Research advances on functional modification of lignocellulose under deep eutectic solvents and their applications

-

摘要: 低共熔溶剂(DES)作为一种新型绿色溶剂,相比离子液体等其它溶剂,其具有制备简单、配制灵活、成本低、效率高等特点,在木质纤维素绿色加工领域有着广泛的应用前景。近年来,基于DES体系下木质纤维素的溶解、组分分离、衍生化改性等研究取得了一系列重要的进展,相比于在传统离子液体或有机溶剂体系,在DES体系下木质纤维素的化学改性更绿色环保,经过改性的木质纤维素在纳米纤维的制备、复合材料的构建等领域得到了广泛的应用。本文综述了在DES体系下木质纤维素的阳离子化、酯化及其它衍生化等功能化改性及DES体系下改性的木质纤维素在纳米分散、复合材料等功能化应用方面的研究进展。最后总结并展望了在DES体系下木质纤维素功能化改性及应用所面临的机遇和挑战。

-

关键词:

- 木质纤维素 /

- 低共熔溶剂(DES) /

- 化学改性 /

- 功能化 /

- 复合材料

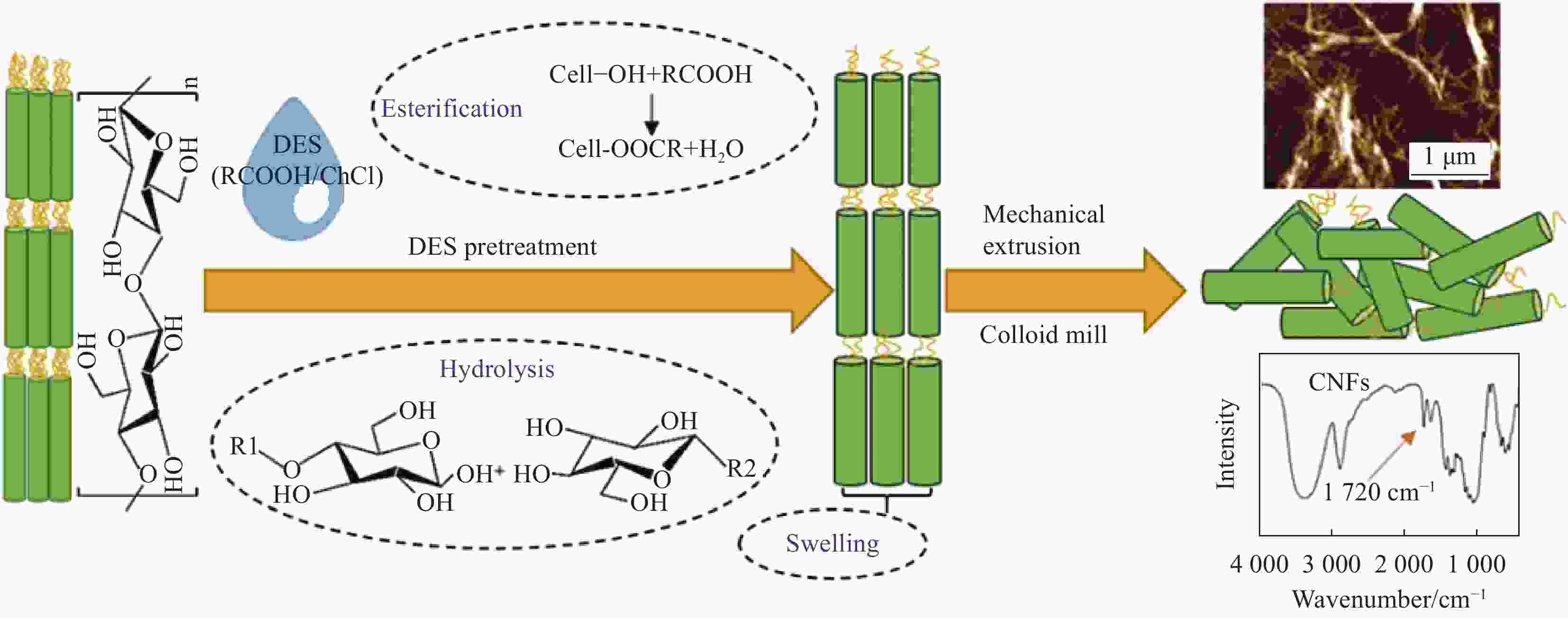

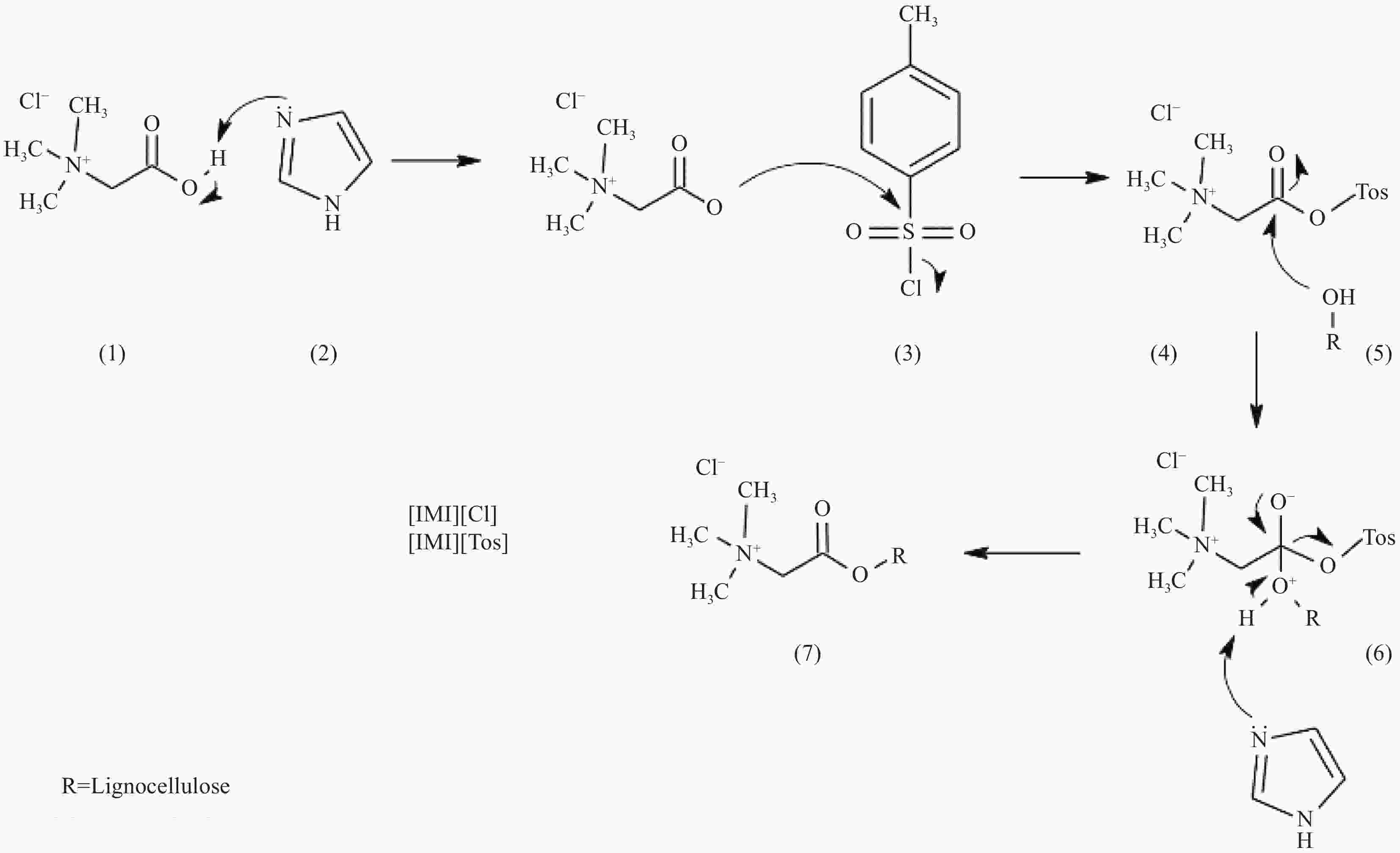

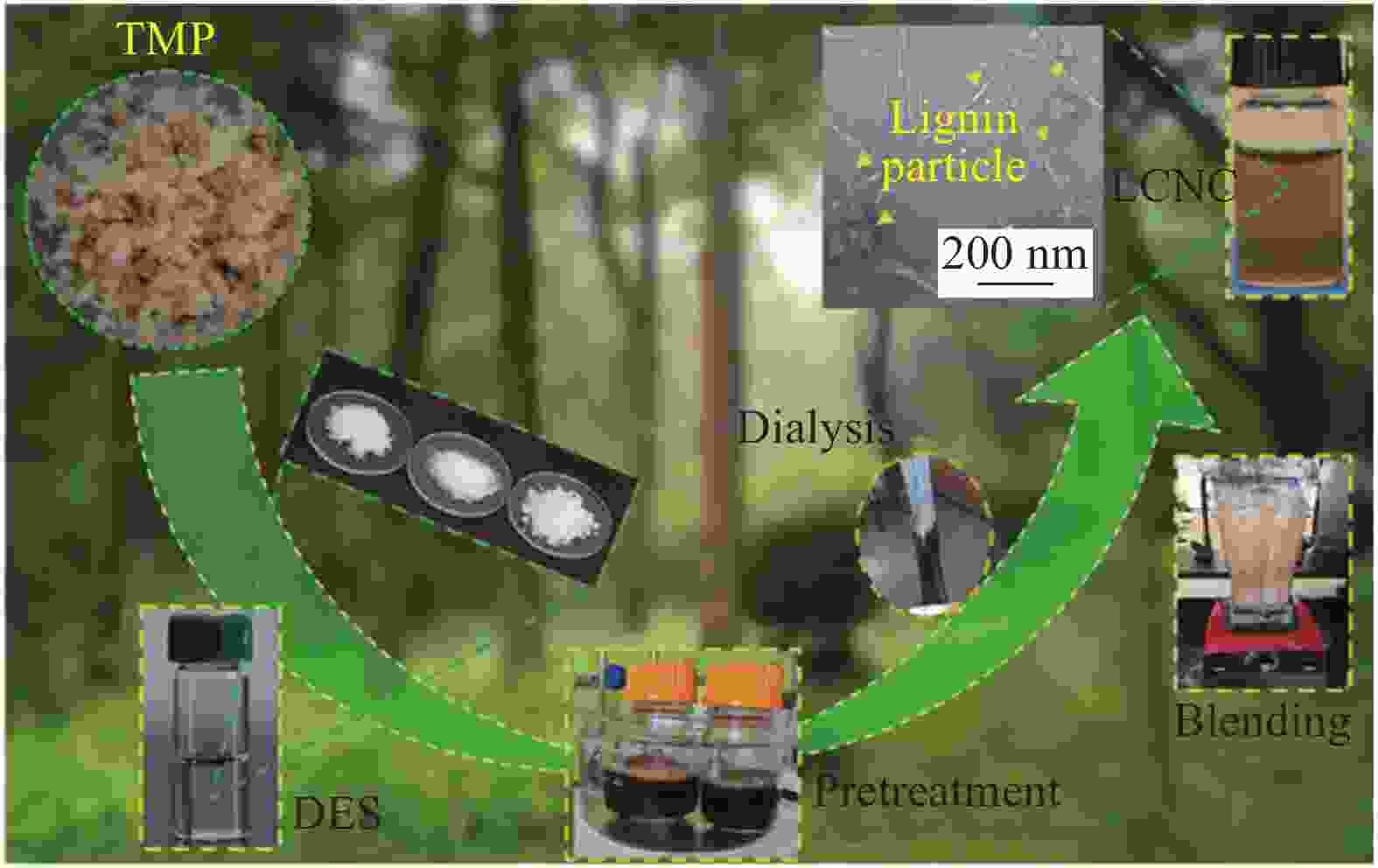

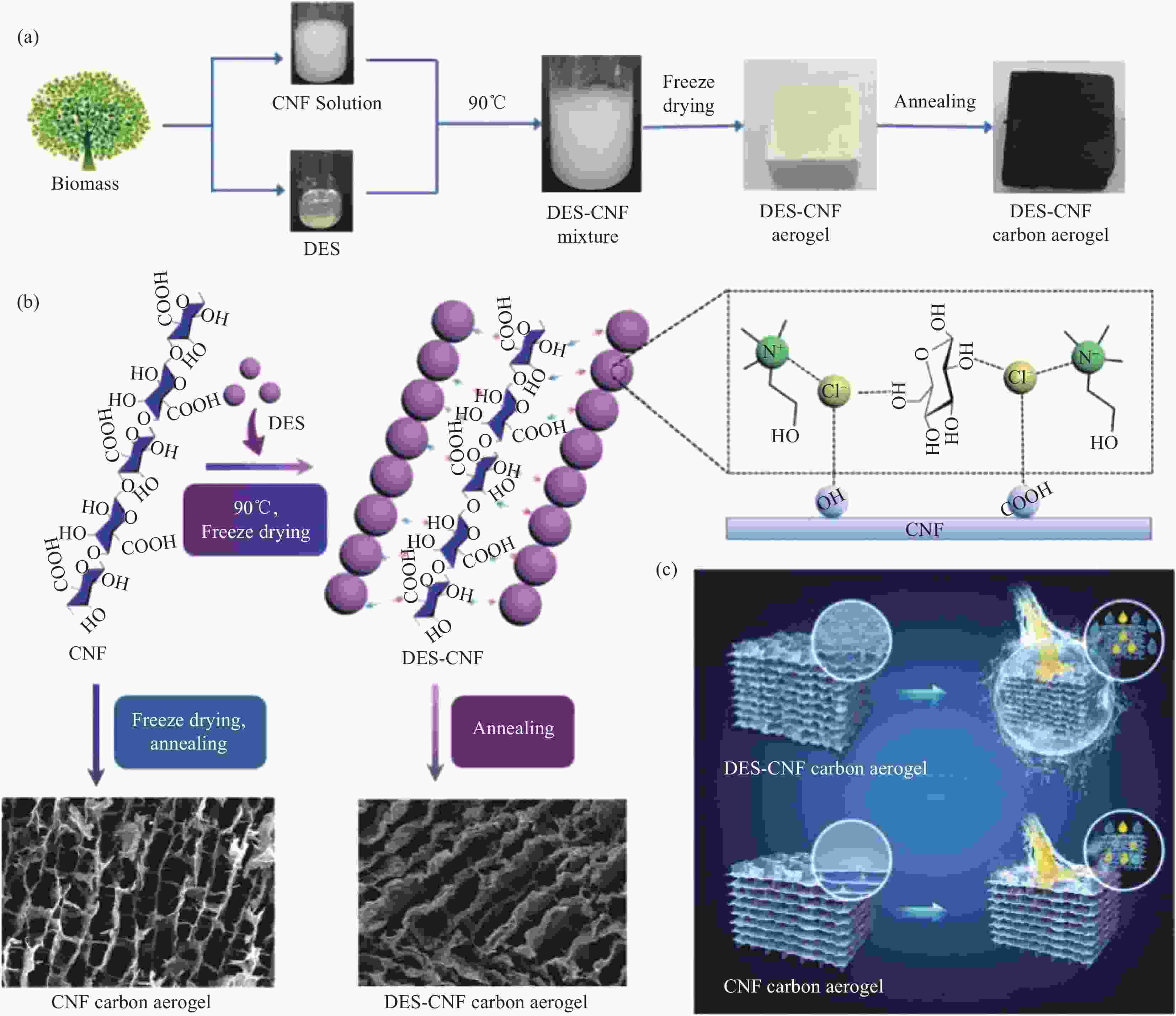

Abstract: Different from ionic liquids or other solvents, deep eutectic solvent (DES), as a novel environmentally friendly solvent, owns the advantages of easy and flexible preparation, low cost and high efficiency, and shows great potential applications in the pretreatment of lignocellulose. A series of important advances have been made related to the dissolution, component separation and modification of lignocellulose in DES system in recent years. The chemical modification with smaller impact on the environment can be achieved in DES system when compared to traditional ionic liquid and other organic solvent systems. Moreover, the modified lignocellulose has been widely applied in the preparation of nanofibers and the construction of composite materials. This article reviews the research advances in the cationization, esterification and other derivatizations of lignocellulose in the DES system. The applications of thus pretreated and modified lignocellulose in nano-dispersion, functional compositing are also included. Finally, the development and challenges of lignocellulose modification based on DES system are discussed. -

表 1 不同种类的DES对木质纤维素的改性

Table 1. Modification of lignocellulose under different DES

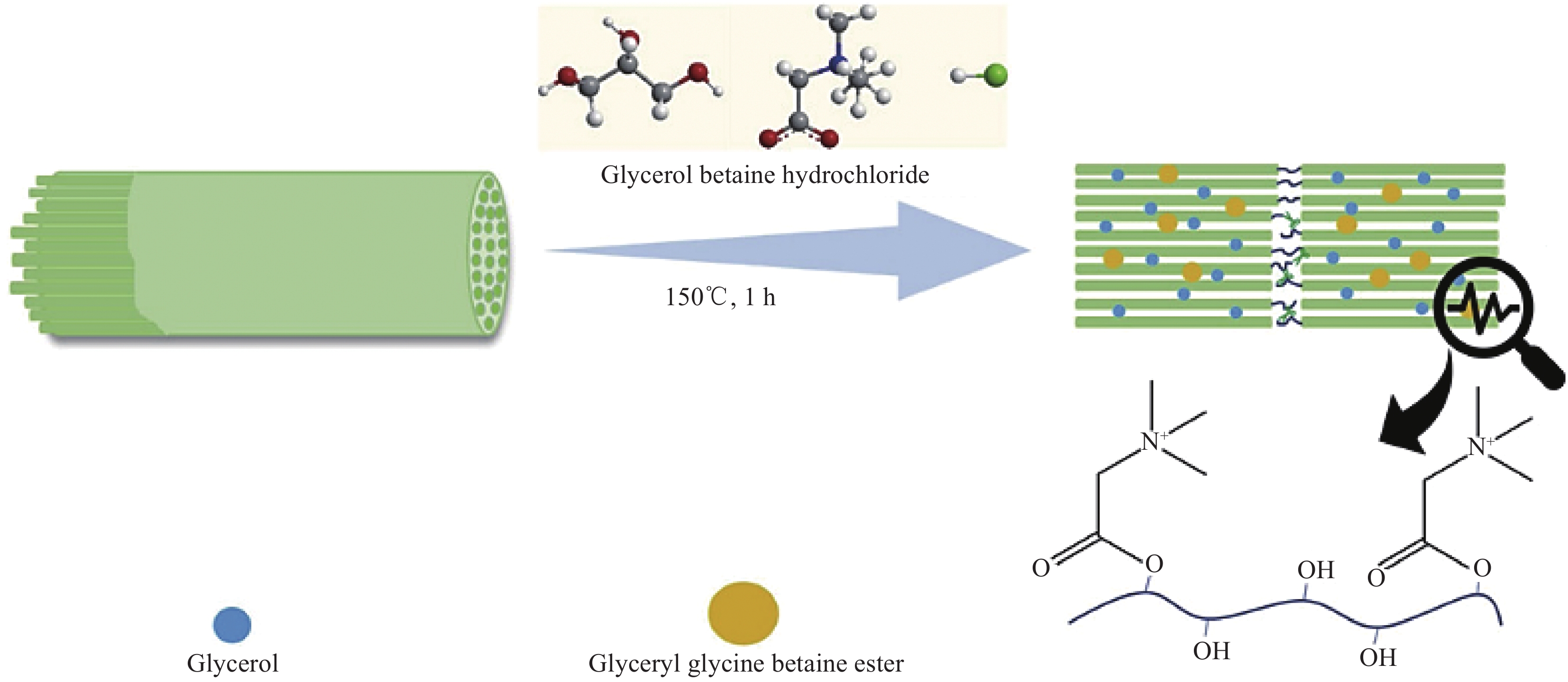

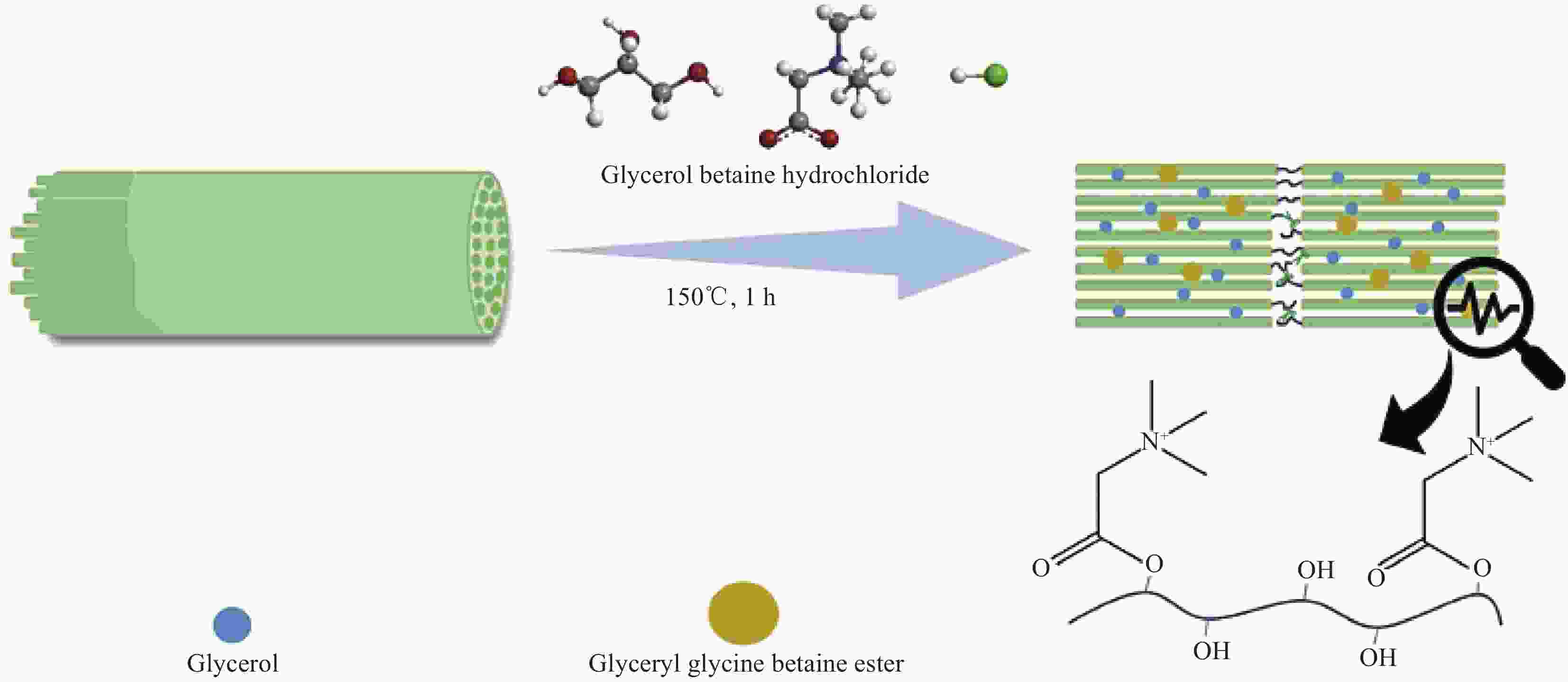

Deep eutectic solvents Molar ratio Material Additives Products Reference ChCl/Urea 1∶2 Cellulose acetate — Cationized cellulose [12] 2∶1/4∶1 Hardwood dissolving pulp — Cellulose carbamates [21] BA/GTAC 1∶3 Softwood dissolving pulp — Cationized cellulose [14] BataineHCl/Glycerol 1∶6/1∶3/1∶2/2∶1 Bleached hardwood pulp — Cationized cellulose [13] Aminoguanidine hydrochloride/Glycerol 1∶2 Dialdehyde cellulose — Cationic dialdehyde cellulose [15, 33] Urea/LiCl 5∶1 Softwood dissolving pulp Succinic anhydride Succinyl cellulose [26, 34] Oxalic/ChCl 1.5∶1 Softwood dissolving pulp — Esterified cellulose [26] 1∶2 Softwood dissolving pulp — Esterified cellulose [24] 1∶1 Bleached hardwood pulp — Esterified cellulose [23] 1∶1 Softwood dissolving pulp — Esterified cellulose [26] 1∶1 Grape pomace — Esterified cellulose [28] 1∶1/1∶2/1∶3 Cotton cellulose — Esterified cellulose [29] 1∶1 Ramie fiber — Esterified cellulose [30] 1.5∶1 Softwood dissolving pulp — Esterified cellulose [25] Sulfamic acid/Urea 1∶3/1∶4/1∶20 Softwood dissolving pulp — Sulfation cellulose [39] P-toluenesulfonic acid/ChCl 1∶1 Softwood dissolving pulp — Unmodified [24] Levulinic acid/ChCl 1∶2 Softwood dissolving pulp — Unmodified [24] Urea/Betaine 2∶1/4∶1 Hardwood dissolving pulp — Cellulose carbamates [21] Urea/BetaineHCl 2∶1/4∶1 Hardwood dissolving pulp — Cellulose carbamates [21] Formic acid/ChCl 2∶1 Bleached hardwood pulp — Esterified cellulose [23] Lactic acid/ChCl 9∶1 Bleached hardwood pulp — Esterified cellulose [23] 9∶1 Lignin Maleic anhydride Esterified cellulose [35] Acetic acid/ChCl 2∶1 Bleached hardwood pulp — Esterified cellulose [23] Malonic acid/ChCl 1∶1 Bleached hardwood pulp — Esterified cellulose [23] Citric acid/ChCl 1∶1 Bleached hardwood pulp — Esterified cellulose [23] Dimethylurea/ZnCl2 10∶3 Softwood dissolving pulp — Cellulose carbamates [22] Oxd/ChCl/FeCl3·6H2O 4∶1∶1 Bleached softwood pulp — Esterified cellulose [27] ChCl/ZnCl2 1∶2 Cellulose Acetic anhydride Acetylated cellulose [31] TEMA/Imidazole 1∶2 Softwood dissolving pulp BataineHCl Cellulose betaine este [32] P-aminobenzoic acid/ChCl — Lignin EPI Lignin-DES catalysts [36] Notes: BA—boric acid; GTAC—Glycidyl trimethyl ammonium chloride; Oxd—Oxalic acid dihydrate; EPI—Epichlorohydrin. -

[1] ABBOTT A P, CAPPER G, DAVIES D L, et al. Novel solvent properties of choline chloride/urea mixtures[J]. Chemical Communications (Cambridge, England),2003,9(1):70-71. [2] YU L L, ENG K N, GE H Y, et al. Potential use of deep eutectic solvents to facilitate lignocellulosic biomass utilization and conversion[J]. Cellulose,2017,24(9):3591-3618. doi: 10.1007/s10570-017-1358-y [3] LYNAM J G, KUMAR N, WONG M J. Deep eutectic solvents’ ability to solubilize lignin, cellulose, and hemicellulose; thermal stability; and density[J]. Bioresource Technology,2017:684-689. [4] LIU Y, CHEN W, XIA Q, et al. Efficient cleavage of lignin-carbohydrate complexes and ultrafast extraction of lignin oligomers from wood biomass by microwave-assisted treatment with deep eutectic solvent[J]. ChemSusChem,2017,10(8):1692-1700. doi: 10.1002/cssc.201601795 [5] DONG J, MEI C, HAN J, et al. 3D printed poly(lactic acid) composites with grafted cellulose nanofibers: Effect of nano-fiber and post-fabrication annealing treatment on compo-site flexural properties[J]. Additive Manufacturing,2019,28:621-628. doi: 10.1016/j.addma.2019.06.004 [6] GAZZOTTI S, RAMPAZZO R, HAKKARAINEN M, et al. Cellulose nanofibrils as reinforcing agents for PLA-based nanocomposites: An in situ approach[J]. Composites Science and Technology,2019,171(FEB. 8):94-102. [7] PRADO H J, MATULEWICZ M C. Cationization of polysaccharides: A path to greener derivatives with many industrial applications[J]. European Polymer Journal,2014,52:53-75. doi: 10.1016/j.eurpolymj.2013.12.011 [8] PEI A, BUTCHOSA N, BERGLUND L A, et al. Surface quaternized cellulose nanofibrils with high water absorbency and adsorption capacity for anionic dyes[J]. Soft Matter,2013,9(6):2047-2055. doi: 10.1039/c2sm27344f [9] HO T T T, ZIMMERMANN T, HAUERT R, et al. Preparation and characterization of cationic nanofibrillated cellulose from etherification and high-shear disintegration processes[J]. Cellulose,2011,18(6):1391-1406. doi: 10.1007/s10570-011-9591-2 [10] SEHAQUI H, LARRAYA U P D, TINGAUT P, et al. Humic acid adsorption onto cationic cellulose nanofibers for bioinspired removal of copper(ii) and a positively charged dye[J]. Soft Matter,2015,11(26):5294-5300. doi: 10.1039/C5SM00566C [11] LIIMATAINEN H, SUOPAJARVI T, SIRVIO J, et al. Fabrication of cationic cellulosic nanofibrils through aqueous quaternization pretreatment and their use in colloid aggregation[J]. Carbohydrate Polymers,2014,103(1):187-192. [12] YANG Z, ASOH T A, UYAMA H. Cationic functionalization of cellulose monoliths using a urea-choline based deep eutectic solvent and their applications[J]. Polymer Degradation and Stability,2019,160:126-135. doi: 10.1016/j.polymdegradstab.2018.12.015 [13] HONG S, YUAN Y, LI P, et al. Enhancement of the nanofibrillation of birch cellulose pretreated with natural deep eutectic solvent[J]. Industrial Crops and Products,2020,154:112677. doi: 10.1016/j.indcrop.2020.112677 [14] VUOTI S, NARASIMHA K, REINIKAINEN K. Green wastewater treatment flocculants and fixatives prepared from cellulose using high-consistency processing and deep eutectic solvents[J]. Journal of Water Process Engineering,2018,26:83-91. doi: 10.1016/j.jwpe.2018.09.003 [15] LI P, SIRVIO J A, ASANTE B, et al. Recyclable deep eutectic solvent for the production of cationic nanocelluloses[J]. Carbohydrate Polymers,2018,199:219-227. doi: 10.1016/j.carbpol.2018.07.024 [16] KLEMM D, HEUBLEIN B, FINK H P, et al. Cellulose: Fascinating biopolymer and sustainable raw material[J]. Angewandte Chemie International Edition,2005,44(22):3358-3393. doi: 10.1002/anie.200460587 [17] YIN Y, LUCIA L A, PAL L, et al. Lipase-catalyzed laurate esterification of cellulose nanocrystals and their use as reinforcement in PLA composites[J]. Cellulose,2020,27(11):6263-6273. doi: 10.1007/s10570-020-03225-3 [18] HAVIMO M, JALOMAKI J, GRANSTROM M, et al. Mechanical strength and water resistance of paperboard coated with long chain cellulose esters[J]. Packaging Technology and Science,2011,24(4):249-258. doi: 10.1002/pts.932 [19] PIA W K, JARMO R, HANNA L A, et al. Cellulose fatty acid ester coated papers for stand-up pouch applications[J]. Journal of Applied Polymer Science,2018,135(48):46936. doi: 10.1002/app.46936 [20] PIA W K, HANNES O, JARMO R. Injection molding of thermoplastic cellulose esters and their compatibility with poly(lactic acid) and polyethylene[J]. Materials (Basel),2018,11(12):2358. doi: 10.3390/ma11122358 [21] PIA W K, HILTUNEN J, ROPPONEN J. Production of cellulose carbamate using urea-based deep eutectic solvents[J]. Cellulose,2017,25(1):195-204. [22] SIRVIO J A, HEISKANEN J P. Synthesis of alkaline-soluble cellulose methyl carbamate using a reactive deep eutectic solvent[J]. ChemSusChem,2017,10(2):455-460. doi: 10.1002/cssc.201601270 [23] LIU S, ZHANG Q, GOU S, et al. Esterification of cellulose using carboxylic acid-based deep eutectic solvents to produce high-yield cellulose nanofibers[J]. Carbohydrate Polymers,2021,251:117018. [24] SIRVIO J A, VISANKO M, LIIMATAINEN H. Acidic deep eutectic solvents as hydrolytic media for cellulose nanocrystal production[J]. Biomacromolecules,2016,17(9):3025-3032. doi: 10.1021/acs.biomac.6b00910 [25] LAITINEN O, OJALA J, SIRVIO J A, et al. Sustainable stabilization of oil in water emulsions by cellulose nanocrystals synthesized from deep eutectic solvents[J]. Cellulose,2017,24(4):1679-1689. doi: 10.1007/s10570-017-1226-9 [26] OJALA J, VISANKO M, LAITINEN O, et al. Emulsion stabilization with functionalized cellulose nanoparticles fabricated using deep eutectic solvents[J]. Molecules,2018,23(11):2765. doi: 10.3390/molecules23112765 [27] YANG X, XIE H, DU H, et al. Facile extraction of thermally stable and dispersible cellulose nanocrystals with high yield via a green and recyclable FeCl3-catalyzed deep eutectic solvent system[J]. ACS Sustainable Chemistry & Engineering,2019,7(7):7200-7208. [28] WU R, LIU K, REN J, et al. Cellulose nanocrystals extracted from grape pomace with deep eutectic solvents and application for self-healing nanocomposite hydrogels[J]. Macromolecular Materials and Engineering,2020,305(3):1900673. [29] LING Z, EDWARDS J V, GUO Z, et al. Structural variations of cotton cellulose nanocrystals from deep eutectic solvent treatment: micro and nano scale[J]. Cellulose,2018,26(2):861-876. [30] YU W, WANG C, YI Y, et al. Choline chloride-based deep eutectic solvent systems as a pretreatment for nanofibrillation of ramie fibers[J]. Cellulose,2019,26(5):3069-3082. doi: 10.1007/s10570-019-02290-7 [31] ABBOTT A P, BELL T J, HANDA S, et al. O-Acetylation of cellulose and monosaccharides using a zinc based ionic liquid[J]. Green Chemistry,2005,7(10):705-707. doi: 10.1039/b511691k [32] SIRVIO J A. Cationization of lignocellulosic fibers with betaine in deep eutectic solvent: Facile route to charge stabilized cellulose and wood nanofibers[J]. Carbohydrate Polymers,2018,198:34-40. doi: 10.1016/j.carbpol.2018.06.051 [33] SELKALA T, SUOPAJARVI T, SIRVIO J A, et al. Surface modification of cured inorganic foams with cationic cellulose nanocrystals and their use as reactive filter media for anionic dye removal[J]. ACS Applied Materials & Interfaces,2020,12(24):27745-27757. [34] SELKALA T, SIRVIO J A, LORITE G S, et al. Anionically stabilized cellulose nanofibrils through succinylation pretreatment in urea-lithium chloride deep eutectic solvent[J]. ChemSusChem,2016,9(21):3074-3083. doi: 10.1002/cssc.201600903 [35] ANUGWOM I, LAHTELA V, KALLIOINEN M, et al. Lignin as a functional additive in a biocomposite: Influence on mechanical properties of polylactic acid composites[J]. Industrial Crops and Products,2019,140:111704. [36] XIONG X, ZHANG H, LAI S L, et al. Lignin modified by deep eutectic solvents as green, reusable, and bio-based catalysts for efficient chemical fixation of CO2[J]. Reactive and Functional Polymers,2020,149:104502.1-104502.11. [37] DE ASSIS C A, HOUTMAN C, PHILLIPS R, et al. Conversion economics of forest biomaterials: Risk and financial analysis of CNC manufacturing[J]. Biofuels, Bioproducts and Biorefining,2017,11(4):682-700. doi: 10.1002/bbb.1782 [38] 李利芬, 吴志刚, 梁坚坤, 等. 低共熔溶剂在木质纤维类生物质研究中的应用[J]. 林业工程学报, 2020, 5(4):20-28.LI L F, WU Z G, LIANG J K, et al. Application of deep eutectic solvents in lignocellulosic biomass processing[J]. Journal of Forestry Engineering,2020,5(4):20-28(in Chinese). [39] SIRVIO J A, UKKOLA J, LIIMATAINEN H. Direct sulfation of cellulose fibers using a reactive deep eutectic solvent to produce highly charged cellulose nanofibers[J]. Cellulose,2019,26(4):2303-2316. doi: 10.1007/s10570-019-02257-8 [40] LI P, SIRVIO J A, HAAPALA A, et al. Cellulose nanofibrils from nonderivatizing urea-based deep eutectic solvent pretreatments[J]. ACS Applied Materials & Interfaces,2017,9(3):2846-2855. [41] SIRVIO J A, VISANKO M, LIIMATAINEN H. Deep eutectic solvent system based on choline chloride-urea as a pre-treatment for nanofibrillation of wood cellulose[J]. Green Chemistry,2015,17(6):3401-3406. doi: 10.1039/C5GC00398A [42] JIANG J, CARRILLO-ENRIQUEZ N C, OGUZLU H, et al. High production yield and more thermally stable lignin-containing cellulose nanocrystals isolated using a ternary acidic deep eutectic solvent[J]. ACS Sustainable Chemistry & Engineering,2020,8(18):7182-7191. [43] HONG S, SONG Y, YUAN Y, et al. Production and characterization of lignin containing nanocellulose from luffa through an acidic deep eutectic solvent treatment and systematic fractionation[J]. Industrial Crops and Products,2020,143:111913. [44] ZHANG Q, MA R, MA L, et al. Contribution of lignin in esterified lignocellulose nanofibers (LCNFs) prepared by deep eutectic solvent treatment to the interface compatibility of LCNF/PLA composites[J]. Industrial Crops and Products,2021,166:113460. doi: 10.1016/j.indcrop.2021.113460 [45] LAITINEN O, SUOPAJARVI T, OSTERBERG M, et al. Hydrophobic, superabsorbing aerogels from choline chloride-based deep eutectic solvent pretreated and silylated cellulose nanofibrils for selective oil removal[J]. ACS Applied Materials & Interfaces,2017,9(29):25029-25037. [46] MA Y, XIA Q, LIU Y, et al. Production of nanocellulose using hydrated deep eutectic solvent combined with ultrasonic treatment[J]. ACS Omega,2019,4(5):8539-8547. doi: 10.1021/acsomega.9b00519 [47] CRAWFORD D E, WRIGHT L A, JAMES S L, et al. Efficient continuous synthesis of high purity deep eutectic solvents by twin screw extrusion[J]. Chemical Communications,2016,52(22):4215-4218. doi: 10.1039/C5CC09685E [48] 储晶晶, 张莉莉, 王志国. 木质素基金属纳米粒子复合材料的制备及其应用研究进展[J]. 复合材料学报, 2020, 37(11):2657-2673.CHU J J, ZHANG L L, WANG Z G. Research progress of preparation and application of lignin-based metal nanoparticles composites[J]. Acta Materiae Compositae Sinica,2020,37(11):2657-2673(in Chinese). [49] 周可可, 唐亚丽, 卢立新, 等. 氧化纳米纤维素增强再生纤维素全纤维素复合薄膜的制备及性能[J]. 复合材料学报, 2020, 37(7):1657-1666.ZHOU K K, TANG Y L, LU L X, et al. Preparation and properties of all-cellulose composite films with oxidized cellulose nanofibrils reinforcing regenerated cellulose[J]. Acta Materiae Compositae Sinica,2020,37(7):1657-1666(in Chinese). [50] VATANSEVER E, ARSLAN D, NOFAR M. Polylactide cellulose-based nanocomposites[J]. International Journal of Biological Macromolecules,2019,137:912-938. doi: 10.1016/j.ijbiomac.2019.06.205 [51] 蒋仙友, 张雅娟, 汪济奎, 等. 纳米纤维素晶须与聚烯烃弹性体协同增韧增强聚丙烯三元复合材料性能研究[J]. 林业工程学报, 2018, 3(1):89-96.JIANG X Y, ZHANG Y J, WANG J K, et al. Significant reinforcement of polypropylene by synergistic compatibilization of nano-cellulose whiskers and POE[J]. Journal of Forestry Engineering,2018,3(1):89-96(in Chinese). [52] LIU C, LI M-C, CHEN W, et al. Production of lignin-containing cellulose nanofibers using deep eutectic solvents for UV-absorbing polymer reinforcement[J]. Carbohydrate Polymers,2020,246:116548. doi: 10.1016/j.carbpol.2020.116548 [53] SELKALA T, SUOPAJARVI T, SIRVIO J A, et al. Rapid uptake of pharmaceutical salbutamol from aqueous solutions with anionic cellulose nanofibrils: The importance of pH and colloidal stability in the interaction with ionizable pollutants[J]. Chemical Engineering Journal,2018,350:378-385. doi: 10.1016/j.cej.2018.05.163 [54] SIRVIO J A, VISANKO M. Anionic wood nanofibers produced from unbleached mechanical pulp by highly efficient chemical modification[J]. Journal of Materials Chemistry,2017,5(41):21828-21835. doi: 10.1039/C7TA05668K [55] LONG S, FENG Y, LIU Y, et al. Renewable and robust biomass carbon aerogel derived from deep eutectic solvents modified cellulose nanofiber under a low carbonization temperature for oil-water separation[J]. Separation and Purification Technology,2021,254:117577. doi: 10.1016/j.seppur.2020.117577 [56] ESLAMI H, TZOGANAKIS C, MEKONNEN T H. Surface graft polymerization of lactic acid from the surface of cellulose nanocrystals and applications in chloroprene rubber film composites[J]. Cellulose,2020,27(9):5267. doi: 10.1007/s10570-020-03167-w [57] SMIRNOV M A, SOKOLOVA M P, TOLMACHEV D A, et al. Green method for preparation of cellulose nanocrystals using deep eutectic solvent[J]. Cellulose,2020,27(8):4305-4317. doi: 10.1007/s10570-020-03100-1 [58] LING Z, GUO Z, HUANG C, et al. Deconstruction of oriented crystalline cellulose by novel levulinic acid based deep eutectic solvents pretreatment for improved enzymatic accessibility[J]. Bioresource Technology,2020,305:123025. doi: 10.1016/j.biortech.2020.123025 -

下载:

下载: