Influence of blank-holder force on the draping process of unbalanced plain woven fabric preform

-

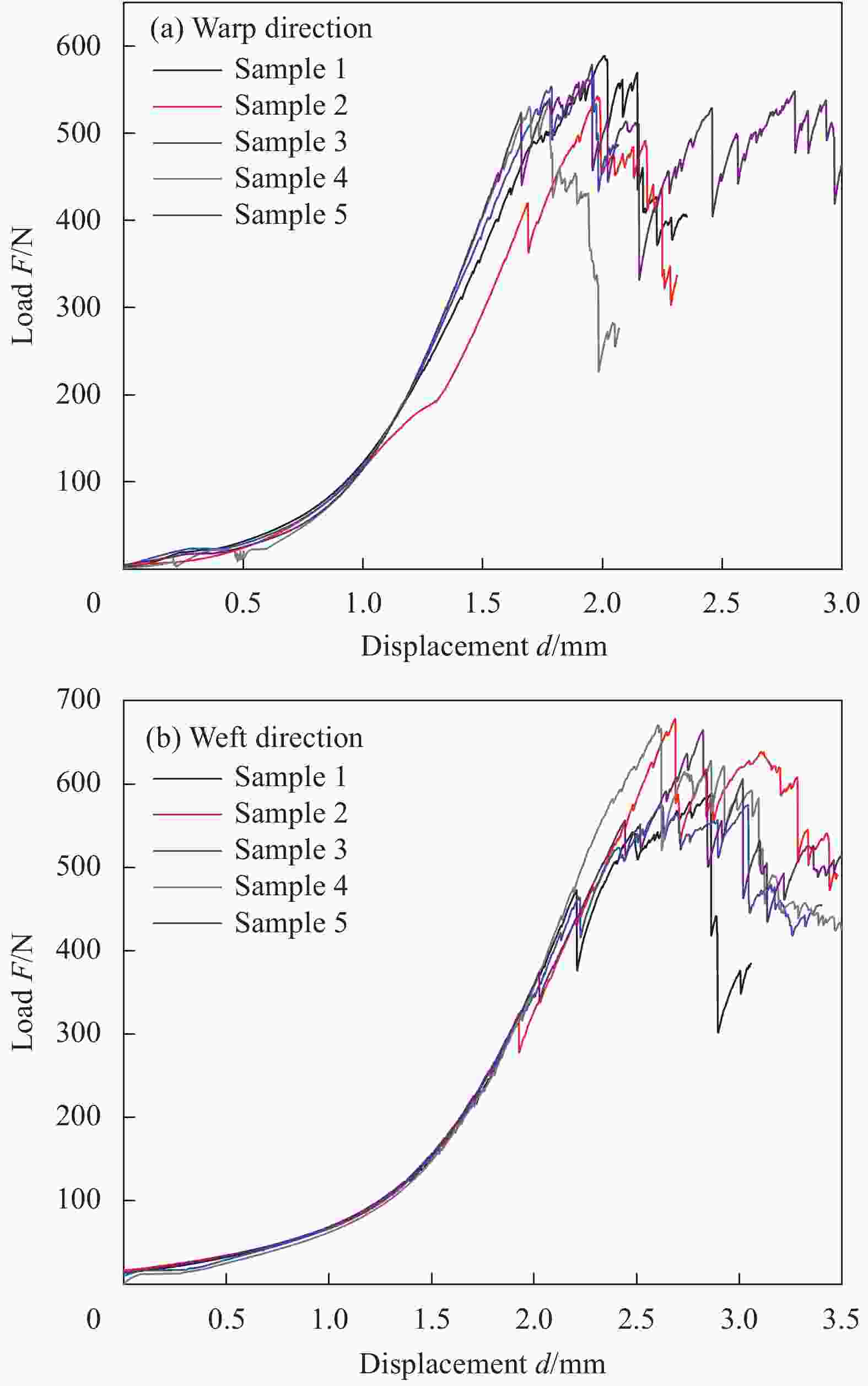

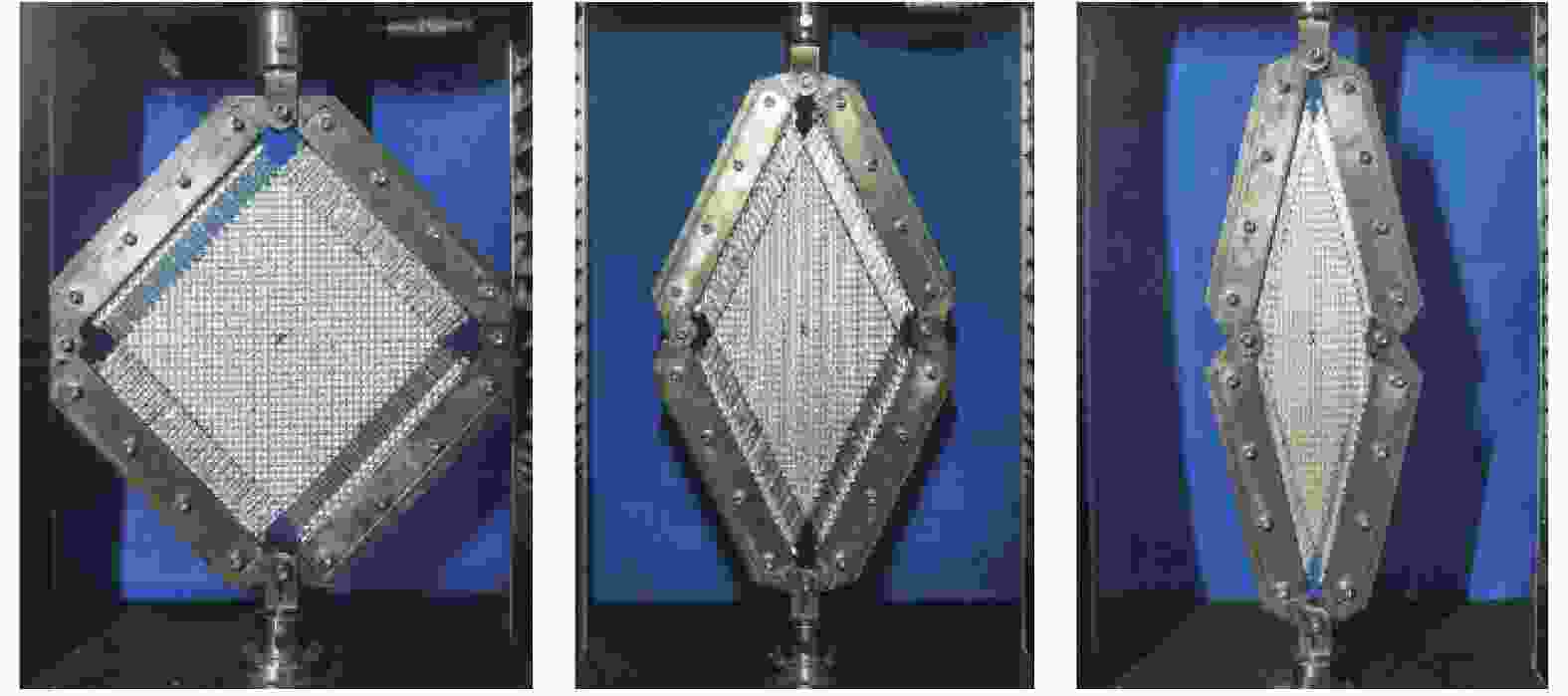

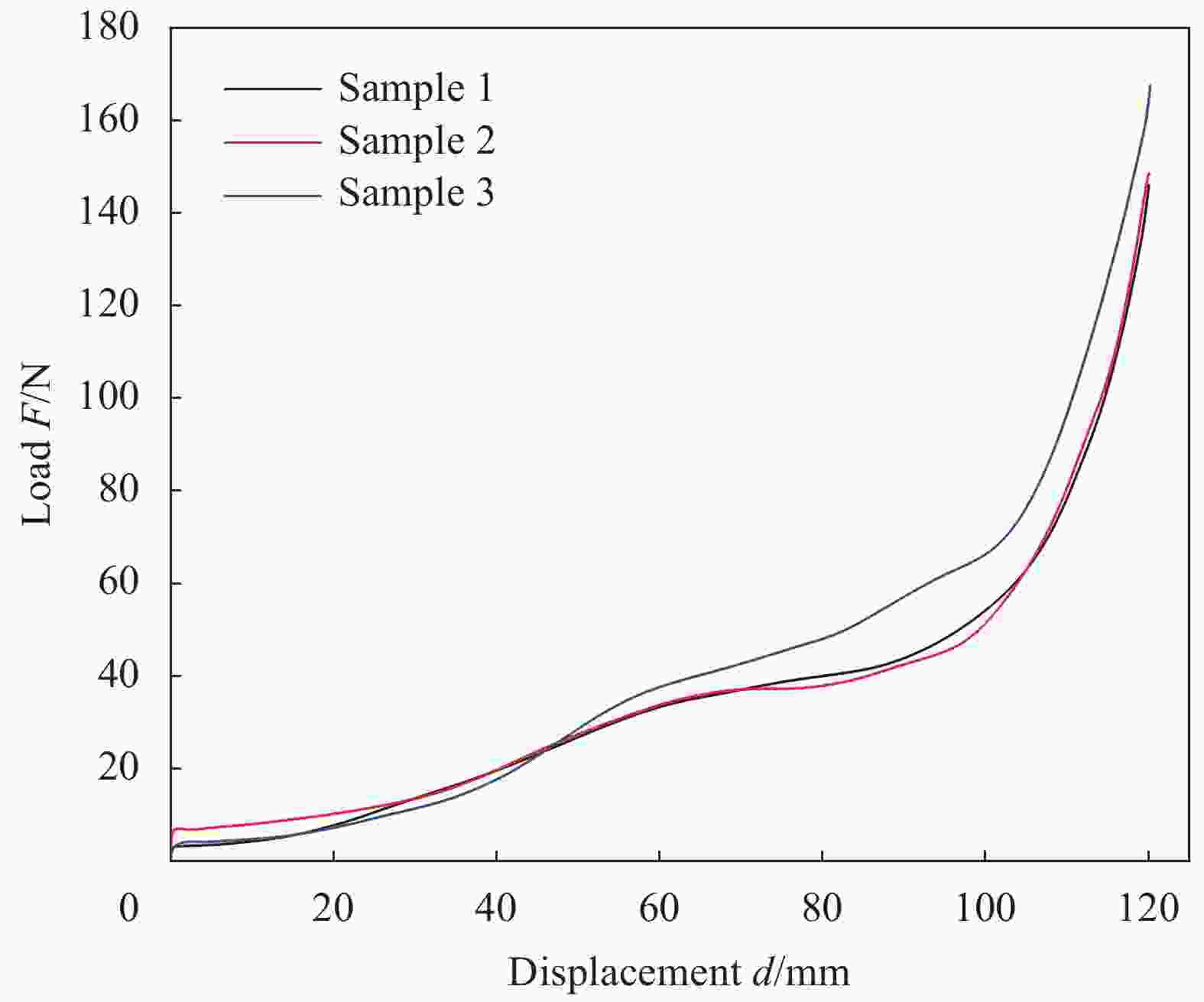

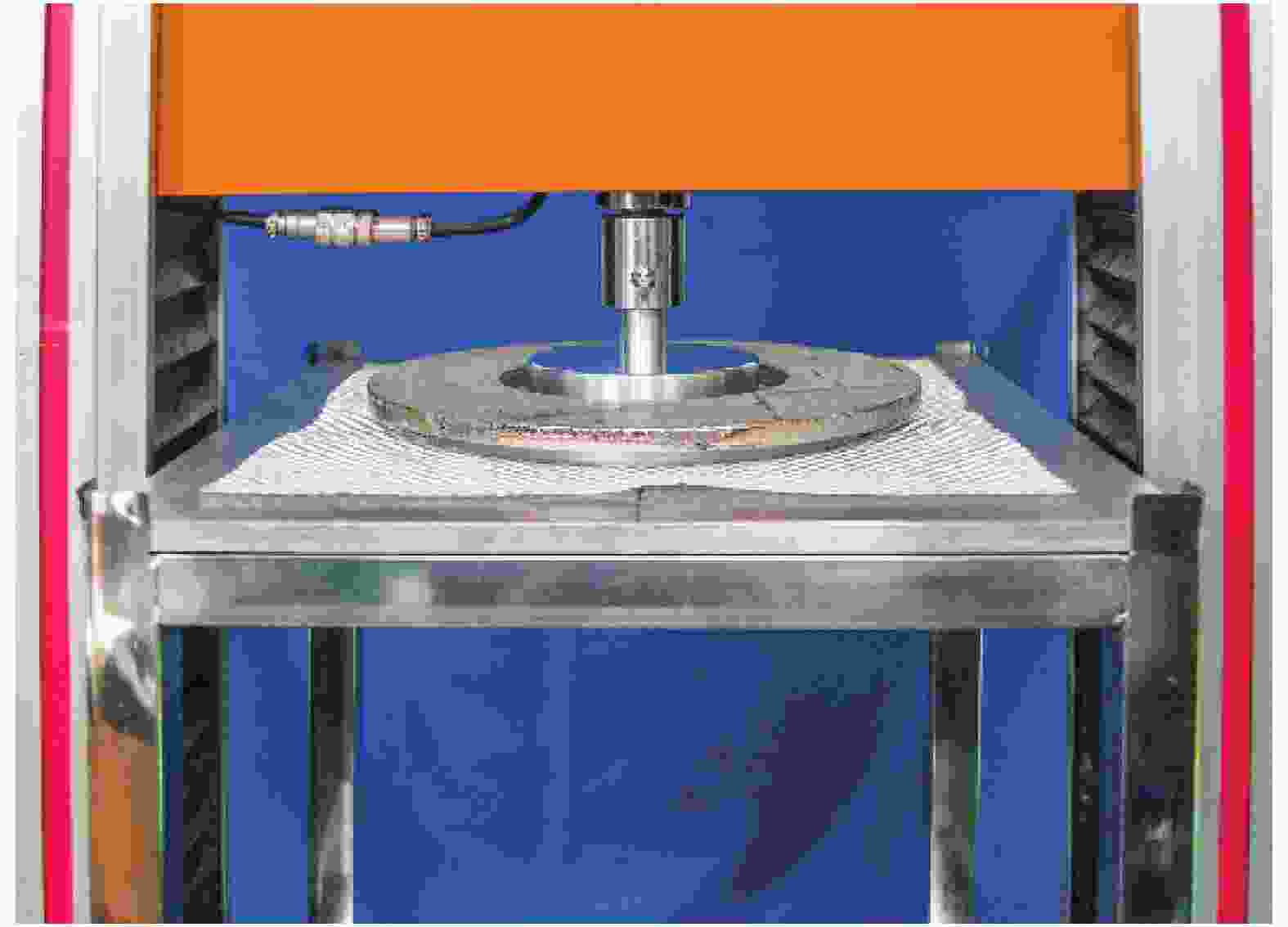

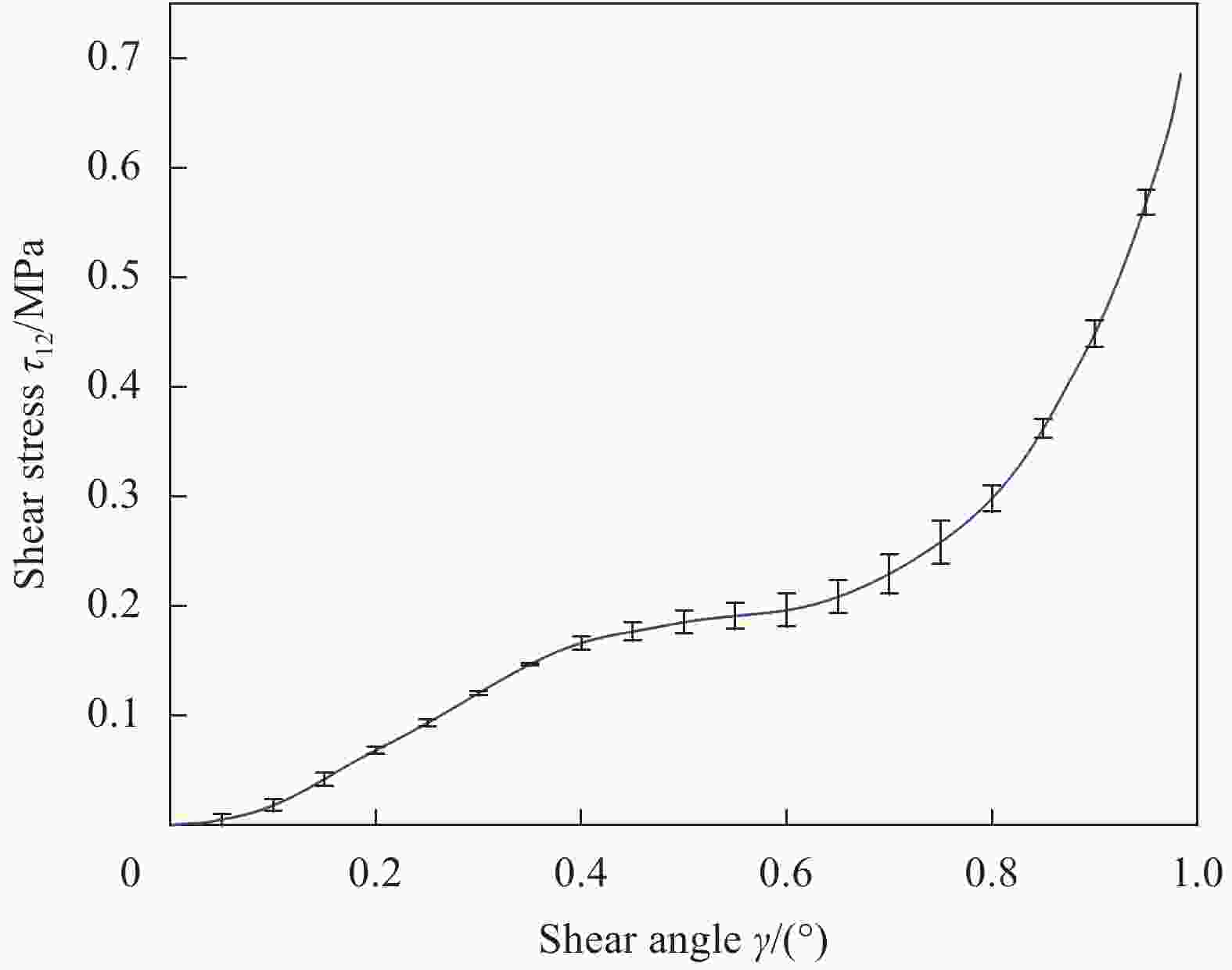

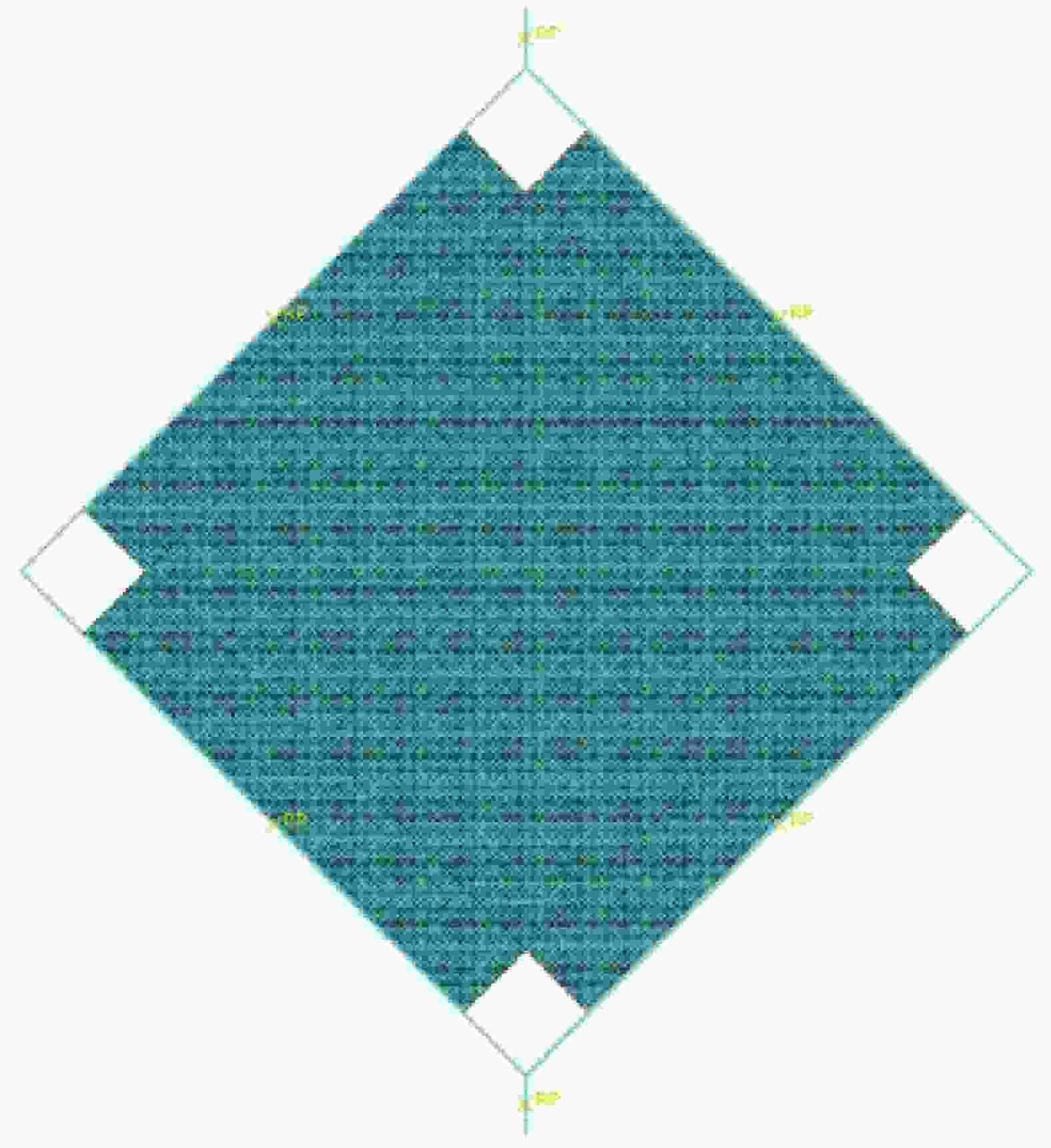

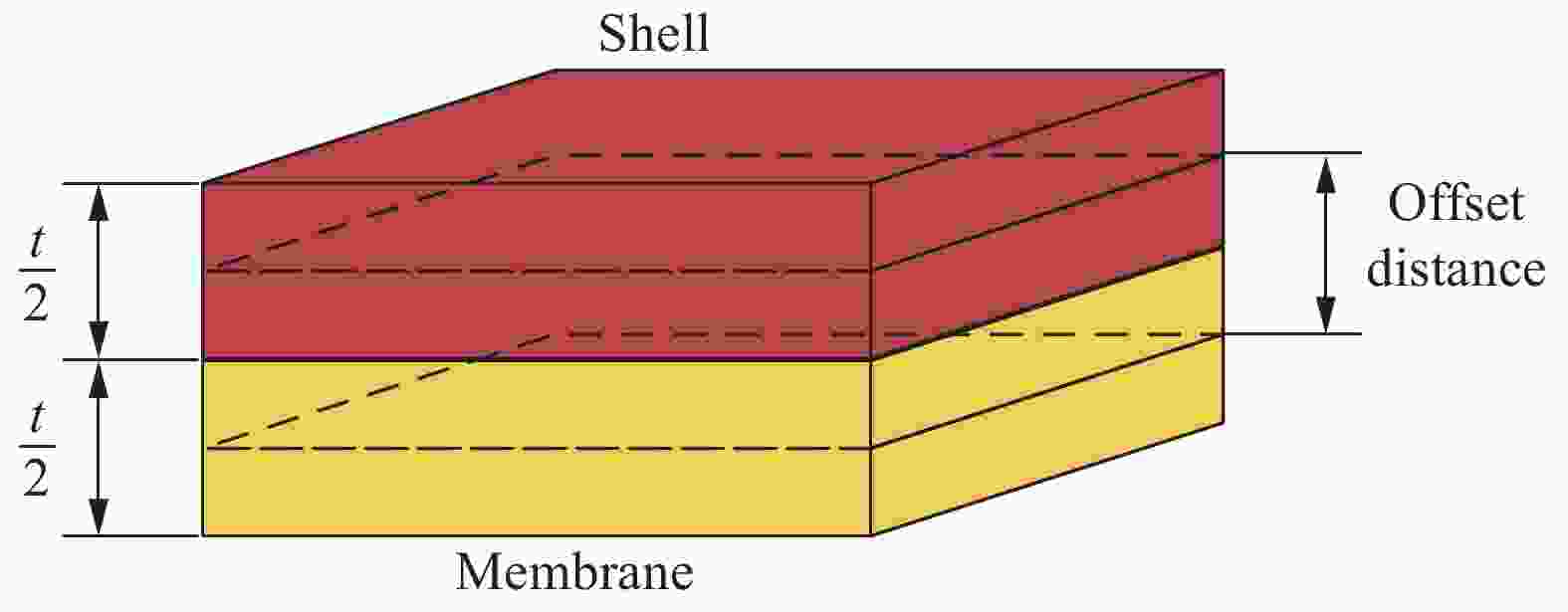

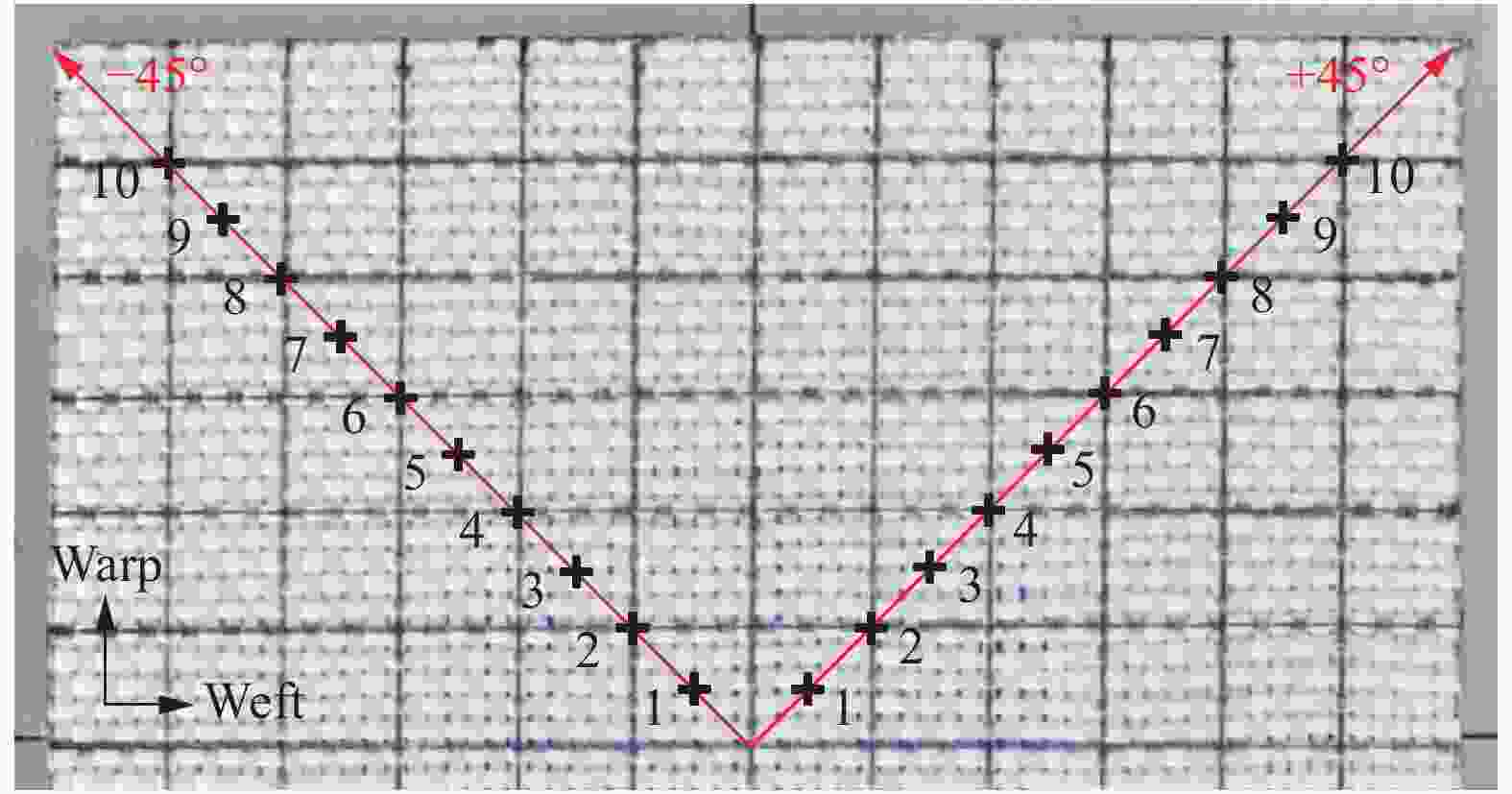

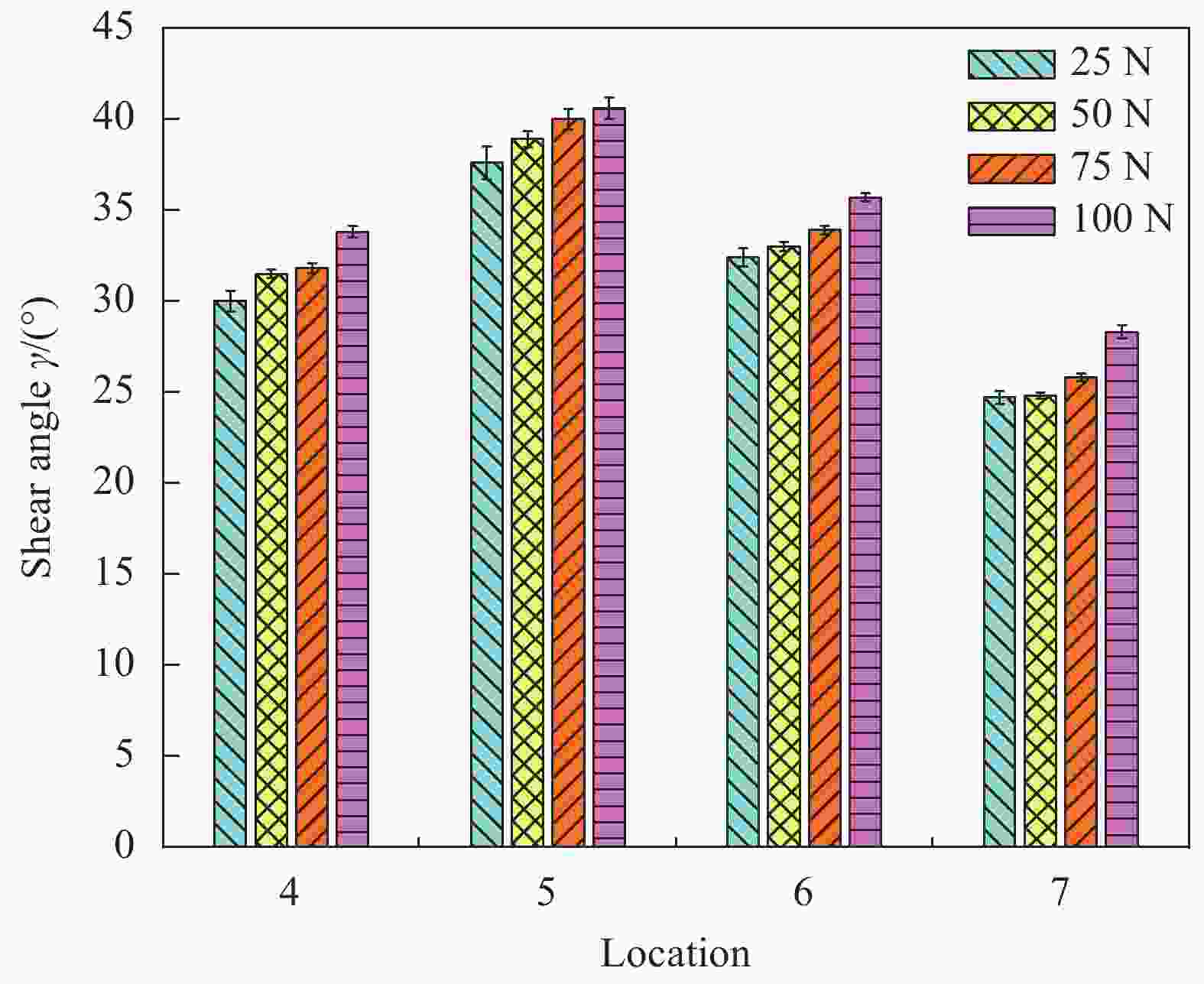

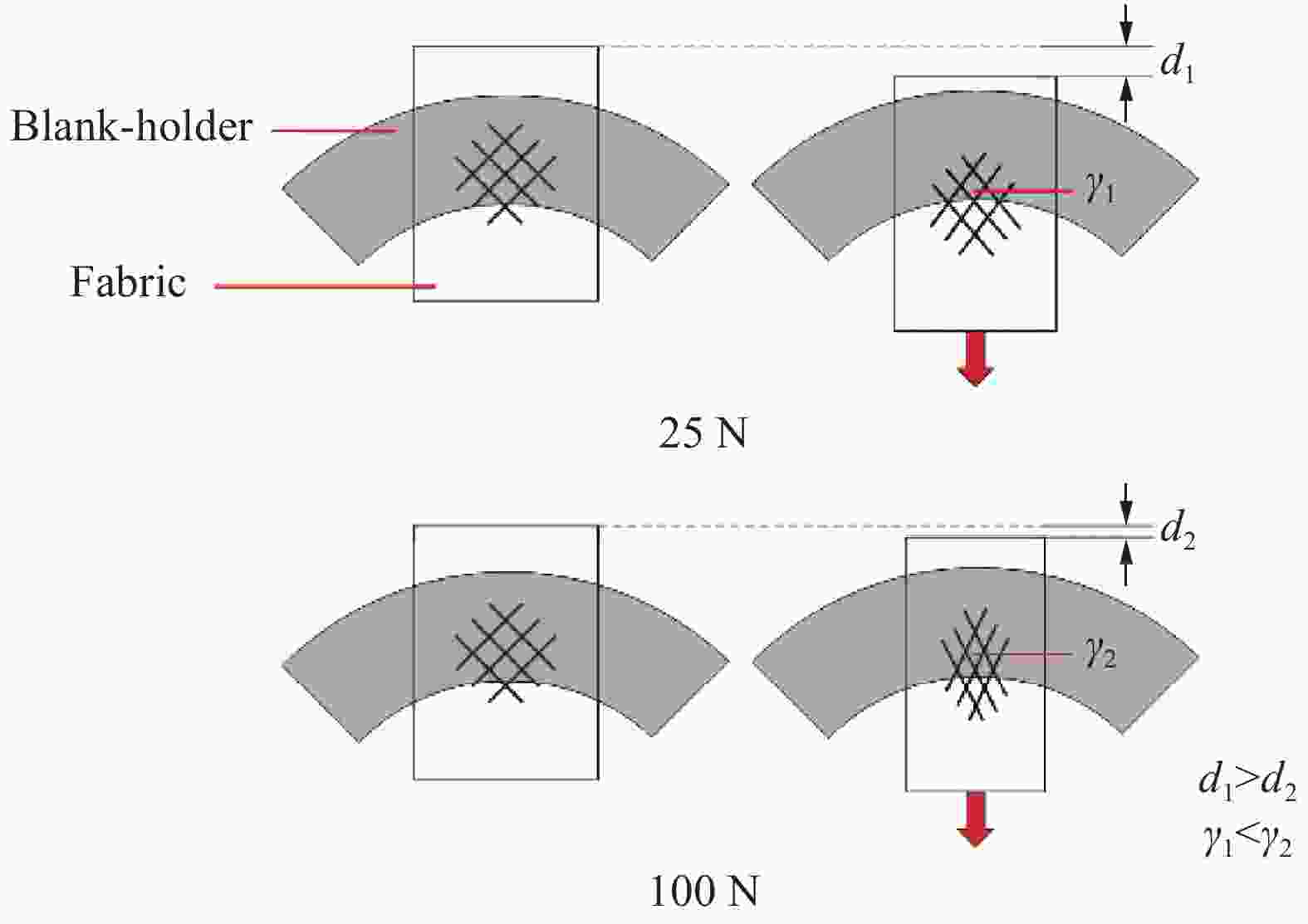

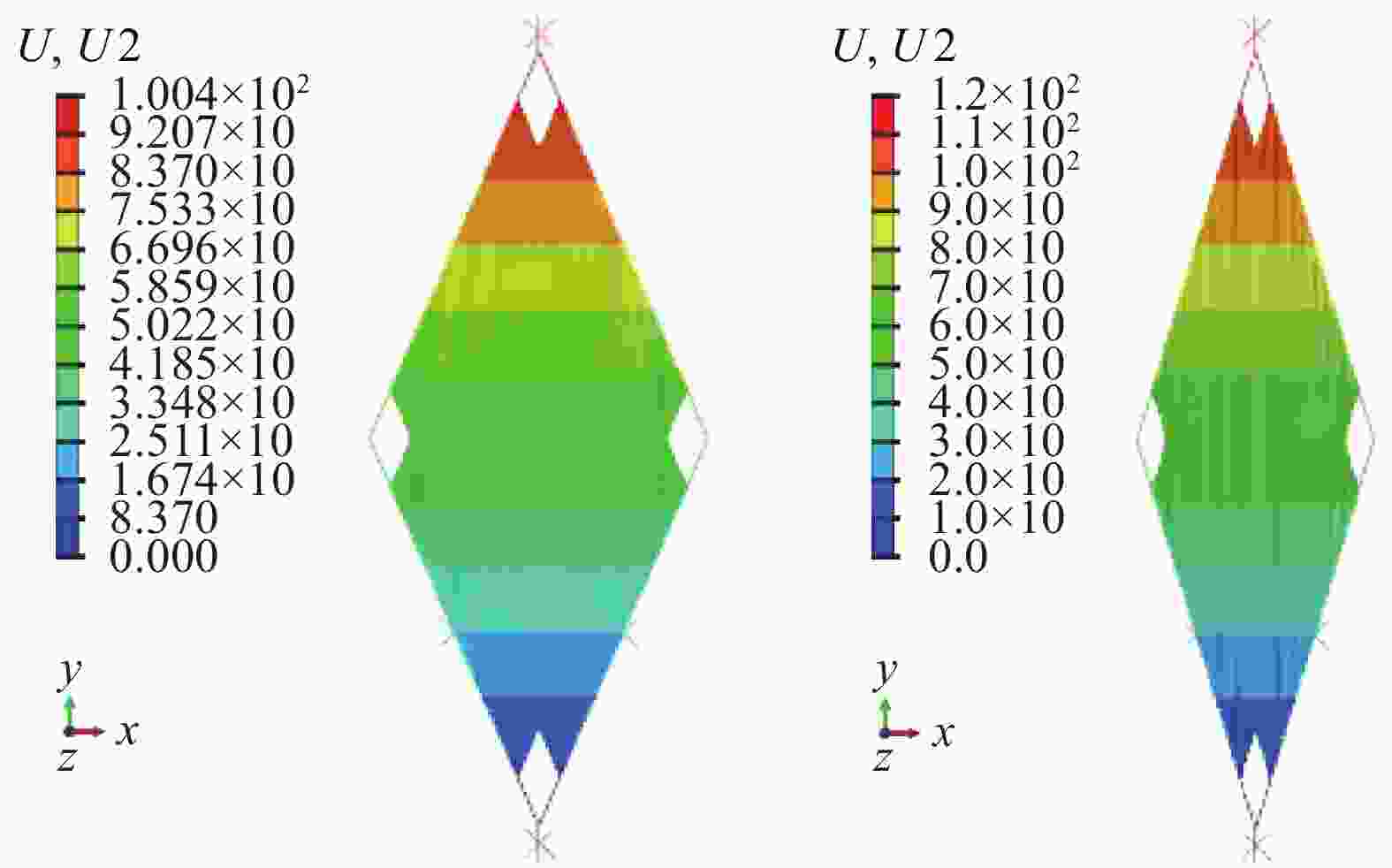

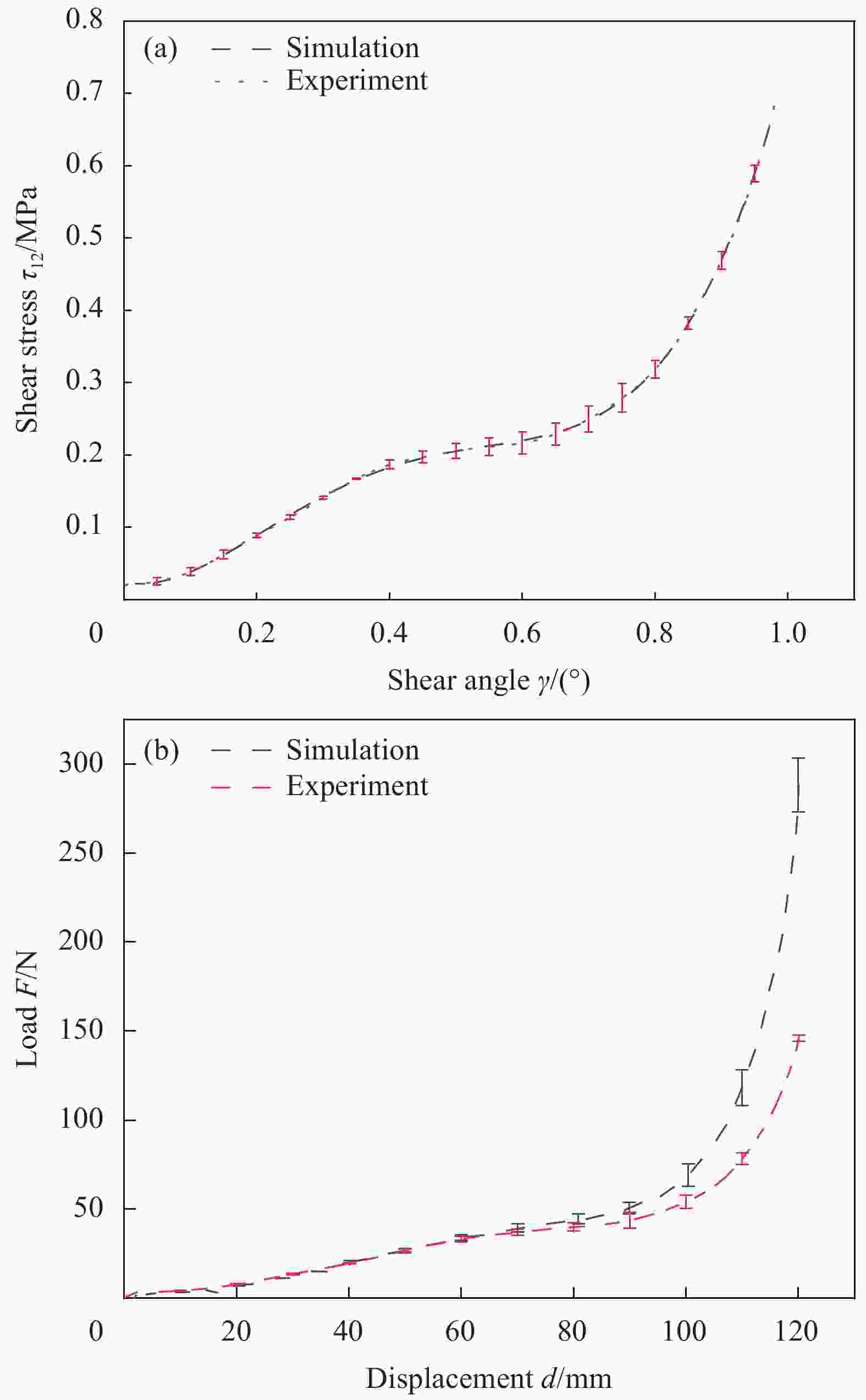

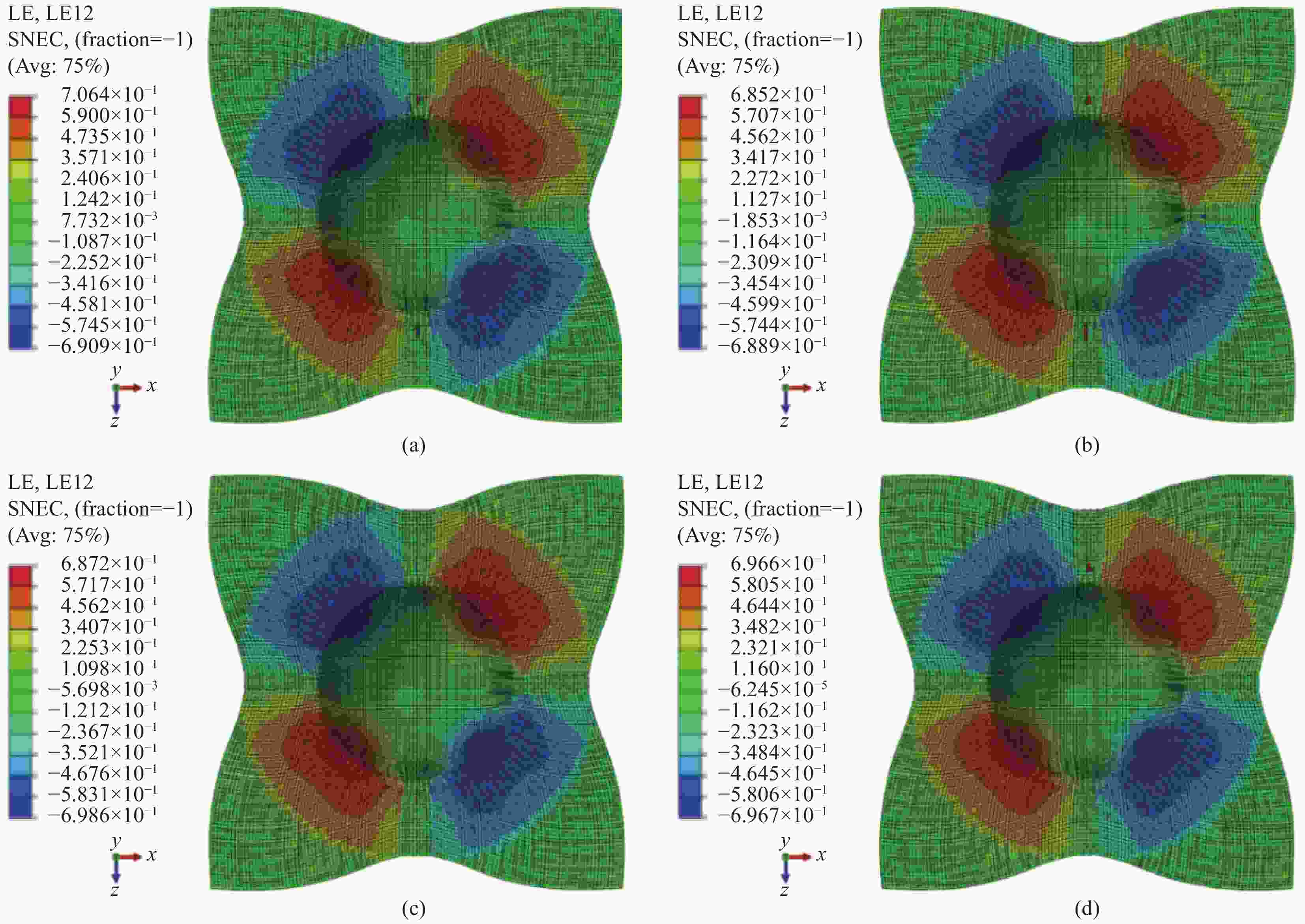

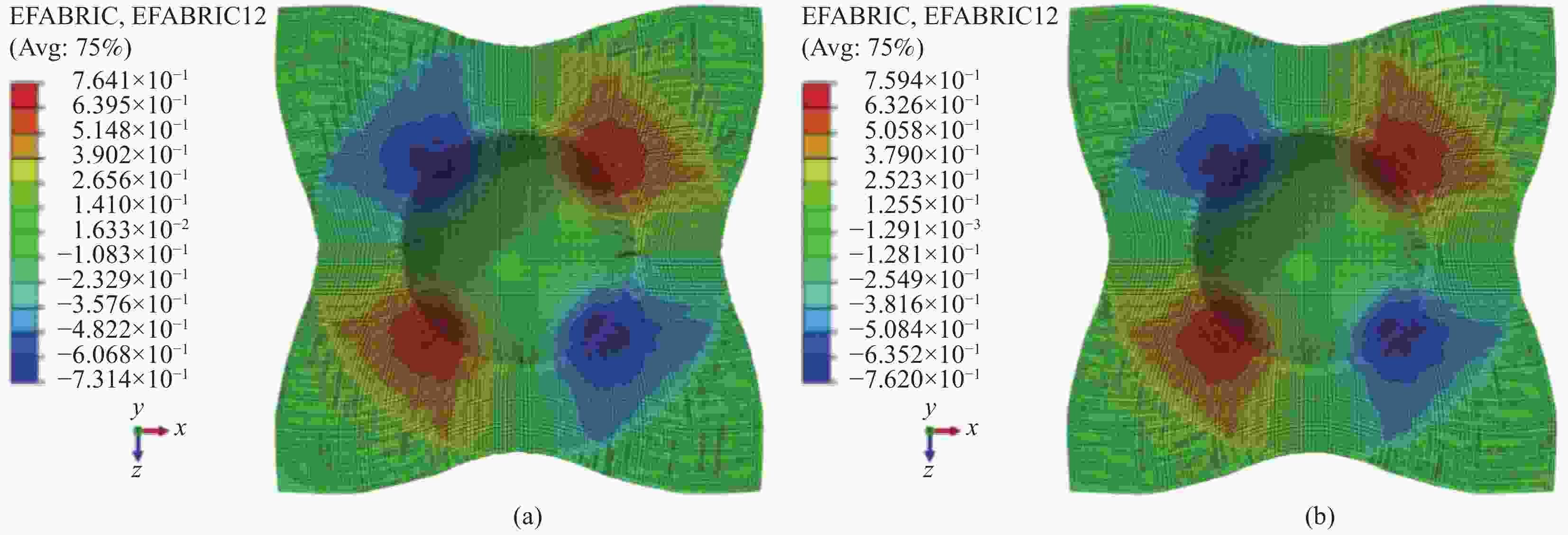

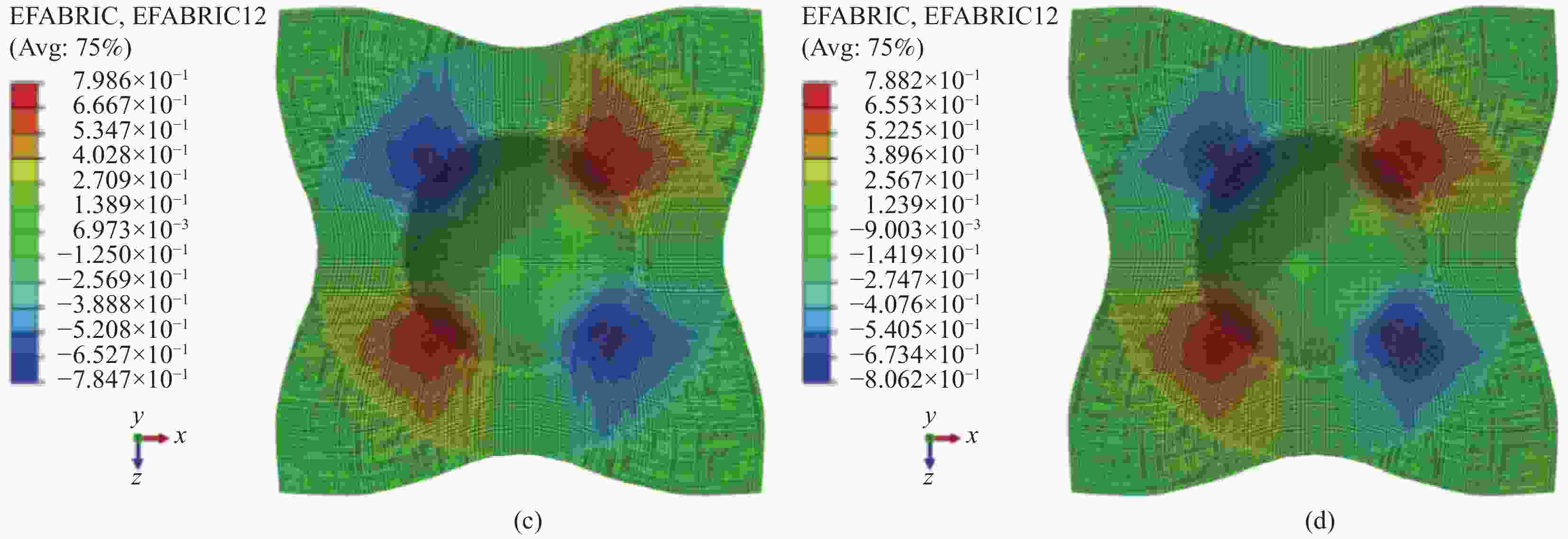

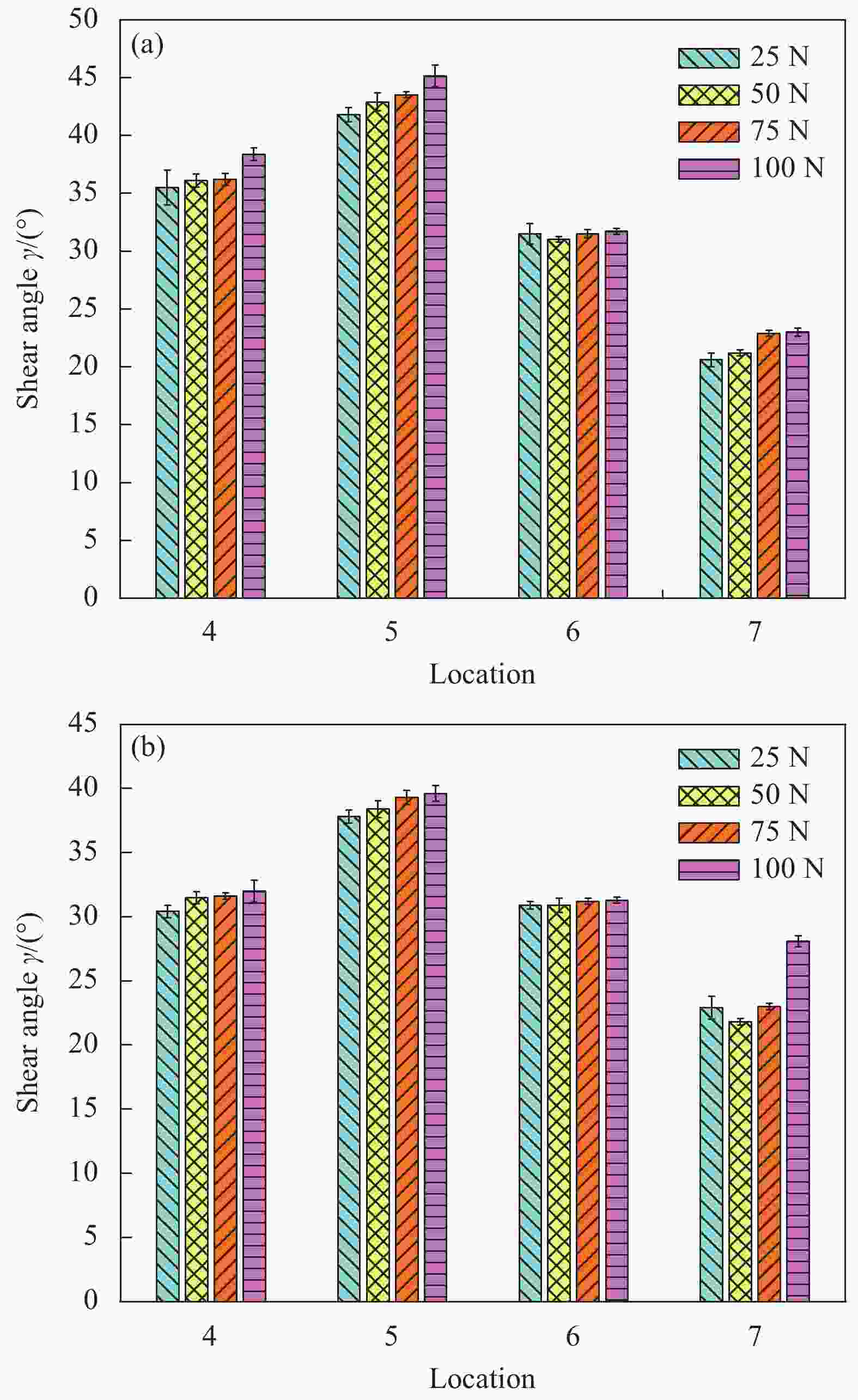

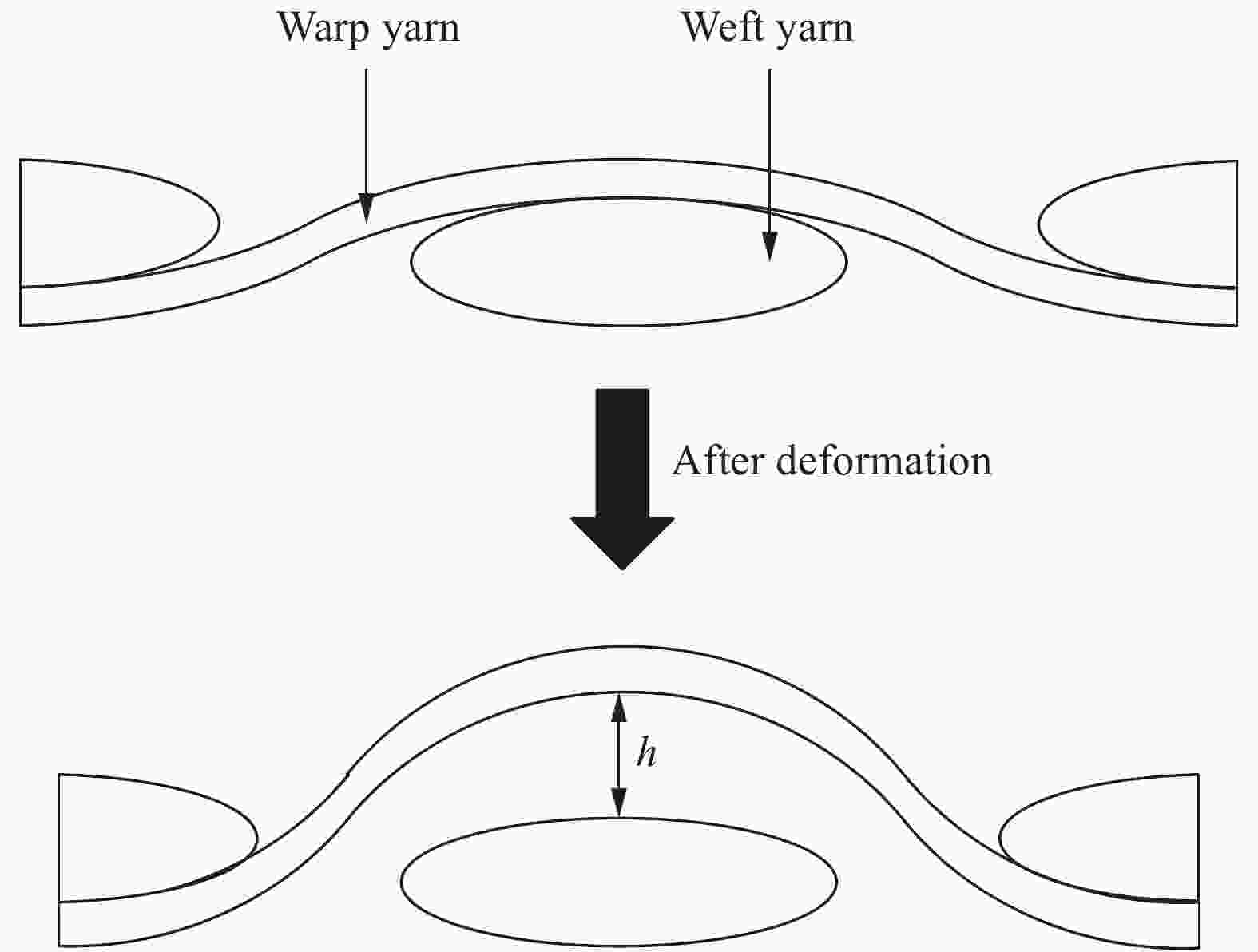

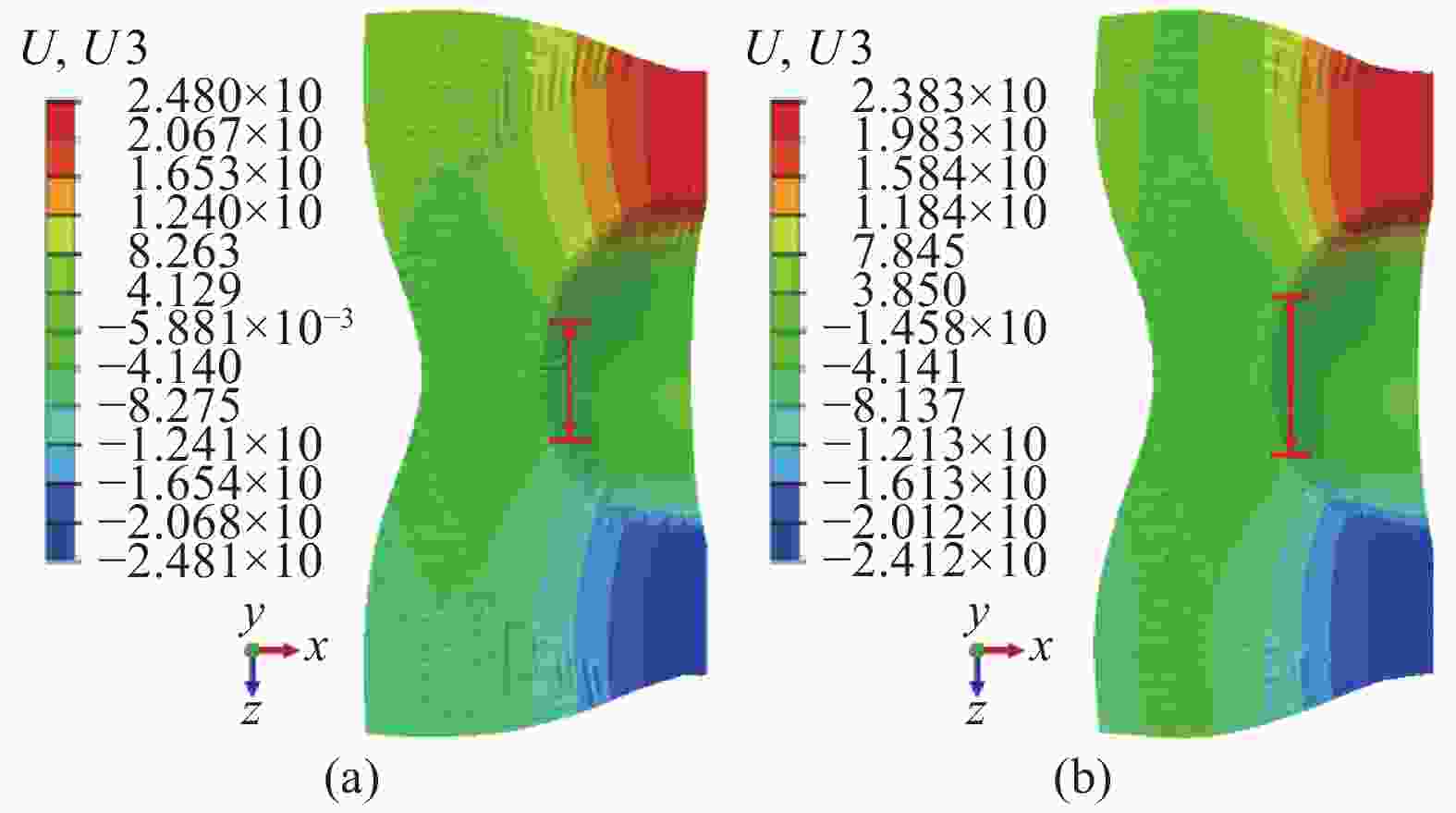

摘要: 为研究压边力对非平衡玻璃纤维平纹机织物预制体铺覆成型的作用规律,针对非平衡平纹机织物在成型过程中的大变形特征,基于非正交材料本构,建立织物面内材料变形本构模型;同时考虑面外弯曲刚度,结合壳单元,建立织物的膜(面内变形)-壳(面外变形)双层模型;利用商业有限元软件ABAQUS,结合实验方法,研究织物在不同压边力条件下的成型规律。结果表明,实验组中预制体的纤维剪切角随压边力的增加而增大;摩擦系数设置对有限元模型的模拟结果有重要影响,随着摩擦系数增大,预制体的纤维剪切角随之增大,摩擦系数为0.20时的模拟结果与实验结果最接近;考虑织物弯曲刚度的膜-壳双层单元模型的模拟结果与实验结果基本一致,而单层膜单元模型的模拟结果精度相对较低。Abstract: Considering the nonlinear deformation characteristics of unbalanced plain woven glass fiber fabric, the in-plane deformation behavior based non-orthogonal material constitutive and out-plane bending behavior were involved into a coupling finite element consisting membrane with shell element to predict the deformation behaviors of the fabric during draping process. Using the commercial finite element software ABAQUS combined with experimental method, the influence of boundary conditions on the deformation behavior was discussed. The results show that the fiber shear angle of the preformed blank increases with the increase of blank holder force in the experiments. The fiber shear angle of the preformed blank increases with the improvement of friction coefficient in the finite element model, and the simulate results are closer to the experimental results when the friction coefficient is 0.20. Compared to the model established with single-layer membrane element, the membrane-shell element model considering bending stiffness shows higher agreement with experimental results. Studies show that the bending stiffness is essential to enhance the accuracy of the simulation model, which plays an important role in the prediction of shear angle in draping process.

-

Key words:

- plain woven fabric /

- draping process /

- preform /

- numerical simulation /

- shear angle /

- blank-holder force

-

表 1 无碱玻璃纤维非平衡平纹机织物参数

Table 1. Parameters of E-glass fiber unbalanced plain woven fabric

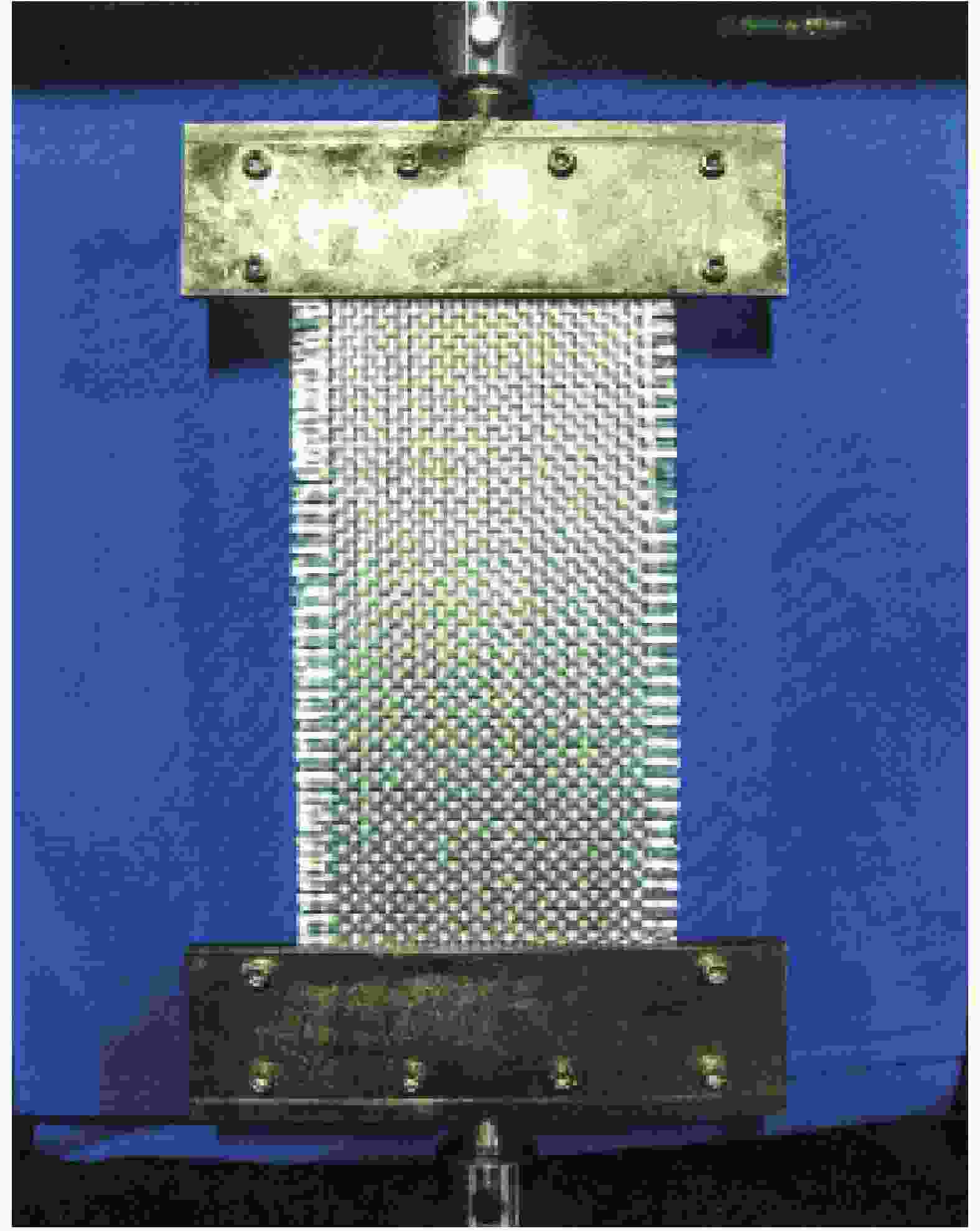

Parameter Fabric Weave Plain Areal density/(g·m−2) 600 Warp yarns/cm 2.8 Weft yarns/cm 2.5 Yarn thickness/mm 0.6 Warp yarn width/mm 2.9 Weft yarn width/mm 2.5 Fabric image

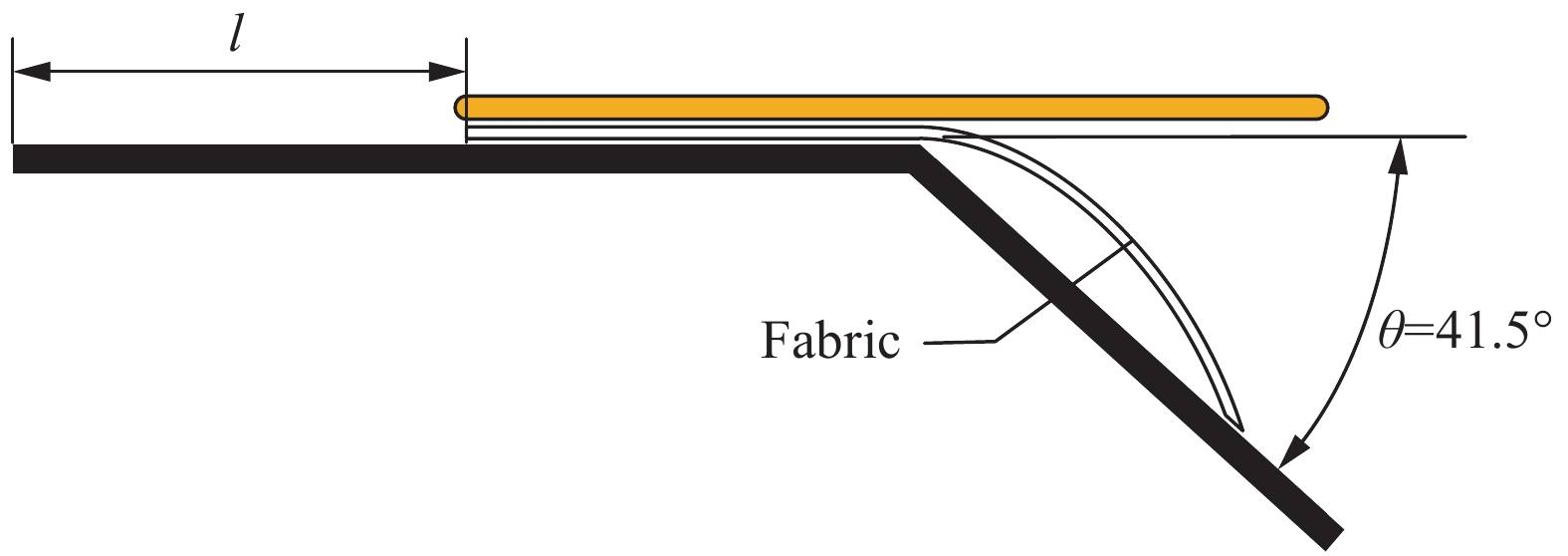

表 2 玻璃纤维平纹机织物经纬向弯曲长度测试结果

Table 2. Bending length of glass fiber plain woven fabric in warp and weft direction

Number of sample Warp/mm Weft/mm Weft/mm 1 118 121 121 2 120 127 127 3 118 127 127 4 117 126 126 5 120 124 124 6 118 128 128 -

[1] DE LUCA P, LEF BURE P, PICKETT A K. Numerical and experimental investigation of some press forming parameters of two fibre reinforced thermoplastics: APC2-AS4 and PEI-CETEX[J]. Composites Part A: Applied Science and Manufacturing,1998,29(1):101-110. [2] BUSSETTA P, CORREIA N. Numerical forming of continuous fibre reinforced composite material: A review[J]. Composites Part A: Applied Science and Manufacturing,2018,113:12-31. doi: 10.1016/j.compositesa.2018.07.010 [3] DURVILLE D. Approach of the constitutive material behaviour of textile composites through simulation[C]. International Conference on Textile Composites and Inflatable Structures, 2005, 307-316. [4] IWATA A, INOUE T, NAOUAR N, et al. Coupled meso-macro simulation of woven fabric local deformation during draping[J]. Composites Part A: Applied Science and Manufacturing,2019,118:267-280. doi: 10.1016/j.compositesa.2019.01.004 [5] PENG X Q, CAO J. A continuum mechanics-based non-orthogonal constitutive model for woven composite fabrics[J]. Composites Part A: Applied Science and Manufacturing,2005,36(6):859-874. doi: 10.1016/j.compositesa.2004.08.008 [6] 丁纺纺, 彭雄奇. 复合材料用机织物非正交本构模型的半球形冲压成型验证[J]. 复合材料学报, 2011, 28(1):156-160.DING F F, PENG X Q. Validation of a non-orthogonal constitutive model for woven composite fabrics via hemispherical stamping simulation[J]. Acta Materiae Compositae Sinica,2011,28(1):156-160(in Chinese). [7] PENG X, DING F F. Validation of a non-orthogonal constitutive model for woven composite fabrics via hemispherical stamping simulation[J]. Composites Part A: Applied Science and Manufacturing,2011,42(4):400-407. doi: 10.1016/j.compositesa.2010.12.014 [8] BOISSE P, AKKERMAN R, CAO J J, et al. Finite element analysis of composite forming[M]. Sawston: Woodhead Publishing, 2007: 46-79. [9] KHAN M A, MABROUKI T, VIDAL-SALLE E, et al. Numerical and experimental analyses of woven composite reinforcement forming using a hypoelastic behaviour. Application to the double dome benchmark[J]. Journal of Materials Processing Technology,2010,210(2):378-388. doi: 10.1016/j.jmatprotec.2009.09.027 [10] PENG X Q, GUO Z Y, DU T L, et al. A simple anisotropic hyperelastic constitutive model for textile fabrics with application to forming simulation[J]. Composites Part B: Engineering,2013,52:275-281. doi: 10.1016/j.compositesb.2013.04.014 [11] YAO Y, HUANG X, PENG X Q, et al. An anisotropic hyperelastic constitutive model for plain weave fabric considering biaxial tension coupling[J]. Textile Research Journal,2019,89(3):434-444. doi: 10.1177/0040517517748495 [12] YAO Y, PENG X Q, GONG Y K. Influence of tension-shear coupling on draping of plain weave fabrics[J]. Journal of Materials Science,2019,54:6310-6322. doi: 10.1007/s10853-019-03334-w [13] KHAN M A, SALEEM W, ASAD M, et al. A parametric sensitivity study on preforming simulations of woven compo-sites using a hypoelastic computational model[J]. Journal of Reinforced Plastics and Composites,2015,35(3):243-257. [14] HARRISON P, ABDIWI F, GUO Z, et al. Characterising the shear-tension coupling and wrinkling behaviour of woven engineering fabrics[J]. Composites Part A: Applied Science and Manufacturing,2012,43(6):903-914. doi: 10.1016/j.compositesa.2012.01.024 [15] BOISSE P, HAMILA N, VIDAL-SALLE E, et al. Simulation of wrinkling during textile composite reinforcement forming. Influence of tensile, in-plane shear and bending stiffnesses[J]. Composites Science and Technology,2011,71(5):683-692. doi: 10.1016/j.compscitech.2011.01.011 [16] DE BILBAO E, SOULAT D, HIVET G, et al. Experimental study of bending behaviour of reinforcements[J]. Experimental Mechanics,2009,50(3):333-351. [17] BOISSE P, COLMARS J, HAMILA N, et al. Bending and wrinkling of composite fiber preforms and prepregs. A review and new developments in the draping simulations[J]. Composites Part B: Engineering,2018,141:234-249. doi: 10.1016/j.compositesb.2017.12.061 [18] LIANG B, BOISSE P. A review of numerical analyses and experimental characterization methods for forming of textile reinforcements[J]. Chinese Journal of Aeronautics,2020,34:143-163. [19] DÖBRICH O, GEREKE T, DIESTEL O, et al. Decoupling the bending behavior and the membrane properties of finite shell elements for a correct description of the mechanical behavior of textiles with a laminate formulation[J]. Jour-nal of Industrial Textiles,2014,44(1):70-84. doi: 10.1177/1528083713477442 [20] NISHII M, HIRASHIMA T, KURASHIKI T. Dry fabric forming analysis considering the influence of tensions on in-plane shear behavior[J]. Journal of the Society of Materials Science, Japan,2014,63(5):380-385. doi: 10.2472/jsms.63.380 [21] LABANIEH A R, GARNIER C, OUAGNE P, et al. Intra-ply yarn sliding defect in hemisphere preforming of a woven preform[J]. Composites Part A: Applied Science and Manufacturing,2018,107:432-446. doi: 10.1016/j.compositesa.2018.01.018 [22] GUZMAN-MALDONADO E, WANG P, HAMILA N, et al. Experimental and numerical analysis of wrinkling during forming of multi-layered textile composites[J]. Composite Structures,2019,208:213-223. doi: 10.1016/j.compstruct.2018.10.018 [23] PENG X Q, CAO J, CHEN J, et al. Experimental and numerical analysis on normalization of picture frame tests for composite materials[J]. Composites Science and Technology,2004,64(1):11-21. doi: 10.1016/S0266-3538(03)00202-1 [24] CAO J, AKKERMAN R, BOISSE P, et al. Characterization of mechanical behavior of woven fabrics: Experimental methods and benchmark results[J]. Composites Part A: Applied Science and Manufacturing,2008,39(6):1037-1053. doi: 10.1016/j.compositesa.2008.02.016 [25] 纺织工业标准化研究所. 纺织品 织物弯曲长度的测定: GB/T 18318—2001[S]. 北京: 国家质量技术监督局, 2001.Standardization Institute of Textile Industry. Textiles-Determination of bending length of fabrics: GB/T 18318—2001[S]. Beijing: The State Bureau of Quality and Technical Supervision, 2001(in Chinese). [26] PENG X Q, REHMAN Z U. Textile composite double dome stamping simulation using a non-orthogonal constitutive model[J]. Composites Science and Technology,2011,71(8):1075-1081. doi: 10.1016/j.compscitech.2011.03.010 [27] KOMEILI M. Multi-scale characterization and modeling of shear-tension interaction in woven fabrics for composite forming and structural applications[D]. Vancouver: University of British Columbia, 2014. -

下载:

下载: