Effect of different pre-soaked aggregate-PVA fiber on the mechanical properties of recycled aggregate concrete

-

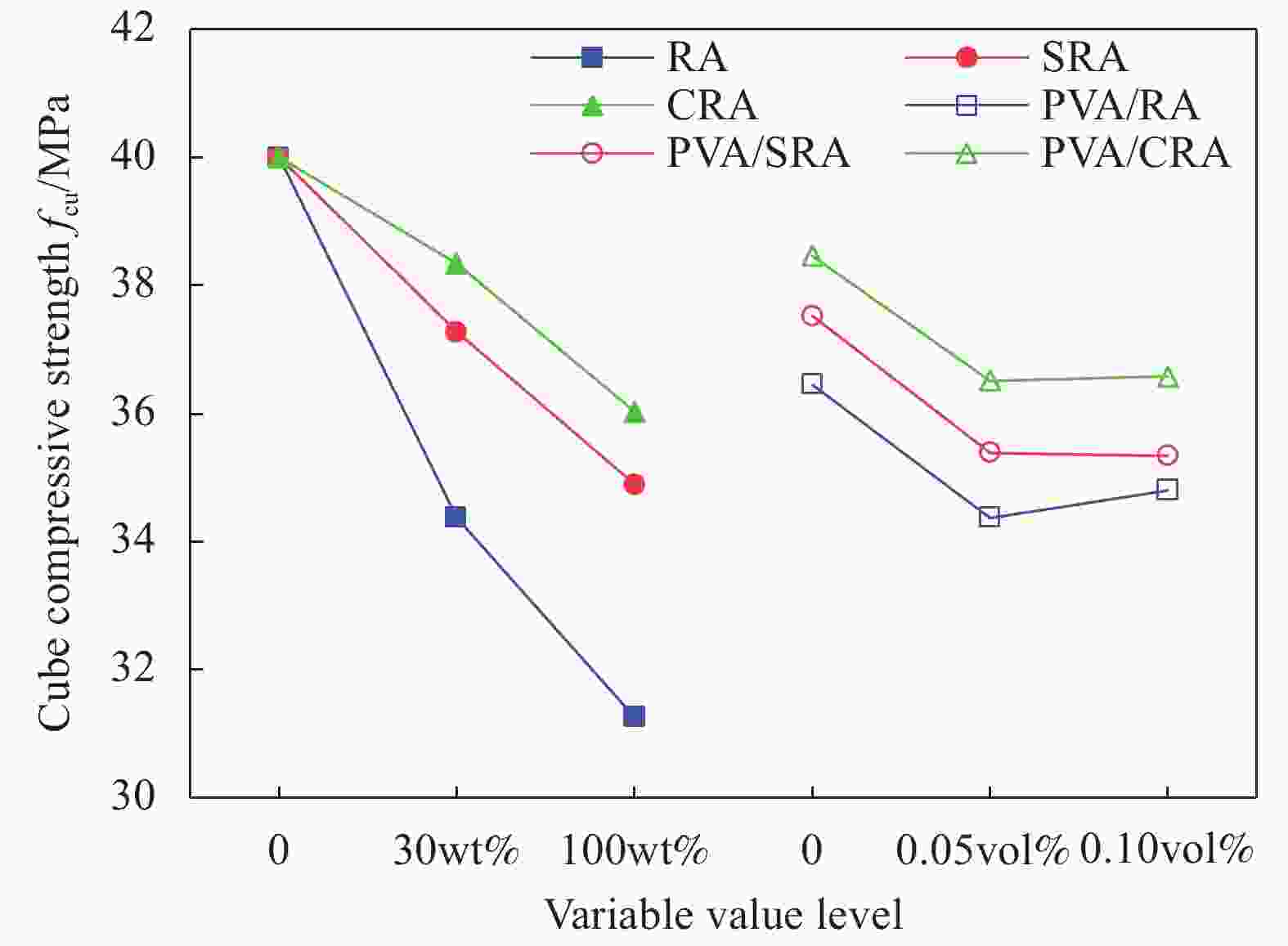

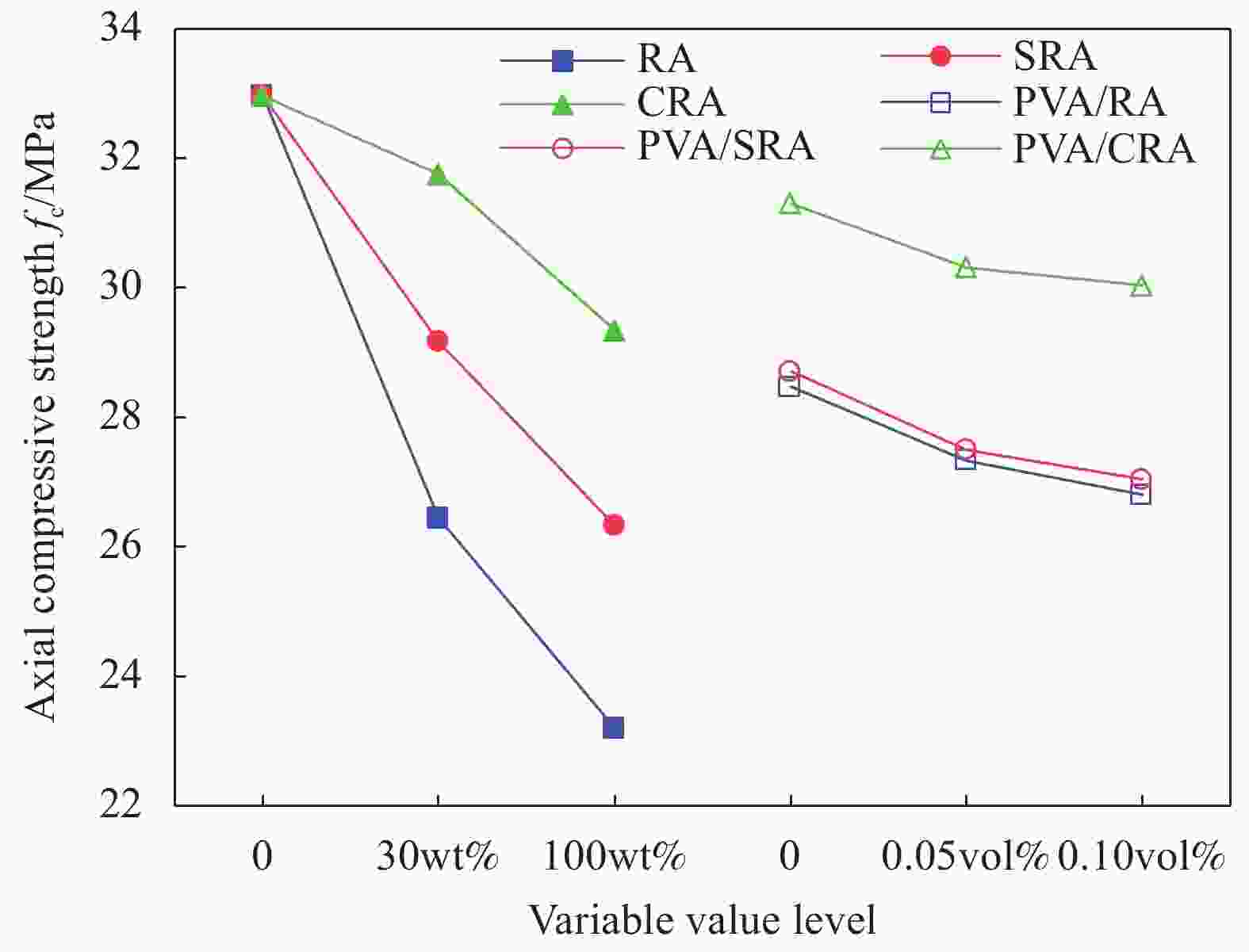

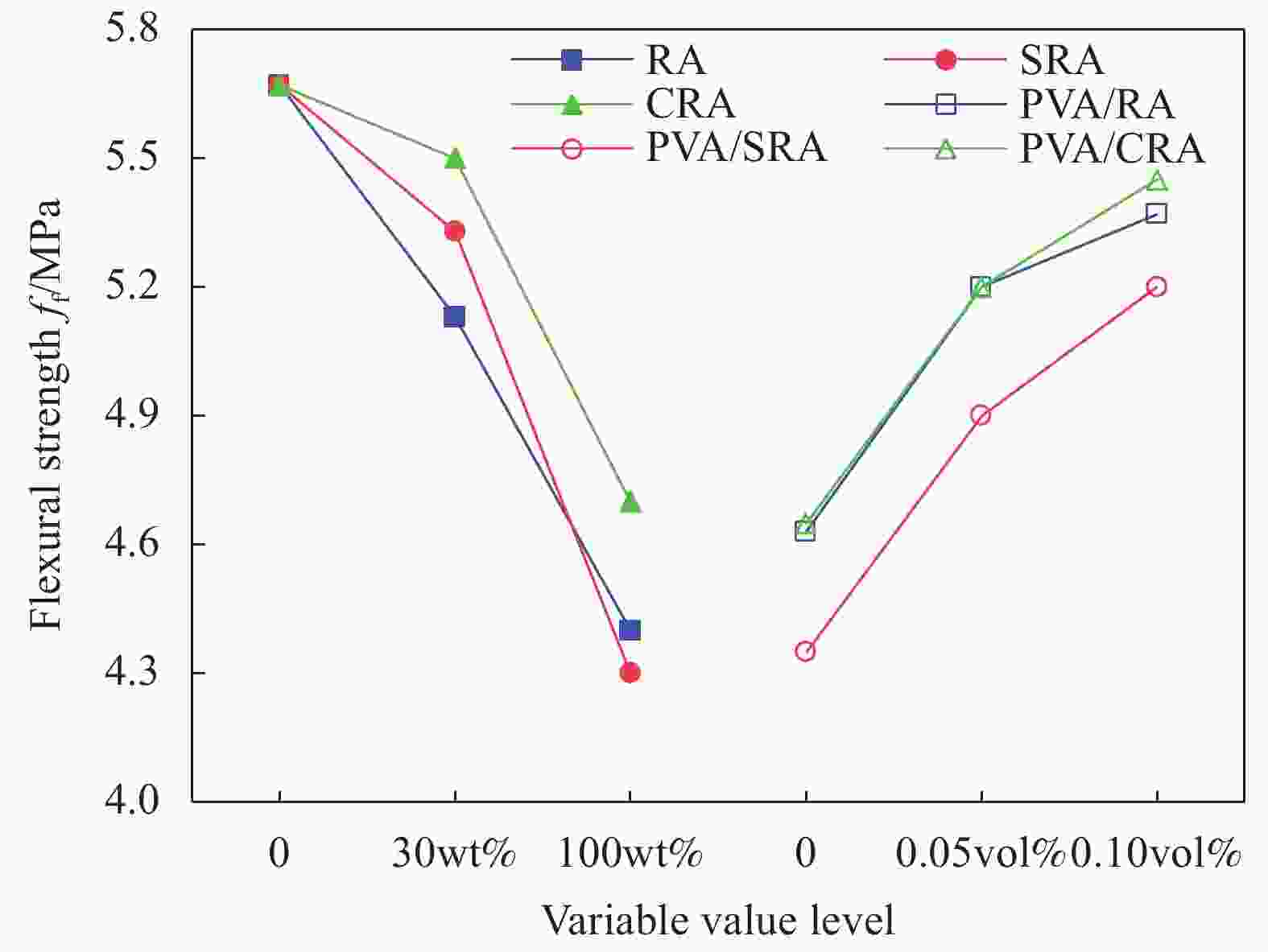

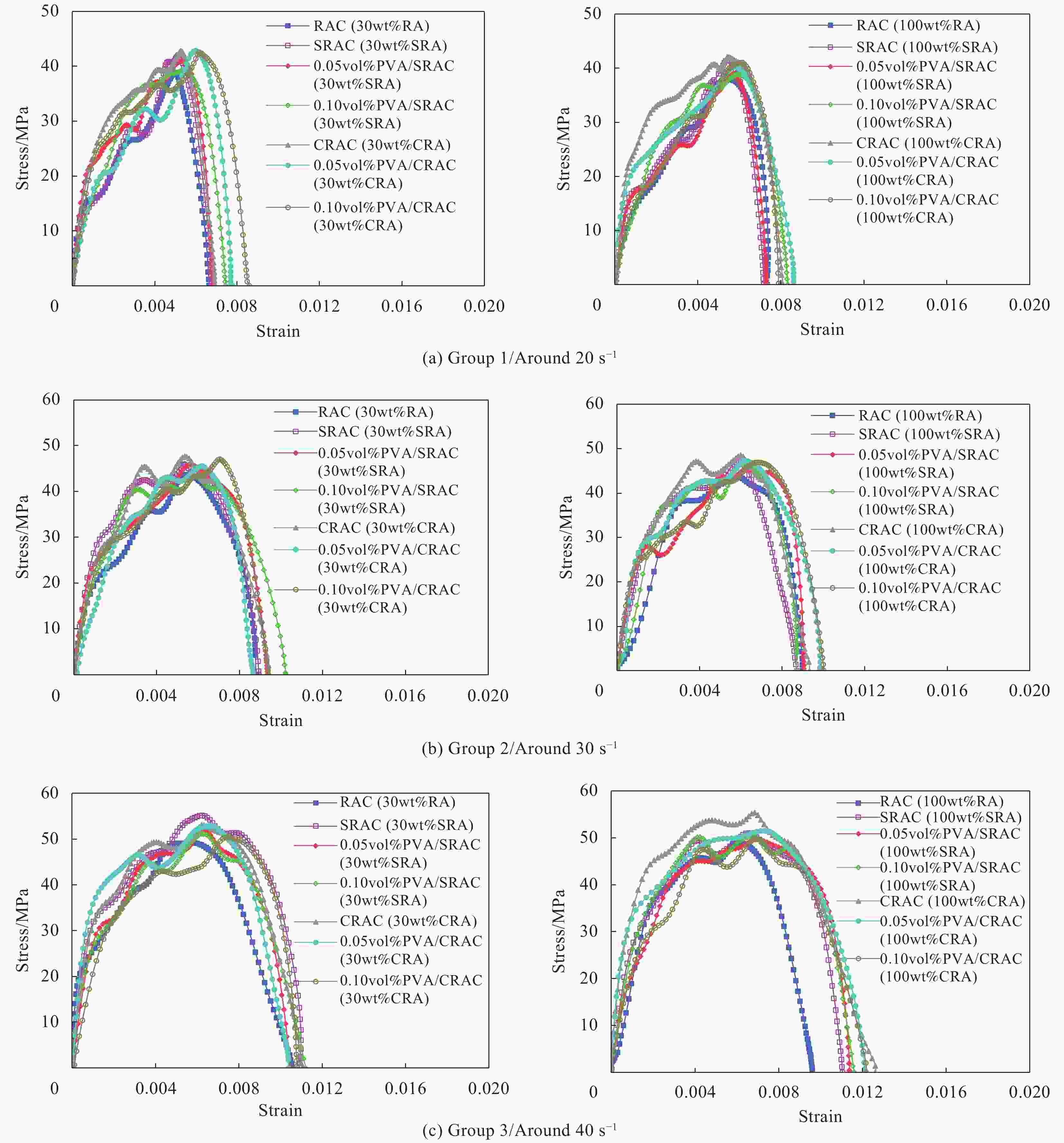

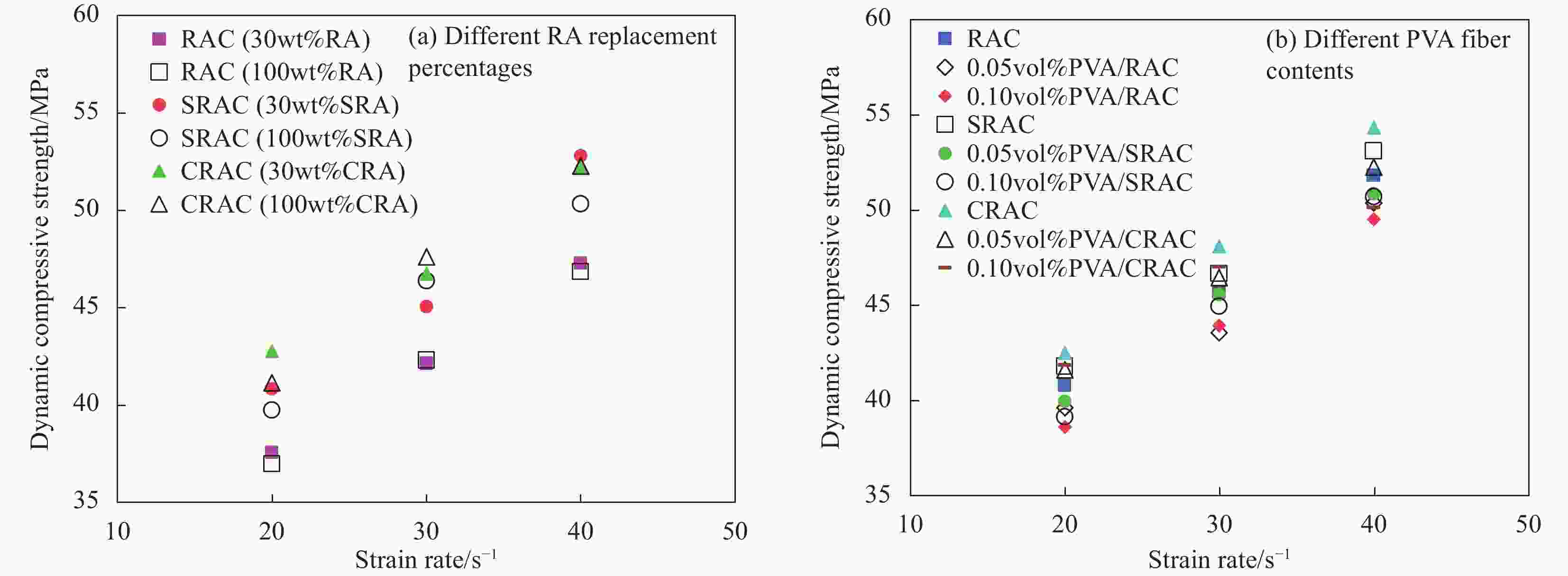

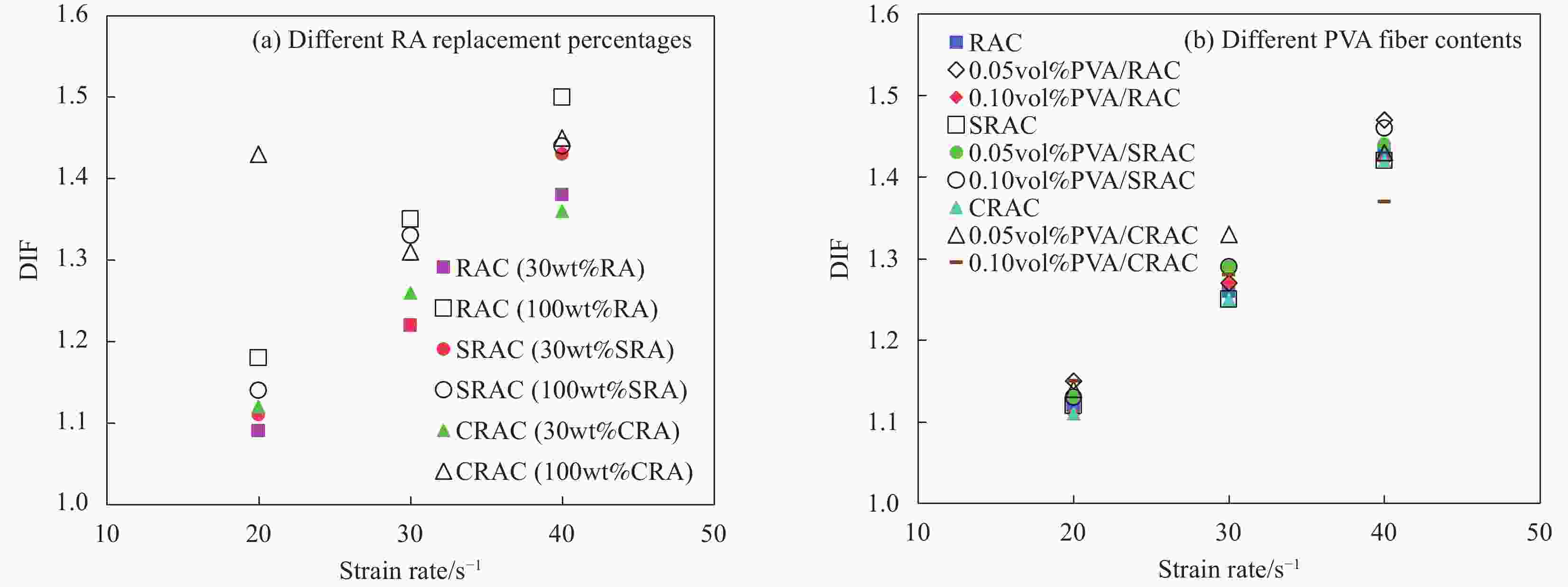

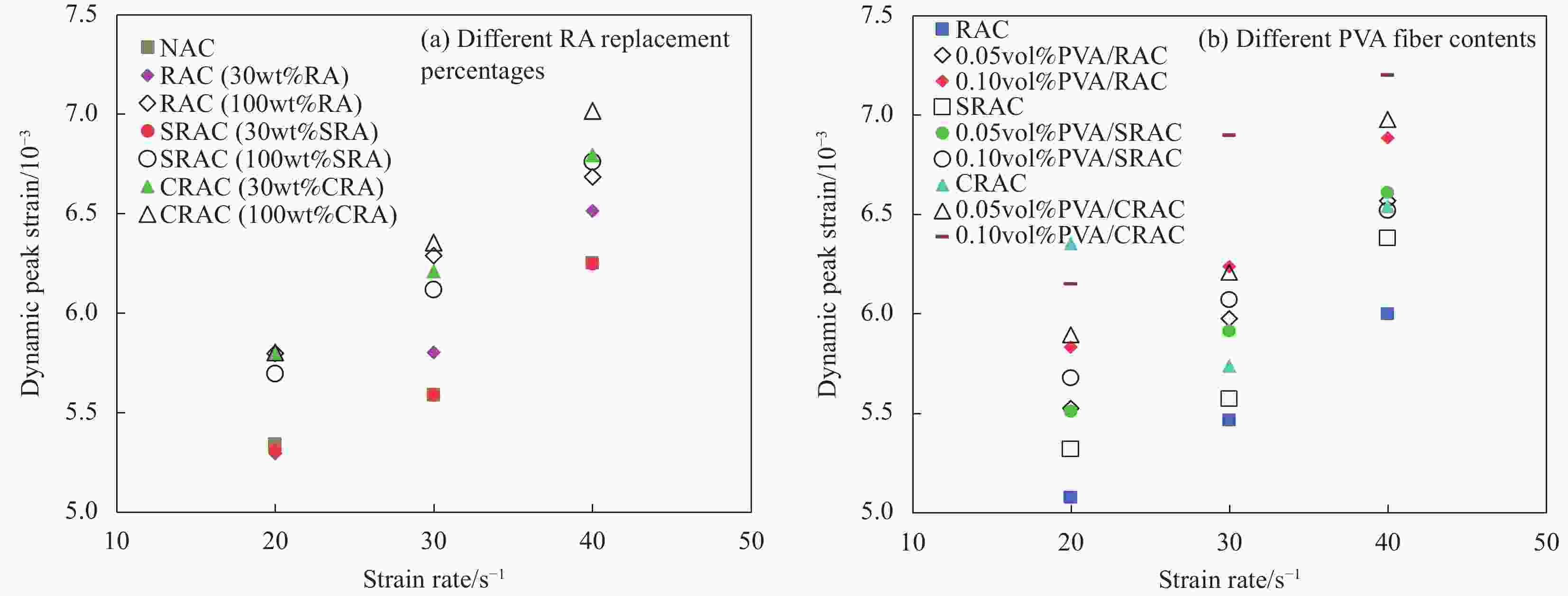

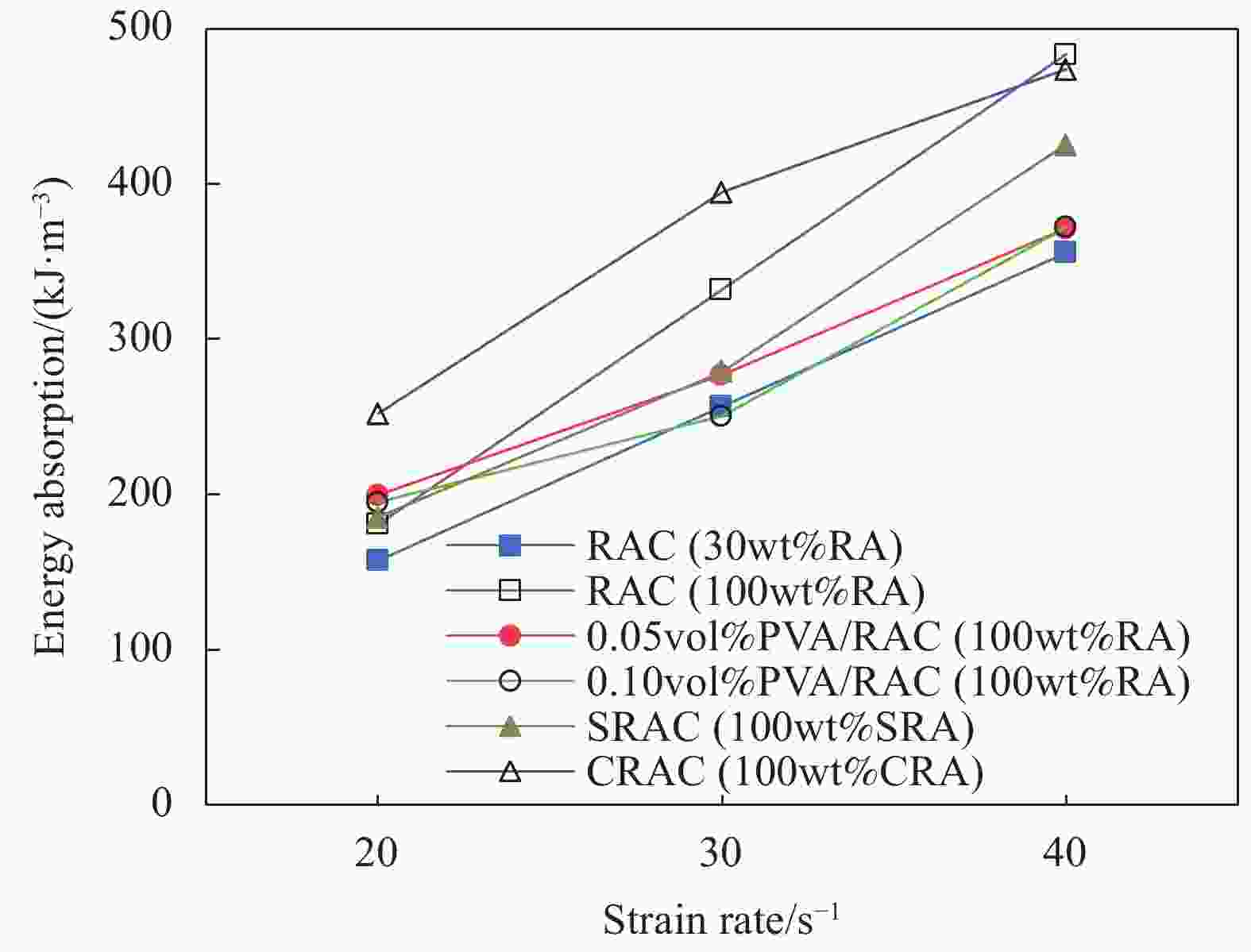

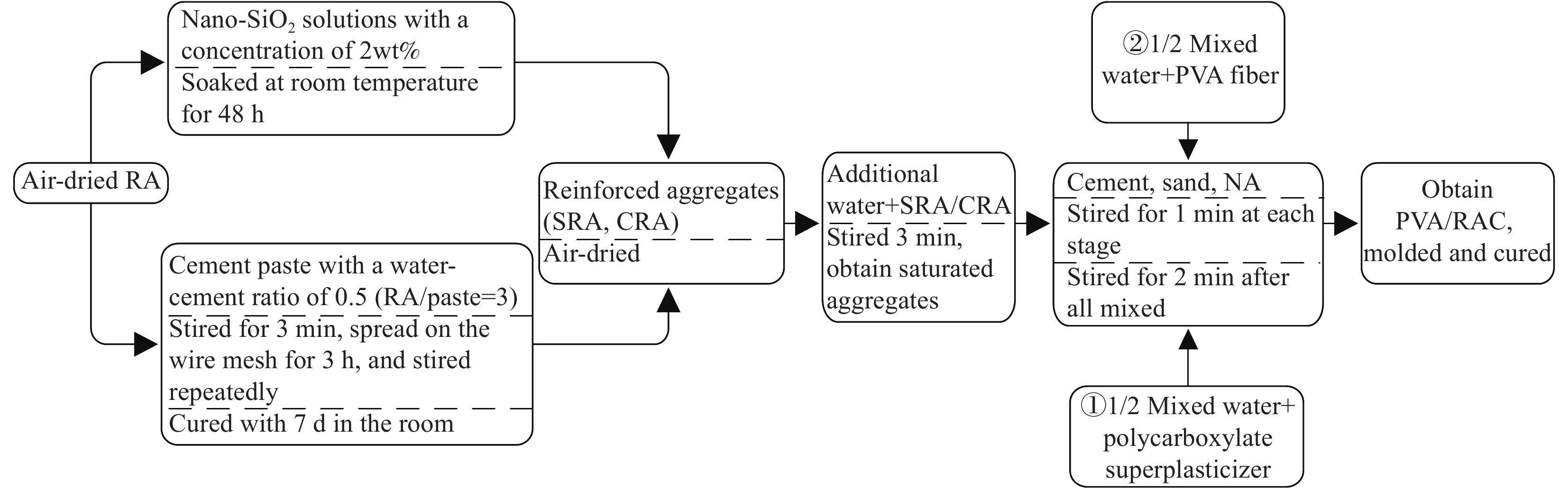

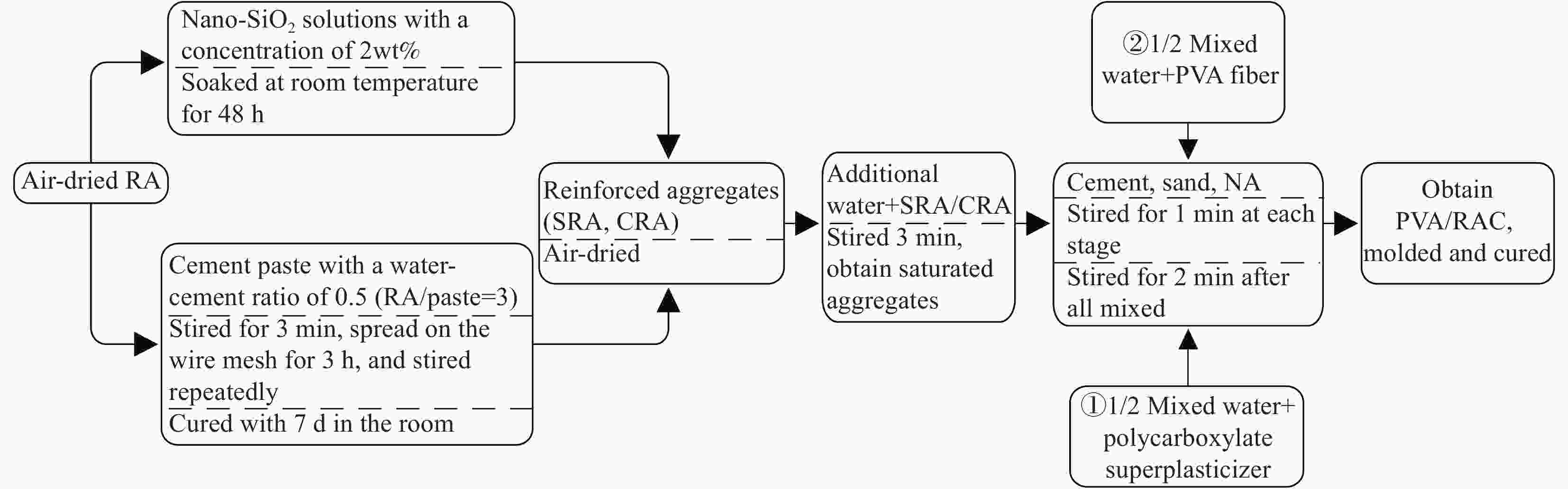

摘要: 为研究纳米SiO2溶液和水泥净浆改性再生粗骨料后,掺入聚乙烯醇(Polyvinyl alcohol, PVA)纤维再生混凝土的基本力学性能和动态力学性能,分别对不同浓度的纳米SiO2溶液和不同水灰比的水泥净浆进行再生骨料浸泡预试验,选定浓度为2wt%的纳米SiO2溶液和水灰比为0.5的水泥净浆,对改性后再生混凝土的力学性能进行对比试验。选取再生粗骨料取代率、PVA纤维掺量和应变率为变量,静力学性能采用万能压力机进行,动态力学性能采用霍普金森压杆(Split Hopkinson pressure bar, SHPB)进行。测试试件28天立方体抗压强度、轴心抗压强度和抗折强度,得到了不同应变率条件下试件的应力-应变曲线,分析了试件静力性能、动态抗压强度、动态增长因子(Dynamic increase factor, DIF)、动态峰值应变和比吸能随变量的变化规律。结果表明:随取代率增加,试件基本力学性能降低,增加PVA纤维掺量,试件抗压强度降低而抗折强度提高;随取代率和PVA纤维掺量增加,试件动态峰值应力呈下降趋势,而动态峰值应变呈增长趋势;取代率的增加提升了试件的DIF值,而PVA纤维对DIF值影响并不明显;应变率的提高增强了试件的动态强度和应变,而水泥净浆改性再生混凝土比纳米SiO2改性再生混凝土具备更高的比吸能。Abstract: In order to study the basic mechanical properties and dynamic mechanical properties of recycled aggregate concrete mixed with polyvinyl alcohol (PVA) fiber after modified recycled coarse aggregate with nano-SiO2 solution and cement paste, recycled aggregate pre-soaking tests were carried out on different concentrations of nano-SiO2 solutions and cement pastes with different water-cement ratios. The nano-SiO2 solutions with a concentration of 2wt% and the cement paste with a water-cement ratio of 0.5 were selected. The mechanical properties of recycled aggregate concrete were tested for comparison. The replacement percentage of recycled coarse aggregate, the content of PVA fiber and the strain rate were variable. The static mechanical properties were tested by a universal press, and the dynamic mechanical properties were tested by using a split Hopkinson pressure bar (SHPB). The 28 days cube compressive strength, axial compressive strength and flexural strength of the specimen were tested, the stress-strain curves of the specimen under different strain rate conditions were obtained, and the static performance, dynamic compressive strength, dynamic increase factor (DIF), dynamic peak strain and specific energy absorption of the specimen changes with variables were analyzed. The results show that with the increase of the replacement percentage, the basic mechanical properties of the specimen decrease, and the content of PVA fiber increases, the compressive strength of the specimen decreases while the flexural strength increases; with the increase of the replacement percentage and PVA fiber content, the dynamic peak stress of the specimen decreases, while the dynamic peak strain shows an increasing trend; the increase of the replacement percentage increases the DIF value of the specimen, while the PVA fiber has no obvious effect on the DIF value; the increase in strain rate enhances the dynamic strength and strain of the specimen, and the cement paste modified recycled aggregate concrete has a higher specific energy absorption than the nano-SiO2 modified recycled aggregate concrete.

-

Key words:

- recycled aggregate concrete /

- nano-SiO2 /

- cement paste /

- PVA fiber /

- static properties /

- impact properties

-

表 1 普通硅酸盐水泥各项指标

Table 1. Various indexes of ordinary Portland cement

Ignition

loss/%SO3/

wt%MgO/

wt%Specific surface

area/(m2·kg−1)Initial setting

time/minFinal setting

time/min28 days compressive

strength/MPa28 days flexural

strength/MPa2.41 2.45 2.11 403 180 265 51 8.5 表 2 不同预浸骨料物理指标

Table 2. Physical indicators of different pre-soaked aggregates

Aggregate type NA RA CRA SRA Indexes content — Control group Water-cement ratio Pre-soaking time/h Pre-concentration/wt% 0.5 0.7 0.9 24 48 72 1 2 3 Apparent density/(kg·m−3) 2712 2564 2545 2556 2560 2586 2603 2608 2587 2602 2608 Crush index/% 8.30 19.70 15.17 18.41 19.54 17.97 15.99 15.67 17.02 16.51 16.09 Water absorption/% 0.38 4.80 5.50 5.30 5.00 4.22 3.92 3.81 4.33 3.86 3.75 Notes: NA—Natural aggregate; RA—Recycled aggregate; CRA—Cement recycled aggregate; SRA—Silica recycled aggregate. 表 3 不同PVA纤维/RAC配合比

Table 3. Mixing proportion of different PVA fiber/RAC

Number Notation Material consumption/(kg·m−3) fcu/MPa fc/MPa ff/MPa NA RA SRA CRA PVA

fiberAdditional

waterNP0 NAC 1060.80 0 0 0 0 0 41.30 33.90 5.1 NP0.05 0.05vol%PVA/NAC 1060.80 0 0 0 0.65 0 38.75 33.29 5.8 NP0.1 0.10vol%PVA/NAC 1060.80 0 0 0 1.30 0 39.95 31.70 6.1 R30P0 RAC(30wt%RA) 742.56 318.24 0 0 0 12.22 35.66 27.56 4.7 R30P0.05 0.05vol%PVA/RAC(30wt%RA) 742.56 318.24 0 0 0.65 12.22 33.07 25.58 5.4 R30P0.1 0.10vol%PVA/RAC(30wt%RA) 742.56 318.42 0 0 1.30 12.22 34.39 26.17 5.3 R100P0 RAC(100wt%RA) 0 1060.80 0 0 0 40.73 32.40 23.95 4.1 R100P0.05 0.05vol%PVA/RAC(100wt%RA) 0 1060.80 0 0 0.65 40.73 31.30 23.13 4.4 R100P0.1 0.10vol%PVA/RAC(100wt%RA) 0 1060.80 0 0 1.30 40.73 30.08 22.53 4.7 SR30P0 SRAC(30wt%SRA) 742.56 0 318.24 0 0 11.64 38.60 30.10 4.8 SR30P0.05 0.05vol%PVA/SRAC(30wt%SRA) 742.56 0 318.24 0 0.65 11.64 37.25 29.46 5.7 SR30P0.1 0.10vol%PVA/SRAC(30wt%SRA) 742.56 0 318.24 0 1.30 11.64 35.97 27.94 5.5 SR100P0 SRAC(100wt%SRA) 0 0 1060.80 0 0 38.08 36.43 27.32 3.9 SR100P0.05 0.05vol%PVA/SRAC(100wt%SRA) 0 0 1060.80 0 0.65 38.08 33.53 25.54 4.1 SR100P0.1 0.10vol%PVA/SRAC(100wt%SRA) 0 0 1060.80 0 1.30 38.08 34.70 26.13 4.9 CR30P0 CRAC(30wt%CRA) 742.56 0 0 318.24 0 10.88 39.69 32.73 5.0 CR30P0.05 0.05vol%PVA/CRAC(30wt%CRA) 742.56 0 0 318.24 0.65 10.88 37.97 31.07 5.6 CR30P0.1 0.10vol%PVA/CRAC(30wt%CRA) 742.56 0 0 318.24 1.30 10.88 37.35 31.44 5.9 CR100P0 CRAC(100wt%CRA) 0 0 0 1060.80 0 36.27 37.23 29.86 4.3 CR100P0.05 0.05vol%PVA/CRAC(100wt%CRA) 0 0 0 1060.80 0.65 36.27 35.05 29.54 4.8 CR100P0.1 0.10vol%PVA/CRAC(100wt%CRA) 0 0 0 1060.80 1.30 36.27 35.80 28.63 5.0 Notes: NAC—Natural aggregate concrete; RAC—Recycled aggregate concrete; SRAC—Silica recycled aggregate concrete; CRAC—Cement recycled aggregate concrete; in ivol% and jwt%, i and j mean the PVA fiber content and aggregate replacement percentage; fcu—Cube compressive strength; fc—Axial compressive strength; ff—Flexural strength. 表 4 PVA/RAC试件设计方案

Table 4. Design scheme of PVA/RAC specimens

Test item Design size/mm Quantity Cube compressive strength 100×100×100 63 Axial compressive strength 100×100×300 63 Flexural strength 100×100×400 63 -

[1] SIDDIQUE R, SINGH G, SINGH M. Recycle option for metallurgical by-product (Spent Foundry Sand) in green concrete for sustainable construction[J]. Journal of Cleaner Production,2018,172:1111-1120. doi: 10.1016/j.jclepro.2017.10.255 [2] GUO Z G, TU A, CHEN C, et al. Mechanical properties, durability, and life-cycle assessment of concrete building blocks incorporating recycled concrete aggregates[J]. Journal of Cleaner Production,2018,199:136-149. doi: 10.1016/j.jclepro.2018.07.069 [3] ALEXANDRIDOU C, ANGELOPOULOS G N, COUTELIERIS F A. Mechanical and durability performance of concrete produced with recycled aggregates from Greek construction and demolition waste plants[J]. Journal of Cleaner Production,2018,176:745-757. doi: 10.1016/j.jclepro.2017.12.081 [4] OIKONOMOU N D. Recycled concrete aggregates[J]. Cement and Concrete Composites,2004,27(2):315-318. [5] MANZI S, MAZZOTTI C, BIGNOZZI M C. Short and long-term behavior of structural concrete with recycled concrete aggregate[J]. Cement and Concrete Composites,2013,37:312-318. doi: 10.1016/j.cemconcomp.2013.01.003 [6] TAM V W Y, GAO X F, TAM C M. Microstructural analysis of recycled aggregate concrete produced from two-stage mixing approach[J]. Cement and Concrete Research,2005,35(6):1195-1203. doi: 10.1016/j.cemconres.2004.10.025 [7] XIAO J Z, LI W G, FAN Y H, et al. An overview of study on recycled aggregate concrete in China (1996-2011)[J]. Construction and Building Materials,2012,31:364-383. doi: 10.1016/j.conbuildmat.2011.12.074 [8] TAM V W Y, TAM C M, WANG Y. Optimization on proportion for recycled aggregate in concrete using two-stage mixing approach[J]. Construction and Building Materials,2007,21(10):1928-1939. doi: 10.1016/j.conbuildmat.2006.05.040 [9] BRU K, TOUZÉ S, BOURGEOIS F, et al. Assessment of a microwave-assisted recycling process for the recovery of high-quality aggregates from concrete waste[J]. International Journal of Mineral Processing,2014,126:90-98. doi: 10.1016/j.minpro.2013.11.009 [10] JOB T, NASSIFN T, WILSON P M. Strength and durability of concrete containing recycled concrete aggregates[J]. Journal of Building Engineering,2018,19:349-365. doi: 10.1016/j.jobe.2018.05.007 [11] KATZ A. Treatments for the improvement of recycled aggregate[J]. Journal of Materials in Civil Engineering,2004,16(6):597-603. doi: 10.1061/(ASCE)0899-1561(2004)16:6(597) [12] KOU S C, POON C S. Properties of concrete prepared with PVA impregnated recycled concrete aggregates[J]. Cement and Concrete Composites,2010,32(8):649-654. doi: 10.1016/j.cemconcomp.2010.05.003 [13] BERNAL J, REYES E, MASSANA J, et al. Fresh and mechanical behavior of a self-compacting concrete with additions of nano-silica, silica fume and ternary mixtures[J]. Construction and Building Materials,2018,160:196-210. doi: 10.1016/j.conbuildmat.2017.11.048 [14] GÜNEYISI E, GESOGLU M, AL-GOODY A, et al. Fresh and rheological behavior of nano-silica and fly ash blended self-compacting concrete[J]. Construction and Building Materials,2015,95:29-44. doi: 10.1016/j.conbuildmat.2015.07.142 [15] SENARTNE S, GERACE D, MIRZA O, et al. The costs and benefits of combining recycled aggregate with steel fibers as a sustainable, structural material[J]. Journal of Cleaner Production,2016,112:2318-2327. doi: 10.1016/j.jclepro.2015.10.041 [16] WANG Y G, LI S P, HUGHES P, et al. Mechanical properties and microstructure of basalt fiber and nano-silica reinforced recycled concrete after exposure to elevated temperatures[J]. Construction and Building Materials,2020,247:118561. doi: 10.1016/j.conbuildmat.2020.118561 [17] WANG L, ZHOU S H, SHI Y, et al. Effect of silica fume and PVA fiber on the abrasion resistance and volume stability of concrete[J]. Composites Part B: Engineering,2017,130:28-37. doi: 10.1016/j.compositesb.2017.07.058 [18] SHI C J, WU Z M, CAO Z J, et al. Performance of mortar prepared with recycled concrete aggregate enhanced by CO2 and pozzolan slurry[J]. Cement and Concrete Composites,2018,86:130-138. doi: 10.1016/j.cemconcomp.2017.10.013 [19] BAHADORI H, HOSSEINI P. Reduction of cement consumption by the aid of silica nano-particles (Investigation on concrete properties)[J]. Journal of Civil Engineering and Management,2012,18(3):416-425. doi: 10.3846/13923730.2012.698912 [20] JUMAH M T, ÖZAKCA M. Developing geopolymer concrete by using cold-bonded fly ash aggregate nano-silica and steel fiber[J]. Construction and Building Materials,2018,180:12-22. doi: 10.1016/j.conbuildmat.2018.05.274 [21] 王仕富, 曾晓辉, 王平, 等. PVA及玄武岩纤维对水泥基复合材料力学性能的影响[J]. 功能材料, 2020, 51(4):4072-4076. doi: 10.3969/j.issn.1001-9731.2020.04.012WANG Shifu, ZENG Xiaohui, WANG Ping, et al. Effect of PVA and basalt fiber on mechanical properties of cement-based composites[J]. Journal of Function Materials,2020,51(4):4072-4076(in Chinese). doi: 10.3969/j.issn.1001-9731.2020.04.012 [22] XIAO J Z, LI L, SHEN L M, et al. Compressive behaviour of recycled aggregate concrete under impact loading[J]. Cement and Concrete Research,2015,71:46-55. doi: 10.1016/j.cemconres.2015.01.014 [23] LI W G, LUO Z Y, LONG C, et al. Effects of nano particle on the dynamic behaviors of recycled aggregate concrete under impact loading[J]. Materials & Design,2016,112:58-66. [24] SHAIKH F, CHAVDA V, MINHAJ N, et al. Effect of mixing methods of nano silica on properties of recycled aggregate concrete[J]. Structural Concrete,2017,150:49-55. [25] 中华人民共和国住房和城乡建设部. GB/T 50081—2019 混凝土物理力学性能试验方法标准[S]. 北京: 中国建筑工业出版社, 2019.Ministry of Housing and Urban-Rural Development of the People’s Republic of China. GB/T 50081—2019 Standard for test methods of concrete physical and mechanical properties[S]. Beijing: China Architecture and Building Press, 2019(in Chinese). [26] HUO J, HE Y, CHEN B. Experimental study on impact behaviour of concrete-filled steel tubes at elevated temperatures up to 800°C[J]. Materials and Structures,2014,47:263-283. doi: 10.1617/s11527-013-0059-8 [27] BIBHUTI B M, SUDHIRKUMAR V B. Influence of nano-silica on the properties of recycled aggregate concrete[J]. Construction and Building Materials,2014,55:29-37. doi: 10.1016/j.conbuildmat.2014.01.003 [28] WANG X G, CHENG F, WANG Y X, et al. Impact properties of recycled aggregate concrete with nanosilica modification[J]. Advances in Civil Engineering,2020(8):1-10. [29] LIU T J, WANG Z Z, ZOU D J, et al. Strength enhancement of recycled aggregate pervious concrete using a cement paste redistribution method[J]. Cement and Concrete Research,2019,122:72-82. doi: 10.1016/j.cemconres.2019.05.004 [30] JALAL A, SHAFIQ N, NIKBAKHT E, et al. Mechanical properties of hybrid basalt-polyvinyl alcohol (PVA) fiber reinforced concrete[J]. Key Engineering Materials,2017,744:3-7. doi: 10.4028/www.scientific.net/KEM.744.3 [31] 肖建庄, 李标, 张凯建, 等. 纳米二氧化硅改性再生混凝土的单轴受压动态力学性能[J]. 同济大学学报(自然科学版), 2021, 49(1):30-39. doi: 10.11908/j.issn.0253-374x.20261XIAO Jianzhuang, LI Biao, ZHANG Kaijian, et al. Dynamic mechanical properties of nano-silica modified recycled aggregate concrete under uniaxial compression[J]. Journal of Tongji University (Natural Science),2021,49(1):30-39(in Chinese). doi: 10.11908/j.issn.0253-374x.20261 [32] LOKTS, ZHAO P J. Impact response of steel fiber-reinforced concrete using a split hopkinson pressure bar[J]. Journal of Materials in Civil Engineering,2004,16(1):54-59. doi: 10.1061/(ASCE)0899-1561(2004)16:1(54) [33] POON C S, SHUI Z H, LAM L. Effect of microstructure of ITZ on compressive strength of concrete prepared with recycled aggregates[J]. Construction and Building Materials,2004,18(6):461-468. doi: 10.1016/j.conbuildmat.2004.03.005 [34] BISCHOFF P H, PERRY S H. Compressive behaviour of concrete at high strain rates[J]. Materials and Structures,1991,24:425-450. doi: 10.1007/BF02472016 [35] LU Y B, CHEN X, TENG X, et al. Dynamic compressive behavior of recycled aggregate concrete based on split Hopkinson pressure bar test[J]. Latin American Journal of Solids and Structures,2014,11(1):131-141. doi: 10.1590/S1679-78252014000100008 -

下载:

下载: