Design, fabrication and performance of flexible pressure sensors based on microstructures

-

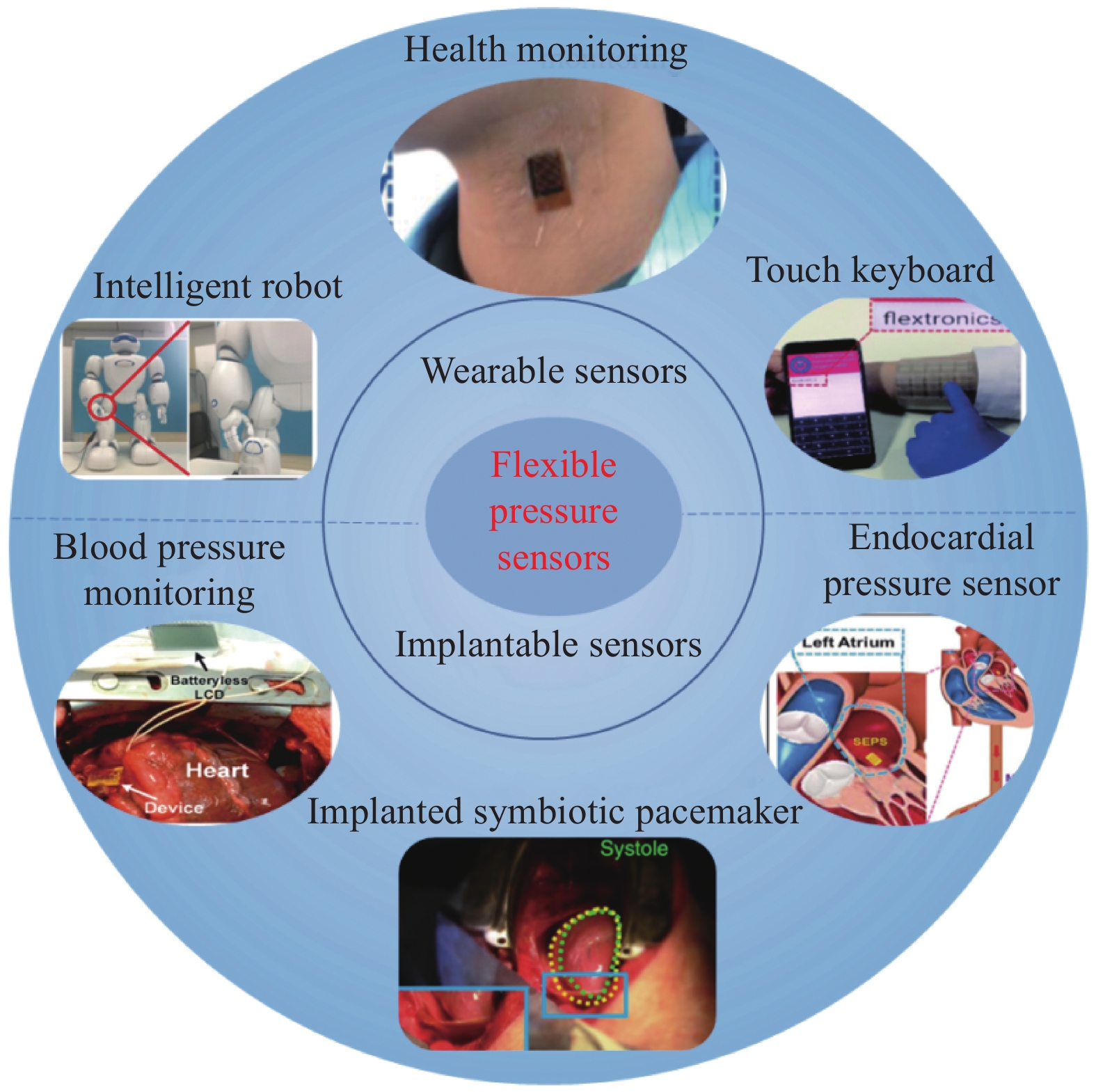

摘要: 随着科技的快速发展,电子皮肤和柔性可穿戴设备由于在人体运动、健康监测、智能机器人等领域具有重要应用而引起了人们广泛的关注。传统的基于贵金属或金属氧化物半导体的压力传感器成本高、柔韧性差,而新型的基于微结构的柔性压力传感器具有灵敏度高、应变范围宽、低成本、低功耗、响应速度快等优势,在电子皮肤和柔性可穿戴设备等方面发挥重要作用,成为当前柔性电子材料与器件主要研究热点之一。本文系统总结了近年来颇受关注的基于金字塔形、微球形、微柱形、仿生结构、褶皱等不同柔性基底微结构和多孔导电聚合物材料的柔性压力传感器在材料选择、结构设计、制备方法、传感性能等方面取得的重要进展,并对柔性压力传感器的未来发展进行了展望。Abstract: With the rapid development of science and technology, electronic skin and flexible wearable devices have attracted wide attention because of their important applications in human motion, health monitoring, intelligent robots and other fields. The traditional pressure sensors based on noble metal or metal oxide semiconductor have high cost or poor flexibility, while the flexible pressure sensors based on microstructures have the advantages of high sensitivity, wide strain range, low cost, low power consumption and fast response, which play an important role in electronic skin and flexible wearable devices and have become one of the main research hotspots of materials and devices in flexible electronics. This review systematically summarizes the important progress made in the material selection, structural design, preparation methods and sensing performance of flexible pressure sensors based on different flexible substrate microstructures such as pyramid, microsphere, micro-column, bionic structure and fold and porous conductive polymer materials. Finally, the future development of flexible pressure sensors is prospected.

-

图 3 微图案化Si模具和柔性微结构化AgNWs/PDMS复合介电膜的制备流程图 (a)、柔性电容式压力传感器的结构 (b)、在施加压力下具有不同类型介电层的压力传感器的灵敏度曲线 (c) 以及传感器对放置和取出小纸片的瞬态响应 (d)[22]

Figure 3. Schematic illustration for the fabrication of micropatterned Si mould and flexible microstructured AgNWs/PDMS composite dielectric film (a), architecture of the flexible capacitive pressure sensor (b), sensitivity curves of the pressure sensor with different types of dielectric layer under applied pressure (c), and transient response of sensor to placing and taking out a small sheet of paper (d)[22]

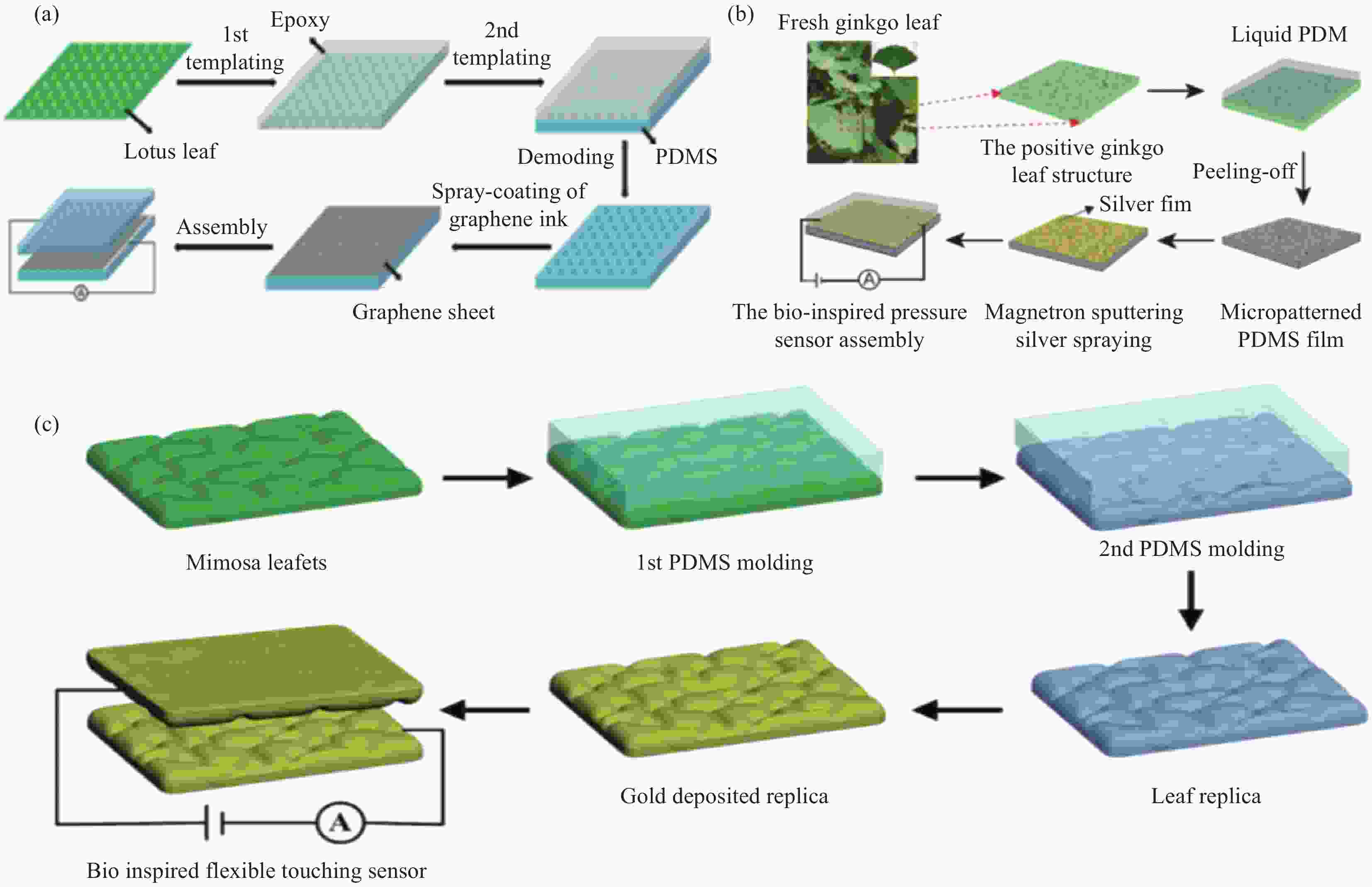

图 4 连锁微柱阵列柔性压力传感器的制作过程示意图 (a)、传感器在100 Pa外部压力下的实时响应曲线 (b)、具有不同微柱阵列HAR值的传感器的灵敏度曲线 (c) 以及在不同压力下传感器的相对电阻变化响应曲线 (d)[80]

Figure 4. Schematic diagram of fabrication process of interlocking micro-column array flexible pressure sensor (a), real-time response curve of sensor under 100 Pa external pressure (b), sensitivity curves of sensors with different micro-column array HAR values (c), andresponse curve of relative resistance change of the sensor under different pressures (d)[80]

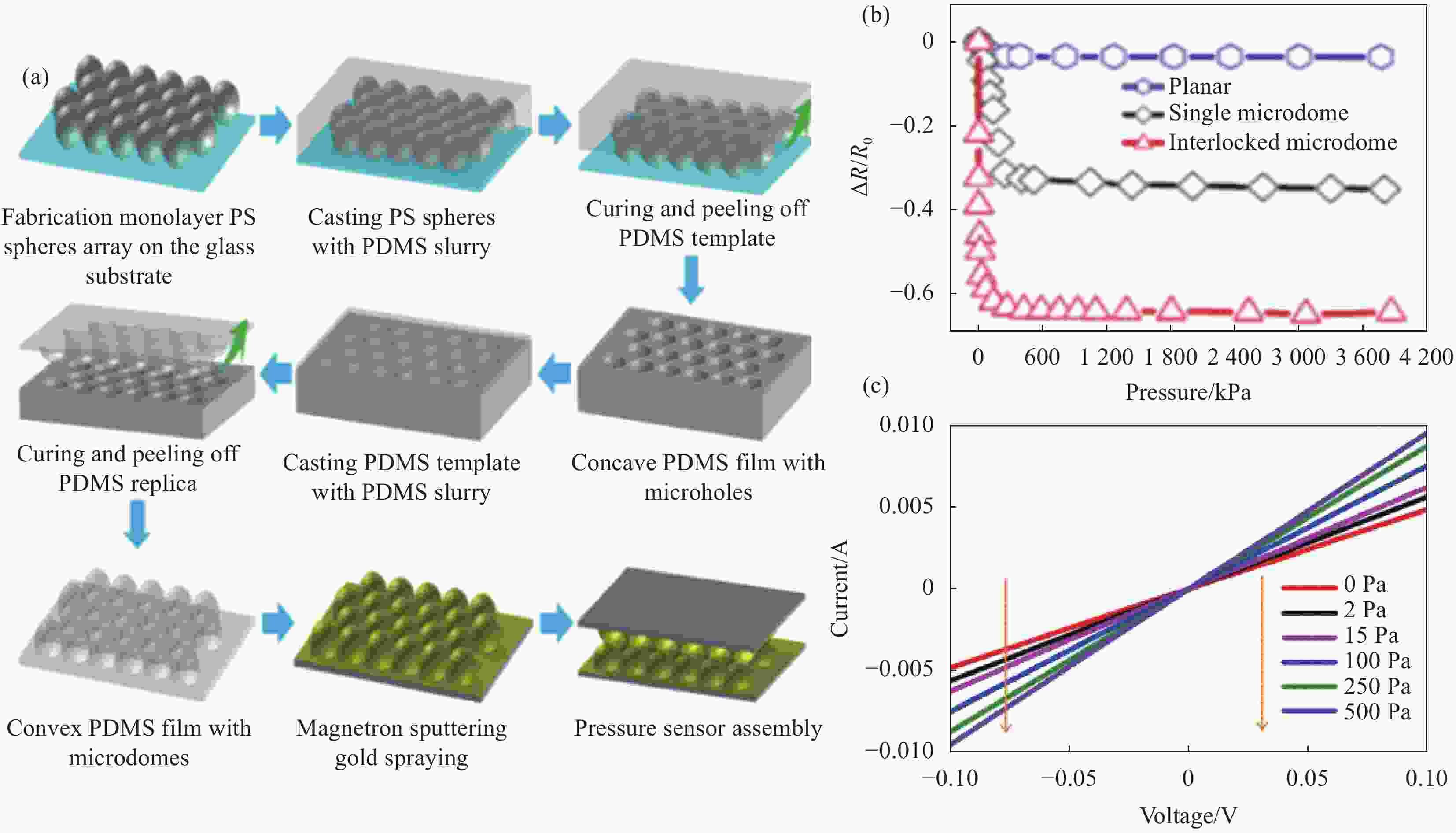

图 5 利用PS微球结构制备可调压阻式压力传感器的制作示意图 (a);三种不同传感器结构的压力敏感度对比 (b);不同施加压力下压力传感器的电流-电压(I-V)曲线 (c)[81]

Figure 5. Schematic diagram of pressure sensor with adjustable pressure resistance made of polystyrene microsphere structure (a);Comparasion of the pressure sensitivity for three different sensor structures (b); Current-voltage (I-V) curve of pressure sensor under different applied pressures (c)[81]

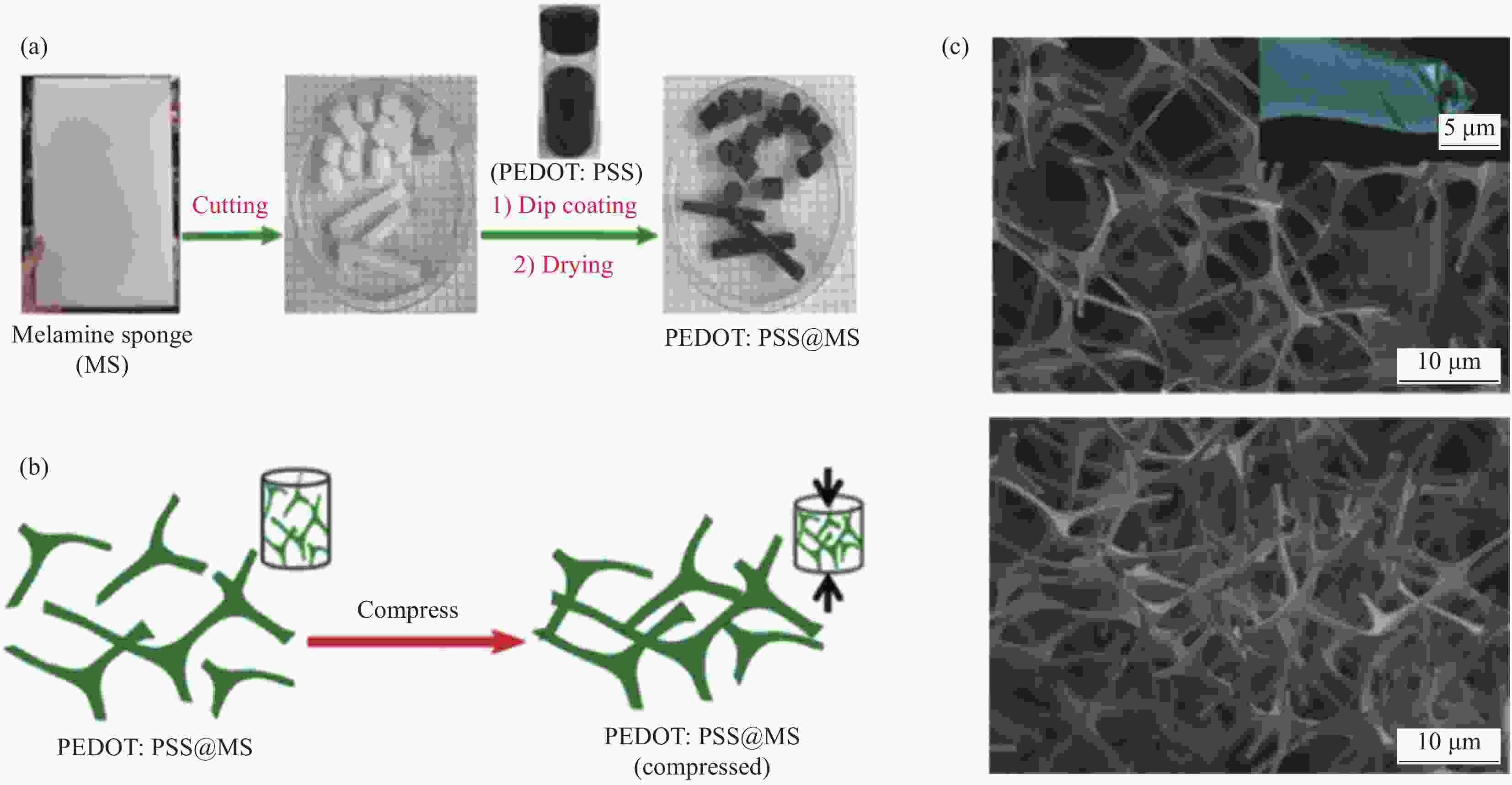

图 8 通过浸涂工艺制备PEDOT:PSS涂覆三聚氰胺海绵的示意图 (a)、压缩条件下PEDOT:PSS@MS的结构变化示意图 (b) 和PEDOT:PSS@MS和压缩下的PEDOT:PSS@MS的SEM图像 (c)[87]

Figure 8. Schematic diagram of PEDOT:PSS coated melamine sponge prepared by dip coating process (a), schematic diagram of structural change of PEDOT:PSS@MS under compression (b), and SEM images of PEDOT:PSS@MS and PEDOT:PSS@MS under compression (c)[87]

图 10 基于泡沫石墨烯制备的柔性压力传感器的原理示意图 (a)、施加压力时传感器相对电阻的变化 (b)、施加相同压力时,传感器的相对电阻变化 (c) 以及人在行走和跳跃时传感器的相对电阻变化 (d)[90]

Figure 10. Schematic diagram of flexible pressure sensor based on foam graphene (a), change of relative resistance of sensor when pressure is applied (b), change of relative resistance of sensor when the same pressure is applied (c), and change of relative resistance of sensor when people walk and jump (d)[90]

图 12 基于网络架构的宽量程压力传感器(NWPS)的制作过程 (a)、蚁巢的照片 (b)、NWPS的分解图 (c)、NWPS用手指弯曲的插图 (d)和利用NWPS的高灵敏度和宽检测范围的各种应用 (e)[7]

Figure 12. Fabrication process of wide range pressure sensor (NWPS) based on network architecture (a), photograph of ant nests (b), exploded diagram of the NWPS (c), illustration of the NWPS bending with a finger (d), and various applications exploiting the high sensitivity and wide detection range of the NWPS (e)[7]

表 1 压阻式、电容式和压电式柔性压力传感器比较

Table 1. Comparison of piezoresistive, capacitive and piezoelectric flexible pressure sensors

Type Working principle Sensitivity Advantages Disadvantages Piezoresistive sensor Resistive change ${{S} } = \dfrac{ {\delta (\Delta {{R} }/{R_0})} }{ {\delta {{P} } } }$ Low cost, simple design and operation, easily detectable signals and high sensitivity Nonlinearity and hysteresis Capacitive sensor Capacitive change ${{S} } = \dfrac{ {\delta (\Delta {{C} }/{C_0})} }{ {\delta {{P} } } }$ Fast response, high accuracy, high sensitivity and low hysteresis High cost, complicated detection circuit, nonlinear output and low load capacity Piezoelectricity sensor Electric current change Piezoelectric effect Wide frequency band, fast response and reliable operation High cost, complicated operation Notes: S—Sensitivity; ΔR—Change in resistance; R0—Initial resistance value of the sensor when it is not under pressure; P—Pressure per unit area of the sensor; ΔC—Change in capacitance; C0—Initial capacitance value in the unstressed state. -

[1] ZANG Y P, ZHANG F J, DI C, et al. Advances of flexible pressure sensors toward artificial intelligence and health care applications[J]. Materials Horizons,2015,2(2):140-156. [2] ZHOU H W, WANG Z W, ZHAO W F, et al. Robust and sensitive pressure/strain sensors from solution processable composite hydrogels enhanced by hollow-structured conducting polymers[J]. Chemical Engineering Journal,2021,403:126307. doi: 10.1016/j.cej.2020.126307 [3] LIU Z, MA Y, OUYANG H, et al. Transcatheter self-powered ultrasensitive endocardial pressure sensor[J]. Advanced Functional Materials,2019,29:1807560. doi: 10.1002/adfm.201807560 [4] OUYANG H, LIU Z, LI N, et al. Symbiotic cardiac pacemaker[J]. Nature communications,2019,10:1821. doi: 10.1038/s41467-019-09851-1 [5] CHENG X L, XUE X, MA Y, et al. Implantable and self-powered blood pressure monitoring based on a piezoelectric thinfilm: Simulated, in vitro and in vivo studies[J]. Nano Energy,2016,22:453-460. doi: 10.1016/j.nanoen.2016.02.037 [6] SHARMA S, CHHETRY A, SHARIFUZZAMAN M, et al. Wearable capacitive pressure sensor based on MXene composite nanofibrous scaffolds for reliable human physiological signal acquisition[J]. ACS Applied Materials & Interfaces,2020,12(19):22212-22224. [7] GUAN X, WANG Z Y, ZHAO W Y, et al. Flexible piezoresistive sensors with wide-range pressure measurements based on a graded nest-like architecture[J]. ACS Applied Materials & Interfaces,2020,12(23):26137-26144. [8] JIANG D J, SHI B J, OUYANG H, et al. Emerging implantable energy harvesters and self-powered implantable medical electronics[J]. ACS Nano,2020,14:6436-6448. doi: 10.1021/acsnano.9b08268 [9] WANG Y L, ZHU W, YU Y D, et al. High-sensitivity flexible pressure sensor with low working voltage based on sphenoid microstructure[J]. IEEE Sensors Journal,2020,20(13):7354-7361. doi: 10.1109/JSEN.2020.2978655 [10] ZHAO L M, LI H, MENG J P, et al. The recent advances in self-powered medical information sensors[J]. InfoMat,2020,2:212-234. doi: 10.1002/inf2.12064 [11] MENG J P, LI Z. Schottky-contacted nanowire sensors[J]. Advanced Materials,2020,32:2000130. doi: 10.1002/adma.202000130 [12] ZHENG Q, TANG Q Z, WANG Z L, et al. Self-powered cardiovascular electronic devices and systems[J]. Nature Reviews Cardiology,2020,18:7-21. [13] WANG Z, CHEN J, CONG Y, et al. Ultrastretchable strain sensors and arrays with high sensitivity and linearity based on super tough conductive hydrogels[J]. Chemistry of Materials,2018,30(21):8062-8069. doi: 10.1021/acs.chemmater.8b03999 [14] LIU M M, PU X, JIANG C Y, et al. Large-area all-textile pressure sensors for monitoring human motion and physiological signals[J]. Advanced Materials,2017,29(41):1703700. doi: 10.1002/adma.201703700 [15] LIU P, LIU J, ZHU X, et al. A highly adhesive flexible strain sensor based on ultra-violet adhesive filled by graphene and carbon black for wearable monitoring[J]. Composites Science and Technology,2019,182:107771. doi: 10.1016/j.compscitech.2019.107771 [16] GUO Y, ZHONG M, FANG Z, et al. A wearable transient pressure sensor made with mxene nanosheets for sensitive broad-range human-machine interfacing[J]. Nano Letters,2019,19(2):1143-1150. doi: 10.1021/acs.nanolett.8b04514 [17] WANG X, GU Y, XIONG Z, et al. Silk-molded flexible, ultrasensitive, and highly stable electronic skin for monitoring human physiological signals[J]. Advanced Materials,2014,26(9):1336-1342. doi: 10.1002/adma.201304248 [18] HAN M, LEE J, KIM J K, et al. Highly sensitive and flexible wearable pressure sensor with dielectric elastomer and carbon nanotube electrodes[J]. Sensors and Actuators A: Physical,2020,305:111941. doi: 10.1016/j.sna.2020.111941 [19] CHEN W F, YAN X. Progress in achieving high-performance piezoresistive and capacitive flexible pressure sensors: A review[J]. Journal of Materials Science & Technology,2020,43:175-188. [20] BAE G Y, HAN J T, LEE G, et al. Pressure/temperature sensing bimodal electronic skin with stimulus discriminability and linear sensitivity[J]. Advanced Materials,2018,30(43):1803388. doi: 10.1002/adma.201803388 [21] CHOI H B, OH J, KIM Y, et al. Transparent pressure sensor with high linearity over a wide pressure range for 3d touch screen applications[J]. ACS Applied Materials & Interfaces,2020,12(14):16691-16699. [22] SHI R L, LOU Z, CHEN S, et al. Flexible and transparent capacitive pressure sensor with patterned microstructured composite rubber dielectric for wearable touch keyboard application[J]. Science China Materials,2018,61(12):1587-1595. doi: 10.1007/s40843-018-9267-3 [23] LIU H, LI Q, ZHANG S, et al. Electrically conductive polymer composites for smart flexible strain sensors: A critical review[J]. Journal of Materials Chemistry C,2018,6(45):12121-12141. doi: 10.1039/C8TC04079F [24] WU S, PENG S, HAN Z J, et al. Ultrasensitive and stretchable strain sensors based on mazelike vertical graphene network[J]. ACS Applied Materials & Interfaces,2018,10(42):36312-36322. doi: 10.1021/acsami.8b15848 [25] ZHAO T, LI T, CHEN L, et al. Highly sensitive flexible piezoresistive pressure sensor developed using biomimetically textured porous materials[J]. ACS Applied Materials & Interfaces,2019,11(32):29466-29473. [26] HAMMOCK M L, CHORTOS A, TEE B C, et al. C, et al. 25th anniversary article: The evolution of electronic skin (e-skin): A brief history, design considerations, and recent progress[J]. Advanced Materials,2013,25(42):5997-6038. doi: 10.1002/adma.201302240 [27] ZHU Y C, WU Y G, WANG G S, et al. A flexible capacitive pressure sensor based on an electrospun polyimide nano-fiber membrane[J]. Organic Electronics,2020,84:105759. doi: 10.1016/j.orgel.2020.105759 [28] LIU H, HUANG W J, YANG X R, et al. Organic vapor sensing behaviors of conductive thermoplastic polyurethane-graphene nanocomposites[J]. Journal of Materials Chemistry C,2016,4(20):4459-4469. doi: 10.1039/C6TC00987E [29] LIU H, DONG M Y, HUANG, W J, et al. Lightweight conductive graphene/thermoplastic polyurethane foams with ultrahigh compressibility for piezoresistive sensing[J]. Journal of Materials Chemistry C,2017,5(1):73-83. doi: 10.1039/C6TC03713E [30] LIU H, LI Y L, DAI K, et al. Electrically conductive thermoplastic elastomer nanocmposites at ultralow graphene loading levels for strain sensor applications[J]. Journal of Materials Chemistry C,2016,4(1):157-166. [31] SEYEDIN M Z, RAZAL J M, INNIS P C, et al. Strain-responsive polyurethane/PEDOT: PSS elastomeric composite fibers with high electrical conductivity[J]. Advanced Functional Materials,2014,24(20):2957-2966. doi: 10.1002/adfm.201303905 [32] LI M, LI H, ZHONG W, et al. Stretchable conductive polypyrrole/polyurethane (PPy/PU) strain sensor with netlike microcracks for human breath detection[J]. ACS Applied Materials & Interfaces,2014,6(2):1313-1319. [33] TRAN M T, TUNG T T, SACHAN A, et al. 3D sprayed polyurethane functionalized graphene/carbon nanotubes hybrid architectures to enhance the piezoresistive response of quantum resistive pressure sensors[J]. Carbon,2020,168:564-579. doi: 10.1016/j.carbon.2020.05.086 [34] LIN Y, LIU S Q, CHEN S, et al. A highly stretchable and sensitive strain sensor based on graphene-elastomer composites with a novel double-interconnected network[J]. Journal of Materials Chemistry C,2016,4(26):6345-6352. doi: 10.1039/C6TC01925K [35] ZHAO S F, LI J H, CAO D X, et al. Percolation threshold-inspired design of hierarchical multiscale hybrid architectures based on carbon nanotubes and silver nanoparticles for stretchable and printable electronics[J]. Journal of Materials Chemistry C,2016,4(27):6666-6674. doi: 10.1039/C6TC01728B [36] WANG Y L, JIA Y Y, ZHOU Y J, et al. Ultra-stretchable, sensitive and durable strain sensors based on polydopamine encapsulated carbon nanotubes/elastic bands[J]. Journal of Materials Chemistry C,2018,6(30):8160-8170. doi: 10.1039/C8TC02702A [37] HUANG J, YANG X, LIU J, et al. Vibration monitoring based on flexible multi-walled carbon nanotube/polydimethylsiloxane film sensor and the application on motion signal acquisition[J]. Nanotechnology,2020,31(33):335504. doi: 10.1088/1361-6528/ab8edd [38] JEONG S H, ZHANG S, HJORT K, et al. PDMS-based elastomer tuned soft, stretchable, and sticky for epidermal electronics[J]. Advanced Materials,2016,28(28):5830-5836. doi: 10.1002/adma.201505372 [39] CUI J, ZHANG B, DUAN J, et al. Flexible pressure sensor with Ag wrinkled electrodes based on PDMS substrate[J]. Sensors,2016,16(12):2131. doi: 10.3390/s16122131 [40] CHOI T Y, HWANG B U, KIM B Y, et al. Stretchable, transparent, and stretch-unresponsive capacitive touch sensor array with selectively patterned silver nanowires/reduced graphene oxide electrodes[J]. ACS Applied Materials Interfaces,2017,9(21):18022-18030. doi: 10.1021/acsami.6b16716 [41] RYU S, LEE P, CHOU J B, et al. Extremely elastic wearable carbon nanotube fiber strain sensor for monitoring of human motion[J]. ACS Nano,2015,9(6):5929-5936. doi: 10.1021/acsnano.5b00599 [42] AMJADI M, YOON Y J, PARK I, et al. Ultra-stretchable and skin-mountable strain sensors using carbon nanotubes-Ecoflex nanocomposites[J]. Nanotechnology,2015,26(37):375501. doi: 10.1088/0957-4484/26/37/375501 [43] ZHANG M C, WANG C Y, WANG H M, et al. Carbonized cotton fabric for high-performance wearable strain sensors[J]. Advanced Functional Materials,2017,27(2):1604795. doi: 10.1002/adfm.201604795 [44] LEE J, PYO S, KWON D S, et al. Ultrasensitive strain sensor based on separation of overlapped carbon nanotubes[J]. Small,2019,15(12):1805120. doi: 10.1002/smll.201805120 [45] JIANG Y, HE Q, CAI J, et al. Flexible strain sensor with tunable sensitivity via microscale electrical breakdown in graphene/polyimide thin films[J]. ACS Applied Materials & Interfaces,2020,12(52):58317-58325. [46] SEKITANI T, ZSCHIESCHANG U, KLAUK H, et al. Flexible organic transistors and circuits with extreme bending stability[J]. Nature Materials,2010,9(12):1015-1022. doi: 10.1038/nmat2896 [47] ROH E, HWANG B U, KIM D, et al. Stretchable, transparent, ultrasensitive, and patchable strain sensor for human-machine interfaces comprising a nanohybrid of carbon nanotubes and conductive elastomers[J]. ACS Nano,2015,9(6):6252-6261. doi: 10.1021/acsnano.5b01613 [48] CHUN S, SON W, CHOI C. Flexible pressure sensors using highly-oriented and free-standing carbon nanotube sheets[J]. Carbon,2018,139:586-592. doi: 10.1016/j.carbon.2018.07.005 [49] LU N S, LU C, YANG S X, et al. Highly sensitive skin-mountable strain gauges based entirely on elastomers[J]. Advanced Functional Materials,2012,22(19):4044-4050. doi: 10.1002/adfm.201200498 [50] CHEN H Y, BAO S J, MA J H, et al. A wearable daily respiration monitoring system using pdms-graphene compound tensile sensor for adult[C]. IEEE, 2019: 1269-1273. [51] HUANG J, WANG J, YANG Z, et al. High-performance graphene sponges reinforced with polyimide for room-temperature piezoresistive sensing[J]. ACS Applied Materials & Interfaces,2018,10(9):8180-8189. [52] IIJIMA S. Helical microtubules of graphitic carbon[J]. Nature,1991,354:56-58. doi: 10.1038/354056a0 [53] IIJIMA S, ICHIHASHI T. Single-shell carbon nanotubes of 1-nm diameter[J]. Nature,1993,363:603-605. doi: 10.1038/363603a0 [54] NOVOSELOV K S, GEIM A K, MOROZOV S V, et al. Electric field effect in atomically thin carbon films[J]. Science, 2004, 306: 666-670. [55] WANG B, LEE B K, KWAK M J, et al. Graphene/polydimethylsiloxane nanocomposite strain sensor[J]. Review of Scientific Instruments,2013,84(10):105005. doi: 10.1063/1.4826496 [56] YAO H B, GE J, WANG C F, et al. A flexible and highly pressure-sensitive graphene- polyurethane sponge based on fractured microstructure design[J]. Advanced Materials,2013,25(46):6692-6698. doi: 10.1002/adma.201303041 [57] LI X S, CAI W W, AN J, et al. Large-area synthesis of high-quality and uniform graphene films on copper foils[J]. Science,2009,324:1312-1314. doi: 10.1126/science.1171245 [58] HASS J, DE HEER W A, CONRAD E H. The growth and morphology of epitaxial multilayer graphene[J]. Journal of Physics: Condensed Matter,2008,20(32):323202. doi: 10.1088/0953-8984/20/32/323202 [59] WENG M, SUN L, QU S, et al. Fingerprint-inspired graphene pressure sensor with wrinkled structure[J]. Extreme Mechanics Letters,2020,37:100714. doi: 10.1016/j.eml.2020.100714 [60] TAO L Q, ZHANG K N, TIAN H, et al. Graphene-paper pressure sensor for detecting human motions[J]. ACS Nano,2017,11(9):8790-8795. doi: 10.1021/acsnano.7b02826 [61] YAO D H, WU L L, PENG S G, et al. Use of surface penetration technology to fabricate superhydrophobic multifunctional strain sensors with an ultrawide sensing range[J]. ACS Applied Materials & Interfaces,2021,13(9):11284-11295. [62] BAI S, SUN C, WAN P, et al. Transparent conducting films of hierarchically nanostructured polyaniline networks on flexible substrates for high-performance gas sensors[J]. Small,2015,11(3):306-310. doi: 10.1002/smll.201401865 [63] ZHAO S F, RAN W H, WANG D P, et al. 3D dielectric layer enabled highly sensitive capacitive pressure sensors for wearable electronics[J]. ACS Applied Materials & Interfaces,2020,12(28):32023-32030. [64] ZHAO X, WANG W L, WANG Z, et al. Flexible PEDOT:PSS/polyimide aerogels with linearly responsive and stable properties for piezoresistive sensor applications[J]. Chemical Engineering Journal,2020,395:125115. doi: 10.1016/j.cej.2020.125115 [65] BHATTACHARJEE M, SONI M, ESCOBEDO P, et al. PEDOT:PSS microchannel-based highly sensitive stretchable strain sensor[J]. Advanced Electronic Materials,2020,6(8):2000445. doi: 10.1002/aelm.202000445 [66] ZHOU Z, ZHANG X, WU X, et al. Self-stabilized polyaniline@graphene aqueous colloids for the construction of assembled conductive network in rubber matrix and its chemical sensing application[J]. Composites Science and Technology,2016,125:1-8. doi: 10.1016/j.compscitech.2016.01.016 [67] TIAN M W, WANG Y J, QU L J, et al. Electromechanical deformation sensors based on polyurethane/polyaniline electrospinning nanofibrous mats[J]. Synthetic Metals,2016,219:11-19. doi: 10.1016/j.synthmet.2016.05.005 [68] HE W N, LI G Y, ZHANG S Q, et al. Polypyrrole/silver coaxial nanowire aero-sponges for temperatureindependent stress sensing and stress-triggered joule heating[J]. ACS Nano,2015,9(4):4244-4251. doi: 10.1021/acsnano.5b00626 [69] WANG X Y, FENG G Y, LI M J, et al. Effect of PEDOT: PSS content on structure and properties of PEDOT: PSS/poly(vinyl alcohol) composite fiber[J]. Polymer Bulletin,2018,76(4):2097-2111. [70] WANG C, HU K, ZHAO C C, et al. Customization of conductive elastomer based on PVA/PEI for stretchable sensors[J]. Small,2020,16:1904758. doi: 10.1002/smll.201904758 [71] YUK H, LU B Y, ZHAO X H. Hydrogel bioelectronics[J]. Chemical Society Reviews,2019,48(6):1642-1667. doi: 10.1039/C8CS00595H [72] MERINO S, MARTIN C, KOSTARELOS K, et al. Nanocomposite hydrogels: 3D polymer- nanoparticle synergies for On-Demand drug delivery[J]. ACS Nano,2015,9(5):4686-4697. doi: 10.1021/acsnano.5b01433 [73] VASHIST A, VASHIST A, GUPTA Y K, et al. Recent advances in hydrogel based drug delivery systems for the human body[J]. Journal of Materials Chemistry B,2014,2:147-166. doi: 10.1039/C3TB21016B [74] SELIKTAR D. Designing cell-compatible hydrogels for biomedical applications[J]. Science,2012,336:1124-1128. doi: 10.1126/science.1214804 [75] SHI L, ZHU T X, GAO G X, et al. Highly stretchable and transparent ionic conducting elastomers[J]. Nature Communications,2018,9:2630. doi: 10.1038/s41467-018-05165-w [76] TONDERA C, AKBAR T F, THOMAS A K, et al. Highly conductive, stretchable, and cell-adhesive hydrogel by nanoclay doping[J]. Small,2019,15:1901406. doi: 10.1002/smll.201901406 [77] WANG J, LIN Y K, MOHAMED A, et al. High strength and flexible aramid nanofiber conductive hydrogels for wearable strain sensors[J]. Journal of Materials Chemistry C,2021,9:575-583. [78] HUANG Z L, GAO M, YAN Z C, et al. Pyramid microstructure with single walled carbon nanotubes for flexible and transparent micro-pressure sensor with ultra-high sensitivity[J]. Sensors and Actuators A: Physical,2017,266:345-351. doi: 10.1016/j.sna.2017.09.054 [79] SHAO Q, NIU Z, HIRTZ M, et al. High-performance and tailorable pressure sensor based on ultrathin conductive polymer film[J]. Small,2014,10(8):1466-1472. doi: 10.1002/smll.201303601 [80] ZHANG X Y, HU Y G, GU H, et al. A highly sensitive and cost-effective flexible pressure sensor with micropillar arrays fabricated by novel metal-assisted chemical etching for wearable electronics[J]. Advanced Materials Technologies,2019,4(9):1900367. doi: 10.1002/admt.201900367 [81] ZHANG Y, HU Y, ZHU P, et al. Flexible and highly sensitive pressure sensor based on microdome-patterned pdms forming with assistance of colloid self-assembly and replica technique for wearable electronics[J]. ACS Applied Materials & Interfaces,2017,9(41):35968-35976. [82] SHI J, WANG L, DAI Z, et al. Multiscale hierarchical design of a flexible piezoresistive pressure sensor with high sensitivity and wide linearity range[J]. Small,2018,14(27):1800819. doi: 10.1002/smll.201800819 [83] WAN Y, QIU Z, HUANG J, et al. Natural plant materials as dielectric layer for highly sensitive flexible electronic skin[J]. Small,2018,14(35):1801657. doi: 10.1002/smll.201801657 [84] SU B, GONG S, MA Z, et al. Mimosa-inspired design of a flexible pressure sensor with touch sensitivity[J]. Small,2015,11(16):1886-1891. doi: 10.1002/smll.201403036 [85] YAN J F, MA Y N, LI X X, et al. Flexible and high-sensitivity piezoresistive sensor based on MXene composite with wrinkle structure[J]. Ceramics International,2020,46(15):23592-23598. doi: 10.1016/j.ceramint.2020.06.131 [86] SHEN Y P, WANG Y B, LUO Z L, et al. Durable, sensitive, and wide-range wearable pressure sensors based on wavy-structured flexible conductive composite film[J]. Macromolecular Materials and Engineering,2020,305(8):2000206. doi: 10.1002/mame.202000206 [87] DING Y C, YANG J, TOLLE C, et al. Flexible and compressible PEDOT PSS melamine conductive sponge prepared via one-step dip coating as piezoresistive pressure sensor for human motion detection[J]. ACS Applied Materials & Interfaces,2018,10:16077-16086. [88] DONG X C, WEI Y, CHEN S, et al. A linear and large-range pressure sensor based on a graphene/silver nanowires nanobiocomposites network and a hierarchical structural sponge[J]. Composites Science and Technology,2018,155:108-116. doi: 10.1016/j.compscitech.2017.11.028 [89] QIN R, HU M, LI X, et al. A highly sensitive piezoresistive sensor based on MXenes and polyvinyl butyral with a wide detection limit and low power consumption[J]. Nanoscale,2020,12(34):17715-17724. doi: 10.1039/D0NR02012E [90] PANG Y, TIAN H, TAO L, et al. Flexible, highly sensitive, and wearable pressure and strain sensors with graphene porous network structure[J]. ACS Applied Materials & Interfaces,2016,8(40):26458-26462. [91] BAI N N, WANG L, WANG Q, et al. Graded intrafillable architecture-based iontronic pressure sensor with ultra-broad-range high sensitivity[J]. Nature Communications,2020,11:209. doi: 10.1038/s41467-019-14054-9 -

下载:

下载: