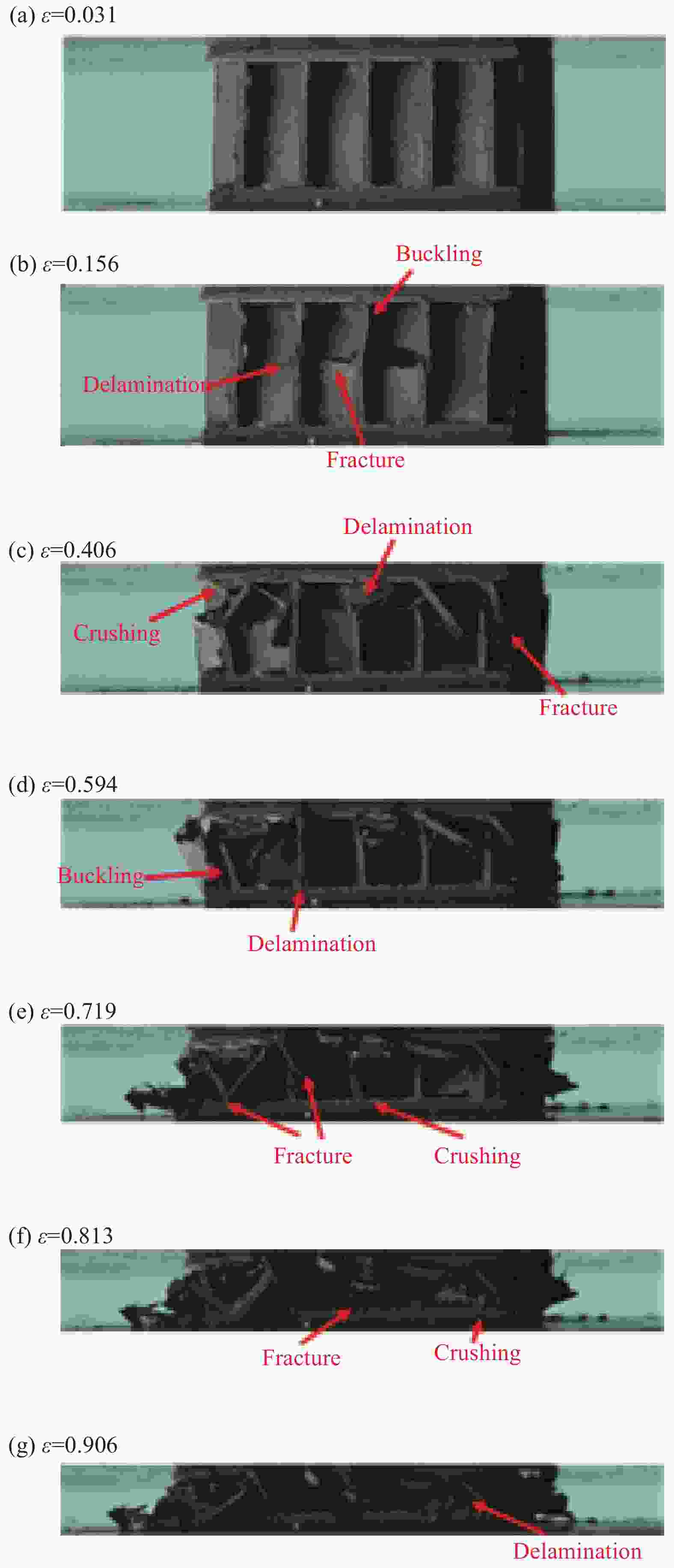

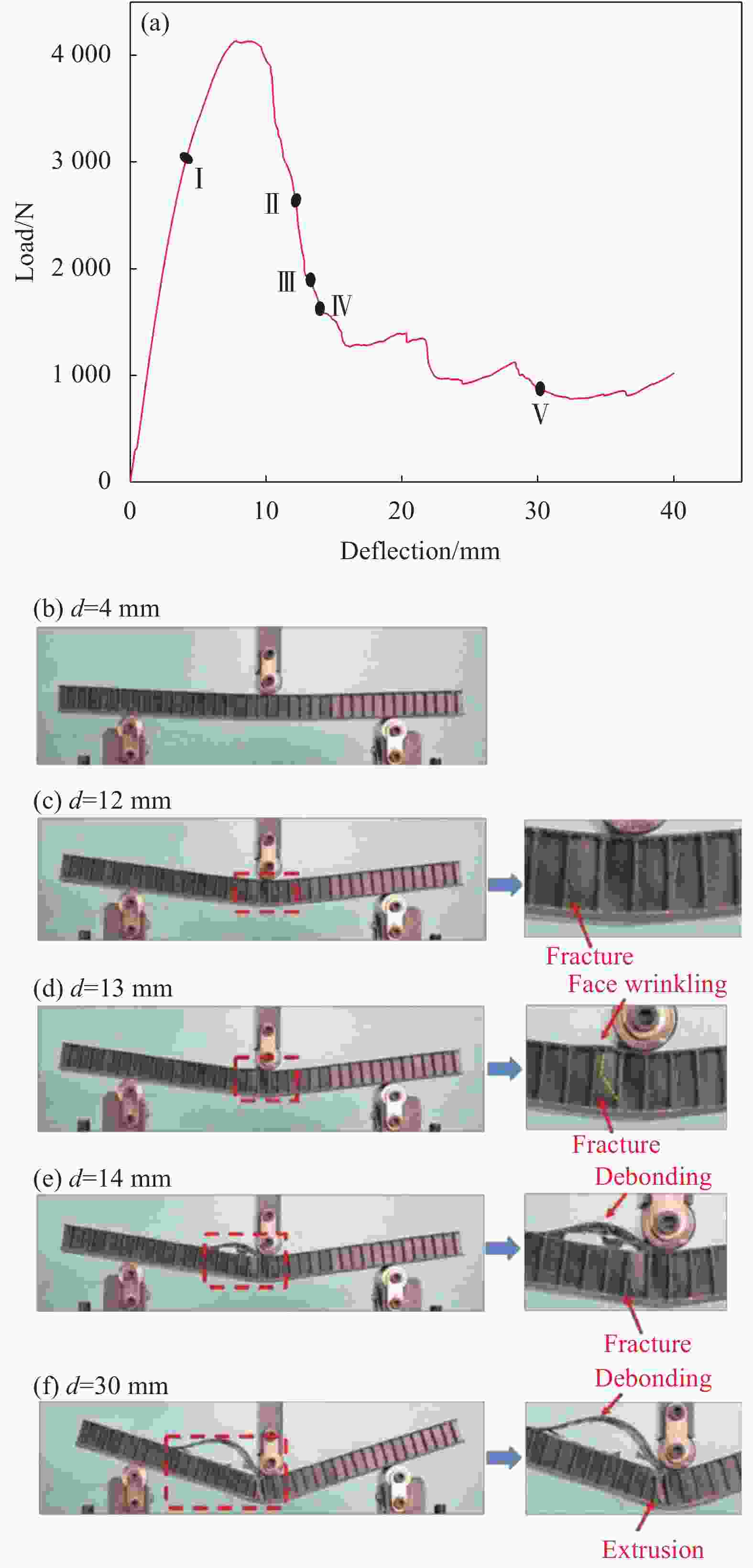

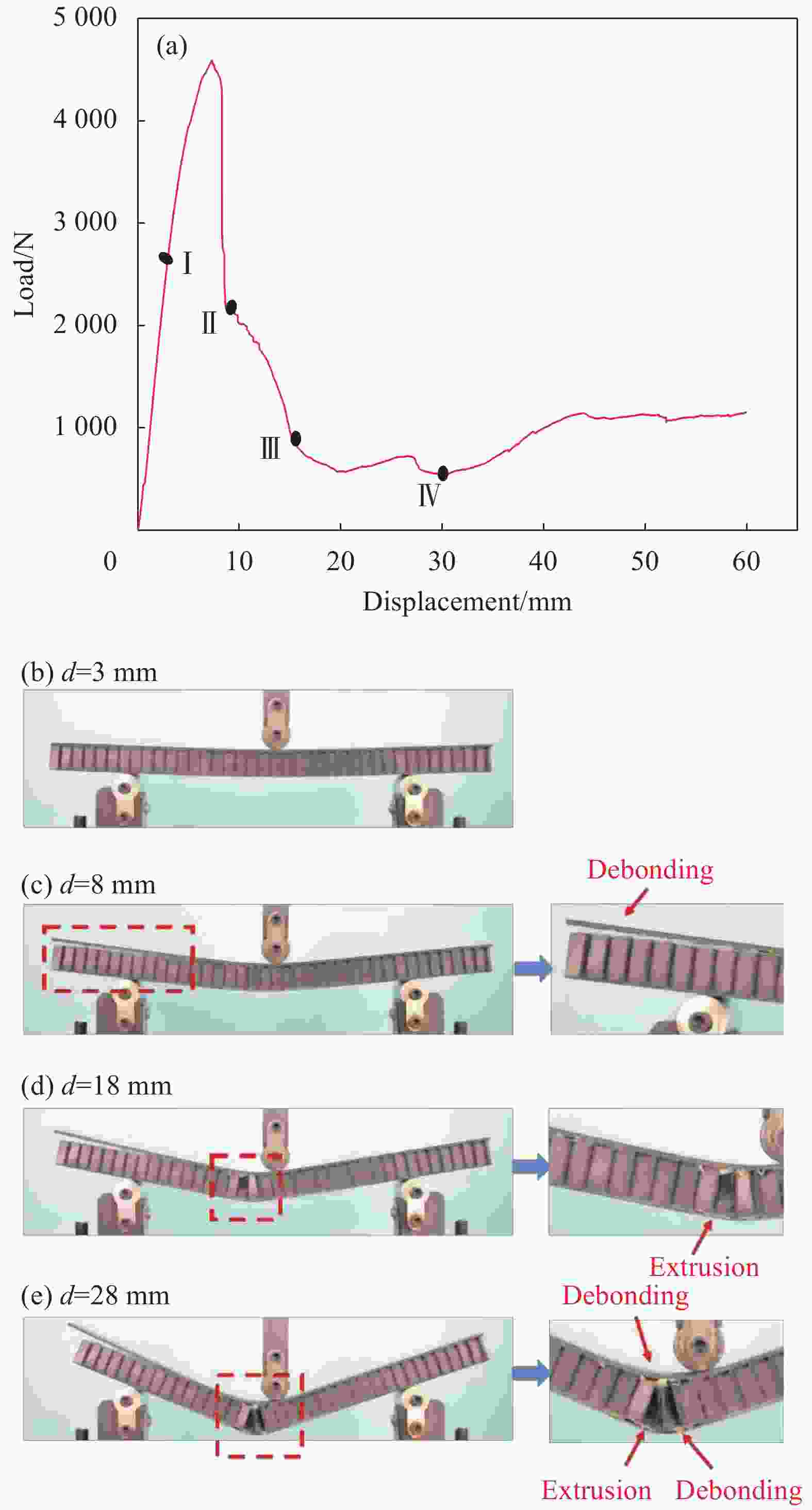

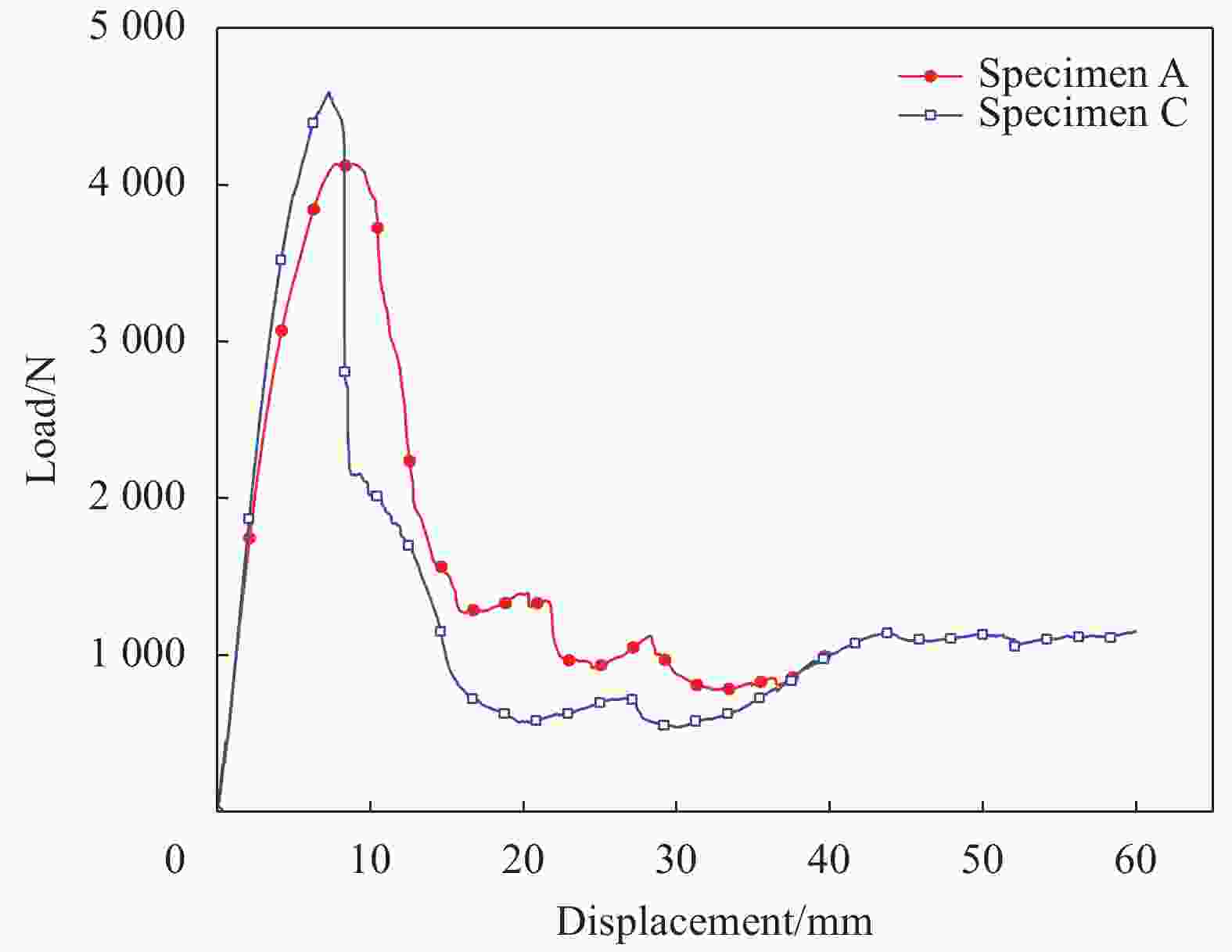

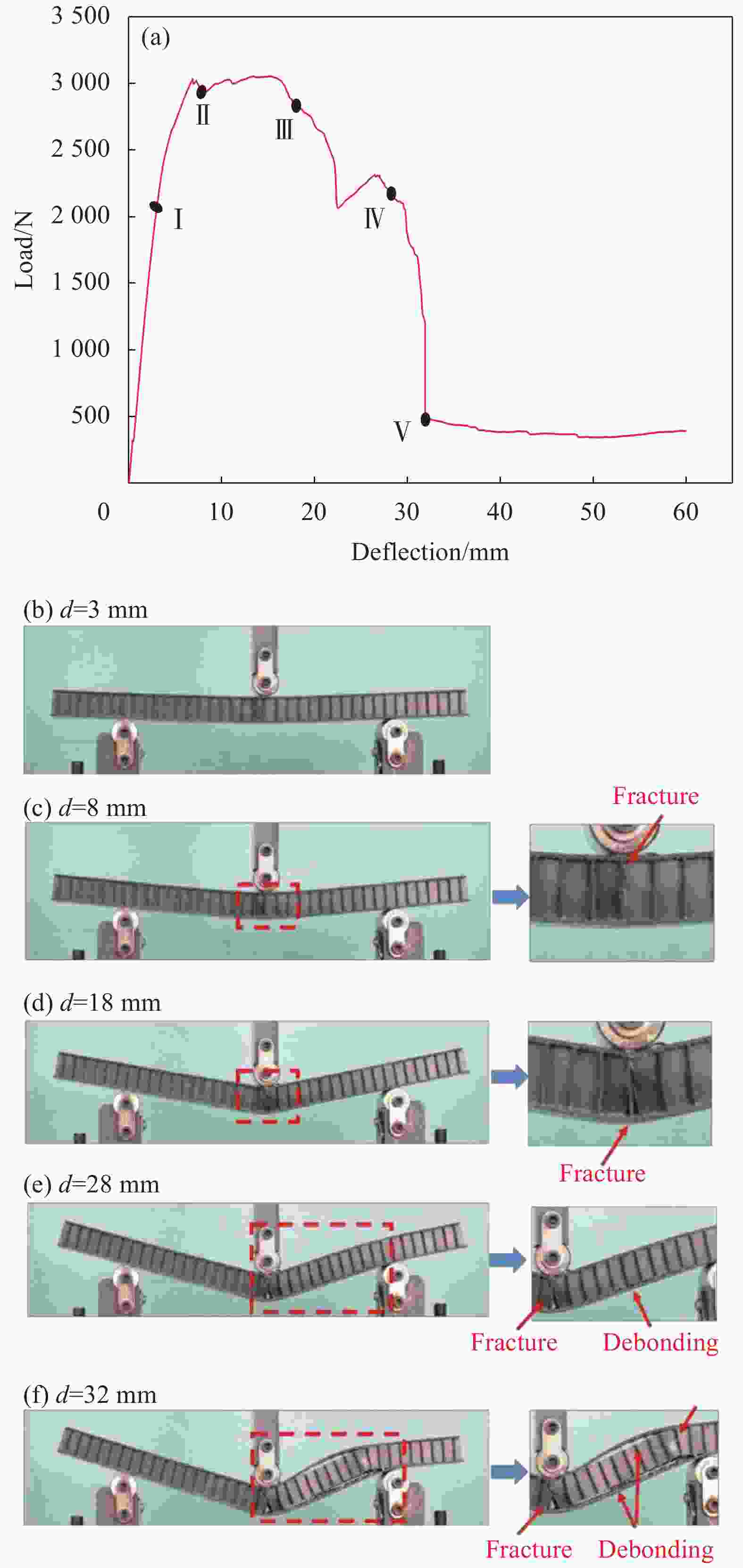

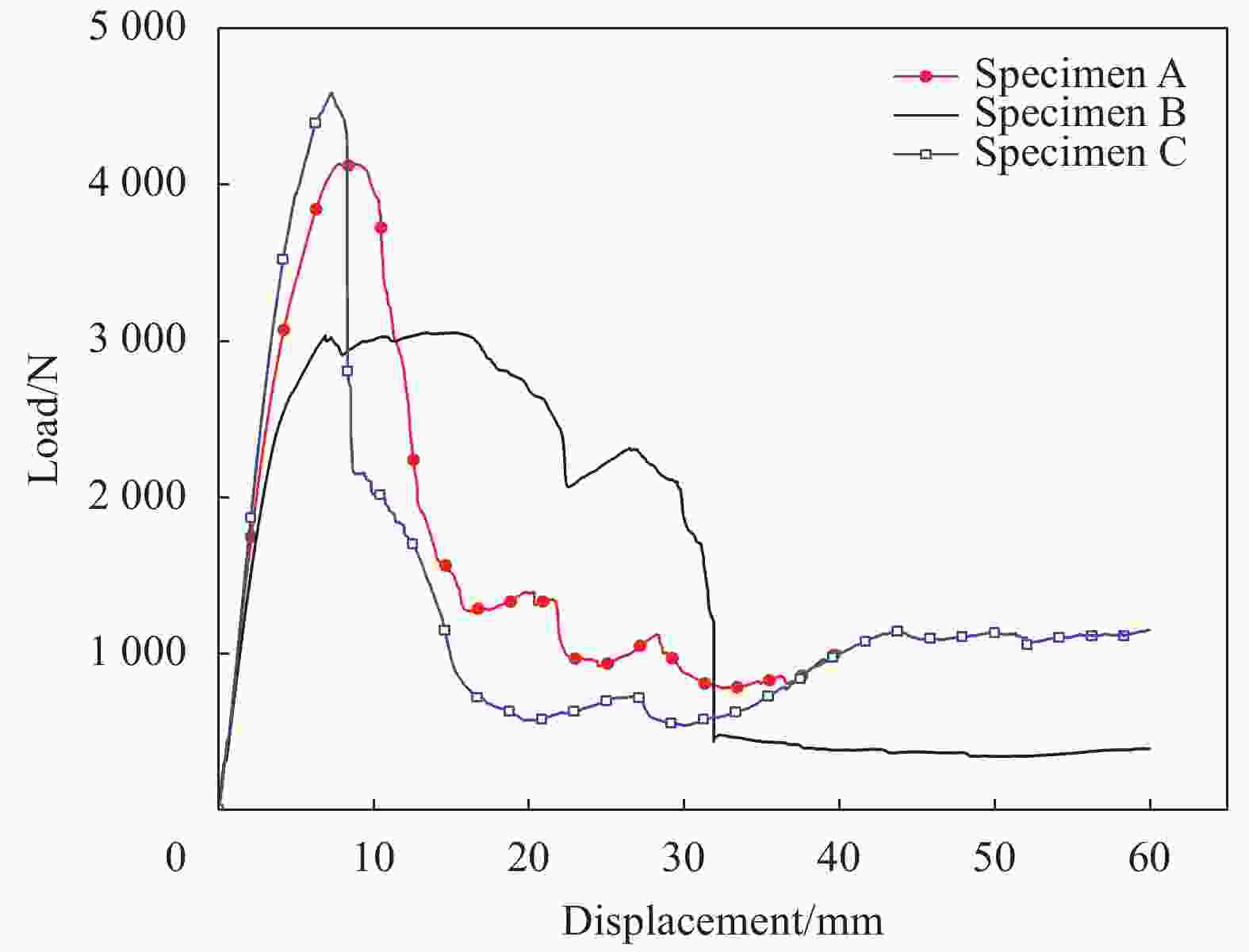

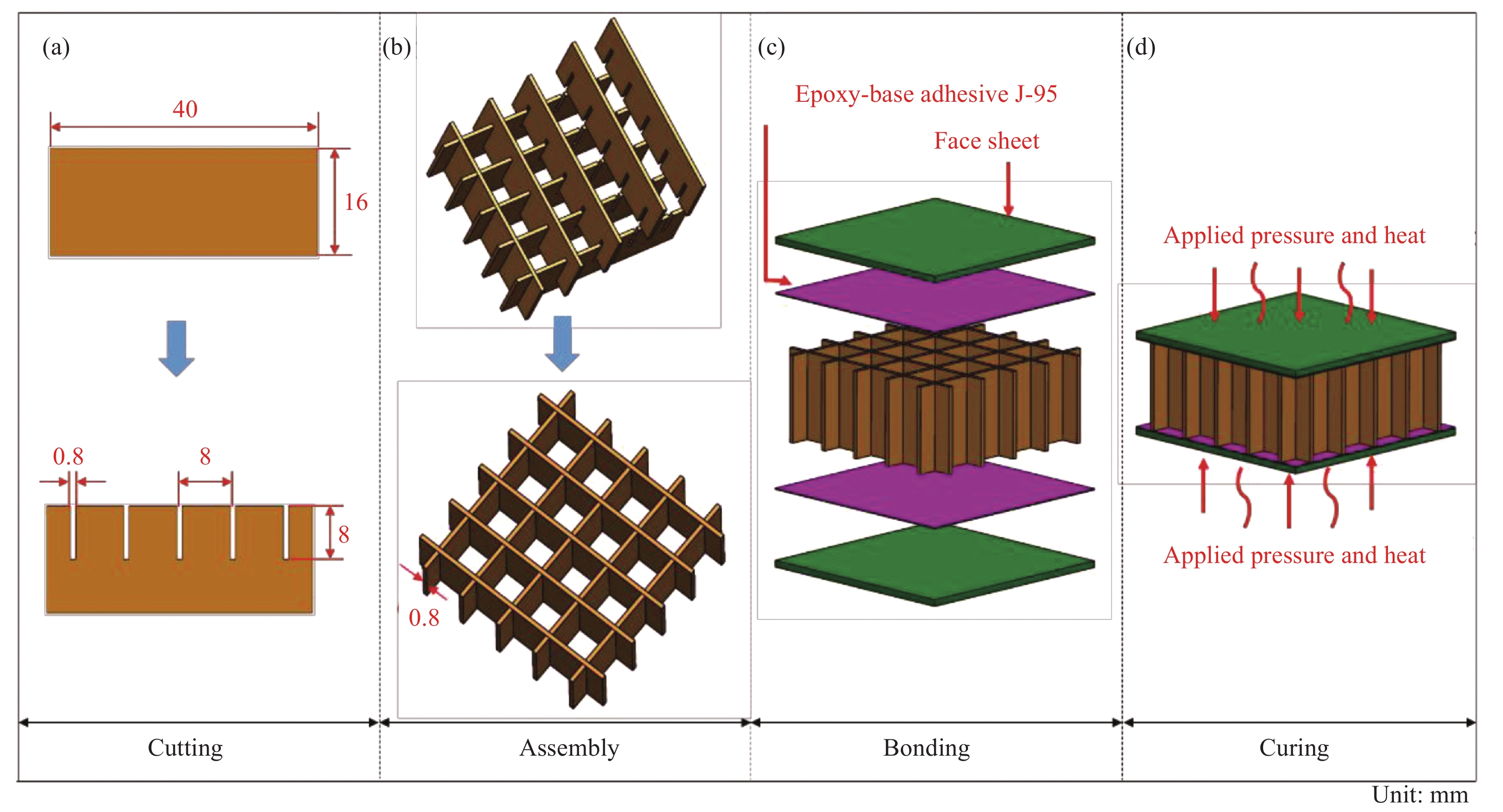

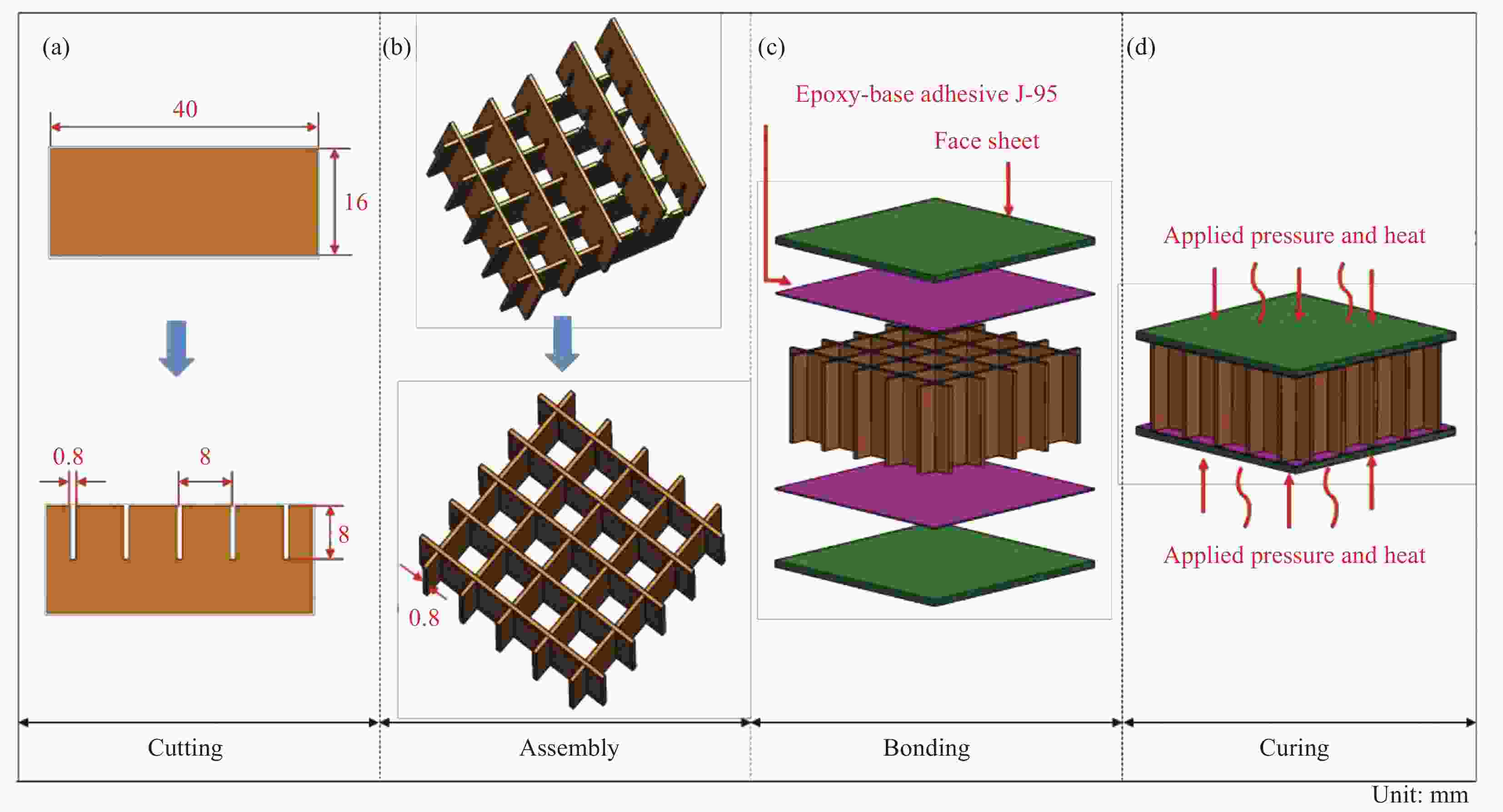

摘要: 设计并采用嵌锁组装工艺制备了碳纤维/树脂基复合材料方形蜂窝夹芯结构,开展了面外平压性能和三点弯曲性能试验研究,获得了夹芯结构在平压载荷作用下的破坏模式,分析了其损伤失效机制及吸能特性,讨论了在三点弯曲载荷作用下面板质量非对称性和槽口方向对夹芯梁的破坏模式及承载能力的影响。研究结果表明嵌锁式碳纤维/树脂基复合材料方形蜂窝夹芯结构在准静态压缩载荷下表现为从槽口附近纤维断裂到开槽侧肋板失稳断裂,再到未开槽侧肋板断裂和压溃的渐进式损伤破坏模式;压缩应力-应变曲线出现明显的二次应力平台,体现出夹芯结构优异的吸能特性;配置较厚的上面板及芯材长肋板槽口向上时,结构的承载能力和初始失效载荷更高。Abstract: Composite sandwich structure with carbon fiber reinforced polymer (CFRP) square honeycomb core was designed and fabricated using the interlocking method. The out-of-plane compressive performance and the three-point bending performance of the sandwich structure were studied experimentally. The failure modes of the sandwich structure under out-of-plane compressive loading were obtained and the failure mechanism and energy absorption characteristics were analyzed. The influences of the asymmetry of the face sheet quality and the direction of the slots on the failure modes and bending strength of the sandwich beam under three-point bending loading were explored, respectively. The experimental results show that the sandwich structure under out-of-plane compressive loading exhibits the progressive failure mode: fiber fracture near the slots, bucking and fracture of the slotted part of ribs, and the fracture and crushing of the unslotted part of ribs. The compressive stress-strain curve has obvious two-stage plateau stress, which means the excellent energy absorption characteristics of the sandwich structure. The sandwich structure has the higher load-carrying capacity and initial failure loading for the thicker upper face sheet and the upward slots of the long ribs of the core.

-

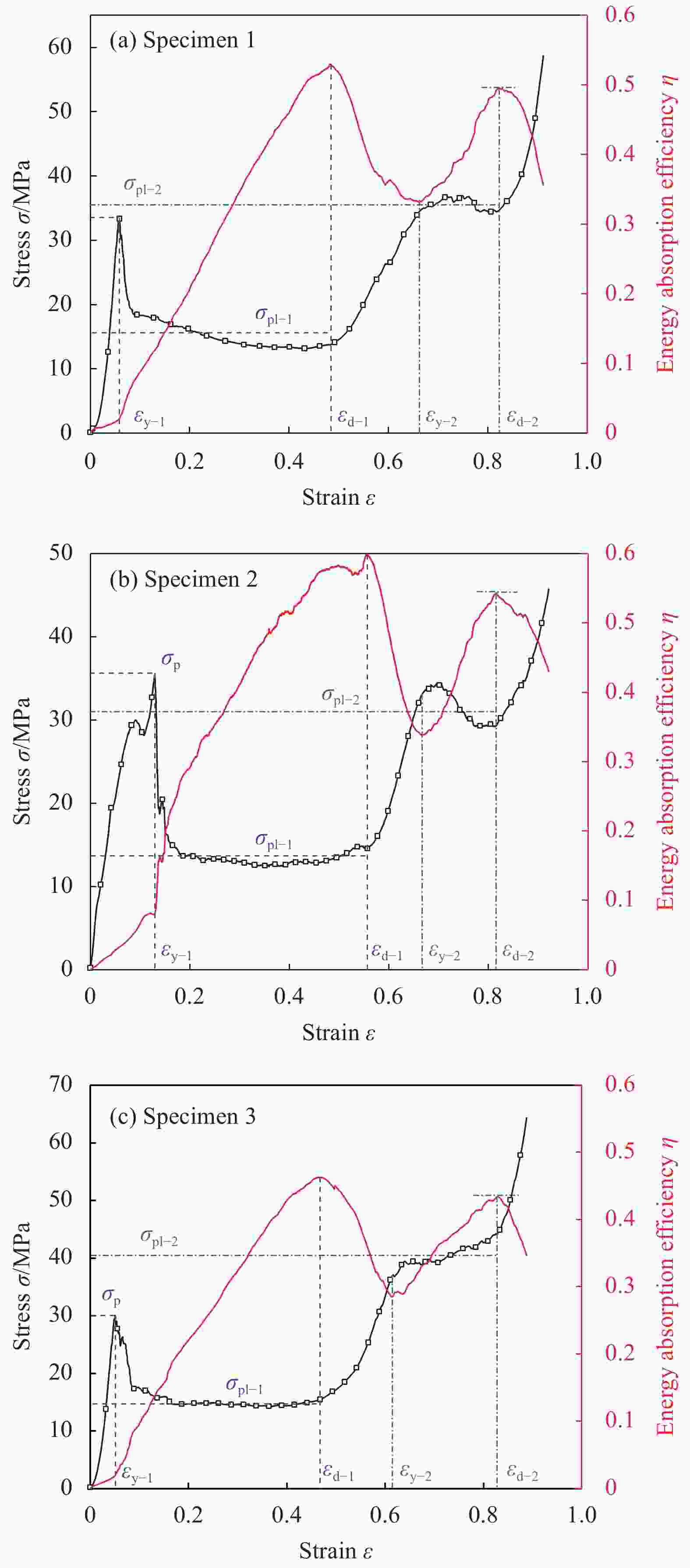

图 5 嵌锁式CFRP方形蜂窝夹芯结构面外平压应力-应变曲线和能量吸收效率-应变曲线

Figure 5. Compressive stress-strain curves and energy absorption efficiency-strain curves of the CFRP sandwich structure with square honeycomb

σpl-1—First plateau stress; σpl-2—Second plateau stress; εd-1—Onset of the first dencification; εd-2—Onset of the full dencification; εy-1—Strain at yield; εy-2—End of the second plateau regime

表 1 嵌锁式CFRP方形蜂窝夹芯结构面外平压试验结果

Table 1. Experimental results of the CFRP sandwich structure with square honeycomb under the out-of-plain compressive loading

${\rho _{\rm{c}}}$/(g·cm−3) Strength/MPa Stiffness/MPa ${\sigma _{{\rm{pl - 1}}}}$/MPa ${\sigma _{{\rm{pl - 2}}}}$/MPa ${\varepsilon _{\rm{d}}}$ ASE/(J·g−1) Specimen1 0.28 33.52 748.99 15.62 35.62 0.82 61.39 Specimen2 0.28 35.60 681.70 13.88 31.65 0.82 56.79 Specimen3 0.28 30.20 713.35 15.80 40.53 0.83 68.54 Average 0.28 33.11 714.68 15.10 35.93 0.82 62.24 Notes:${\rho _{\rm{c}}}$—Density of the core; ${\varepsilon _{\rm{d}}}$—Onset strain of densification; ASE—Specific energy absorption. -

[1] RIZOV V, SHIPSHA A, ZENKERT D. Indentation study of foam core sandwich composite panels[J]. Composite Structures,2005,69(1):95-102. doi: 10.1016/j.compstruct.2004.05.013 [2] WANG Z, ZHANG G, ZHU Y, et al. Theoretical analysis of braiding strand trajectories and simulation of three-dimensional parametric geometrical models for multilayer interlock three-dimensional tubular braided preforms[J]. Textile Research Journal,2019,89(19-20):4306-4322. doi: 10.1177/0040517519826888 [3] PEHLIVAN L, BAYKASOĞLU C. An experimental study on the compressive response of CFRP honeycombs with various cell configurations[J]. Composites Part B: Engineering,2019,162:653-661. doi: 10.1016/j.compositesb.2019.01.044 [4] LIU J, LIU J, MEI J, et al. Investigation on manufacturing and mechanical behavior of all-composite sandwich structure with Y-shaped cores[J]. Composites Science and Technology,2018,159:87-102. doi: 10.1016/j.compscitech.2018.01.026 [5] VITALE J P, FRANCUCCI G, XIONG J, et al. Failure mode maps of natural and synthetic fiber reinforced composite sandwich panels[J]. Composites Part A: Applied Science and Manufacturing,2017,94:217-225. doi: 10.1016/j.compositesa.2016.12.021 [6] SHROFF S, ACAR E, KASSAPOGLOU C. Design, analysis, fabrication, and testing of composite grid-stiffened panels for aircraft structures[J]. Thin-Walled Structures,2017,119:235-246. doi: 10.1016/j.tws.2017.06.006 [7] COMPTON B G, LEWIS J A. 3D-printing of lightweight cellular composites[J]. Advanced Materials,2014,26(34):5930-5935. doi: 10.1002/adma.201401804 [8] SUGIYAMA K, MATSUZAKI R, UEDA M, et al. 3D printing of composite sandwich structures using continuous carbon fiber and fiber tension[J]. Composites Part A: Applied Science and Manufacturing,2018,113:114-121. doi: 10.1016/j.compositesa.2018.07.029 [9] 陈向明, 姚辽军, 果立成, 等. 3D打印连续纤维增强复合材料研究现状综述[J]. 航空学报, 2021, 42(10): 167-191.CHEN X M, YAO L J, GUO L C, et al. 3D printed continuous fiber-reinforced composites: State of art and perspective[J]. Acta Aeronautica et Astronautica Sinica, 2021, 42(10): 167-191(in Chinese). [10] 熊健, 韦兴宇, 李达夫, 等 一种复合材料蜂窝芯子及其制备方法: 中国, CN110667091A[P]. 2020-01-10.XIONG J, WEI X Y, LI D F, et al. A kind of composite honeycomb core and its preparation method: China, CN110667091A[P]. 2020-01-10(in Chinese). [11] WEI X, LI D, XIONG J. Fabrication and mechanical behaviors of an all-composite sandwich structure with a hexagon honeycomb core based on the tailor-folding approach[J]. Composites Science and Technology,2019,184:107878. [12] WEI X, WU Q, GAO Y, et al. Bending characteristics of all-composite hexagon honeycomb sandwich beams: Experimental tests and a three-dimensional failure mechanism map[J]. Mechanics of Materials,2020,148:103401. [13] HAN D, TSAI S W. Interlocked composite grids design and manufacturing[J]. International Conference on Composite, 2003, 37(4): 287-316. [14] XIONG J, ZHANG M, STOCCHI A, et al. Mechanical behaviors of carbon fiber composite sandwich columns with three dimensional honeycomb cores under in-plane compression[J]. Composites Part B: Engineering,2014,60:350-358. doi: 10.1016/j.compositesb.2013.12.049 [15] XIONG J, VAZIRI A, GHOSH R, et al. Compression behavior and energy absorption of carbon fiber reinforced composite sandwich panels made of three-dimensional honeycomb grid cores[J]. Extreme Mechanics Letters,2016,7:114-120. doi: 10.1016/j.eml.2016.02.012 [16] XIONG J, MA L, STOCCHI A, et al. Bending response of carbon fiber composite sandwich beams with three dimensional honeycomb cores[J]. Composite Structures,2014,108:234-242. doi: 10.1016/j.compstruct.2013.09.035 [17] FAN H L, MENG F H, YANG W. Mechanical behaviors and bending effects of carbon fiber reinforced lattice materials[J]. Archive of Applied Mechanics,2006,75(10-12):635-647. doi: 10.1007/s00419-006-0032-x [18] FAN H L, MENG F H, YANG W. Sandwich panels with Kagome lattice cores reinforced by carbon fibers[J]. Composite Structures,2007,81(4):533-539. doi: 10.1016/j.compstruct.2006.09.011 [19] 熊健. 轻质复合材料新型点阵结构设计及其力学行为研究[D]. 哈尔滨: 哈尔滨工业大学, 2013.XIONG J. Design and mechanical behavior of lightweight composite innovative lattice truss structures[D]. Harbin: Harbin Institute of Technology, 2013(in Chinese). [20] RUSSELL B, DESHPANDE V S, WADLEY H N G. Quasi-static deformation and failure modes of composite square honeycombs[J]. Journal of Mechanics of Materials and Structures,2008,3:1315-1340. doi: 10.2140/jomms.2008.3.1315 [21] ZHOU H, LIU T, GUO R, et al. Numerical investigation on water blast response of freestanding carbon fiber reinforced composite sandwich plates with square honeycomb cores[J]. Applied Composite Materials,2018,26(2):605-625. [22] 周昊, 郭锐, 刘荣忠, 等. 碳纤维增强聚合物复合材料方形蜂窝夹层结构水下爆炸动态响应数值模拟[J]. 复合材料学报, 2019, 36(5):1226-1234.ZHOU H, GUO R, LIU R Z, et al. Simulations on dynamic responses of carbon fiber reinforced polymer composite sandwich plates with square honeycomb cores subjected to water blast[J]. Acta Materiae Compositae Sinica,2019,36(5):1226-1234(in Chinese). [23] 杨志韬, 于国财, 刘鑫, 等. 多级复合材料蜂窝结构的力学性能[J]. 复合材料学报, 2019, 36(9):2110-2118.YANG Z T, YU G C, LIU X, et al. Mechanical properties of hierarchical composite honeycomb structures[J]. Acta Materiae Compositae Sinica,2019,36(9):2110-2118(in Chinese). [24] 张笑瑜. 多级复合材料蜂窝结构的力学性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2017.ZHANG X Y. Mechanical property study of hierarchical composite honeycomb structure[D]. Harbin: Harbin Institute of Technology, 2017(in Chinese). [25] ZHOU H, LIU R, HU Y, et al. Quasi-static compressive strength of polymethacrylimide foam-filled square carbon fiber reinforced composite honeycombs[J]. Journal of Sandwich Structures & Materials,2020,23(6):109963622090981. [26] RUSSELL B P, LIU T, FLECK N A, et al. The soft impact of composite sandwich beams with a square-honeycomb core[J]. International Journal of Impact Engineering,2012,48:65-81. doi: 10.1016/j.ijimpeng.2011.04.007 [27] RUSSELL B P, LIU T, FLECK N A, et al. Quasi-static three-point bending of carbon fiber sandwich beams with square honeycomb cores[J]. Journal of Applied Mechanics,2011,78(3):1-15. [28] PARK S, RUSSELL B P, DESHPANDE V S, et al. Dynamic compressive response of composite square honeycombs[J]. Composites Part A: Applied Science and Manufacturing,2012,43(3):527-536. doi: 10.1016/j.compositesa.2011.11.022 [29] American Society of Testing Materials. Standard test method for flatwise compressive properties of sandwich cores: C365/C365M-11a[S]. West Conshohocken: American Society of Testing Materials International, 2011. [30] LI Q M, MAGKIRIADIS I, HARRIGAN J J. Compressive strain at the onset of densification of cellular solids[J]. Journal of Cellular Plastics,2016,42(5):371-392. [31] American Society of Testing Materials. Standard test method for flexural properties of sandwich constructions: ASTM C393—00[S]. West Conshohocken: American Society of Testing Materials International, 2000. -

下载:

下载: