Effect of fiber content on the properties of bamboo fiber/epoxy resin composites prepared by VARTM

-

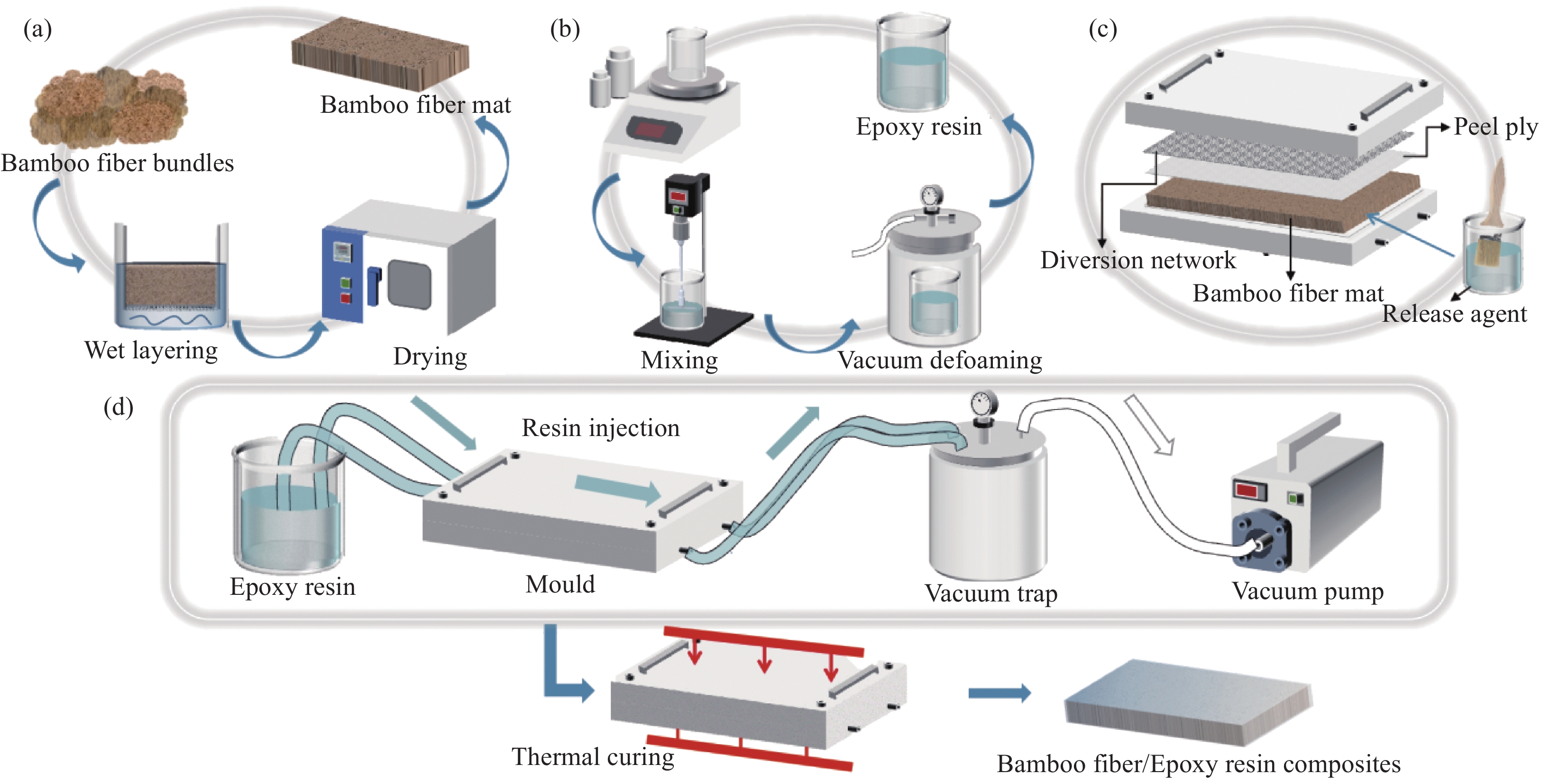

摘要: 纤维含量是影响真空辅助树脂传递模塑成型(VARTM)技术制备高性能纤维复合材料的关键因素之一,通过考察竹纤维(BF)含量对VARTM成型过程中环氧树脂(EP)浸渍BF效果及BF/EP复合材料性能的影响,为竹纤维复合材料实际应用提供理论支撑。利用湿法层铺工艺将竹纤维束制作成竹纤维毡,再利用VARTM成型工艺制备出BF含量为0wt%、15wt%、25wt%、35wt%和45wt%的BF/EP复合材料。采用ESEM、超景深显微镜、力学试验机、TG、DMA对BF/EP复合材料的树脂浸渍纤维效果、吸水性、力学性能和耐热性能进行表征。研究结果表明:EP注射难度随BF含量增加而增大,BF/EP复合材料的吸水率随BF含量的增加逐步增加,35wt%时显著增加。随着BF含量的增加BF之间机械互锁性更强,能有效分散复合材料破坏应力,45wt%的BF/EP复合材料与15wt%相比弯曲强度、弯曲模量、剪切强度和冲击韧性分别提升了84%、64%、103%和101%。BF含量的增加使BF/EP复合材料在380℃之前热解速率加快,在此之后热解速率减缓,当BF含量多于35wt%时,BF/EP复合材料中的BF热分解剩余的无定形碳作为保护层能减少挥发性降解产物渗透到BF/EP复合材料中延缓热解反应。BF含量为45wt%时,致密的竹纤维毡能够限制树脂分子链段运动从而提高BF/EP复合材料的耐热性。当有高性能、低成本、使用场景为室内需求时可采用BF含量为45wt%制备BF/EP复合材料。Abstract: Fiber mass fraction was one of the key factors that affect the preparation of high-performance fiber composites by vacuum assisted resin transfer molding (VARTM). This research studied the influence of bamboo fiber (BF) mass fraction on the epoxy resin (EP) impregnated fiber effect and the performance of BF/EP composites made by VARTM, which provided theoretical support for the practical application of bamboo fiber composites. The bamboo fiber bundles were made into bamboo fiber mat by wet layering, using the VARTM process to prepare the fiber mass fraction of 0wt%, 15wt%, 25wt%, 35wt% and 45wt% BF/EP composites. The resin-impregnated fiber effect, water absorption, mechanical properties, and heat resistance of BF/EP composites were characterized by ESEM, ultra-depth-of-field microscope, mechanical testing machine, TG and DMA. It is observed that the difficulty of EP injection and the water absorption rate of BF/EP composites gradually increases with increasing fiber mass fraction. The water absorption rate of the BF/EP composites increases significantly when the fiber mass fraction is 35wt% or more. The mechanical interlocking between BF is stronger in BF/EP composites with higher fiber mass fraction, which can effectively disperse the failure stress, leading to higher mechanical performance, compared with 15wt%, the flexural strength, flexural modulus, shear strength and impact toughness of 45wt% BF/EP composites are significantly improved by 84%, 64%, 103% and 101%, respectively. The pyrolysis rate of BF/EP composites with increasing fiber mass fraction increases when the temperature is lower than 380℃ and decreases when higher than 380℃, when the fiber mass fraction is more than 35wt%, the amorphous carbon obtained from the thermal decomposition of the BF can be used as a protective layer to reduce the penetration of volatile degradation products into the BF/EP composites and delay the pyrolysis reaction. When the fiber mass fraction is 45wt%, the dense bamboo fiber mat can limit the movement of the resin molecular segments, thereby improving the heat resistance of the BF/EP composites. The BF/EP composites prepared with fiber mass fraction at 45wt% can be used in the fields where the characteristics of high performance, low cost are required, such as indoor decoration.

-

Key words:

- bamboo fiber /

- VARTM /

- fiber content /

- composites /

- plant fiber composites /

- epoxy resin

-

表 1 不同BF质量分数的BF/EP复合材料密度

Table 1. Density of BF/EP composites with different BF mass fraction

BF mass fraction/wt% 0 15 25 35 45 Density/(g·cm−3) 1.210 1.129 1.226 1.245 1.251 -

[1] KAUR N, SAXENA S, GAUR H, et al. A review on bamboo fiber composites and its applications[C]. International Conference on Infocom Technologies and Unmanned Systems, 2017: 843-849. [2] SONG K, REN X, ZHANG L. Bamboo fiber-polymer composites: overview of fabrications, mechanical characterizations and applications[M]. Berlin: Springer International Publishing, 2017. [3] 李玉敏, 冯鹏飞. 基于第九次全国森林资源清查的中国竹资源分析[J]. 世界竹藤通讯, 2019, 17(6):45-48.LI Yumin, FENG Pengfei. Bamboo resources in China based on the ninth national forest inventory data[J]. World bamboo and rattan,2019,17(6):45-48(in Chinese). [4] 黄慧. 长竹纤维束提取及其增强聚丙烯复合材料制备[D]. 南京: 南京林业大学, 2018.HUANG Hui. Extraction of long bamboo fiber bundles and preparation of their reinforcing polypropylene composites[D]. Nanjing: Nanjing Forestry University, 2018(in Chinese). [5] 范宏玥, 陈礼辉, 苗庆显, 等. 毛竹竹原纤维的制备及其表征[J]. 林业机械与木工设备, 2020, 48(5):37-41.FAN Hongyue, CHEN Lihui, MIAO Qingxia, et al. Preparation and characterization of natural moso bamboo Fiber[J]. Forestry Machinery & Woodworking Equipment,2020,48(5):37-41(in Chinese). [6] 金霄, 张效林, 邓祥胜, 等. 竹纤维增强热塑性塑料复合材料研究进展[J]. 中国塑料, 2017, 31(10):6-11.JIN Xiao, ZHANG Xiaolin, DENG Xi, et al. Research progress of bamboo fiber reinforced thermoplastic compo-sites[J]. China Plastics,2017,31(10):6-11(in Chinese). [7] 陈祥宝. 先进复合材料技术导论[M]. 北京: 航空工业出版社, 2017.CHEN Xiangbao. Introduction of advanced composite technology[M]. Beijing: Aviation Industry Press, 2017(in Chinese). [8] 周少雄. 提高竹纤维增强复合材料的力学性能及应用研究[D]. 银川: 宁夏大学, 2020.ZHOU Shaoxiong. Research on improving the mechanical properties and application of bamboo fiber reinforced composites[D]. Yinchuan: Ningxia University, 2020(in Chinese). [9] XIA C, SHI S Q, CAI L, et al. Property enhancement of kenaf fiber composites by means of vacuum-assisted resin transfer molding (VARTM)[J]. Holzforschung,2015,69(3):307-312. doi: 10.1515/hf-2014-0054 [10] 范豪. VARTM中树脂充模过程的数值模拟与实验研究[D]. 哈尔滨: 东北林业大学, 2017.FAN Hao. Numerical simulation and experimental study on resin filling process in VARTM[D]. Haerbing: Northeast Forestry University, 2017(in Chinese). [11] 徐硕. 植物纤维真空辅助模塑下树脂浸润流动过程的研究[D]. 哈尔滨: 东北林业大学, 2019.XU Shuo. Study on resin infiltration flow process under vacuum assisted molding of plant fiber[D]. Haerbing: Northeast Forestry University, 2019(in Chinese). [12] WANG D, BAI T, CHENG W, et al. Surface modification of bamboo fibers to enhance the interfacial adhesion of epoxy resin-based composites prepared by resin transfer molding[J]. Polymers,2019,11(12):2107. [13] 徐灿, 陆继倾, 白天, 等. 纳米SiO2改性竹纤维/乙烯基树脂复合材料界面相容性[J]. 复合材料学报, 2021, 38(9):2776-2786.XU Can, LU Jiqing, BAI Tian, et al. Study on interfacial compatibility of nano-SiO2 modified bamboo fiber/vinyl ester resin composites[J]. Acta Materiae Compositae Sinica,2021,38(9):2776-2786(in Chinese). [14] 中国国家标准化管理委员会. GB/T 1463—2005 纤维增强塑料密度和相对密度试验方法[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. GB/T 1463—2005 Test methods for density and relative of fiber reinforced plastics[S]. Beijing: China Standards Press, 2005(in Chinese). [15] 中国国家标准化管理委员会. GB/T 1462—2005 纤维增强塑料吸水性试验方法[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. GB/T 1462—2005 Test methods for water absorption of fiber reinforced plastics[S]. Beijing: China Standards Press, 2005(in Chinese). [16] 中国国家标准化管理委员会. GB/T 1449—2005 纤维增强塑料弯曲性能试验方法[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. GB/T 1449—2005 Fiber-reinforced plastic composites—Determination of flexural poperties[S]. Beijing: China Standards Press, 2005(in Chinese). [17] ASTM D2344/ D2344M-16 Standard test method for short-beam strength of polymer matrix composite materials and their laminates[S]. West Conshohocken, ASTM International, 2016. [18] 中国国家标准化管理委员会. GB/T 1451—2005 纤维增强塑料简支梁式冲击韧性试验方法[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. GB/T 1451—2005 Fiber-reinforced plastic composites—Determination of charpy impact properties[S]. Beijing: China Standards Press, 2005(in Chinese). [19] ISHIKAWA H, TAKAGI H, NAKAGAITO A N, et al. Effect of surface treatments on the mechanical properties of natural fiber textile composites made by VARTM method[J]. Composite Interfaces,2014,21(4):329-336. doi: 10.1080/15685543.2013.876322 [20] GUPTA A. Synthesis, chemical resistance, and water absorption of bamboo fiber reinforced epoxy composites[J]. Polymer Composites,2016,37(1):141-145. doi: 10.1002/pc.23164 [21] KIM H, OKUBO K, FUJII T, et al. Influence of fiber extraction and surface modification on mechanical properties of green composites with bamboo fiber[J]. Journal of Adhesion Science & Technology,2013,27(12):1348-1358. [22] NABINEJAD O, DEBNATH S, BEH J K, et al. Mechanical performance and moisture absorption of unidirectional bamboo fiber polyester composite[J]. Materials Science Forum,2018,911:88-94. doi: 10.4028/www.scientific.net/MSF.911.88 [23] KHAN Z, YOUSIF B F, ISLAM M. Fracture behaviour of bamboo fiber reinforced epoxy composites[J]. Compo-sites Part B: Engineering,2017,116:186-199. [24] 纪雨辛, 郑霞, 李新功, 等. 竹纤维含量对其增强聚己内酯复合材料性能的影响[J]. 中国塑料, 2016, 30(5):28-33.JI Yuxin, ZHENG Xia, LI Xingong, et al. Effect of mass fraction on properties of bamboo fibers reinforced polycaprolactone composites[J]. China Plastics,2016,30(5):28-33(in Chinese). [25] 董庆, 张书平, 张理, 等. 竹材热解动力学特性分析[J]. 过程工程学报, 2015, 15(1):89-93.DONG Qing, ZHANG Shuping, ZHANG Li, et al. Study on pyrolysis kinetics of bamboo[J]. The Chinese Journal of Process Engineering,2015,15(1):89-93(in Chinese). [26] 段国晨, 赵景丽, 赵伟超. 环氧树脂/酸酐固化剂体系的热性能研究[J]. 中国胶粘剂, 2017, 26(2):9-12.DUAN Guochen, ZHAO Jingli, ZHAO Weichao. Study on thermal properties of epoxy resin/anhydride curing agent system[J]. China Adhesives,2017,26(2):9-12(in Chinese). [27] 周姝珏. 竹原纤维增强复合材料界面调控及其对热机械性能的影响[D]. 重庆: 西南大学, 2019.ZHOU S J. Interface regulation of bamboo fiber reinforced composites and its effect on thermo-mechanical properties[D]. Chongqing: Southwest University, 2019(in Chinese). [28] WANG C, WANG G, CHENG H, et al. CaCO3 in situ treated bamboo pulp fiber reinforced composites obtained by vacuum-assisted resin infusion[J]. Wood Science & Technology,2017,51(3):1-14. [29] 张成林, 董抒华, 李丽君, 等. E-玻纤/环氧树脂预浸料固化动力学及其动态热力学性能[J]. 材料工程, 2020, 48(9):152-157.ZHANG Chenglin, DONG Shuhua, LI Lijun, et al. Curing kinetic and dynamic thermodynamic properties of E-glass fiber/epoxy resin prepreg[J]. Journal of Materials Engineering,2020,48(9):152-157(in Chinese). [30] 马甜, 贺鹏飞, 李文晓. 环氧/酸酐体系网络结构对形状记忆性能的影响[J]. 材料导报, 2021, 35(2):2145-2150.MA Tian, HE Pengfei, LI Wenxiao. Shape memory properties of epoxy/anhydride systems with different network structures[J]. Materials Reports,2021,35(2):2145-2150(in Chinese). -

下载:

下载: