Wrinkles in fiber-reinforced resin composites: Heterogeneity and virtual test

-

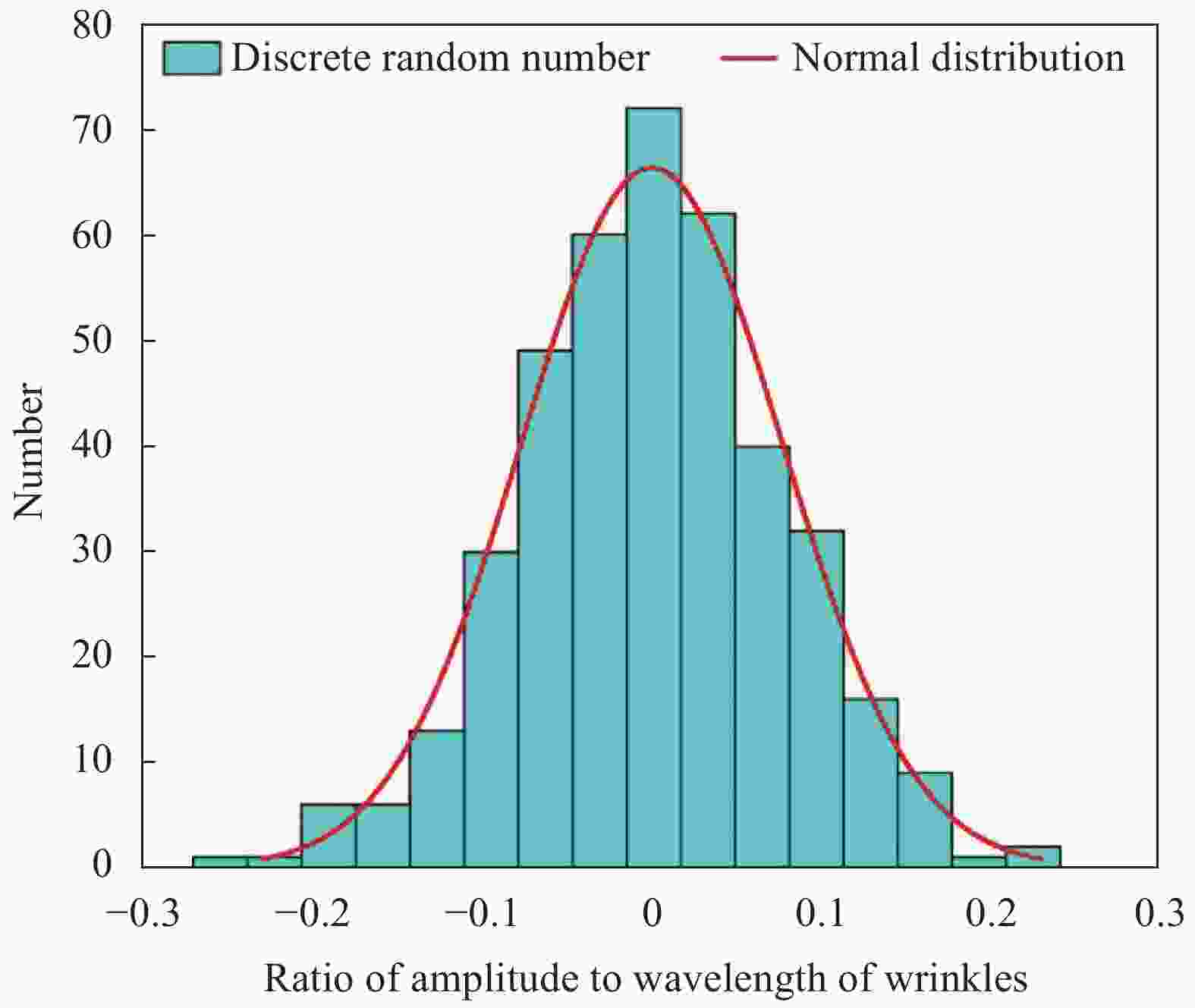

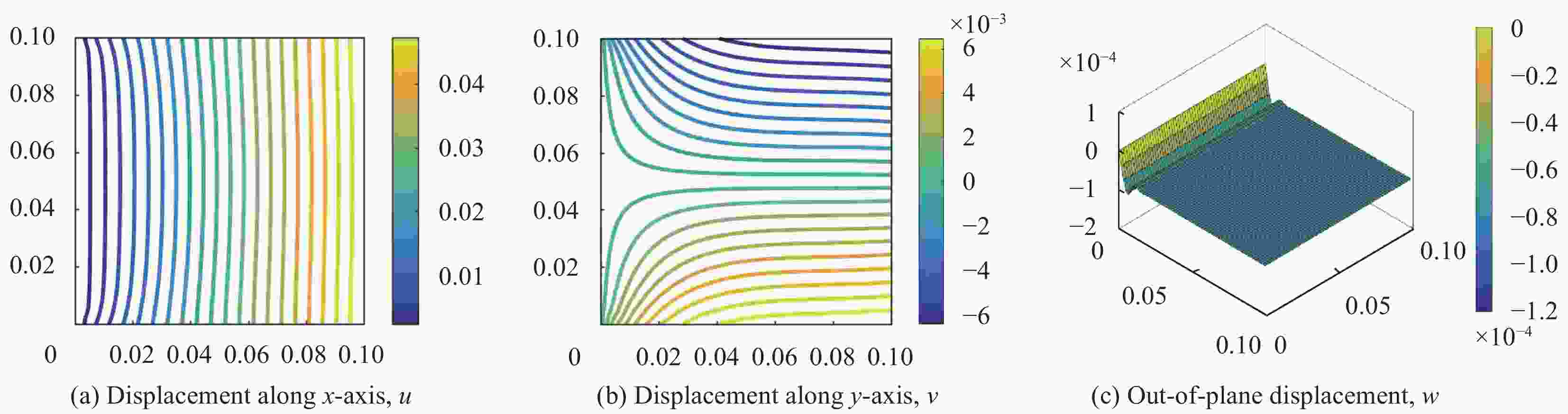

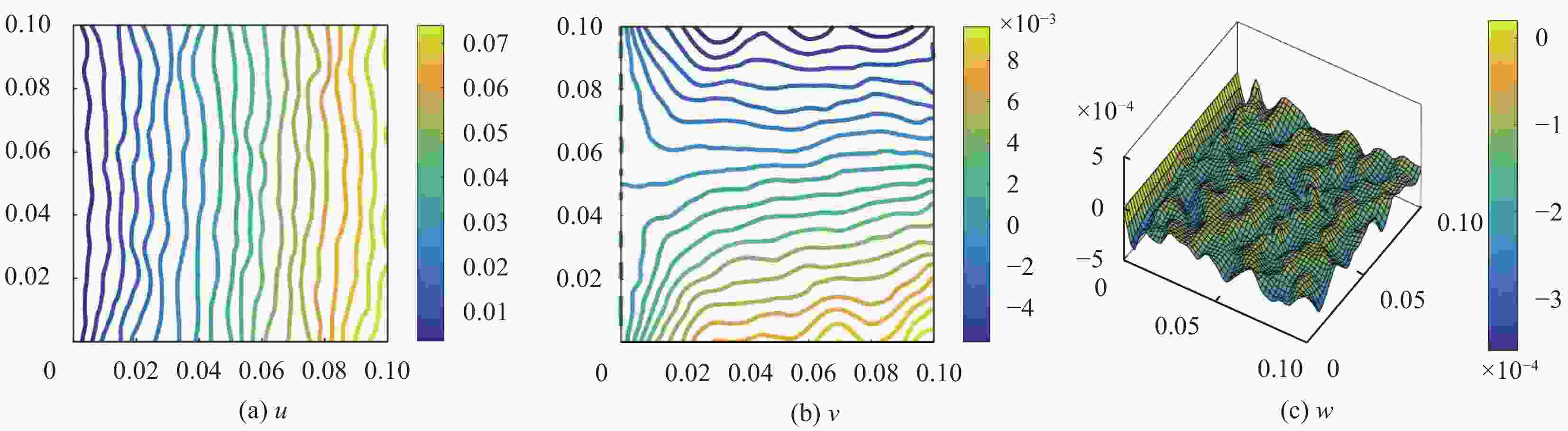

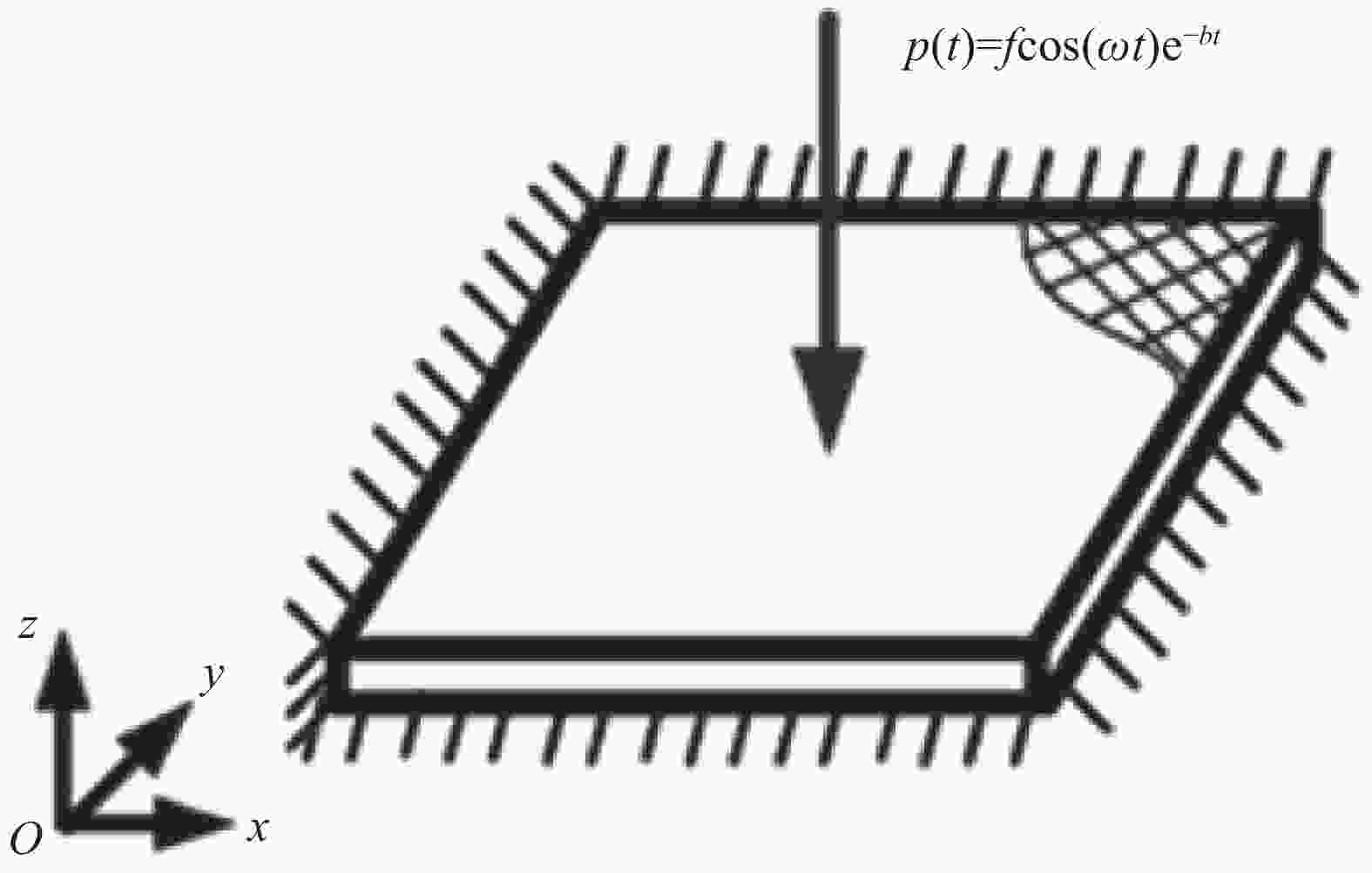

摘要: 在纤维增强树脂复合材料结构中,褶皱缺陷的物理形态及其空间分布通常具有分散性,如果仅追踪某个单一褶皱缺陷的行为演化,则不能有效控制复合材料批量构件性能的一致性。本论文提出了一种褶皱缺陷分散性模型,该模型包括褶皱形态的正态分布和空间位置的随机分布,以及将该模型植入自主开发的有限元程序的算法实现。由于计算程序中考虑了褶皱缺陷的概率分布,每进行一次力学响应计算就相当于进行一次复合材料结构虚拟测试,计算程序运行多次即可获得结构响应的上、下限,在设计阶段就可以预测褶皱缺陷分散性对结构宏观力学响应的影响,并在缺陷的统计指标和构件的力学性能之间建立量化关系。所建立的虚拟测试方法是复合材料创新设计方法的关键,能有效减少工程实践中复合材料结构对大批量试验的依赖。

-

关键词:

- 纤维增强树脂复合材料 /

- 褶皱缺陷 /

- 分散性 /

- 概率分布 /

- 虚拟测试

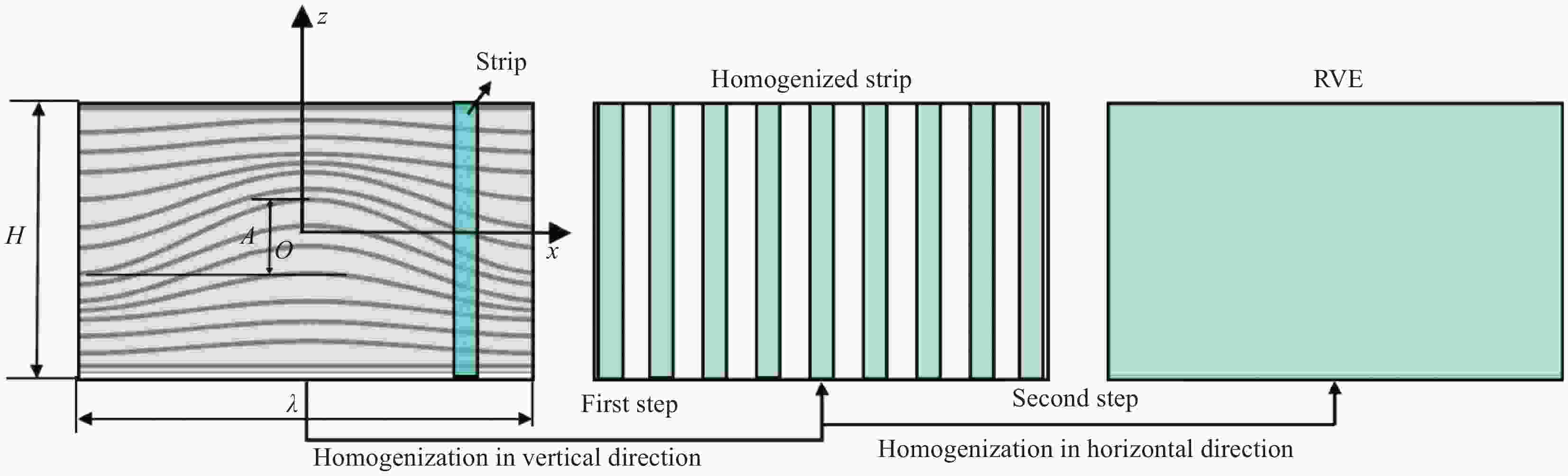

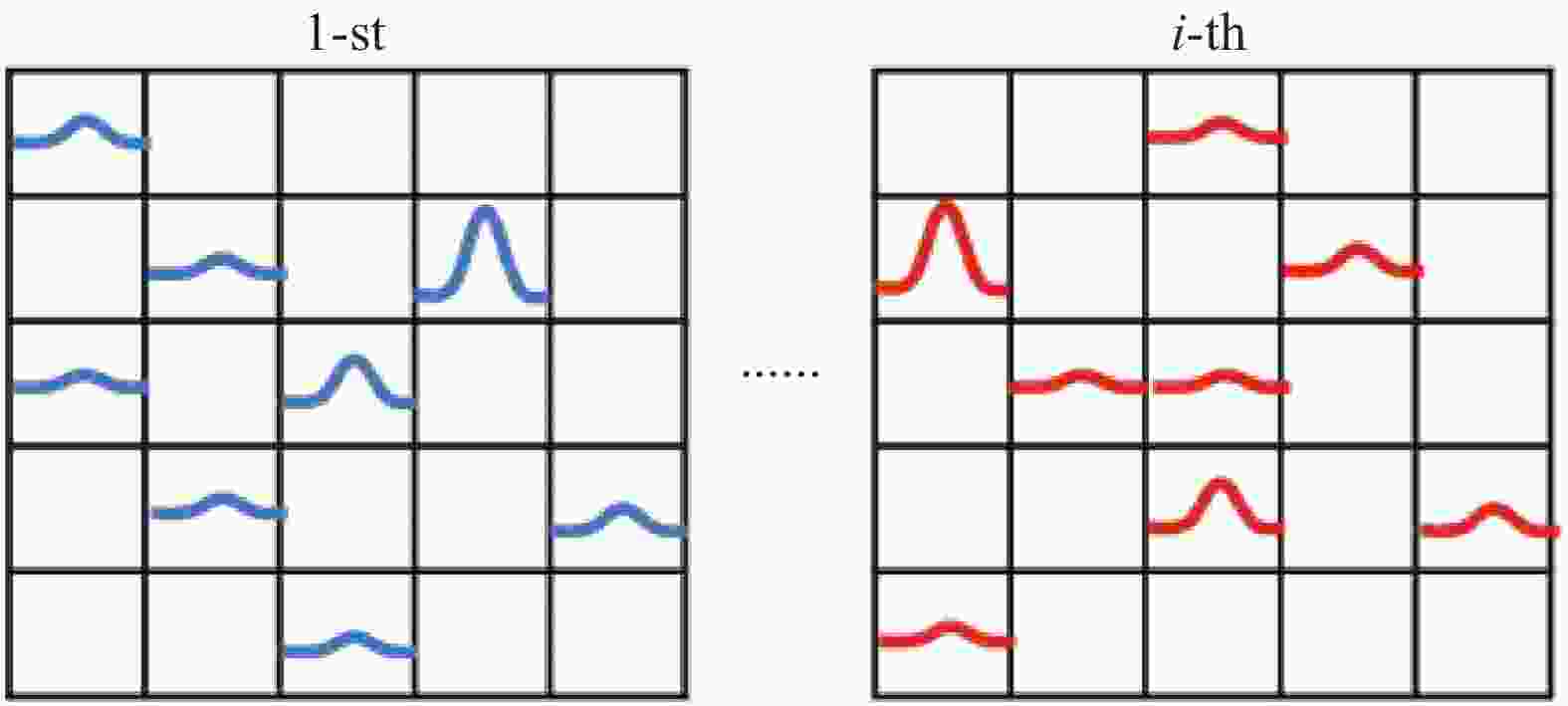

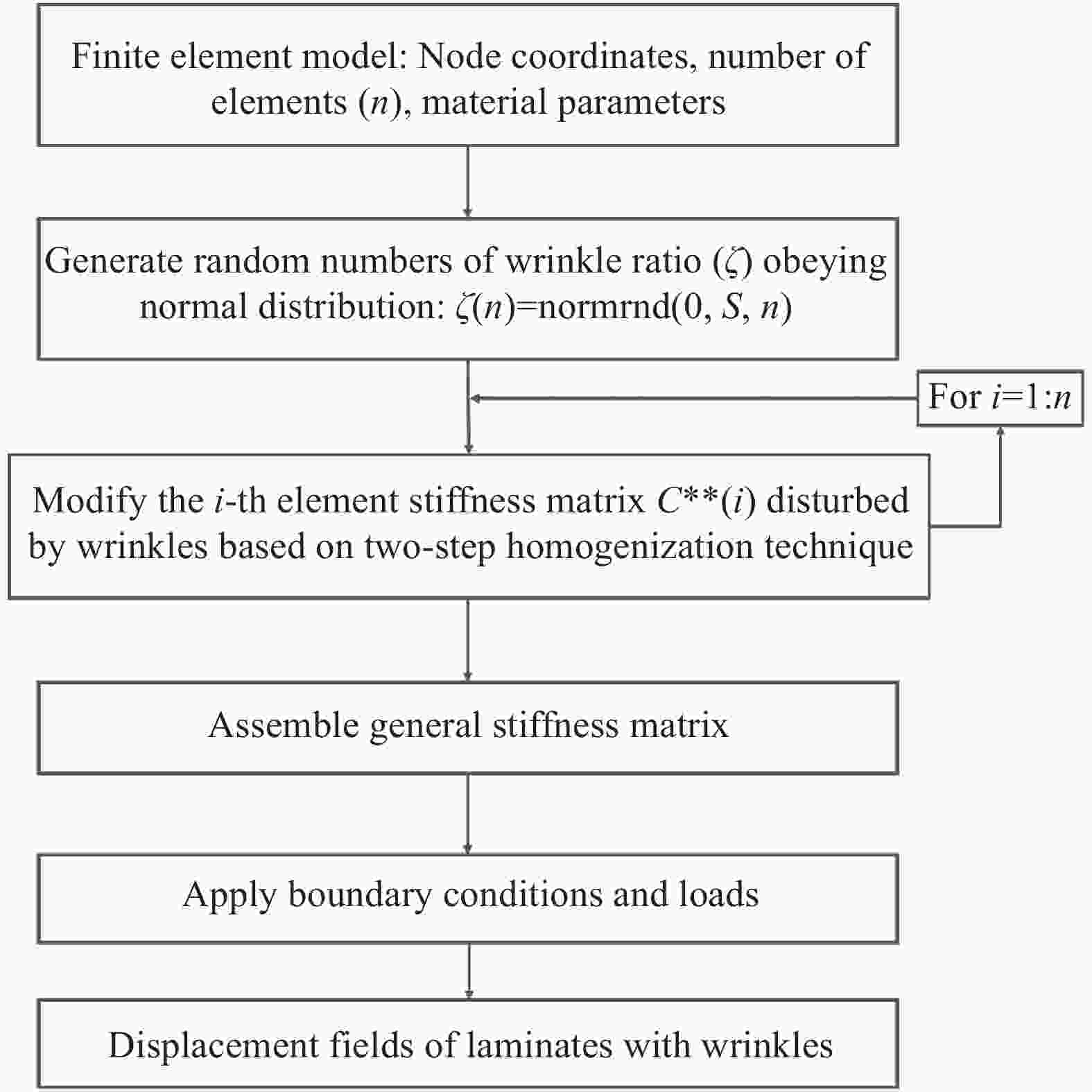

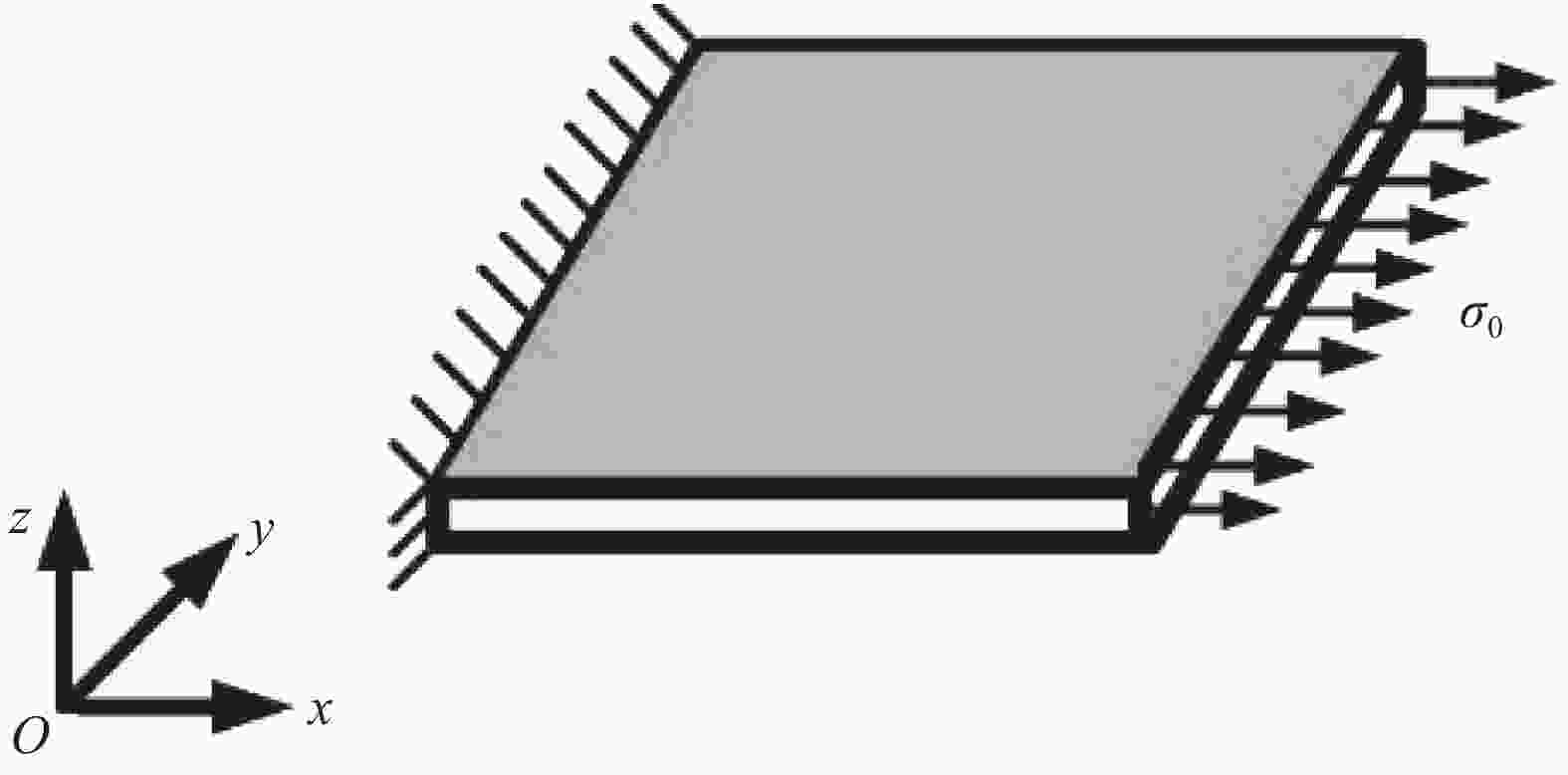

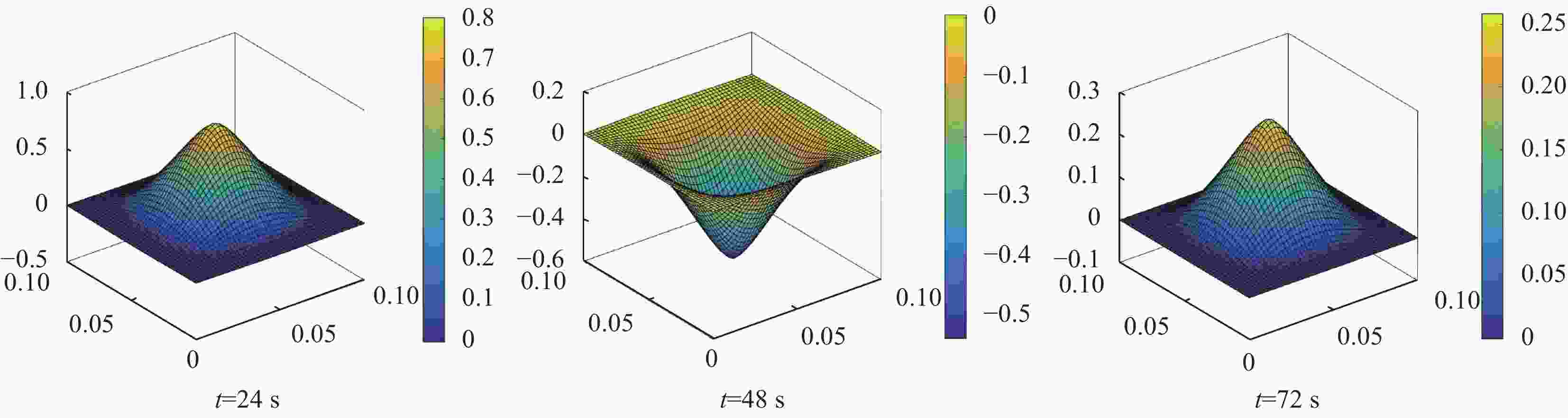

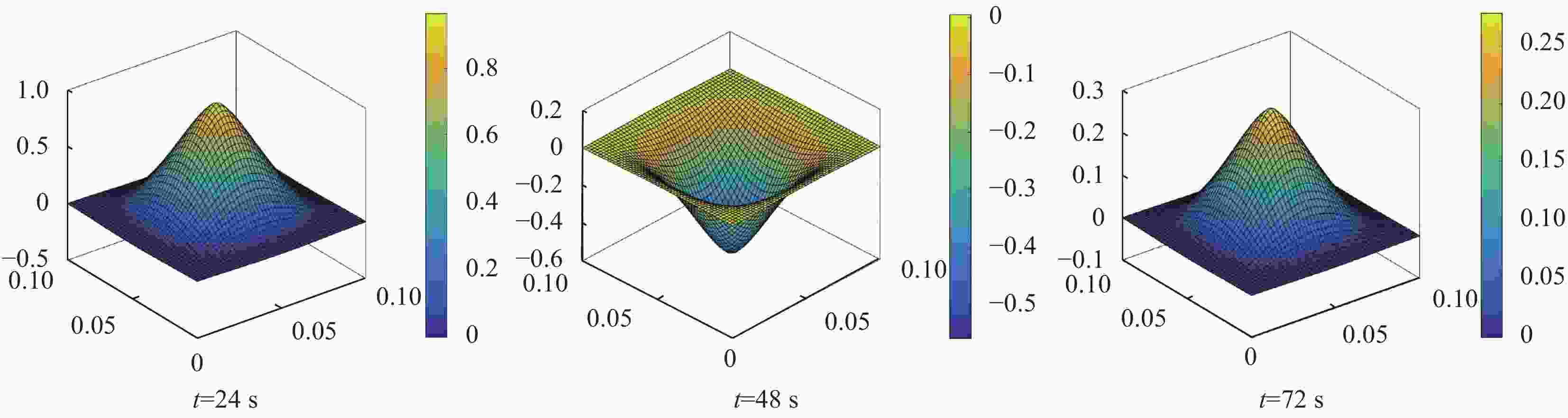

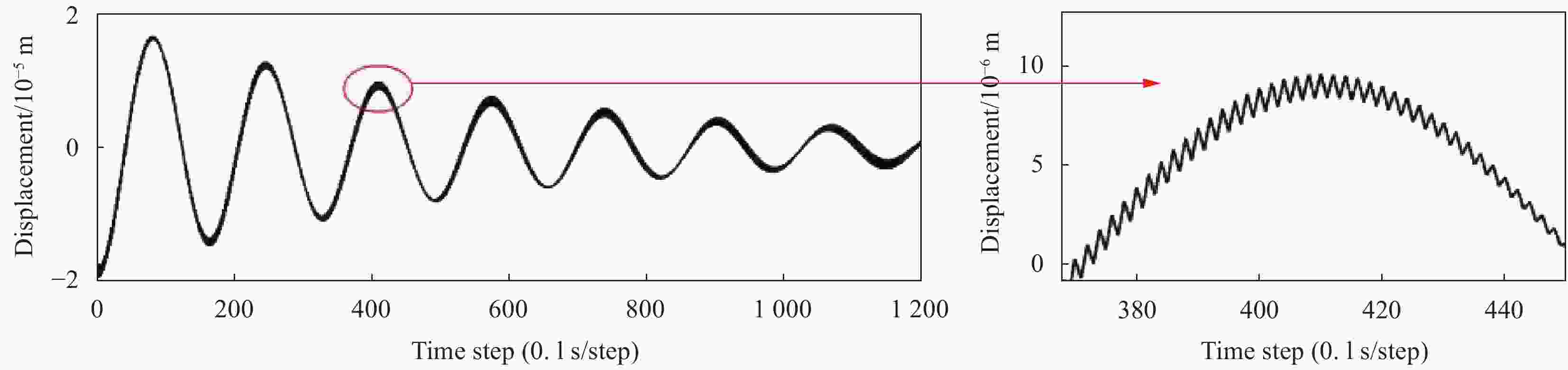

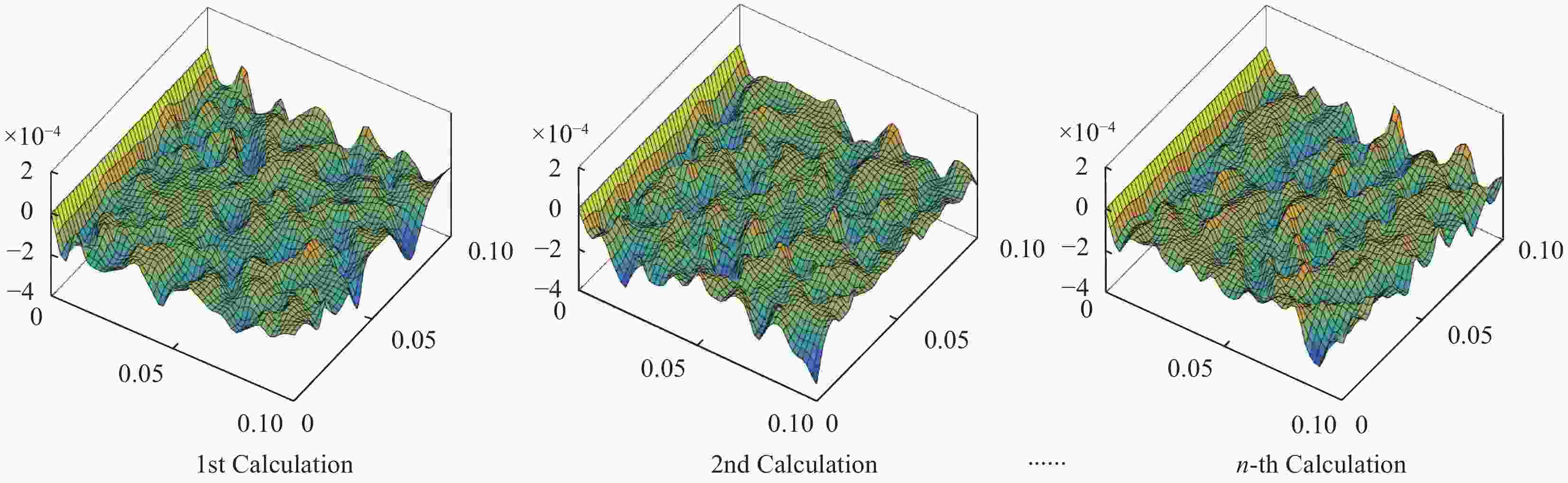

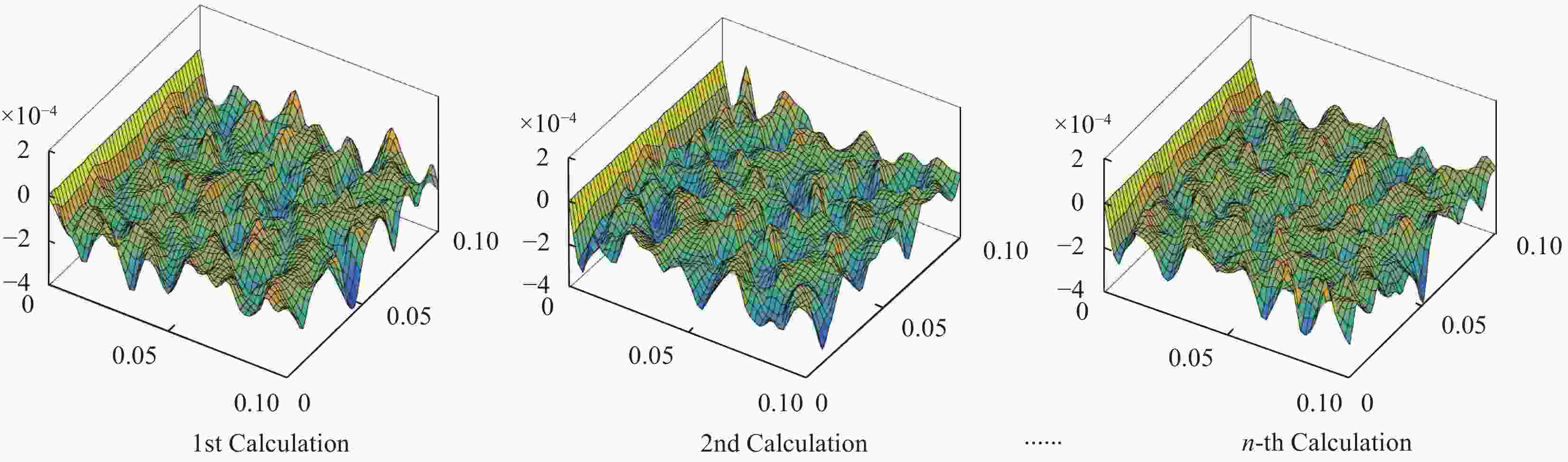

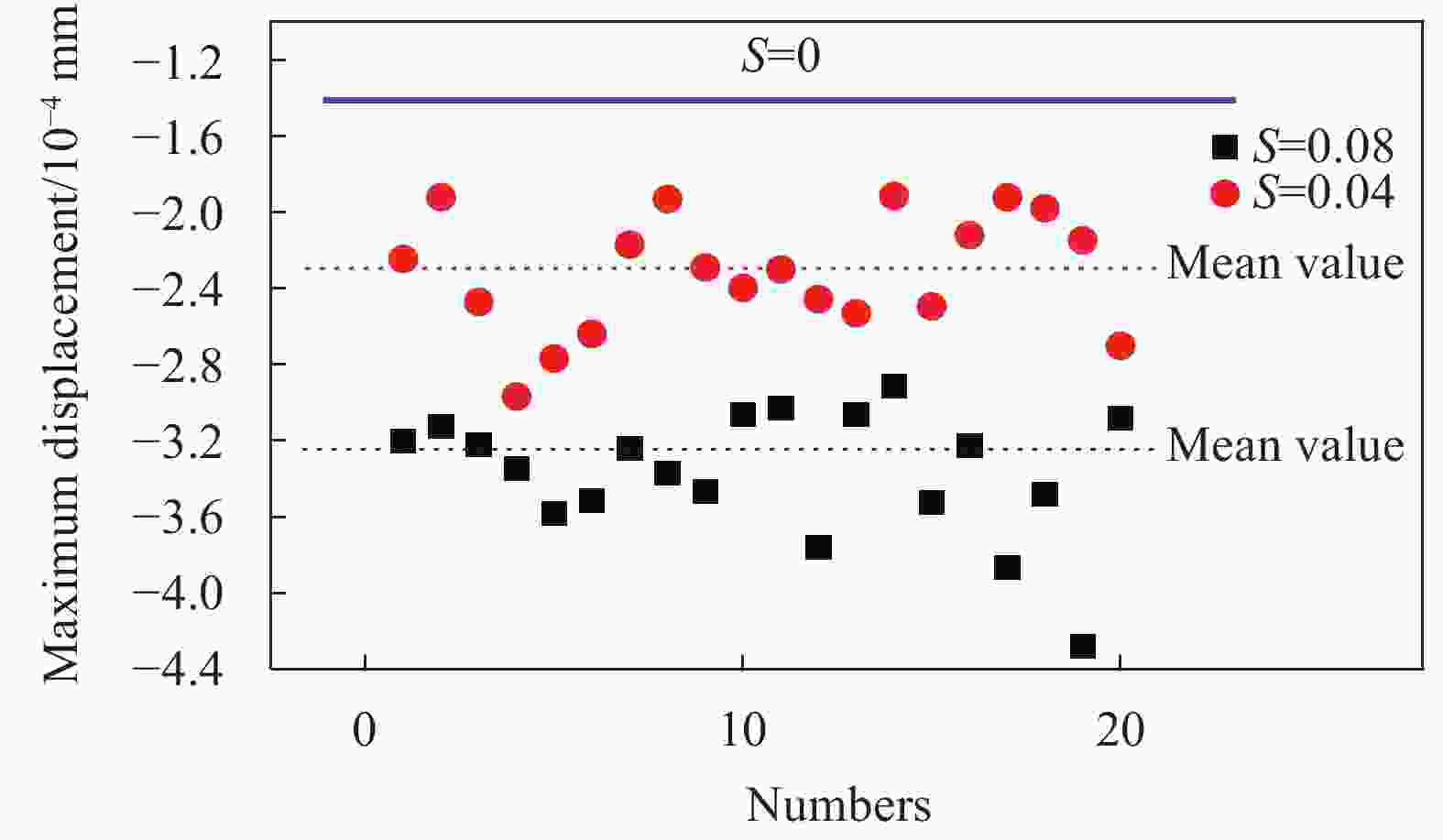

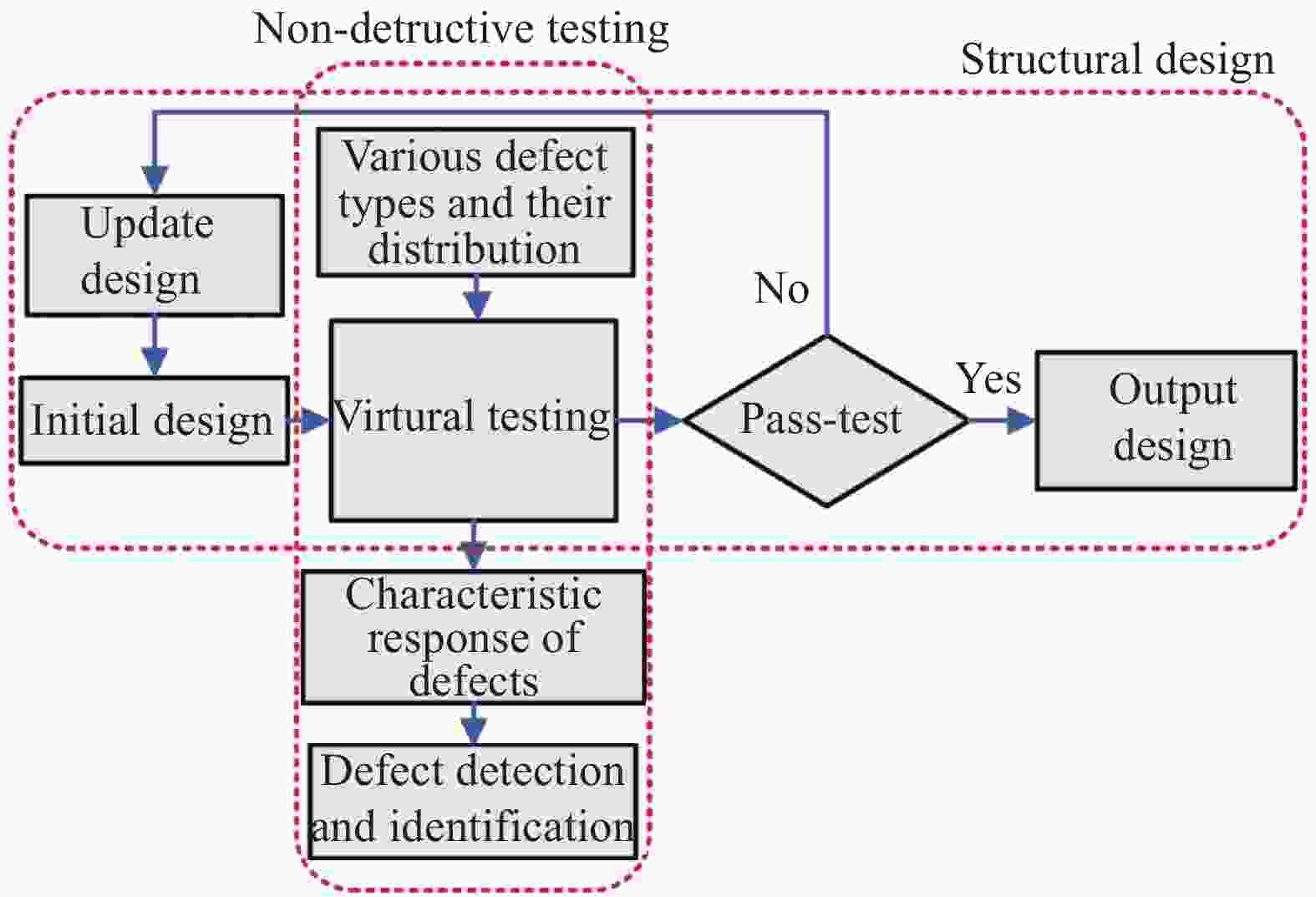

Abstract: The physical morphology of wrinkles and their spatial distribution in fiber-reinforced resin composites show inhomogeneity. It’s no use to improve the performance consistency of composite structures if just tracking the evolution and effect of a specific wrinkle. This paper proposed a novel model which considered the normal distribution of wrinkle’s geometrical size and the spatial random distribution, and the implementation algorithm of the model implanted in a self-developed finite element procedure is achieved. The computation combining hetero-geneous wrinkles can be considered as a virtual test since it allows every computation to produce a different result, thus the upper and lower limits of structural response can be obtained by multiple computations. The influence of wrinkle heterogeneity on macro-mechanical response can be predicted in design stage, and a quantitative relationship between the statistical parameters of defects and mechanical properties can be established. The virtual test method is the key to the innovative design method of composites, which can effectively reduce the dependence of mass testing of composite material in engineering practice.-

Key words:

- fiber-reinforced resin composites /

- wrinkle defects /

- heterogeneity /

- random distribution /

- virtual test

-

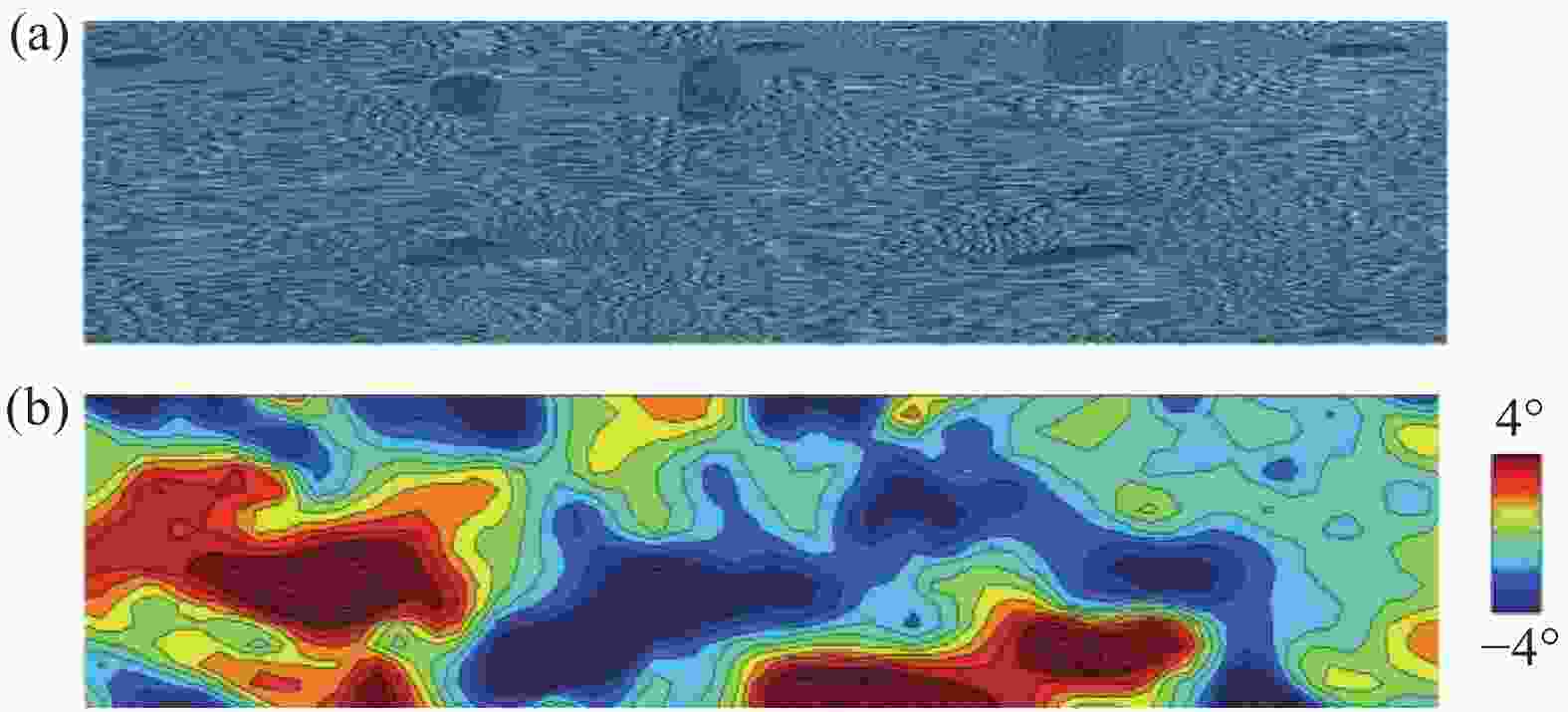

图 1 纤维偏转角随机正态分布[12]:(a)显微照相;(b)等值线图

Figure 1. Normal distribution of fiber orientations: (a) Micrograph section; (b) Contours of corresponding to fiber orientations

表 1 用于数值模拟的碳纤维/环氧树脂(CF/EP)复合材料弹性参数

Table 1. Elastic parameters of carbon fiber/epoxy resin (CF/EP) composites used in numerical simulation

E11/GPa (E22/E33)/GPa G23/GPa G31/GPa G12/GPa ν21 ν32 ν31 133.3 9.09 3.16 7.24 7.23 0.261 0.436 0.261 Notes: E11, E22, E33—Elastic modulus (direction 11, 22, 33); G12, G23, G31—Shear modulus (direction 12, 23, 31); v21, v32, v31—Poisson’s ratio (direction 21, 32, 31). -

[1] ZHU J, WANG J, ZU L. Influence of out-of-plane ply waviness on elastic properties of composite laminates under uniaxial loading[J]. Composite Structures,2015,132:440-450. [2] 庞艳荣, 赵文政, 张燕南, 等. 复合材料波纹褶皱区域损伤变形测量及声发射监测[J]. 玻璃钢/复合材料, 2017(8):53-60.PANG Yanrong, ZHAO Wenzheng, ZHANG Yannan, et al. Damage deformation measurement and acoustic emission monitoring of waves in composite materials[J]. Fiber Reinforced Plastics/Composites,2017(8):53-60(in Chinese). [3] TAKEDA T. Micromechanics model for three-dimensional effective elastic properties of composite laminates with ply wrinkles[J]. Composite Structures,2018,189:419-427. doi: 10.1016/j.compstruct.2017.10.086 [4] BLOOM L D, WANG J, POTTER K D. Damage progression and defect sensitivity: An experimental study of representative wrinkles in tension[J]. Composites Part B: Engineering,2013,45(1):449-458. doi: 10.1016/j.compositesb.2012.05.021 [5] EL-HAJJAR R F, PETERSEN D R. Gaussian function characterization of unnotched tension behavior in a carbon/epoxy composite containing localized fiber waviness[J]. Composite Structures,2011,93(9):2400-2408. doi: 10.1016/j.compstruct.2011.03.029 [6] HSIAO H M, DANIEL I M. Effect of fiber waviness on stiffness and strength reduction of unidirectional composites under compressive loading[J]. Composites Science and Technology,1996,56(5):581-593. doi: 10.1016/0266-3538(96)00045-0 [7] HSIAO H M, DANIEL I M. Elastic properties of composites with fiber waviness[J]. Composites Part A: Applied Science and Manufacturing,1996,27(10):931-941. doi: 10.1016/1359-835X(96)00034-6 [8] RAI H G, ROGERS C W, CRANE D A. Mechanics of curved fiber composites[J]. Journal of Reinforced Plastics and Composites,1992,11(5):552-566. doi: 10.1177/073168449201100505 [9] ZHU J, WANG J, NI A, et al. A multi-parameter model for stiffness prediction of composite laminates with out-of-plane ply waviness[J]. Composite Structures,2018,185:327-337. doi: 10.1016/j.compstruct.2017.11.020 [10] 朱俊, 郭万涛, 李想, 等. 含面内波纹缺陷的复合材料层合板刚度性能[J]. 复合材料学报, 2018, 35(4):793-803.ZHU Jun, GUO Wantao, LI Xiang, et al. Stiffness of compo-site laminates with in-plane waviness defect[J]. Acta Materiae Compositae Sinica,2018,35(4):793-803(in Chinese). [11] 朱俊, 吴维清, 欧阳佳斯, 等. 面外波纹对复合材料层合板弹性性能的影响[J]. 复合材料学报, 2016, 33(9):1981-1988.ZHU Jun, WU Weiqing, OUYANG Jiasi, et al. Influence of out-of-plane waviness on elastic properties of composite laminates[J]. Acta Materiae Compositae Sinica,2016,33(9):1981-1988(in Chinese). [12] LEMANSKI S L, SUTCLIFFE M P F. Compressive failure of finite size unidirectional composite laminates with a region of fibre waviness[J]. Composites Part A: Applied Science and Manufacturing,2012,43(3):435-444. doi: 10.1016/j.compositesa.2011.11.007 [13] WISNOM M R, ATKINSON J W. Compressive failure due to shear instability: Experimental investigation of waviness and correlation with analysis[J]. Journal of Reinforced Plastics and Composites,1996,15(4):420-439. doi: 10.1177/073168449601500404 [14] XIE N, SMITH R A, MUKHOPADHYAY S, et al. A numerical study on the influence of composite wrinkle defect geometry on compressive strength[J]. Materials & Design,2018,140:7-20. [15] CHUN H, SHIN J, DANIEL I M. Effects of material and geometric nonlinearities on the tensile and compressive behavior of composite materials with fiber waviness[J]. Composites Science and Technology,2001,61(1):125-134. doi: 10.1016/S0266-3538(00)00201-3 [16] MUKHOPADHYAY S, JONES M I, HALLETT S R. Compressive failure of laminates containing an embedded wrinkle: Experimental and numerical study[J]. Composites Part A: Applied Science and Manufacturing,2015,73:132-142. doi: 10.1016/j.compositesa.2015.03.012 [17] MUKHOPADHYAY S, JONES M I, HALLETT S R. Tensile failure of laminates containing an embedded wrinkle: Numerical and experimental study[J]. Composites Part A: Applied Science and Manufacturing,2015,77:219-228. doi: 10.1016/j.compositesa.2015.07.007 [18] CREIGHTON C J, SUTCLIFFE M, CLYNE T W. A multiple field image analysis procedure for characterisation of fibre alignment in composites[J]. Composites Part A: Applied Science and Manufacturing,2001,32(2):221-229. doi: 10.1016/S1359-835X(00)00115-9 [19] LEMANSKI S L, SUTCLIFFE M P F, SCOTT A E. Characterisation of waviness defects in industrial composite samples [C]. Korea: Proceedings of the 18th International Conference on Composite Materials, 2011. [20] 崔深山. 面向积木式试验的复合材料典型结构件分析与验证[D]. 哈尔滨: 哈尔滨工业大学, 2017.CUI Shenshan. Analysis and verification of typical structure of composite materials for building experiment[D]. Harbin: Harbin Institute of Technology, 2017(in Chinese). [21] 齐雯雯. 复合材料结构件多尺度虚拟测试及模型重用技术研究[D]. 哈尔滨: 哈尔滨工业大学, 2016.QI Wenwen. Research on multi-scale virtual testing and model reusing of composites structures[D]. Harbin: Harbin Institute of Technology, 2016(in Chinese). [22] FAWCETTL A, ROSTLE J, WARD S. 777 Empennage certification approach[C]. Australia: Proceedings of the 11th International Conference on Composite Materials, 1997: 178-199. [23] SHAW A, SRIRAMULA S, GOSLING P D, et al. A critical reliability evaluation of fibre reinforced composite mater-ials based on probabilistic micro and macro-mechanical analysis[J]. Composites Part B: Engineering,2010,41(6):446-453. doi: 10.1016/j.compositesb.2010.05.005 [24] SAFF C, HAHN G, GRIFFITH J. Accelerated insertion of materials-composites[C]. Texas: 46th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, 2005. [25] RIDDLE T W, CAIRNS D S, NELSON J W. Characterization of manufacturing defects common to composite wind turbine blades: Flaw characterization[C]. Colorado: 52nd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, 2011. [26] MA L, SHEN C, ZHANG A, et al. Virtual tests of elastodynamic response of natural fiber-reinforced orthotropic plates[J]. Composite Structures,2018,192:264-273. doi: 10.1016/j.compstruct.2018.02.093 -

下载:

下载: