Research progress in construction and applications of surface patterned fibers

-

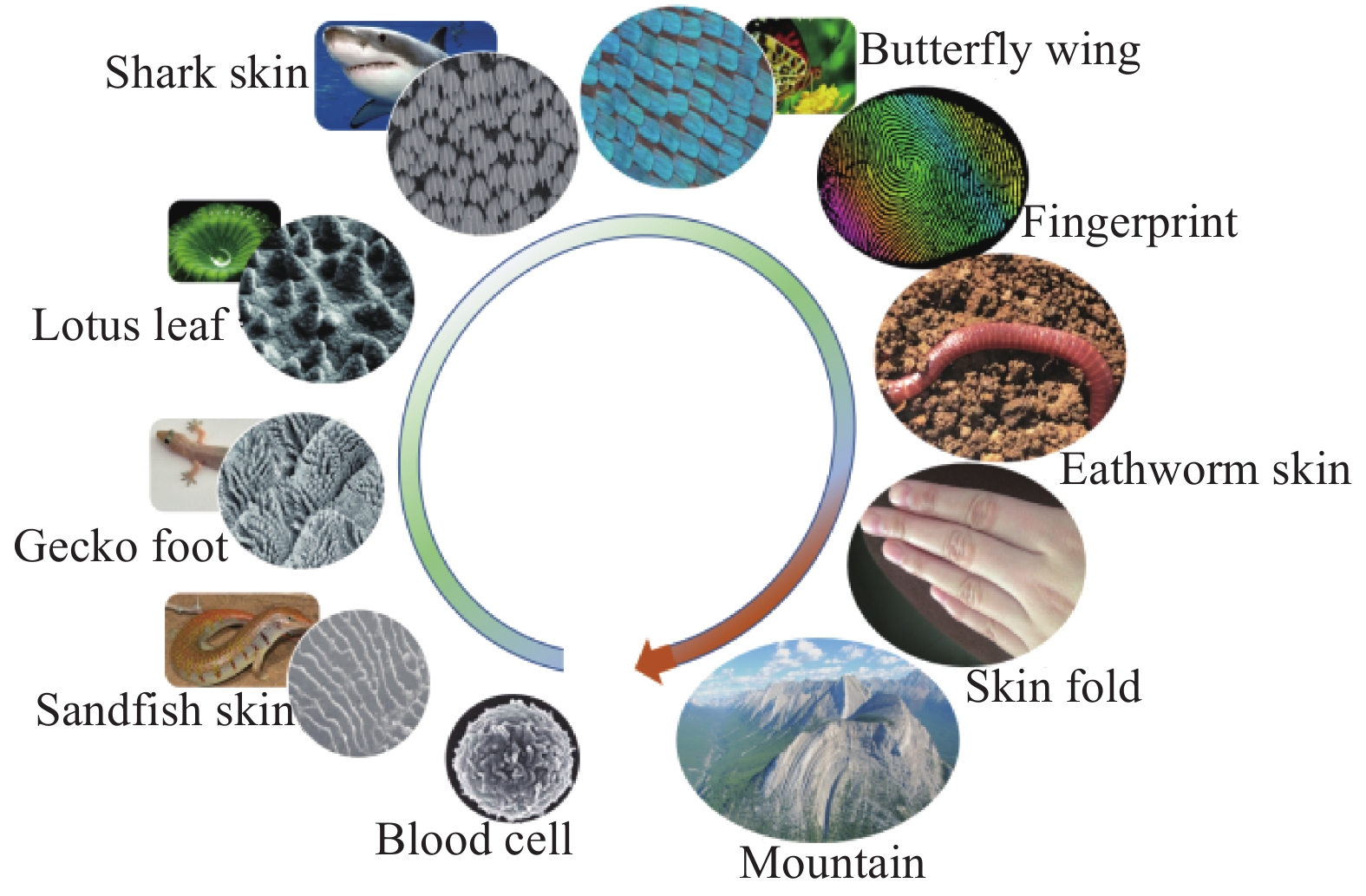

摘要: 自然界中生物体表面形形色色的图案赋予其减阻、强黏附、超疏水等多样的功能特性。受自然界的启发,研究者在平面基底表面构筑图案方面已经取得了很大研究进展。然而,纤维材料表面的图案化构筑及对纤维材料功能的影响等研究尚不深入。本文总结了目前纤维材料表面图案化的构筑方法,简述了三种“自下而上”策略的图案化形成机制;另外分析了纤维材料表面图案化对其功能的影响,展望了纤维材料表面图案化的潜在应用;最后对构筑方法、形成机制、应用领域提出了展望。本文旨在为纤维材料表面图案的构筑及功能纤维/织物更广阔的工程应用提供借鉴。Abstract: In nature, surface morphologies of organisms endow them versatile functions, e.g., drag reduction, strong adhesion, superhydrophobicity. Inspired by nature, researchers have made great progress in building micro/nano- patterns on planar substrate surfaces. However, the research on the patterning on fiber surface and its effect on the properties of fiber materials is still insufficient. In this paper, current construction methods of surface patterning on fiber surfaces were summarized, and fundamental mechanism of three “bottom-up” strategies was briefly described. Additionally, the influence of surface patterning on their properties was analyzed, and other potential applications of fiber materials in the future was prospected. Finally, the development trends of construction methods, formation mechanism and application were prospected. The purpose of this paper is to provide reference for both the construction of surface patterning on fibers and wide engineering applications of functional fiber/fabric.

-

Key words:

- fiber /

- surface patterning /

- wrinkle /

- functional fabric /

- engineering applications

-

图 2 热辊压印和机械雕刻实现纤维表面图案化((a)热辊压印技术示意图;(b)聚酰胺纤维表面图案化;(c)纤维表面裂纹产生装置示意图;(d)聚丙烯纤维表面产生规则的环向裂纹)

Figure 2. Patterning of fiber surface by hot roll imprinting and mechanical engraving ((a) Schematic for the roll embossing technique; (b) Surface patten of polyamide fibers; (c) Experimental apparatus for crazing the filaments; (d) SEM picture of crazed polypropylene filaments)

图 4 “自下而上法”构筑表面图案化的三种策略((a)基于“软芯/硬壳”结构的预拉伸法;(b)基于“软芯/硬壳”结构的外界刺激法;(c)基于纤维/渐变涂层结构的构筑方法)

Figure 4. Three strategies of "Bottom-up Method" for constructing patterned surface ((a) Pre-straining based on “softcore/rigid shell” model; (b) External stimulus method based on “softcore/rigid shell” model; (c) Construction of Gradient shell model)

图 6 弹性纤维预拉伸构筑表面图案化((a)橡胶纤维表面图案化示意图及表面双向屈曲的多壁碳纳米管(MWCNT)层[35];(b)预拉伸后UV照射法及形成的单侧褶皱图;(c)预拉伸后旋转照射UV法及形成的全表面褶皱图[36])

Figure 6. Surface patterning of elastic fiber pre stretching construction((a) Schematic illustration and SEM image of bidirectional buckling on rubber fiber surface of multiwalled carbon nanotube (MWCNT) layers[35]; Schematic and SEM images of wrinkled pattern (b) on one side and entire (c) surface[36])

图 7 辐照与加热法形成纤维表面图案化((a)~(b) 高通量紫外辐照前后聚对苯二甲酸乙二酯(PET)纤维[37];(c)~(d) 镀金聚氨酯(PU)纤维加热后表面褶皱图案[38])

Figure 7. Fiber surface patterning by irradiation and heating((a)-(b) polyethylene terephthalate (PET) fiber before and after high-fluence laser irradiation[37]; (c)-(d) Surface wrinkling on Au coated polyurethane (PU) fiber[38])

图 8 热处理法实现聚丙烯腈(PAN)纤维表面图案化((a)~(b) 3D和截面显示PAN纤维表面屈曲过程示意图;(c)~(e)不同加热温度后表面屈曲SEM图像[39])

Figure 8. Surface patterning of polyacrylonitrile (PAN) fiber by heat treatment ((a)-(b) 3D and cross-sectional schematic diagrams of surface buckling on PAN fiber; (c)-(e) SEM images of buckling BN skin layer at different heating temperatures[39])

图 9 等离子体渐变交联获得纤维表面褶皱结构((a) PET织物表面褶皱图案化示意图和机制;(b)随着Ar等离子处理时间加大PET纤维表面SEM图像;(c)处理后PET手套显示出超疏水性)

Figure 9. Surface fold structure of fiber obtained by plasma gradient cross-linking ((a) Schematic and mechanism for the fabrication of wrinkled patten on PET fabric fibers; (b) SEM images of PET fiber with different Ar plasma time; (c) Superhydrophobicity of treated PET glove)

PDMS—Polydimethylsiloxane

-

[1] WANG Q, ZHAO X. Beyond wrinkles: Multimodal surface instabilities for multifunctional patterning[J]. MRS Bulletin,2016,41(2):115-122. doi: 10.1557/mrs.2015.338 [2] WANG L, CASTRO C E, BOYCE M C. Growth strain-induced wrinkled membrane morphology of white blood cells[J]. Soft Matter,2011,7(24):11319. doi: 10.1039/c1sm06637d [3] SAMAHA M A, TAFRESHI H V, GAD-El-HAK M. Superhydrophobic surfaces: From the lotus leaf to the submarine[J]. Comptes Rendus Mecanique,2012,340(s1-2):18-34. [4] BALL P. Engineering shark skin and other solutions[J]. Nature,1999,400(6744):507-509. doi: 10.1038/22883 [5] YU T, PESIKA N, ZENG H, et al. Adhesion and friction in gecko toe attachment and detachment[J]. Proceedings of the National Academy of Sciences of the United States of America, 2018, 2006, 103(51): 19320-19325. [6] OTNES G, HEURLIN M, GRACZYK M, et al. Strategies to obtain pattern fidelity in nanowire growth from large-area surfaces patterned using nanoimprint lithography[J]. Nano Research,2016,9(10):1-10. [7] LONG J Y, PAN L, FAN P X, et al. Cassie-state stability of metallic superhydrophobic surfaces with various micro/nanostructures produced by a femtosecond laser[J]. Langmuir the Acs Journal of Surfaces & Colloids,2016,32(4):1065-1072. [8] LEE E K, PARK C H, LEE J, et al. Chemically robust ambipolar organic transistor array directly patterned by photolithography[J]. Advanced Materials,2017,29(11):1605282. [9] WEN L, WEAVER J C, LAUDER G V. Biomimetic shark skin: Design, fabrication and hydrodynamic function[J]. Journal of Experimental Biology,2014,217(10):1656-1666. doi: 10.1242/jeb.097097 [10] STUDART A R. Additive manufacturing of biologically-inspired materials[J]. Chemical Society Reviews,2016,45(2):359-376. [11] SUN J Y, BHUSHAN B. Nanomanufacturing of bioinspired surfaces[J]. Tribology International,2019,129:67-74. doi: 10.1016/j.triboint.2018.08.007 [12] 高晓东, 杨卫民, 程礼盛, 等. 导电玻璃纤维及其功能复合材料研究进展[J]. 复合材料学报, 2021, 38(1):36-44.GAO X D, YANG W M, CHENG L S, et al. Recent research progress in conductive glass fiber and polymer-based functional composites[J]. Acta Materiae Compositae Sinica,2021,38(1):36-44(in Chinese). [13] ZHU M, KIKUTANI T, LIU T, et al. Fiber changes our life[J]. Advanced Fiber Materials,2019,1(1):1-2. doi: 10.1007/s42765-019-0004-x [14] 刘旭华, 苗锦雷, 曲丽君, 等. 用于可穿戴智能纺织品的复合导电纤维研究进展[J]. 复合材料学报, 2021, 38(1):67-83.LIU X H, MIAO J L, QU L J, et al. Research progress of composite conductive fiber in wearable intelligent textiles[J]. Acta Materiae Compositae Sinica,2021,38(1):67-83(in Chinese). [15] SHI Q, SUN J, HOU C, et al. Advanced functional fiber and smart textile[J]. Advanced Fiber Materials,2019(18):3-31. [16] BALILONDA A, LI Q, TEBYETEKERWA M, et al. Perovskite solar fibers: Current status, issues and challenges[J]. Advanced Fiber Materials,2019,1(1):101-125. [17] YIN Z, SHI S, LIANG X, et al. Sweat-driven silk-yarn switches enabled by highly aligned gaps for air-conditioning textiles[J]. Advanced Fiber Materials,2019,1(3-4):197-204. [18] DING B. Advanced nanofiber materials and systems: Solving global issues[J]. Advanced Fiber Materials,2020,2(2):45. doi: 10.1007/s42765-020-00039-7 [19] WEI, HUANG, YUN C, et al. Construction of electrospun organic/inorganic hybrid nanofibers for drug delivery and tissue engineering applications[J]. Advanced Fiber Materials,2019,1(1):32-45. doi: 10.1007/s42765-019-00007-w [20] ZHAO J, CUI W. Functional electrospun fibers for local therapy of cancer[J]. Advanced Fiber Materials,2020,2(5):229-245. doi: 10.1007/s42765-020-00053-9 [21] BUKHARY H, WILLIAMS G R, ORUL M. Fabrication of electrospun levodopa-carbidopa fixed-dose combinations[J]. Advanced Fiber Materials,2020,2(4):194-203. doi: 10.1007/s42765-020-00031-1 [22] HUA Z, WANG H, NIU H, et al. Fluoroalkyl silane modified silicone rubber/nanoparticle composite: A super durable, robust superhydrophobic fabric coating[J]. Advanced Materials,2012,24(18):2409-2412. doi: 10.1002/adma.201200184 [23] MAMUN M, ISLAM M T, ISLAM M M, et al. Scalable process to develop durable conductive cotton fabric[J]. Advanced Fiber Materials,2020(19):291-301. [24] SCHIFT H, HALBEISEN M, SCHUTZ U, et al. Surface structuring of textile fibers using roll embossing[J]. Microelectronic Engineering,2006,83(4-9):855-858. doi: 10.1016/j.mee.2006.01.120 [25] TAKENO A, NAKAGAKI N, MIWA M. Anisotropic transparency of polystyrene film with crazes[J]. Advanced Compo-site Materials,1998,7(1):35-46. doi: 10.1163/156855198X00039 [26] KEISHI, NAITO, AKIYOSHI, et al. Variation of periodic crazing based on polymer blends of an ultra-high and a low molecular weight poly(methyl methacrylate)[J]. Journal of Applied Polymer Science,2016,134(1):44331-44338. [27] NAITO K, TAKENO A, MIWA M. Periodic crazing on polymethylmethacrylate film by localized bending[J]. Journal of Applied Polymer Science,2014,127(3):2307-2313. [28] HORIGUCHI Y, TAKAHASHI S, TAKENO A. Growth of craze phase and control of void diameter by Laplace-pressure in crazing films[J]. Japanese Journal of Applied Physics,2019,58:SAAD05. doi: 10.7567/1347-4065/aaec88 [29] TAKENO A, MIWA M, YOKOI T, et al. A new technique for generating regularly spaced crazes to facilitate piece dyeing of polypropylene filaments[J]. Journal of Applied Polymer Science,2013,128(6):3564-3569. doi: 10.1002/app.38485 [30] SHEN Y, YAO L, LI Z, et al. Double transfer UV-curing nanoimprint lithography[J]. Nanotechnology,2013,24(46):465304. doi: 10.1088/0957-4484/24/46/465304 [31] BOWDEN N, BRITTAIN S, EANS A G, et al. Spontaneous formation of ordered structures in thin films of metals supported on an elastomeric polymer[J]. Nature,1998,393(6681):146-149. doi: 10.1038/30193 [32] CHUNG J Y, NOLTE A, STAFFORD C M. Surface wrinkling: A versatile platform for measuring thin-film properties[J]. Advanced Materials,2011,23(3):349-368. doi: 10.1002/adma.201001759 [33] CERDA E, MAHADEVAN L. Geometry and physics of wrinkling[J]. Physical Review Letters,2003,90(7):074302. doi: 10.1103/PhysRevLett.90.074302 [34] CAO Y P, LI B, FENG X Q, Surface wrinkling and folding of core-shell soft cylinders[J]. Soft Matter, 2012, 8: 556. [35] LIU Z F, FANG S, MOURA F A, et al. Hierarchically buckled sheath-core fibers for superelastic electronics, sensors, and muscles[J]. Science,2015,349(6246):400-404. doi: 10.1126/science.aaa7952 [36] GENG J, RAHMAN M T, PANAT R, et al. Self-assembled axisymmetric microscale periodic wrinkles on elastomer fibers[J]. Journal of Micro & Nano Manufacturing,2017,5(2):021006. [37] KAN C W. Impact on textile properties of polyester with laser[J]. Optics & Laser Technology,2008,40(1):113-119. [38] ZHAO Y, HUANG W M, FU Y Q. Formation of micro/nano-scale wrinkling patterns atop shape memory polymers[J]. Journal of Micromechanics & Microengineering,2011,21(6):067007. [39] TAN Y, YAN J, CHU Z. Thermal-shrinking-induced ring-patterned boron nitride wrinkles on carbon fibers[J]. Carbon,2019,152:532-536. doi: 10.1016/j.carbon.2019.06.058 [40] XU L, YANG L, YANG S, et al. Earthworm-inspired ultradurable superhydrophobic fabrics from adaptive wrinkled skin[J]. ACS Applied Materials & Interfaces,2021,13(5):6758-6766. [41] WEN Z, YEH M H, GUO H, et al. Self-powered textile for wearable electronics by hybridizing fiber-shaped nanogenerators, solar cells, and supercapacitors[J]. Science Advances,2016,2(10):e1600097. doi: 10.1126/sciadv.1600097 [42] WEI Z, LIN S, LI Q, et al. Fiber-based wearable electronics: A review of materials, fabrication, devices, and applications[J]. Advanced Materials,2014,26(31):5310. doi: 10.1002/adma.201400633 [43] COYLE S, WU Y, LAU K L, et al. Smart nanotextiles: A review of materials and applications[J]. MRS Bulletin,2007,32(5):434-442. doi: 10.1557/mrs2007.67 [44] FAN H, LIi K, LIU X, et al. Continuously-processed, long-range electrochromic fibers with multi-environmental stability[J]. ACS Applied Materials & Interfaces,2020,12(25):28451-28460. -

下载:

下载: