Preparation and thermal conductivity of MXene/silicone rubber composites

-

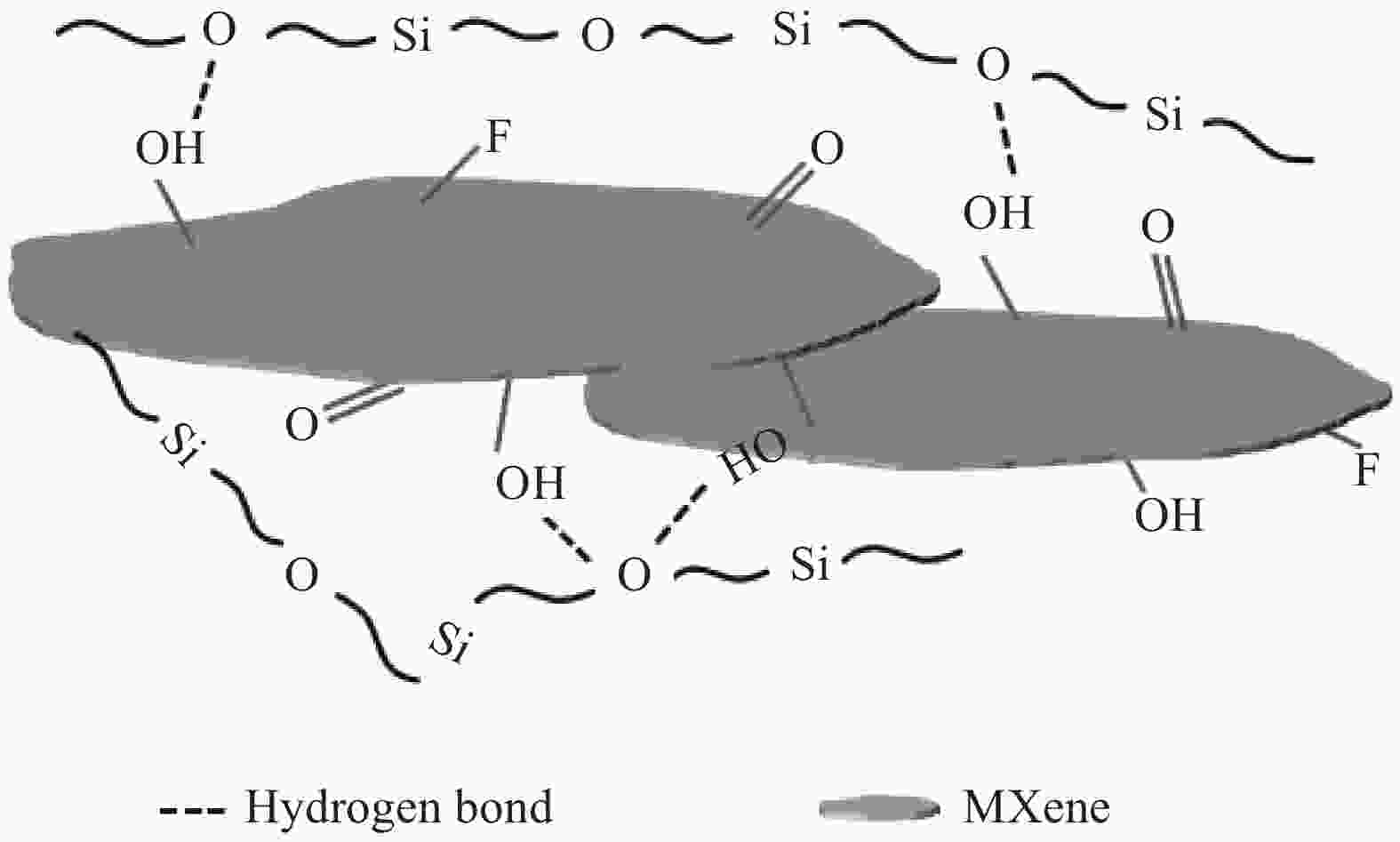

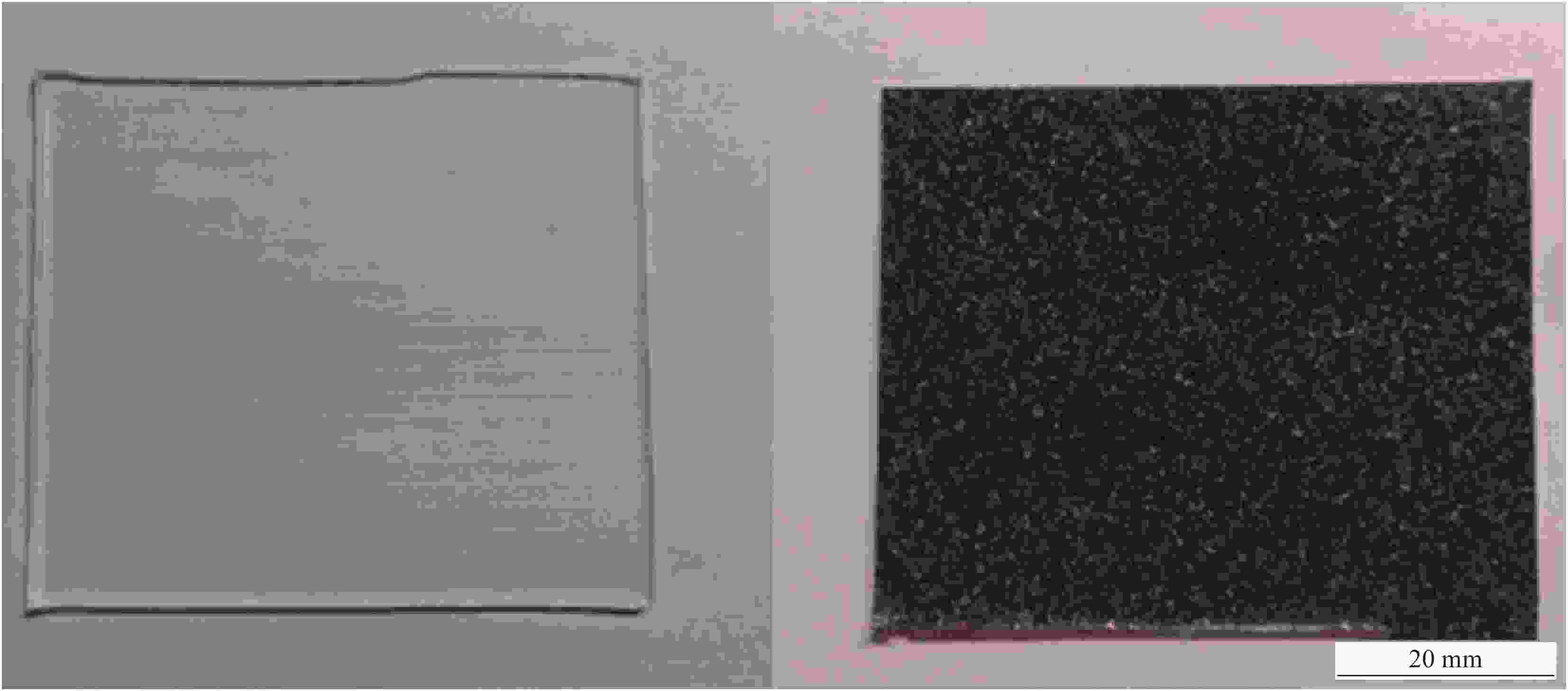

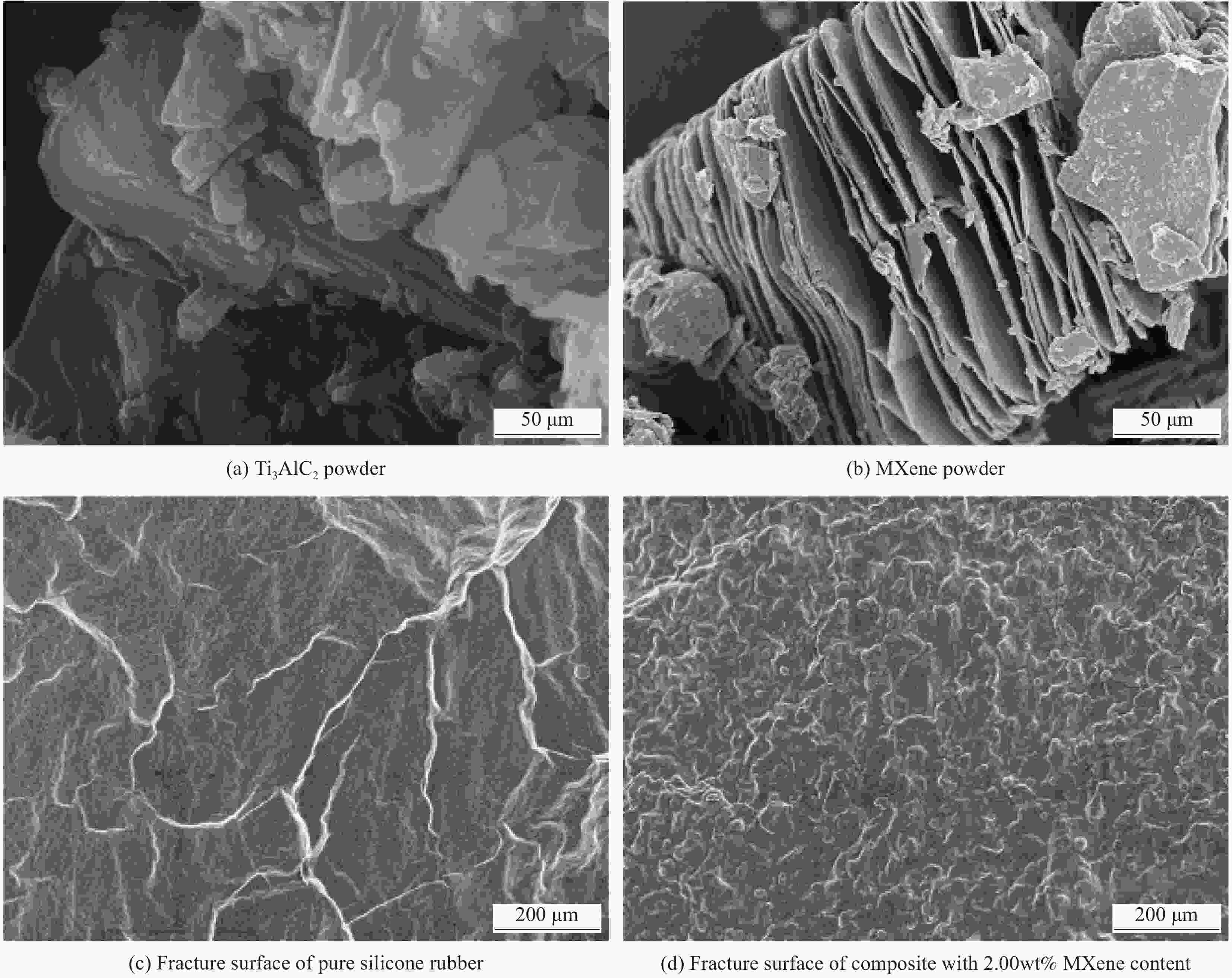

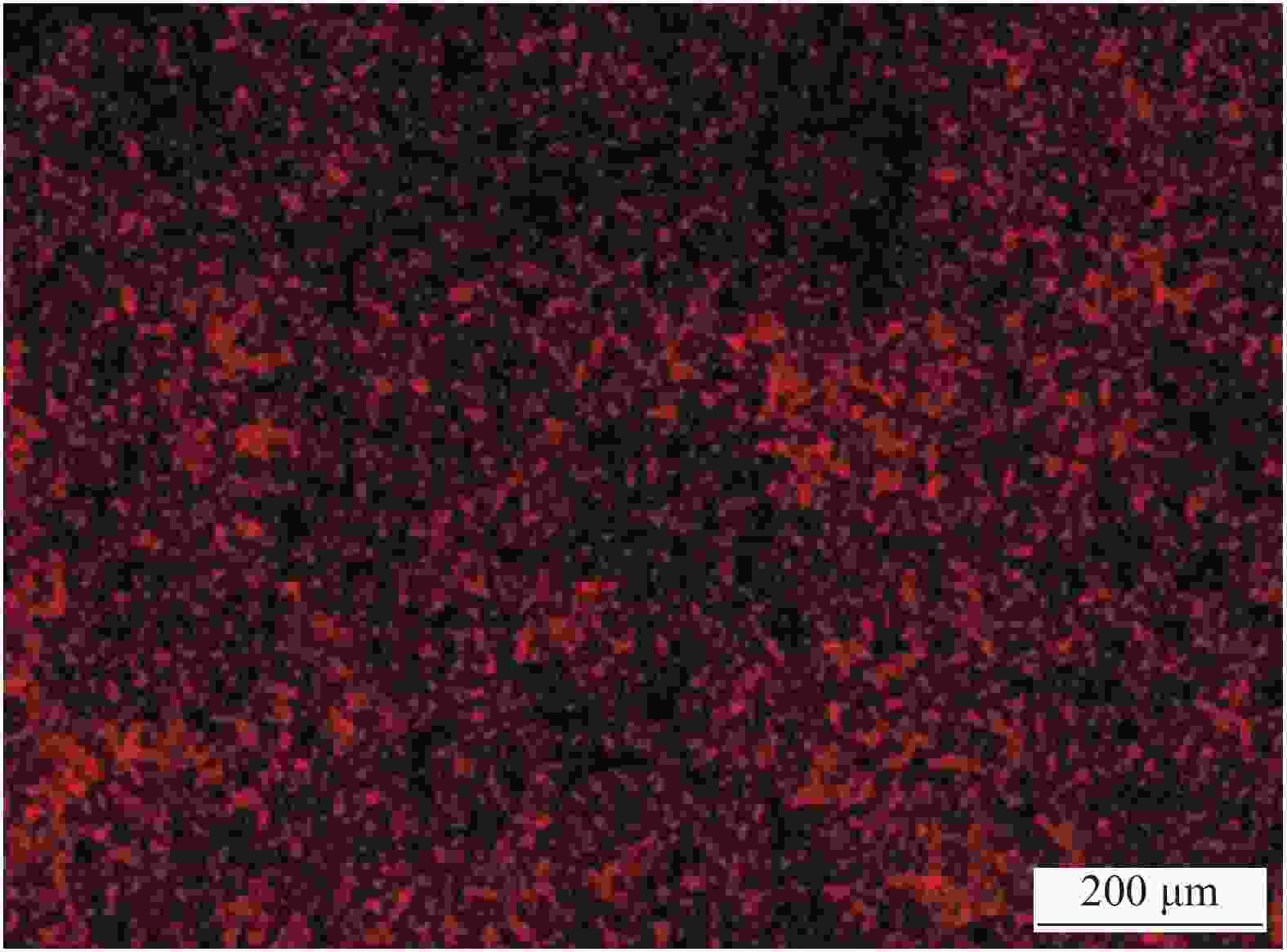

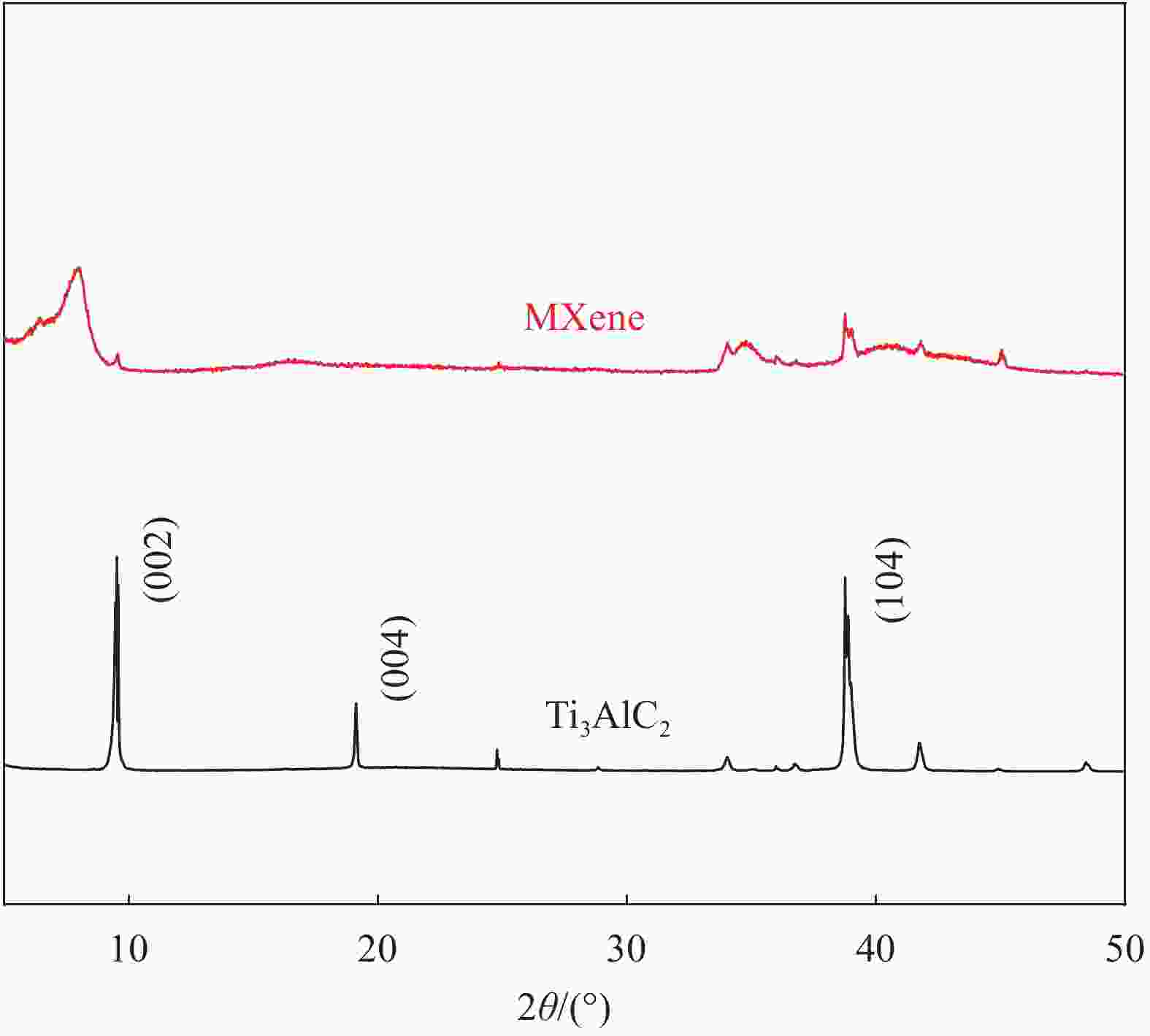

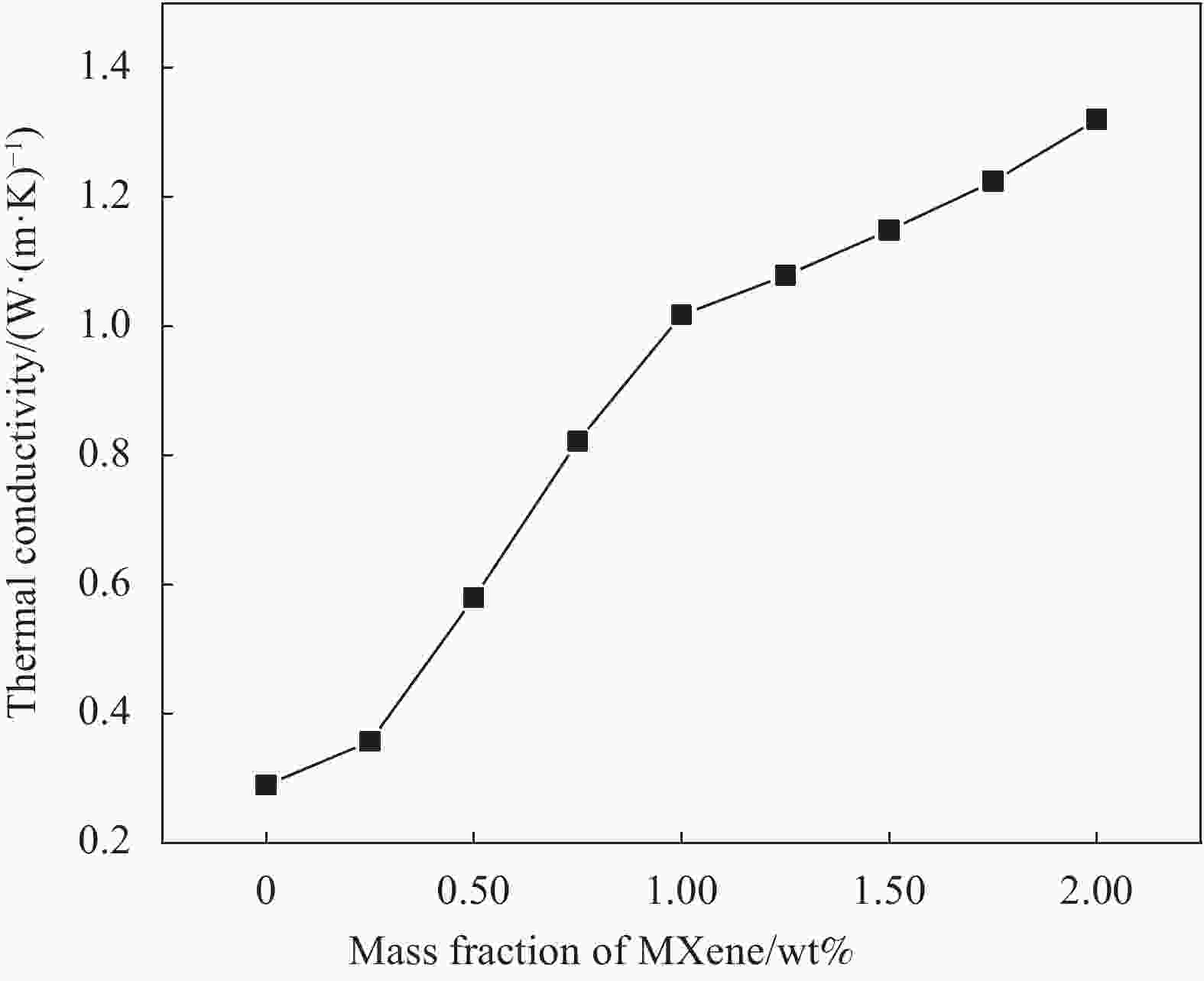

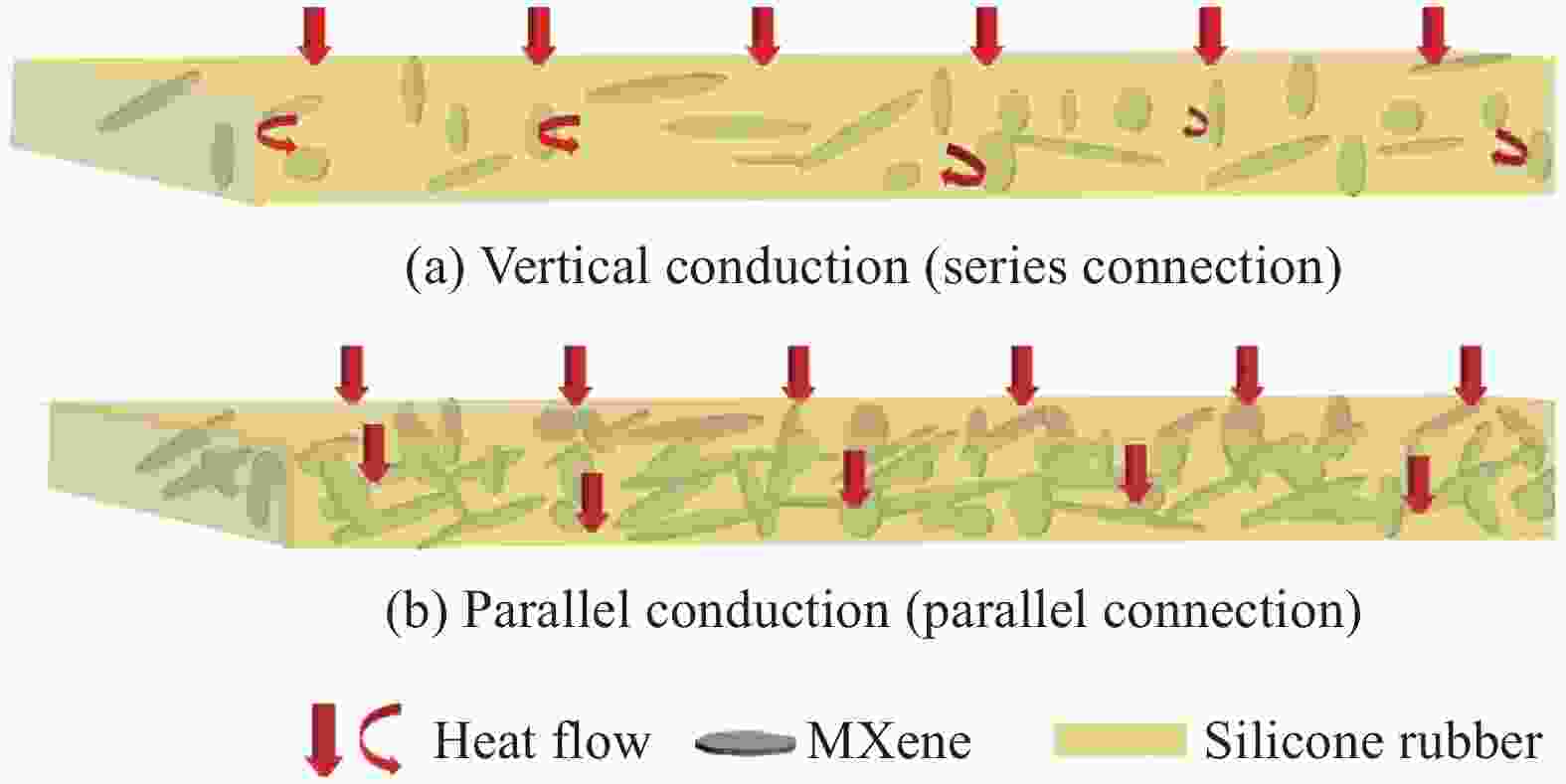

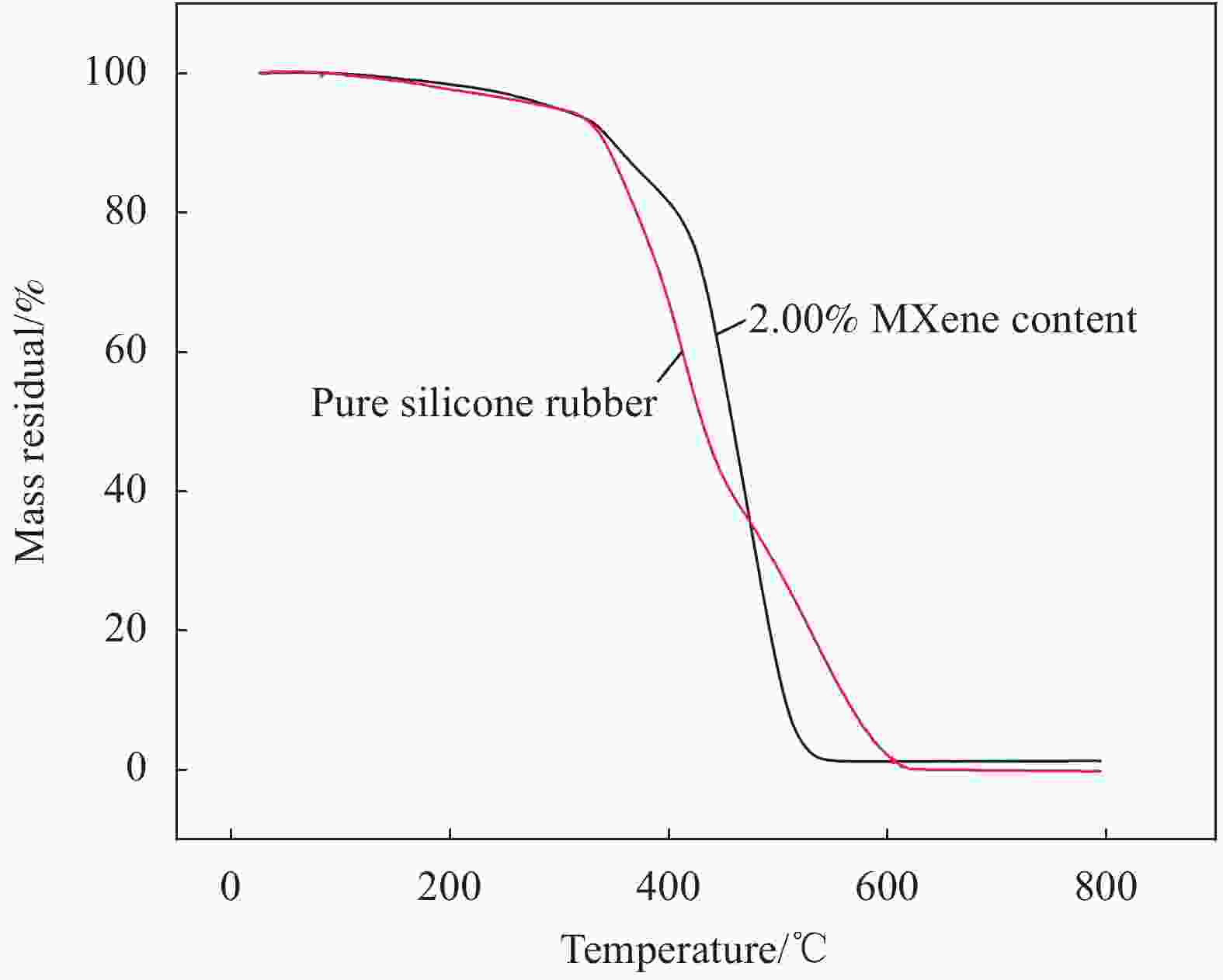

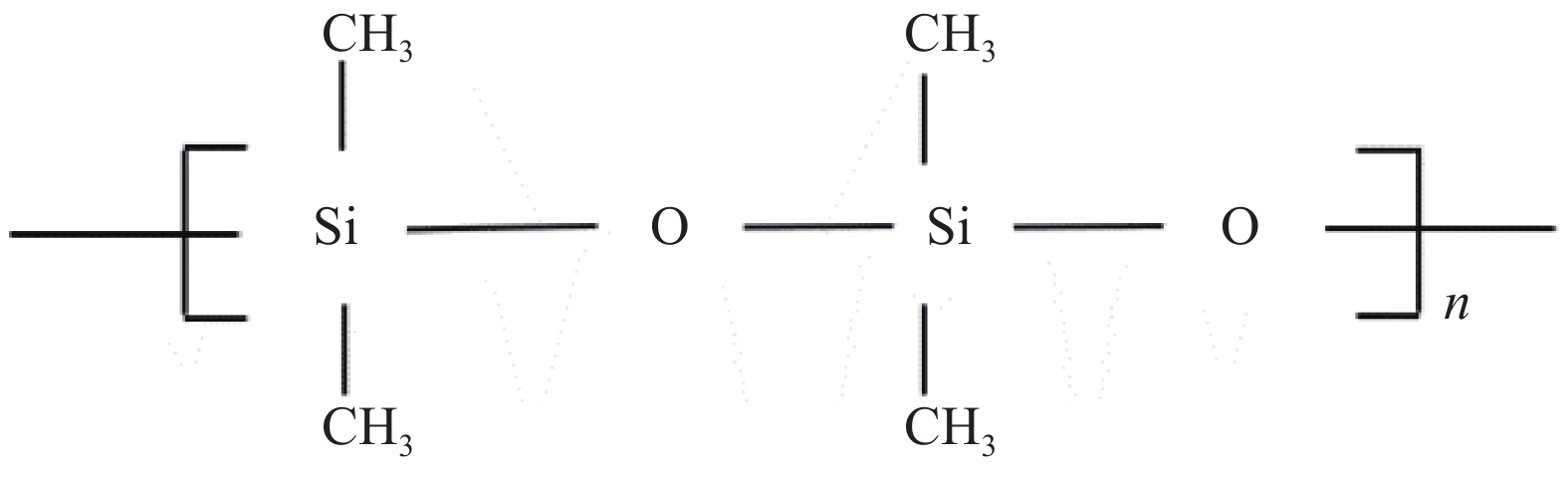

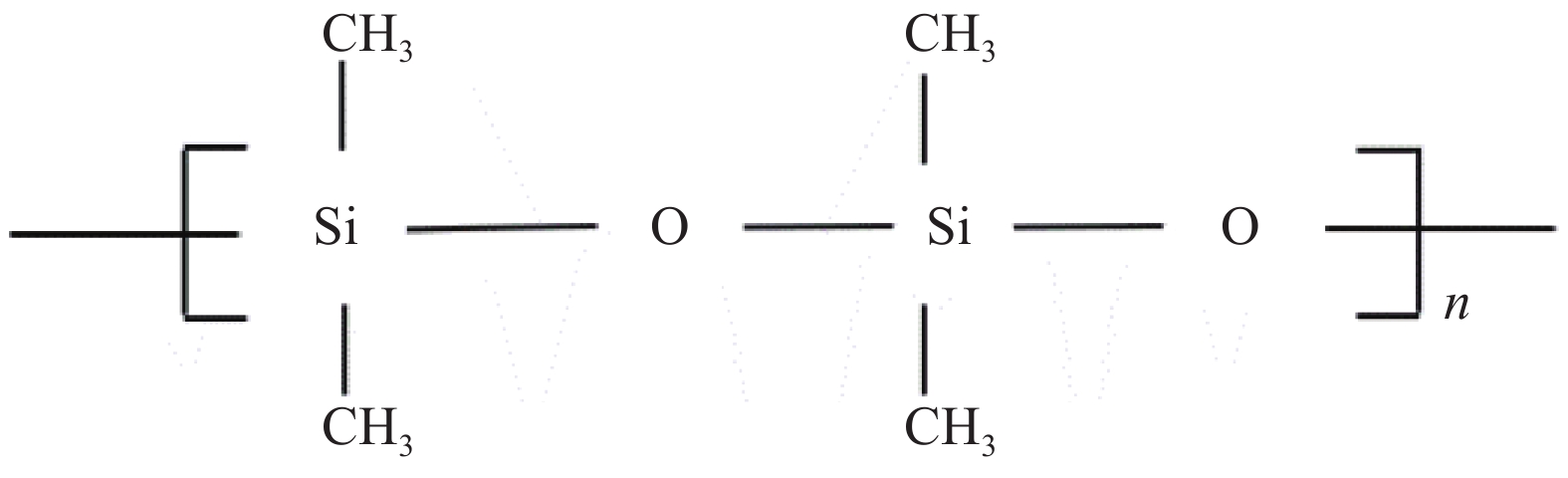

摘要: 随着5G时代的来临,各类电子元器件发热功率明显增大。因此,电子元器件及设备的散热问题亟待解决,使得对高导热材料的需求日益迫切。为此,利用化学刻蚀法制备二维MXene材料(Ti3C2Tx),采用标准溶液共混法,将制备得到的MXene与硅橡胶复合,得到MXene/硅橡胶复合材料,研究了MXene添加量对MXene/硅橡胶导热性能的影响。使用SEM和XRD对MXene进行结构表征,并测试纯硅橡胶与MXene/硅橡胶复合材料的力学性能、导热导电性能和热稳定性等。结果表明:化学刻蚀法成功制备了呈经典“手风琴”层状结构的MXene,当MXene添加量为2.00wt%时,MXene/硅橡胶复合材料的热导率最高可达1.32 W/(m·K),是纯硅橡胶的4.55倍,此时,体积电阻率降低4个数量级,力学性能和热稳定性也得到了显著提高。Abstract: With the advent of 5G era, the heating power of various electronic components has increased significantly. Therefore, the problem of heat dissipation of electronic components and equipment needs to be solved urgently, which makes the demand for high thermal conductivity materials increasingly urgent. The two-dimensional MXene material (Ti3C2Tx) was prepared by chemical etching method, and the MXene/silicone rubber composites were obtained by using standard solution blending method. The effect of the addition amount of MXene on the thermal conductivity of the MXene/silicone rubber composites were studied. SEM and XRD were used to characterize the structure of MXene, and the mechanical properties, thermal conductivity and thermal stability of pure silicone rubber and the composites were tested. The results show that the classic accordion layered MXene is successfully prepared by chemical etch method. When the added MXene is 2.00wt%, the thermal conductivity of the composites is up to 1.32 W/(m·K), which is 4.55 times that of pure silicone rubber. At this time, the volume resistivity of the composites is reduced by 4 orders of magnitude. The mechanical properties and thermal stability of silicone rubber are also improved remarkably.

-

Key words:

- MXene /

- silicone rubber /

- thermal conductivity /

- chemical etching /

- two-dimensional materials

-

表 1 MXene添加量对MXene/硅橡胶复合材料力学性能的影响

Table 1. Effect of MXene content on mechanical properties of MXene/silicone rubber composites

Content of

MXene/wt%Elongation

at break/%Tensile

strength/MPa0 107±2.4 0.54±0.02 0.25 118±2.6 0.78±0.02 0.50 127±3.0 1.03±0.03 0.75 140±3.1 1.25±0.04 1.00 161±3.3 1.38±0.06 1.25 173±3.6 1.63±0.07 1.50 170±3.1 1.70±0.07 1.75 166±2.8 2.02±0.09 2.00 162±2.8 2.52±0.10 表 2 MXene/硅橡胶复合材料的体积电阻率

Table 2. Volume resistivity of MXene/silicone rubber composites

Content of MXene/wt% 0 0.25 0.50 0.75 1.00 1.25 1.50 1.75 2.00 Volume resistivity/(1011 Ω·cm) 475.70 327.57 160.76 87.06 10.21 1.63 0.69 0.20 0.07 -

[1] 刘旺冠, 郭建华, 蒋兴华. 填充型导热绝缘硅橡胶的研究进展[J]. 弹性体, 2020, 30(5):55-63. doi: 10.3969/j.issn.1005-3174.2020.05.013LIU Wangguan, GUO Jianhua, JIANG Xinghua. Advances in research on thermal insulating silicone rubber[J]. Elastomer,2020,30(5):55-63(in Chinese). doi: 10.3969/j.issn.1005-3174.2020.05.013 [2] DAI W, MA T F, YAN Q W, et al. Metal-level thermally conductive yet soft graphene thermal interface materials[J]. ACS Nano,2019,13(10):11561-11571. doi: 10.1021/acsnano.9b05163 [3] 刘少刚, 王李波, 王晓龙, 等. 高导热网络聚合物基复合材料的研究进展[J]. 中国塑料, 2019, 33(8):127-135.LIU Shaogang, WANG Libo, WANG Xiaolong, et al. Research progress of polymer matrix composites with high thermal conductivity network[J]. China Plastics,2019,33(8):127-135(in Chinese). [4] ZHANG F, FENG Y Y, FENG W. Three-dimensional interconnected networks for thermally conductive polymer composites: Design, preparation, properties, and mechanisms[J]. Materials Science & Engineering R: Reports,2020,142:100580. [5] 杜伯学, 孔晓晓, 肖萌, 等. 高导热聚合物基复合材料研究进展[J]. 电工技术学报, 2018, 33(14):3149-3159.DU Boxue, KONG Xiaoxiao, XIAO Meng, et al. Research progress of polymer matrix composites with high thermal conductivity[J]. Transactions of China Electrotechnical Society,2018,33(14):3149-3159(in Chinese). [6] WANG X, DOU W. Preparation of graphite oxide (GO) and the thermal stability of silicone rubber/GO nanocompo-sites[J]. Thermochimica Acta,2011,529:25-28. [7] ANASORI B, LUKATSKAYA M R, GOGOTSI Y. 2D metal carbides and nitrides (MXenes) for energy storage[J]. Nature Reviews Materials,2017,2(2):1-17. [8] 郑伟, 孙正明, 张培根, 等. MXene的研究进展[J]. 材料导报, 2017, 31(5):1-14. doi: 10.11896/j.issn.1005-023X.2017.05.001ZHENG Wei, SUN Zhengming, ZHANG Peigen, et al. Research progress of MXene[J]. Material Guide,2017,31(5):1-14(in Chinese). doi: 10.11896/j.issn.1005-023X.2017.05.001 [9] FENG A L, HOU T Q, JIA Z R, et al. Preparation and characterization of epoxy resin filled with Ti3C2Tx MXene nanosheets with excellent electric conductivity[J]. Nanomaterials,2020,10(1):162. [10] MA T M, SONG G C, WANG B, et al. Effective usage of 2D MXene nanosheets as solid lubricant-Influence of contact pressure and relative humidity[J]. Applied Surface Science,2020,531:147311. [11] LIU R, LI W. High-thermal-stability and high-thermal-conductivity Ti3C2Tx MXene/poly(vinyl alcohol) (PVA) composites[J]. ACS Omega,2018,3:2609-2617. doi: 10.1021/acsomega.7b02001 [12] 刘超, 李茜, 郝丽芬, 等. MXene的功能化改性及其应用研究进展[J]. 复合材料学报, 2021, 38(4):1020-1028.LIU Chao, LI Qian, HAO Lifen, et al. Progress in functionalized modification of MXene and its application[J]. Acta Materiae Compositae Sinica,2021,38(4):1020-1028(in Chinese). [13] SONG D, LI X, LI X P, et al. Hollow-structured MXene-PDMS composites as flexible, wearable and highly bendable sensors with wide working range[J]. Journal of Colloid and Interface Science,2019,555:751-758. doi: 10.1016/j.jcis.2019.08.020 [14] HE W, SOHN M, MA R, et al. Flexible single-electrode triboelectric nanogenerators with MXene/PDMS composite film for biomechanical motion sensors[J]. Nano Energy,2020,78:105383. [15] CAI Y W, ZHANG X N, WANG G G, et al. A flexible ultra-sensitive triboelectric tactile sensor of wrinkled PDMS/MXene composite films for E-skin[J]. Nano Energy,2021,81:105663. [16] CAO Y, DENG Q H, LIU Z D, et al. Enhanced thermal properties of poly(vinylidene fluoride) composites with ultrathin nanosheets of MXene[J]. RSC Advances,2017,7(33):20494-20501. doi: 10.1039/C7RA00184C [17] LI J, DU Y, HUO C, et al. Thermal stability of two-dimensional Ti2C nanosheets[J]. Ceramics International,2015,41(2):2631-2635. doi: 10.1016/j.ceramint.2014.10.070 [18] 中国国家标准化管理委员会. GB/T 528—2009硫化橡胶或热塑性橡胶拉伸应力应变性能的测定[S]. 北京: 中国标准出版社, 2009.Standardization Administration of the People’s Republic of China. GB/T 528—2009 Rubber, vulcanized or thermoplastic—Determination of tensile stress-strain properties[S]. Beijing: China Standards Press, 2009(in Chinese). [19] 中国国家标准化管理委员会. GB/T 1410—2006固体绝缘材料体积电阻率和表面电阻率试验方法[S]. 北京: 中国标准出版社, 2006.Standardization Administration of the People’s Republic of China. GB/T 1410—2006 Methods of test for volume resistivity and surface resistivity of solid electrical insulating materials[S]. Beijing: China Standards Press, 2006(in Chinese). [20] International Organization for Standardization. Plastics: Determination of thermal conductivity and thermal diffusivity Part 2: Transient plane heat source (hot disc) method: ISO 22007-2: 2008[S]. Switzerland: International Organization for Standardization, 2008. [21] 赵敬棋, 孟凡成, 申景博, 等. 导热高分子复合材料的研究进展[J]. 化学工业与工程, 2020, 37(3):67-73.ZHAO Jingqi, MENG Fancheng, SHEN Jingbo, et al. Research progress of thermally conductive polymer compo-sites[J]. Chemical Industry and Engineering,2020,37(3):67-73(in Chinese). [22] MU Q H, FENG S Y. Thermal conductivity of graphite/silicone rubber prepared by solution intercalation[J]. Thermochimica Acta,2007,462(1-2):70-75. doi: 10.1016/j.tca.2007.06.006 [23] TANG J J, YAO W, LI W L, et al. Study on a novel composite coating based on PDMS doped with modified graphene oxide[J]. Journal of Coatings Technology and Research,2018,15(2):375-383. doi: 10.1007/s11998-017-9991-9 [24] 索军营, 陈雅素, 文友谊, 等. 硅烷改性石墨烯纳米片复合硅橡胶的性能研究[J]. 有机硅材料, 2020, 34(6):6-15.SUO Junying, CHEN Yasu, WEN Youyi, et al. Properties of silane modified graphene nanocrystalline composite silicone rubber[J]. Organic Silicon Materials,2020,34(6):6-15(in Chinese). [25] 吴其光, 张海燕, 张琇滨. 碳包覆纳米铜颗粒/硫化硅橡胶导热复合材料的制备及性能[J]. 高分子材料科学与工程, 2016, 32(1):142-146.WU Qiguang, ZHANG Haiyan, ZHANG Xiubin. Preparation and properties of carbon coated copper nanoparticle/vulcanized silicone rubber thermal conductive composites[J]. Polymer Materials Science and Engineering,2016,32(1):142-146(in Chinese). [26] 陈玉琦, 冯亚凯, 赵敬棋, 等. 导热硅橡胶应用问题研究进展[J]. 化工新型材料, 2017, 45(6):244-246.CHEN Yuqi, FENG Yakai, ZHAO Jingqi, et al. Research progress on application of thermal conductive silicone rubber[J]. New Chemical Caterials,2017,45(6):244-246(in Chinese). -

下载:

下载: