| [1] |

HA Ngocsan, LU Guoxing. A review of recent research on bio-inspired structures and materials for energy absorption applications[J]. Composites Part B: Engineering,2020,181(15):1-38.

|

| [2] |

XU S Q, BEYNON J H, RUAN D, et al. Experimental study of the out-of-plane dynamic compression of hexagonal honeycombs[J]. Composite Structures,2012,94(8):2326-2336. doi: 10.1016/j.compstruct.2012.02.024

|

| [3] |

ZHANG Qiancheng, YANG Xiaohu, LI Peng, et al. Bioinspired engineering of honeycomb structure-Using nature to inspire human innovation[J]. Progress in Materials Science,2015,74:322-400.

|

| [4] |

WANG Jianfeng, GAO Haibo, DING Liang, et al. Enhancement of tensile strength of embedded parts in carbon fiber-reinforced plastic/aluminum honeycomb sandwich structures for vehicle[J]. Composite Structures,2016,152(15):800-806.

|

| [5] |

ZHANG Yanqin, ZONG Zhijian, LIU Qiang, et al. Static and dynamic crushing responses of CFRP sandwich panels filled with different reinforced materials[J]. Materials& Design,2017,117(5):396-408.

|

| [6] |

WU Yinghan, LIU Qiang, FU Jie, et al. Dynamic crash responses of bio-inspired aluminum honeycomb sandwich structures with CFRP panels[J]. Composites Part B: Engineering,2017,121(15):122-133.

|

| [7] |

SUN Guangyong, HUO Xintao, CHEN Dongdong, et al. Experimental and numerical study on honeycomb sandwich panels under bending and in-panel compression[J]. Materials & Design,2017,133(5):154-168.

|

| [8] |

ZHU Shengqing, CHAI Ginboay. Damage and failure mode maps of composite sandwich panel subjected to quasi-static indentation and low velocity impact[J]. Composite Structures,2013,101:204-214. doi: 10.1016/j.compstruct.2013.02.010

|

| [9] |

樊建中, 姚忠凯, 杜善义, 等. SiC颗粒增强金属基复合材料弹性模量与界面结合状况关系研究[J]. 复合材料学报, 1998, 15(2):1-5.FAN Jianzhong, YAO Zhongkai, DU Shanyi, et al. Research on relationship between elastic modules and interfacial bonding in SiC article reinforced metal matrix compo-sites[J]. Acta Materiae Compositae Sinica,1998,15(2):1-5(in Chinese).

|

| [10] |

QI Guocheng, DU Shanyi, ZHANG Boming, et al. Evaluation of carbon fiber/epoxy interfacial strength in transverse fiber bundle composite: Experiment and multiscale failure modeling[J]. Composites Science and Technology,2014,105(10):1-8.

|

| [11] |

TOMASHEVSKII V T, SITNIKOV S Y, SHALYGIN V N, et al. A method of calculating technological regimes of transversal reinforcement of composites with short-fiber microparticles[J]. Mechanics of Composite Materials,1989,25:400-406. doi: 10.1007/BF00614810

|

| [12] |

LASCOUP B, ABOURA Z, KHELLIL K, et al. Core-skin interfacial toughness of stitched sandwich structure[J]. Composites Part B: Engineering,2014,67:363-370. doi: 10.1016/j.compositesb.2014.07.006

|

| [13] |

YANG Feiyu, ZHANG Xinghong, HAN Jiecai, et al. Characterization of hot-pressed short carbon fiber reinforced ZrB2-SiC ultra-high temperature ceramic composites[J]. Journal of Alloys and Compounds,2009,472(1-2):395-399. doi: 10.1016/j.jallcom.2008.04.092

|

| [14] |

YANG Feiyu, ZHANG Xinghong, HAN Jiecai, et al. Mechanical properties of short carbon fiber reinforced ZrB2-SiC ceramic matrix composites[J]. Materials Letters,2008,62(17-18):2925-2927. doi: 10.1016/j.matlet.2008.01.076

|

| [15] |

WANG Chao, LI Yibin, TONG Liyong, et al. The role of grafting force and surface wettability in interfacial enhancement of carbon nanotube/carbon fiber hierarchical composites[J]. Carbon,2014,69:239-246. doi: 10.1016/j.carbon.2013.12.020

|

| [16] |

LI Yan, CHEN Chaozhong, XU Jie, et al. Improved mechanical properties of carbon nanotubes-coated flax fiber reinforced composites[J]. Journal of Materials Science,2015,50:1117-1128. doi: 10.1007/s10853-014-8668-3

|

| [17] |

LI Yan, CAI Shenming, HUANG Xiaolei. Multi-scaled enhancement of damping property for carbon fiber reinforced composites[J]. Composites Science and Technology,2017,143(3):89-97.

|

| [18] |

LI Yan, LI Qian, MA Hao. The voids formation mechanisms and their effects on the mechanical properties of flax fiber reinforced epoxy composites[J]. Composites Part A: Applied Science and Manufacturing,2015,72:40-48.

|

| [19] |

ZHANG Yongli, LI Yan, MA Hao, et al. Tensile and interfacial properties of unidirectional flax/glass fiber reinforced hybrid composites[J]. Composites Science and Technology,2013,88(14):172-177.

|

| [20] |

YASAEE M, BOND I P, TRASK R S, et al. Mode I interfacial toughening through discontinuous interleaves for damage suppression and control[J]. Composites Part A: Applied Science and Manufacturing,2012,43(1):198-207. doi: 10.1016/j.compositesa.2011.10.009

|

| [21] |

YASAEE M, BOND I P, TRASK R S, et al. Mode II interfacial toughening through discontinuous interleaves for damage suppression and control[J]. Composites Part A: Applied Science and Manufacturing,2012,43(1):121-128. doi: 10.1016/j.compositesa.2011.09.026

|

| [22] |

WALKER L, HU X Z. Comparison of carbon fiber/epoxy composites reinforced by short aramid and carbon fibers[J]. Scripta Materialia,1999,41(6):575-582. doi: 10.1016/S1359-6462(99)00193-1

|

| [23] |

YUAN B Y, WEE E P, CHEONG J L K, et al. Quasi-Z-directional toughening from un-bonded non-woven veil at interface in laminar composites[J]. Composites Communications,2017,6:20-24. doi: 10.1016/j.coco.2017.07.007

|

| [24] |

WONG D W Y, ZHANG H, BILOTTI E, et al. Interlaminar toughening of woven fabric carbon/epoxy composite laminates using hybrid aramid/phenoxy interleaves[J]. Composites Part A: Applied Science and Manufacturing,2017,101:151-159. doi: 10.1016/j.compositesa.2017.06.001

|

| [25] |

YUAN Bingyan, YE Mingxin, HU Yunsen, et al. Flexure and flexure-after-impact properties of carbon fibre composites interleaved with ultra-thin non-woven aramid fibre veils[J]. Composites Part A: Applied Science and Manufacturing,2020,131:1-10.

|

| [26] |

HU Yuan, LIU Weiwei, SHI Yaoyao. Low-velocity impact damage research on CFRPs with Kevlar-fiber toughening[J]. Composite Structure,2019,216:127-141. doi: 10.1016/j.compstruct.2019.02.051

|

| [27] |

WANG Binhua, BAI Yuxuan, HU Xiaozhi, et al. Enhanced epoxy adhesion between steel plates by surface treatment and CNT/short-fibre reinforcement[J]. Composites Science and Technology,2016,127:149-157. doi: 10.1016/j.compscitech.2016.03.008

|

| [28] |

SUN Zhi, HU Xiaozhi, SUN Shiyong, et al. Energy-absorption enhancement in carbon-fiber aluminum-foam sandwich structures from short aramid-fiber interfacial reinforcement[J]. Composites Science and Technology,2013,77(22):14-21.

|

| [29] |

SUN Zhi, HU Xiaozhi, CHEN Haoran. Effects of aramid-fibre toughening on interfacial fracture toughness of epoxy adhesive joint between carbon-fibre face sheet and aluminium substrate[J]. International Journal of Adhesion and Adhesives,2014,48(1):288-294.

|

| [30] |

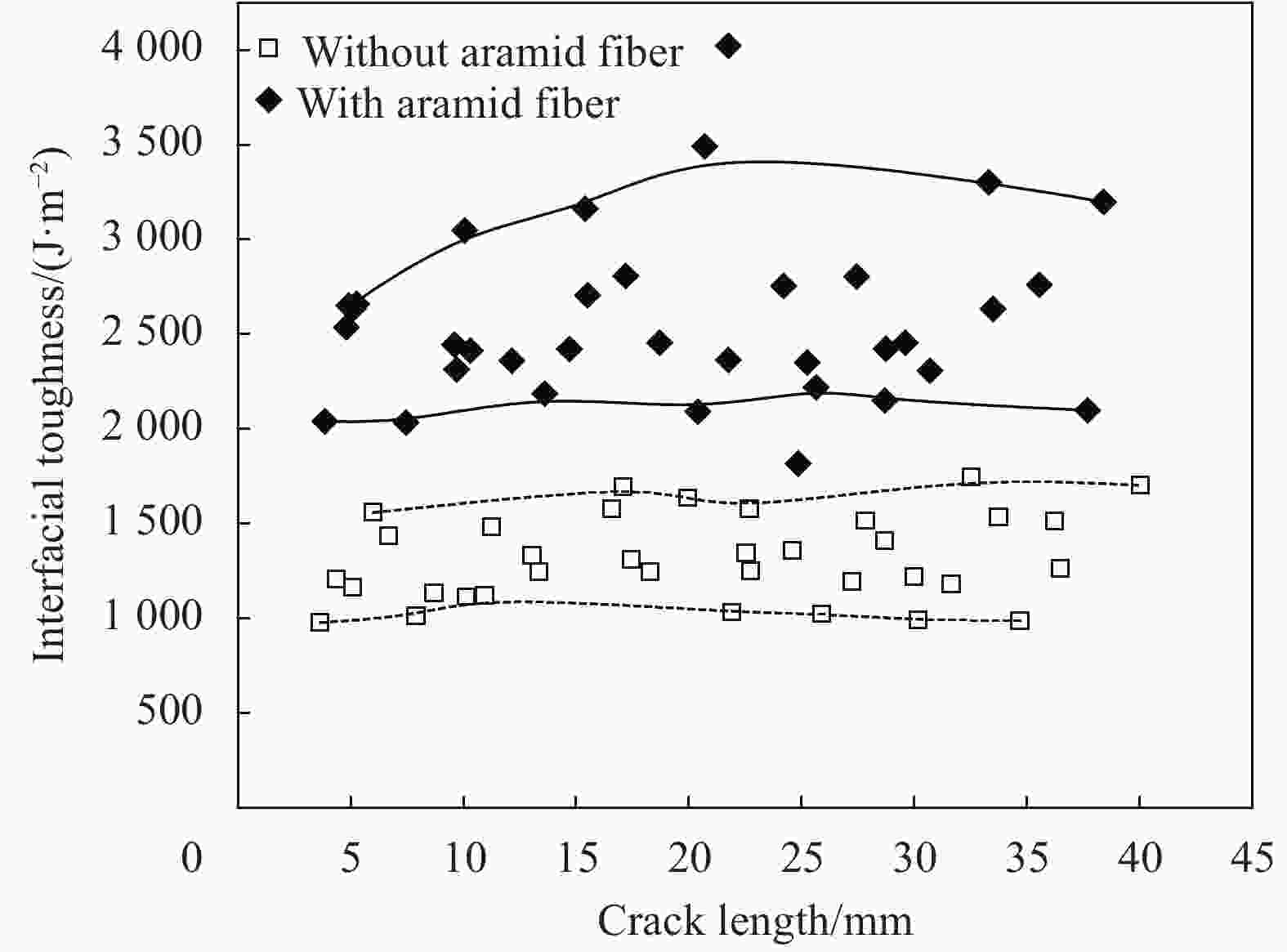

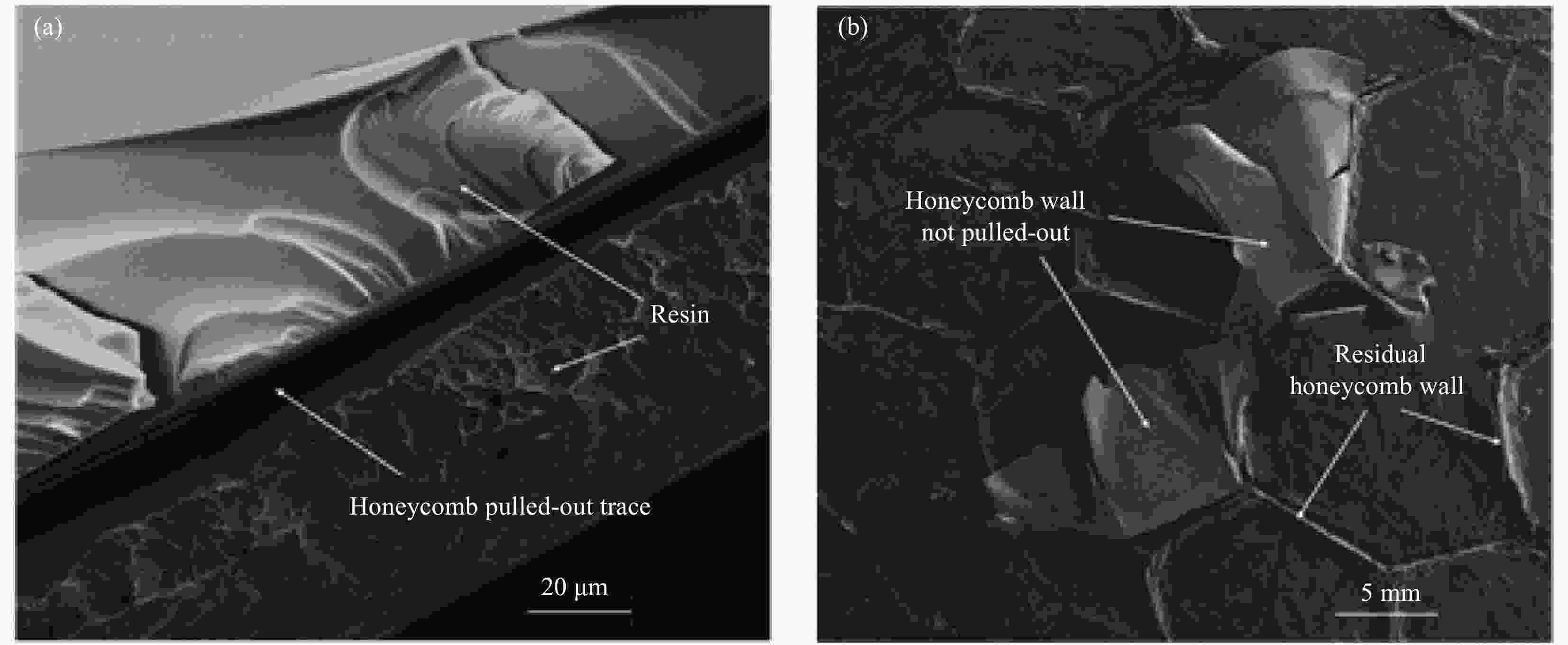

SHI Shanshan, SUN Zhi, HU Xiaozhi, et al. Carbon-fiber and aluminum-honeycomb sandwich composites with and without Kevlar-fiber interfacial toughening[J]. Compo-sites Part A: Applied Science and Manufacturing,2014,67:102-110. doi: 10.1016/j.compositesa.2014.08.017

|

| [31] |

SUN Z, JEYARAMAN J, SUN S Y, et al. Carbon-fiber aluminum-foam sandwich with short aramid-fiber interfacial toughening[J]. Composites Part A: Applied Science and Manufacturing,2012,43(11):2059-2064. doi: 10.1016/j.compositesa.2012.06.002

|

| [32] |

SUN Zhi, SHI Shanshan, HU Xiaozhi, et al. Short-aramid-fiber toughening of epoxy adhesive joint between carbon fiber composites and metal substrates with different surface morphology[J]. Composites Part B: Engineering,2015,77:38-45. doi: 10.1016/j.compositesb.2015.03.010

|

| [33] |

SUN Z, JEYARAMAN J, SHI S S, et al. Processing and property of carbon-fiber aluminum-foam sandwich with aramid-fiber composite adhesive joints[J]. Journal of Adhesion Science and Technology,2014,28(18):1835-1845. doi: 10.1080/01694243.2014.925385

|

| [34] |

石姗姗, 陈秉智, 陈浩然, 等. Kevlar短纤维增韧碳纤维/铝蜂窝夹芯板三点弯曲与面内压缩性能[J]. 复合材料学报, 2017, 34(9):1953-1959.SHI Shanshan, CHEN Bingzhi, CHEN Haoran, et al. Three-point bending and in-plane compression properties of carbon-fiber/aluminum-honeycomb sandwich panels with short-Kevlar-fiber toughening[J]. Acta Materiae Compo-sitae Sinica,2017,34(9):1953-1959(in Chinese).

|

| [35] |

ASTM. Standard test method for mode I interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites: ASTM D5528—01[S]. West Conhohocken: ASTM, 2007.

|

下载:

下载: