Microstructure and mechanical behavior of CF-B4C/Al neutron absorbing composites

-

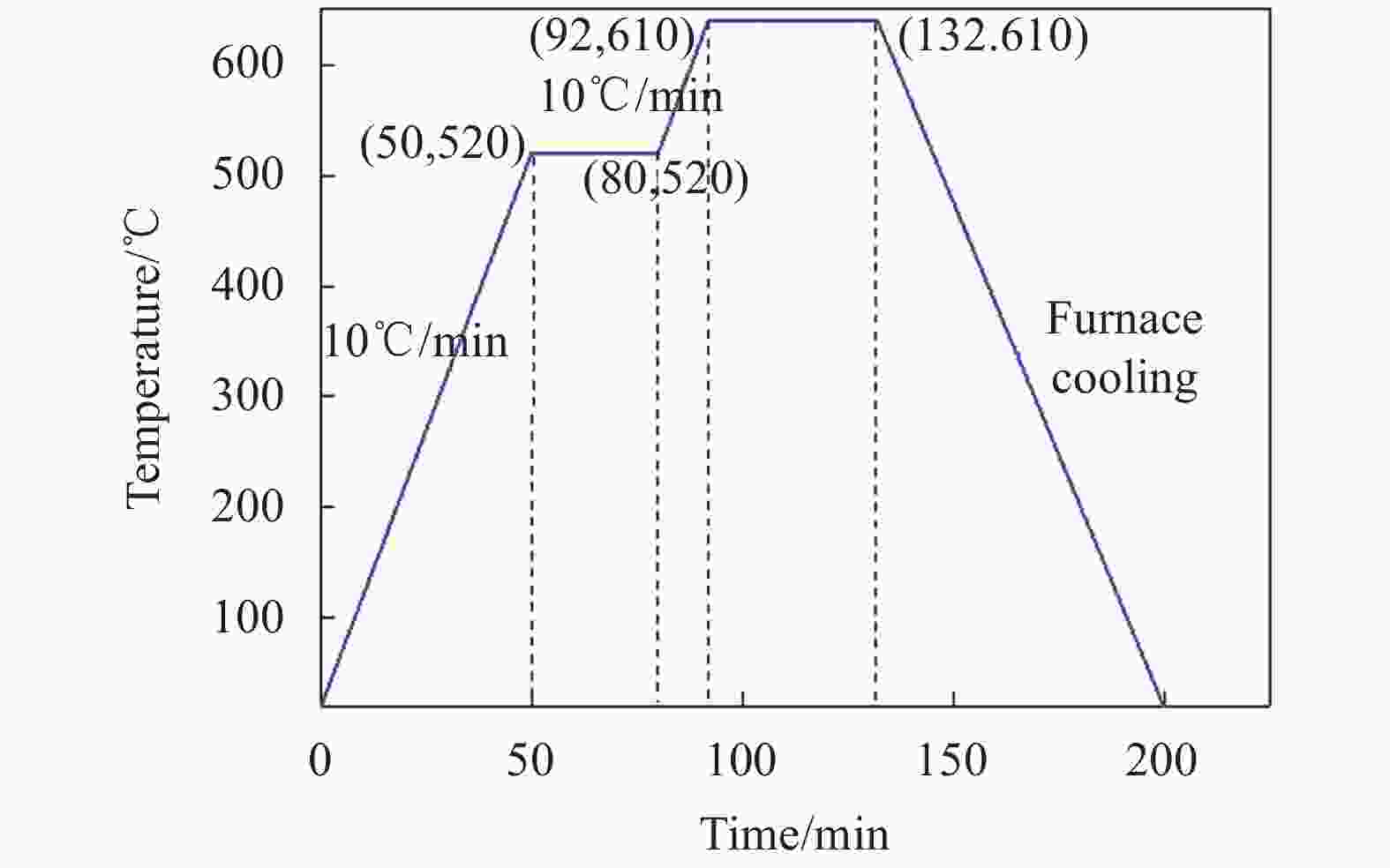

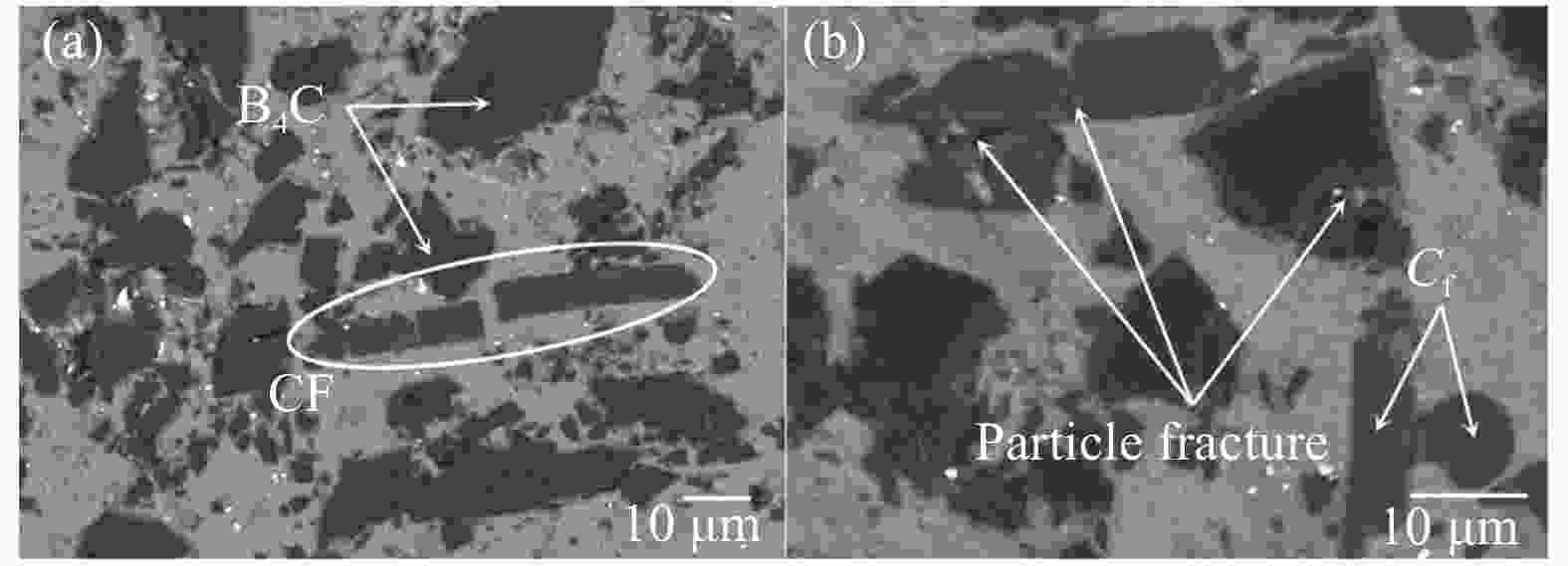

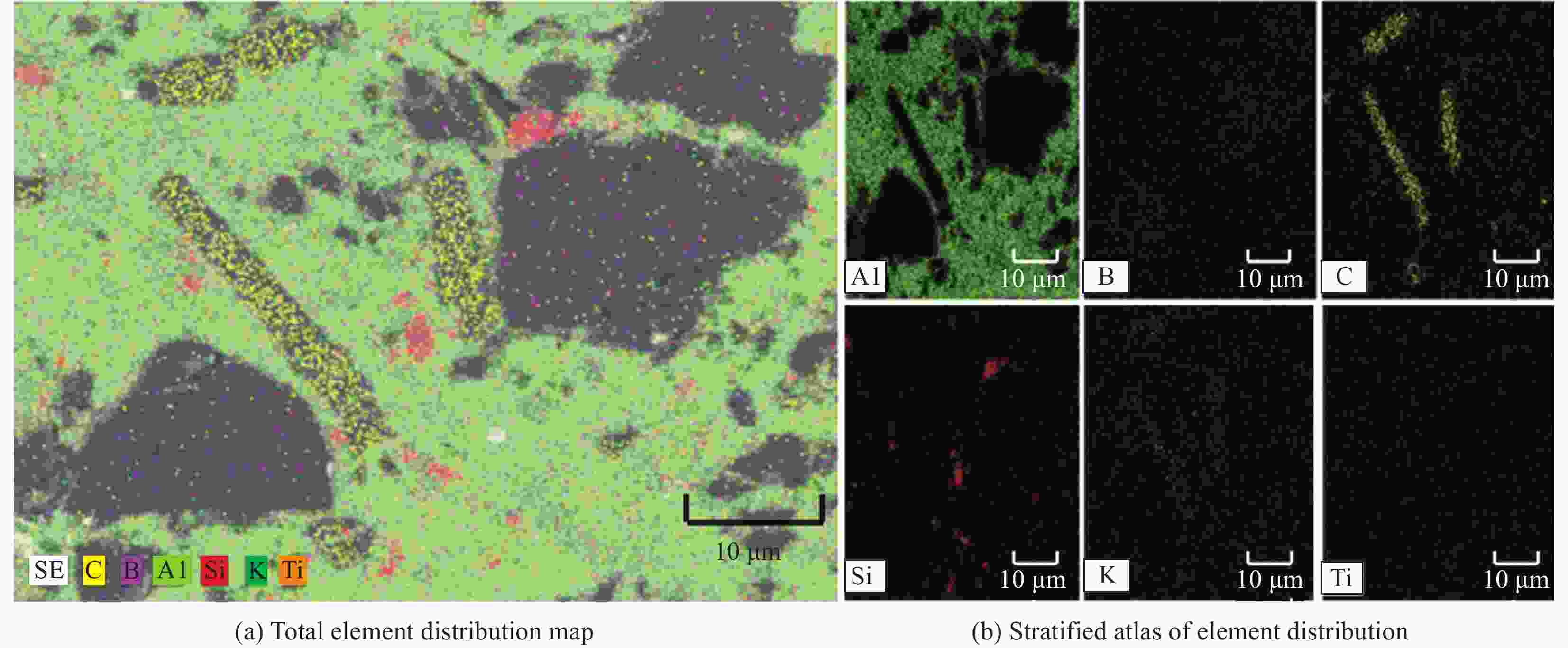

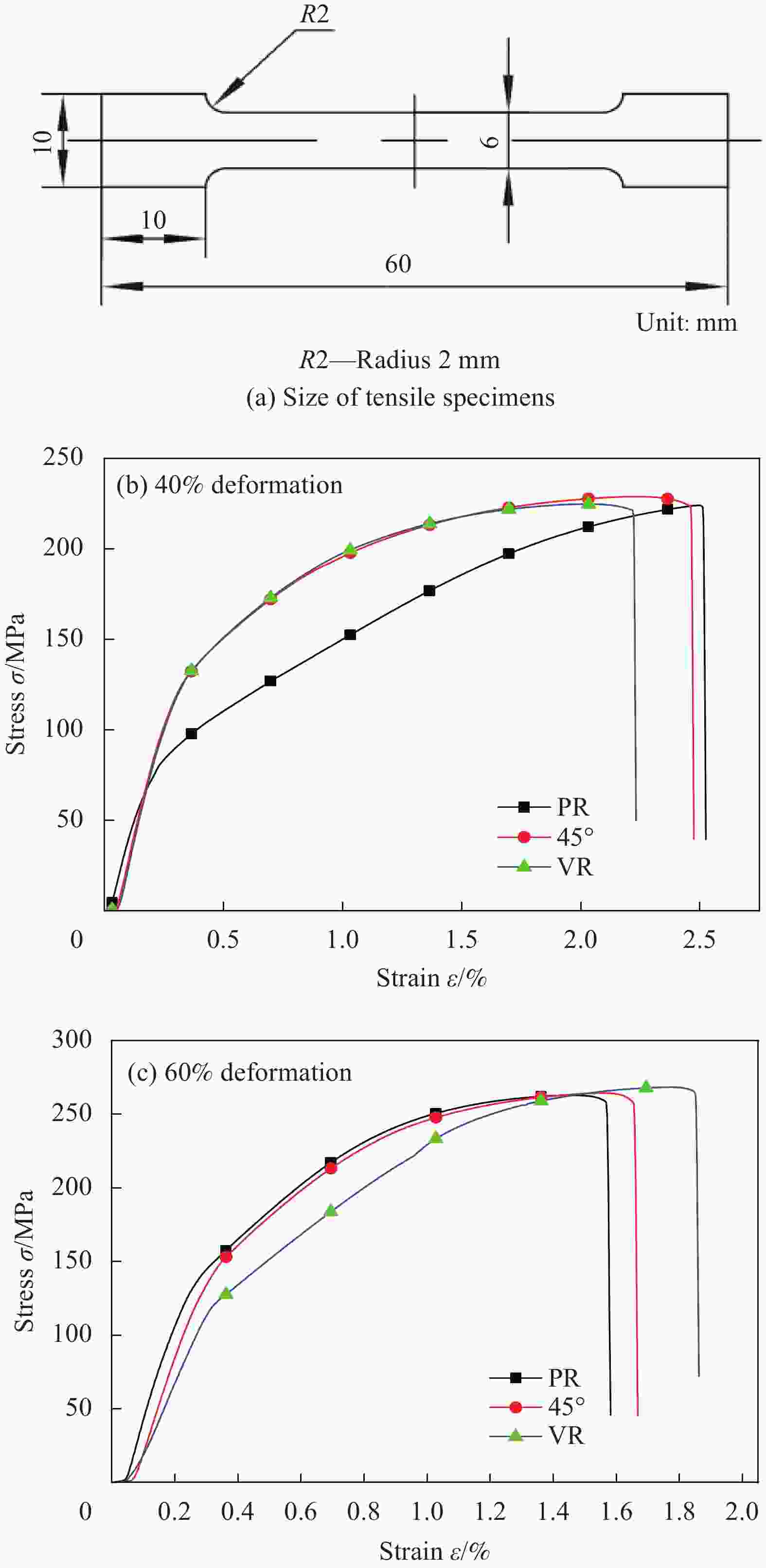

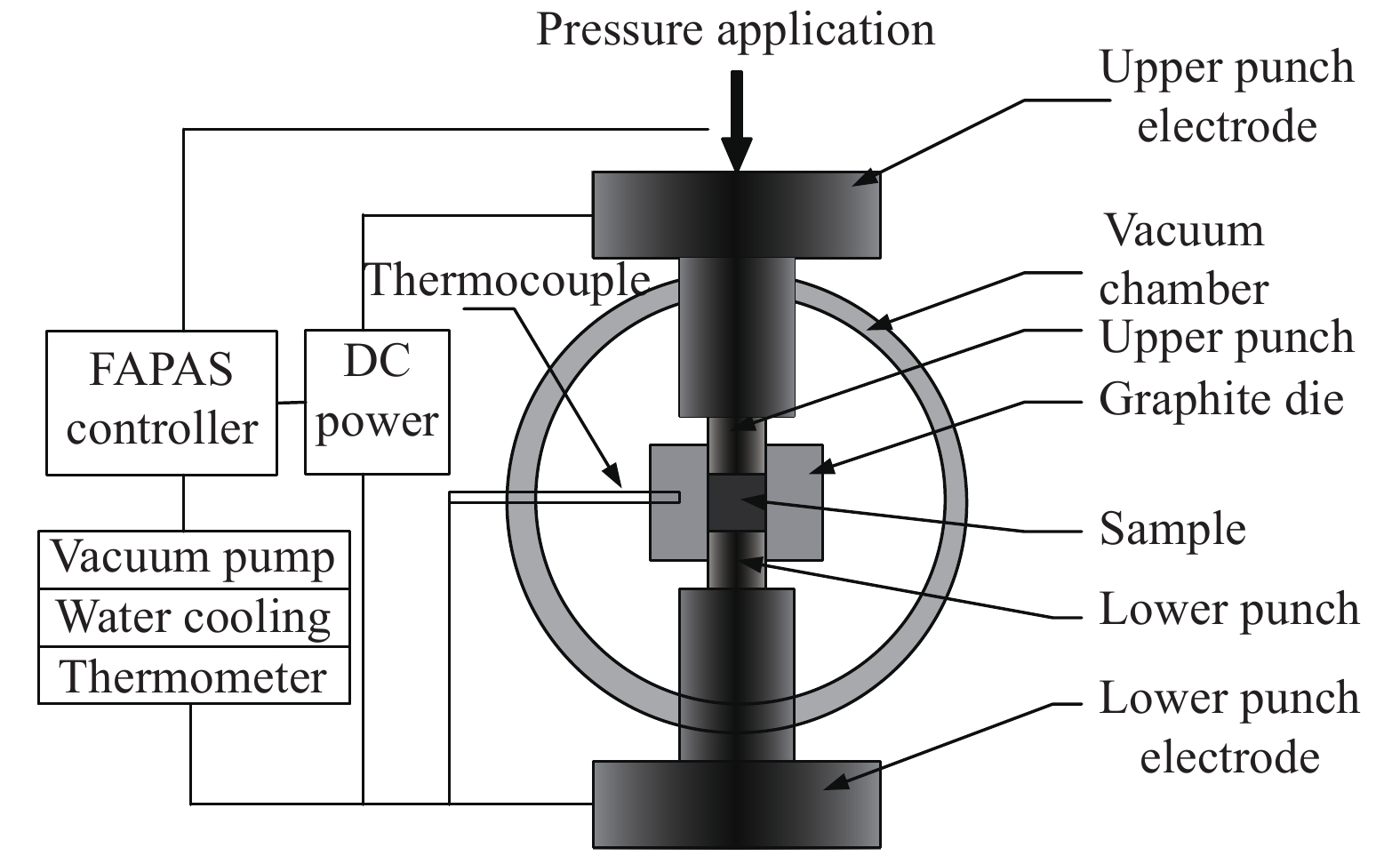

摘要: 基于B4C良好的中子吸收性能和碳纤维(CF)慢化中子的性能,采用真空热压烧结方法制备了集结构与功能一体具有不同CF含量的CF-B4C混合增强6061Al基复合材料,并对热轧后的组织形貌和力学性能进行分析。结果表明,大变形量热轧后B4C颗粒和CF分布较均匀,没有出现大面积的聚集现象,但是少量B4C颗粒和CF在轧制压力的作用下发生了断裂。当变形量达到60%时,复合材料的抗拉强度可达(265±3) MPa,与6061Al合金的抗拉强度相比,不同厚度的CF-B4C/Al复合材料的抗拉强度分别提高了80%和112%。随着CF含量的增加,CF-B4C/Al复合材料的强度和延伸率均减小。当CF含量达到5wt%时,断裂的主要原因是有纤维的聚集及纤维沿断裂方向排布。Abstract: Based on the good neutron absorption property of B4C and the moderated neutron property of carbon fiber (CF), CF-B4C mixed-reinforced 6061Al matrix composites with different CF contents were prepared by vacuum hot pressing sintering method. The microstructure and mechanical properties of the composites were analyzed. After hot rolling with large deformation, the B4C particles are distributed evenly without large area of particle aggregation, but a small amount of B4C particles and CF are brittle. When the deformation reaches 60%, the tensile strength of the material can reach (265±3) MPa. Compared with the tensile strength of 6061Al alloy, the tensile strength values of CF-B4C/Al composites with different thicknesses increase by 80% and 112% respectively. With the increase of CF content, the strength and elongation of CF-B4C/Al composites decrease. When the content of CF reaches 5wt%, the main reason of fracture is the aggregation of fibers and the arrangement of fibers along the fracture direction.

-

表 1 6061铝合金化学成分

Table 1. Chemical composition of 6061Al alloy

wt% Si Fe Cu Mn Mg Cr Zn Ti Al 0.6 0.7 0.25 0.15 0.8 0.1 0.25 0.15 Rest 表 2 B4C化学成分

Table 2. Chemical composition of B4C

wt% B C Ca Fe Si F Cl 80.0 18.1 0.3 1.0 0.5 0.025 0.075 表 3 CF-B4C/Al复合材料的拉伸性能

Table 3. Tensile properties of CF-B4C/Al composites

Carbon fiber content/wt% Deformation/% σ0.2/MPa σUTS/MPa ε/% 1 40 154.3 198.2 2.92 1 50 161 216.7 2.88 1 60 184.6 268 1.89 5 40 132.7 175.6 2.18 5 50 140.5 182.3 2.36 5 60 142.3 185.2 2.78 Notes: σ0.2—Yield strength; σUTS—Ultimate strength; ε—Ultimate elongation after aging. -

[1] 曹玉鹏, 戴志强, 刘建涛, 等. 金属基复合材料研究进展及展望[J]. 铸造技术, 2017, 38(10):8-11.CAO Yupeng, DAI Zhiqiang, LIU Jiantao, et al. Research progress and prospect of metal matrix composite materials[J]. Foundry Technology,2017,38(10):8-11(in Chinese). [2] SATHISH K G, RAJAGURU K, RAMKUMAR R, et al. Evaluation of Al-C-B4C composites fabricated by powder metallurgy for hardness and wear behaviour[J]. Materials Today: Proceedings,2021,37:2991-2996. [3] MEI X M, MEI Q S, LI C L, et al. Enhanced strengthening of Al-SiC nanocomposites containing a uniform dispersion of dense nanoparticles fabricated by a hybrid accumulative roll-bonding process[J]. Materials Science & Engineering A,2020,09:140-217. [4] KULDEEP Pal, KUMAR Navin, RAJNISH Kurchania, et al. Study of structural and mechanical behaviour of Al-ZrO2 metal matrix nanocomposites prepared by powder metallurgy method[J]. Materials Today: Proceedings,2020,2:2714-2719. [5] SONG J I, SAN K H. Effect of volume fraction of carbon fibers on wear behavior of Al/Al2O3/C hybrid metal matrix composites[J]. Composite Structures,1997,39(4):309-318. [6] SUN W, DUAN C, YIN W. Modeling of force and tempera-ture in cutting of particle reinforced metal matrix compo-sites considering particle effects[J]. Journal of Materials Processing Technology,2021,290:116991. doi: 10.1016/j.jmatprotec.2020.116991 [7] AVCOLU S, BULDU M, KAYA F, et al. Processing and properties of boron carbide (B4C) reinforced LDPE composites for radiation shielding[J]. Ceramics International,2020,46(1):343-352. [8] CELLI M, GRAZZI F, ZOPPI M. A new ceramic material for shielding pulsed neutron scattering instruments[J]. Nuclear Instruments and Methods in Physics Research Section A Accelerators Spectrometers Detectors and Associated Equipment,2006,565(2):861-863. doi: 10.1016/j.nima.2006.05.234 [9] ZHANG P, LI Y, WANG W, et al. The design, fabrication and properties of B4C/Al neutron absorbers[J]. Journal of Nuclear Materials,2013,437(1-3):350-358. [10] KANG P C, CAO Z W, WU G H, et al. Phase identification of Al–B4C ceramic composites synthesized by reaction hot-press sintering[J]. International Journal of Refractory Metals & Hard Materials,2010,28(2):297-300. [11] LI Y Z, WANG Q Z, WANG W G, et al. Effect of interfacial reaction on age-hardening ability of B4C/6061Al composites[J]. Materials Science & Engineering A,2015,620:445-453. [12] JIANG L T, XU Z G, FEI Y K, et al. The design of novel neutron shielding (Gd + B4C)/6061Al composites and its properties after hot rolling[J]. Composites,2019,168:183-194. [13] CHEN Hongsheng, WANG Wenxian, LI Yuli, et al. Microstructure evolution and mechanical properties of B4C/6061Al neutron absorber composite sheets fabricated by powder metallurgy[J]. Journal of Alloys and Compounds,2015,632(6):342-351. [14] WANG Peng, TANG Xiaobin, CHAI Hao, et al. Design, fabrication, and properties of a continuous carbon-fiber reinforced Sm2O3/polyimide gamma ray/neutron shielding material[J]. Fusion Engineering and Design,2015,101(9):218-225. [15] UĞUR Akbaba, AHMET Emre Kasapoğlu, EMRE Gür, et al. Gamma and neutron irradiation effects on multi-walled carbon nanotubes[J]. Materials Diamond & Related Materials,2018,87(6):242-247. [16] CHEN Huan, ZENG Fanhao, LI Wenjie, et al. Effect of interfacial residual thermal stress on the fracture behavior of Cf/B4C composites prepared by spark plasma sintering[J]. Ceramics International,2019,46(4):4587-4594. [17] FARHAD Adibpur, SEYED Ali Tayebifard, MOHAMMAD Zakeri, et al. Co-reinforcing of ZrB2-SiC ceramics with optimized ZrC to Cf ratio[J]. Ceramics International,2020,46(1):22661-22673. [18] MAHAVIRADHAN N, SIVAGANESAN S, SRAVYA N P, et al. Experimental investigation on mechanical properties of carbon fiber reinforced aluminum metal matrix composite[J]. Materials Today: Proceedings,2020,39:743-747. [19] ZHANG Peng, LI Jing, WANG Wenxian, et al. Design, shielding mechanism and tensile property of a novel (B4C+6061Al)/Cf/6061Al laminar neutron-shielding composite[J]. Vacuum,2020,177:109383. [20] CHEN H S, WANG W X, LI Y L, et al. The design, microstructure and tensile properties of B4C particulate reinforced 6061Al neutron absorber composites[J]. Journal of Alloys and Compounds,2015,632:23-29. doi: 10.1016/j.jallcom.2015.01.048 [21] SREE MANU K M, AJAY RAAG L, RAJAN T P D, et al. Self-lubricating bidirectional carbon fiber reinforced smart aluminum composites by squeeze infiltration process[J]. Journal of Materials Science & Technology,2019,35(11):2559-2569. [22] FENG Lei, LI Kezhi, LU Jinhua, et al. Effect of growth temperature on carbon nanotube grafting morphology and mechanical behavior of carbon fibers and carbon/carbon composites[J]. Journal of Materials Science & Technology,2017,33(1):65-70. [23] ZHOU Jiming, ZHONG Kangdi, ZHAO Chentong, et al. Effect of carbon nanotubes grown temperature on the fracture behavior of carbon fiber reinforced magnesium matrix composites: Interlaminar shear strength and tensile strength[J]. Ceramics International,2020,47(5):6597-6607. -

下载:

下载: